Automatic navel orange peel shearing and heating and cleaning device

A cleaning device and automatic technology, applied to cleaning methods and appliances, mobile filter element filters, cleaning methods using liquids, etc., can solve the problems of high labor costs, splashing water droplets, low efficiency, etc., and achieve power saving and control Soaking time, effect of improving soaking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

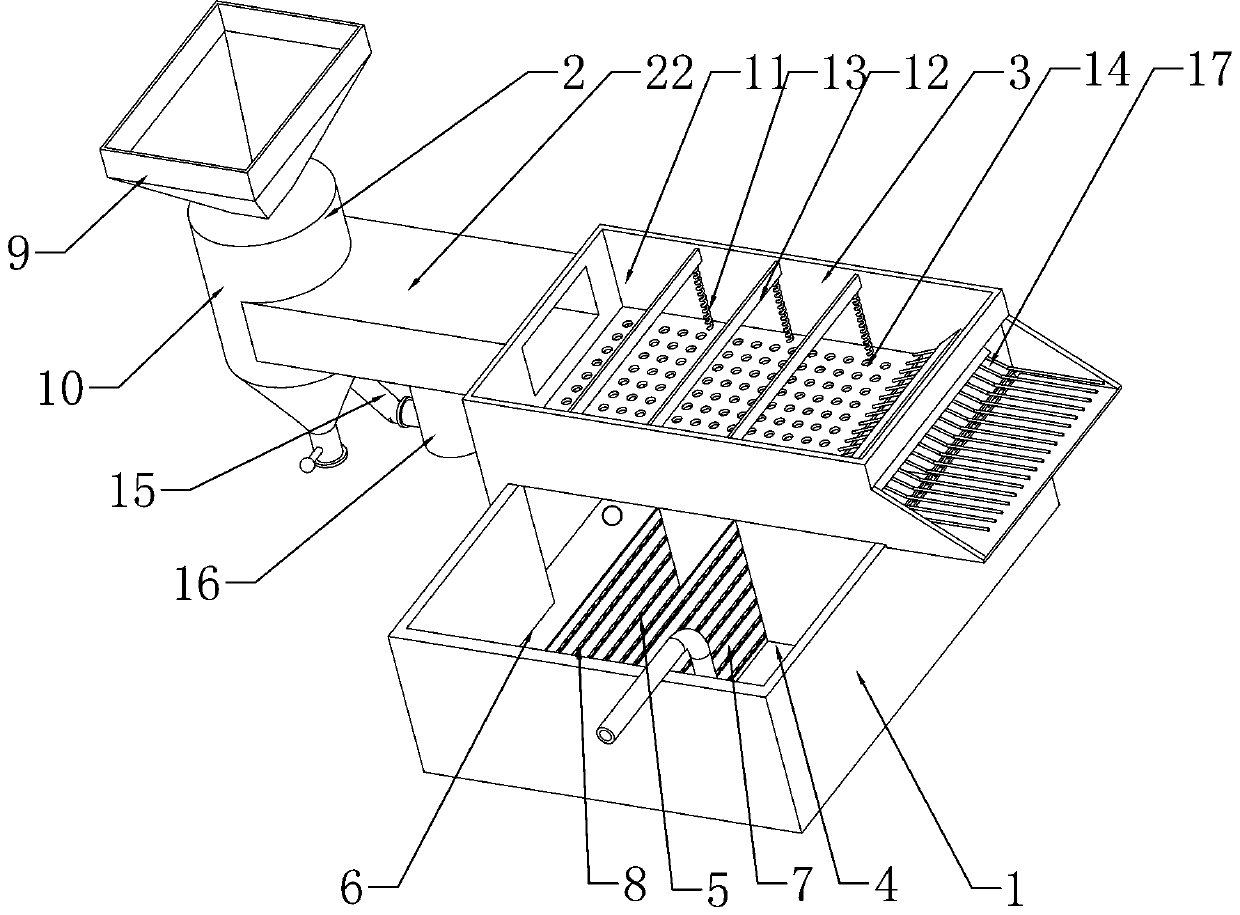

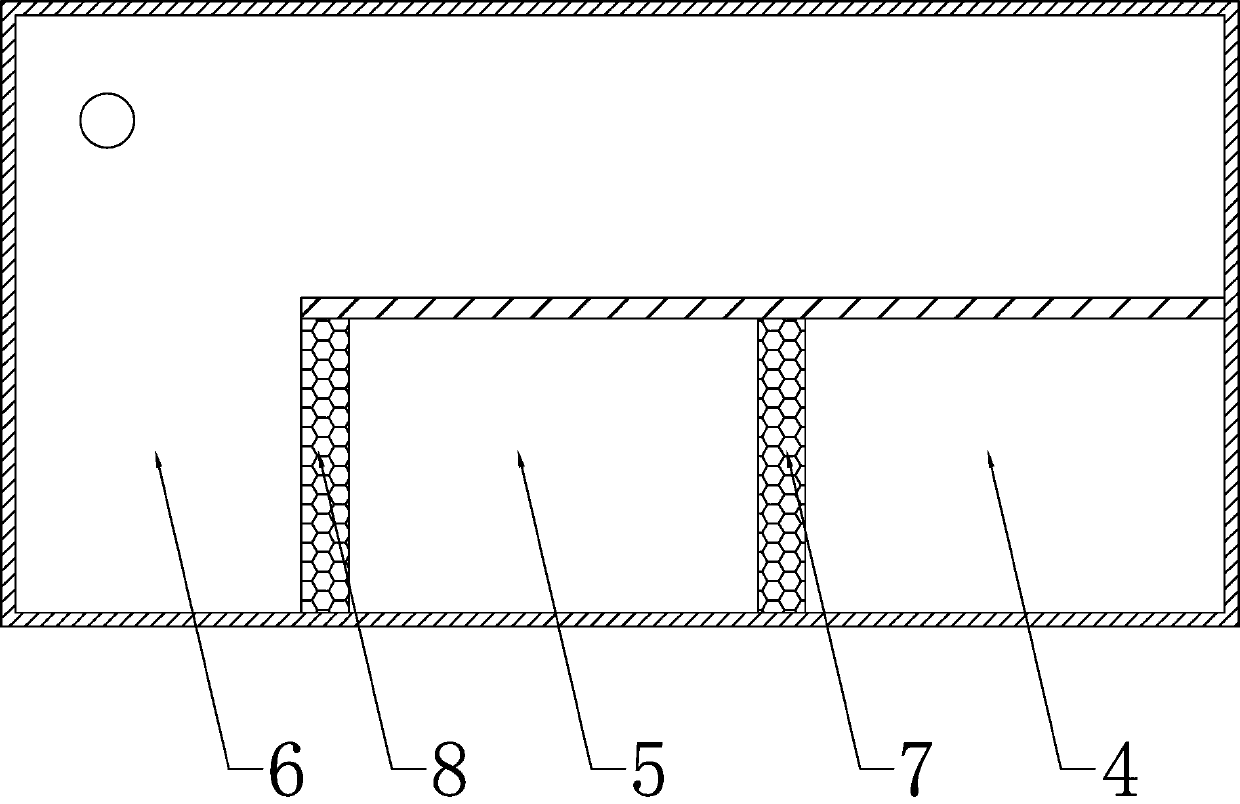

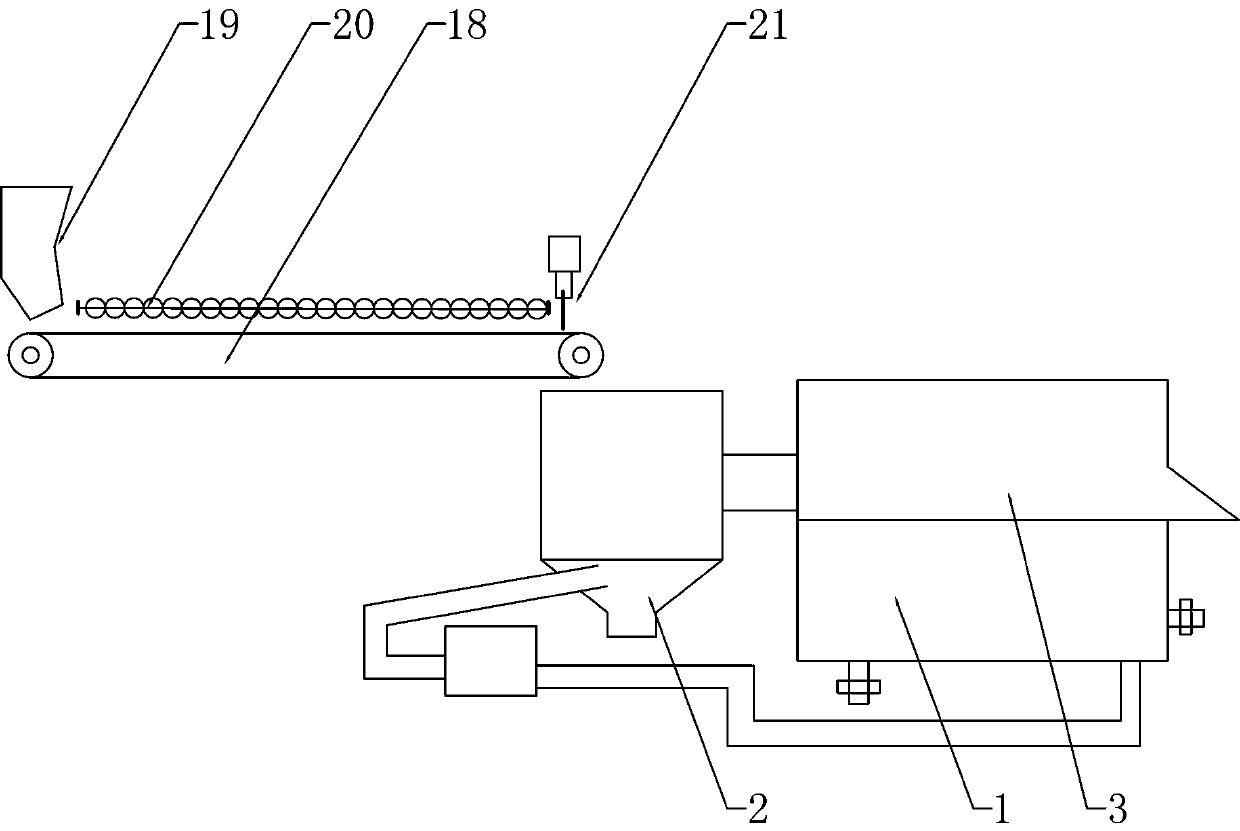

[0017] Such as Figure 1-3 Shown, a kind of navel orange peel automatic shearing heating cleaning device comprises shearing mechanism, heating cleaning mechanism, and the shearing mechanism here is identical with original, and shearing mechanism comprises conveyer belt 18, and conveyer belt 18 tops are successively provided with hopper 19, extruding Pressure roller 20 and cutter 21.

[0018] Wherein, the conveyor belt 18 is formed by a plurality of steel plates hinged to each other, and a wear-resistant PE plate is tiled on it. And squeeze roller 20 is that a plurality of cylinders are installed above the frame by series connection, and the upper and lower planes formed with conveyor belt 18 can limit and squeeze navel orange peel to a certain extent, so that navel orange peel is flattened and convenient for cutting behind. What cutter 21 adopted is a square blade, and the upper end of the square blade is connected with the cutter control cylinder. The air cylinder piston is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com