Conversion method for m-dinitrobenzene, process for producing meta-nitroaniline and m-phenylenediamine

A technology for m-dinitrobenzene and fermentation medium, which is applied in the field of conversion of m-dinitrobenzene, can solve problems such as environmental pollution, high production cost, low yield, etc., achieves low cost, mild conditions, and is conducive to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

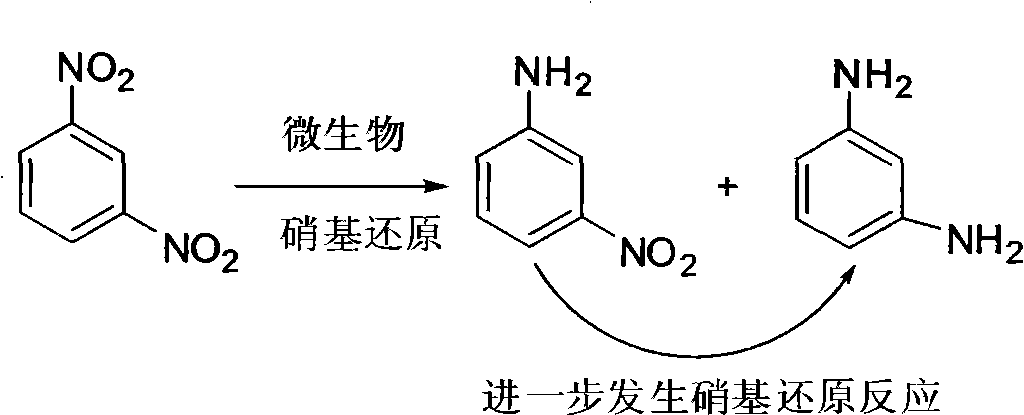

Method used

Image

Examples

Embodiment 1

[0035] 1. Microbial transformation reaction of Aeromonas hydrophila to m-dinitrobenzene

[0036] The biotransformation of m-dinitrobenzene was carried out by Aeromonas hydrophila, and the bacterial culture medium was: 5 grams of peptone, 1 gram of yeast extract, 23 grams of crude sea salt, 1 liter of water, and the pH of the medium was 7.5. The sterilized medium was inoculated with Aeromonas hydrophila, and cultured in a shake flask at room temperature at a rotational speed of 120 rpm.

[0037] After Aeromonas hydrophila was inserted into the medium and cultivated for 24 hours, m-dinitrobenzene was dissolved in ethanol solvent, 1 g / L m-dinitrobenzene was added to the transformation group, and a blank control group was established at the same time. , that is, adding 1 g / L of m-dinitrobenzene to the blank medium.

[0038] 2. Extraction, separation and identification of transformation products of m-dinitrobenzene transformed by Aeromonas htdrophila

[0039] 1. Extraction of tra...

Embodiment 2

[0049] Vibrio cholerae Vibrio cholerae was used, and others were the same as in Example 1.

Embodiment 3

[0051] Aspergillus sp. was used, and others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com