Extracting and separating method and device for waste acid generated in production procedure of m-dinitrobenzene

A technology for the production process of m-dinitrobenzene, which is applied in the field of extraction, separation and installation of waste acid produced in the production process of m-dinitrobenzene, and can solve the problems of high energy consumption cost, high safety, and high content of nitrates , achieve the effect of low energy consumption cost, high separation efficiency and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

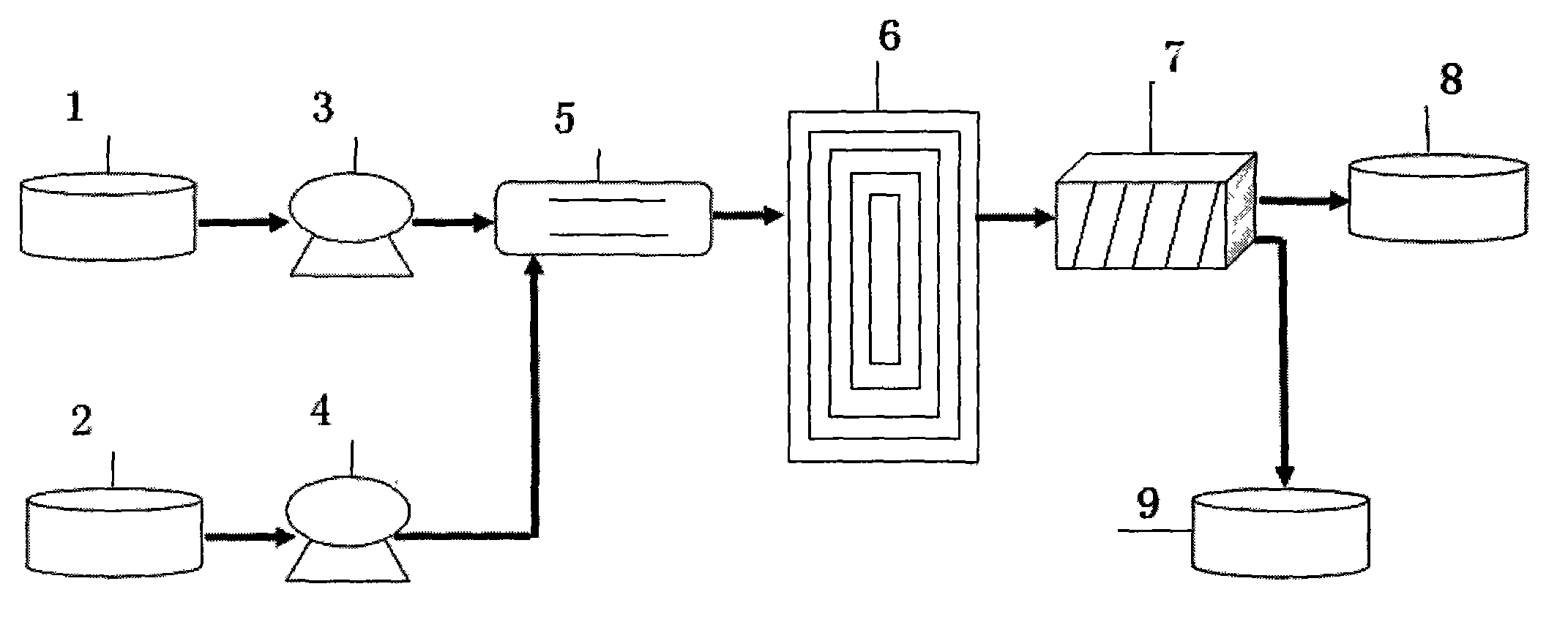

[0025] A kind of extraction separation method that produces waste acid in the m-dinitrobenzene production process of the present invention, concrete steps are as follows:

[0026] Step 1, put benzene and waste acid with a mass concentration of 68% into the injector 5 for mixing, the volume ratio of benzene and waste acid is 7:1, and a mixed solution is obtained;

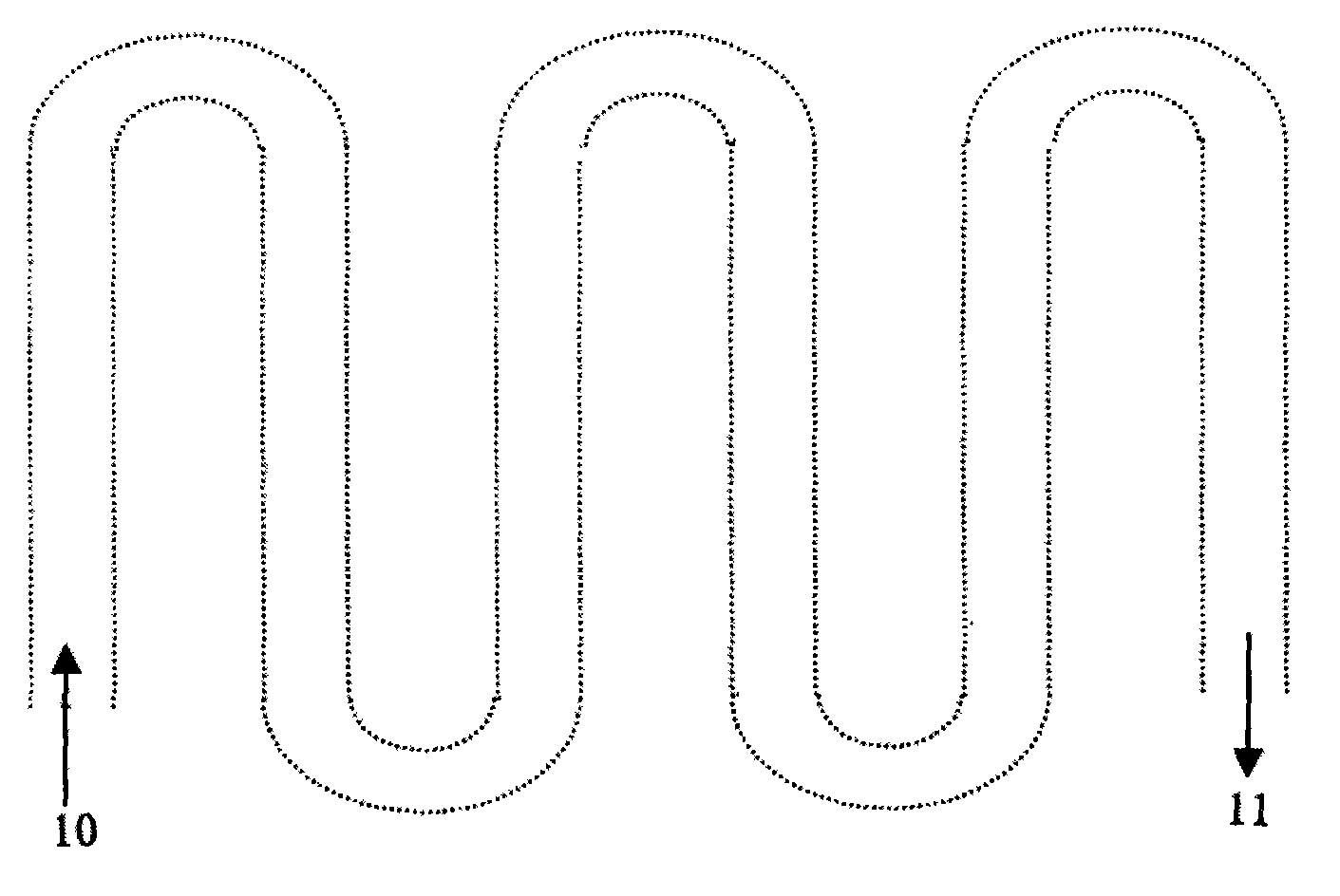

[0027] Step 2. Spray the mixed solution obtained in Step 1 to the static mixing tube 6 with the injector 5. The temperature in the static mixing tube is 20-22° C., fully mixed, and the extraction process is completed at the same time, and the mixed solution extracted by benzene will be obtained;

[0028] Step 3, the benzene-extracted mixed solution in step 2 flows into the inclined plate separator 7 for separation, and the angle of inclination of the inclined plate separator 7 is 30°, so as to obtain acidic benzene and the extracted waste acid solution;

[0029] Step 4, the acidic benzene obtained in step 3 is transf...

Embodiment 2

[0034] Step 1, put benzene and waste acid with a mass concentration of 70% into the injector 5 for mixing, the volume ratio of benzene and waste acid is 7.5:1, to obtain a mixed solution;

[0035] Step 2. Spray the mixed solution obtained in Step 1 to the static mixing tube 6 with the injector 5. The temperature in the static mixing tube is 24-28° C., fully mixed, and the extraction process is completed at the same time, and the mixed solution extracted by benzene will be obtained;

[0036] Step 3, the benzene-extracted mixed solution in step 2 flows into the inclined plate separator 7 for separation, and the angle of inclination of the inclined plate separator 7 is 45°, so as to obtain acidic benzene and the extracted waste acid solution;

[0037] Step 4, the acidic benzene obtained in step 3 is transferred to the acidic benzene transfer tank 8, and the extracted waste acid solution obtained in step 3 is transferred to the waste acid storage tank 9, and its nitrate content is ...

Embodiment 3

[0042] Step 1, put benzene and waste acid with a mass concentration of 73% into the injector 5 for mixing, the volume ratio of benzene to waste acid is 8:1, and a mixed solution is obtained;

[0043] Step 2. Spray the mixed solution obtained in Step 1 to the static mixing tube 6 with the injector 5. The temperature in the static mixing tube is 27-31° C., fully mixed, and the extraction process is completed at the same time, and the mixed solution extracted by benzene will be obtained;

[0044]Step 3, the benzene-extracted mixed solution in step 2 flows into the inclined plate separator 7 for separation, and the angle of inclination of the inclined plate separator 7 is 40°, so as to obtain acidic benzene and the extracted waste acid solution;

[0045] Step 4, the acidic benzene obtained in step 3 is transferred to the acidic benzene transfer tank 8, and the extracted waste acid solution obtained in step 3 is transferred to the waste acid storage tank 9, and its nitrate content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com