Preparation method of high-dispersibility m-dinitrobenzene hydrogenation structuring catalyst

A structured catalyst, m-dinitrobenzene technology, applied in the chemical industry, can solve the problems of low specific surface area, low dispersion, large metal particles, etc., achieve simple process, reduce production cost, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

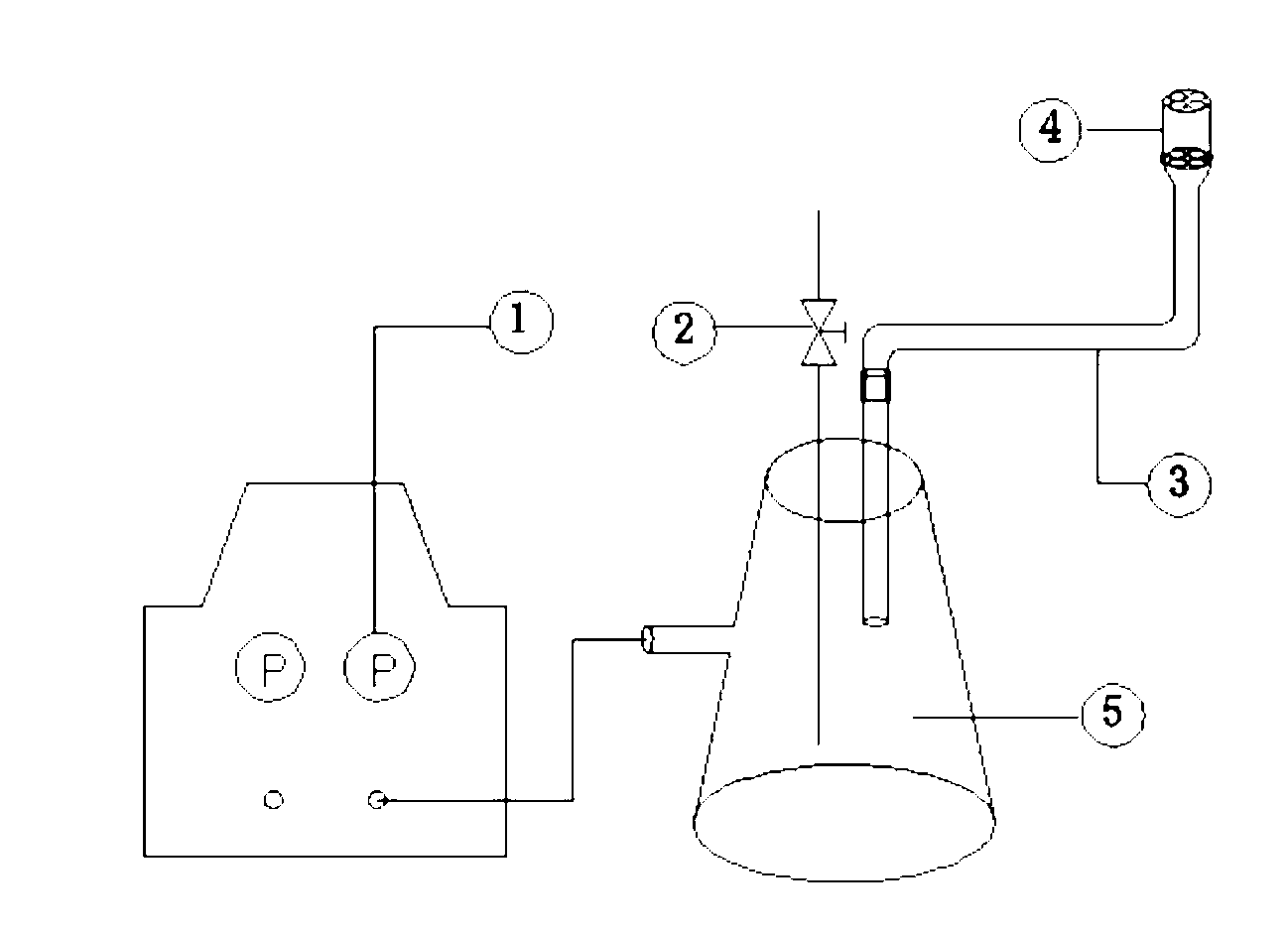

Image

Examples

Embodiment 1

[0035] A kind of preparation method of highly dispersed m-dinitrobenzene hydrogenation structured catalyst, comprises the following steps:

[0036](1) Excessive impregnation: The cordierite honeycomb ceramic substrate coated with γ-Al2O3, as a structured substrate, is immersed in a nickel nitrate impregnation solution with a concentration of 0.5mol / L, and the impregnation time is 1h;

[0037] (2) Drying and roasting: The structured substrate treated by vacuum suction was first rotated and dried at room temperature for 24 hours, then dried at a constant temperature of 120°C for 2 hours, and finally roasted at a constant temperature of 400°C for 3 hours to obtain Ni / γ-Al 2 o 3 / cordierite structured catalyst precursor;

[0038] (3) Repeated load: according to the obtained Ni / γ-Al 2 o 3 / The quality difference between the cordierite structured catalyst precursor and the cordierite honeycomb ceramic matrix coated with γ-Al2O3, calculate the loading amount of the active compone...

Embodiment 2

[0043] A kind of preparation method of highly dispersed m-dinitrobenzene hydrogenation structured catalyst, comprises the following steps:

[0044] (1) Excessive impregnation: The cordierite honeycomb ceramic substrate coated with γ-Al2O3, as a structured substrate, is immersed in a nickel nitrate impregnation solution with a concentration of 0.5mol / L, and the impregnation time is 1h;

[0045] (2) Vacuum suction: Take out the impregnated structured matrix, put it into the vacuum suction system, adjust the vacuum degree to 0.05MPa, and the vacuum time to 2min;

[0046] (3) Drying and roasting: The structured substrate treated by vacuum suction was first rotated and dried at room temperature for 24 hours, then dried at a constant temperature of 120°C for 2 hours, and finally roasted at a constant temperature of 400°C for 3 hours to obtain Ni / γ-Al 2 o 3 / cordierite structured catalyst precursor;

[0047] (4) Repeated load: according to the obtained Ni / γ-Al 2 o 3 / The quality ...

Embodiment 3

[0051] A kind of preparation method of highly dispersed m-dinitrobenzene hydrogenation structured catalyst, comprises the following steps:

[0052] (1) Excessive impregnation: The cordierite honeycomb ceramic substrate coated with γ-Al2O3, as a structured substrate, is immersed in a nickel nitrate impregnation solution with a concentration of 0.2mol / L, and the impregnation time is 2h;

[0053] (2) Vacuum suction: Take out the impregnated structured matrix, put it into the vacuum suction system, adjust the vacuum degree to 0.095MPa, and the vacuum time to 1min;

[0054] (3) Drying and roasting: The structured substrate treated by vacuum suction was first rotated and dried at room temperature for 24 hours, then dried at a constant temperature of 120°C for 2 hours, and finally roasted at a constant temperature of 400°C for 3 hours to obtain Ni / γ-Al 2 o 3 / cordierite structured catalyst precursor;

[0055] (5) Repeated load: according to the obtained Ni / γ-Al 2 o 3 / The quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com