Core shell catalyst by taking hydrotalcite as shell and molecular sieve as core as well as preparation and application thereof

A technology of core-shell catalyst and core-shell molecular sieve, which is applied in the direction of molecular sieve catalyst, physical/chemical process catalyst, amino compound preparation, etc. It can solve the problems of poor stability and easy sintering, low metal loading, uncontrollable size, etc., and achieve high utilization rate High, simple preparation process, easy to industrialized production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Dissolve 1 g of silica-alumina molecular sieve with FAU topological structure in 50 mL of deionized water, stir at room temperature for half an hour, and ultrasonicate for half an hour to make it uniformly dispersed into a solution for later use.

[0030] b. Dissolve 1.5 g of nickel nitrate and 1.5 g of ammonium chloride in 50 mL of deionized water, stir evenly at room temperature to form b solution for later use.

[0031] c. Slowly add the above-mentioned solution b into the solution a, stir evenly at room temperature, then slowly add ammonia water dropwise, and prepare C solution with pH=8 for later use.

[0032] d. The above C solution was stirred at 70°C for 12 hours, the filtrate was alternately washed with water and ethanol until neutral, and vacuum-dried at room temperature to obtain a core-shell structure with molecular sieve as the core and petal-shaped hydrotalcite as the shell. Appearance of FAU / NiAl LDHs molecular sieves.

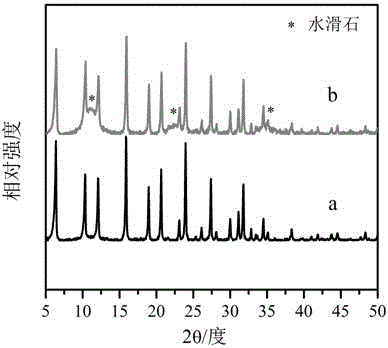

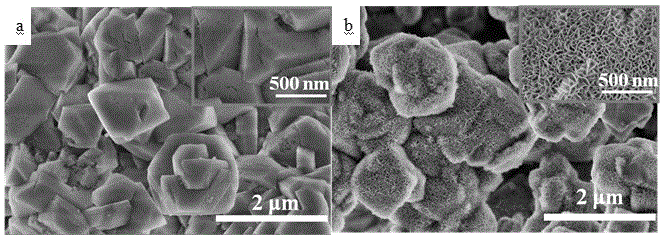

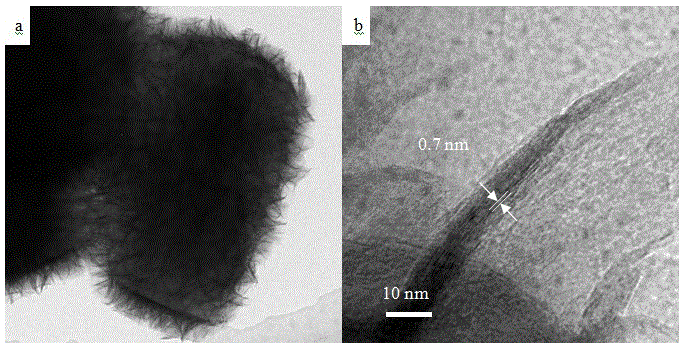

[0033] See attached figure 1 ...

Embodiment 2

[0037] a. Dissolve 0.8 g of silica-alumina molecular sieve with FAU topological structure in 50 ml of deionized water, stir at room temperature for half an hour, and ultrasonically disperse evenly for half an hour to form a solution for later use.

[0038] b. Dissolve 1.5 g of nickel nitrate and 2.4 g of ammonium nitrate in 50 ml of deionized water, stir evenly at room temperature to form b solution for later use.

[0039] c. Slowly add the above-mentioned solution b into solution a, stir evenly at room temperature, then slowly add ammonia water dropwise, and prepare C solution with pH=9 for use.

[0040] d. The above C solution was stirred at 50°C for 20 hours, the filtrate was alternately washed with water and ethanol until neutral, and vacuum-dried at room temperature to obtain a core-shell structure with molecular sieve as the core and petal-shaped hydrotalcite as the shell. Appearance of FAU / NiAl LDHs molecular sieves.

Embodiment 3

[0042] a. Dissolve 1.5g of silica-alumina molecular sieve with FAU topological structure in 50 ml of deionized water, stir at room temperature for half an hour, and ultrasonicate for half an hour to make it uniformly dispersed into a solution for later use.

[0043] b. Dissolve 1.9g of magnesium nitrate and 2.4g of ammonium nitrate in 50ml of deionized water, stir evenly at room temperature to form b solution for later use.

[0044] c. Slowly add the above-mentioned solution b into solution a, stir evenly at room temperature, then slowly add ammonia water dropwise, and prepare C solution with pH=7.5 for use.

[0045] d. The above C solution was stirred at 75°C for 45 hours, the filtrate was alternately washed with water and ethanol until neutral, and vacuum-dried at room temperature to obtain a core-shell structure with molecular sieve as the core and petal-shaped hydrotalcite as the shell. Appearance of FAU / MgAl LDHs molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com