Patents

Literature

109results about How to "Practical craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

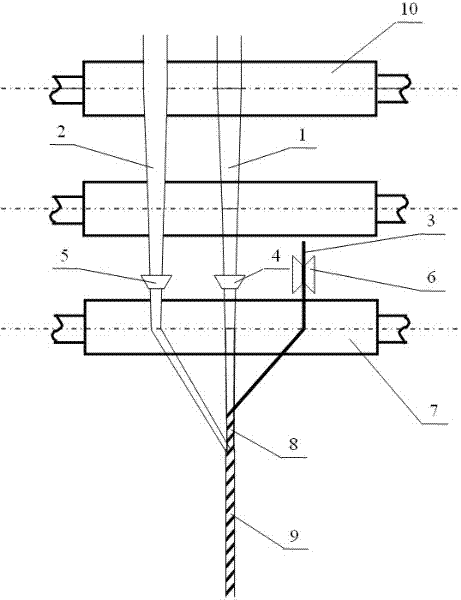

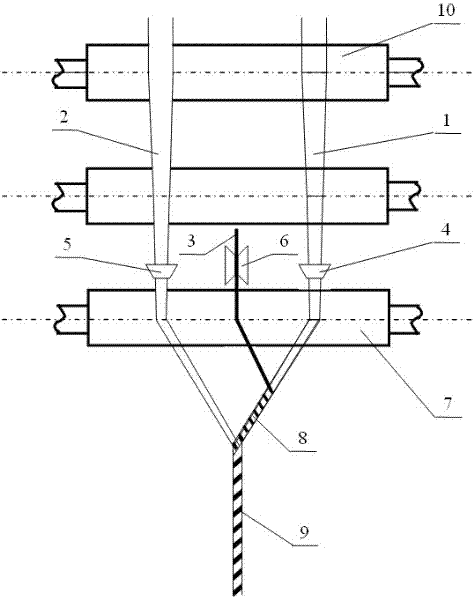

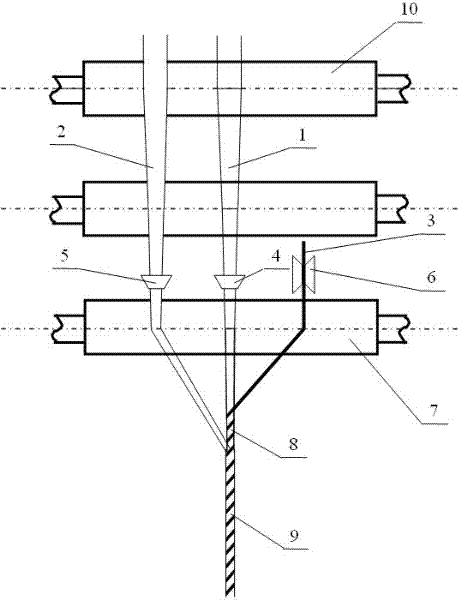

Three-axis-system composite spinning device and spinning method for tow-apt-to-fall staple

The invention provides a three-axis-system composite spinning device and a spinning method for tow-apt-to-fall staple. The three-axis-system composite spinning method is characterized in that the method comprises the steps of: feeding roving silvers containing the tow-apt-to-fall staple and cotton roving silvers into the back roller of a ring spinning machine, and conducting drafting to form a tow-apt-to-fall staple strand and a cotton strand which stretch straight in parallel; after the tow-apt-to-fall staple strand and the cotton strand are respectively positioned by using a tow-apt-to-fall staple strand positioner and a cotton strand positioner, feeding the tow-apt-to-fall staple strand and the cotton strand into the jaw of a front roller and directly feeding filament adjustable tension pulley into the jaw of the front roller; and after the tow-apt-to-fall staple strand, the cotton strand and the filament are output from the jaw of the front roller, twisting the tow-apt-to-fall staple strand and the filament at a first converging point outside the jaw of the front roller to form a structural section, and twisting the structural section and the cotton strand at a second converging point to form a three-axis-system composite yarn. The device and the method provided by the invention has the advantages that not only can the content of the tow-apt-to-fall staples in the spun composite yarn be improved, but also the situations of fiber damage and tow falling can be effectively avoided.

Owner:DONGHUA UNIV

Production process of high-elasticity non-woven three-dimensional cotton

The invention discloses a production process of high-elasticity non-woven three-dimensional cotton, comprising the following steps: mixing a low melting point hot melting viscose fiber and at least two fibers of other fibers in proportion; opening and scotching, and feeding cotton and carding and delivering to a vertical lapping forming machine to carry out vertical forming process. A fiber net is continuously folded and descends in a forming curtain at the action that a pendulum-type swinging folding mechanism swings left and right reciprocately, becomes continuous fiber net layers which are arranged in a vertical direction in a steerable channel, and finally forming the three-dimensional cotton which is arranged in a vertical direction through heat setting and cooling setting. The production process in the invention realizes production through a conventional non-woven heat setting machine at the condition of not adding any chemical adhesive, and sets the product thickness and density according to the process requirements; the process is simple, practical and efficient; any fiber can be used as the basic fiber of the material; the regenerated fiber also can be used for forming; and the material source is wide, is easy to obtain, and is relatively environment-friendly.

Owner:杭州缔星纤维科技有限公司

Rare-earth doped leadless and low-melting point sealing glass and its preparation method

InactiveCN101456674AMaintain the ability to formExpand the scope of glass formingRare earthCopper oxide

The invention relates to a method for preparing rare earth doped lead-free sealing glass with low melting point, which comprises the following steps: based on raw materials adopted by a Bi2O3-ZnO-B2O3 glass system, adding proper amount of rare earth oxide into the raw materials, and mixing, melting, annealing, grinding and sieving the mixture to obtain the rare earth doped lead-free sealing glass with the low melting point. The sealing glass comprises the following main components by weight portion: 65.22 to 85.22 portions of bismuth oxide, 4.63 to 11.78 portions of boric acid, 5.76 to 10.76 portions of zinc oxide, 0.80 to 2.80 portions of copper oxide, 0.42 to 2.42 portions of cobalt oxide, 3.32 to 8.47 portions of barium carbonate, 0.4 to 1.8 portions of aluminum oxide, and 0.1 to 6.0 portions of rare earth oxide. The method solves the problems that the sealing glass with the low melting point has low sealing temperature, high sealing strength, stable glass structure and the like under lead-free conditions, and has the advantages of simple process, practicability and reliability; and the prepared rare earth doped lead-free sealing glass with the low melting point is particularly suitable for sealing and closing of stainless steel materials, electrons and electric appliances.

Owner:WUHAN UNIV OF TECH

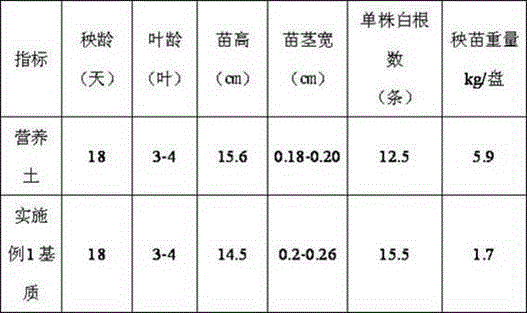

Preparation method of organic substrate for raising rice seedlings

InactiveCN104478595APromotes robust growthFull of nutritionBioloigcal waste fertilisersPotassium fertilisersNutritionEffective microorganism

The invention discloses a preparation method of an organic substrate for raising rice seedlings. The substrate consists of a fermented mixed material of vinegar residue, cassava residue and straw powder, coconut chaff wet materials, plant ash, grass carbon and vermiculite. The preparation method comprises the following steps: airing crop straws, and crushing the crop straws into particles of which the sizes are smaller than 5mm; composting, thoroughly decomposing and fermenting the mixed material by using fermentation strains containing beneficial microorganisms, wherein the vinegar residue accounts for 25-35 percent, the cassava residue accounts for 40-50 percent, and the straw powder accounts for 15-25 percent; adding the coconut chaff wet materials, the plant ash, the grass carbon, the vermiculite, a compound fertilizer, a synergist and chlormequat chloride; fully stirring and uniformly mixing the raw and auxiliary materials, and then performing bagging, weighing, packaging and warehousing. Organic wastes serve as raw materials, so that the nutrition is comprehensive; pest and disease damages and worm eggs are eliminated due to fermentation by virtue of the beneficial microorganisms, the application effect is particularly good, and the method is suitable for raising the rice seedlings, can promote the healthy growth of the seedlings and can be popularized and applied all over the country.

Owner:江苏兴农基质科技有限公司

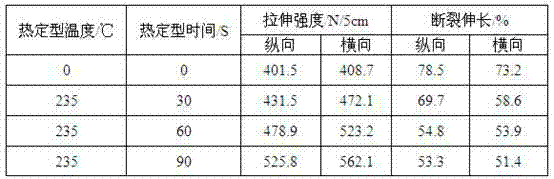

Method for manufacturing high-strength needling nonwoven geotextiles

InactiveCN102454046AIncrease the strength of collusionGood dimensional stabilityHeating/cooling textile fabricsNon-woven fabricsPolymer scienceHeat setting

The invention discloses a method for manufacturing high-strength needling nonwoven geotextiles. The method comprises the steps of loosening fibers, blending the fibers, carding the fibers into a mesh, spreading the mesh, needling the mesh, carrying out heat setting on the needled mesh and winding the finished product. According to the invention, a heat setting procedure is additionally increased in the traditional process for manufacturing staple fiber needling nonwoven geotextiles; residual stresses, which are accumulated within the fibers and the geotextiles and generated in the procedures of loosening the fibers, blending the fibers, carding the fibers into the mesh, spreading the mesh as well as needling and solidifying the mesh, are eliminated through heat setting treatment so that the knot strength between the fibers is enhanced and the physical mechanical performance of the geotextile is improved and enhanced; and simple and practical process is obtained.

Owner:江苏苏豪不动产经营管理有限公司 +1

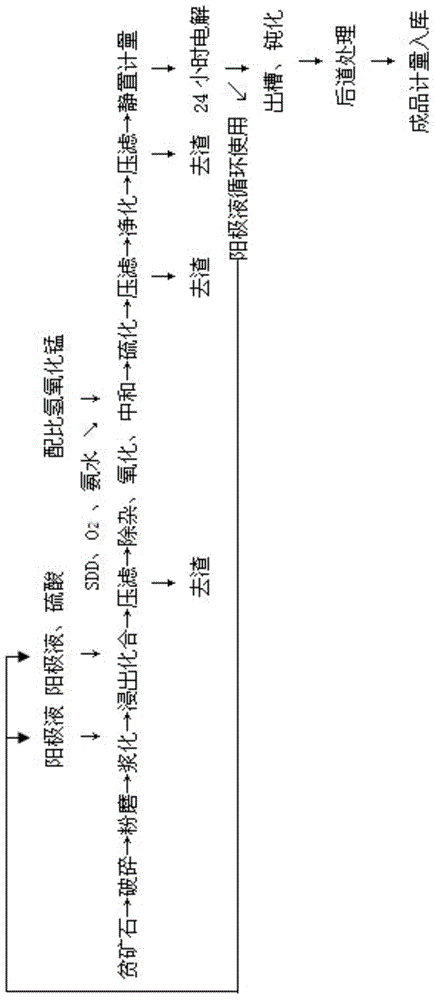

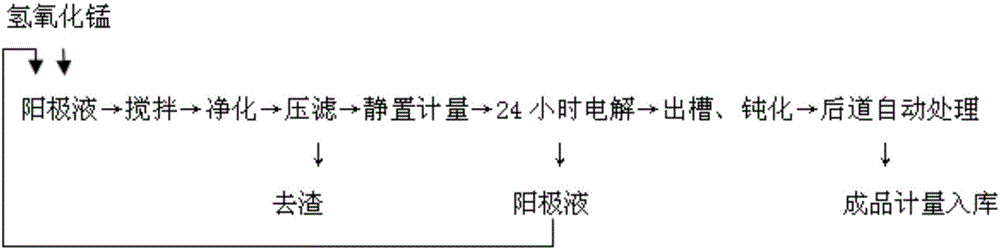

Brand new method of producing electrolytic manganese metal

ActiveCN104018184AImprove leaching rateImprove total manganese recoveryPhotography auxillary processesElectrolysis componentsElectrolysisSlag

The invention discloses a brand new method of producing electrolytic manganese metal. The method comprises the following steps: (1) grinding lean manganese ore powder, adding an anode liquor of electrolytic manganese and then adding the anode liquor of electrolytic manganese to be reacted with sulfuric acid to obtain a reaction leachate; (2) carrying out press filtering on the reaction leachate so as to remove slags, adding SDD (Sodium Dimethyl Dithiocarbamate) to remove impurites, introducing oxygen to oxidize, then adding manganese hydroxide to react, supplementing ammonium water to neutralize, and then adding a vulcanizing agent to further remove impurities; (3) after further carrying out press filtering so as to slags, carrying out deep purification and press filtering so as to remove slags, standing and metering to obtain an electrolyte; (4) electrolyzing the electrolyte to obtain the electrolytic manganese metal, wherein the anode liquor of electrolytic manganese is recycled. The invention further discloses a method of producing electrolytic manganese metal by fully replacing manganese ores by manganese hydroxide. The two methods disclosed by the invention can be used for improving the manganese leaching efficiency, saving the use level of auxiliary materials, lowering the production cost, simplifying the production flow and reducing the amount of waste residues, is free from influence on electrolysis and is mature, simple and practical in process.

Owner:张安良 +1

Method for using waste concrete as active admixture in cement production

ActiveCN103396020AReduce heat consumptionDoes not affect normal productionCement productionClinker (waste)Process engineering

The invention relates to a method for using waste concrete as active admixture in cement production, which comprises steps as follows: waste concrete is crushed into a particle material with the particle size of at most 40mm; in a rotary kiln cement production process, high-temperature clinker is added to a section between a clinker cooling zone of the rotary kiln head and the blanking port, or a high-temperature space section with the clinker temperature of at least 550 DEG C in the grate cooler; waste heat of the high-temperature clinker is directly utilized to perform thermal activation treatment on the particle waste concrete, and the waste concrete subjected to clinker waste heat activation treatment is mixed in the clinker to be directly used as the active admixture in the clinker; and the waste concrete accounts for 1-30 wt% of the primary clinker fired in the rotary kiln. The invention is simple and easy to implement, has the advantages of no investment pressure and favorable economical efficiency, can be accepted by people, can solve the problems of shortage and cost of the admixture to some extent, is beneficial to inhibiting abundant utilization of inferior admixtures, especially raw shale, raw dirt, douke and the like, in the cement grinding, and lowers the probability of jerry-built projects.

Owner:长沙紫宸科技开发有限公司

Formation method of anode aluminum foil for high-voltage aluminum electrolytic capacitor

InactiveCN101748462AIncrease capacityPractical craftAnodisationElectrolytic capacitorsPhosphateMetallurgy

The invention relates to a formation process of an anode aluminum foil for a high-voltage aluminum electrolytic capacitor, which comprises the following steps sequentially: pretreatment, 100-240V first order formation treatment, 300-450V second order formation treatment, 400-600V third order formation treatment, 500-620V fourth order formation treatment, depolarizing treatment and drying, wherein in the pretreatment step, the aluminum foil after erosion pore expanding is put in de-ionized water of 92-100 DEG C for soaking treatment, and the treating solution of the formation treatment is a mixed water solution of some materials of boric acid, phosphate and ammonium pentaborate. The invention has the beneficial effects that the process is practical and can improve the volume of the anode aluminum foil by 8-10% for the high-voltage aluminum electrolytic capacitor with voltage of 400-650V.

Owner:YIDU DONGYANGGUANG FORMED FOIL

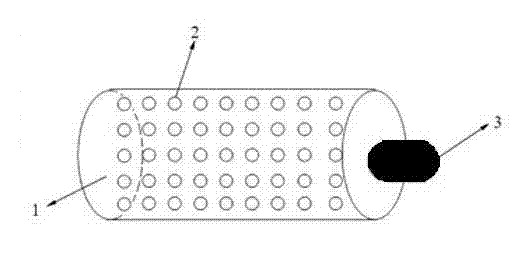

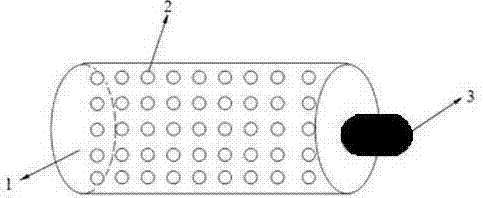

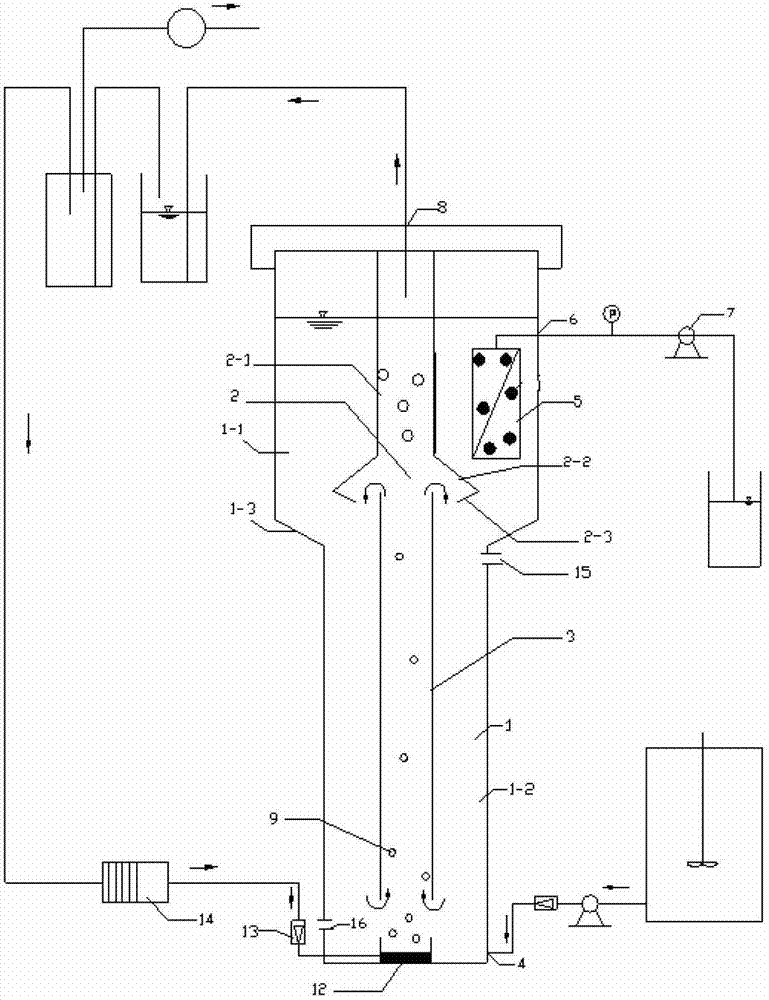

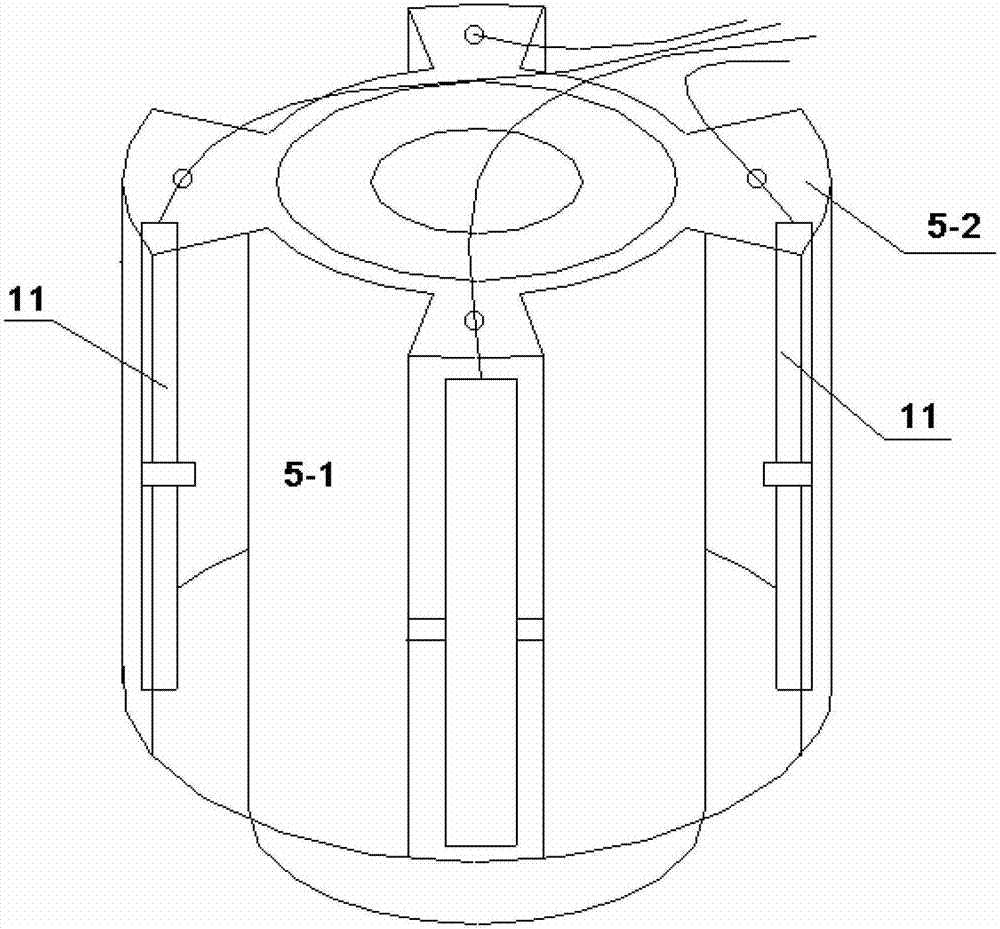

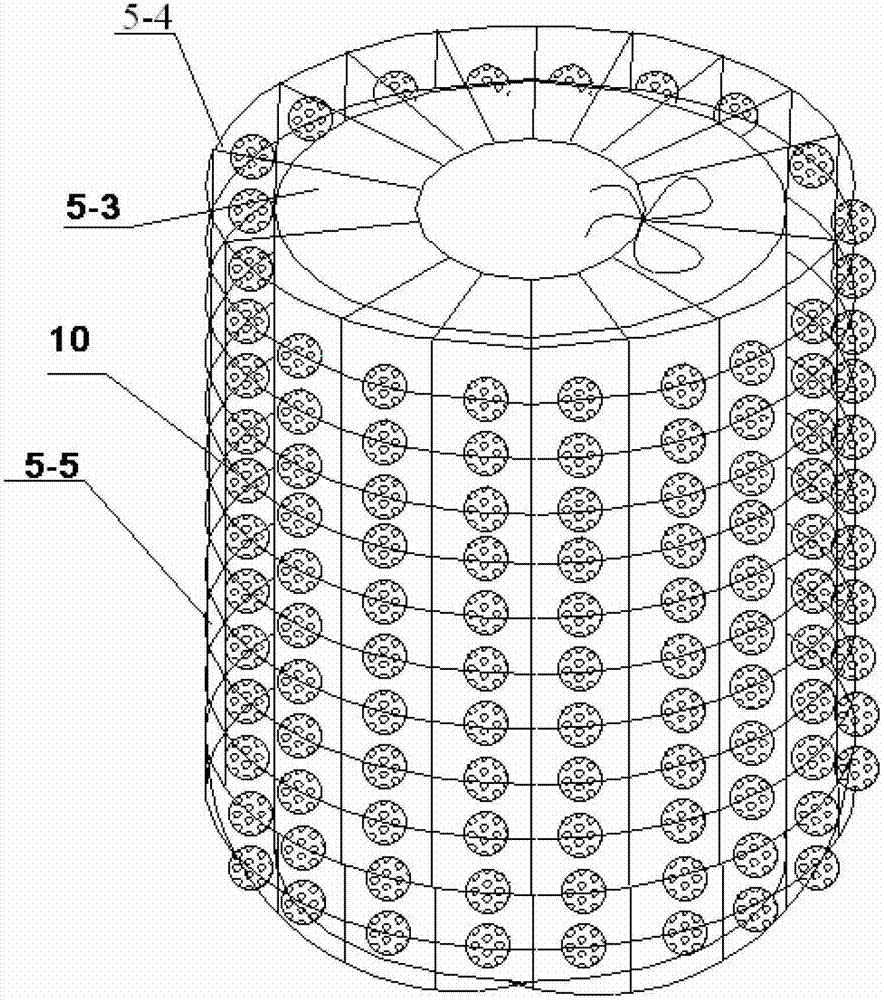

Photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor and working method thereof

InactiveCN103073150AEasy to handleAchieve the purpose of recyclingWater/sewage treatment by irradiationWaste based fuelFiberPhotocatalytic reaction

The invention relates to a photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor. The photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor comprises a reaction barrel, a gas stripping barrel, a three-phase separator and a membrane assembly, wherein a water inlet pipe and a gas inlet pipe are arranged at the bottom of the reaction barrel; and the membrane assembly is a cylindrical ceramic membrane loaded with nano-titanium dioxide particles, or the membrane assembly is a hollow fiber ultrafiltration membrane of which a light titanium dioxide particle mesh is hung on the outer surface. The invention further discloses a working method of the photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor. An internal-circulation anaerobic treatment technology and a titanium dioxide photocatalytic technology are combined, and advantages of an anaerobic membrane bioreactor and a photocatalytic bioreactor are combined, so that quality of outlet water is obviously improved; and the membrane assembly is arranged at a supernatant part of a three-phase separation zone and doses not directly contact sludge, and nano-titanium dioxide has a photocatalytic effect, so that membrane pollution is greatly reduced, the service life of the membrane assembly is prolonged, and manpower and material resources required in a membrane replacing cycle are reduced.

Owner:SHANDONG UNIV

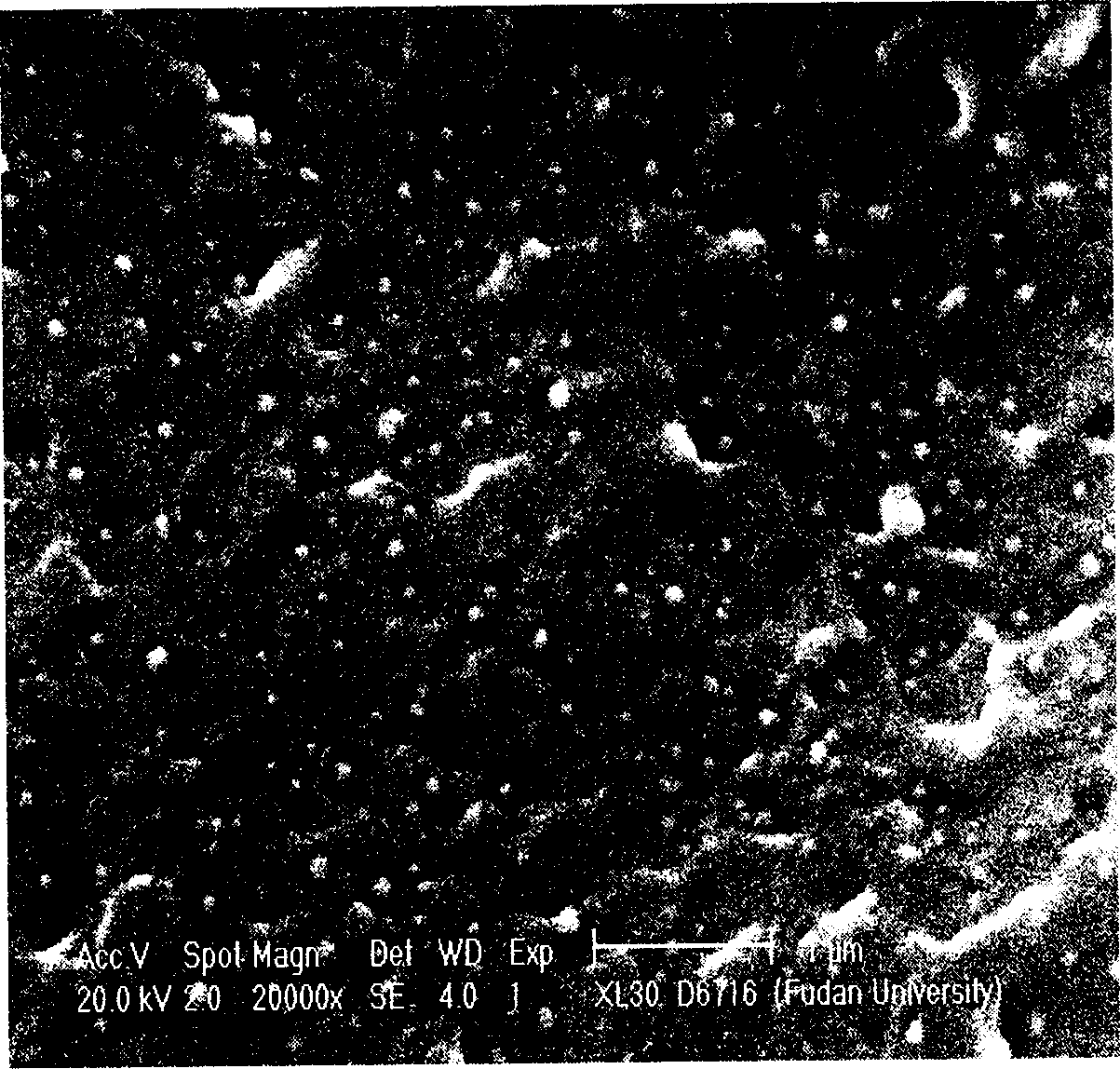

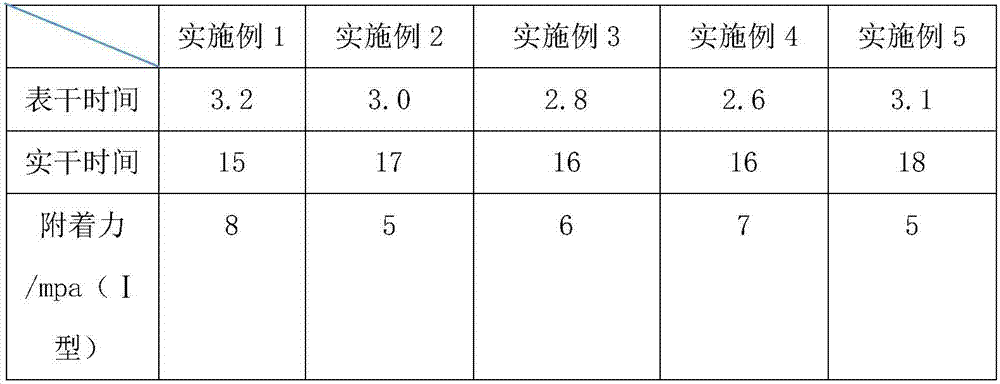

Nanometer composite acrylic resin with high solid content and low viscosity and the prepn of its coating

The present invention belongs to the field of new chemical material, and is one kind of nanometer composite acrylic resin with high solid content and low viscosity and the preparation of its coating. The nanometer composite acrylic resin is prepared with nanometer oxide sol and acrolactic ester monomer or acrolactic ester resin, and through mixing, decompression distillation to eliminate alcohol or water, and in-situ polymerization or mixing. It has solid content higher than 70 wt%, viscosity lower than 2500 mPa.s, and content of nanometer oxide dispersed homogeneously in the resin system in 1-30 wt%. The nanometer composite acrylic resin may be cross-linked and cured together with isocyanate or amino resin to obtain nanometer composite acrylic resin coating, and the coating has high transparency and glossiness, high antiwear performance, high scratch resistance, high hardness, high weather resistance, etc. and may be used for automobile, plastic, metal, etc.

Owner:FUDAN UNIV

Novel bentonite sodium modification process

The invention discloses a novel bentonite sodium modification process. The process comprises the following steps of screening mineral resources, cutting and crushing through a rotary cultivator, adding a modifier for mixing and performing sodium treatment, turning and uniformly mixing, ageing, drying, grinding, detecting, metering and packaging, thereby obtaining a finished product. Compared with the prior art, the method has the advantages that indoor crushing is changed into field mine crushing, so that the occupied indoor space is greatly reduced; two processes of double spiral mixing and double-roller extruding are canceled, so that the process can be simplified; devices such as a double spiral mixer, a double-roller extruder and a belt conveyor are saved, and the driving energy consumption of the saved devices is saved. Therefore, the process is simple, practical, efficient, less in environmental pollution, high in sodium treatment efficiency and suitable for the bentonite industry.

Owner:湖南飞来峰非金属矿物材料有限公司

Double-redundancy six-phase moment motor for precision instrument and device, and control method thereof

InactiveCN104184285AAchieve direct driveEasy to processElectronic commutation motor controlAC motor controlControl systemElectric machine

The invention discloses a double-redundancy six-phase moment motor for a precision instrument and device, and a control method thereof. The motor is an AC permanent magnetic synchronous servo motor, is formed by assembling stators and a rotor, and is characterized in that the stator and the rotor employ a double-stator and single-rotor structure. A double-stator structure is as follows: double stators employ a splicing type structure and are provided with two independent stator windings; the two independent stator windings share one permanent magnet; the housing of the motor stators is provided with cooling grooves, the two sides of the housing are provided with sealing grooves, through a cooling system, the operation temperature of the stator can be reduced, and the output power of the motor is improved; and the two independent stator windings are controlled by a control system so as to realize individual operation of one of the stator windings and parallel operation of the two stator windings. According to the invention, through double-redundancy control, when a certain control system fails, the other system can still work normally, such that the system reliability is improved. The motor and the method provided by the invention can also be applied to other high-precision instruments and devices.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

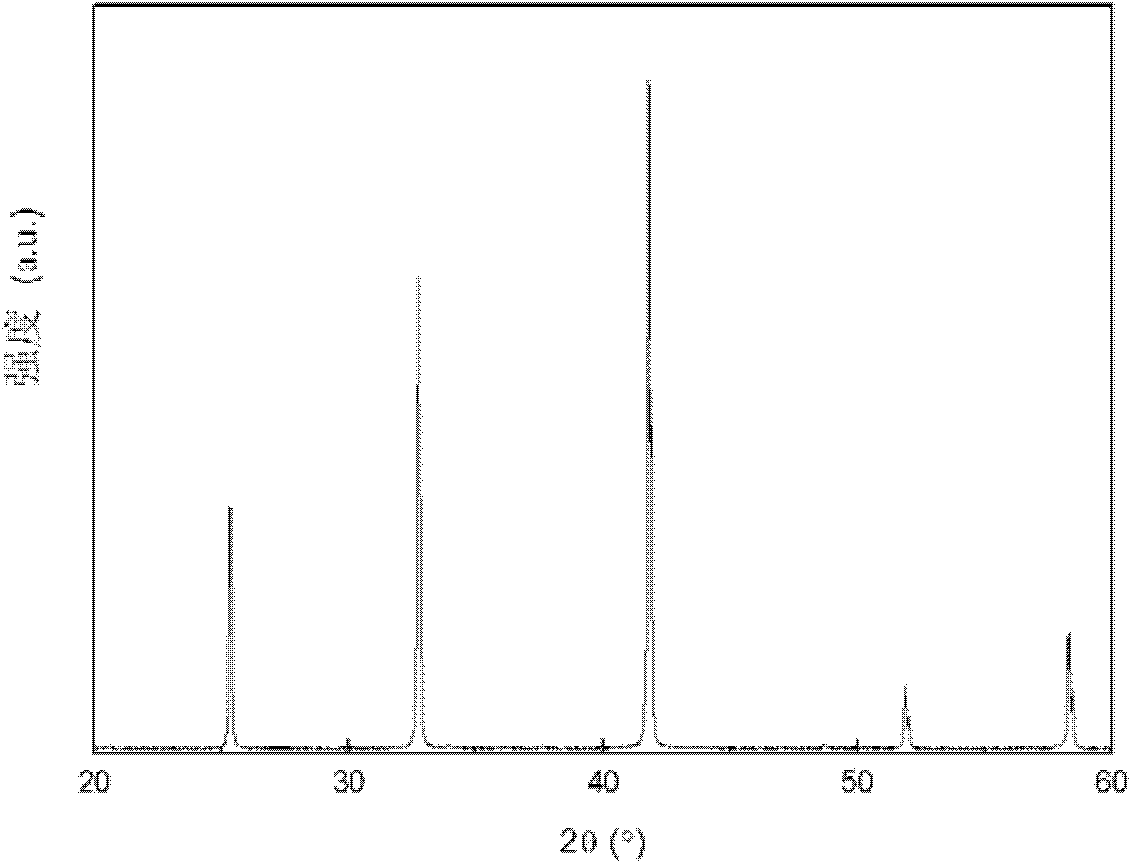

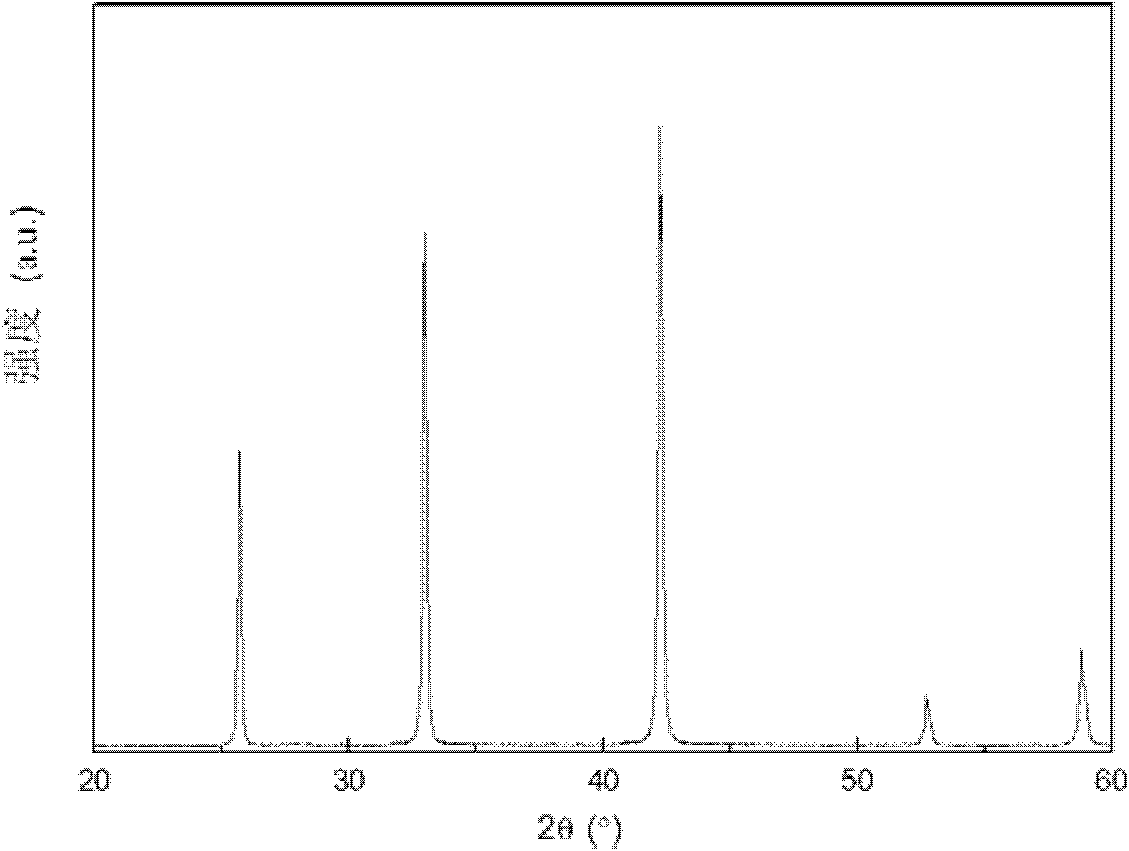

Preparation method of submicron transition metal boride powder with low oxygen content

The invention discloses a preparation method of a submicron transition metal boride powder with low oxygen content. The method comprises the following steps: first carrying out ball milling mixing and drying on a transition metal oxide and elementary substance boron to obtain a MO2 / B mixed powder carrying out heat treatment on the MO2 / B mixed powder to obtain a MB2 / B2O3 powder; adding the obtained MB2 / B2O3 powder into water, heating and stirring to dissolve out B2O3 therein and centrifuging to obtain a MB2 powder; carrying out heat treatment on the obtained MB2 powder again. Compared with a prior art, the transition metal boride powder prepared by the method of the invention has advantages of a small particle size of 200-700 nm, low degree of aggregation and an oxygen content about 0.01-1.0wt%; besides the process of the preparation method of the present invention is simple and practical, has strong controllability and is easy for realization of large scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

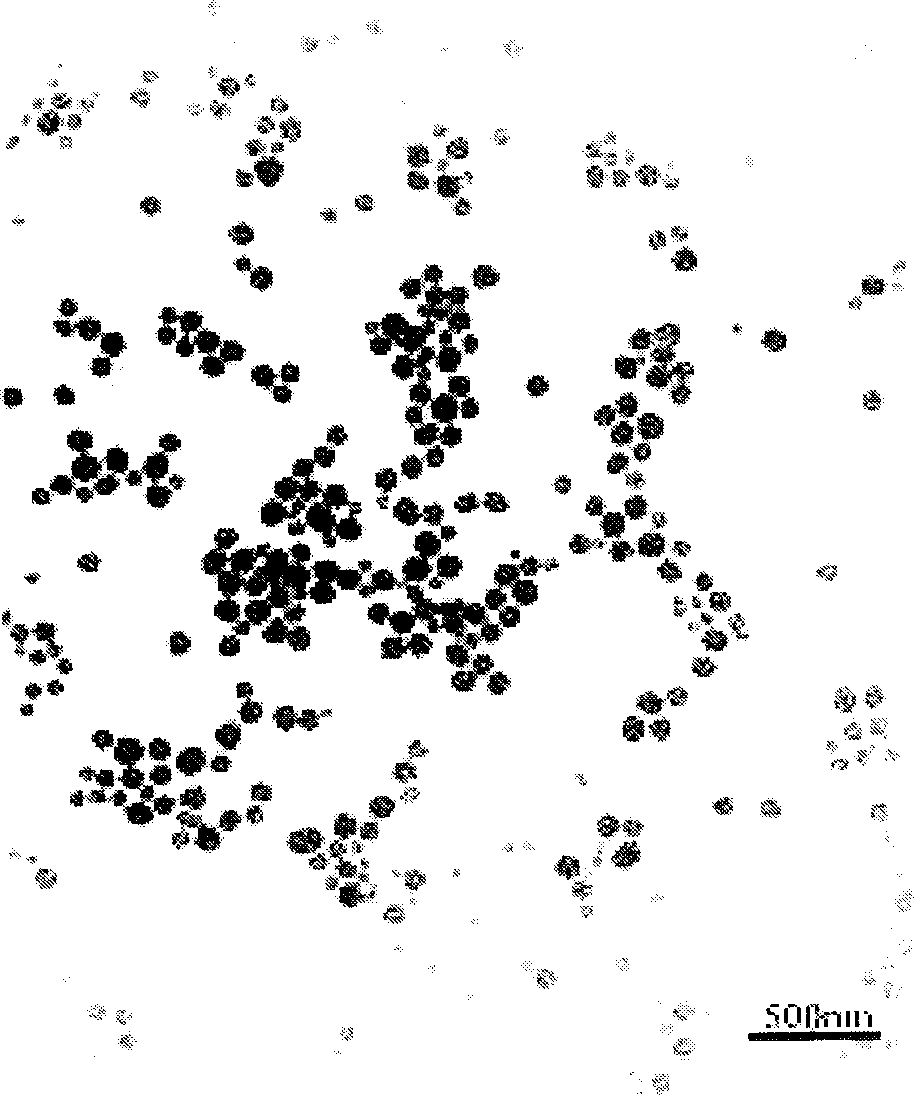

Preparation method and application of ecological finishing agent used for cellulose and protein fiber fabrics

InactiveCN103603195AImprove stabilityInhibition of agglomerationVegetal fibresAnimal fibresCelluloseNatural fiber

The invention relates to a preparation method and application of a deacetylated chitosan ecological finishing agent used for finishing natural fibers and regenerated natural fiber fabrics. The invention aims to solve the technical problems of a crosslinking problem, size and uniformity of chitosan acetic acid sol particles and stability of the finishing agent. The method is technically characterized by comprising the following steps: mixing chitosan and lacial acetic acid to form an acetic acid aqueous solution with the acetic acid concentration of 1.5-3 percent, dripping a 10g / L of ion stabilizer agar solution, regulating the size of the chitosan colloid particles to be in a distribution range of 60-100nm, forming a uniform and stable acetic acid-chitosan colloid solution of which the colloid size is in a nanoscale, controlling the pH value to be 4-7, wherein the viscosity of the colloid solution is 2-60mPa.s. The method has good chitosan fixation effect, does not have harmful or chemical residues and is environment-friendly, high-efficiency, harmless to human bodies and rich in raw material source.

Owner:安徽甲特生物科技有限公司

Antibacterial chitosan gauze and manufacturing method thereof

InactiveCN102134809AImprove antibacterialGood moisture absorption and air permeabilityFibre treatmentSURFACTANT BLENDChemistry

The invention relates to antibacterial chitosan gauze and a manufacturing method thereof, belonging to the technical field of antibacterial chitosan gauze manufacturing. The manufacturing method is technically characterized by comprising the following steps of: preparing chitosan, a crosslinking agent and water into a solution, adding water to dilute the solution, and preparing into a multifunctional chitosan finishing agent; preparing a cationic surfactant and water into a cationic surfactant solution, and adding a pH adjuster to adjust the pH value of the cationic surfactant solution to 9-11; heating the multifunctional chitosan finishing agent to 25-40 DEG C, immersing common gauze in the solution, rolling the immersed gauze, dehydrating the rolled gauze, and performing primary drying;immersing the dried gauze in an alkaline surfactant solution, maintaining the temperature at 25-40 DEG C, rolling the immersed gauze, removing the alkaline surfactant solution, and performing stentering formation and secondary drying. The antibacterial chitosan gauze has the advantages of good antibacterial action, small investment to production equipment, simple process and no influence on dyeing uniformity.

Owner:安徽甲特生物科技有限公司

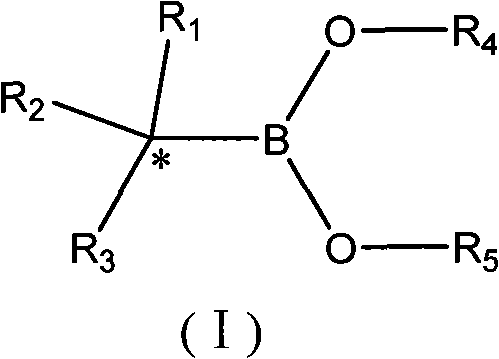

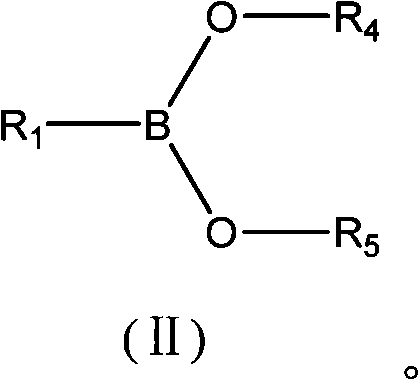

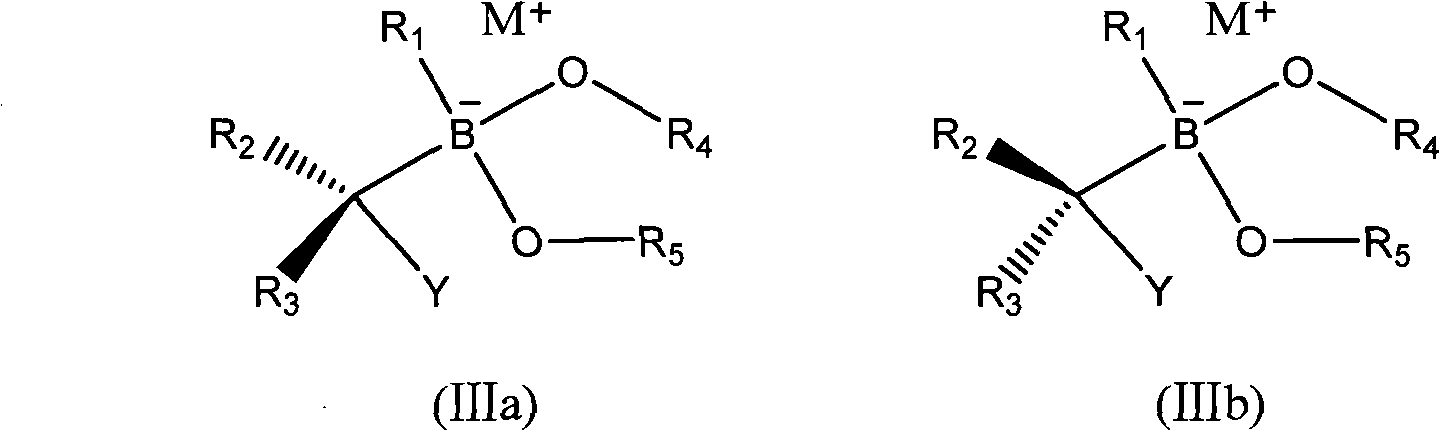

Synthesis technology of alpha-chiral boric acid and boric acid ester

ActiveCN101899062AHigh yieldLow costPeptidesGroup 3/13 element organic compoundsProduction rateBoric acid

The invention discloses an alpha-chiral boric acid ester compound disclosed by a general formula (I) and a technology for forming the alpha-chiral boric acid ester compound by detracting chiral protecting groups R4 and R5 of boric acid ester (1), wherein the general formula (I), the definitions of substituted groups in the alpha-chiral boric acid ester compound and the alpha-chiral boric acid compound are the same with the definition in a specification. The invention discloses the boric acid ester compound disclosed by the general formula (I) and a boric acid compound corresponding to the boric acid ester compound and comprises a synthesis technology of a dipeptide boric acid protease inhibitor (bortezomib). The synthesis technology has the advantages of higher route total production rate, lower cost, easier control of technical conditions and higher purity of products, recycle of byproducts and suitability for mass production when being used for synthesizing the boric acid and the boric acid ester compounds.

Owner:SHANGHAI VIWIT PHARMA CO LTD

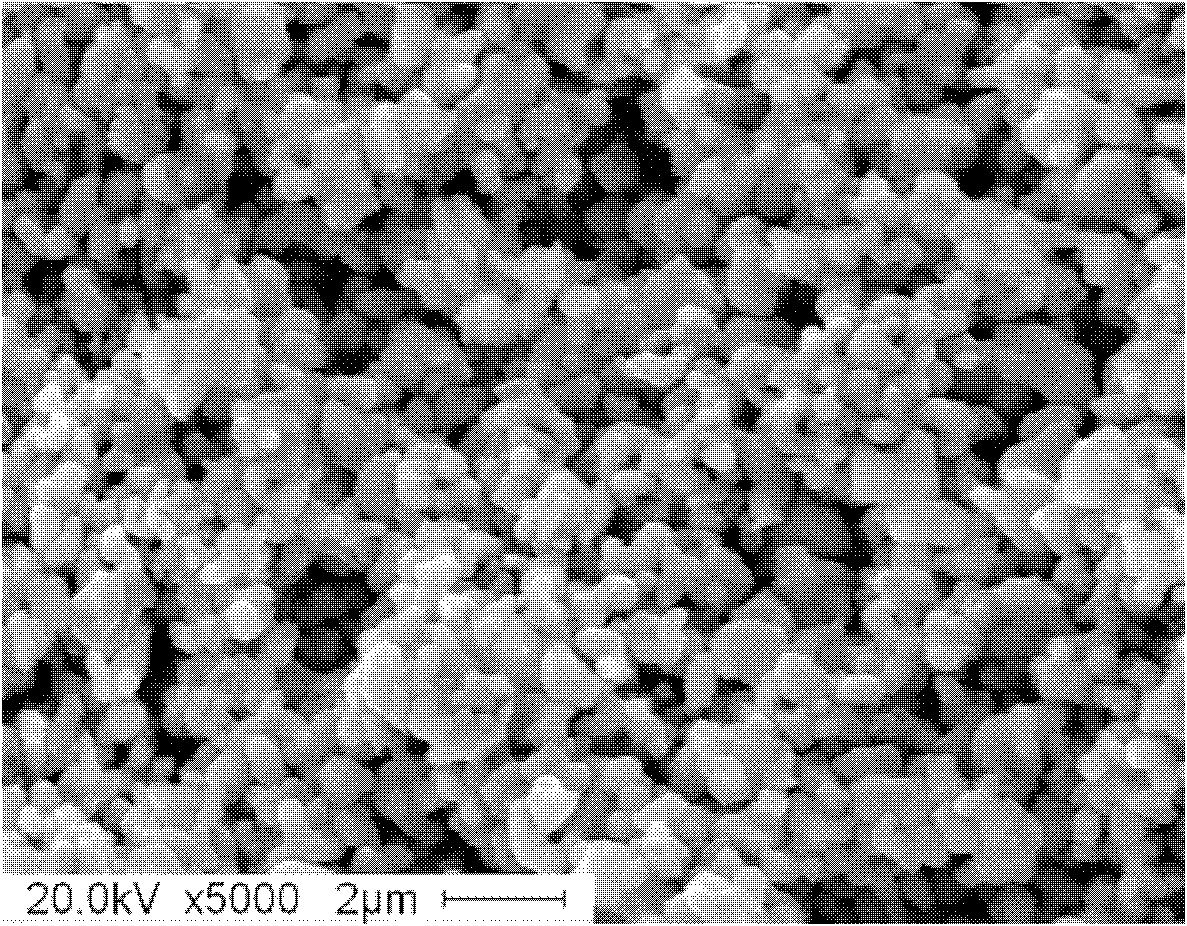

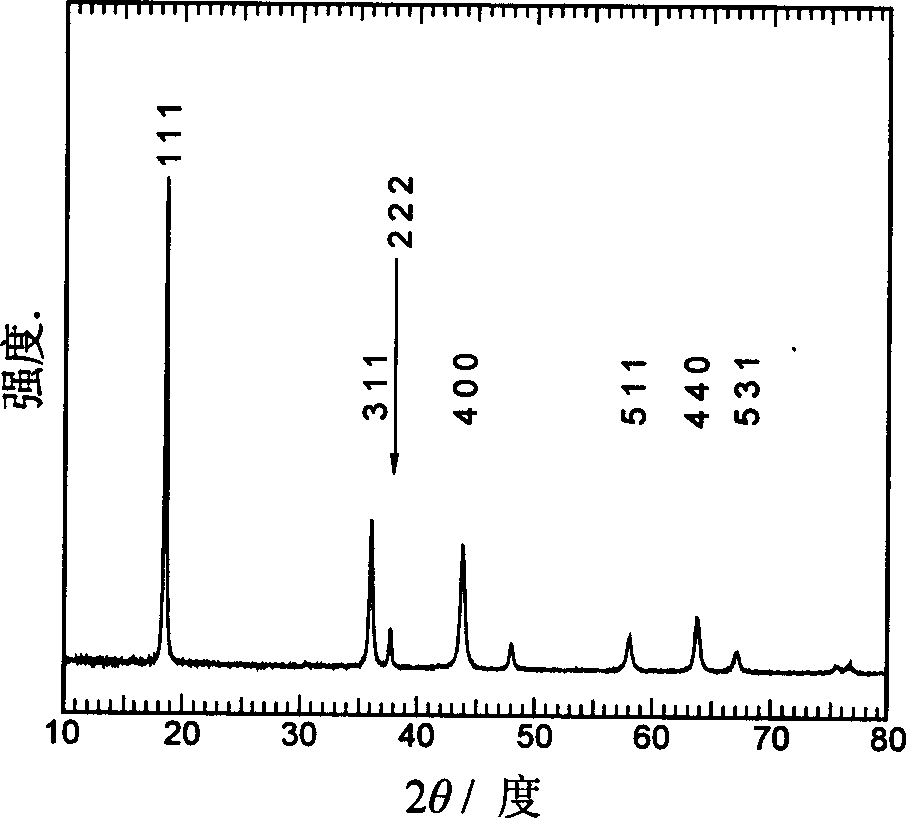

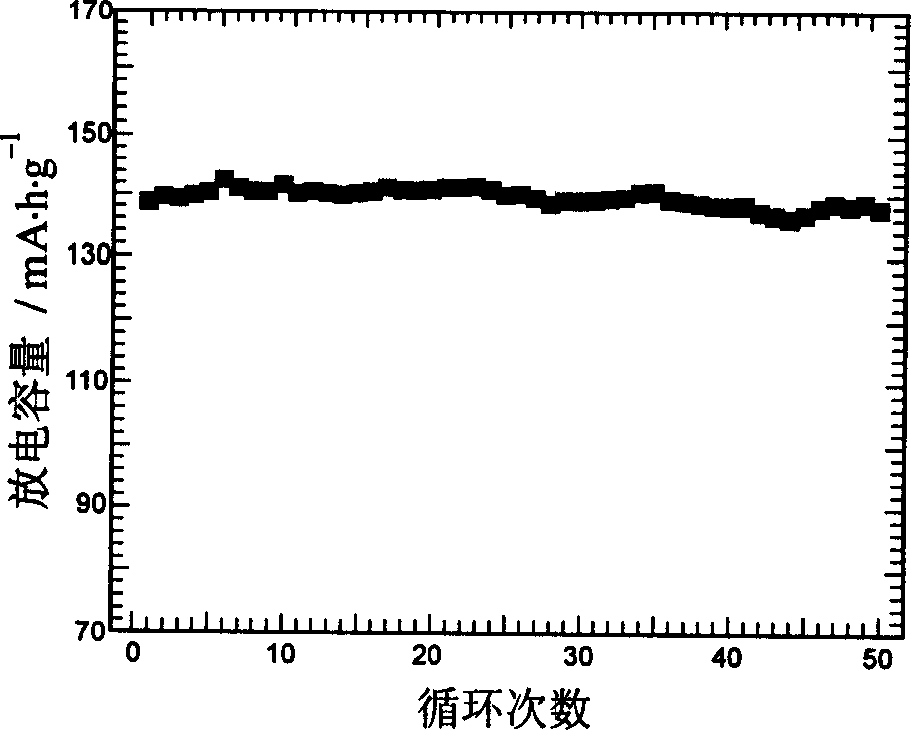

Anode material of lithium ion cell and its prepn method

InactiveCN1834022AEasy to wrapMicro stress reliefCell electrodesManganates/permanganatesLithiumElectrical battery

This invention discloses a method to prepare anode materials in lithium ion cells, which includes following steps: LiMxMn2-xO4 powder is adopted as substrate and mixed with low-melting-point salt powder to form a mixture. The melting point of low-melting-point salt is below 650 deg. C. In LiMxMn2-xO4, x is not less than 0.01 and not larger than 0.2 and M can be aluminium, cobalt, nickel or zincum. The metal amount in low-melting-point salt is 2~8wt% of LiMxMn2-xO4. The preceding mixture is pressed into blocks at a pressure of 4~8MPa. The blocks are kept first at 90~120 deg. C for 2~4.0 hours and then at 400~700 deg. C for 2~6.0 hours. Lithium ion cells which adopt anode materials prepared in this invention have relatively high capacitance and perform good circulative properties in wide potential ranges.

Owner:ZHEJIANG UNIV

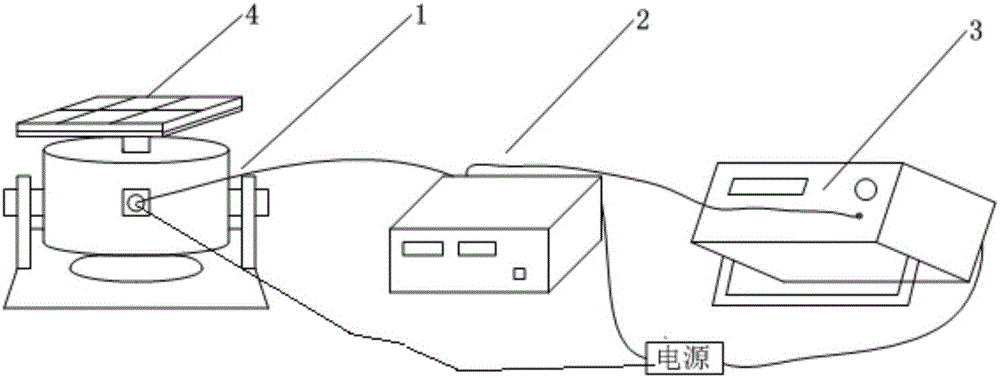

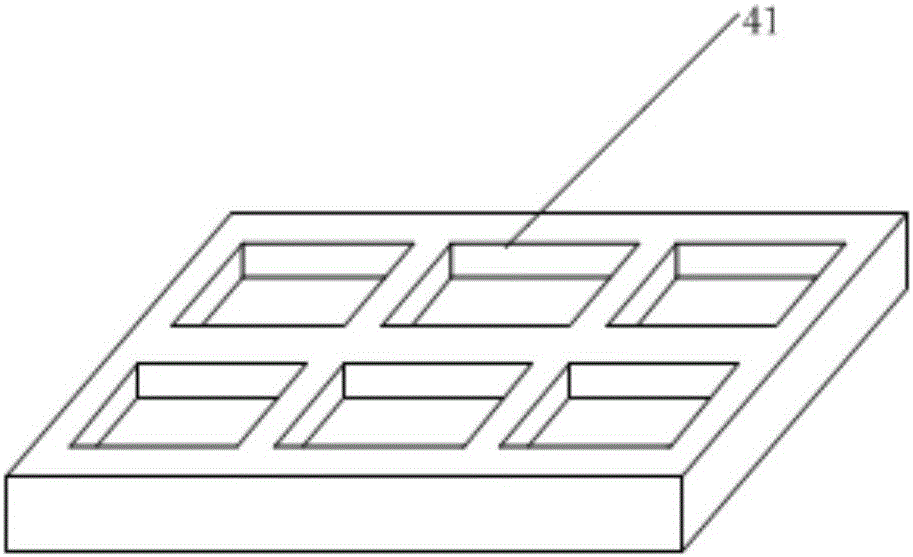

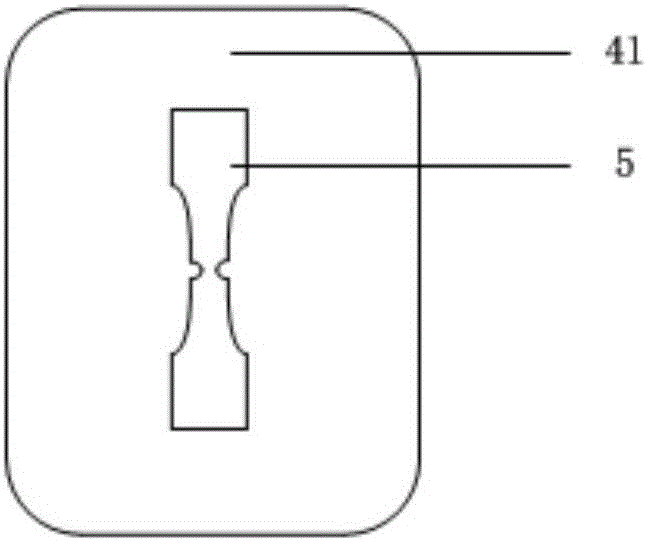

Vibration treatment method for repairing copper thin film test piece with fatigue damage

The invention provides a vibration treatment method for repairing a copper thin film test piece with fatigue damage, and relates to the technical field of machine manufacturing and vibration treatment application. A mode vibration exciter, a power amplifier and a signal generator are connected in sequence. The copper thin film is put in a test piece separation device in the mode vibration exciter; power amplification, sine waves, frequency and voltage output are set; the test piece is made in a free vibration state; after a while, the signal generator and the power amplifier are switched off in sequence, and the copper thin film test piece is taken out of the test piece separation device. According to the vibration treatment method for repairing the copper thin film test piece with fatigue damage, a stress field is formed in the material through the influence on the vibration mode through force and frequency applied to the material, the fatigue damage of the copper thin film test piece is effectively eliminated, and the fatigue life of the copper thin film test piece can be greatly prolonged. Meanwhile, the vibration treatment method in simple in process, convenient to implement, high in practicability, remarkable in effect, and great in engineering practical potential.

Owner:BEIJING UNIV OF TECH

High-pressure-resistant sealing glass ceramic and use thereof

The invention discloses high-pressure-resistant sealing glass ceramic, which comprises the following main components: 60 to 75 parts of SiO2, 10 to 16 parts of Li2O, 2.0 to 5.5 parts of P2O5, 2.0 to 4.6 parts of Al2O3, 1.0 to 3.8 parts of K2O, 1.0 to 2.1 parts of B2O3, 0.5 to 1.5 parts of TiO2, 1.0 to 6.0 parts of ZnO, and 0.5 to 8.0 parts of ZrO2. The high-pressure-resistant sealing glass ceramic is prepared by the following steps: uniformly mixing the components; smelting the mixture for 4 to 6 hours in a molybdenum silicide high-temperature electrical furnace at 1,450 to 1,550 DEG C; afterthe mixture is molten and clear completely, pouring the mixture into cold water, and quenching and cracking into glass slag; and drying, ball milling, and screening to obtain high-pressure-resistant sealing glass powder. The high-pressure-resistant sealing glass ceramic is particularly suitable for sealing stainless steel, copper and Ni-based inconel ally, and a high-pressure-resistant sealing element is obtained by high-temperature sealing and heat treatment. The sealing glass ceramic disclosed by the invention has a higher sealing strength, a higher thermal expansion factor, higher chemicalstability and a higher mechanical strength, and the process is simple, practical and suitable for industrial production.

Owner:LIAONING SILICATE RES INST

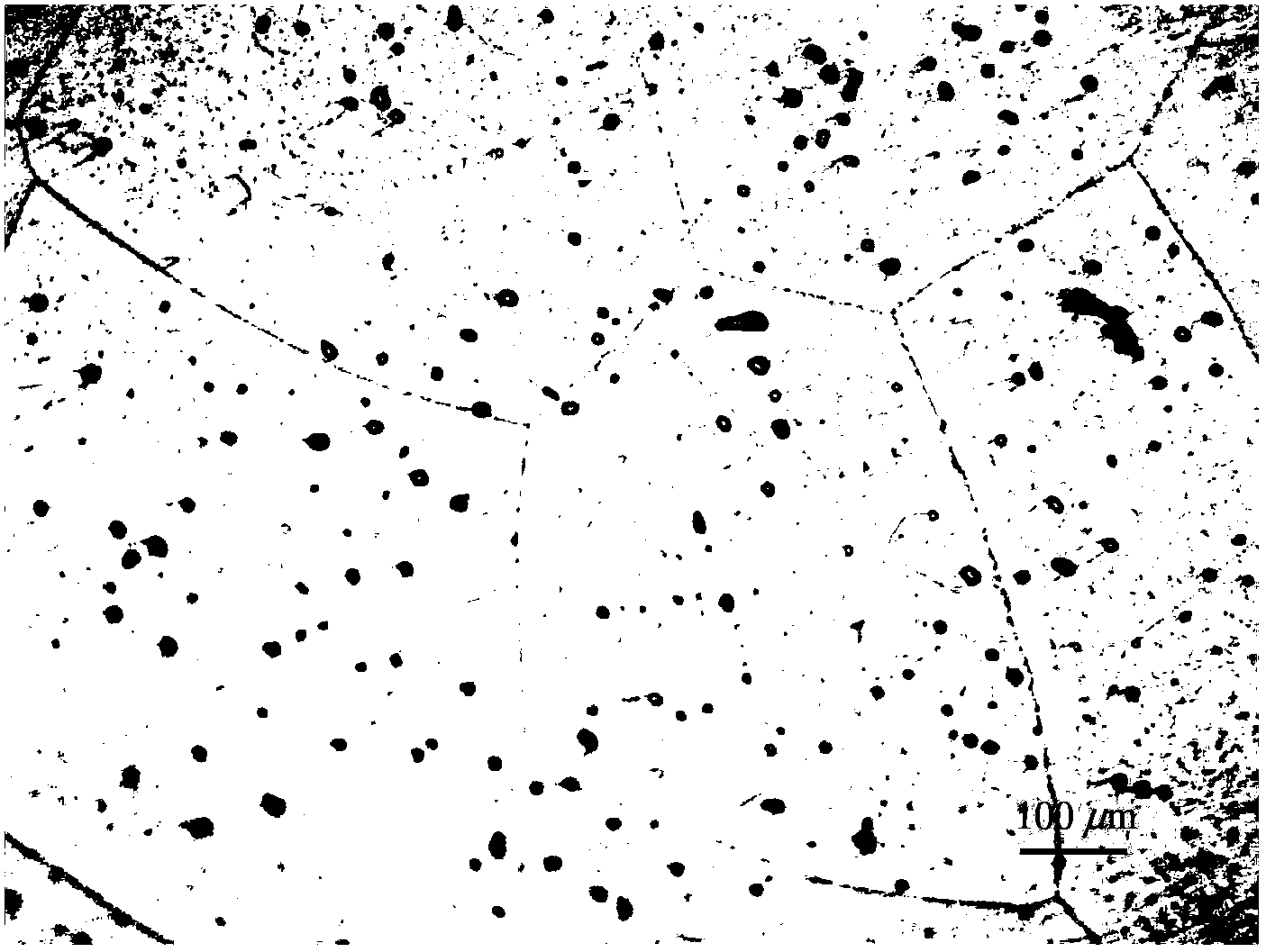

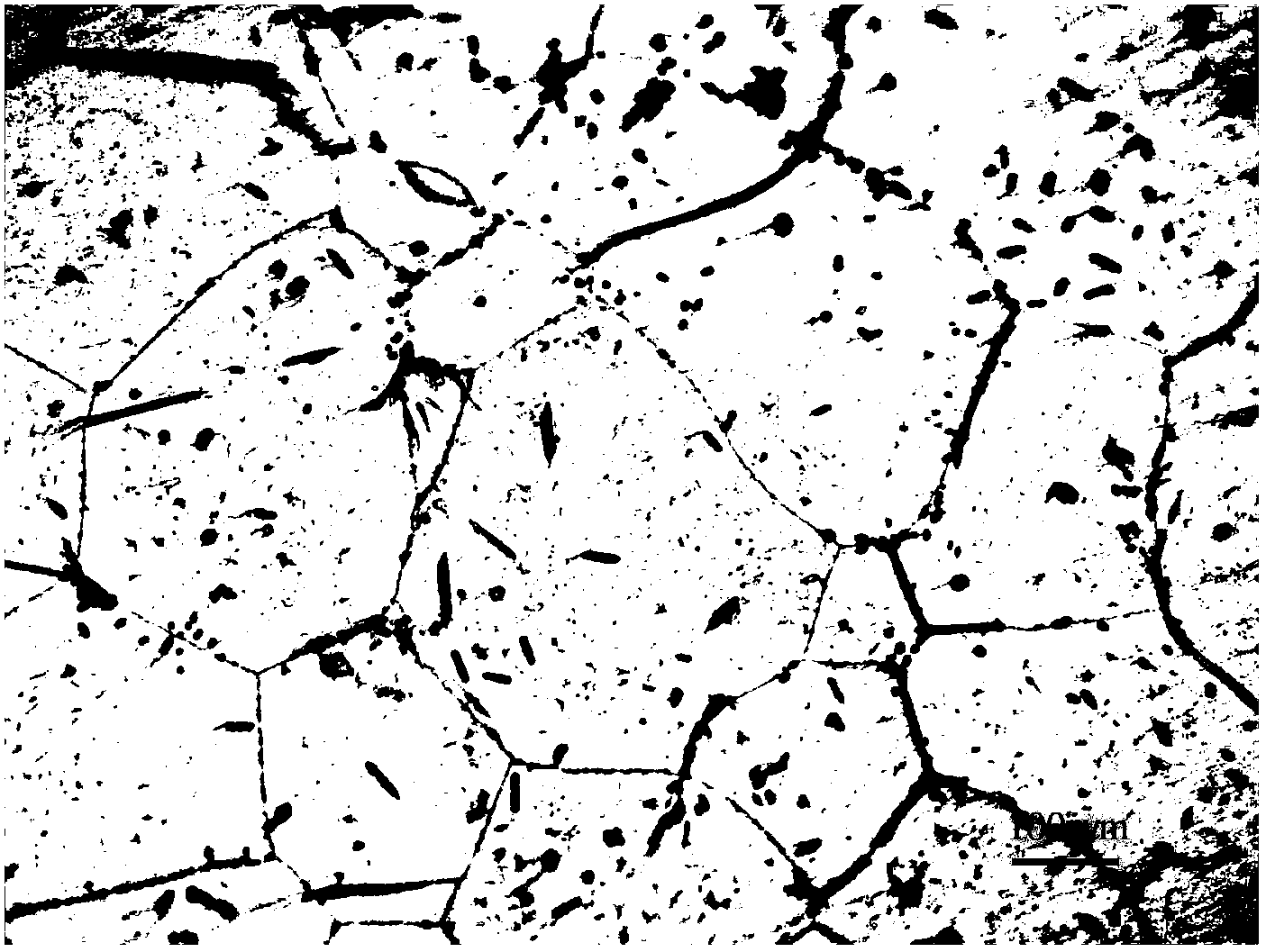

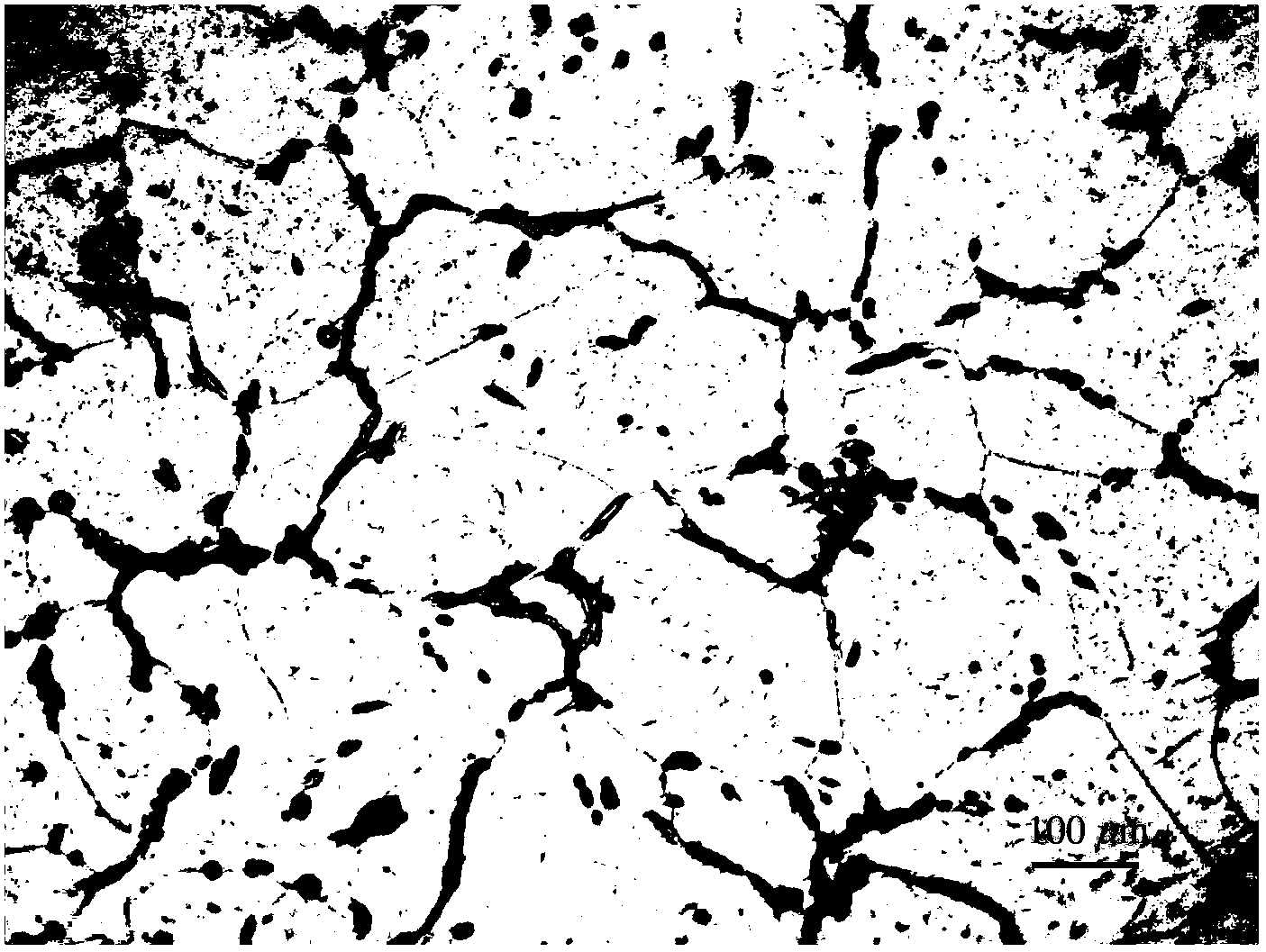

Niobium titanium aluminum alloy added with trace boron and preparation method thereof

The invention relates to a niobium titanium aluminum alloy added with trace boron and a preparation method of the alloy, wherein 0.5-5% of boron measured by atomic percent is added in the niobium titanium aluminum alloy. The experiments prove that trace boron (0.5-5%) is added as grain refiner in high-temperature structure materials which contain 30-60% of niobium, 10-50% of titanium and 0-30% of aluminum so as to significantly refine grains and microstructures of the alloy, thereby increasing mechanical property of the alloy, strengthening, toughening and preventing alloy cracking. Main components of the alloy with component region of 0-60% of niobium, 10-50% of titanium and 0-30% of aluminum are beta / B 2 phases, so that the grain refining technology is effective for described component region. Processes for refining niobium titanium aluminum alloy structures with the preparation method provided by the invention are simple and practical, and simultaneously are capable of playing a role of strengthening and toughening the niobium titanium aluminum alloy.

Owner:NAT ENG RES CENT FOR SPECIAL METAL MATERIALS OF TANTALUM & NIOBIUM

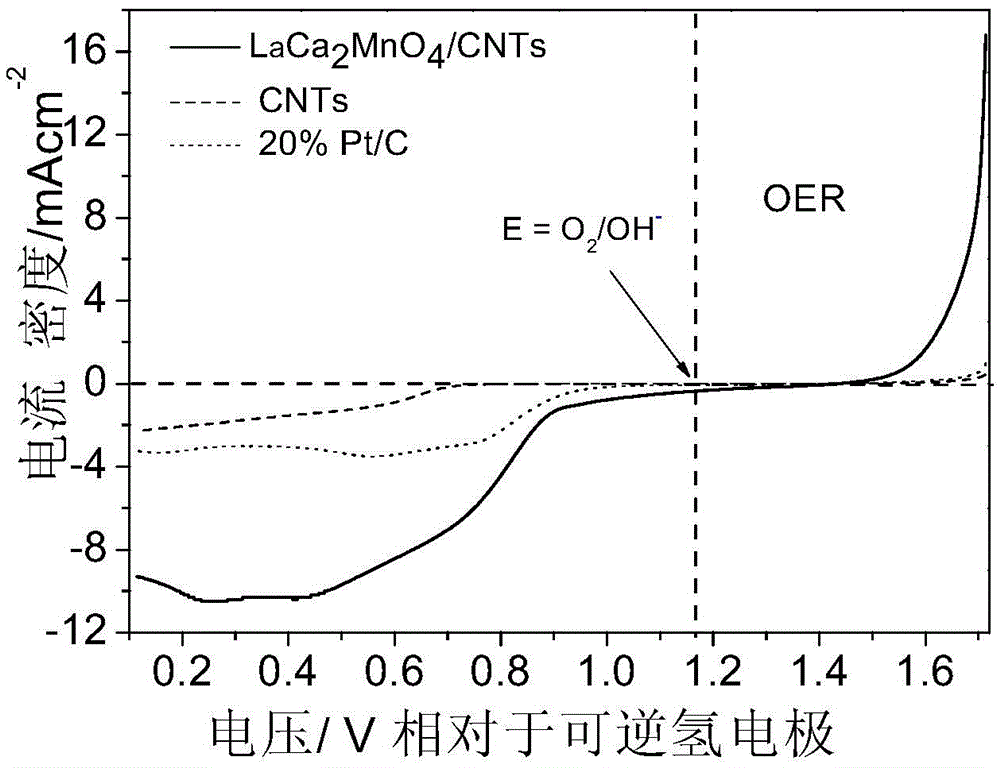

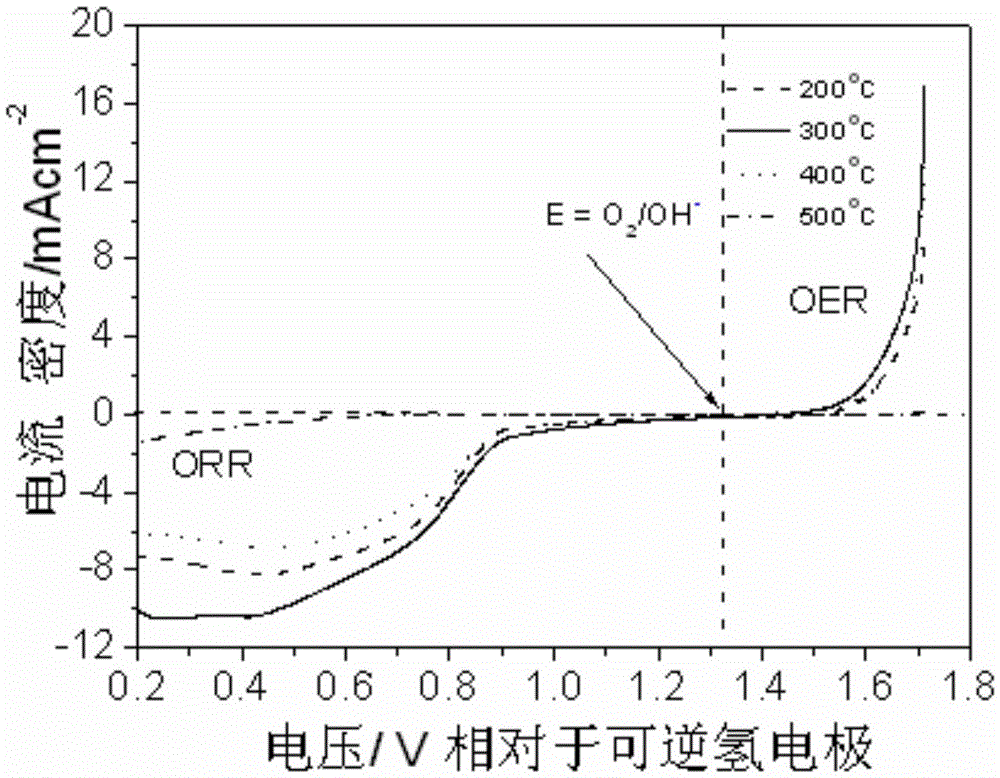

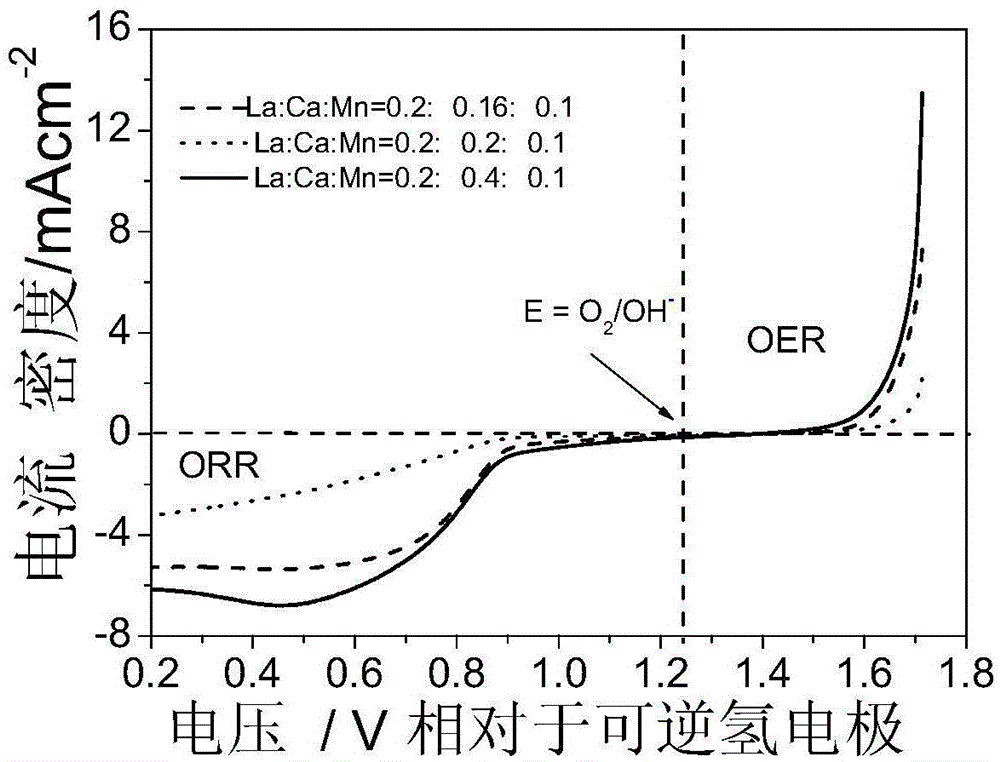

La-Ca-Mn/carbon nanotube dual-functional composite catalyst and preparation and application thereof

InactiveCN105609792AEasy to prepareEase of industrial productionMaterial nanotechnologyFuel and primary cellsCarbon nanotubeUltrasonic dispersion

The invention relates to a La-Ca-Mn / carbon nanotube dual-functional composite catalyst and preparation and application thereof. The catalyst comprises a composite of carbon nanotubes, nanometer lanthanum oxide, nanometer calcium oxide and nanometer manganese dioxide and is prepared according to the following steps of weighing lanthanum nitrate, calcium nitrate, a manganese dioxide precursor and the carbon nanotubes according to a mass ratio of 0.2:(0.16-0.4):0.1:(0-0.05) and dissolving the materials in ammonia water, carrying out ultrasonic dispersion, carrying out a hydrothermal reaction for 5 hours at 160 DEG C, cooling the obtained product to a room temperature, and carrying out washing, drying, calcinating and grinding. The invention also relates to the application of the dual-functional composite catalyst in preparation of an air electrode of a metal-air battery. The La-Ca-Mn / carbon nanotube dual-functional composite catalyst has the advantages of greenness, environmental friendliness, availability in raw material, low cost, moderate reaction condition, short reaction time, simplicity and practicability in process, high controllability and the like, is easy to produce in a large scale, and is a favorable air electrode catalyst which can be applied to the fields of metal-air batteries such as zinc-air, aluminum-air and magnesium-air batteries.

Owner:DONGHUA UNIV

Manufacturing method of molten iron desulfurizer-coating particulate magnesium

A kind of coated magnesium particles as the desulfurizing agent of molten iron is prepared from metal magnesium through cutting, granulating, screening, proportioning more kinds of chlorine salts, dissolving the mixture in water at 100 deg.c, loading said particles, in rotating container at 210-240 deg.c, spraying said solution onto particles, and baking. Its advantages are low cost, less electric consumption, and low pollution.

Owner:赖祥武

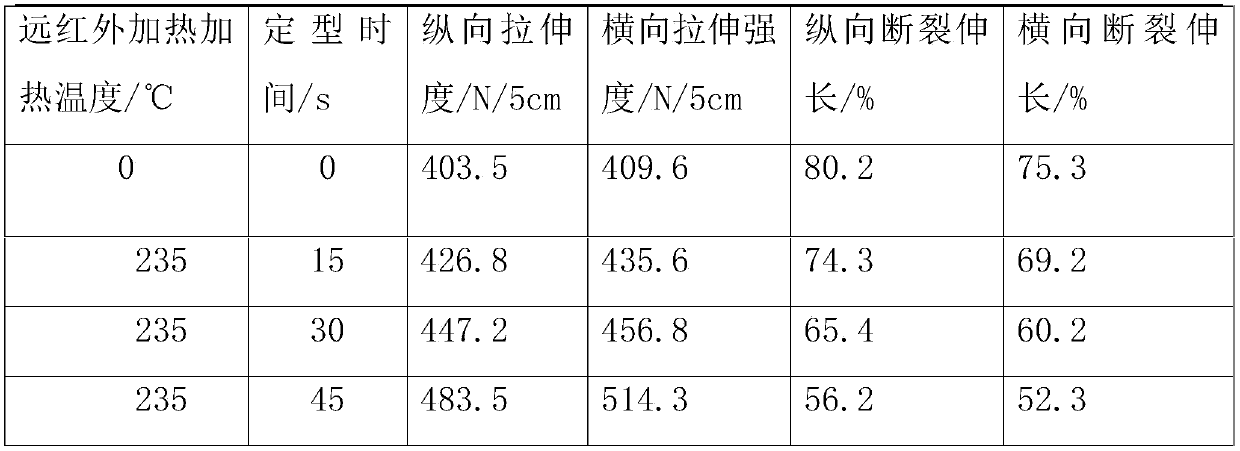

High-strength geotechnical cloth and manufacturing method thereof

InactiveCN107675356AIncrease the strength of collusionGood dimensional stabilityHeating/cooling textile fabricsGeotextilesBursting strengthHigh intensity

The invention relates to the technical field of textiles, in particular to high-strength geotechnical cloth and a manufacturing method thereof. The method comprises the following steps of opening of non-woven production equipment, carding, cluttering, lapping, needling, heat setting and finished product winding. A far infrared heat shaping method is used for handling residual stress generated in the procedures of opening, carding into nets, cluttering, lapping, needling and solidifying and accumulated in fibers and in the geotechnical cloth, the connection strength between the fibers is improved, and the physical and mechanical properties of the fibers are improved, so that the overall size stability and mechanical strength (tensile strength, tearing strength and burst strength) of the geotechnical cloth are improved; moreover, the technology is simple, practical and convenient to use and popularize.

Owner:合肥华福土工合成材料有限公司

Fried broad bean and preparation method thereof

The invention discloses fried broad beans and a preparation method thereof. The fried broad beans are characterized by comprising the following raw materials in parts by weight: 100-120 parts of broad beans and main frying materials, wherein the main frying materials comprise 2-4 parts of soybean oil, 2-3 parts of ginger oil, 2-3 parts of scallion oil, 2-3 parts of garlic oil, 2-3 parts of aginomoto, 2-3 parts of edible salt, 0.5-1.5 parts of white sugar and 4-6 parts of mature vinegar. The preparation method comprises the following steps: a) frying the broad beans, namely, airing the broad beans, washing, soaking for 42-60 hours, washing, mechanically opening the broad beans, washing, boiling in water, mechanically centrifuging to remove the water, frying the broad beans by using a frying machine for 18-25 minutes, and fishing out the fried broad beans; b) preparing the frying materials, namely, weighing the frying materials according to a weight ratio; c) frying the broad beans; d) weighing and packaging the fried broad beans. The preparation method of the fried broad beans is advanced and practical, and the fried board bean produced by using the preparation method is unique in fragrance, good in taste, rich in nutrition and beneficial for sale in market.

Owner:CHONGQING PINYOU AGRI DEV

Antirust coating for steel facilities under oceanity condition and preparation method thereof

InactiveCN107384136AEvenly dispersedSimple methodAnti-corrosive paintsEpoxy resin coatingsEpoxyPetrochemical

The invention provides an anti-rust coating for steel facilities under an oceanity condition and a preparation method thereof. The anti-rust coating provided by the invention is prepared from the following components in percentage by mass: 26-28 percent of diphenol propane epoxy resin, 5-8 percent of vapor-phase corrosion inhibitor, 13-18 percent of organic solvent, 43-55 percent of pigment and filler and 1-3 percent of auxiliary agent. The technical scheme provided by the invention overcomes the defect that the traditional anti-rust pigment has great toxicity while improving corrosion resistance of a coating layer, can quickly act on a metal surface, provides corrosion inhibition protection, has long-lasting protection and has a high utilization rate. The anti-rust coating can be applied to the protection of steel facilities under the oceanity condition, such as the construction and maintenance of of ships, petrochemical facilities and large bridges.

Owner:ZHEJIANG YUTONG NEW MATERIAL

Filling for cantonese crispy chili and preparation method thereof

The invention discloses a filling for cantonese crispy chili and a preparation method of the filling. The filling is prepared from the following raw materials in parts by weight: 10-15 parts of dried fruit power, 5-20 parts of rice flour, 20-30 parts of starch, 4-8 parts of white sugar, 2-4 parts of pepper powder and 2-4 parts of other seasonings. The other seasonings consist of chicken power and salt in the ratio of 2: 1. The preparation method comprises the following steps: (a) taking the dried fruit power, rice flour, starch, white sugar, pepper power and the other seasonings according to the weight ratio; and (b) putting the filling into an agitator, adding water and stirring, wherein the ratio of the filling to the water is 100: (15-18), and the stirring time is 3-5min, and taking the filling out for standby. The filling for cantonese crispy chili is scientific, reasonable, fragrant, crispy and special in taste, and rich in nutrition. The preparation method of the filling for cantonese crispy chili is advanced and practical.

Owner:CHONGQING PINYOU AGRI DEV

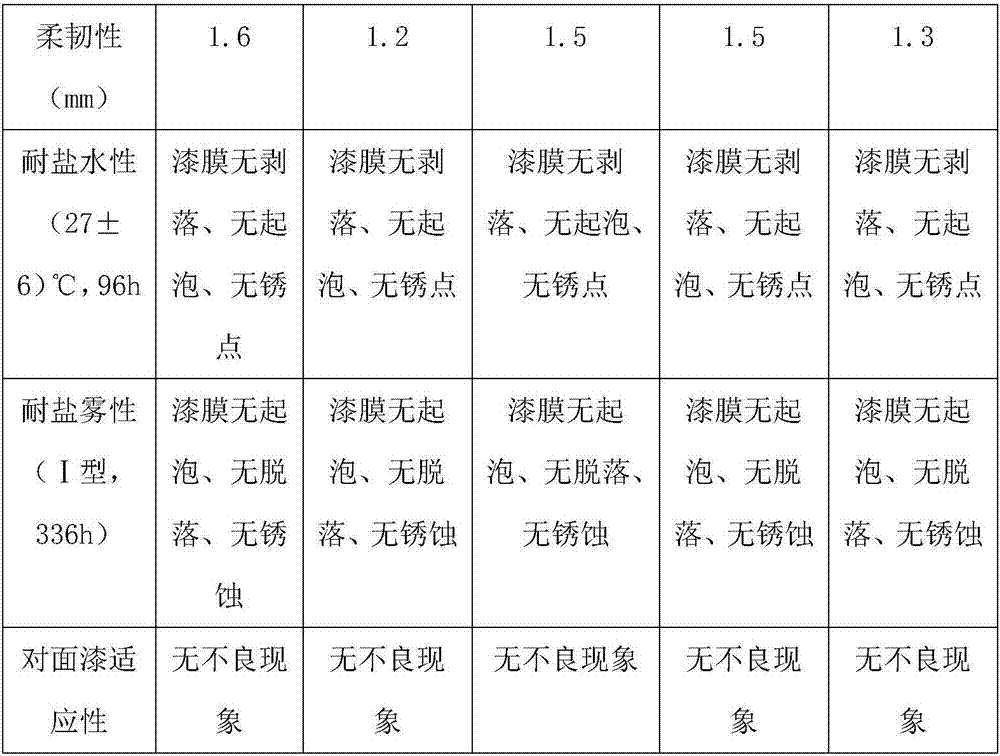

Chlorohydrocarbon waste liquid treating method

InactiveCN101037250ASimple processEasy to operateWater/sewage treatment by neutralisationWater/sewage treatment by heatingSolid phasesDistillation

The present invention relates to a chloro hydrocarbon waste liquid treatment method, which comprises the procedures of distillation, incineration, etc,. By adopting a neutralizer to neutralize and a decompress dry distillation technology, the gas phase of the waste liquid breaks away by an organic matter fashion which can be directly incinerated, while the solid phase of the waste liquid is landfilled in a solid waste landfill. The technology of the present invention is capable of effectively solve the problem of waste liquor recovery and discharge, and realizing the innocent treatment of waste liquid; besides, the technology is adapted to the construction of industrialization apparatus and solves the domestic bottleneck problem of freon substitute.

Owner:JUHUA GROUP TECH CENT +2

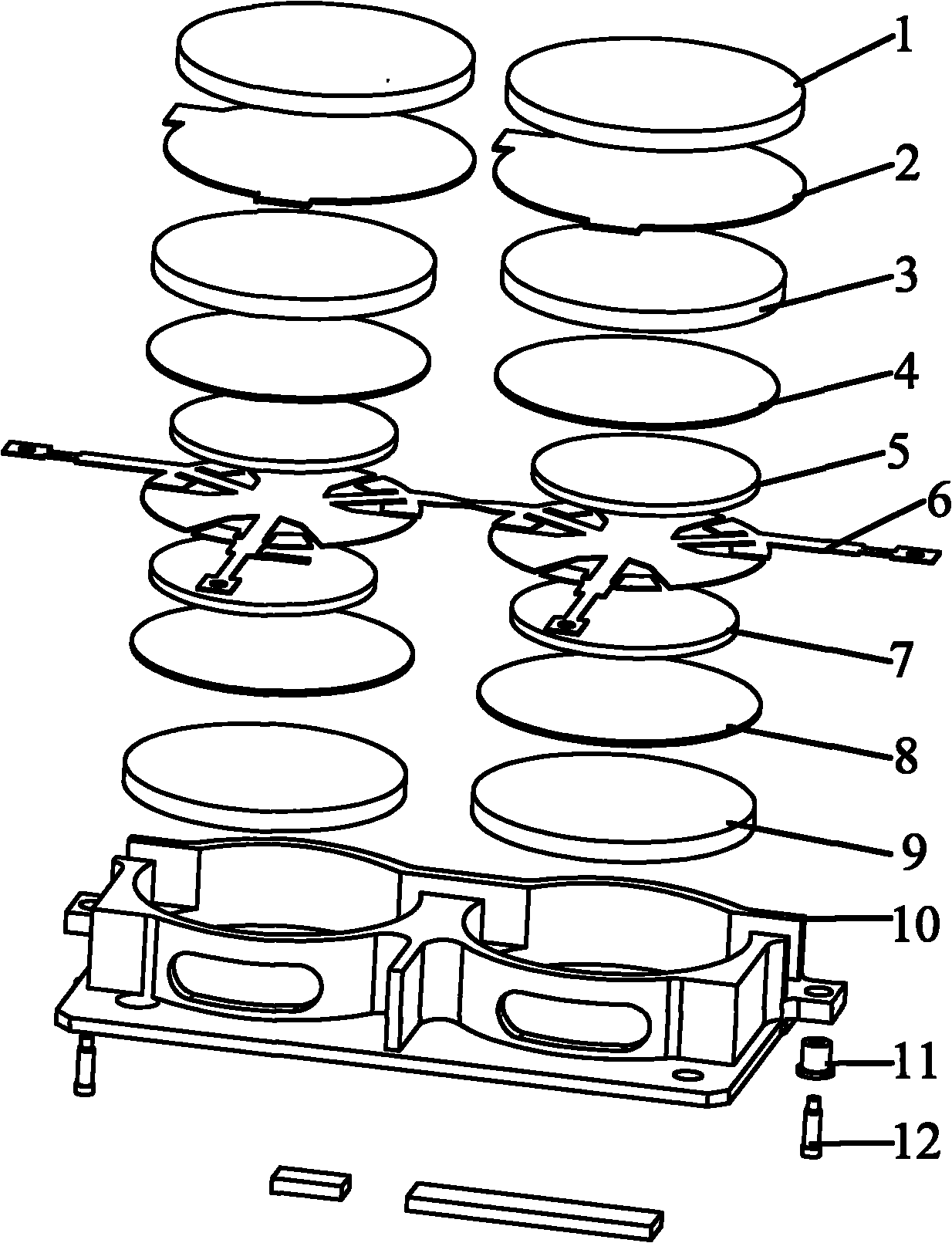

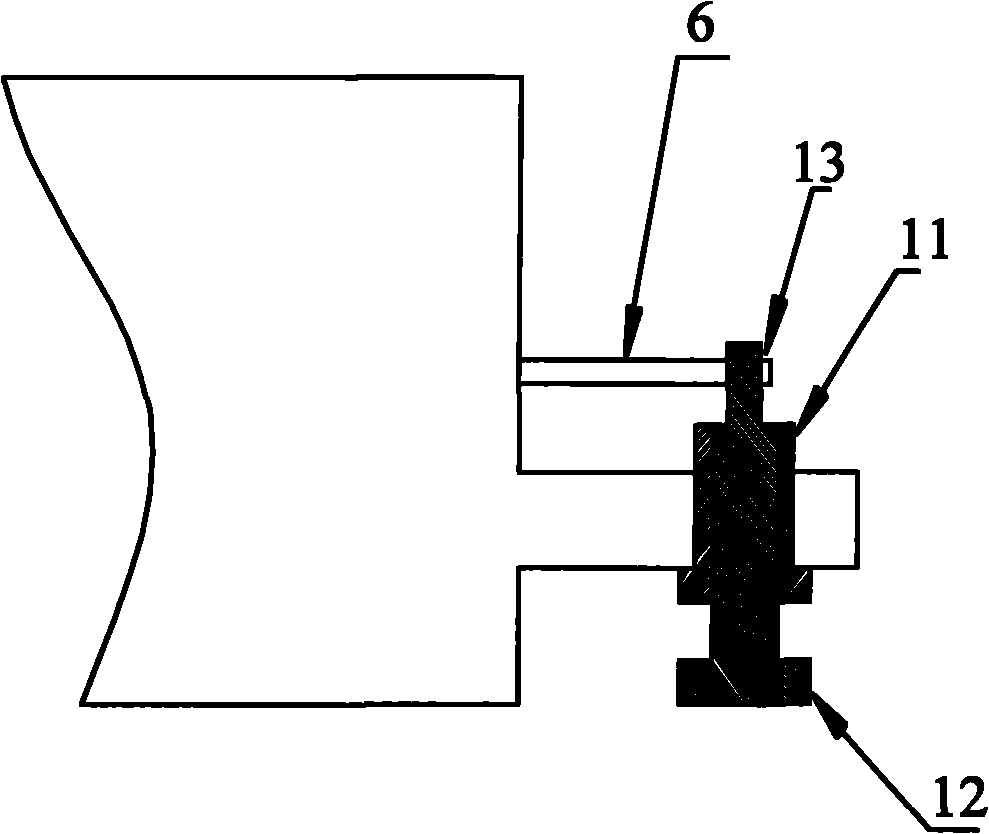

Novel surface mount-type microwave isolator

InactiveCN101777681AMake electrical connectionsPractical craftWaveguide type devicesMicrowaveElectrical conductor

The invention relates to a surface mount-type microwave isolator, wherein a casing thereof is formed with a half-opened cylindrical cavity body and is provided with a port at the sidewall thereof, a lug boss which is provided with a through hole is arranged at the position, opposite to the port, on the sidewall of the casing; the half-opened cylindrical cavity body of the casing is internally provided with a permanent magnet, a uniform magnet conducting chip, a ferrite, a central conductor and a temperature compensation plate, and is also covered by a cover board, the central conductor passes through the port on the sidewall of the casing to stretch out of the cavity body; a port pin insulator is installed in the through hole of the lug boss at the sidewall of the casing, and a port pin is installed in the port pin insulator and is electrically connected with the central conductor. Due to the tight fit between the port pin insulator and the through hole of the lug boss as well as between the port pin and the port pin insulator, the central conductor is welded with the port pin so that the size and the position of the port pin are quite firm and stable, thereby obviously enhancing the reliability of the isolator on the basis of not changing the performance of devices, in addition, the surface mount-type microwave isolator is easy for large-scale production.

Owner:SDP TELECOM SUZHOU

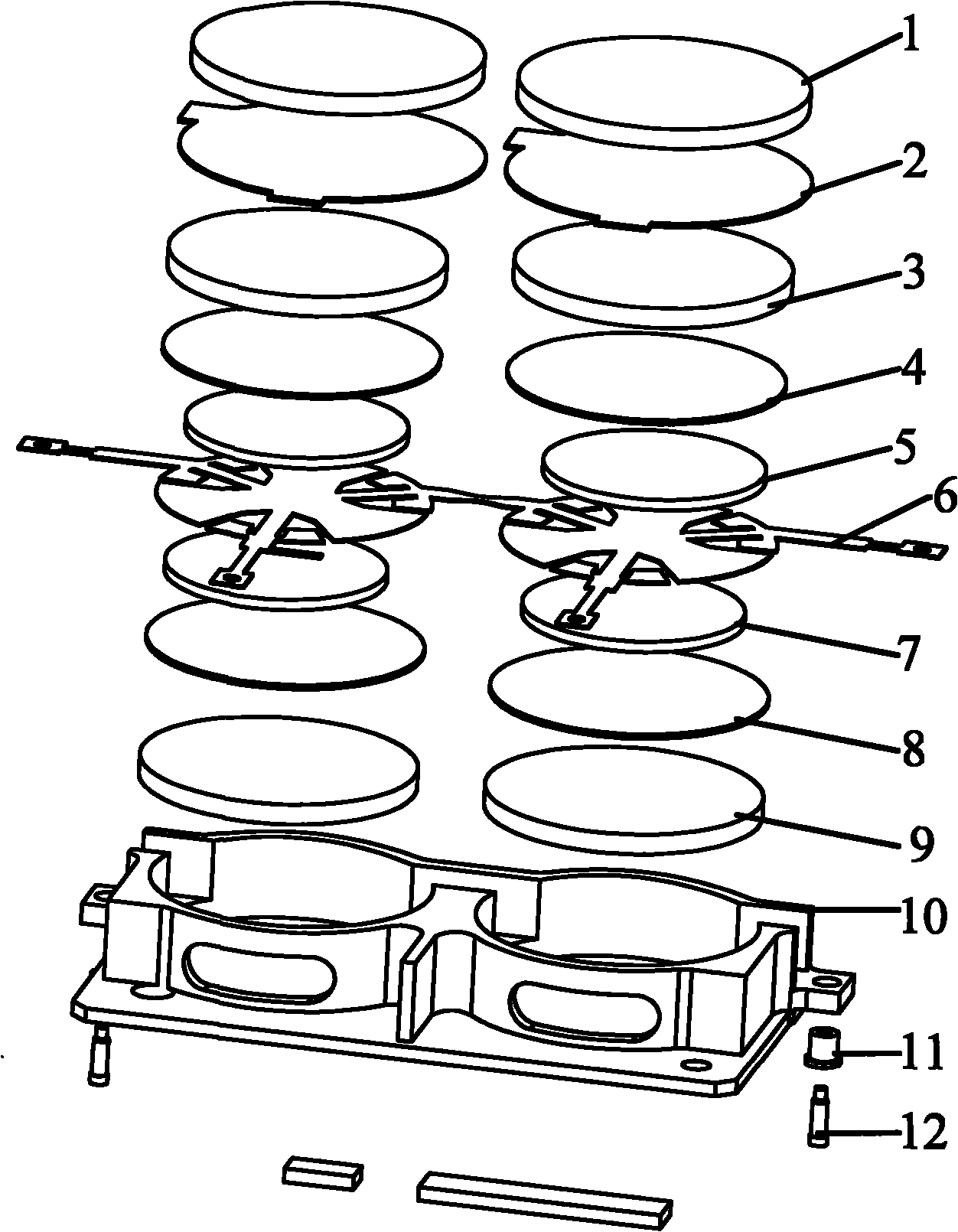

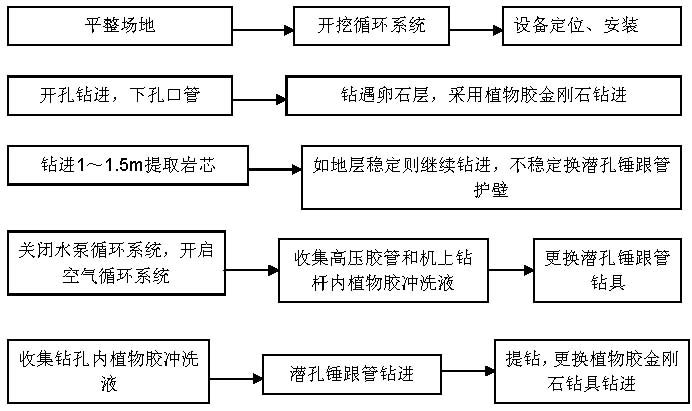

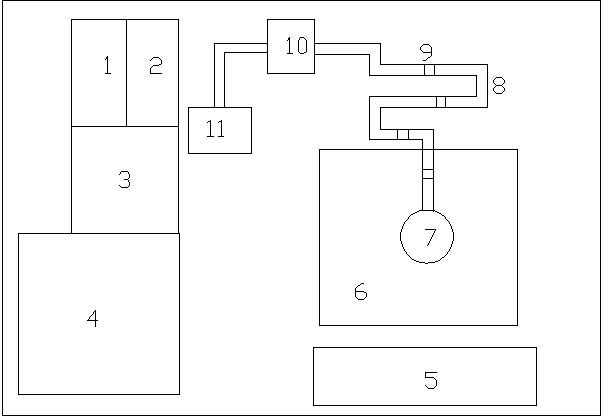

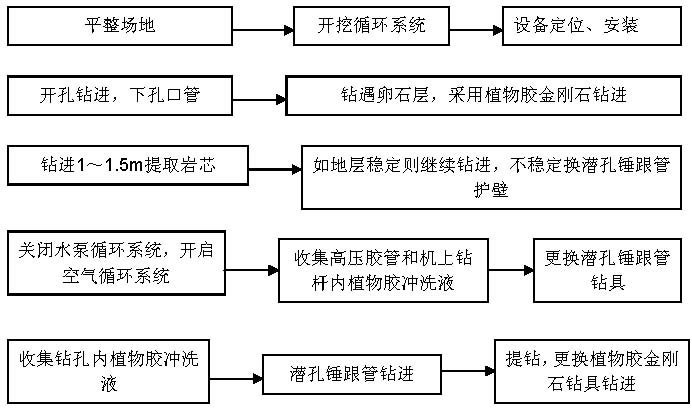

Combined drilling technique of vegetable gum diamond coring and downhole hammer casing drilling

ActiveCN102606070ASolve the difficulty of forming holesSolve efficiency problemsFlushingCore removalCoringDrill

The invention relates to a combined drilling technique of vegetable gum diamond coring and downhole hammer casing drilling, which can be used for effectively solving the problem that the requirements of practical engineering exploration cannot be met due to difficulty in forming holes, low core recovery rate, low drilling efficiency and more hole accidents in a sandy cobble stratum. The technical scheme for solving the problem includes that the technique includes the steps: leveling land; positioning and mounting equipment; forming an excavation circulating system; drilling holes; performing vegetable gum diamond coring; recycling flushing fluid; performing downhole hammer casing drilling; and discharging residues, lifting a drill, replacing the drill for drilling and supplementing vegetable gum flushing fluid into the holes. The technique is simple and practical, effectively solves the problems of difficulty in forming the holes, low drilling efficiency, low core recovery rate and more hole accidents in the sandy cobble stratum, and is innovative in terms of drilling techniques.

Owner:YELLOW RIVER ENG CONSULTING

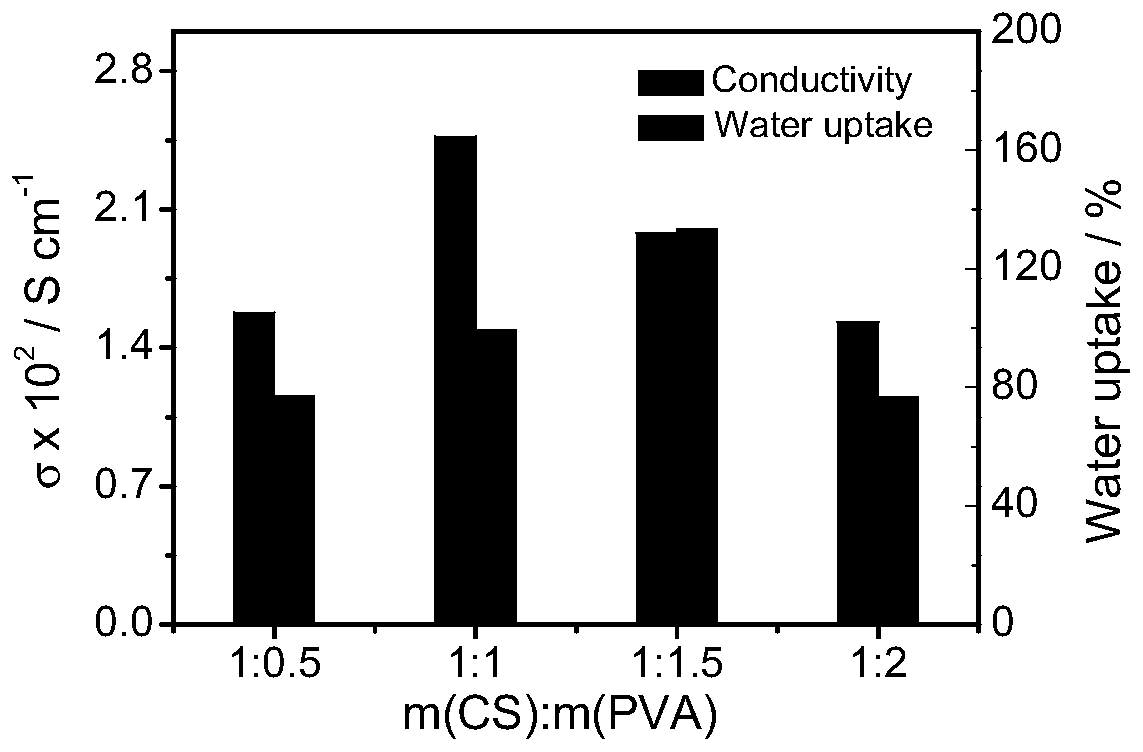

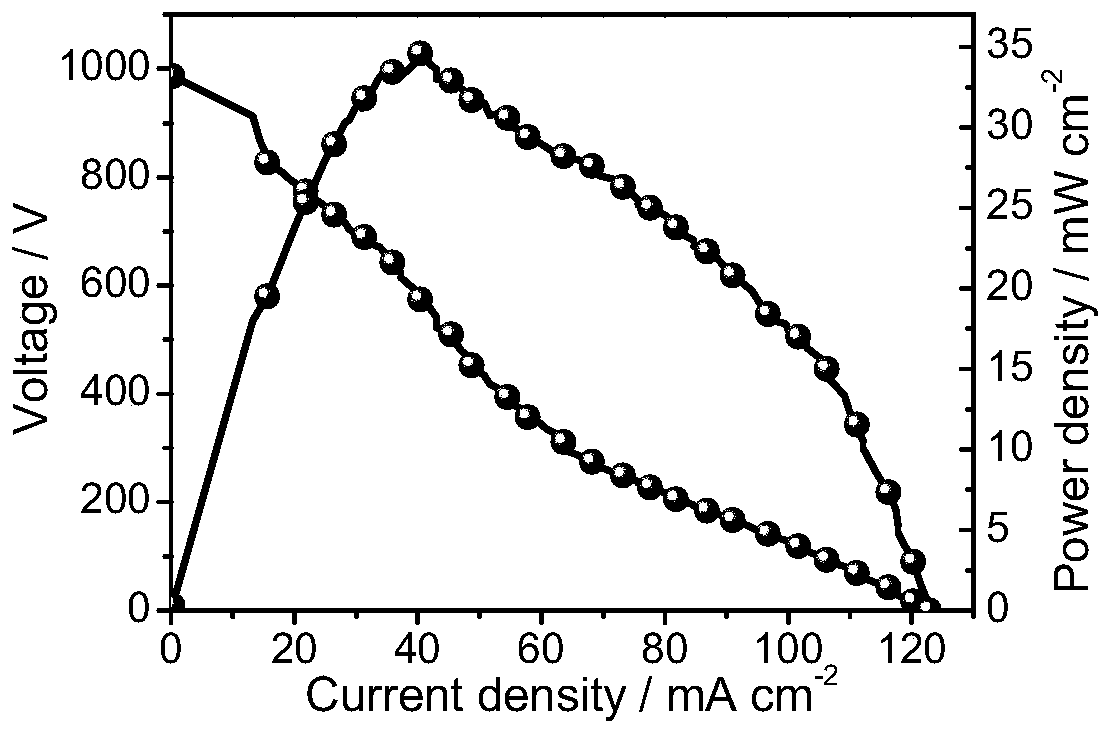

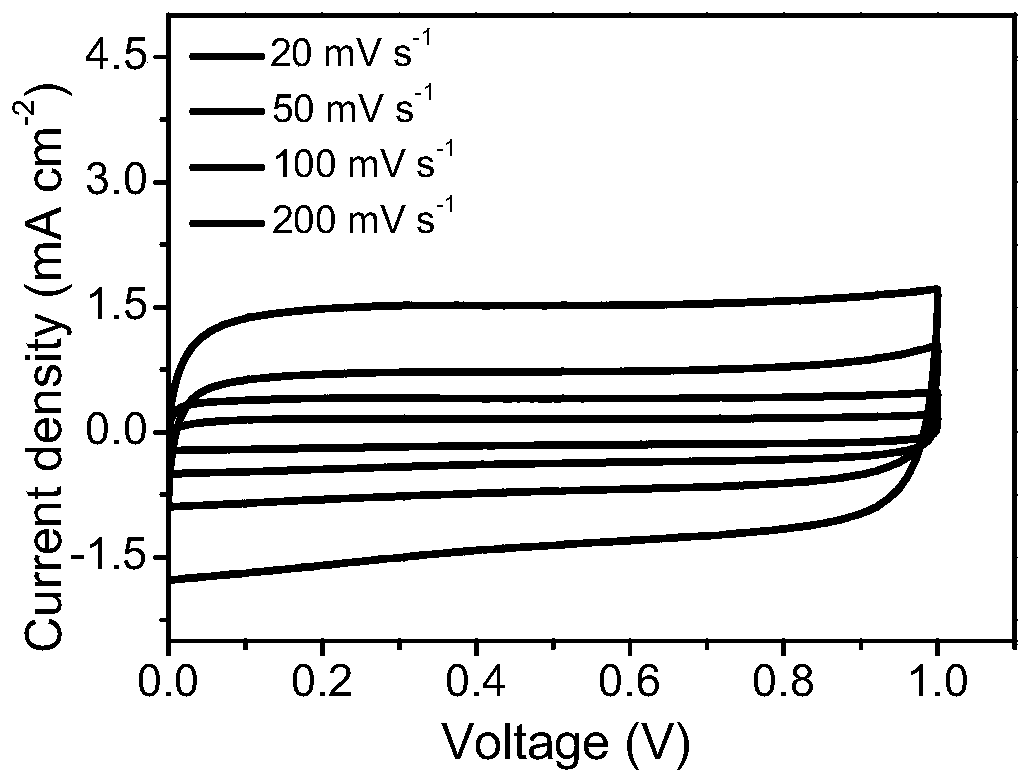

Electrochemical energy device and manufacturing method thereof

InactiveCN110676072AImprove the lack of conductivityRich sourcesElectrolyte holding meansHybrid capacitor electrolytesSolid state electrolytePolyvinyl alcohol

The invention discloses an electrochemical energy device and a manufacturing method thereof. The electrochemical energy device uses an alkaline anion exchange composite film as a solid electrolyte anda support layer, and the alkaline anion exchange composite film is a quaternized chitosan-polyvinyl alcohol film. The quaternized chitosan-polyvinyl alcohol film is a good all-solid-state electrolyte. A low-cost non-toxic material with high ionic conductivity at an ambient temperature is achieved and good mechanical strength and excellent electrochemical performance are possessed. The quaternizedchitosan-polyvinyl alcohol film is applied to the electrochemical energy device, a problem that a traditional electrolyte is easy to leak is solved, packaging difficulty is reduced, cost is saved toa certain extent, and the device and the method are suitable for industrial production.

Owner:上海元城汽车技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com