Brand new method of producing electrolytic manganese metal

A technology of electrolytic manganese metal and electrolytic manganese, applied in electrolytic process, electrolytic components, photographic technology, etc., can solve the problems of increased difficulty in the production of electrolytic manganese metal, hazards of groundwater pollution, and small profit margins, and achieve saving of auxiliary materials usage, The effect of eliminating press filter residue and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

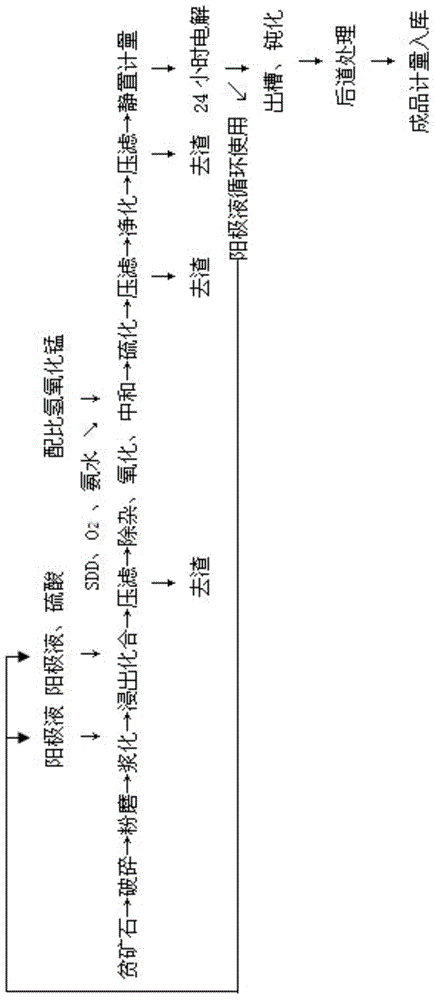

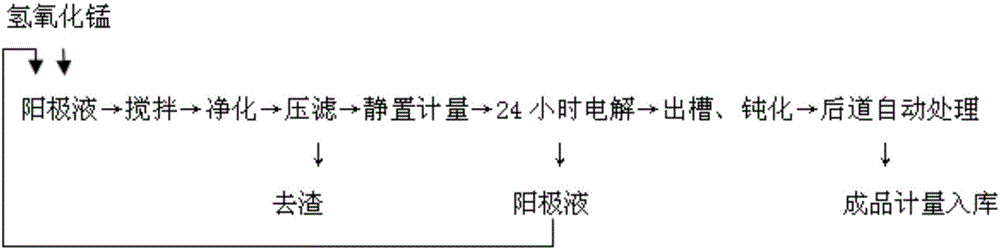

Method used

Image

Examples

Embodiment

[0022] (1) First crush and grind 5 tons of poor manganese ore with a manganese content of 8% into powder, add an appropriate amount of electrolytic manganese anolyte to make a slurry, and then add electrolytic manganese anolyte and 96% sulfuric acid to carry out manganese leaching compound reaction , to obtain the reaction leaching solution, wherein the total addition of electrolytic manganese anolyte is 65m 3 , the adding amount of the sulfuric acid of 96% concentration is 2 tons;

[0023] (2) After the reaction leaching solution in step (1) is filtered to remove slag, add SDD to remove impurities, so that heavy metal ions form sulfide precipitation and remove, and then feed oxygen to remove Fe 2+ Oxidized to Fe 3+ and remove, then add 1.18 tons of manganese hydroxide with a manganese content of 56% according to the process requirements, and then add a small amount of ammonia to neutralize the leachate after the final reaction to pH=6.4, then add a vulcanizing agent to vulca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com