Anode material of lithium ion cell and its prepn method

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., and can solve problems such as infeasibility of large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

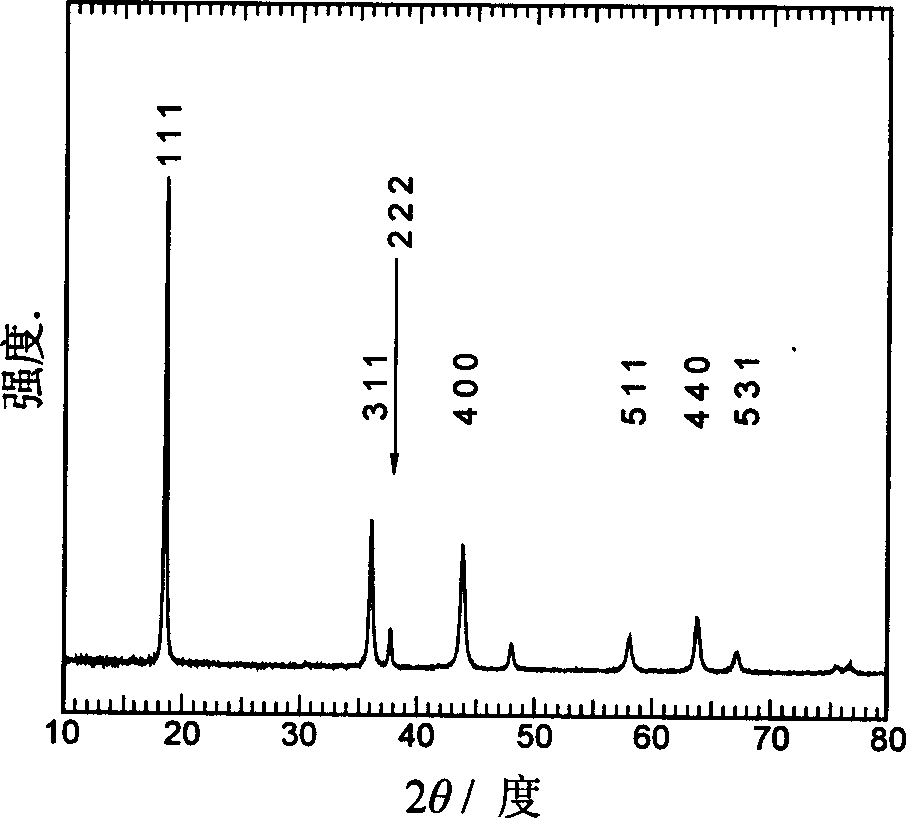

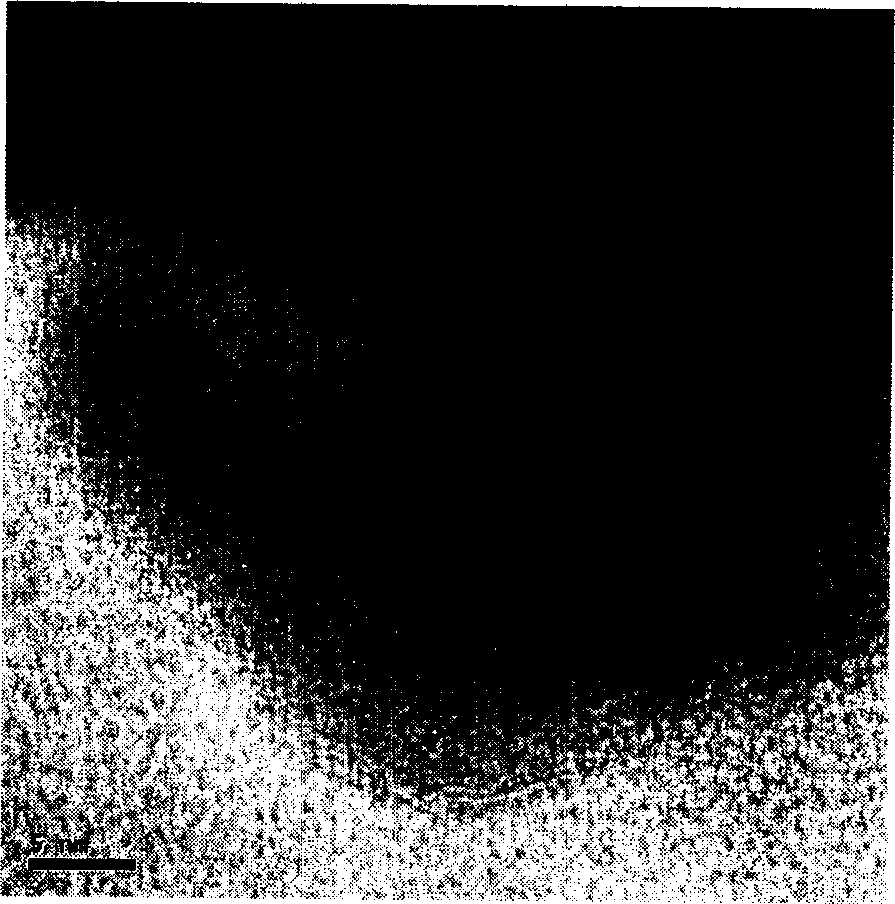

[0021] Embodiment 1, a kind of lithium-ion battery cathode material preparation method, carries out following steps successively:

[0022] 1), with Li: Mn: Al according to the molar ratio of 1: 1.96: 0.04 (ideal stoichiometric ratio in molecular formula) lithium carbonate Li 2 CO 3 and electrolytic manganese dioxide MnO 2 With Aluminum Hydroxide Al(OH) 3 After uniform mixing in a ball mill, heat treatment at 750°C for 20 hours to obtain lithium manganate LiAl with an average particle size of 10-15 μm 0.04 mn 1.96 o 4 . Zinc nitrate whose Zn weight accounts for 2% of the lithium manganate weight is also put into the ball mill and uniformly mixed with the lithium manganate to form a mixture. At this time, the zinc nitrate and lithium manganate were both in powder form.

[0023] 2), above-mentioned mixture is pressed into block under the pressure of 5MPa;

[0024] 3) The above-mentioned blocks were first incubated and reacted at 120°C for 2 hours, and then incubated at 50...

Embodiment 2

[0029] Embodiment 2, a kind of lithium-ion battery cathode material preparation method, carries out following steps successively:

[0030] 1), Li: Mn: Ni is mixed lithium carbonate Li according to the molar ratio of 1: 1.90: 0.1 (ideal stoichiometric ratio in molecular formula) 2 CO 3 and electrolytic manganese dioxide MnO 2 After uniformly mixing with nickel oxide NiO with a ball mill, heat treatment at 750°C for 20 hours to obtain lithium manganate LiNi with an average particle size of 10-15 μm 0.1 mn 1.9 o 4 . Zinc nitrate Zn (NO 3 ) 2 It is also placed in a ball mill and mixed evenly with lithium manganate to form a mixture. At this time, the zinc nitrate and lithium manganate were both in powder form.

[0031] 2), above-mentioned mixture is pressed into block under the pressure of 5MPa;

[0032] 3) The above-mentioned blocks were first incubated and reacted at 120°C for 2 hours, and then incubated at 400°C for 6 hours.

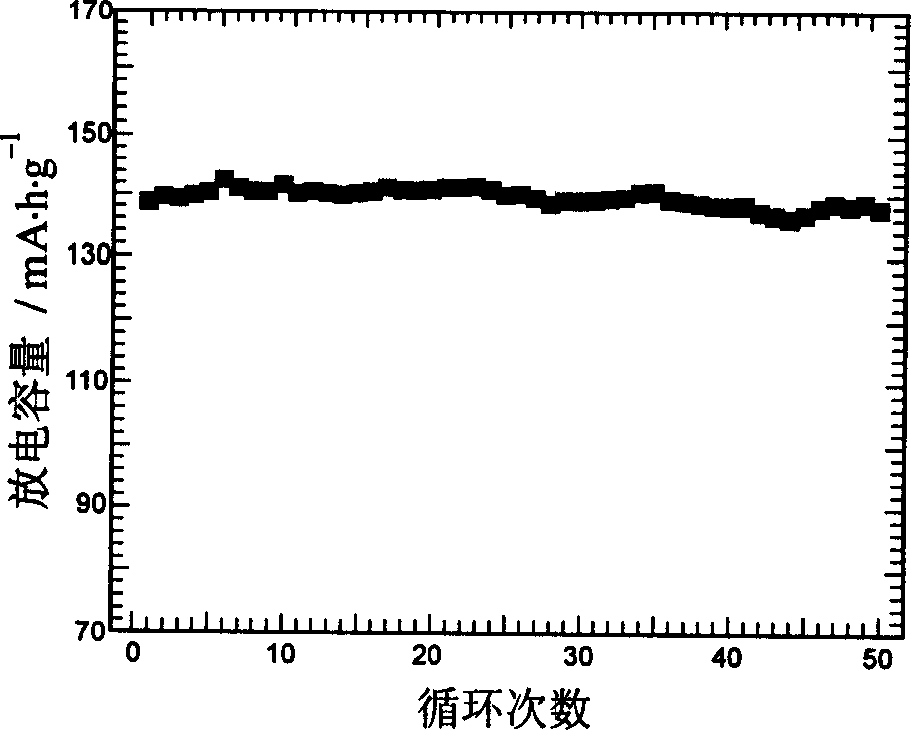

[0033] Adopt the battery cathode material o...

Embodiment 3

[0034] Embodiment 3, a kind of lithium-ion battery cathode material preparation method, carries out following steps successively:

[0035] 1), with Li:Mn:Co according to the molar ratio of 1:1.80:0.2 (ideal stoichiometric ratio in molecular formula) Li 2 CO 3 and electrolytic manganese dioxide MnO 2 with nickel oxide Co 2 o 3 After uniform mixing with a ball mill, heat treatment at 750°C for 20 hours to obtain lithium manganate LiCo with an average particle size of 10-15 μm. 0.2 mn 1.8 o 4 . Lithium nitrate LiNO with the sum of the weight of Li and Co accounting for 5% of the weight of lithium manganate 3 with cobalt nitrate Co(NO3) 2 It is also placed in a ball mill and mixed evenly with lithium manganate to form a mixture. At this time, lithium nitrate, cobalt nitrate and lithium manganate are all in powder form, LiNO 3 with Co(NO3) 2 They can be mixed with each other in any proportion.

[0036] 2), above-mentioned mixture is pressed into block under the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com