La-Ca-Mn/carbon nanotube dual-functional composite catalyst and preparation and application thereof

A technology of composite catalysts and carbon nanotubes, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the cumbersome preparation process, rare reports in the field of zinc-air batteries, and sufficient electrochemical performance. Discharge performance cycle life needs to be improved, etc., to achieve the effect of simple process, excellent electrochemical performance, charge and discharge performance, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

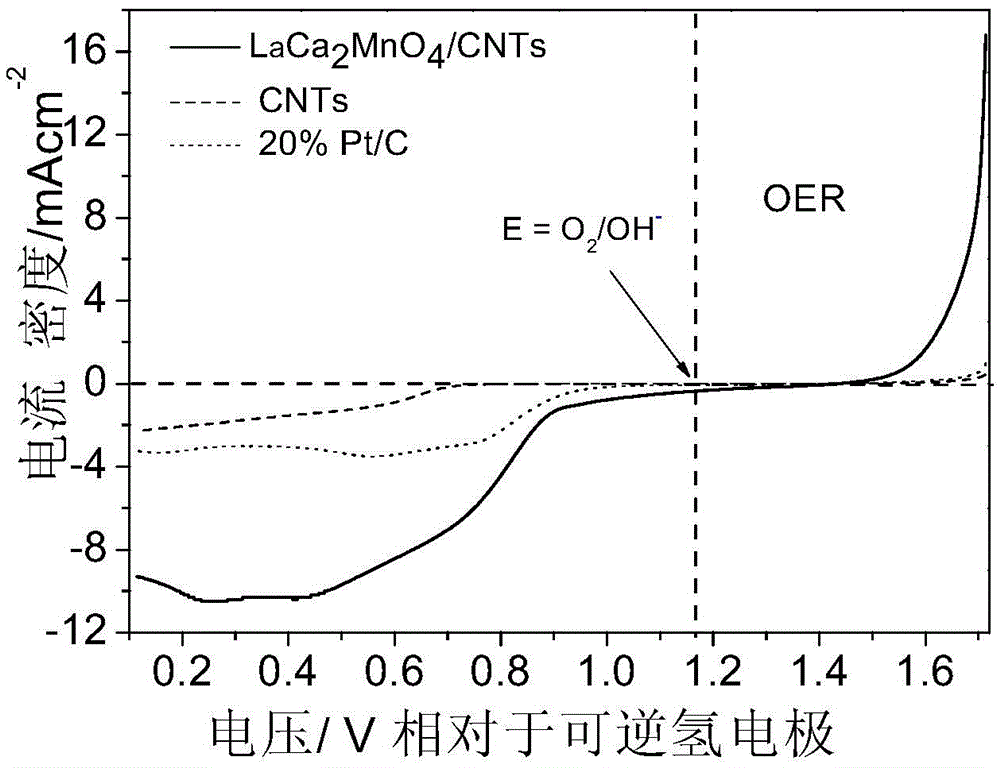

Embodiment 1

[0041] A bifunctional catalyst comprising carbon nanotubes, lanthanum oxide, calcium oxide and manganese dioxide. The manganese dioxide is tubular, with a length of 1-3 μm and an inner diameter of 7-10 nm; the calcium oxide is nanoparticles with a diameter of 10-30 nm; The diameter of the carbon nanotube is 10nm and the length is 3-10μm, and the carbon nanotube, calcium oxide and manganese dioxide are composited together.

[0042] The preparation method of bifunctional catalyst of the present invention is:

[0043] (1) configuration potassium permanganate and the mass ratio of water are the homogeneous mixed aqueous solution of 1.2:50, under room temperature the ratio of potassium permanganate solution and concentrated hydrochloric acid (concentration is 37.5%, the same below) is 51.2g:2ml Slowly add concentrated hydrochloric acid into the stirred potassium permanganate solution, stir until the mixture is uniform, pour the uniform solution into an autoclave at 140°C for 10 ho...

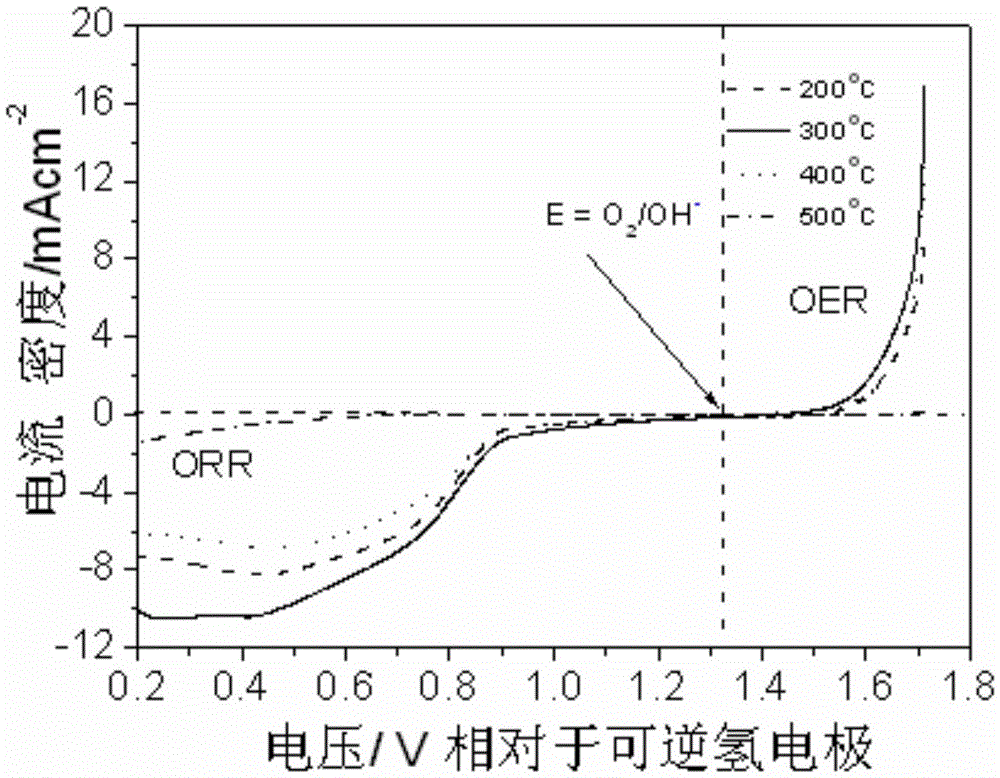

Embodiment 2

[0050] A bifunctional catalyst comprising carbon nanotubes, lanthanum oxide, calcium oxide and manganese dioxide. The manganese dioxide is tubular, with a length of 1-3 μm and an inner diameter of 7-10 nm; calcium oxide is nanoparticles with a diameter of 10-30 nm; the length of lanthanum oxide is 0.2-0.5 μm, and the length of carbon nanotubes with a diameter of 10 nm is 3-10μm, carbon nanotubes, calcium oxide and manganese dioxide are composited together.

[0051] Preparation of three-way catalysts at different calcination temperatures:

[0052] (1) configuration potassium permanganate and the mass ratio of water are the homogeneous mixed aqueous solution of 1.2:50, under room temperature the ratio of potassium permanganate solution and concentrated hydrochloric acid (concentration is 37.5%, the same below) is 51.2g:2ml Slowly add concentrated hydrochloric acid into the stirred potassium permanganate solution, stir until the mixture is uniform, pour the uniform solution into...

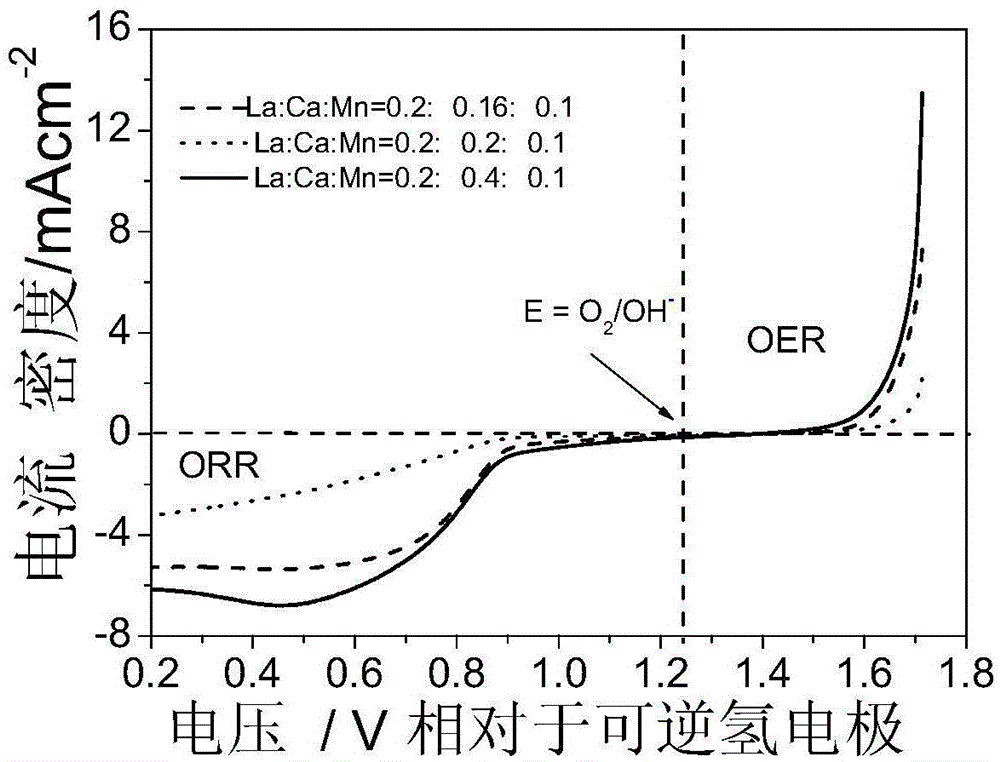

Embodiment 3

[0058] A bifunctional catalyst comprising carbon nanotubes, lanthanum oxide, calcium oxide and manganese dioxide. The manganese dioxide is tubular with a length of 1-3 μm and an inner diameter of 7-10 nm; calcium oxide is a nanoparticle with a diameter of 10-30 nm; lanthanum oxide is a nanorod with a length of 0.2-0.5 μm and a diameter of The length of 10nm carbon nanotubes is 3-10μm, and carbon nanotubes, cobalt oxide and manganese dioxide are composited together.

[0059] Preparation methods of different mass ratios of bifunctional catalyst raw materials:

[0060] (1) The mass ratio of configuration potassium permanganate and water is a homogeneous mixed aqueous solution of 1.2:100. At room temperature, the ratio of potassium permanganate solution and concentrated hydrochloric acid is 51.2g: 2ml of concentrated hydrochloric acid is slowly added to the stirred permanganate Potassium solution, stirred until evenly mixed, poured the homogeneous solution into an autoclave for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com