Niobium titanium aluminum alloy added with trace boron and preparation method thereof

An aluminum alloy, niobium-titanium technology, applied in the field of niobium-titanium aluminum alloy and its preparation, can solve problems such as value discounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

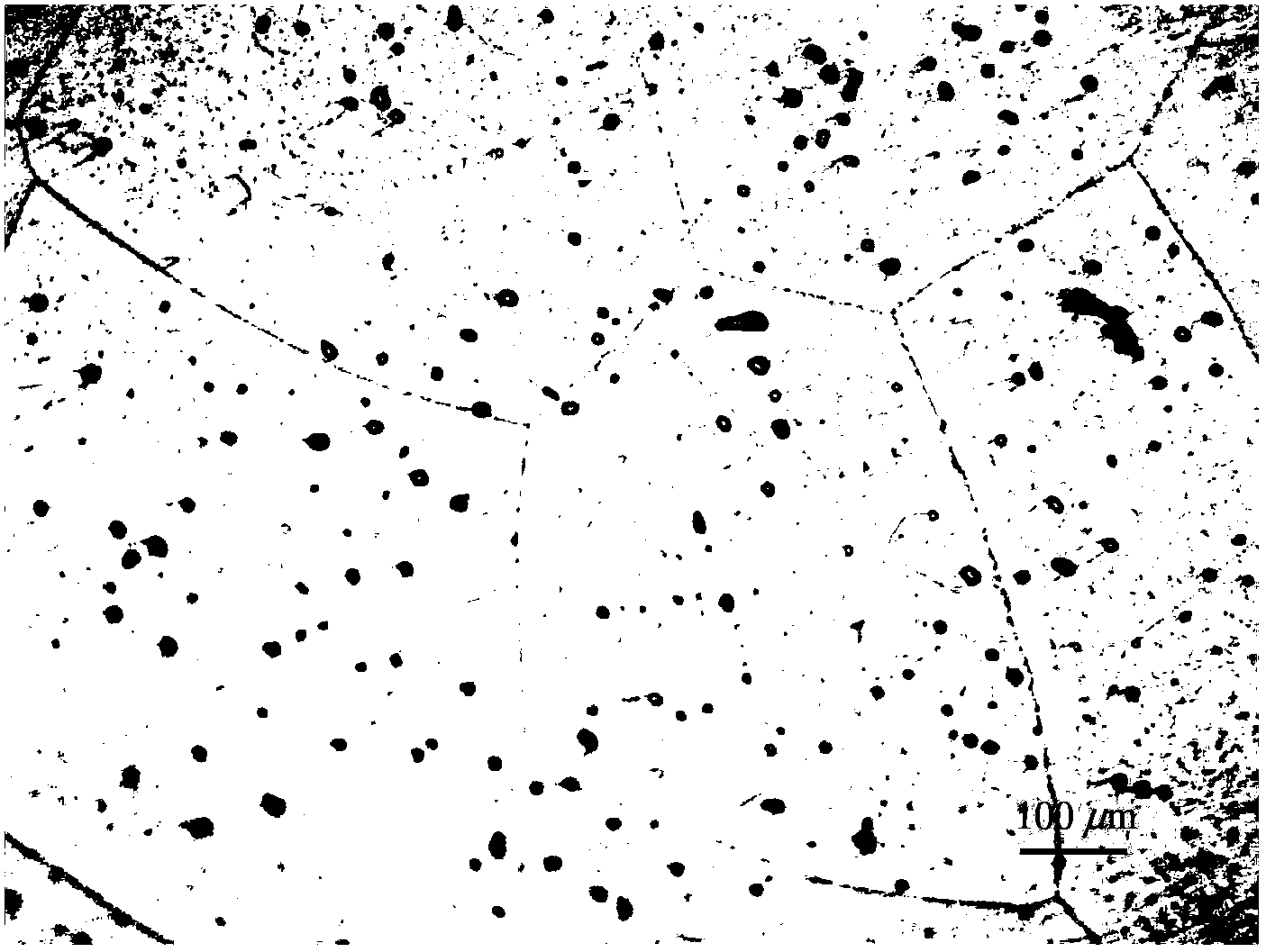

[0024] In this embodiment, boron as the grain refiner of the Nb-Ti-Al alloy is added in the form of elemental boron, and the atomic percentage of boron is 0.2% of the smelted alloy. The contents of niobium, titanium and aluminum in the alloy after smelting are within the following ranges: 44.8 atomic percent niobium, 40 atomic percent titanium, 15 atomic percent aluminum, and 0.2 atomic percent boron, totaling 100 percent. Its microstructure is as attached figure 2 .

Embodiment 2

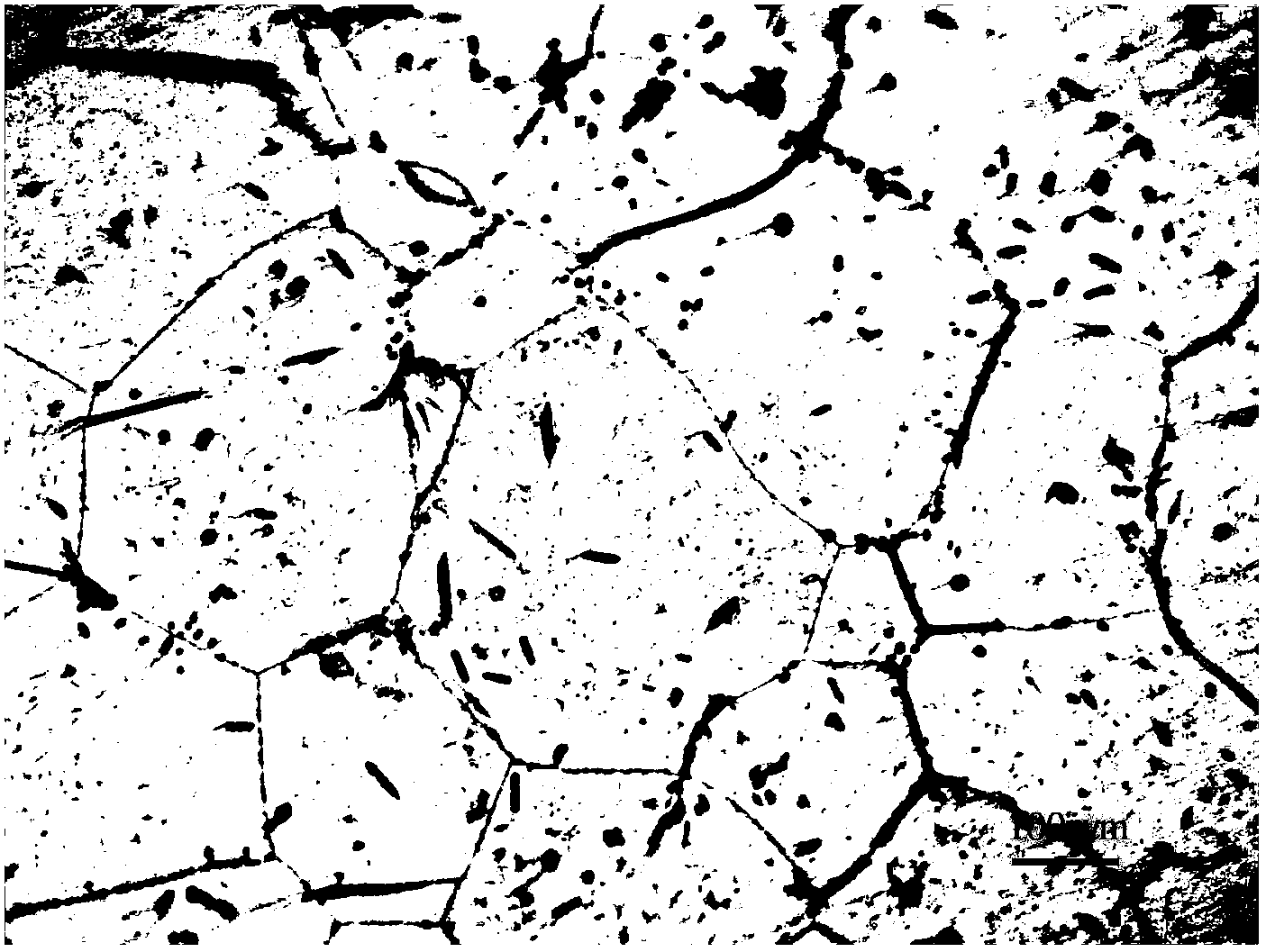

[0026] In this embodiment, boron as the grain refiner of Nb-Ti-Al alloy is added in the form of aluminum-boron alloy and aluminum-boron intermetallic compound in any proportion, and the atomic percentage of boron accounts for 0.5% of the alloy ingot after smelting. The contents of niobium, titanium and aluminum in the alloy after smelting are within the following ranges: 44.5 atomic percent niobium, 40 atomic percent titanium, 15 atomic percent aluminum, and 0.5 atomic percent boron, totaling 100 percent. Its microstructure is as attached image 3 .

Embodiment 3

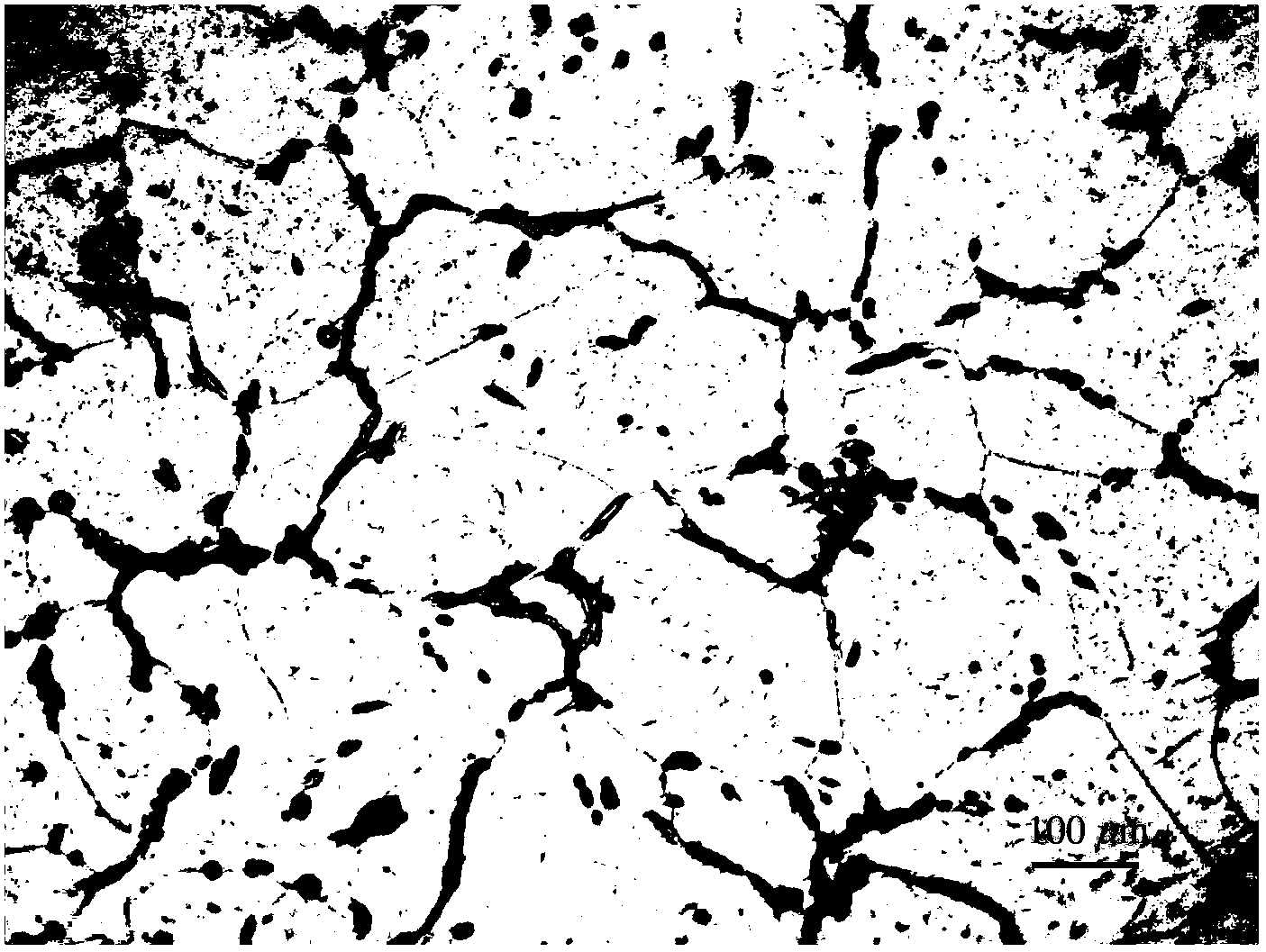

[0028] In this embodiment, boron as the grain refiner of Nb-Ti-Al alloy is added in the form of titanium-boron alloy and titanium-boron intermetallic compound in any proportion, and the atomic percentage of boron accounts for 0.8% of the smelted alloy ingot. The contents of niobium, titanium and aluminum in the alloy after smelting are within the following ranges: 44.2 atomic percent niobium, 40 atomic percent titanium, 15 atomic percent aluminum, and 0.8 atomic percent boron, totaling 100 percent. Its microstructure is as attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com