Novel surface mount-type microwave isolator

A mounted, isolator technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of increased cost, low production efficiency, poor strength, etc., to achieve firm and stable size and position, and improved welding pass rate , the effect of reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

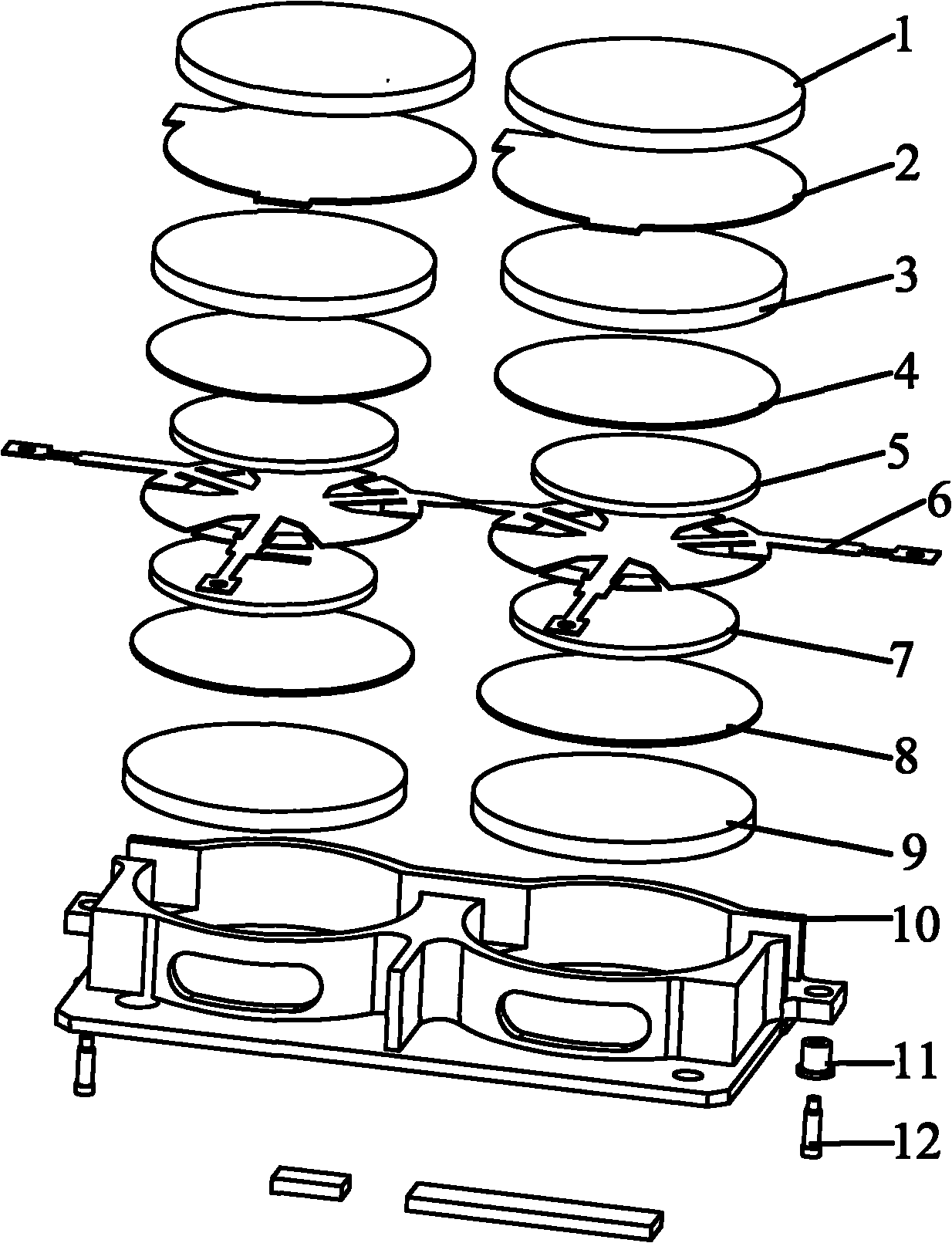

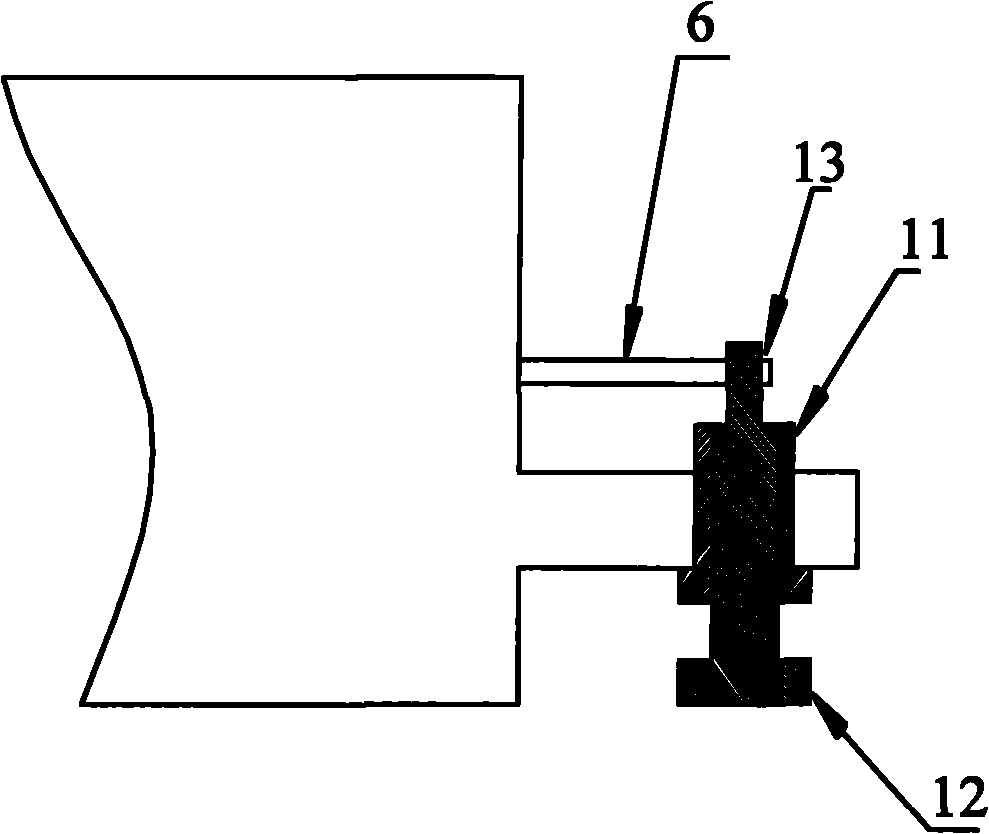

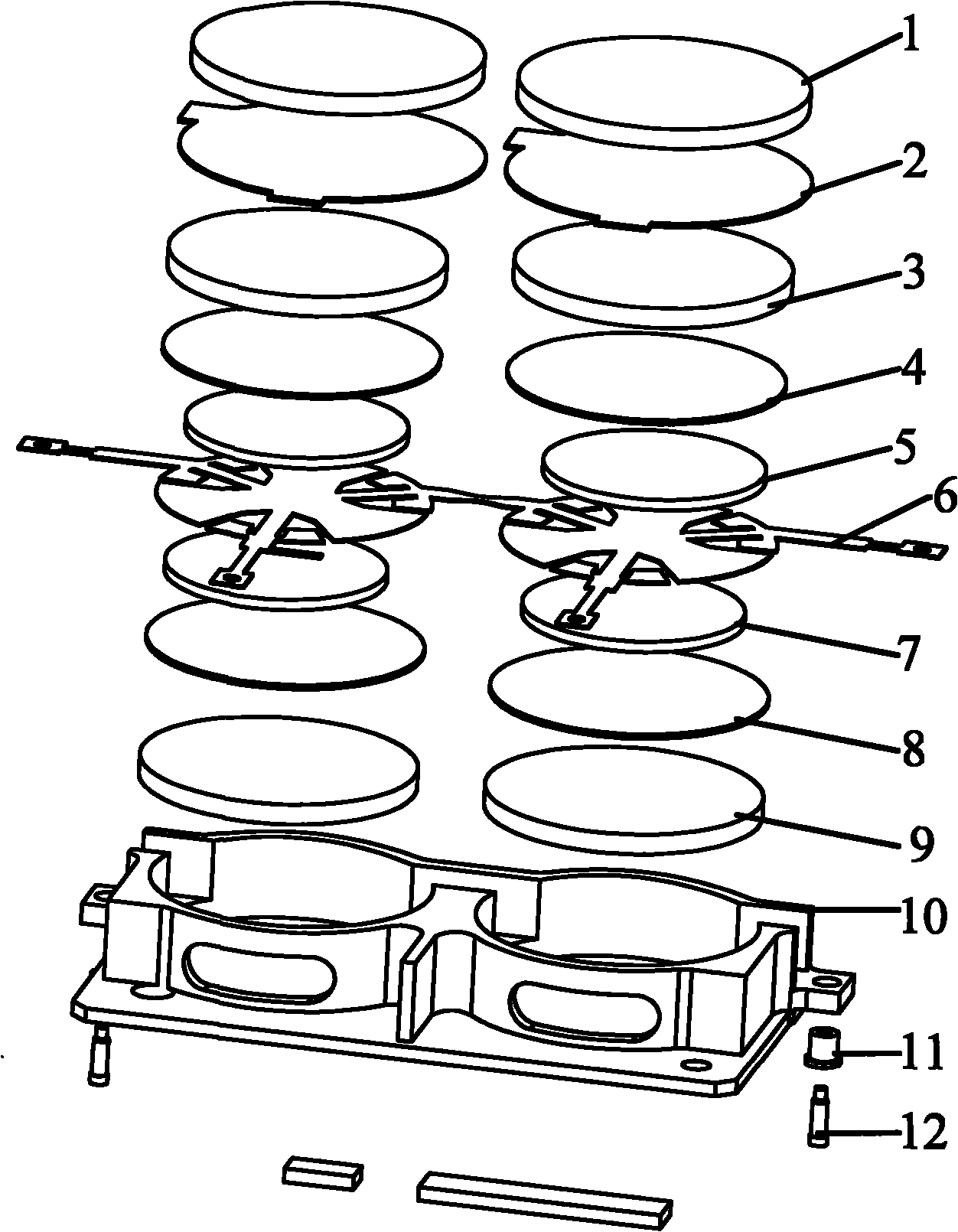

[0019] Such as figure 1 , figure 2 As shown, the new surface mount microwave isolator includes a housing 10 and a cover plate 1. The housing 10 is formed with a semi-open cylindrical cavity. The left and right side walls of the housing 10 have ports. There are convex bosses on the position opposite to the port, one on the left and one on the left and a through hole on the boss; a permanent magnet 9, a uniform magnetic conductive sheet 8, and a ferrite 7 are placed in the semi-open cylindrical cavity of the housing 10 , Central conductor 6, ferrite 5, uniform magnetic conductive sheet 4, constant magnet 3 and temperature compensation sheet 2, and covered with a cover plate 1, and the central conductor 6 extends out of the cavity through the port on the side wall of the housing 1 ; Install the port pin insulator 11 in the through hole of the side wall boss of the housing 10, the material of the port pin insulator 11 is PTFE, the port pin insulator 11 and the through hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com