Photocatalytic postposed internal-circulation anaerobic fluidized membrane bioreactor and working method thereof

A membrane bioreactor, anaerobic fluidization technology, applied in chemical instruments and methods, anaerobic digestion treatment, waste fuels, etc. To deal with problems such as high cost of raw materials and insignificant mineralization effect, to achieve the effect of realizing the treatment of organic pollutants that are easy to biochemically degrade and difficult to biochemically degrade, reducing reaction toxicity, and practical sewage and wastewater treatment and reuse processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

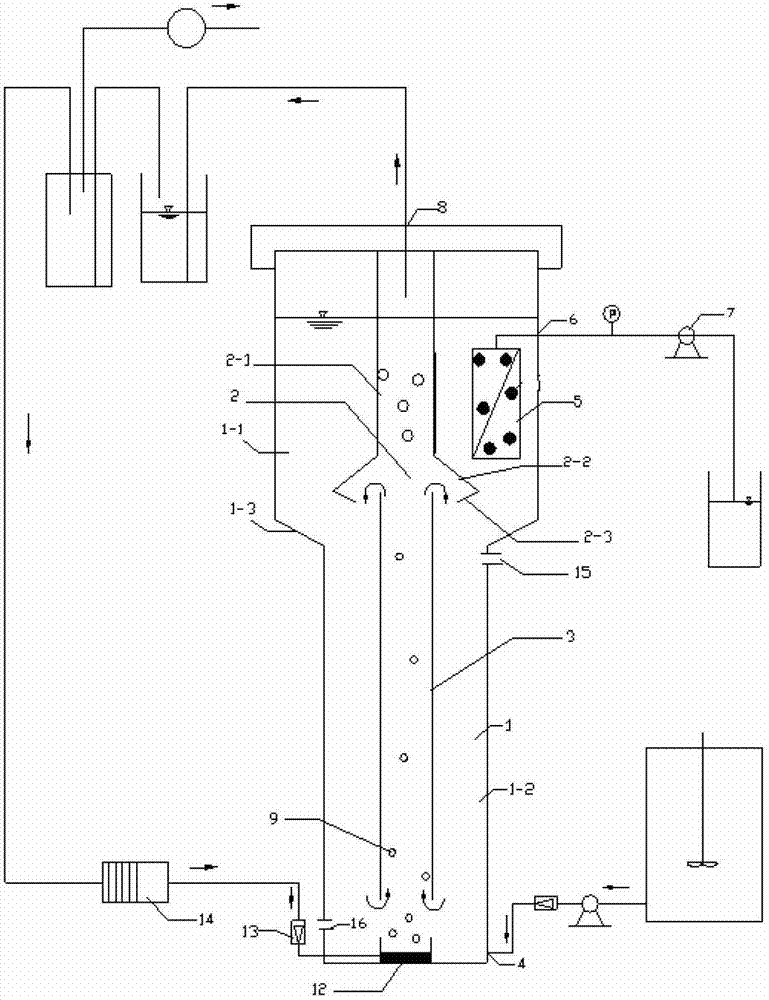

[0046] Such as Figure 1-2 shown.

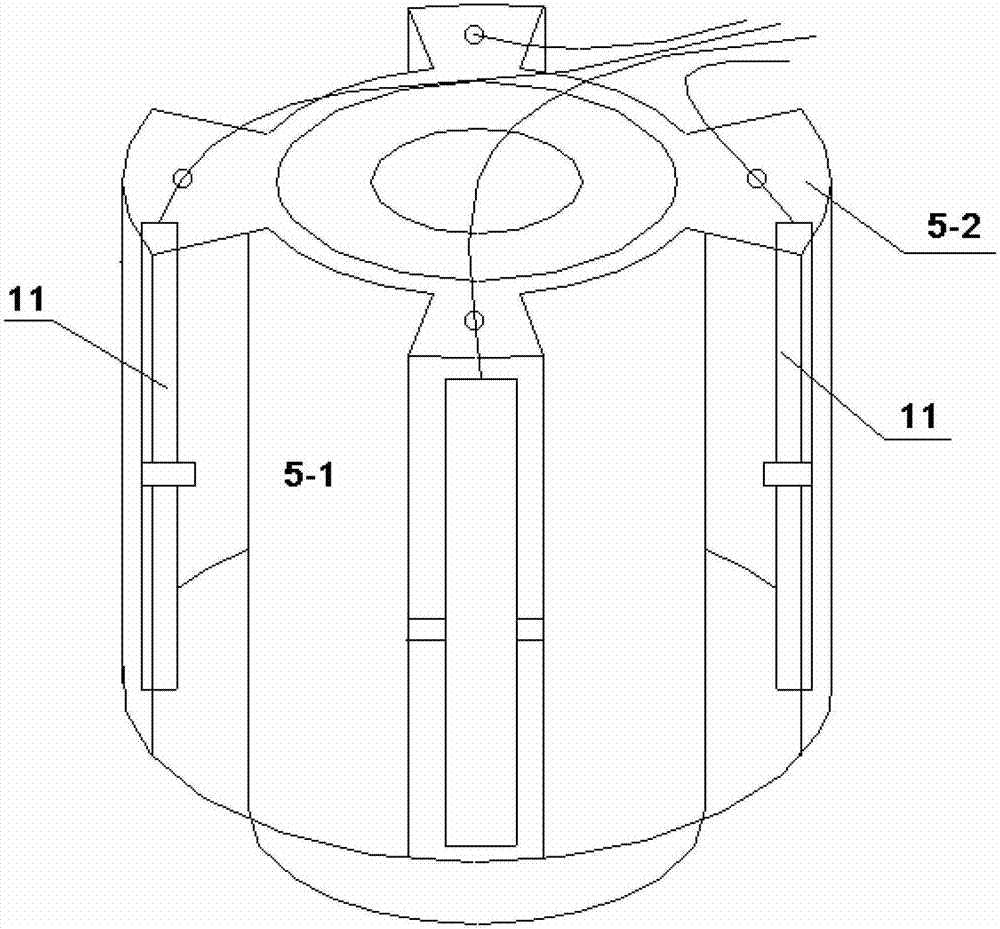

[0047] A post-photocatalytic internal circulation anaerobic fluidized membrane bioreactor, including a reaction cylinder 1, a stripping cylinder 3, a three-phase separator 2 and a membrane module 5, and an inlet is installed at the bottom of the reaction cylinder 1 Water pipe 4 and air inlet pipe 14; biogas aeration disc 12, stripping cylinder 3 and three-phase separator 2 are arranged axially inside reaction cylinder 1 from bottom to top; The phase separator 2, the three-phase separator 2 includes a top-down guide tube 2-1 and an umbrella-shaped guide cover 2-2, and a direction is arranged on the outer edge of the umbrella-shaped guide cover 2-2. Inwardly folded guide edge 2-3, the upper end of the guide tube 2-1 communicates with the external gas outlet pipe 8 through the top cover of the reaction tube 1, and connects with the biogas aeration tray 12 through the air pump In the reaction cylinder 1, a membrane assembly 5 is arranged at a ...

Embodiment 2

[0057] Such as figure 1 , 3 shown.

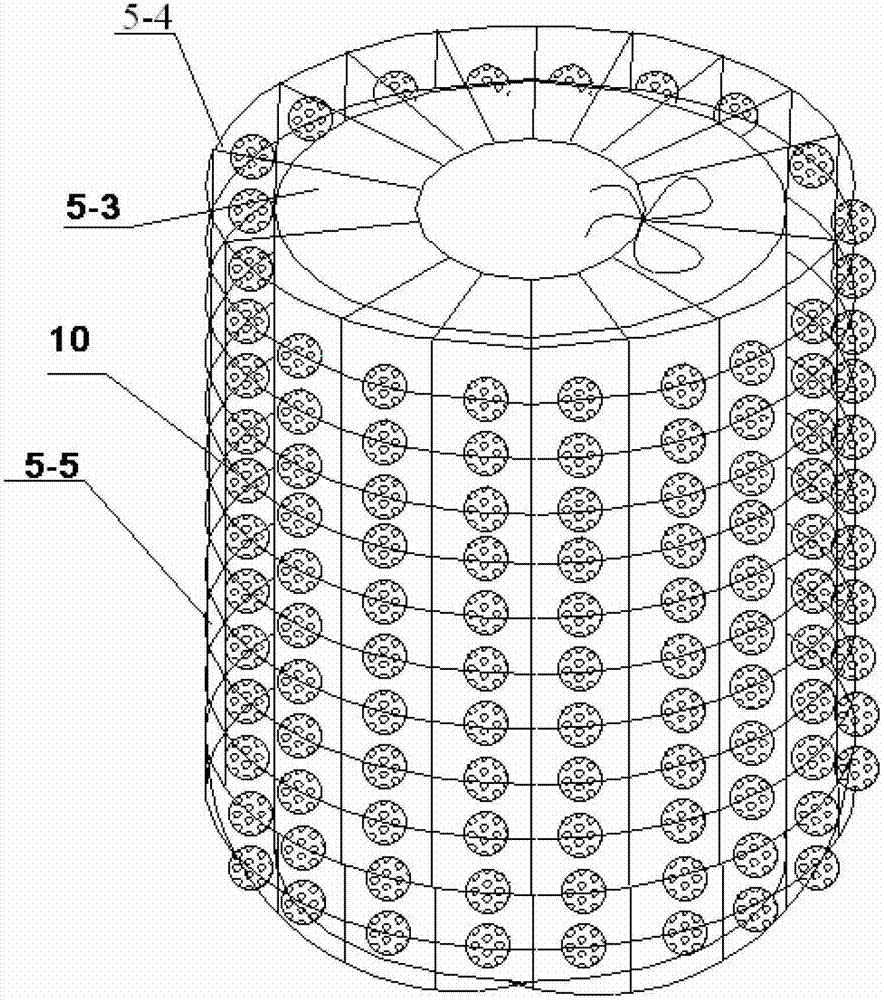

[0058] The internal circulation anaerobic fluidized membrane bioreactor with photocatalysis as described in Example 1, the difference is that the membrane module 5 is a hollow fiber ultrafiltration with a titanium dioxide light particle net 5-4 hanging on the outside. The film 5-3; the titanium dioxide light particle net 5-4 includes mesh wires 5-5 arranged in warp and weft, and titanium dioxide light particles 10 are hung on the mesh wires 5-5. The diameter range of the titanium dioxide light particles 5-4: 2-4mm.

[0059] The mesh wire 5-5 is sheathed on the outer surface of the hollow fiber ultrafiltration membrane 5-3 in the shape of a net bag. The rated pore diameter of the hollow fiber ultrafiltration membrane 5-3 is 0.01 micron. The total volume of the titanium dioxide light particles is 1 / 5 of the total volume of the hollow fiber ultrafiltration membrane.

[0060] Wherein, the preparation method of the titanium dioxide light pa...

Embodiment 3

[0069] A kind of working method that utilizes reactor treatment sewage as described in embodiment 1 or embodiment 2, comprises steps as follows:

[0070] (1) Add anaerobic activated sludge to the reaction cylinder 1 through the sludge filling port 15, and the volume of the added anaerobic sludge accounts for 1 / 6-1 / 5 of the volume of the entire reaction cylinder 1; Set hollow support 5-2, turn on the ultraviolet light source 11 on the hollow support;

[0071] (2) Open the water inlet 4, inject sewage into the reaction cylinder 1; open the biogas aeration disc 12, inject biogas into the reaction cylinder 1;

[0072] (3) The sewage rises to the three-phase separator 2 along the stripper 3: the biogas is discharged along the three-phase separator 2 and the outlet pipe 8; the sediment in the sewage settles along the space of the stripper 3 and is mixed with the active Anaerobic biological reaction occurs in sludge;

[0073] (4) The clear liquid in the sewage stays in the upper pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com