Method for manufacturing high-strength needling nonwoven geotextiles

A non-woven, geotextile technology, applied in non-woven fabrics, textiles and papermaking, fabric surface trimming and other directions, can solve the problems of poor deformation resistance, difficult to enhance, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Process flow

[0015] Fiber opening and mixing → carding (or airflow) into web → web laying → needle punching → heat setting → finished product winding.

[0016] Fiber opening and mixing: loosen the fiber raw materials to dissociate large fiber blocks and fiber clusters, so that the fibers can be evenly mixed;

[0017] Carding into a web: through a carding machine, the small cotton bundles that have been opened and mixed are combed into a thin web composed of single fibers;

[0018] Laying: Laying the thin fiber web carded by layer-by-layer carding machine through the web-laying machine to increase the surface density and thickness of the non-woven fabric product;

[0019] Acupuncture: The fiber web is repeatedly punctured by an acupuncture machine equipped with needles, so that the fibers in the fiber web are entangled with each other to form an acupuncture nonwoven fabric;

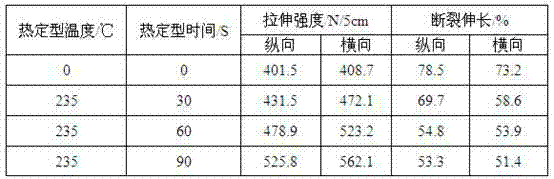

[0020] Heat setting: The heat setting method adopts hot air setting, and the non-woven fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com