Ultrasonic atomized steam assisted double-roller carbon fiber drying and heating device

A technology of ultrasonic atomization and heating devices, applied in heating devices, electric heating devices, ohmic resistance heating, etc., can solve the problems of uneven drying and densification temperature, poor temperature accuracy, difficult temperature control, etc., and achieve stable and controllable temperature and humidity , prevent wire parallel problems, and improve the effect of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

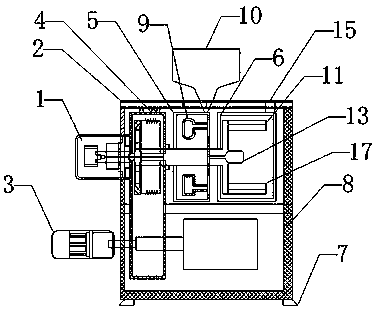

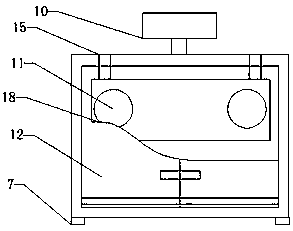

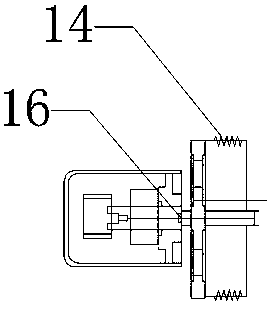

[0027]An ultrasonic atomized steam-assisted double-roller carbon fiber drying and heating device is characterized in that it mainly includes a temperature transmitter 1 and a heating box 2, wherein a freely slidable universal wheel 7 is installed at the bottom of the heating box 2, The heating box 2 is divided into upper and lower layers, and a servo motor 3 is installed in the bottom motor room 8. On the upper layer of the heating box 2, the device with the temperature transmitter 1 is an ultrasonic atomization auxiliary device 5. Directly in front of the auxiliary device 5 horizontally, a double-roller heating roller 11 is installed, wherein, on the top of the heating box 2, a water storage tank 10 connected to the ultrasonic atomization auxiliary device 5 is also provided, and on the upper surface of the heating box 2, An adjustable air hole 15 is provided. Inside the heating box, the connection between the double-roller heating roller 11, the ultrasonic atomization auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com