Detachable axial-butting and quick-locking mechanism

A locking mechanism, fast technology, applied in the direction of mechanical equipment, fixing devices, etc., can solve the problems of wasting time, low connection accuracy, and the accuracy cannot be well guaranteed, etc., to achieve simple manufacturing, simple structure, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

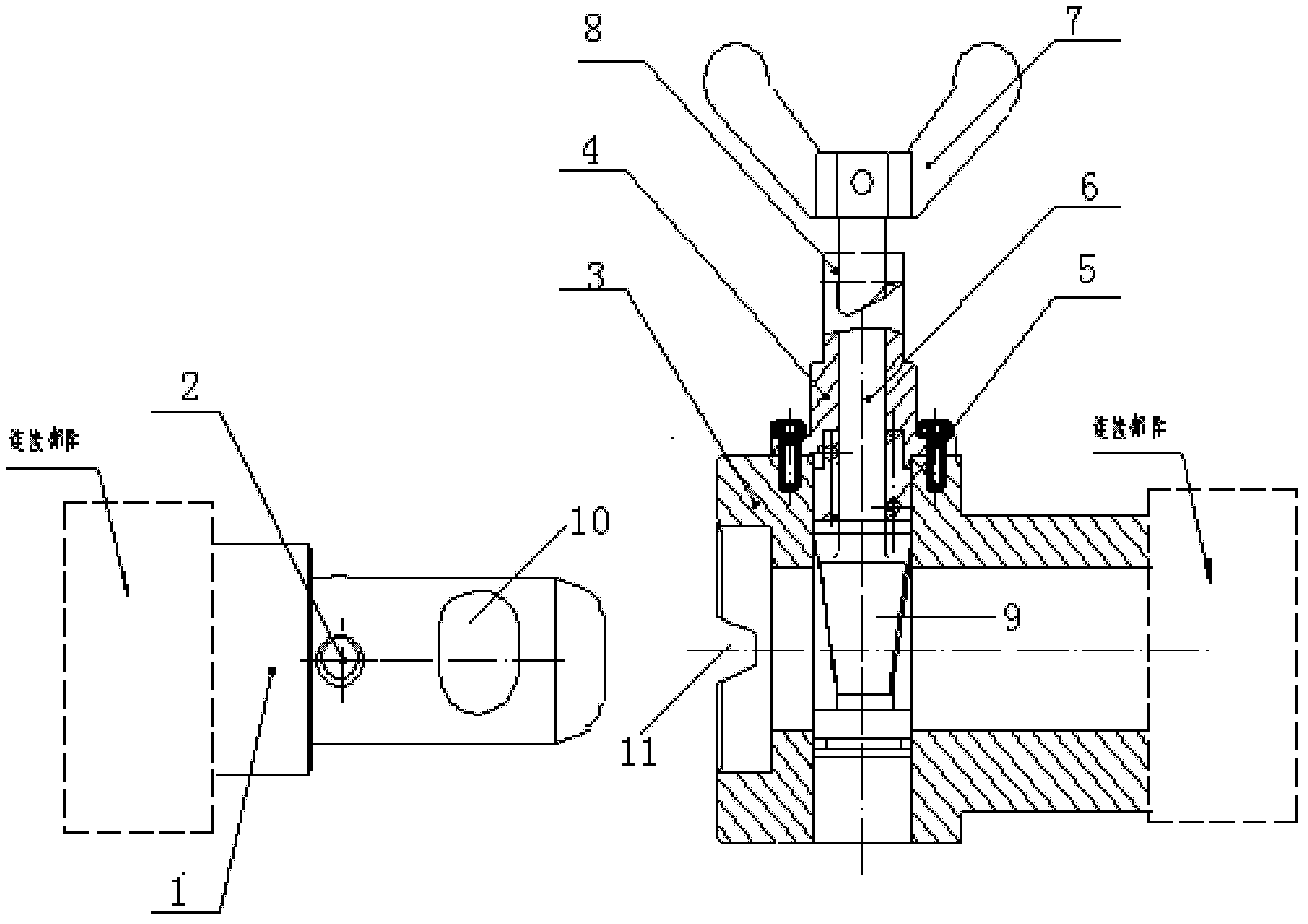

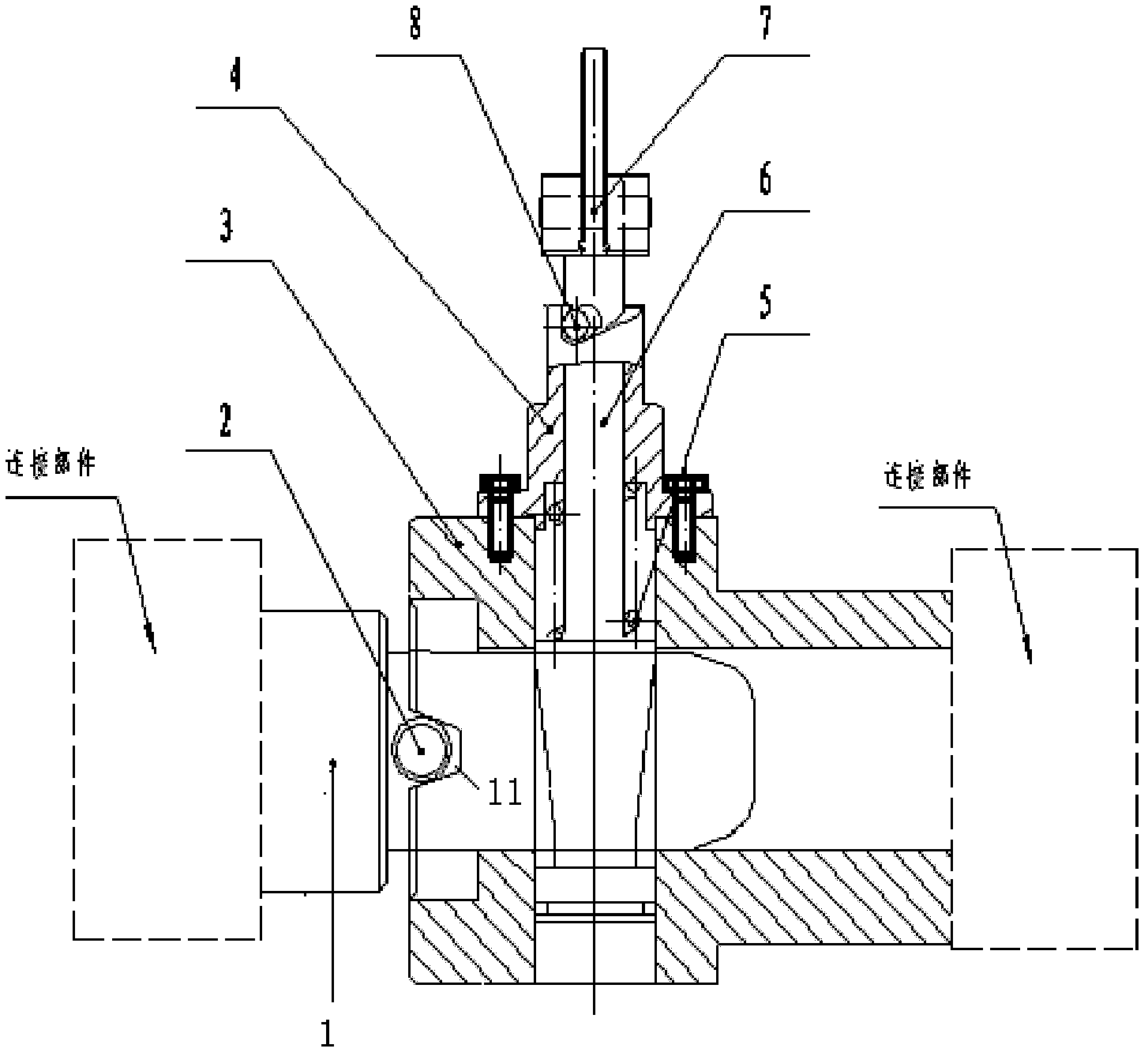

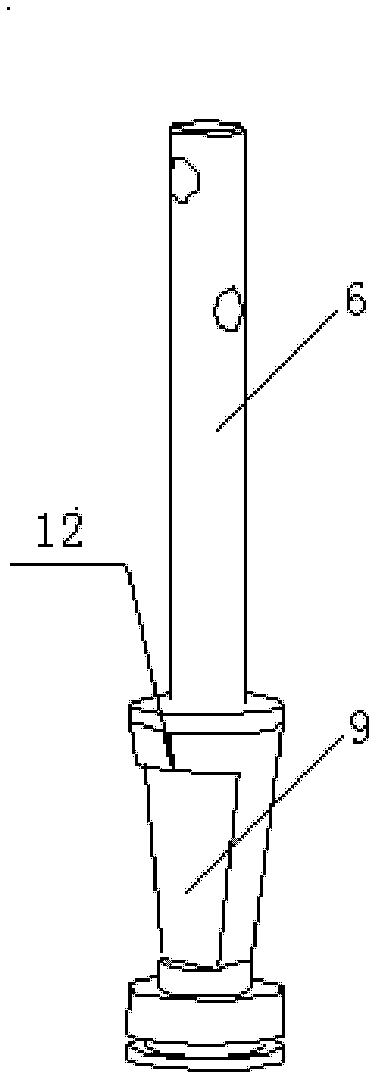

[0013] refer to figure 1 . In the detachable axial butt joint quick locking mechanism described in the figure, it mainly includes and can be divided into two parts respectively connecting two components. The two parts are a connecting shaft 1 with a positioning pin 2 at one end and a connecting seat 3 that cooperates with the connecting shaft 1 to connect the connected parts coaxially. The positioning pin 2 is in contact with the V-shaped groove 11 of the connecting seat 3 when locked, so that the connecting shaft 1 and the connecting seat 3 are quickly fixed in place. The left end of connecting shaft 1 is connected with parts, and its connection mode can be determined according to the structure and shape of parts, and the structure of connecting shaft 1 can also be designed on parts. Another part of parts is based on the right-hand connecting seat 3, and its connection method can be determined according to the structure and shape of the parts, and the structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com