Preparation method of organic substrate for raising rice seedlings

An organic substrate, a technology for raising rice seedlings, applied in the directions of organic fertilizers, inorganic fertilizers, fertilizers made of biological waste, etc., can solve the problems of difficult crushing and processing, high fiber content, long decomposing cycle, etc., and achieve low production costs. , the process is practical, the effect of promoting robust growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

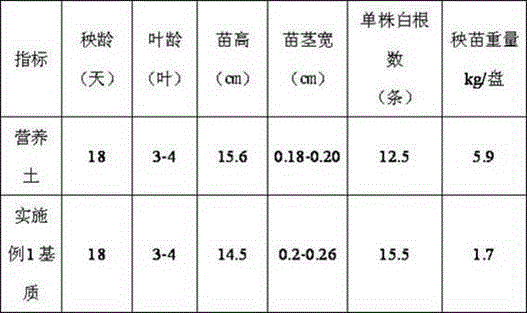

Embodiment 1

[0036]A method for making an organic substrate for rice seedling raising. The substrate is composed of fermented vinegar residue, a mixture of cassava residue and straw powder, coconut chaff wet material, plant ash, peat, and vermiculite. The method is characterized in that: the method first The straw is dried in the sun and crushed into particles below 5mm; the mixture of vinegar residue accounting for 25%, cassava residue accounting for 50%, and straw powder accounting for 25% is composted and fermented with a fermentation agent containing beneficial microorganisms; then add coconut peat Wet material, plant ash, peat, vermiculite, compound fertilizer, synergist and dwarfing agent; then these raw and auxiliary materials are fully stirred and evenly mixed, and then bagged, weighed, packaged and put into storage; the specific operation steps are as follows:

[0037] 1) Collection and treatment of raw and auxiliary materials: collect organic waste vinegar residue, cassava residue...

Embodiment 2

[0049] A method for making an organic substrate for rice seedling raising. The substrate is composed of fermented vinegar residue, a mixture of cassava residue and straw powder, coconut chaff wet material, plant ash, peat, and vermiculite. The method is characterized in that: the method first The straw is dried in the sun and crushed into particles below 5mm; the mixture of vinegar residue accounting for 35%, cassava residue accounting for 50%, and straw powder 15% is composted and fermented with a fermentation agent containing beneficial microorganisms; raw materials, plant ash, peat, vermiculite, compound fertilizer, synergist and dwarf agent; then these raw and auxiliary materials are fully stirred, evenly mixed, and then bagged, weighed, packaged and put into storage; the specific operation steps are as follows:

[0050] 1) Collection and treatment of raw and auxiliary materials: collect organic waste vinegar residue, cassava residue, crop straw and coconut bran as the main...

Embodiment 3

[0062] A method for making an organic substrate for rice seedling raising. The substrate is composed of fermented vinegar residue, a mixture of cassava residue and straw powder, coconut chaff wet material, plant ash, peat, and vermiculite. The method is characterized in that: the method first The straw is dried in the sun and crushed into particles below 5mm; the mixture of vinegar residue accounting for 35%, cassava residue accounting for 40%, and straw powder accounting for 25% is composted and fermented with a fermentation agent containing beneficial microorganisms; then add coconut peat Wet material, plant ash, peat, vermiculite, compound fertilizer, synergist and dwarfing agent; then these raw and auxiliary materials are fully stirred and evenly mixed, and then bagged, weighed, packaged and put into storage; the specific operation steps are as follows:

[0063] 1) Collection and treatment of raw and auxiliary materials: collect organic waste vinegar residue, cassava residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com