Chlorohydrocarbon waste liquid treating method

A treatment method and waste liquid technology, applied in the direction of heating water/sewage treatment, neutralizing water/sewage treatment, etc., can solve problems such as resource waste, environmental pollution, and no good treatment methods, and achieve easy operation, simple process, Realize the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

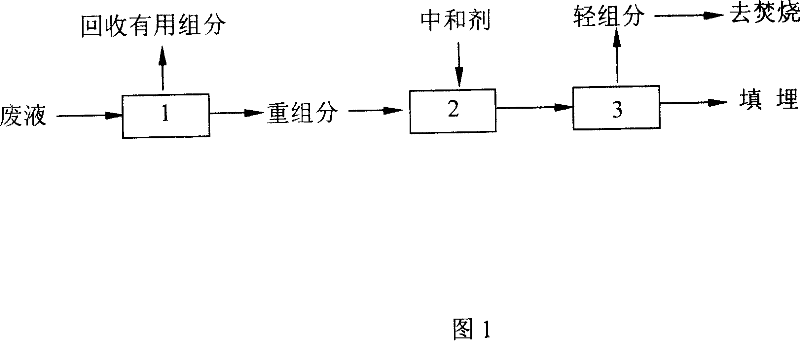

Method used

Image

Examples

Embodiment 1

[0017] Take 200ml of HCC-230 waste liquid and add it to a container equipped with a mechanical stirrer, a heating bath, and a reflux condenser, add 150g of calcium oxide, and connect the condensation receiver and tail gas absorption device, heat after stirring, and control the pressure at 0.090Mpa Carry out heating and dry distillation, and control the temperature of the dry distillation process not to exceed 260° C. until the waste liquid is burned to dryness to obtain 291 g of effluent and 193 g of slag.

[0018] The effluent is directly incinerated, and the slag is harmlessly landfilled.

Embodiment 2

[0020] Same as in Example 1, the pressure was controlled at 0.095Mpa to obtain 245g of effluent and 206g of slag.

Embodiment 3

[0022] Same as in Example 1, take 200ml of HCC-240 waste liquid, control the pressure at 0.092Mpa, change 150g of calcium oxide to 150g of carbide slag, and obtain effluent 194, the amount of slag is 287g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com