Patents

Literature

49results about How to "Achieve direct drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for controlling stepping motor

InactiveCN104092418AAchieve direct driveAvoid Torque LimitationsDynamo-electric converter controlControl signalElectric machine

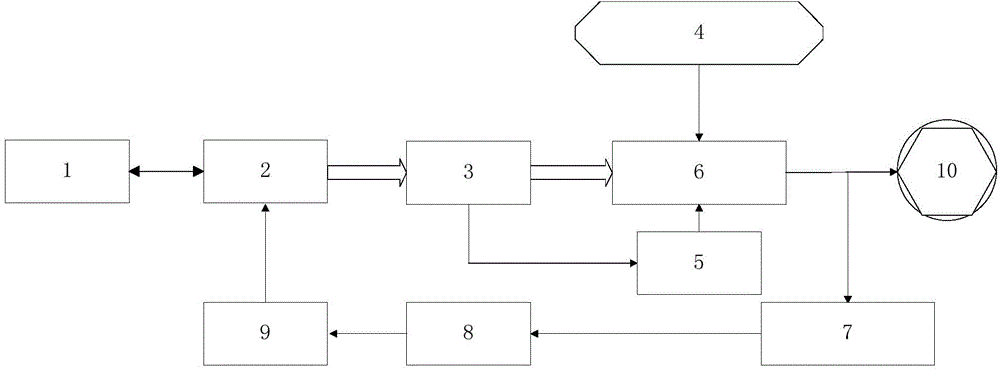

The invention belongs to the field of electric control and particularly relates to a device and method for controlling a stepping motor. The device for controlling the stepping motor is composed of a computer, a single-chip microcomputer, a control signal optoelectronic isolation circuit, a linear non-stabilized-voltage supply, an output current control circuit, a driving circuit, a winding current acquisition circuit, a reference voltage comparison circuit and a feedback signal optoelectronic isolation circuit, wherein the computer is in communication with the single-chip microcomputer so that remote setting of parameters of the stepping motor can be achieved, the single-chip microcomputer controls the high-precision rotation, achieved through the stepping motor driving circuit, of the stepping motor according to the set parameters, current signals fed back by the winding current acquisition circuit and the number of actual walking pulses are acquired at the same time, and thus high-precision control over the high-power stepping motor is achieved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

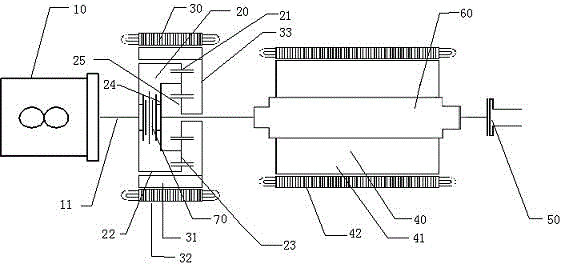

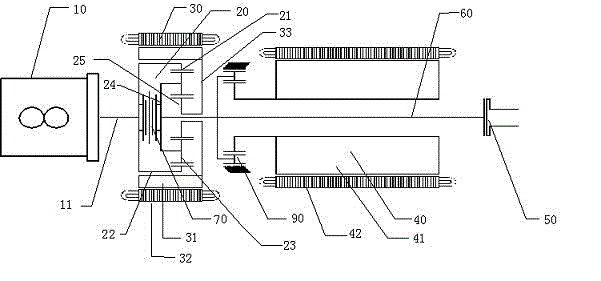

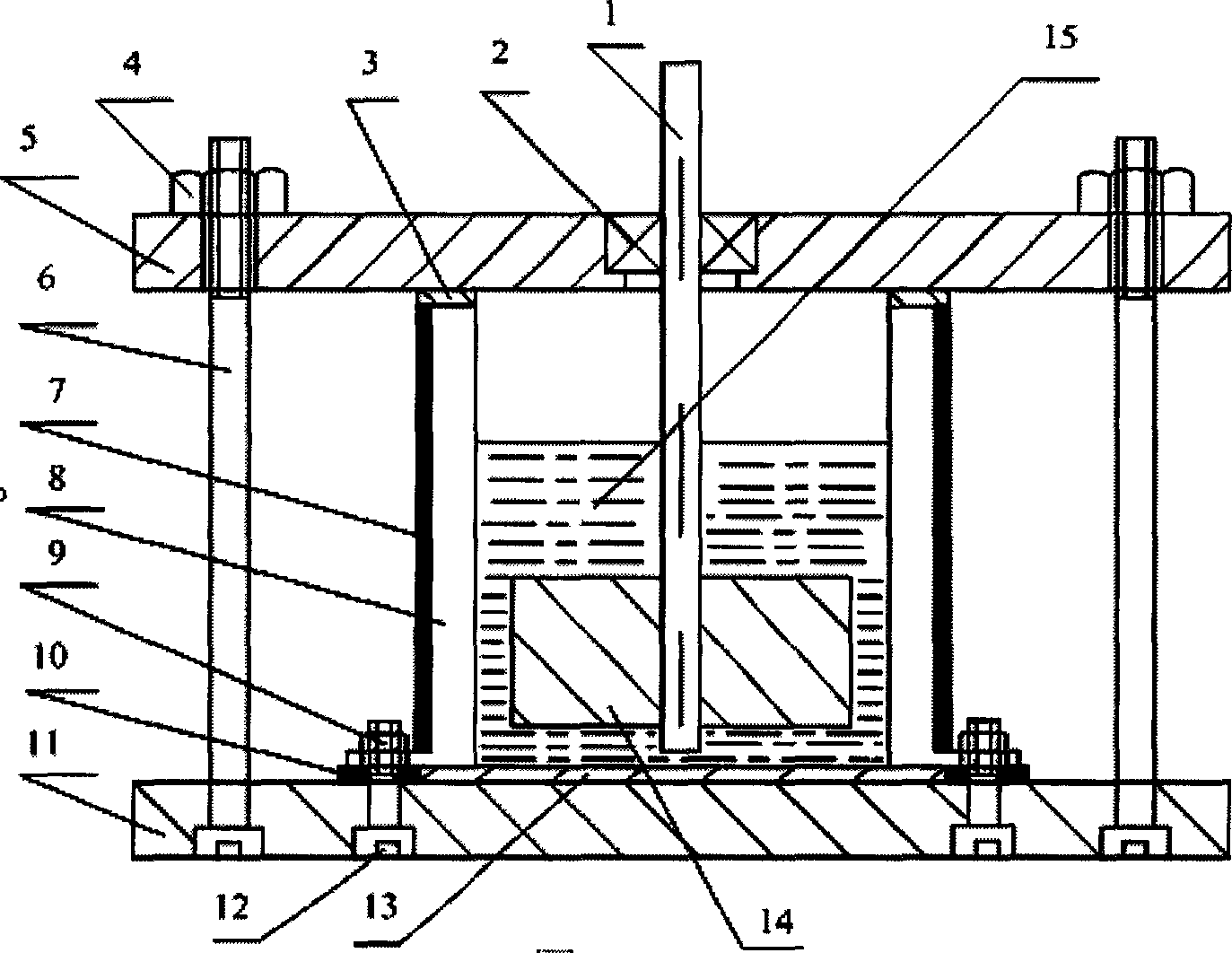

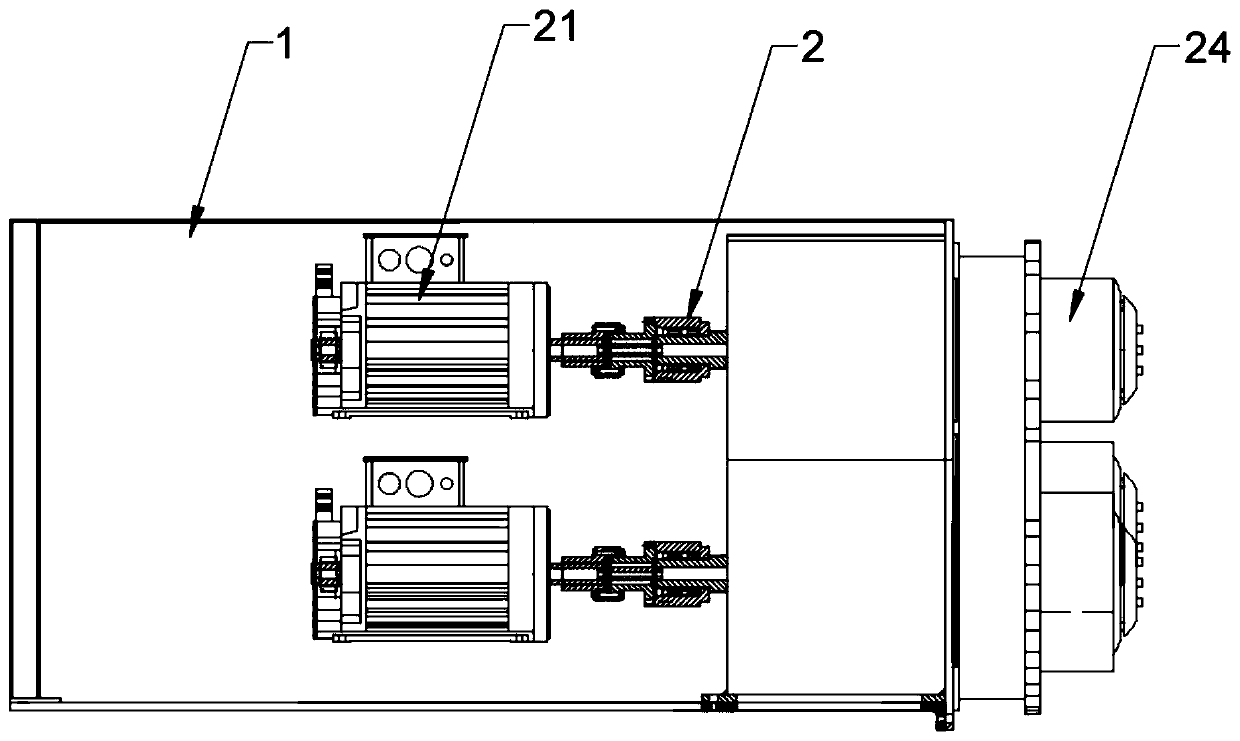

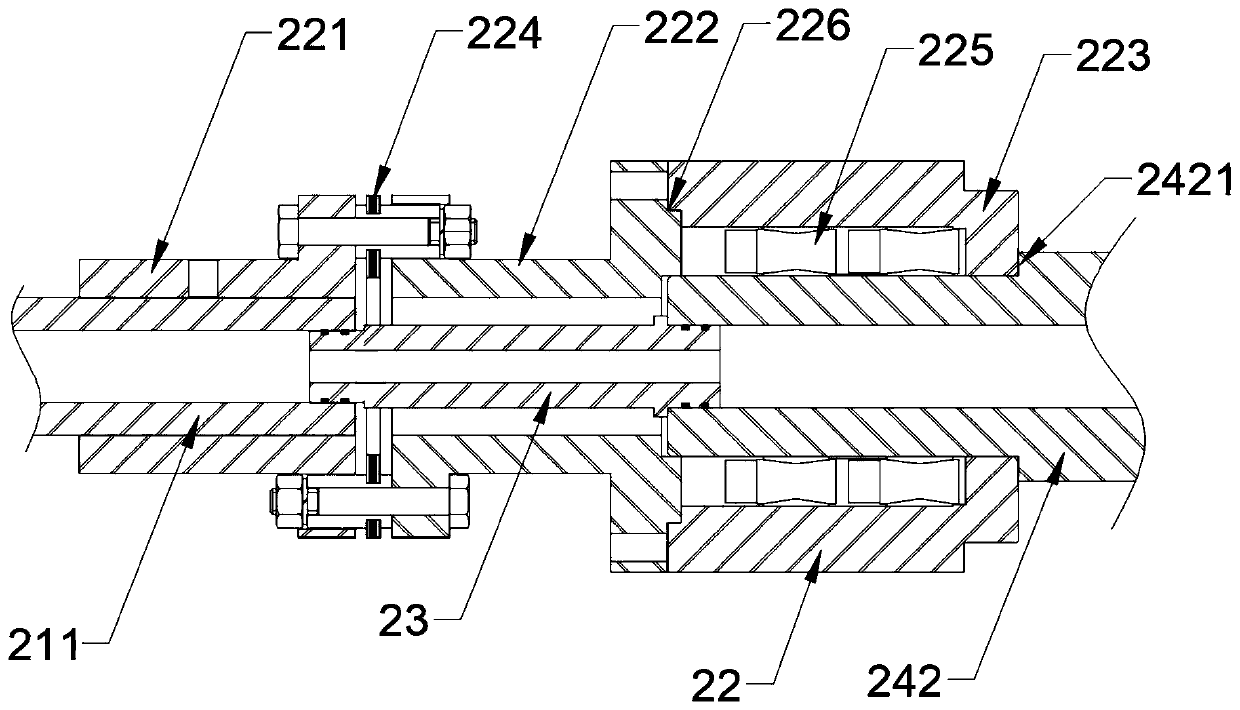

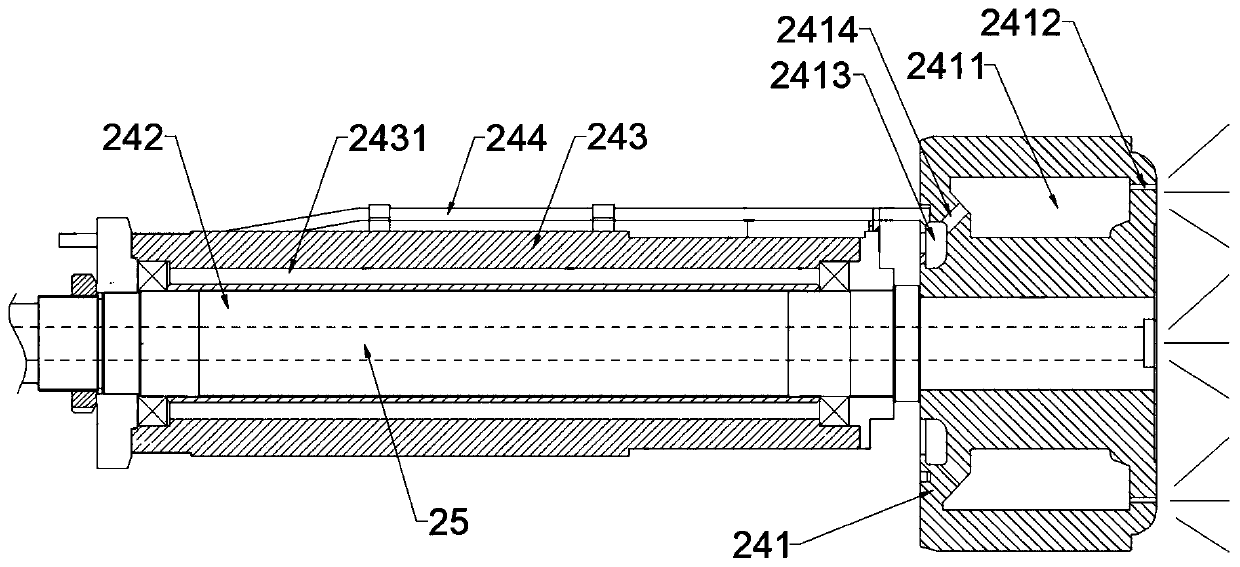

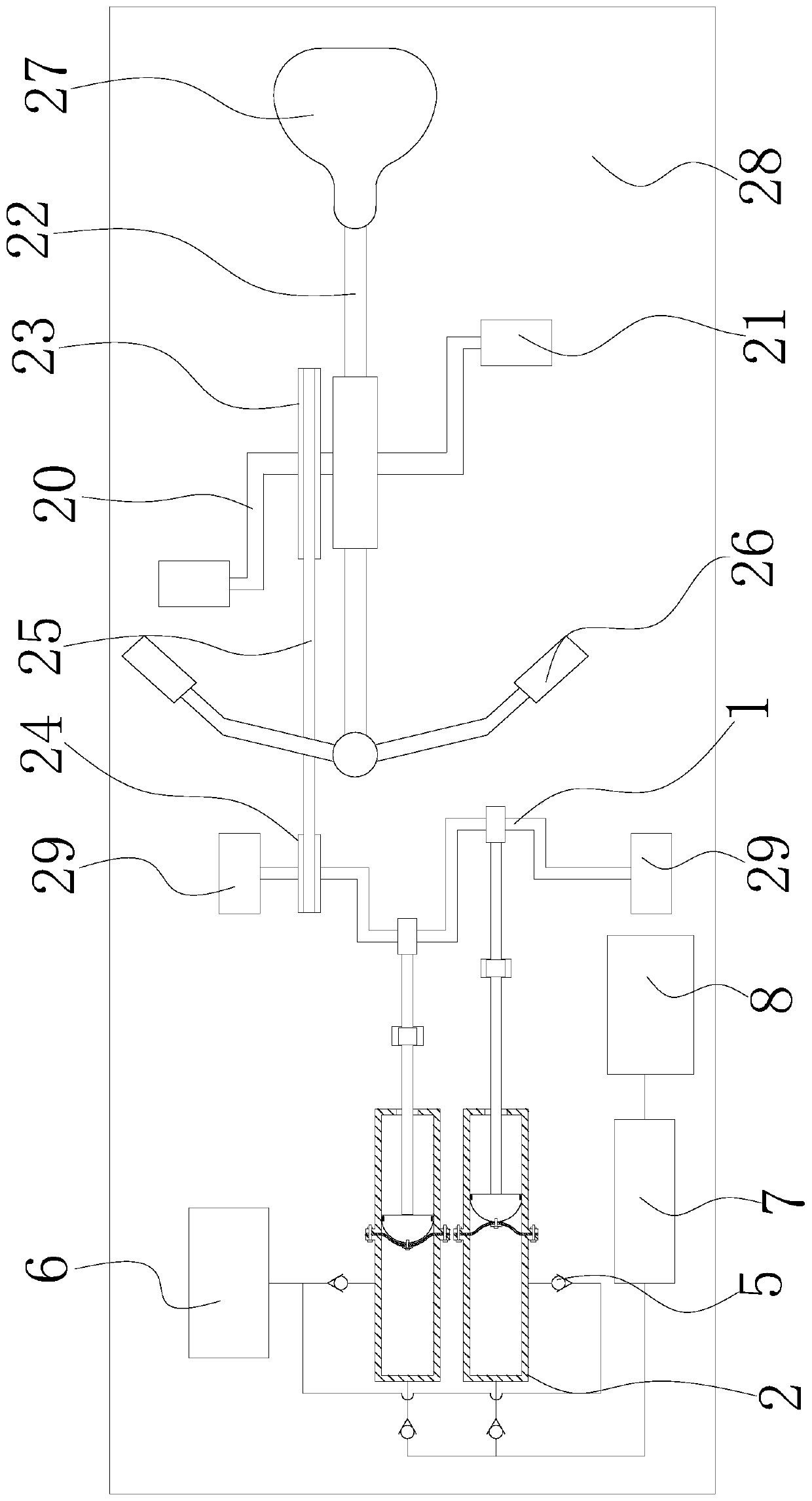

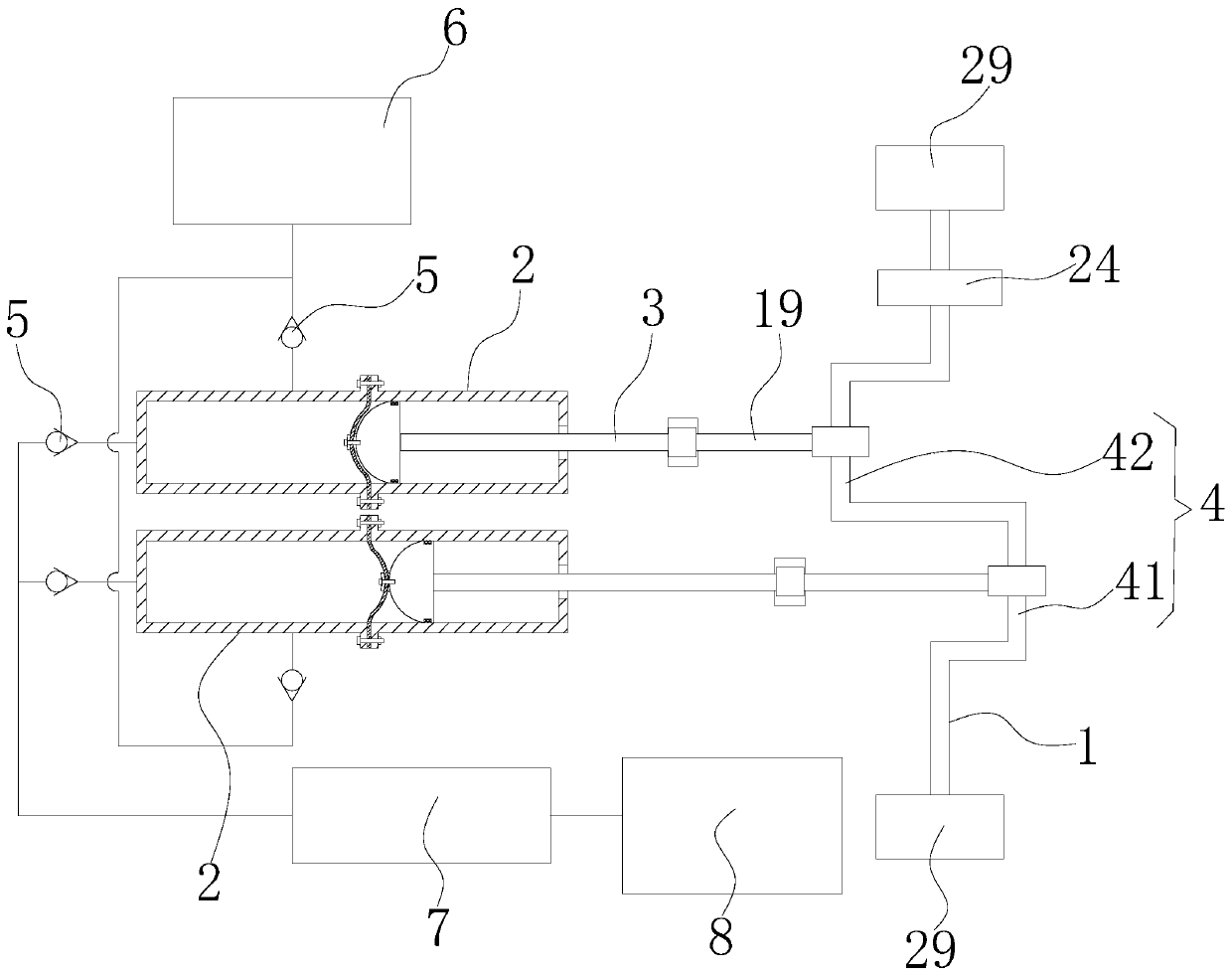

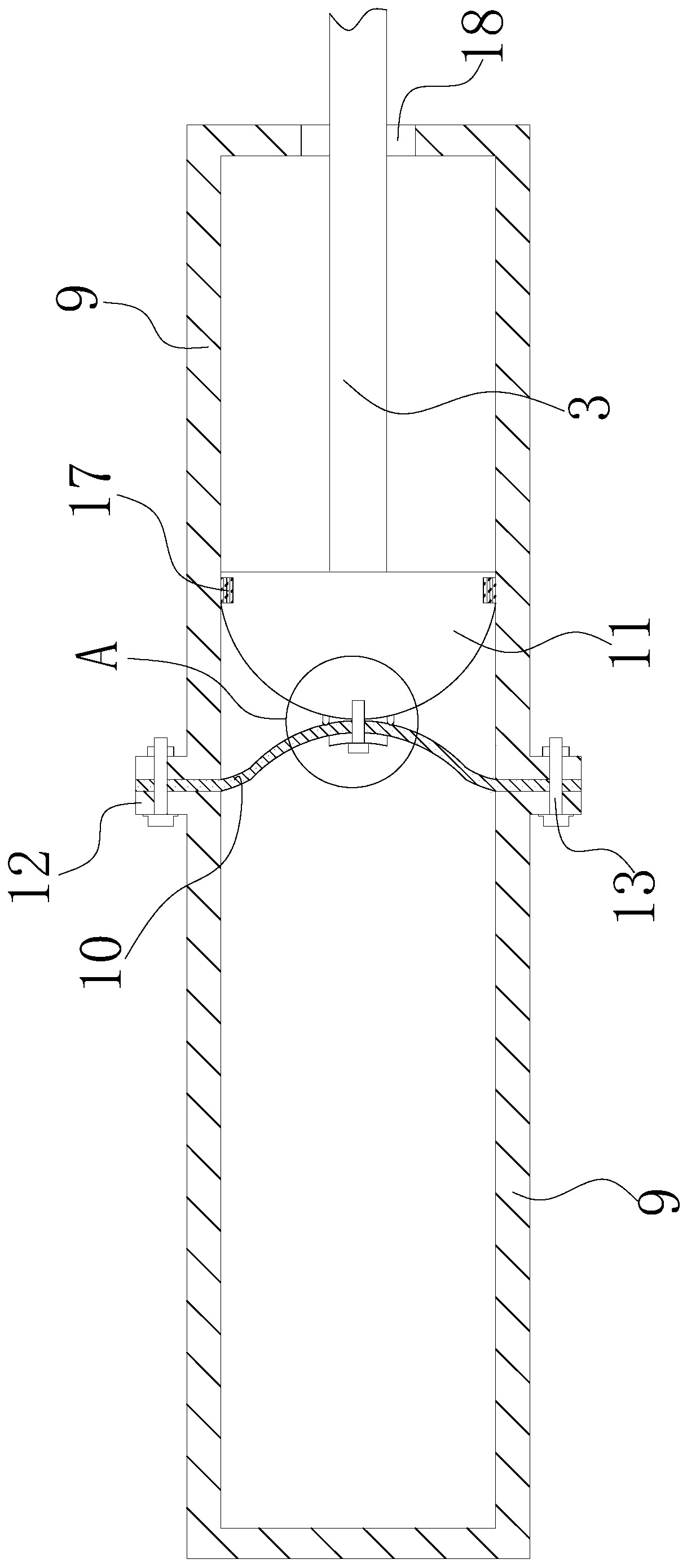

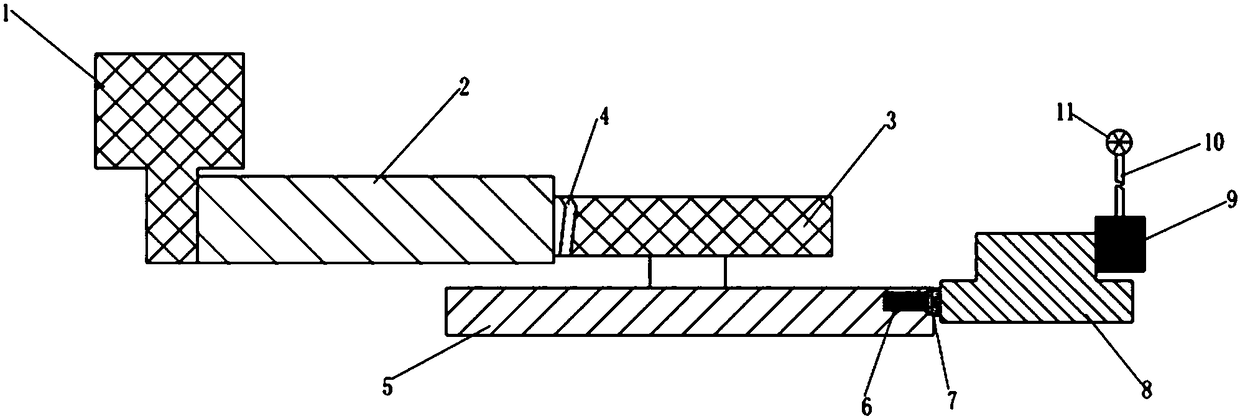

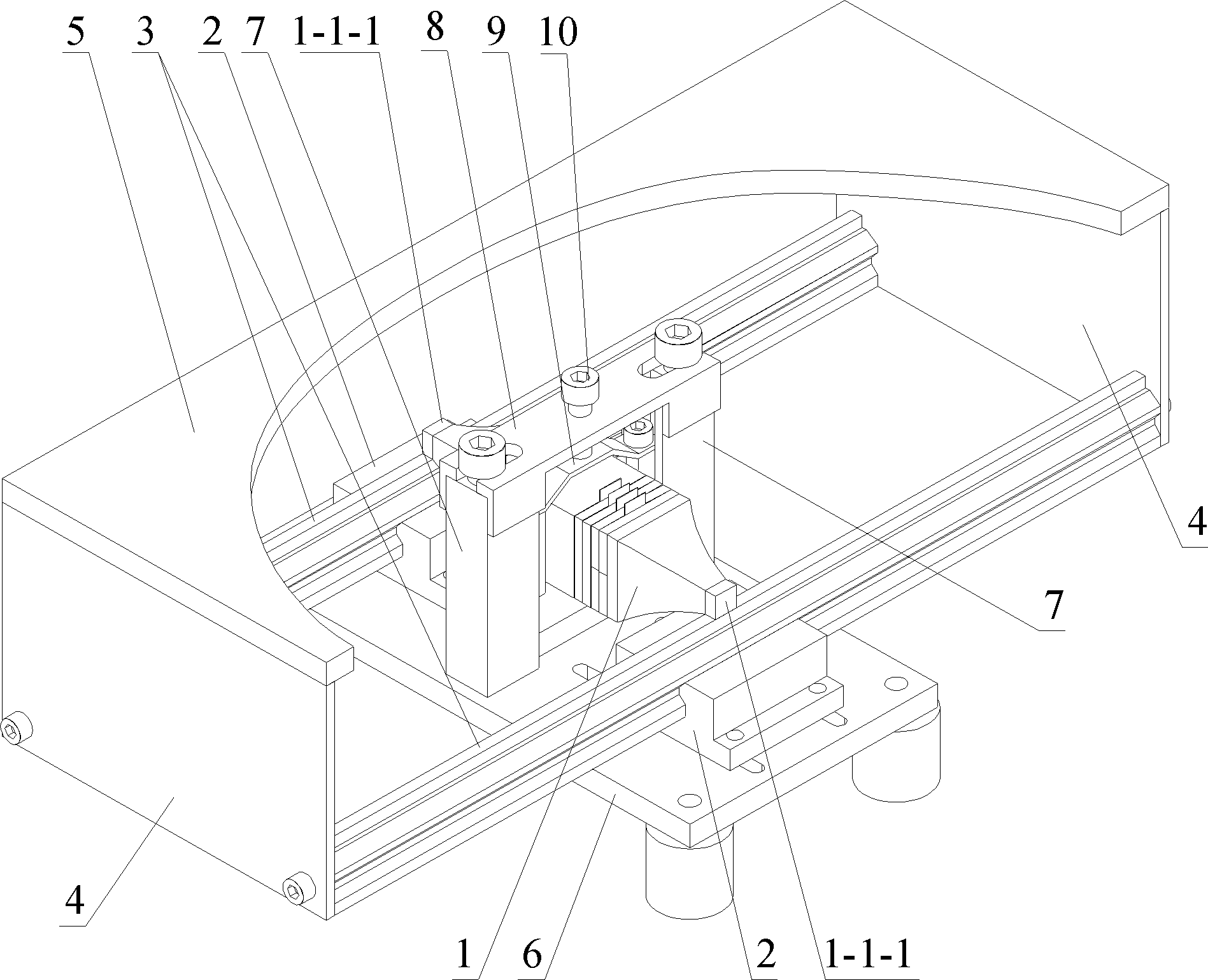

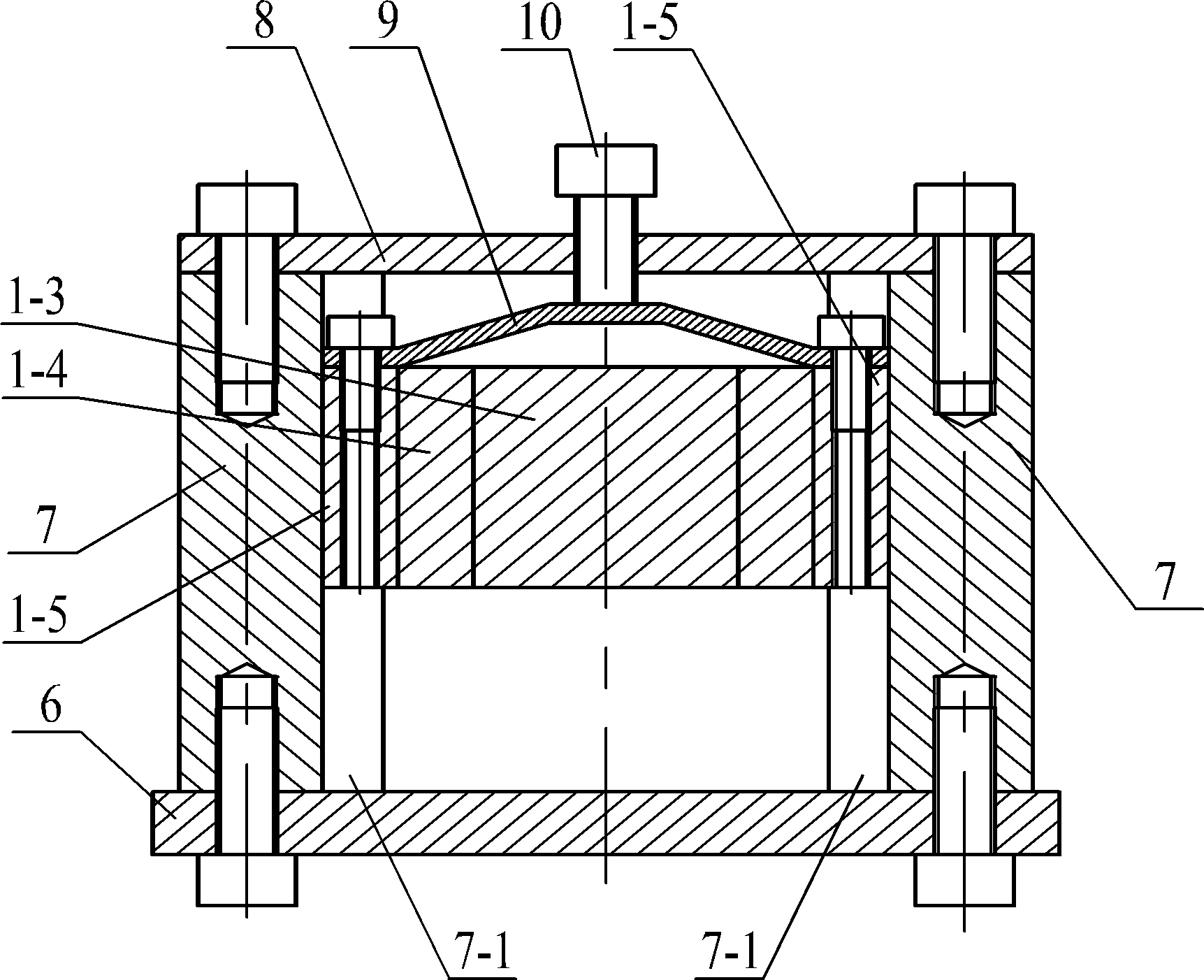

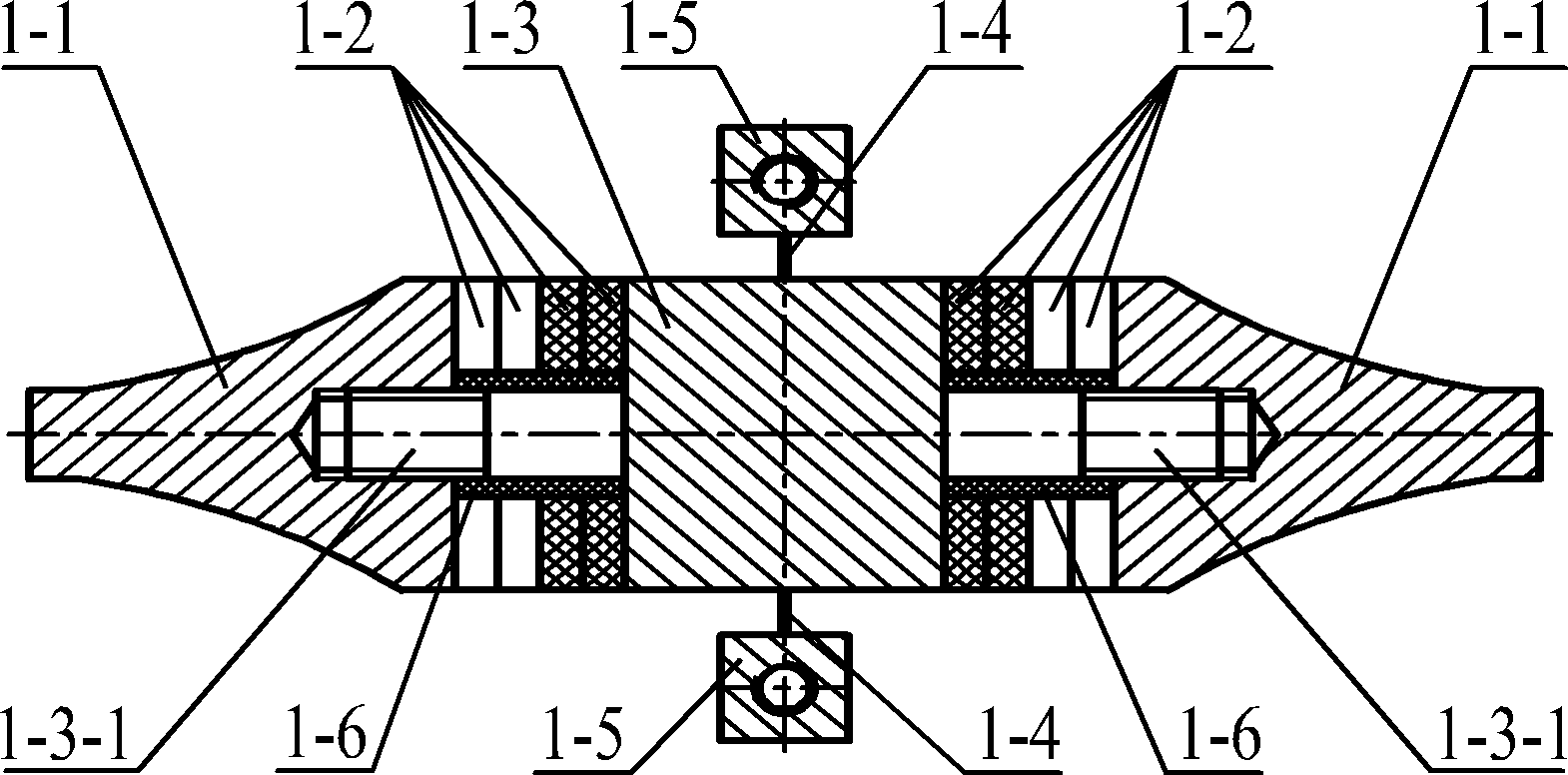

High-frequency in-situ imaging fatigue tester

PendingCN108562506AHigh frequencyHigh precisionMaterial strength using repeated/pulsating forcesMaterial analysis by transmitting radiationFatigue damageHigh energy

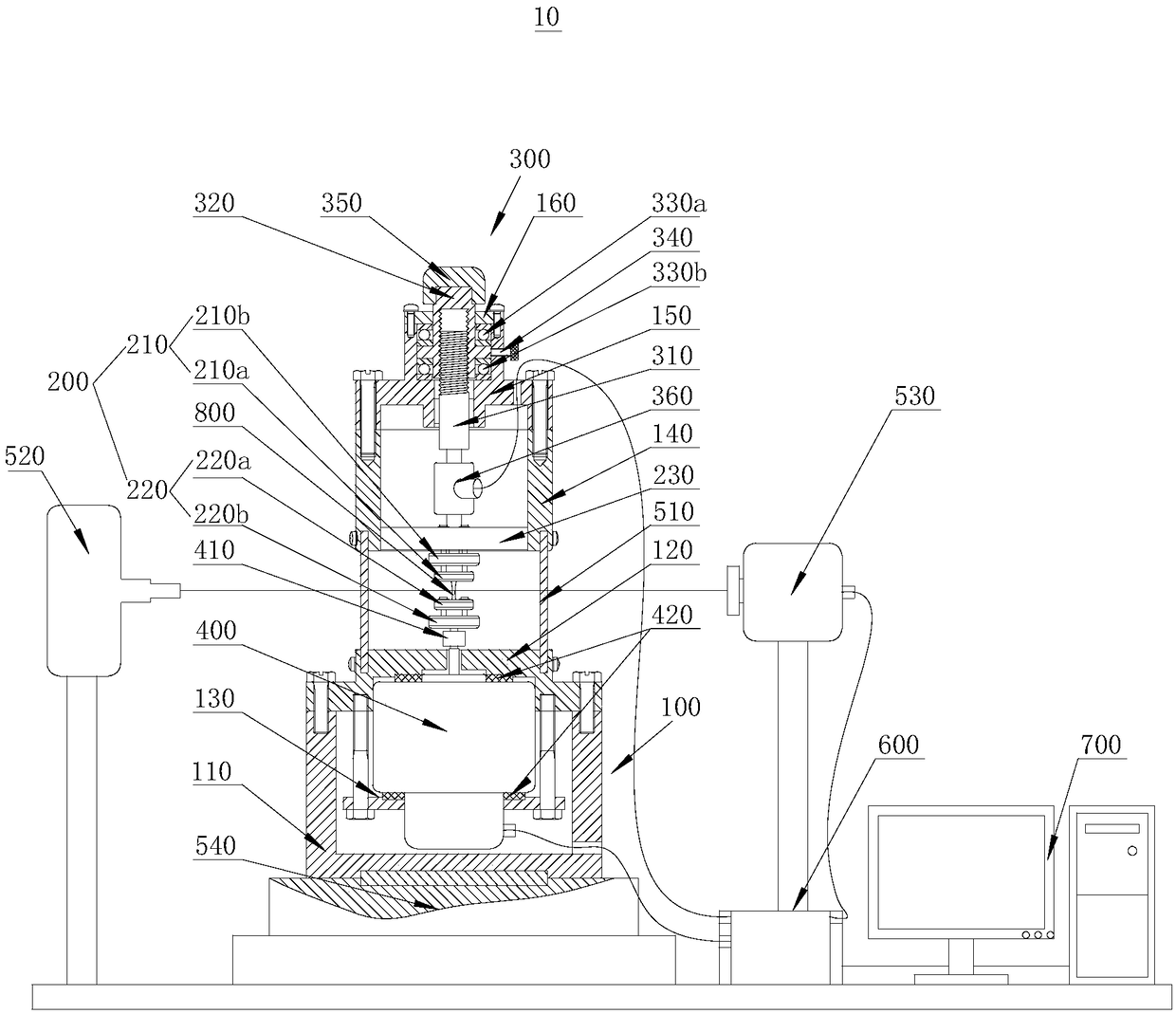

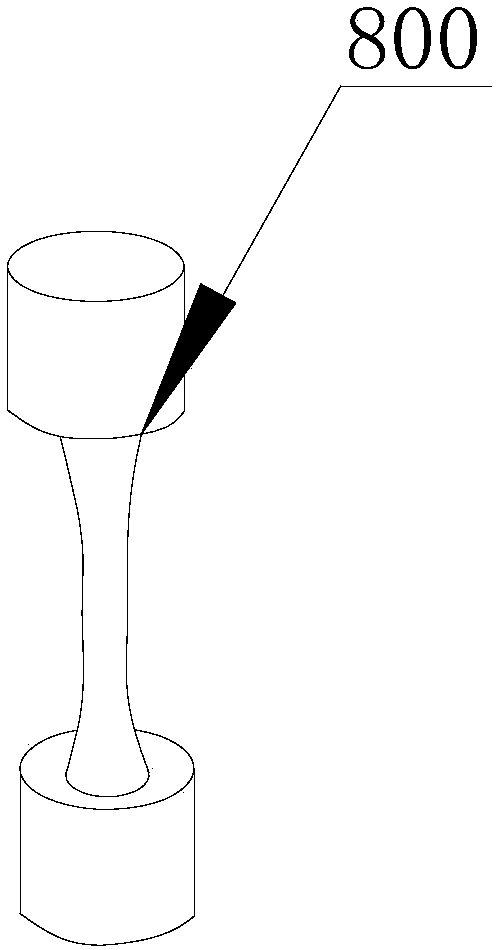

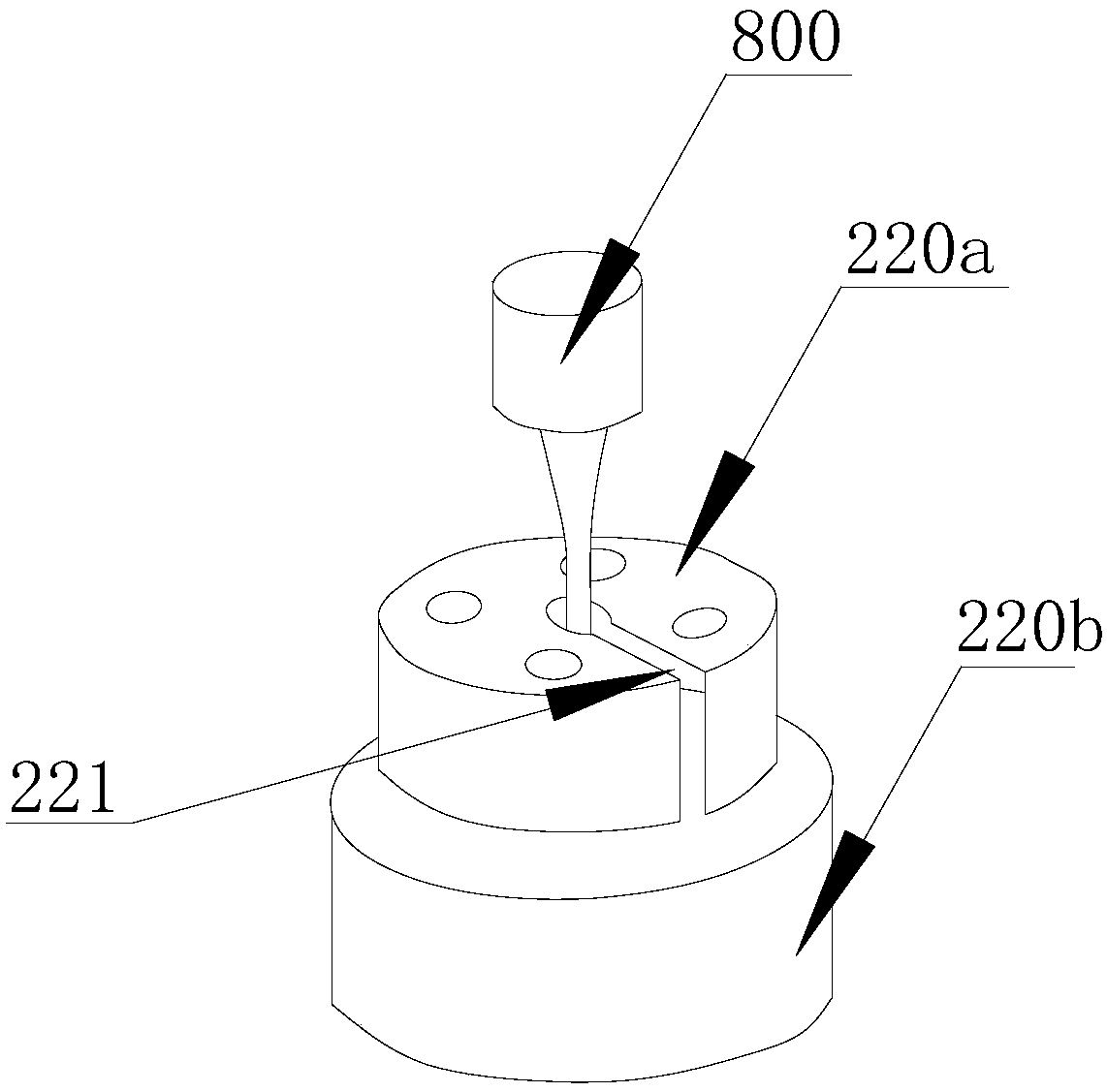

The invention relates to the technical field of material testing and particularly relates to a high-frequency in-situ imaging fatigue tester. The tester comprises a tester body, a test sample clampingmechanism, a preset force loading mechanism and a voice coil motor, wherein the test sample clamping mechanism is used for clamping and fixing a test sample, and the test sample clamping mechanism comprises a first clamping assembly and a second clamping assembly which are arranged oppositely; the preset force loading mechanism is arranged at one side of the first clamping assembly of the test sample clamping mechanism and is used for applying preset tension and pressure to the test sample; and the voice coil motor is fixedly connected to the tester body, and a moving shaft of the voice coilmotor is connected to the second clamping assembly. The voice coil motor is utilized for realizing high-frequency actuation to perform high-frequency fatigue on the test sample, and high-energy X-raysare utilized for performing three-dimensional imaging on fatigue damage inside materials, thereby researching the high-cycle and even ultra-high-cycle fatigue failure mechanism of the materials.

Owner:SOUTHWEST JIAOTONG UNIV

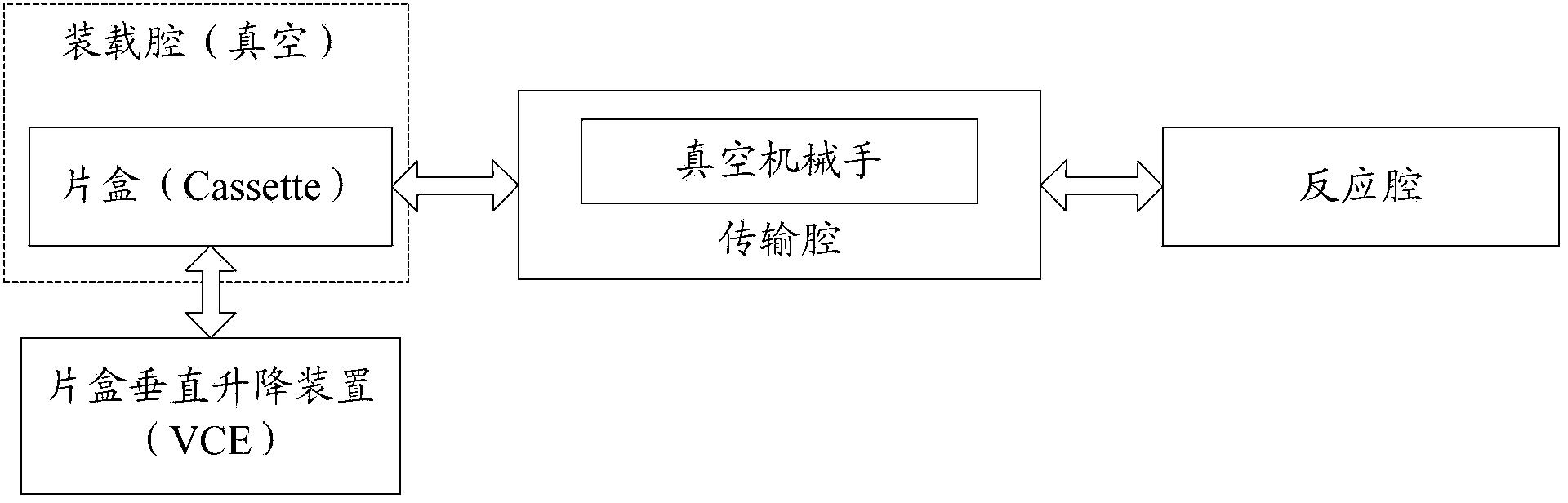

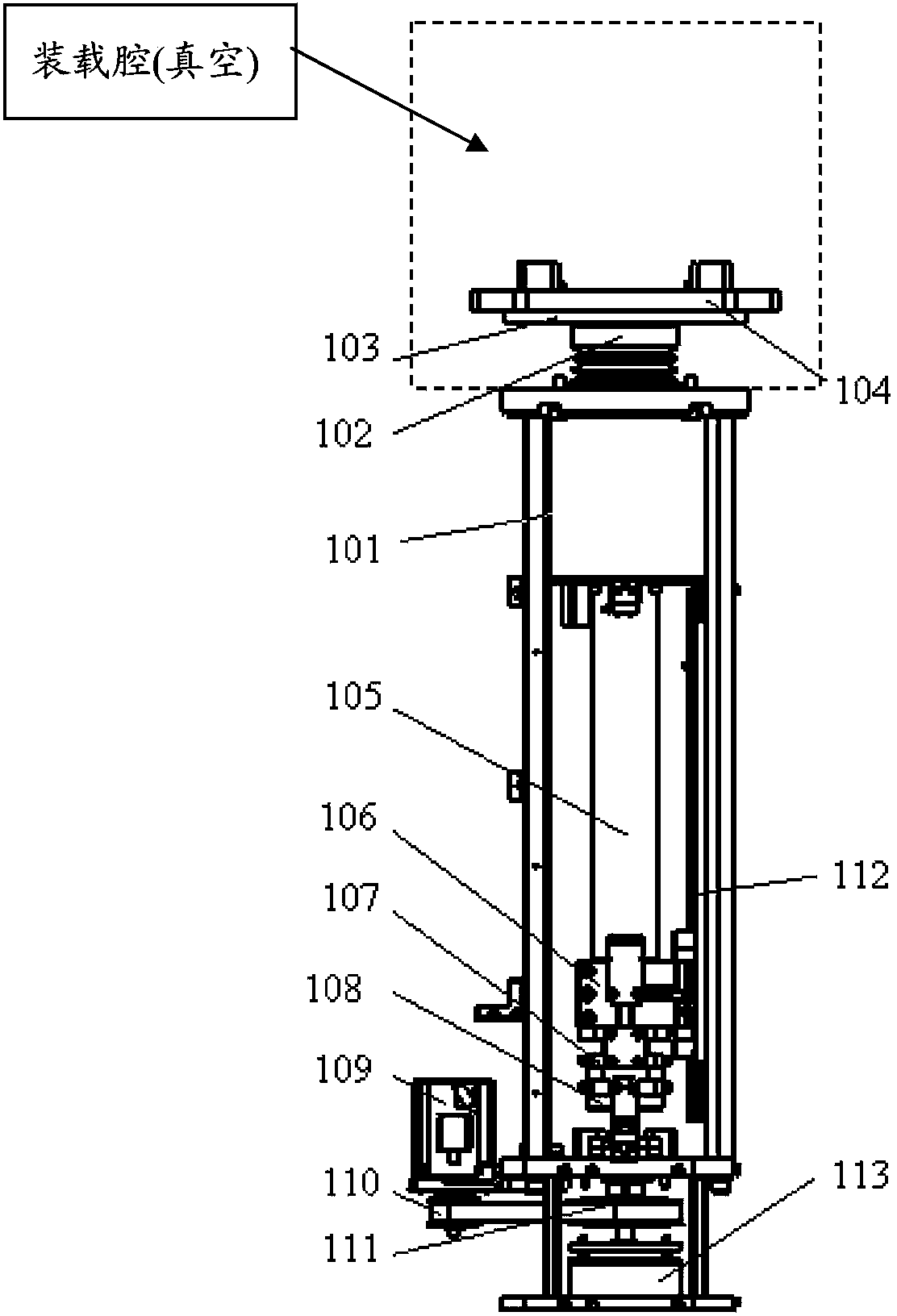

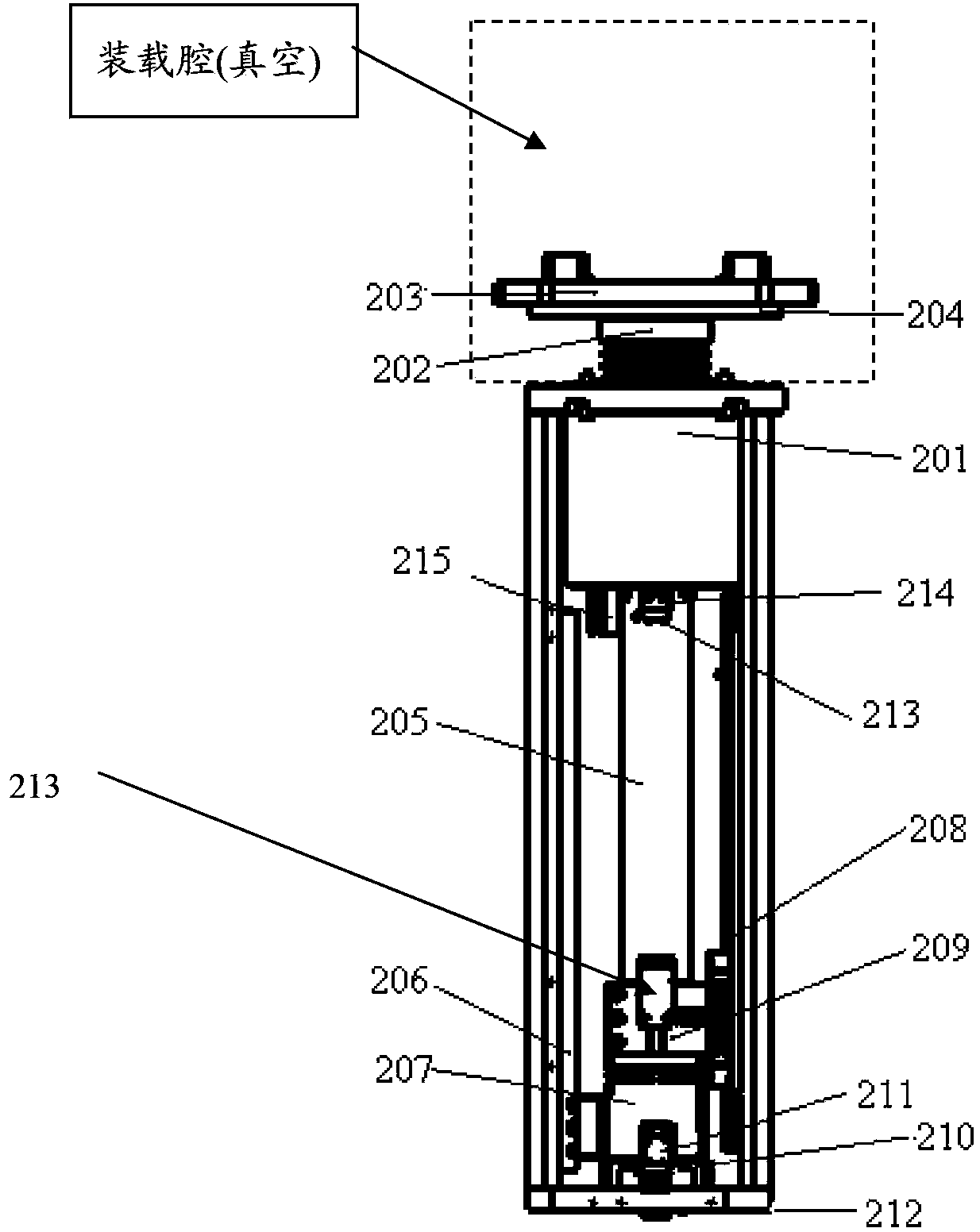

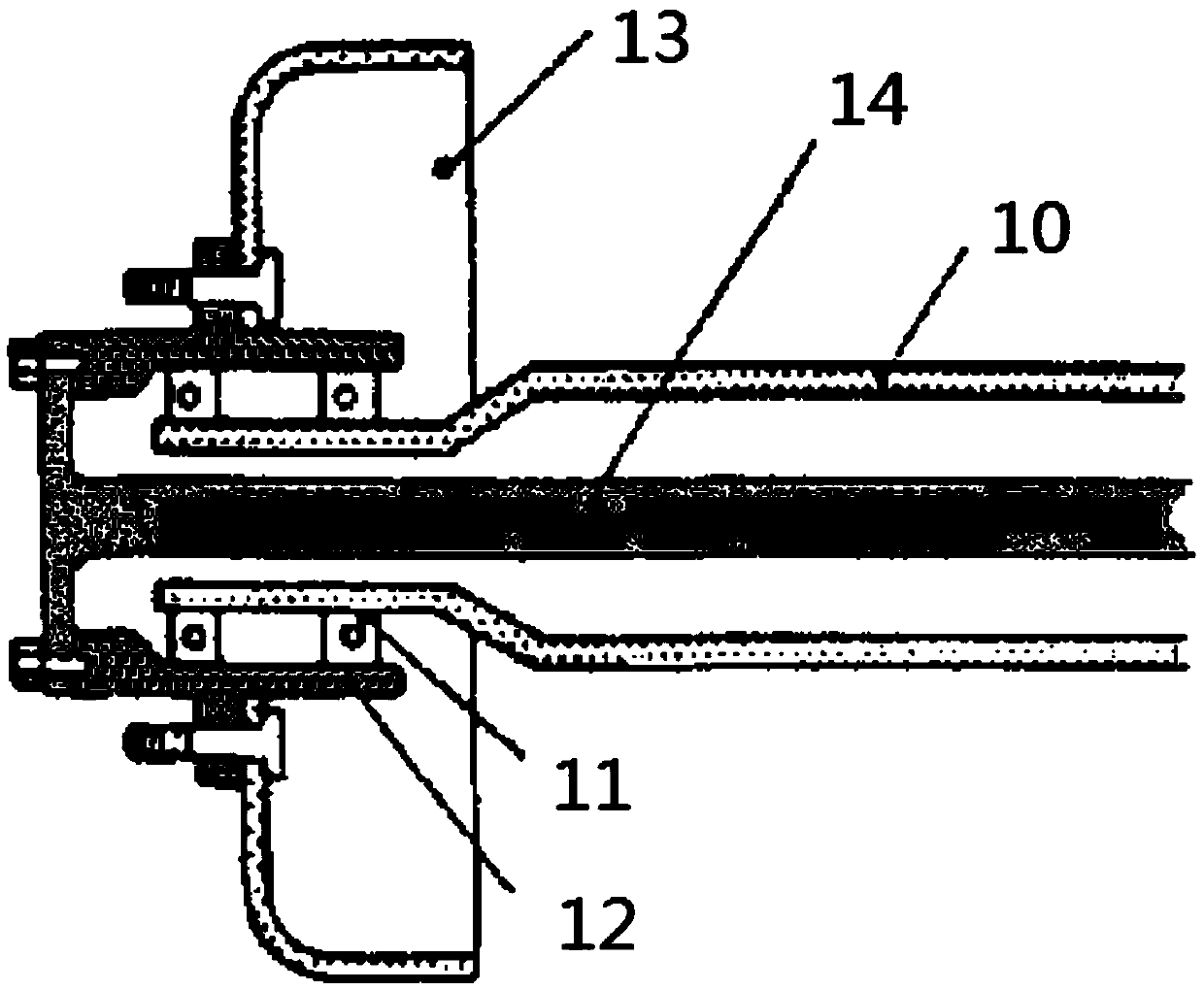

Vertical lifting device for cassette

InactiveCN104140062ASolution to short lifeSimple organizationLifting framesConveyor partsLinear motionEngineering

The invention provides a vertical lifting device for a cassette. The vertical lifting device for the cassette comprises an installation flange, a lifting corrugated tube, a lifting sleeve, a connecting element and a vertically-installed linear motor, wherein the upper end of the lifting corrugated tube is connected with the cassette, and the lower end of the lifting corrugated tube is connected with the installation flange; the upper end of the lifting sleeve is connected with the lifting corrugated tube, the lower end of the lifting sleeve is connected with the connecting element, and the linear motor is connected with the connecting element; the linear motor is used for driving the connecting element to carry out a linear motion along a vertical direction, the connecting element is used for pushing the lifting sleeve to drive the lifting corrugated tube to move, and then drive the cassette to ascend or descend along the vertical direction. On one hand, the vertical lifting device for the cassette provided by the invention is capable of simplifying the mechanism of the drive portion of the whole lifting device, and convenient to detach, install and maintain; on the other hand, the vertical lifting device for the cassette provided by the invention is capable of eliminating various location errors brought by intermediate links, and improving the location accuracy thereof.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

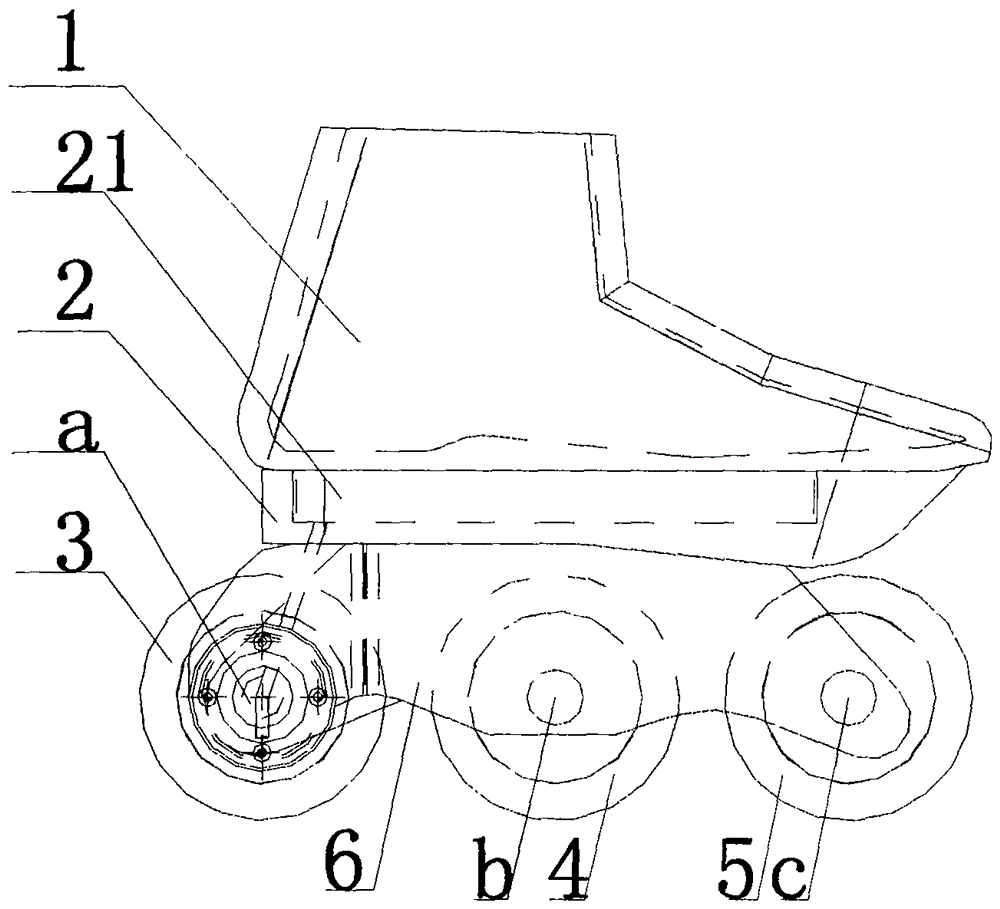

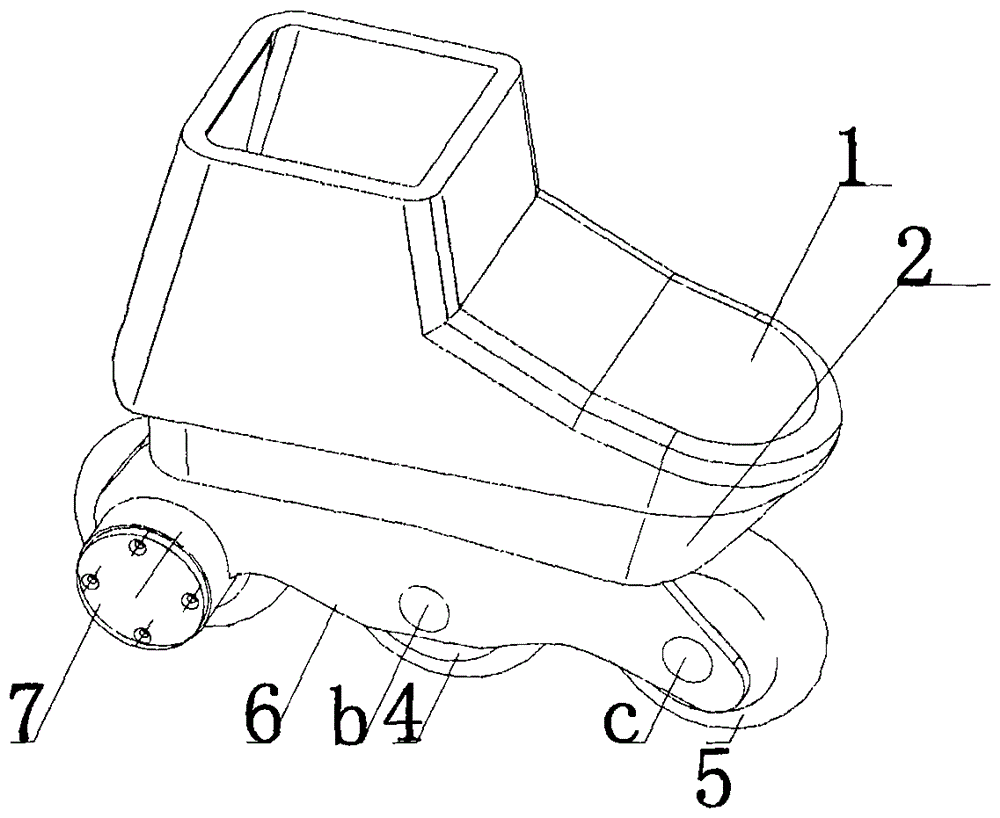

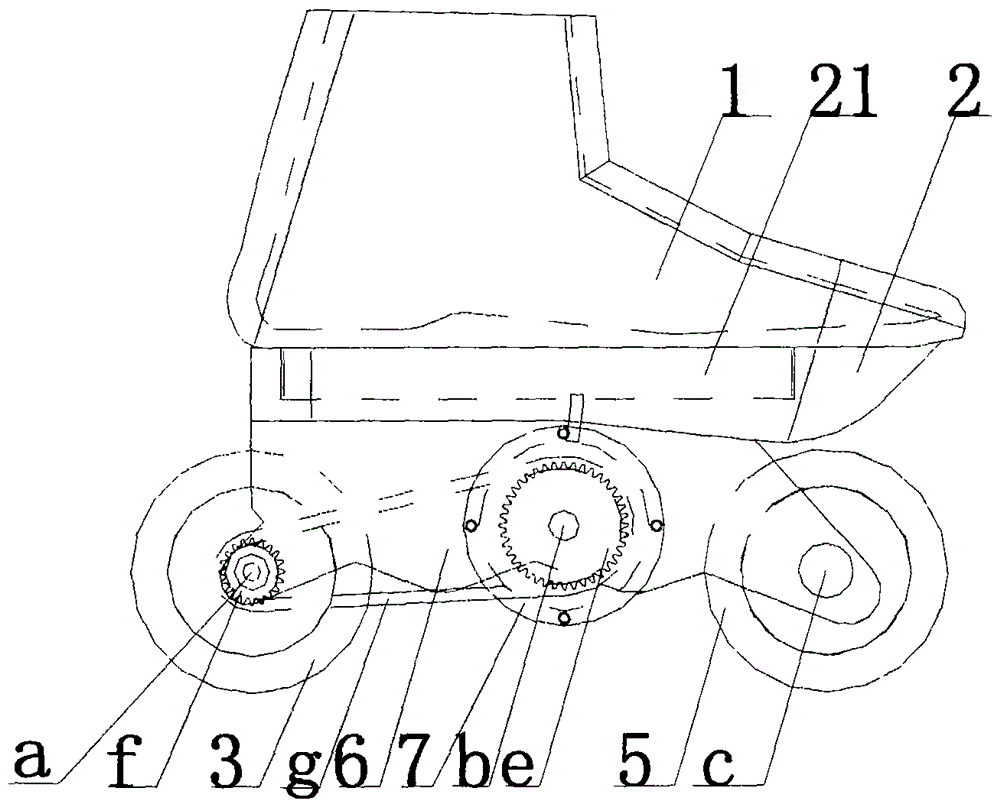

Intelligent electric roller skate

InactiveCN105214299AEasy to produceMeet production needsSkate-boardsRoller skatesGear driveGear wheel

The invention relates to an intelligent electric roller skate. The intelligent electric roller skate can be an electric roller skate, a gear transmission type roller skate, a belt / chain transmission type roller skate, a gears-driving-hollow toothed ring transmission type roller skate and a gear and chain-driving-hollow toothed ring transmission type roller skate. The electric roller skate comprises a skate body, a battery compartment shell, a back roller, a middle roller, a front roller and supporting plates, wherein the battery compartment shell is fixedly mounted at the bottom end of the skate body, the supporting plates are connected at the bottom end of the battery compartment shell, and the back roller, the middle roller and the front roller are mounted on a back axle, a middle axle and a front axle respectively. The back axle, the middle axle and the front axle are connected to the supporting plates, a battery pack is arranged in the battery compartment shell, and a motor is mounted on the back axle and is connected to the battery pack through a wire. The intelligent electric roller skate has the advantages that the intelligent electric roller skate is provided with an intelligent control component based on the prior art so as to be capable of achieving automatic operation and completing a series of actions under control of sound of a sporter; the intelligent electric roller skate is simple in integral structure, high in practicality and easy to popularize and use.

Owner:黄冠洲

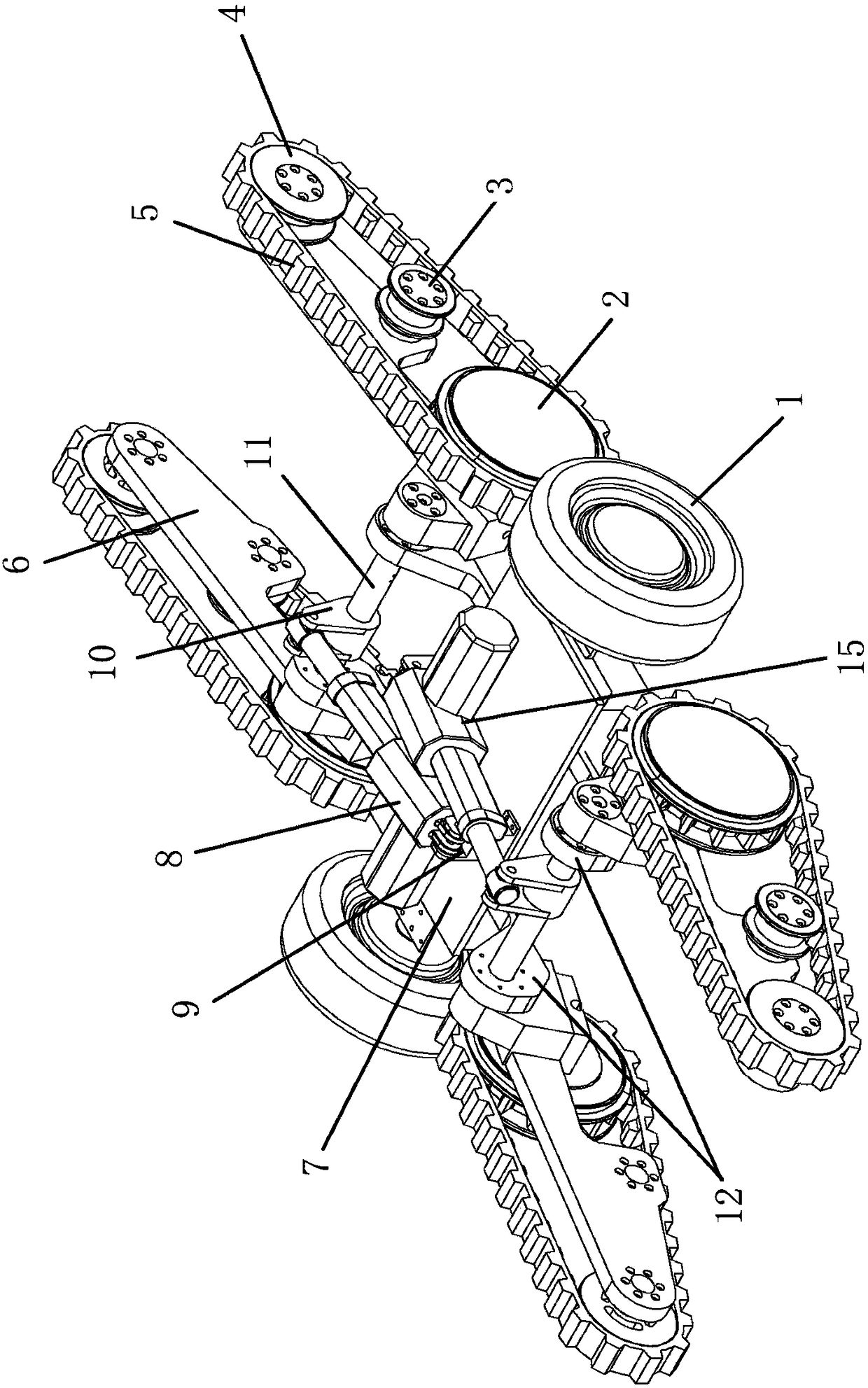

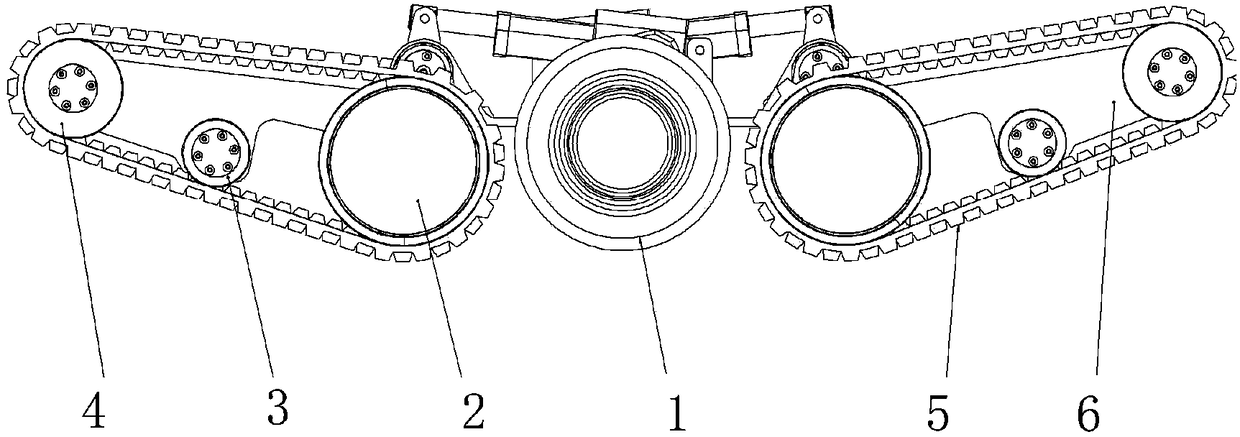

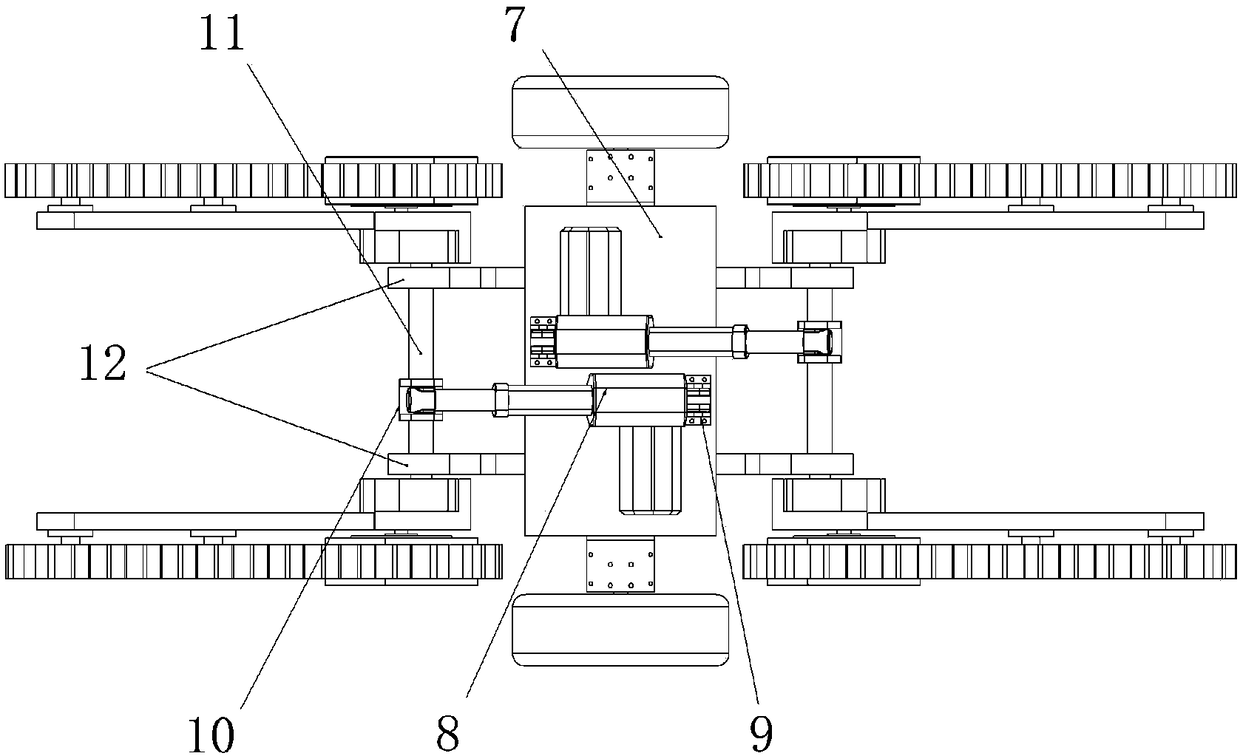

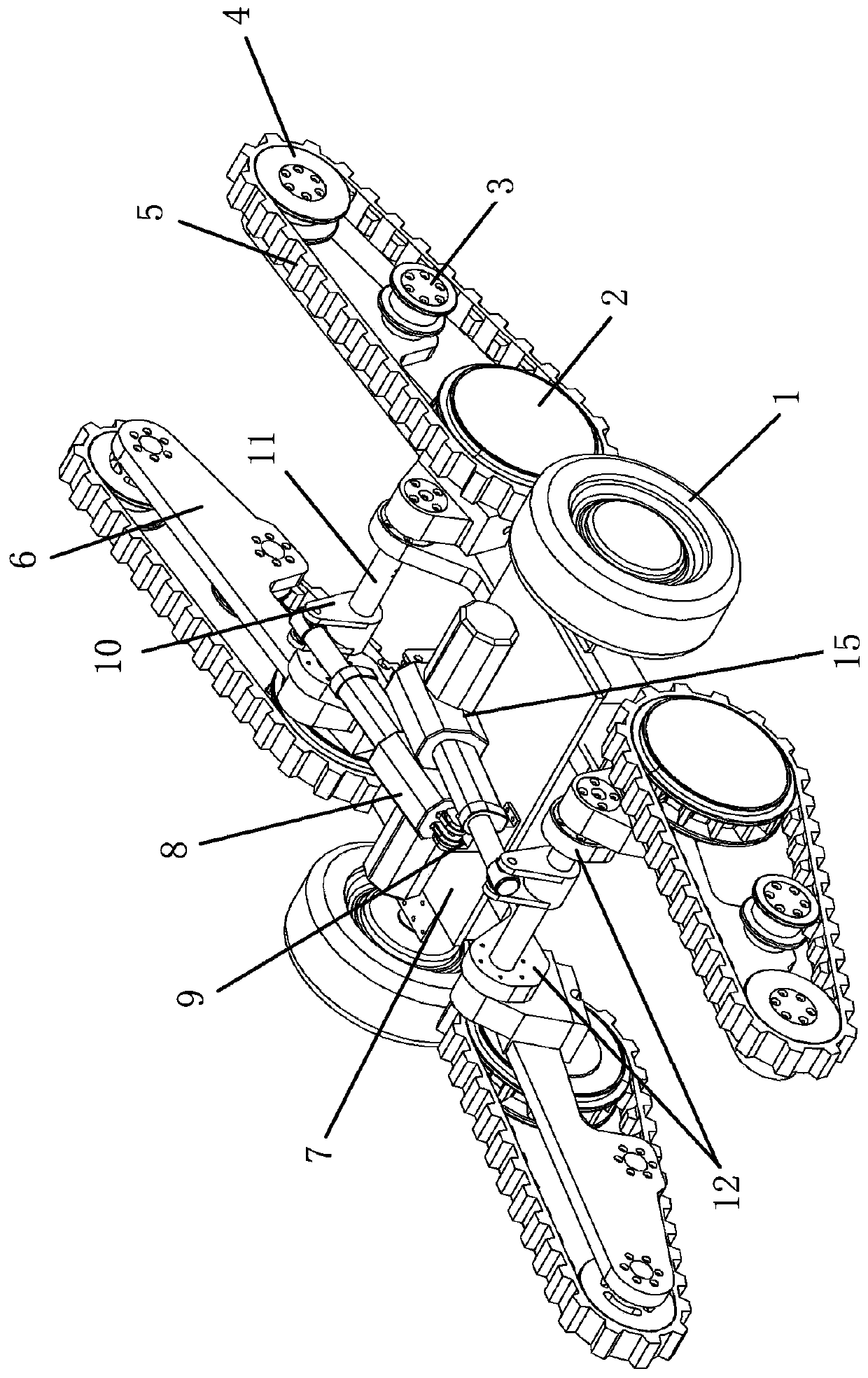

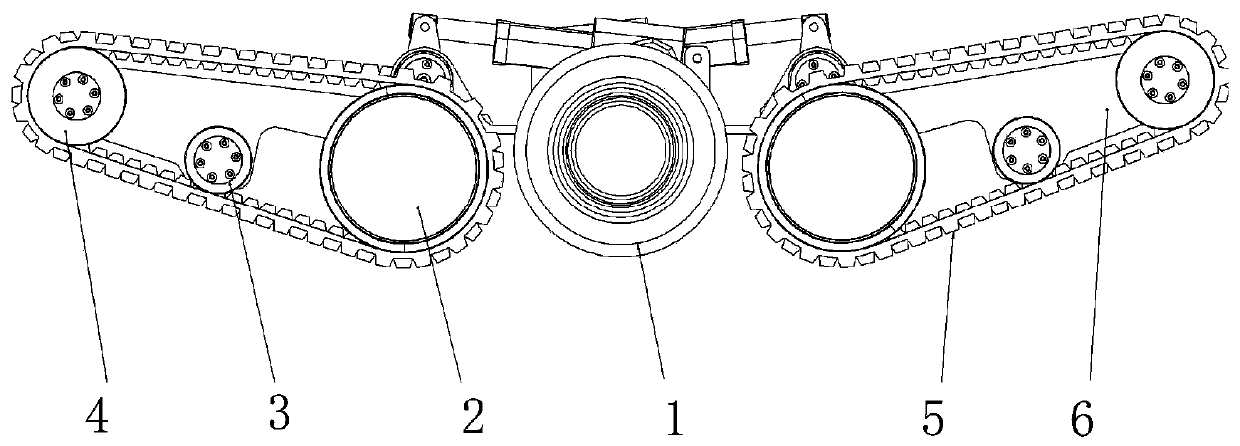

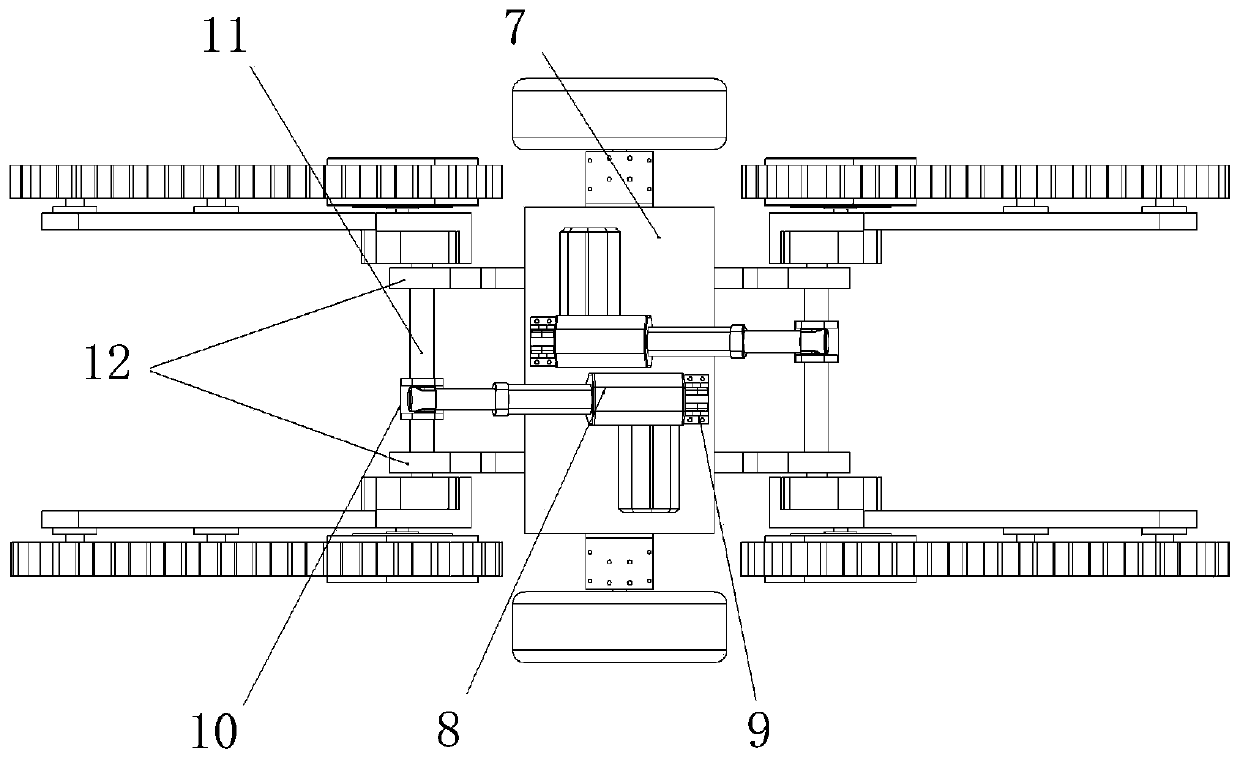

Two-wheel-leg-caterpillar band compound type movement mechanism

ActiveCN108791548AImprove mobile efficiencyAchieve direct driveEndless track vehiclesTerrainDrive shaft

The invention relates to the technical field of specialized robots, in particular to a two-wheel-leg-caterpillar band compound type movement mechanism. The two-wheel-leg-caterpillar band compound typemovement mechanism comprises a movement seat body, walking wheels, swing leg drive mechanisms and swing leg assemblies. The two walking wheels are installed at the left end and the right end of the movement seat body. Walking wheel drive motors are arranged in the walking wheels. The swing leg assemblies are arranged on the front side and the rear side of the movement seat body. The two swing legdrive mechanisms are arranged on the movement seat body. The swing leg assemblies on the two sides of the movement seat body are driven by the different swing leg drive mechanisms to swing. The swingleg assemblies located on the same side of the movement seat body are connected through a swing leg drive shaft. The swing leg drive shafts are driven by the swing leg drive mechanisms to rotate anddrive the swing leg assemblies to swing. The swing leg assemblies are provided with caterpillar bands. When the walking wheels make contact with the ground to rotate, the caterpillar bands leave the ground, and when the caterpillar bands make contact with the ground to rotate, the walking wheels leave the ground. The problems that an existing robot movement mechanism is poor in maneuvering flexibility, low in movement efficiency and the like on a complex terrain are solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

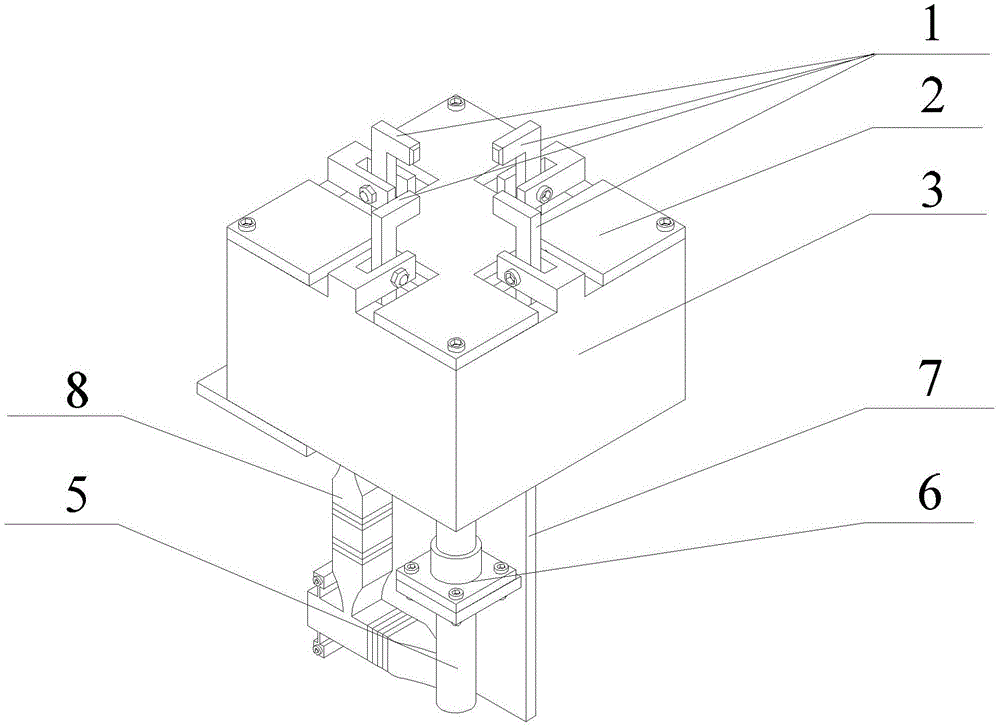

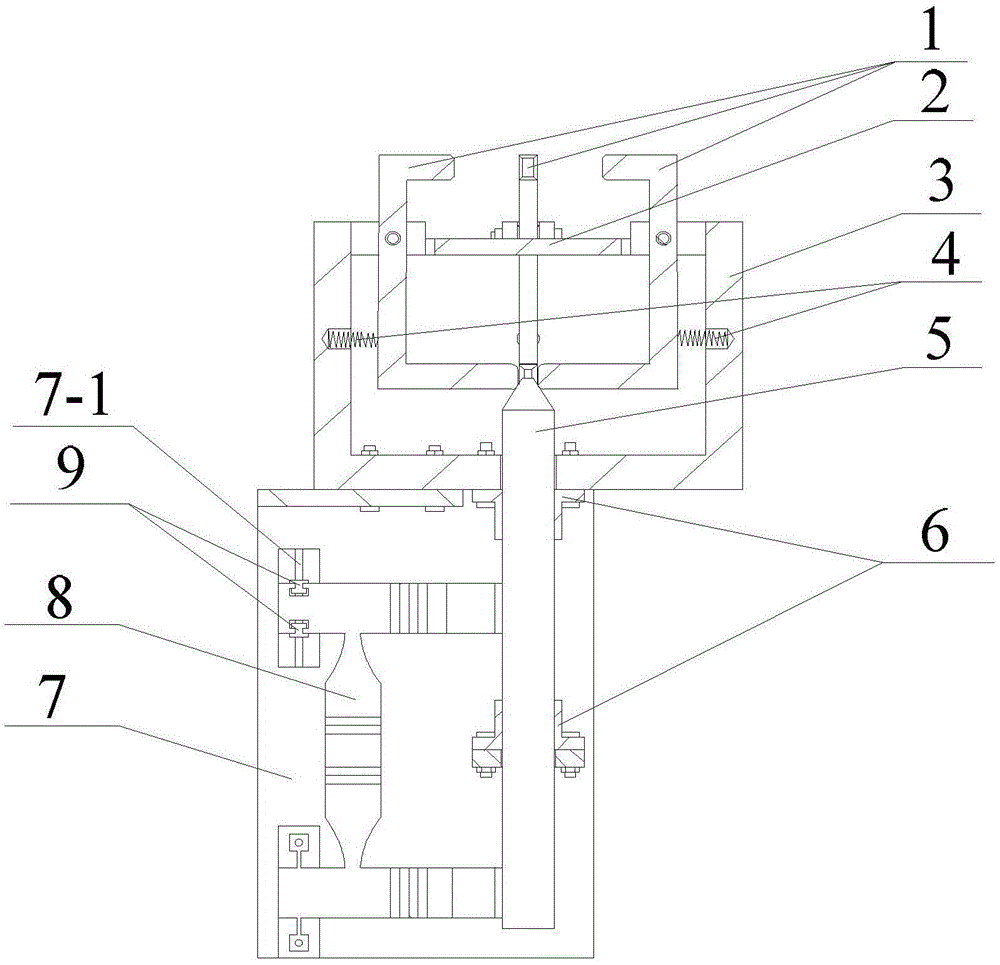

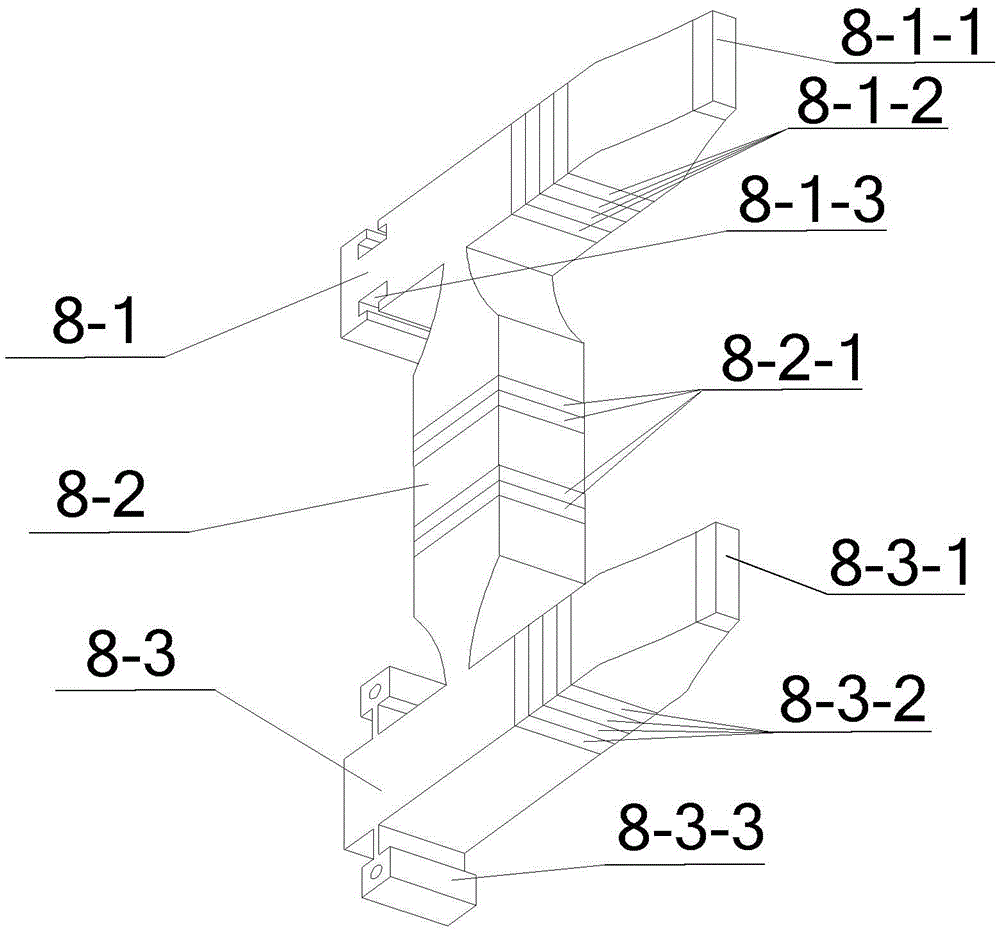

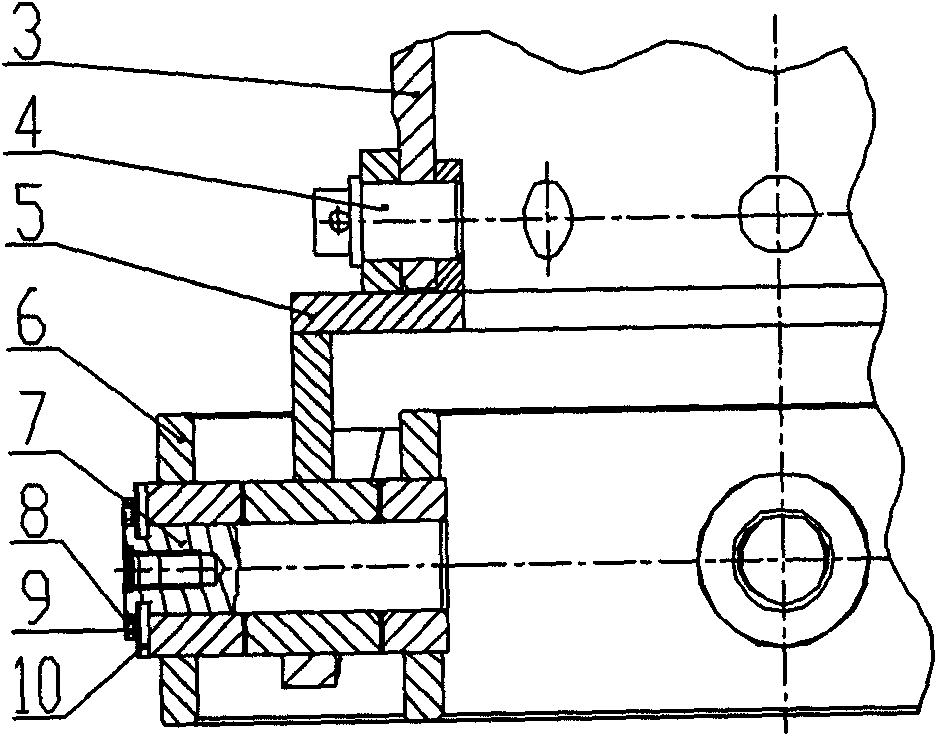

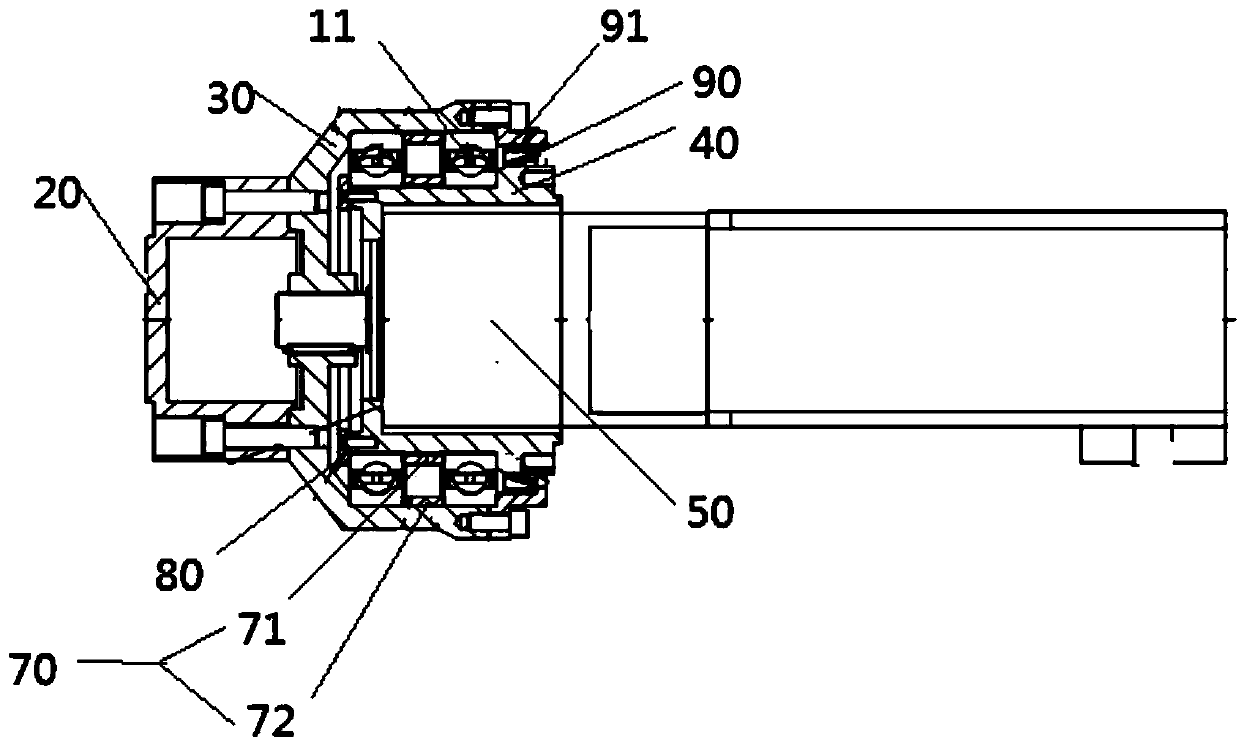

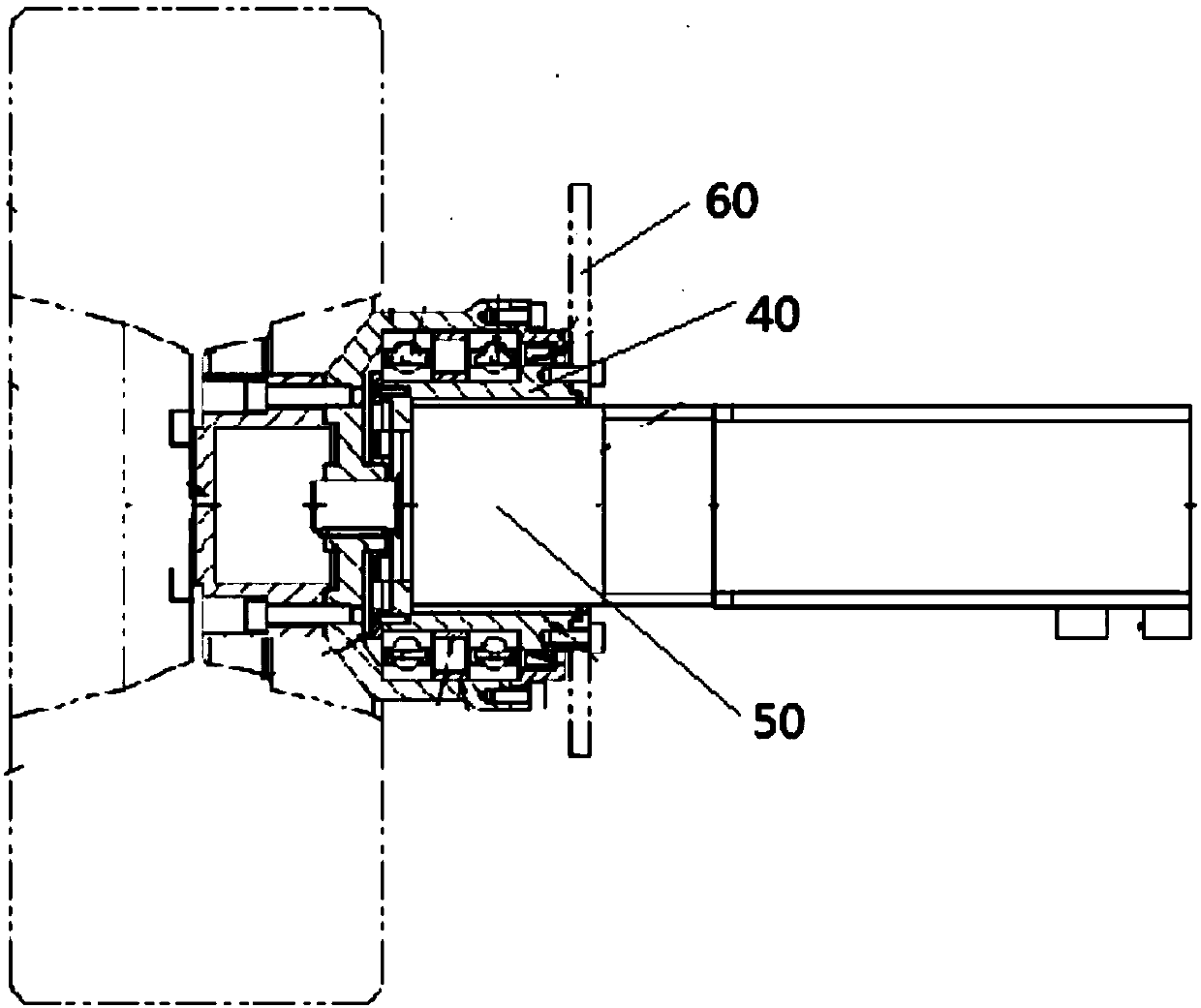

Centering type locking mechanism based on piezoelectric motor drive

ActiveCN105598723AQuick responseSimple structurePiezoelectric/electrostriction/magnetostriction machinesPositioning apparatusElectromagnetic interferenceMotor drive

The invention discloses a centering type locking mechanism based on piezoelectric motor drive and relates to the technical field of automatic clamping mechanism equipment of machine tools or machining centers. The centering type locking mechanism aims at solving the problems that an existing electromagnetic motor drive type locking mechanism is complex in structure, and electromagnetic interference exists. According to the centering type locking mechanism, a clamp and clamping claws are hinged through bolts, limiting plates are connected with the top ends of side walls of the clamp, a wedge head driving shaft penetrates through two output shaft sleeves, one output shaft sleeve is connected with the center of the bottom surface of the clamp to be fixed, the other output shaft sleeve is connected with a motor fixing plate, a wedge head of the wedge head driving shaft is connected with the bottom ends of the four clamping claws, two driving feet of a piezoelectric motor are connected with the output shaft sleeves, forward voltage and backward voltage are applied to all piezoelectric ceramic pieces on the piezoelectric motor, reciprocating motion of the wedge head driving shaft is controlled by controlling the timing sequence of applying the voltage to the piezoelectric ceramic pieces, and thus the locking and unlocking functions of the locking mechanism are achieved. The centering type locking mechanism can be applied to manufacturing of automatic locking mechanism equipment of numerical control machine tools or machining centers.

Owner:圣昌(鸡西)科技开发有限公司

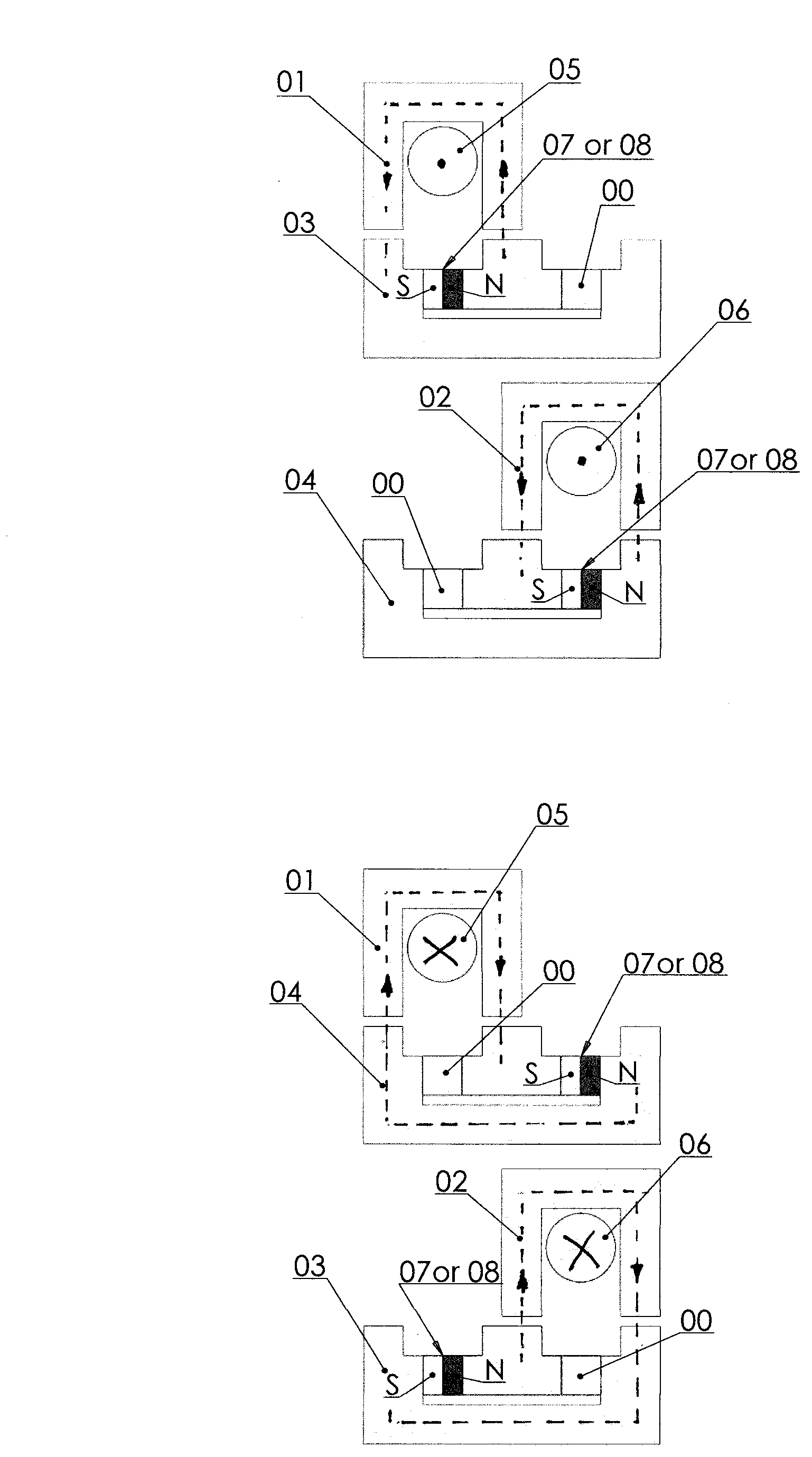

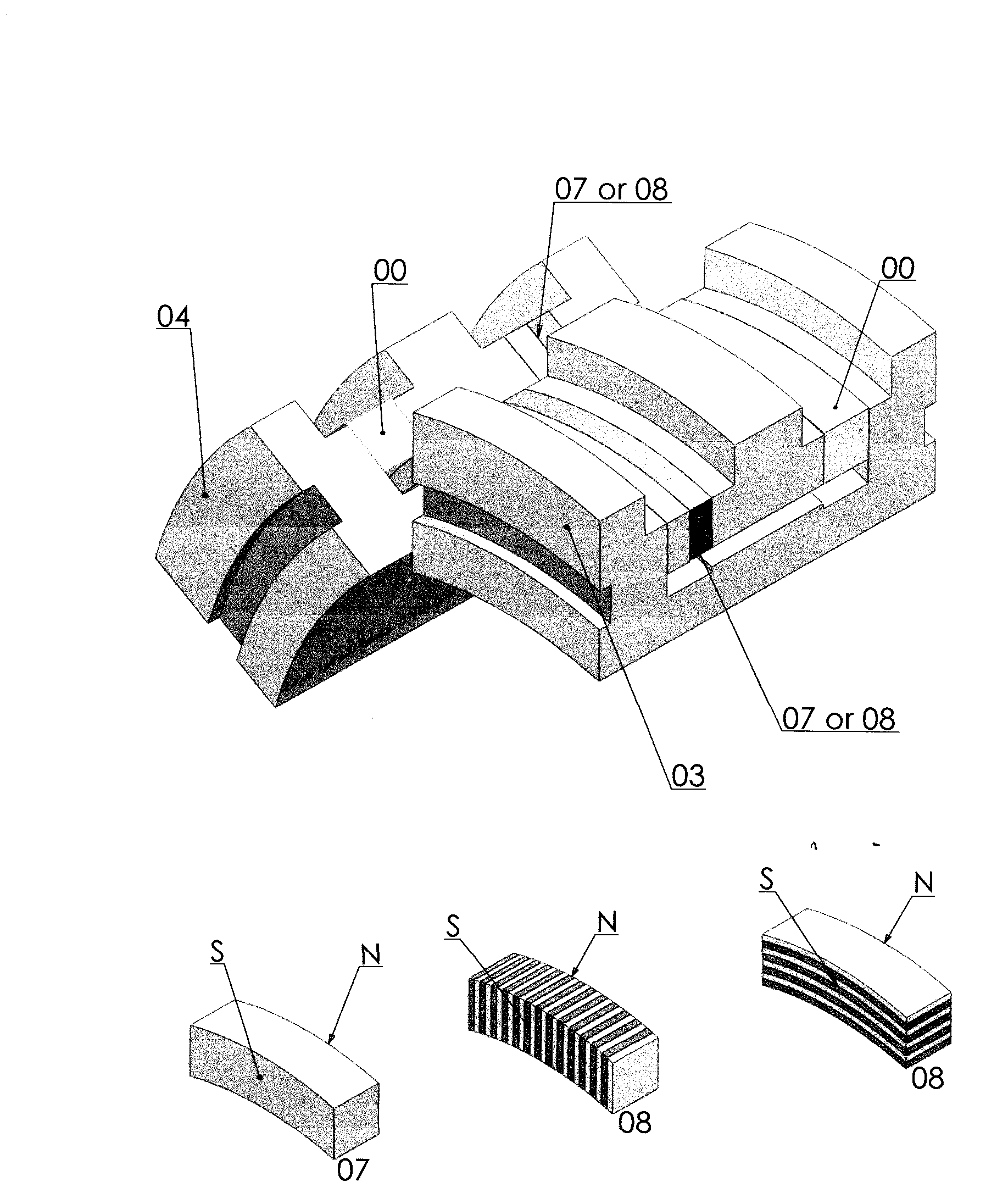

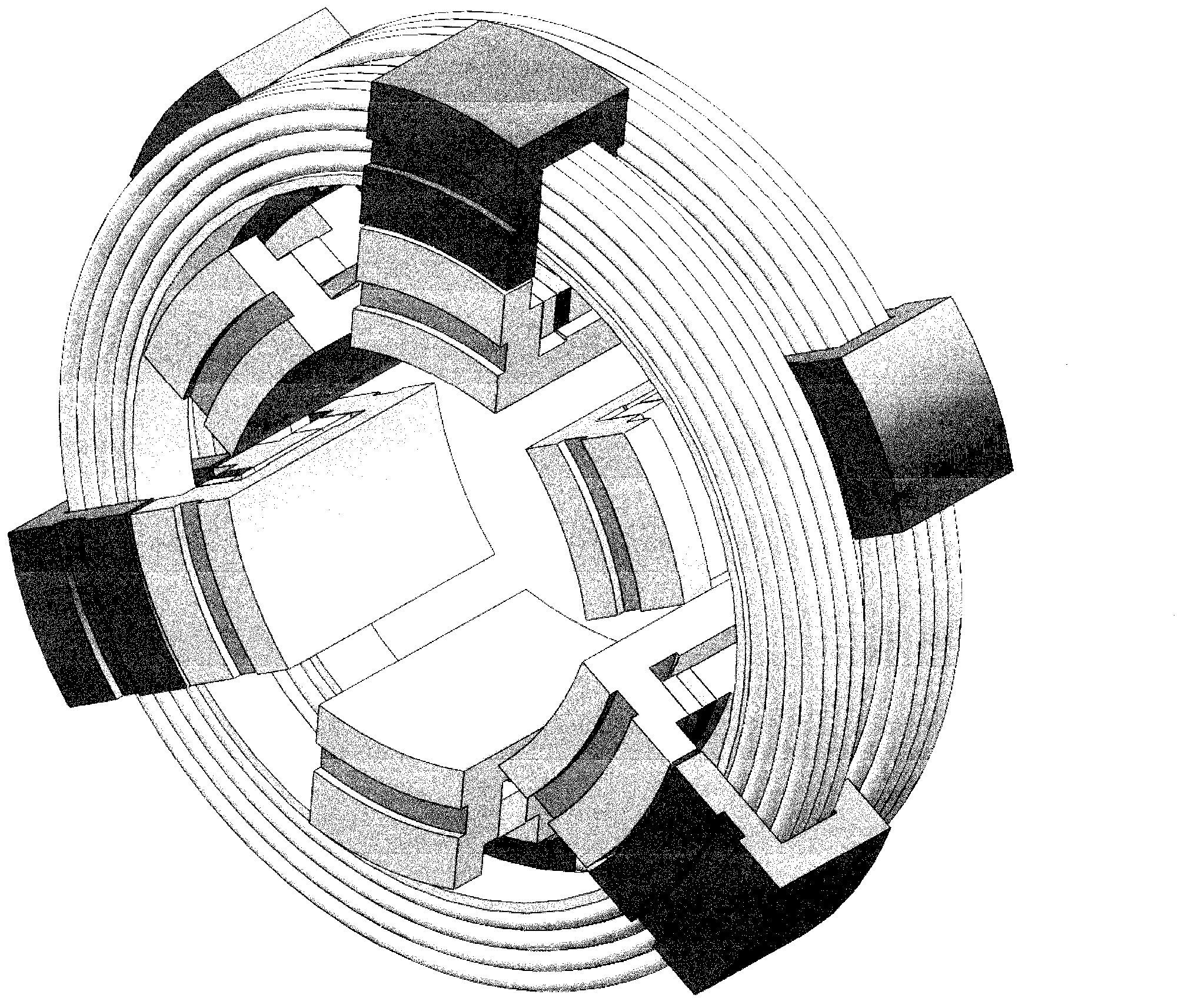

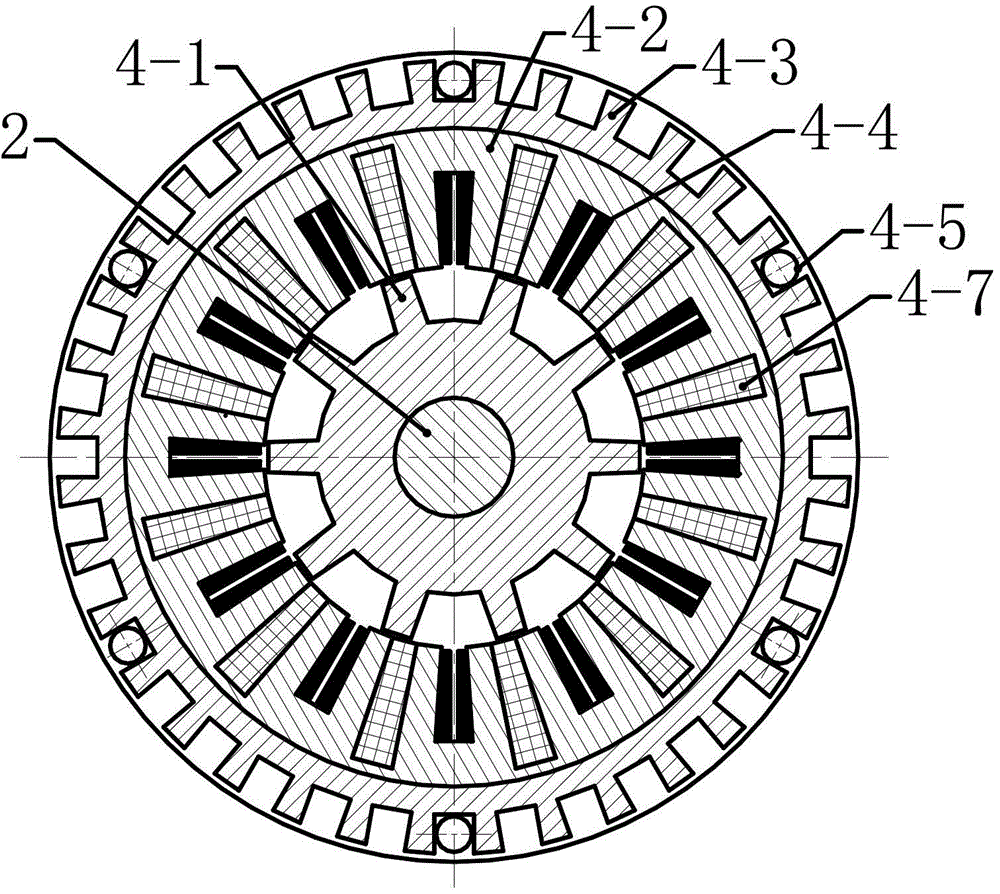

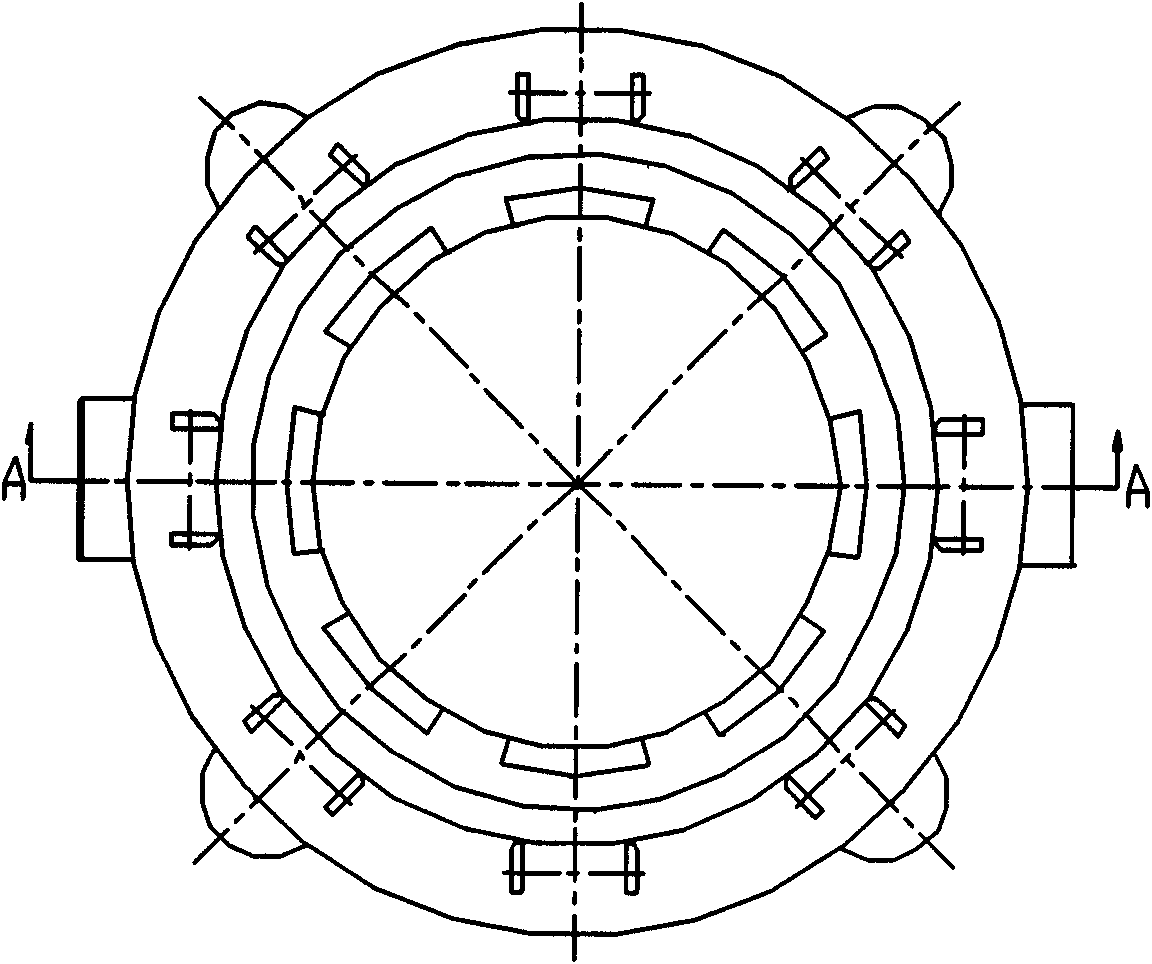

Transverse flux permanent magnetic or reluctance permanent magnetic motor of ring box structure

InactiveCN103269133APaste method is simpleIncrease axial dimensionMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse fluxMagnetic poles

The invention discloses a transverse flux permanent magnetic or reluctance permanent magnetic motor of a ring body box structure, and aims at manufacturing an integrated phase stator and phase rotor, installing a discrete iron core and a winding thereof, and creating an odd-even electromagnetic switching way of the phase rotor core and phase stator iron core. A phase stator ring body is provided with two series of odd-even iron cores and two windings which are in serial connection with the iron cores inside a left ring body box, a middle ring body box and a right ring body box, and three columns of iron core end surfaces are exposed out of an inner ring of the ring body box; a phase rotor ring body is provided with a circumferential array phase rotor iron core with an E-shaped cross section inside the left ring body box and the right ring body box, a left magnetic pole and a right magnetic pole of the E-shaped iron core are communicated with each other, a permanent magnet or a reluctance and permanent magnetic material laminated body is embedded between a middle magnetic pole and a right magnetic pole of each iron core in odd number, a non-magnetic steel structural body is embedded between the middle magnetic pole and the right magnetic pole, and components which are assembled in the even-number iron core and the odd-number iron core are replaced laterally; the polarity directions of the permanent magnet or the reluctance and permanent magnetic material laminated body in the odd-number iron core is identical to that of the permanent magnet or reluctance and permanent magnetic material laminated body in the even-number iron core, and three columns of iron core end surfaces are exposed out of an outer ring of the ring body box; and the phase stator ring body and the phase rotor ring body are assembled in a segmentation way along the axial direction. The transverse flux permanent magnetic or reluctance permanent magnetic motor is applicable to the motor or a generator.

Owner:王新

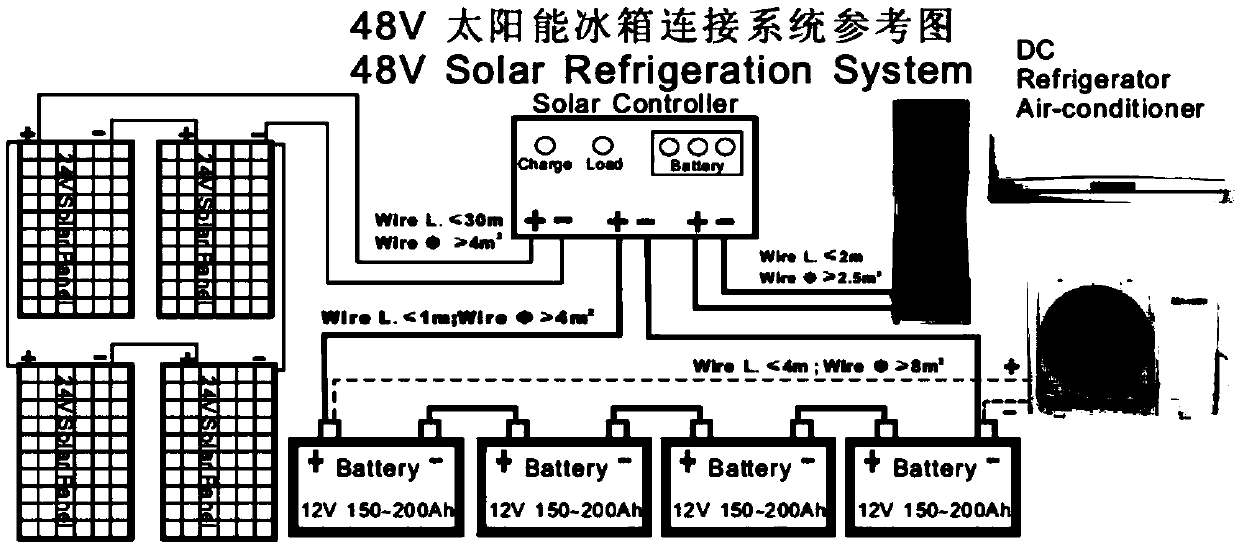

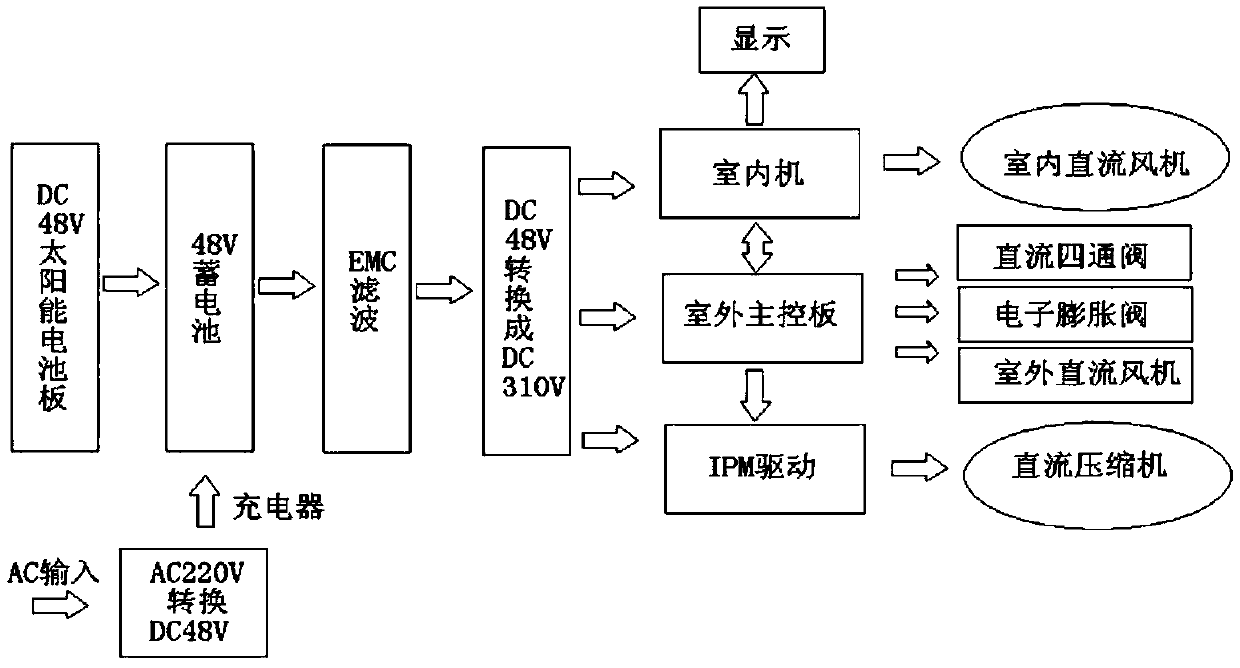

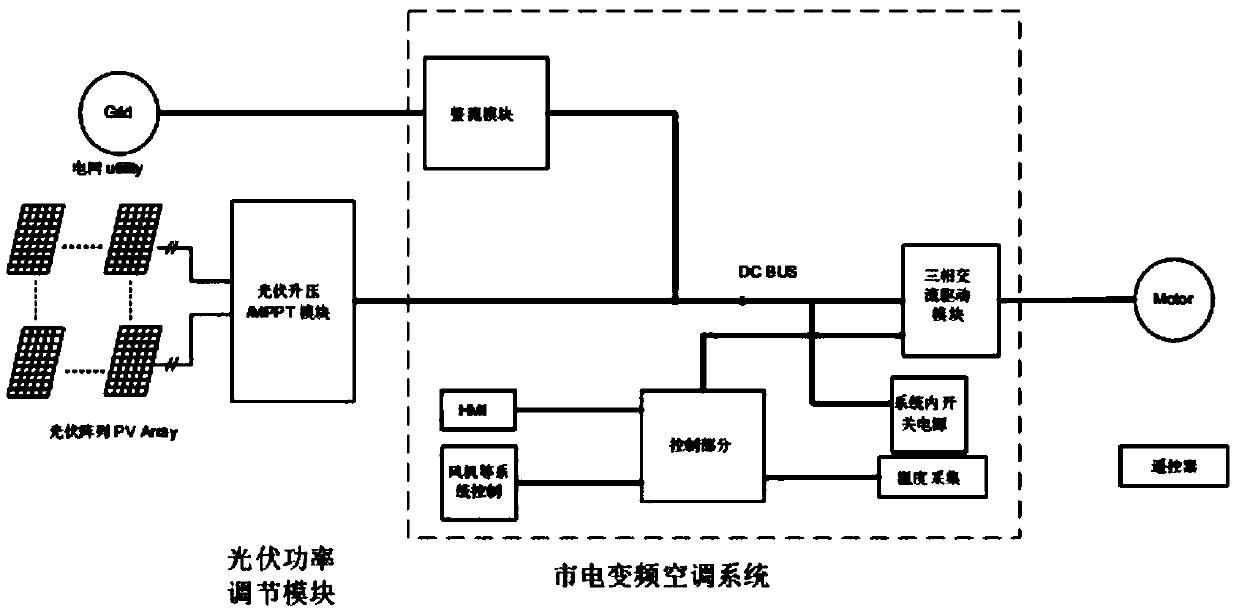

Controlling method enabling solar photovoltaic air conditioning system to independently operate

InactiveCN109668282AAchieve direct driveAchieving the purpose of direct driveSpace heating and ventilation safety systemsLighting and heating apparatusInstabilityEngineering

The invention discloses a controlling method enabling a solar photovoltaic air conditioning system to independently operate. The technical problem that solar batteries in a current solar photovoltaicair conditioning system cannot be used individually to achieve independent operation can be solved. The method comprises the following steps: S100, directly switching solar photovoltaic power into a direct current circuit obtained by performing rectifying filter on original alternating current of a direct-current frequency-conversion air conditioner, wherein direct current bus voltage of the system is photovoltaic array output end voltage; S200, embedding a photovoltaic maximum power point tracking program into a variable frequency program of an air conditioner frequency converter module; andS300, adopting the photovoltaic maximum power point tracking program to adjust output power of a compressor by adopting a disturbance hill-climbing method or CVT (Continuously Variable Transmission) feedback type method so as to adapt instability of photovoltaic input. The controlling method disclosed by the invention has the advantages that power is generated individually by the solar batteries to achieve normal operation of the air conditioner under the conditions of no commercial power or no energy storage in the daytime, the air conditioner can continuously work under the situation that the photovoltaic input energy reaches 10 percent of the rated power of the air conditioner, and the operation effect of the air conditioner is in positive proportion to illumination; and meanwhile, theoriginal alternating current input part and the rectification part are kept, so that standby demands of regular power outage areas can be met.

Owner:余海东

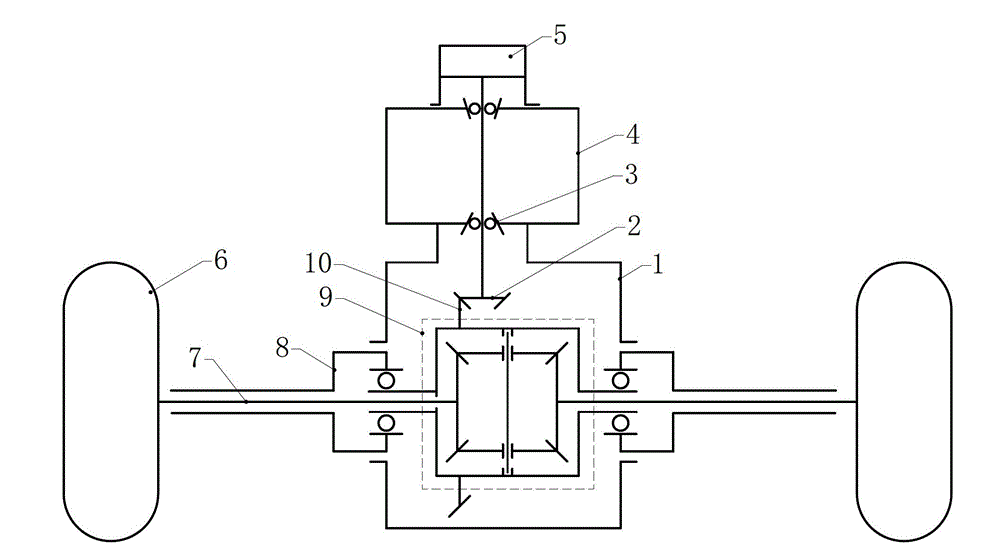

Hybrid power driving system

InactiveCN102745060AReduce energy lossImprove energy efficiencyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchEnergy loss

The invention relates to a hybrid power driving system, comprising an engine, a planet gear mechanism, a generator and a motor, wherein the engine is provided with an output shaft, the planet gear mechanism comprises a gear ring, a planet frame and a sun gear, the gear ring is connected with the output shaft of the engine, the generator is provided with a generator rotor, the generator rotor is coaxially fixed with the sun gear, the motor is provided with a motor rotor, the motor rotor is connected with the planet frame by virtue of a middle shaft; and a clutch device is arranged between the gear ring and the planet frame. The invention solves the problems that transmission energy loss of the planet gear in an engine hybrid operating mode is high in the series-parallel hybrid power system and a vehicle which is frequently in low-speed traveling operating state is difficult to be located in an high-efficiency operation region in the prior art and further provides a series-parallel hybrid power system which is applicable to a vehicle frequently in low-speed traveling operating state and can cause the vehicle to be located in the high-efficiency operation region.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

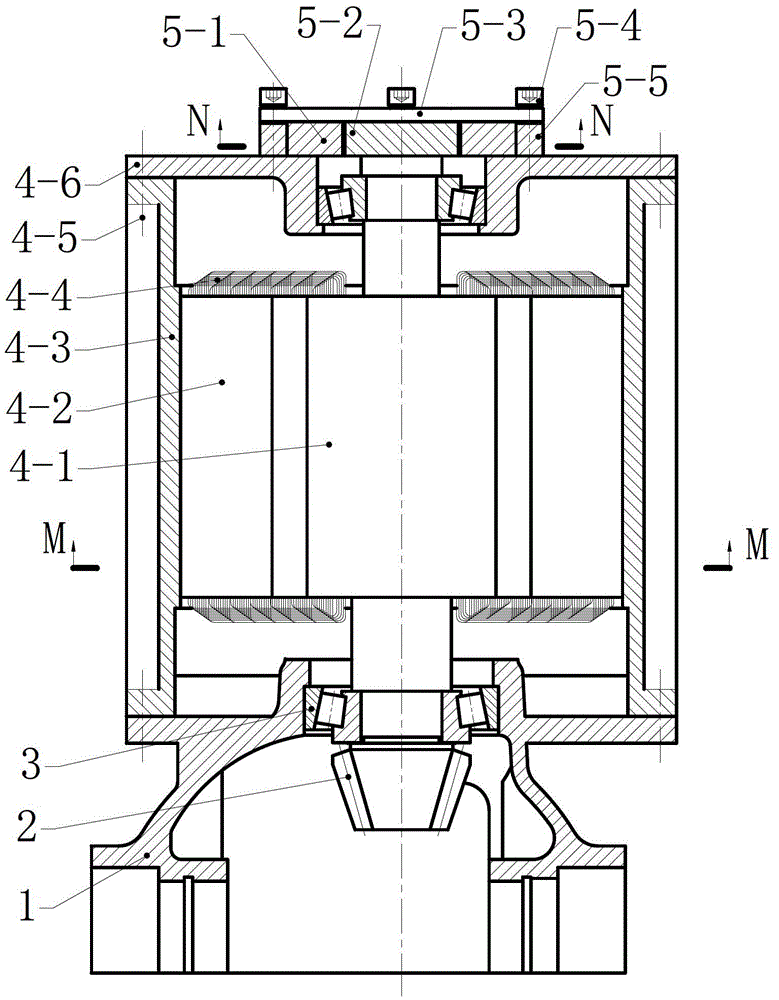

Switch magnetic flux motor for directly driven electric vehicle

InactiveCN102975614AThe overall structure is compactRotor structure is simpleControl devicesMotor shaftMagnetic flux

The invention provides a switch magnetic flux motor for a directly driven electric vehicle, and the motor comprises a switch magnetic flux motor, a rotary transformer, a main reducing gear, a differential mechanism, a semi-axis, an axle housing and driving wheels. The speed of the output power end of the switch magnetic flux motor is reduced by the main reducing gear, the differential operation among the driving wheels is realized through the differential mechanism and transmitted to the driving wheels by the semi-axis so as to realize the power transmission of the whole vehicle; the device is of an integral rotor structure without any coil winding or permanent magnet body and realizes the direct driving of the motor and a driving axle with the rotary transformer as the monitoring and feedback device of the output rotating speed of the motor and the phase of a rotor, with the driving gear shaft of the main reducing gear of the vehicle as a motor shaft, and with the main reducing gear shell of the vehicle as part of the outer shell of the motor. According to the device, the whole structure is compact, particularly a motor rotor has the advantages of simple structure, convenience in use and maintenance, good capability in resisting impact and vibration, low production cost, large output torque, high output rotating speed and the like, and the requirements on the running of the vehicle under various complicated working conditions are met.

Owner:XI AN JIAOTONG UNIV

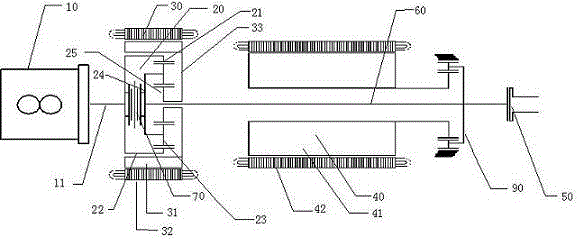

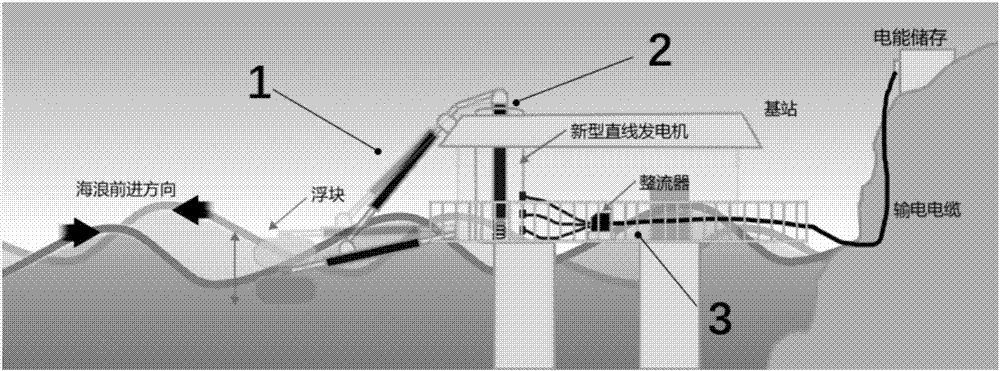

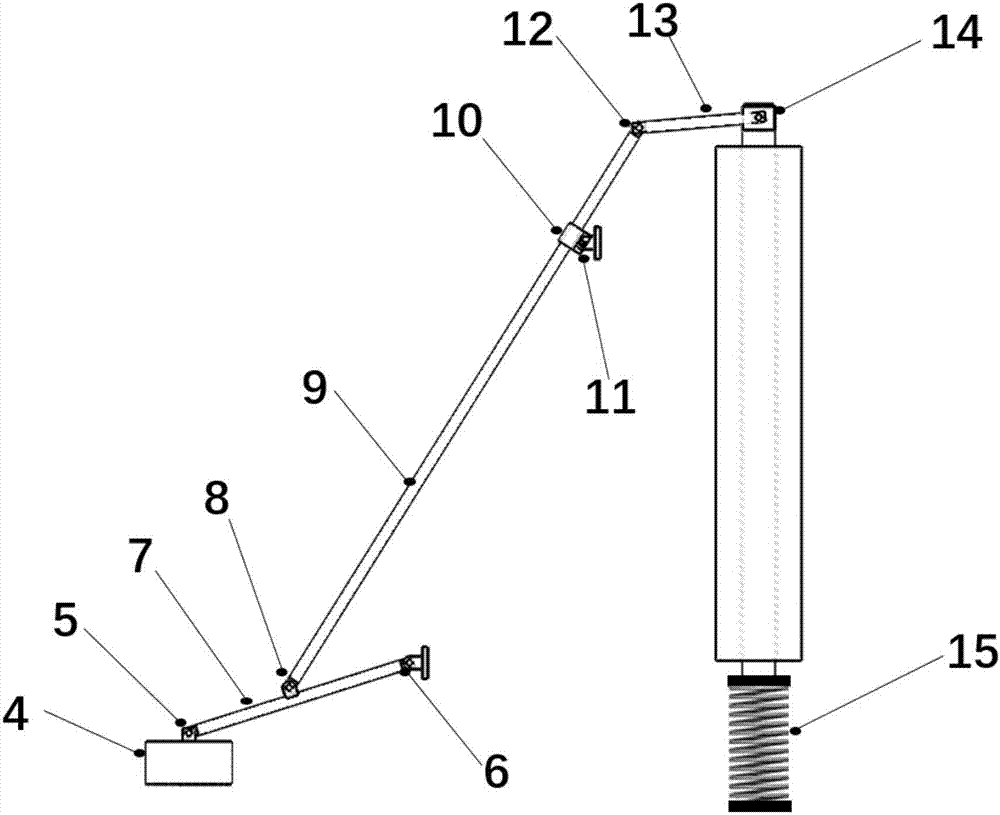

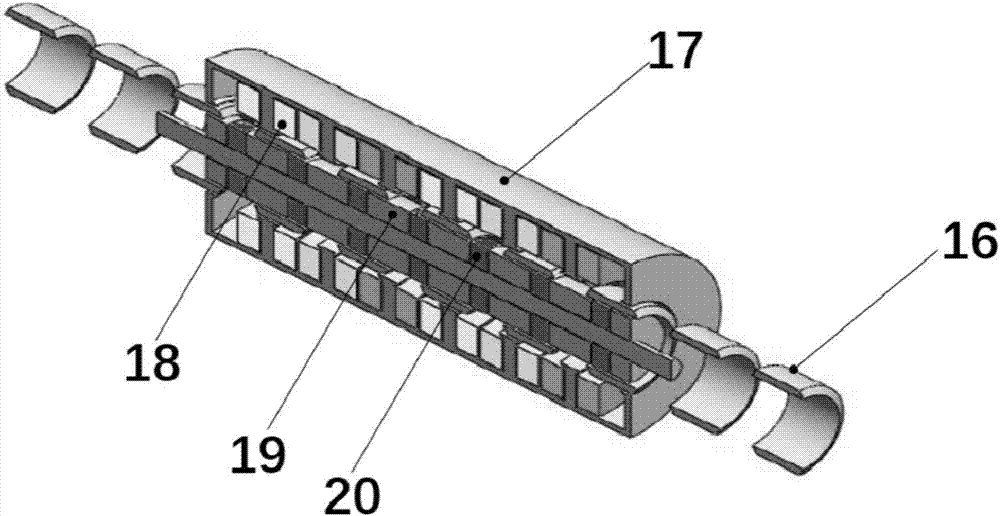

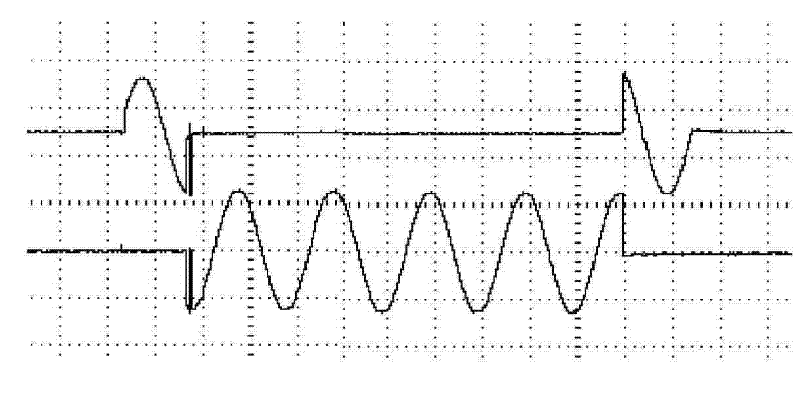

Linear motor direct-driven wave power generation system

ActiveCN106899142AImprove conversion efficiencySimple structureBatteries circuit arrangementsMachines/enginesMagnetic fluxWave shape

The invention discloses a linear motor direct-driven wave power generation system. The system includes a mechanical energy extraction module, a linear generator set module and an electric energy postprocessing module. The mechanical energy extraction module drives a buoy to move by waves, and the buoy is connected with a linear motor rotor iron core through three link rods; the linear generator set module drives the linear motor rotor iron core to vertically move through a hinge connected with a second driven rod, a path that magnetic lines of force pass which are emitted by a permanent magnet inside the motor changes accordingly, so that through constant change of the magnetic flux of copper coils in motor outer stator slots, three phases of approximately sinusoidal counter potential waveforms with constantly changing frequency and amplitude are generated and output; and then rectification, filtering, energy storage and inversion are performed through the electric energy postprocessing module, and usable three-phase alternating current with fixed frequency and amplitude is finally output and is used for electric energy supply of an offshore area or grid-connection processing.

Owner:ZHEJIANG UNIV

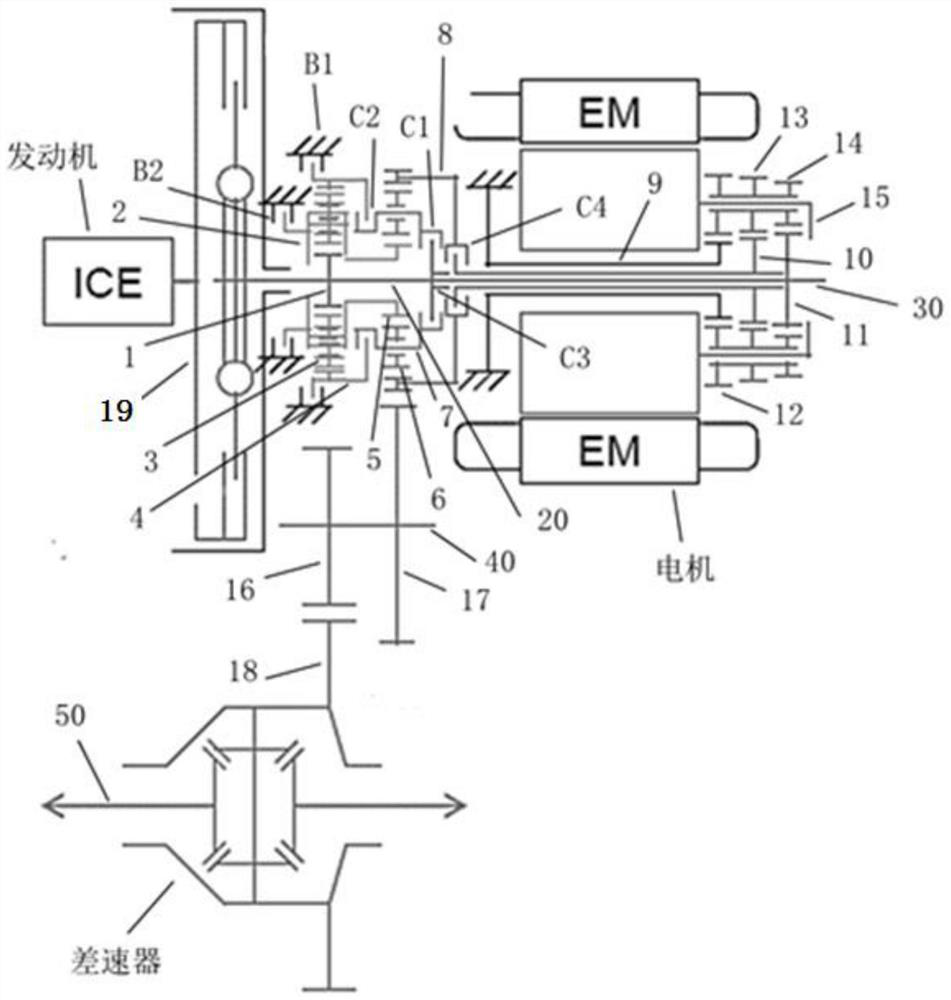

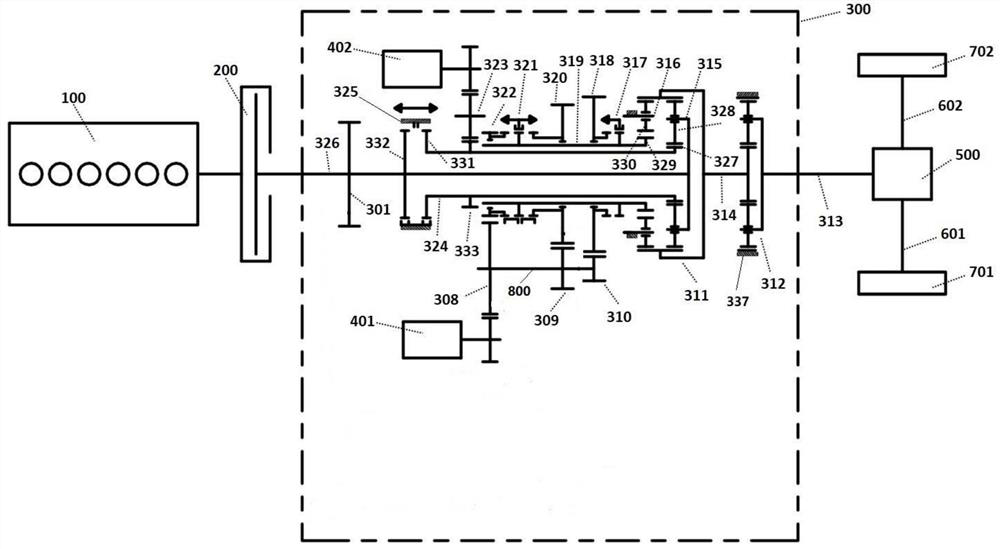

Multi-mode hybrid power special transmission

ActiveCN112224007ARealize dynamic decouplingAchieve direct driveHybrid vehiclesGas pressure propulsion mountingGear wheelEngineering

The invention discloses a multi-mode transmission special for hybrid power. The multi-mode transmission comprises an input shaft, a first planetary gear train, a second planetary gear train, an intermediate shaft, a differential mechanism, a first clutch, a second clutch, a first brake and a second brake. The input shaft is connected with an engine through a torque limiting shock absorber; the first planetary gear train comprises a sun gear A, a planet gear A, a planet carrier A and a gear ring A, the planet gear A is arranged between the sun gear A and the gear ring A and installed on the planet carrier A, and the planet gear A is meshed with the sun gear A and the gear ring A; the sun gear A is mounted on the input shaft; the second planetary gear train comprises a sun gear B, a planet gear B, a planet carrier B and a gear ring B. The invention has the beneficial effects that through the arrangement of the first clutch, the second clutch, the first brake and the second brake, the fixed connection mode of the first planetary gear train and the second planetary gear train is changed, static elements in the planetary gear trains are changed, and various transmission ratios are achieved under the condition that no extra gear pair is additionally arranged.

Owner:DONGFENG MOTOR CORP HUBEI

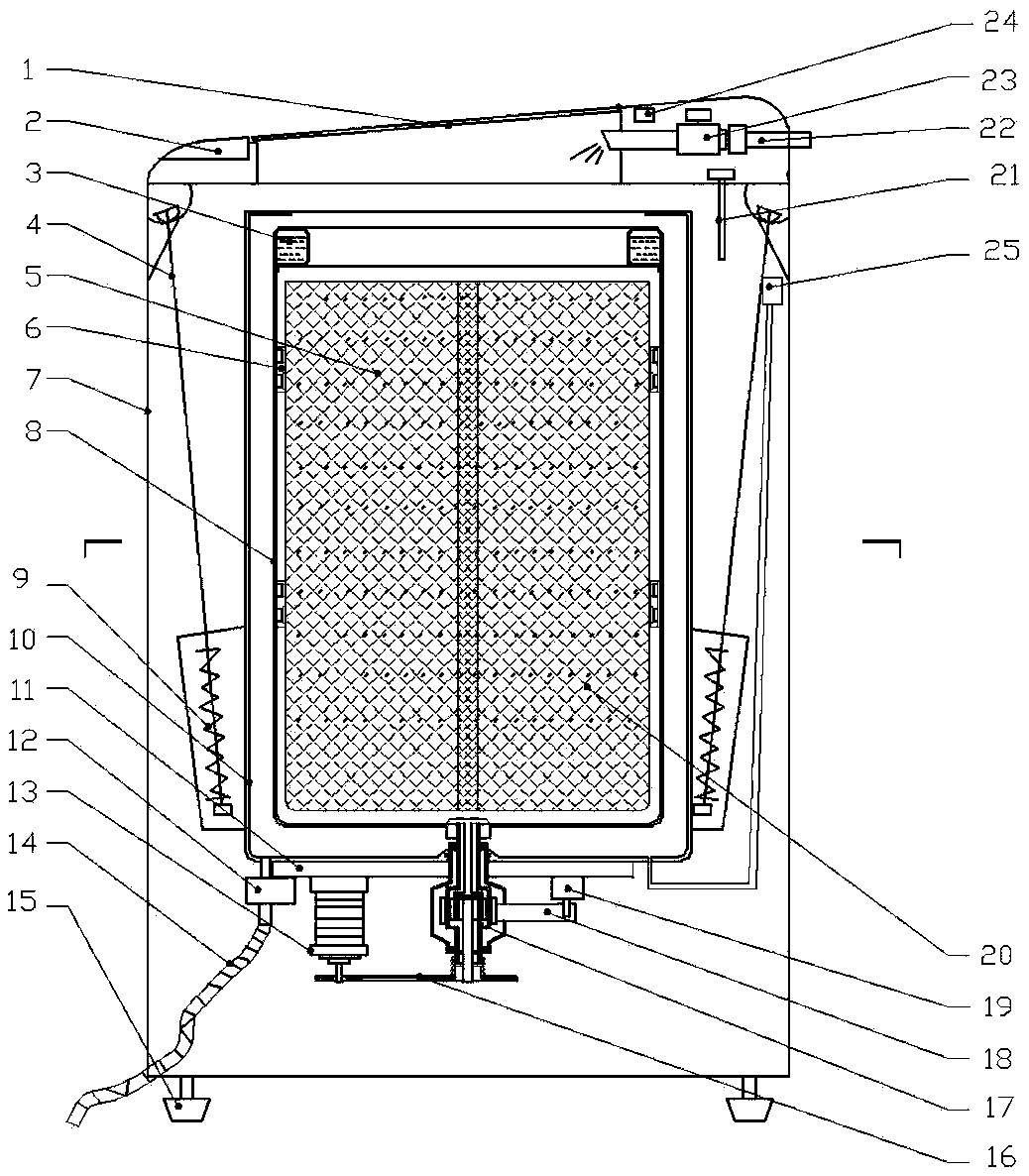

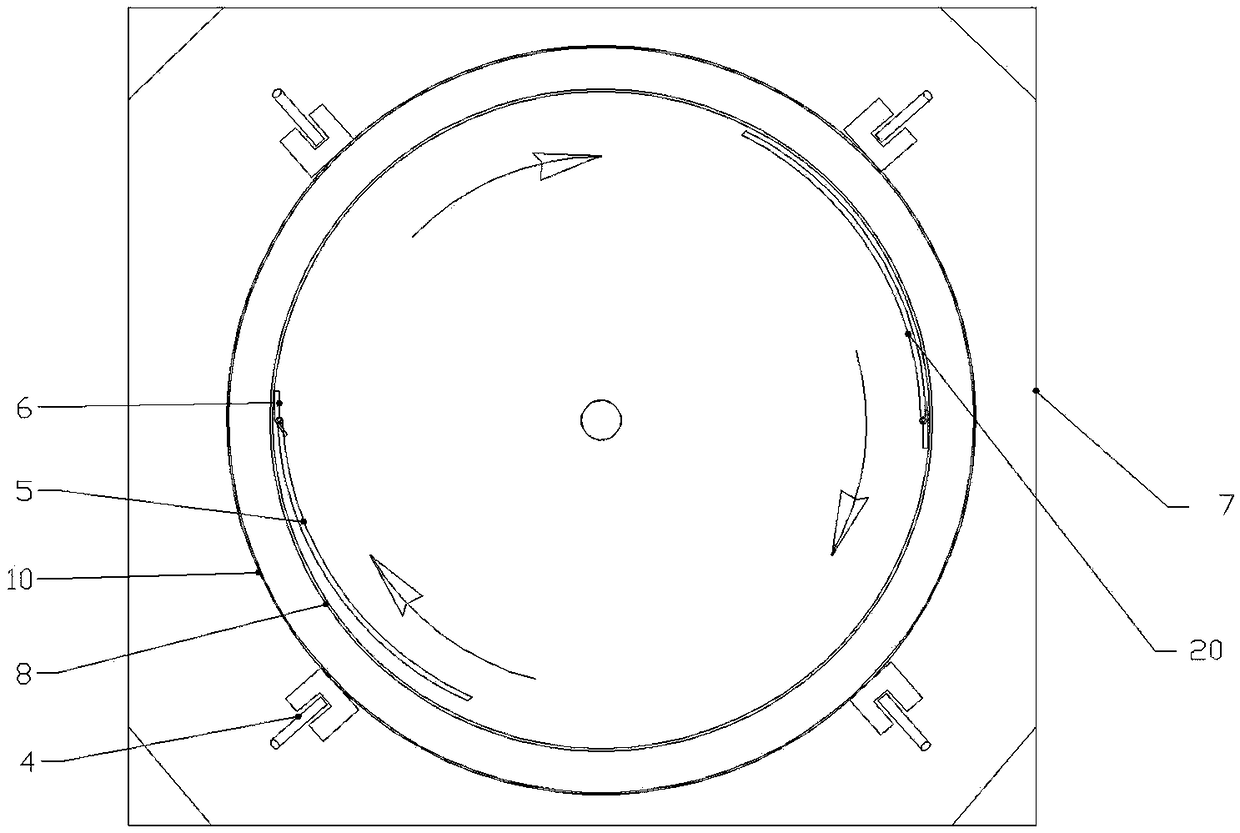

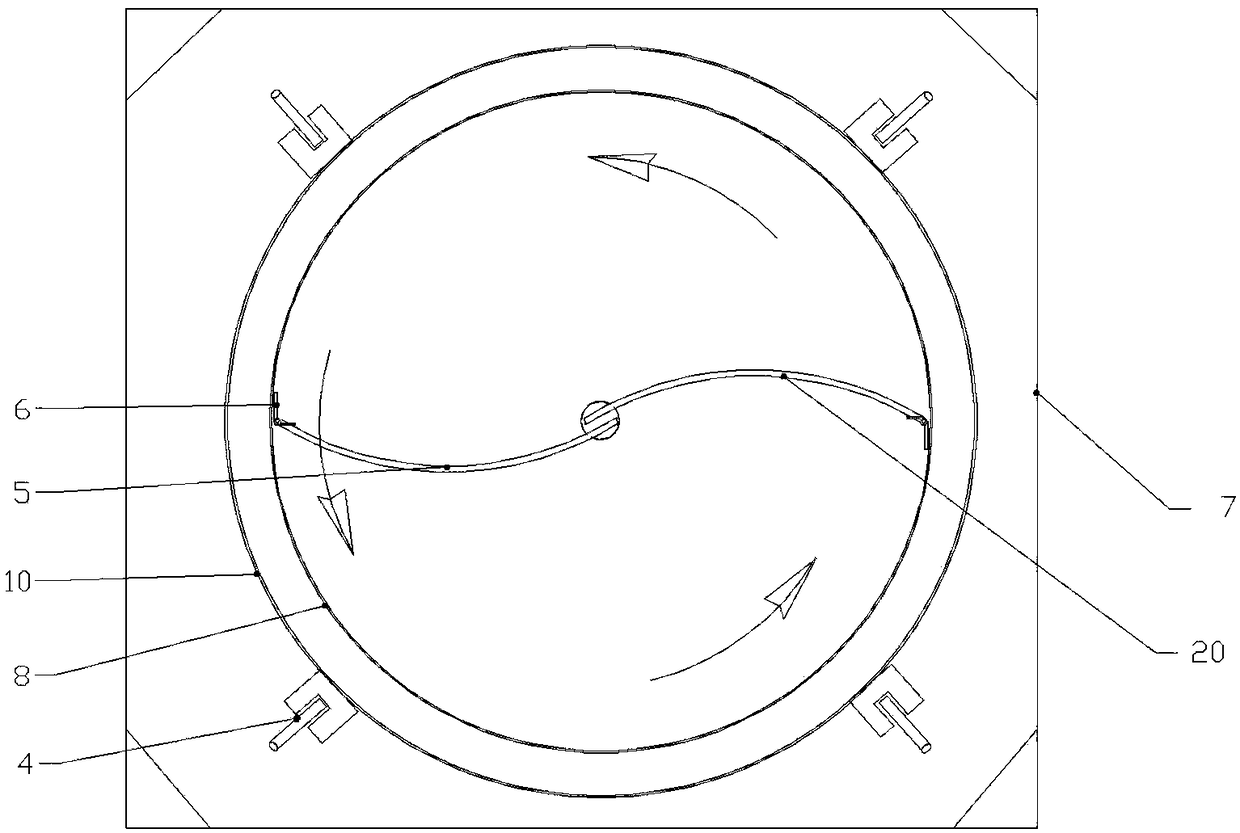

Drum extrusion type washing machine

PendingCN109023825AAchieve direct driveShort rinse timeOther washing machinesWashing machine with receptaclesWater supplyEnergy consumption

The invention provides a drum extrusion type washing machine improved based on a conventional washing machine, and through change of the washing mode, the washing capability is obviously improved, theabrasion rate is reduced, and the energy consumption is reduced. The drum extrusion type washing machine comprises a housing, a damping device, a water-containing tub, a dehydration tub, an extrusiondevice, an electric control device, a water supply and drainage device, and a driving device. Four corners of the housing are connected to the water-containing tub through the damping device, the dehydration tub is arranged in the water-containing tub, an inner wall of the dehydration tub is provided with two movable extrusion plates, the extrusion plates are rectangular meshed plates bent in a certain radian, the extrusion plates are folded during washing, the extrusion plates isolate the dehydration tub into two independent spaces, clothes can rotate in the water with the dehydration tub and extruded during rotation, the clothes roll over and absorb water when rotation is stopped, and extrusion washing of the clothes can be realized in a circulated and repeated manner. During drying, the two extrusion plates are attached to the inner wall of the dehydration tub under the effect of a centrifugal force due to the special shape of the extrusion plates, and centrifugal dehydration and drying of the clothes are not influenced.

Owner:龙港乐家创新科技(深圳)有限责任公司

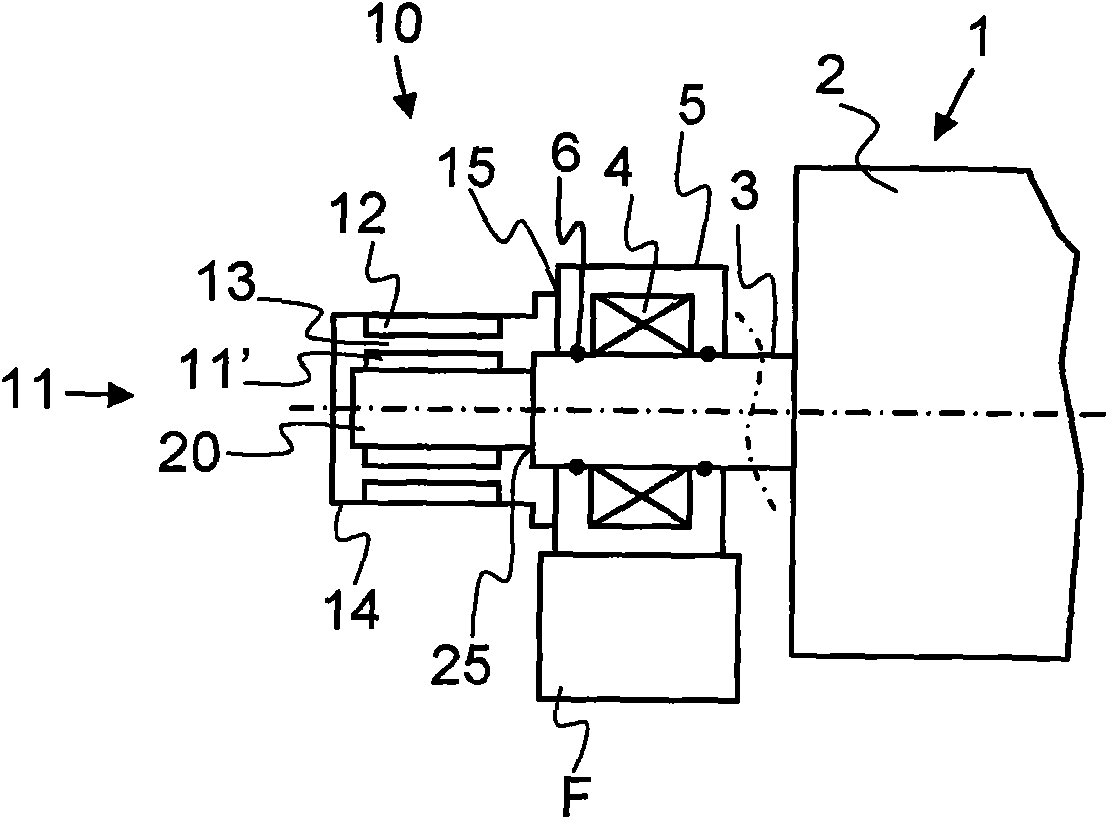

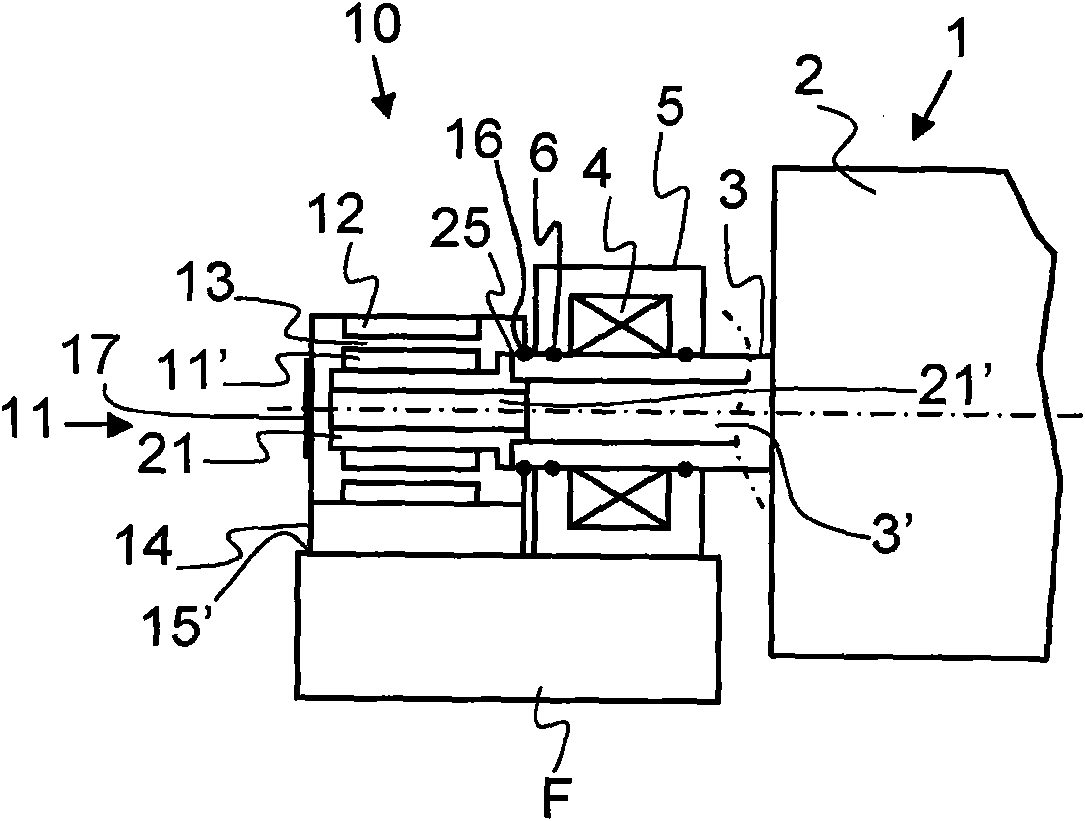

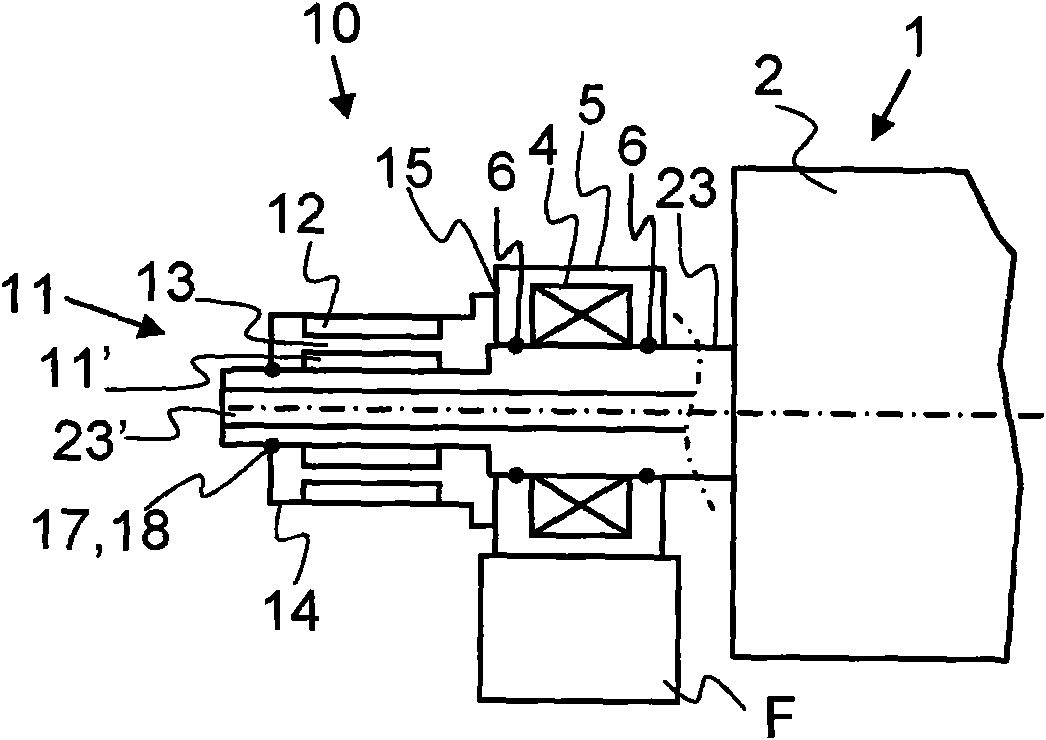

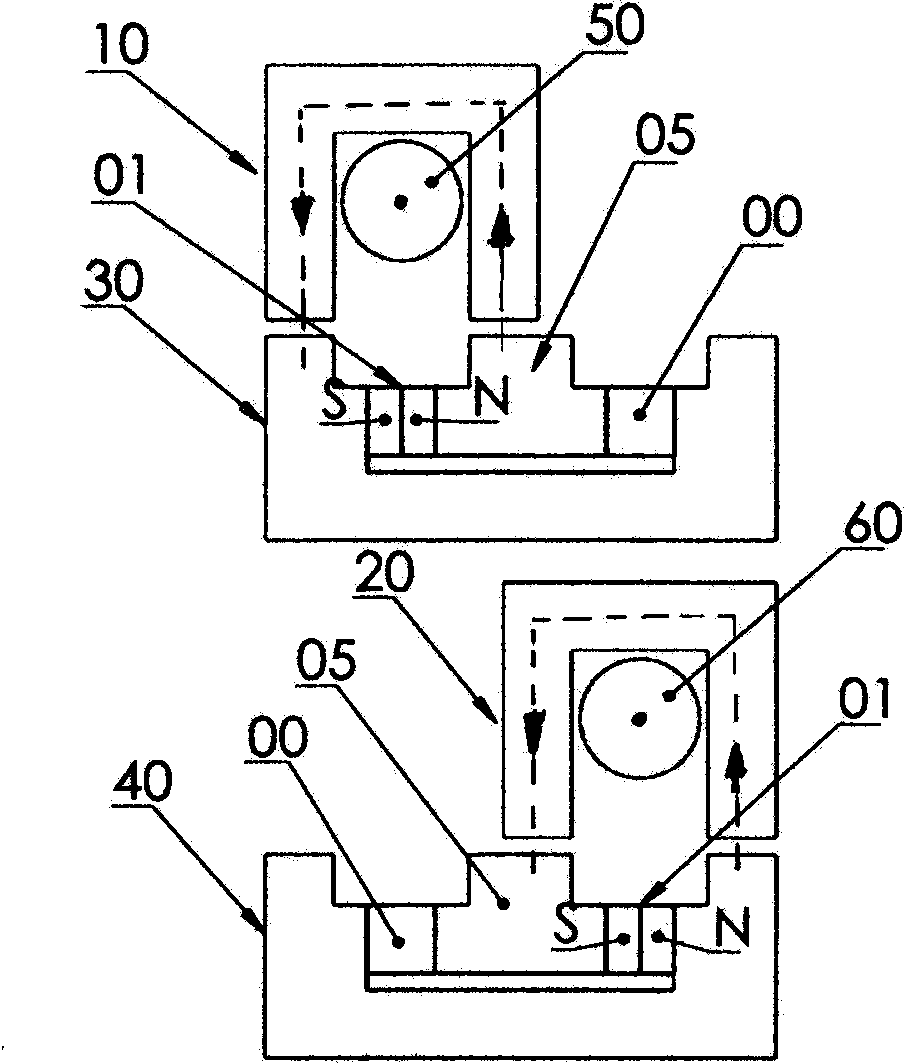

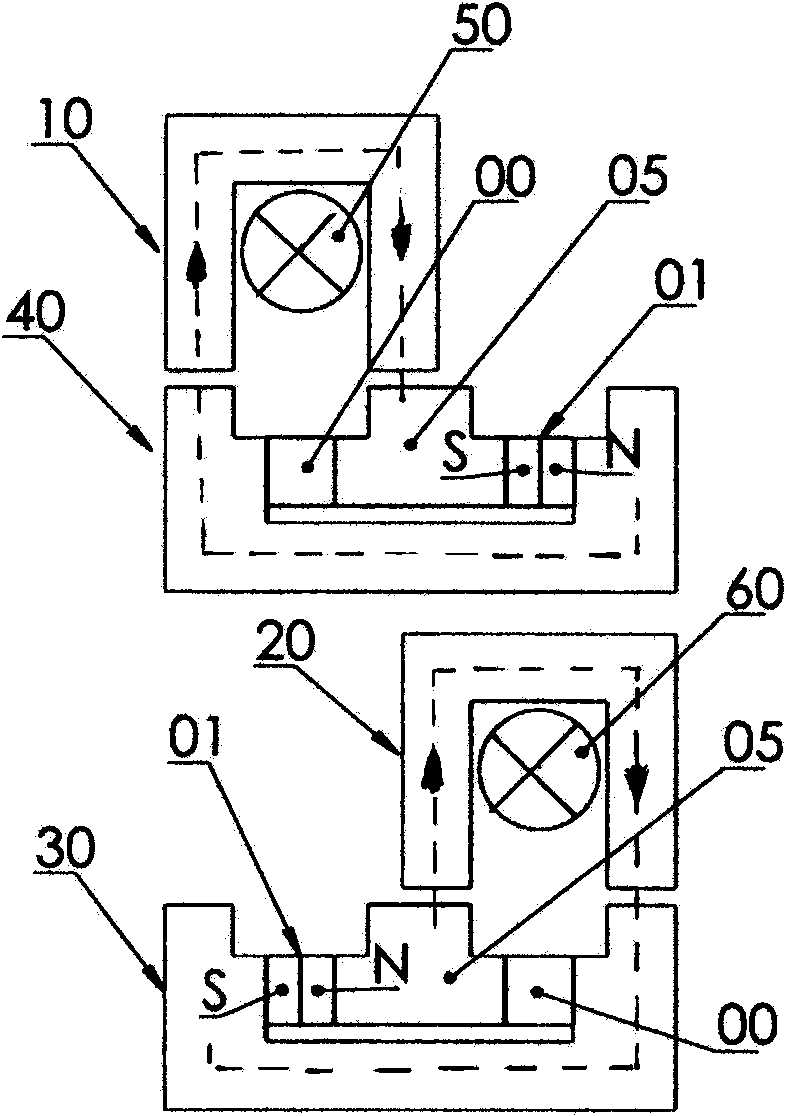

Roller driver, roller and method

InactiveCN102075046AAchieve direct driveReduce in quantityMagnetic circuit rotating partsCalendersConductor CoilMechanical engineering

The invention discloses a roller driver (10) for a fiber sheet machine, a sheath (2) of a roller (1) is rotated through shafts (3, 23), the shafts can be rotatably supported on a device support (F) through a bearing (4) arranged in a bearing housing (5); the roller driver is provided with a rotor housing (14) and a stator with a rotor winding, wherein the rotor (12) is arranged in the rotor housing (14); the roller driver comprises a rotor (11) rotatably acting on the shaft, the rotor is surrounded by the stator winding during operation so as to generate an air gap between the rotor and the stator. The rotor is permanently magnetized for achieving the large air gap; for fixing the rotor on the shaft, the rotor is designed that the shaft can support the mass of the rotor; for fixing the stator housing out of the bearing housing, the stator housing is designed for supporting the mass of the stator and the stator housing in a manner independent from the supporting manner of the rotor. The invention further relates to a roller equipped with the roller driver and a method for mounting the roller driver on the roller.

Owner:METSO PAPER INC

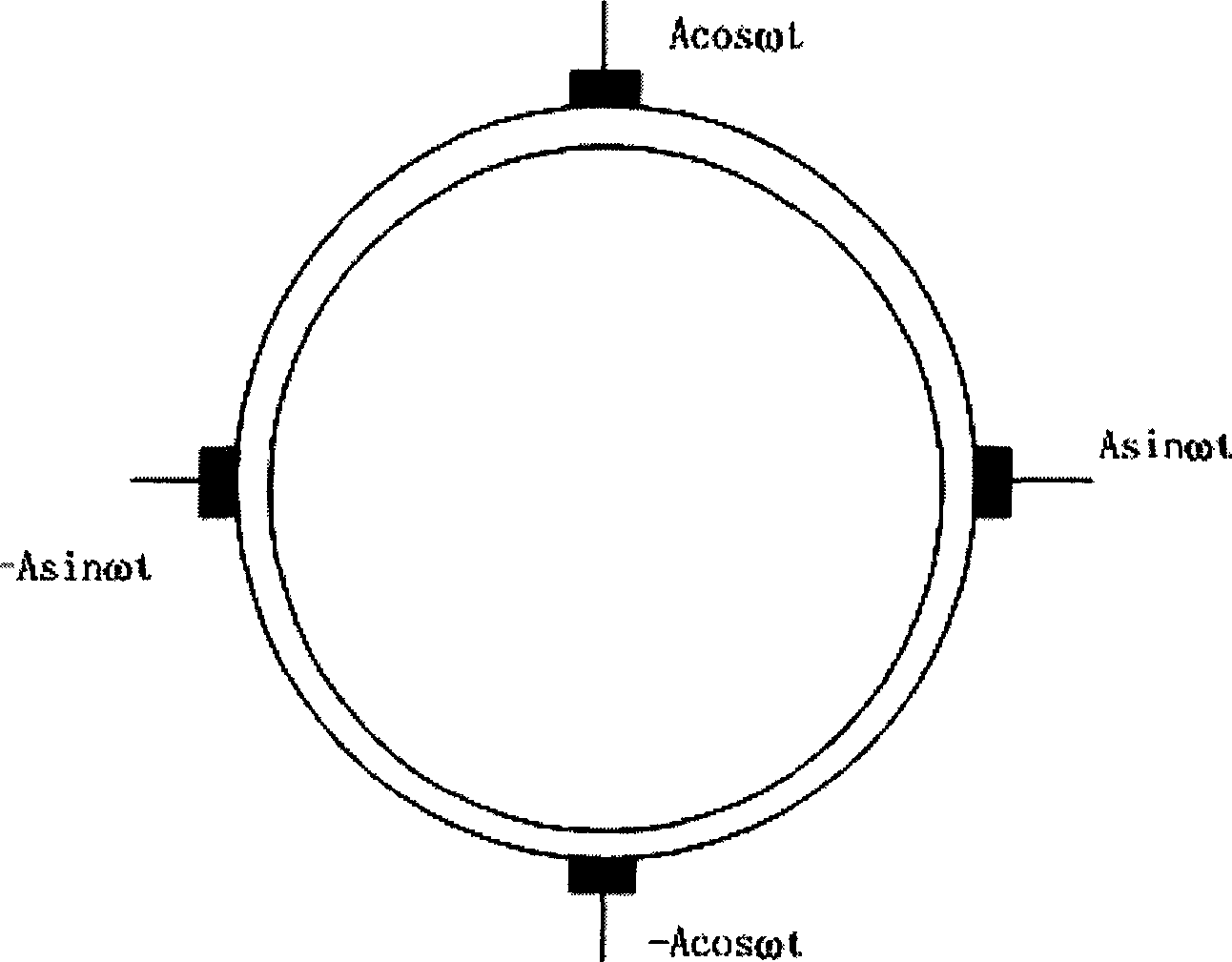

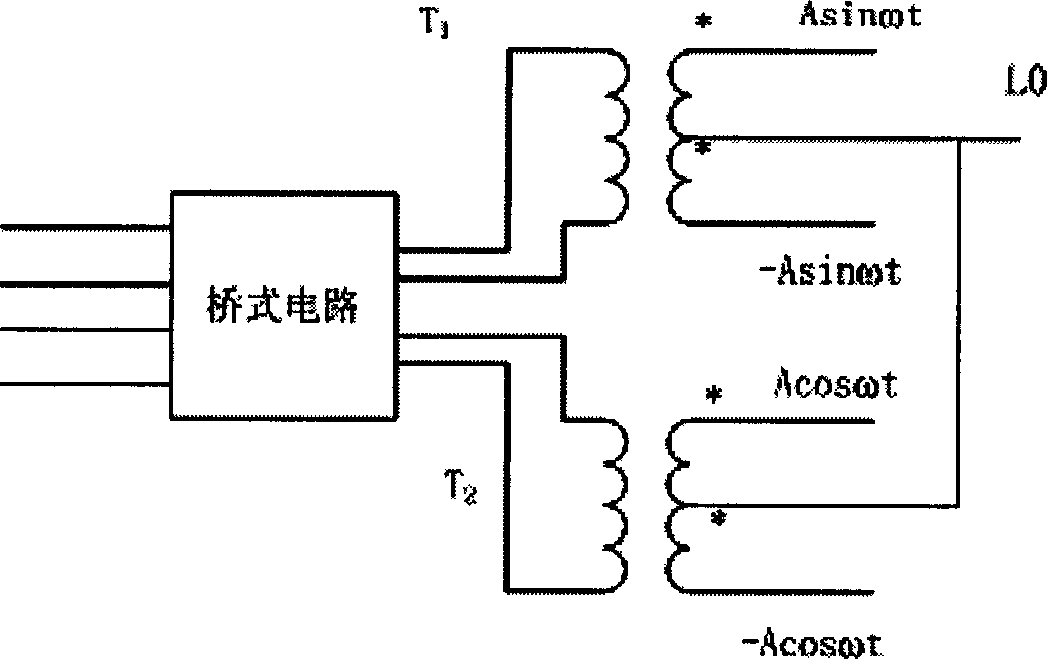

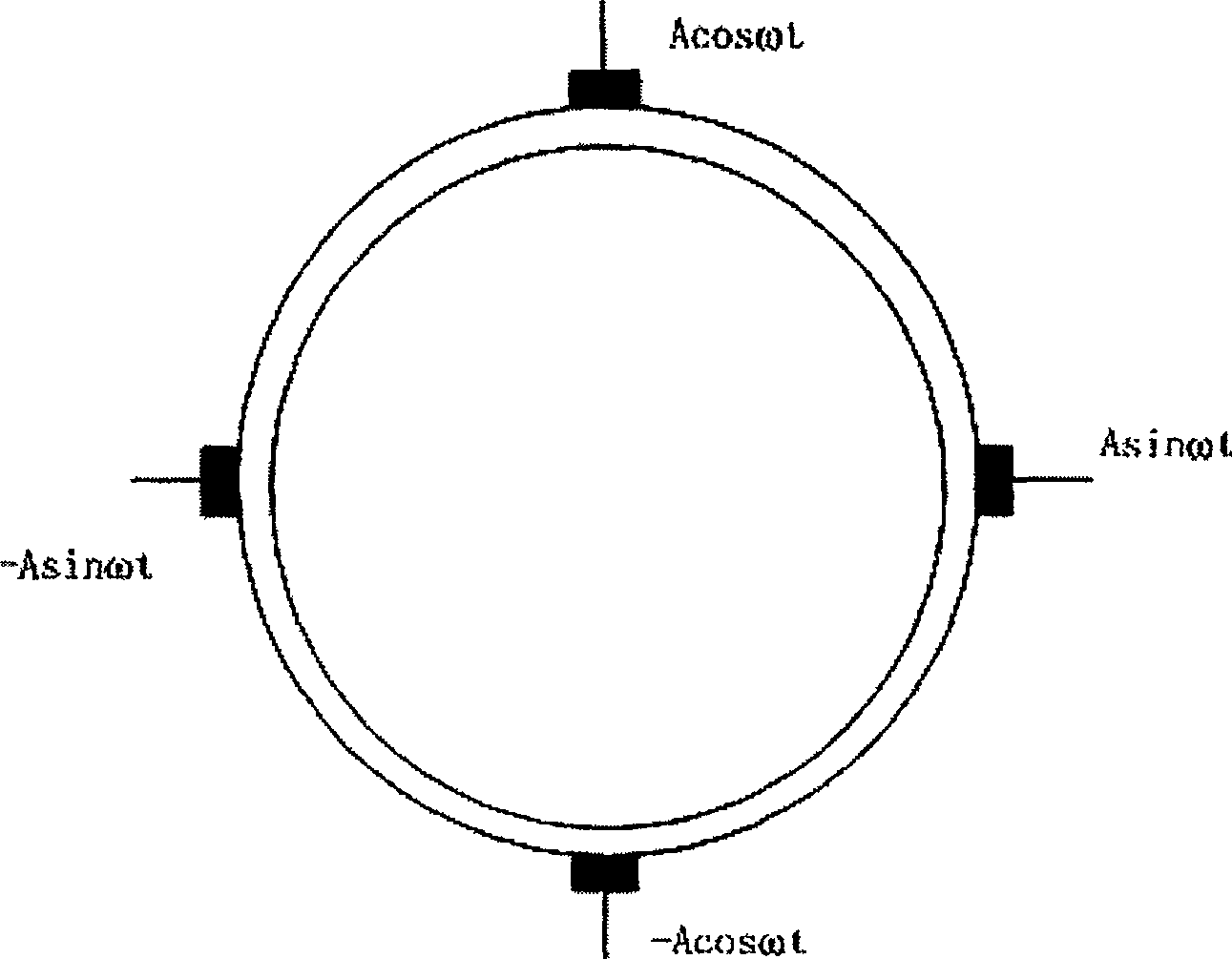

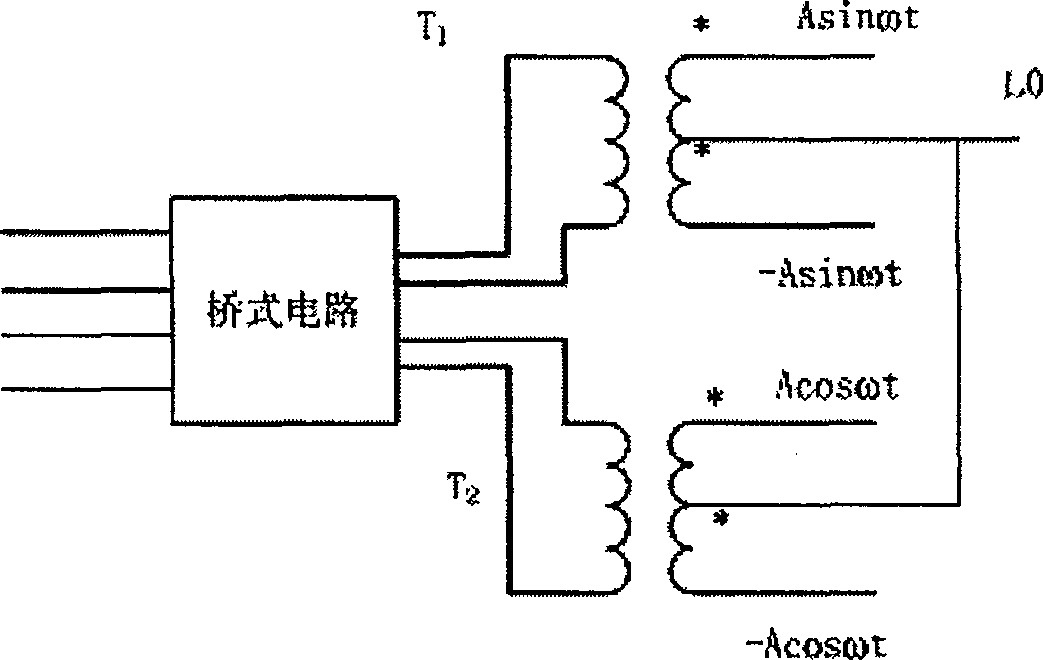

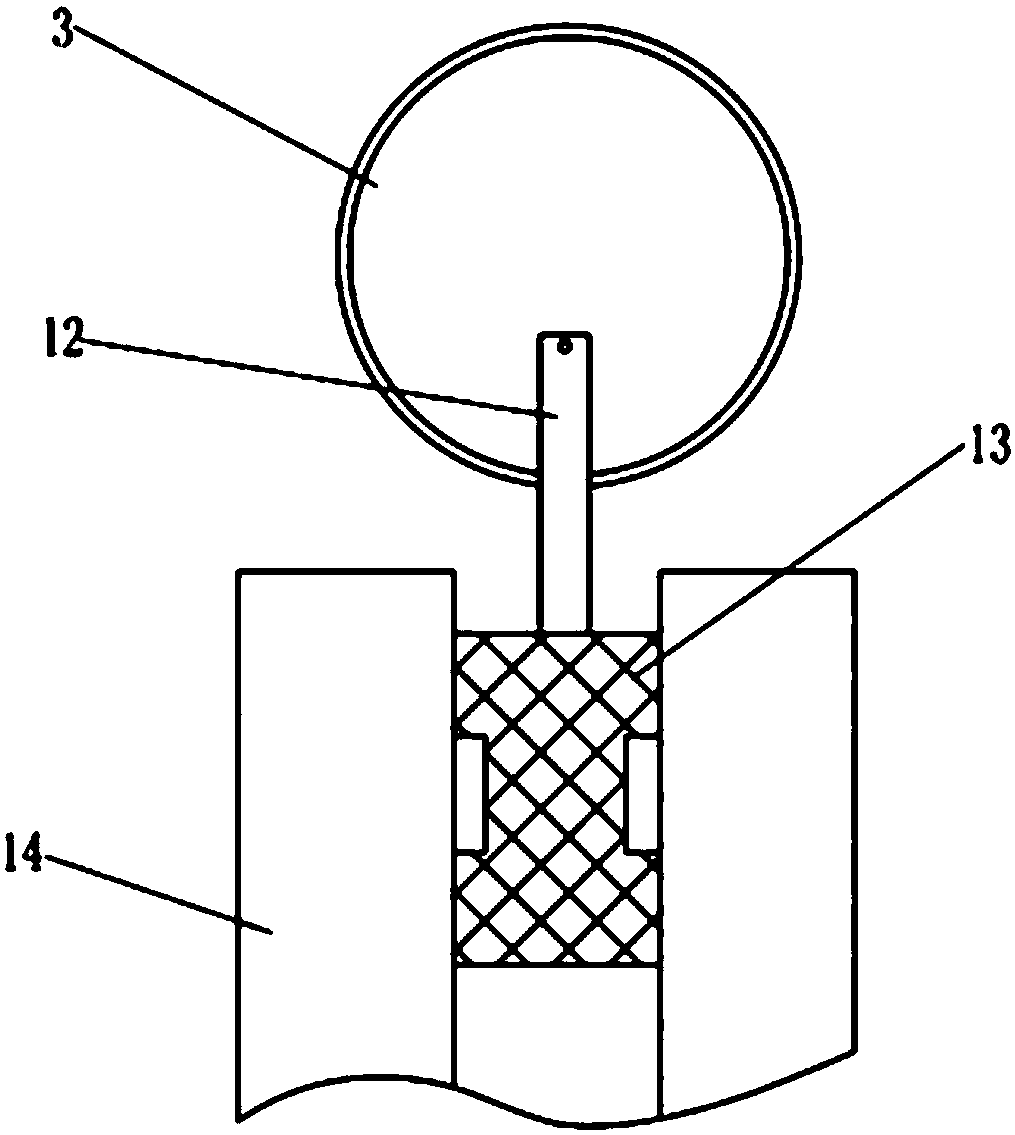

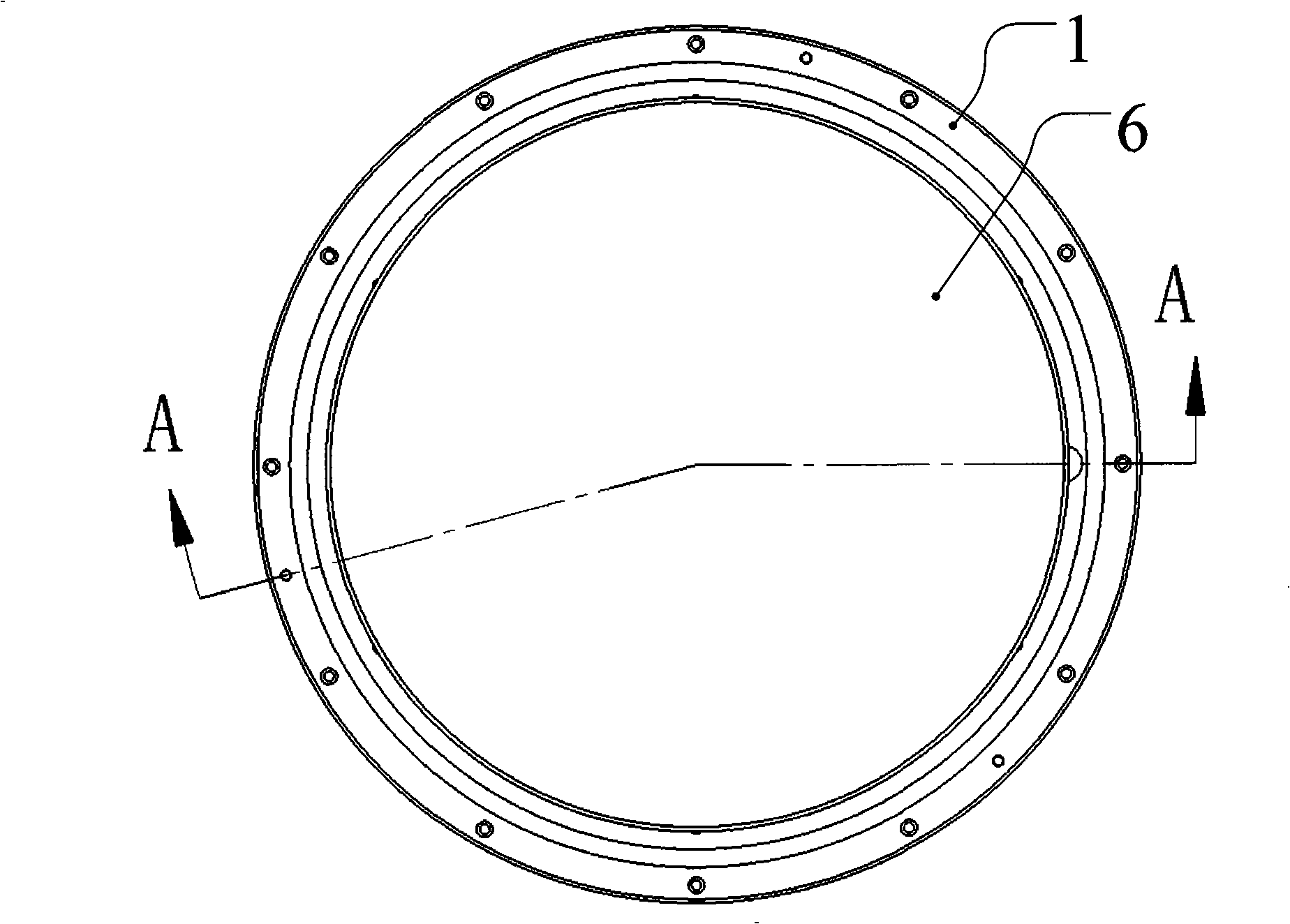

Ring structured lin wave contactless liquid medium ultrasonic wave electric machine

InactiveCN1794556AExtend your lifeSimple processPiezoelectric/electrostriction/magnetostriction machinesLiquid mediumControl signal

This invention relates to a non-contacted supersonic motor including a stator, a rotor, a reversible drive circuit and a rotation speed following control device, in which, the stator is a ring post, the outside of which is set with ring piezoelectric ceramic plates and electrodes, in which, the reversible drive circuit includes a DC supply, a square wave generator, a frequency dividing phase shifter, a power amplified circuit and a transformer boosting circuit, in which, the rotation control device includes a control signal interface circuit, a controller and a motor vibration test circuit, which includes an integral phase shift circuit, a proportion amplified circuit, a subtraction circuit and a discriminating circuit.

Owner:TIANJIN UNIV

Rock wool fiberizing centrifuge

PendingCN110668690AAchieve direct driveReduce volumeGlass making apparatusGlass productionElectric machineCoupling

The invention discloses a rock wool fiberizing centrifuge. The rock wool fiberizing centrifuge comprises a frame, a plurality of centrifuging roller assemblies arranged on the frame, a split type gluespraying ring arranged around the centrifuging roller assemblies, and a glue supply mechanism for supplying glue to the centrifuging roller assemblies and the split type glue spraying ring; every centrifuging roller assembly comprises a motor, a shaft coupling, a connecting tube and a roller body; the output shaft of the motor is a hollow shaft penetrating through two ends of the motor; the output shaft of the motor is fixedly connected with the roller body through the shaft coupling; the connecting tube is located in the shaft coupling, and two ends of the connecting tube are connected withthe output shaft of the motor and the roller body correspondingly; a glue spraying tube communicated with the connecting tube is arranged in the roller body; and the output shaft of the motor, the connecting tube and the glue spraying tube in the roller body form the glue channel of the centrifuging roller assembly. The defects of large occupied space in transmission and easy slipping of an original belt are fundamentally overcome, the size of the rock wool fiberizing centrifuge is reduced, and the yield of rock wool is increased.

Owner:CHANGZHOU YINGLAI MACHINERY

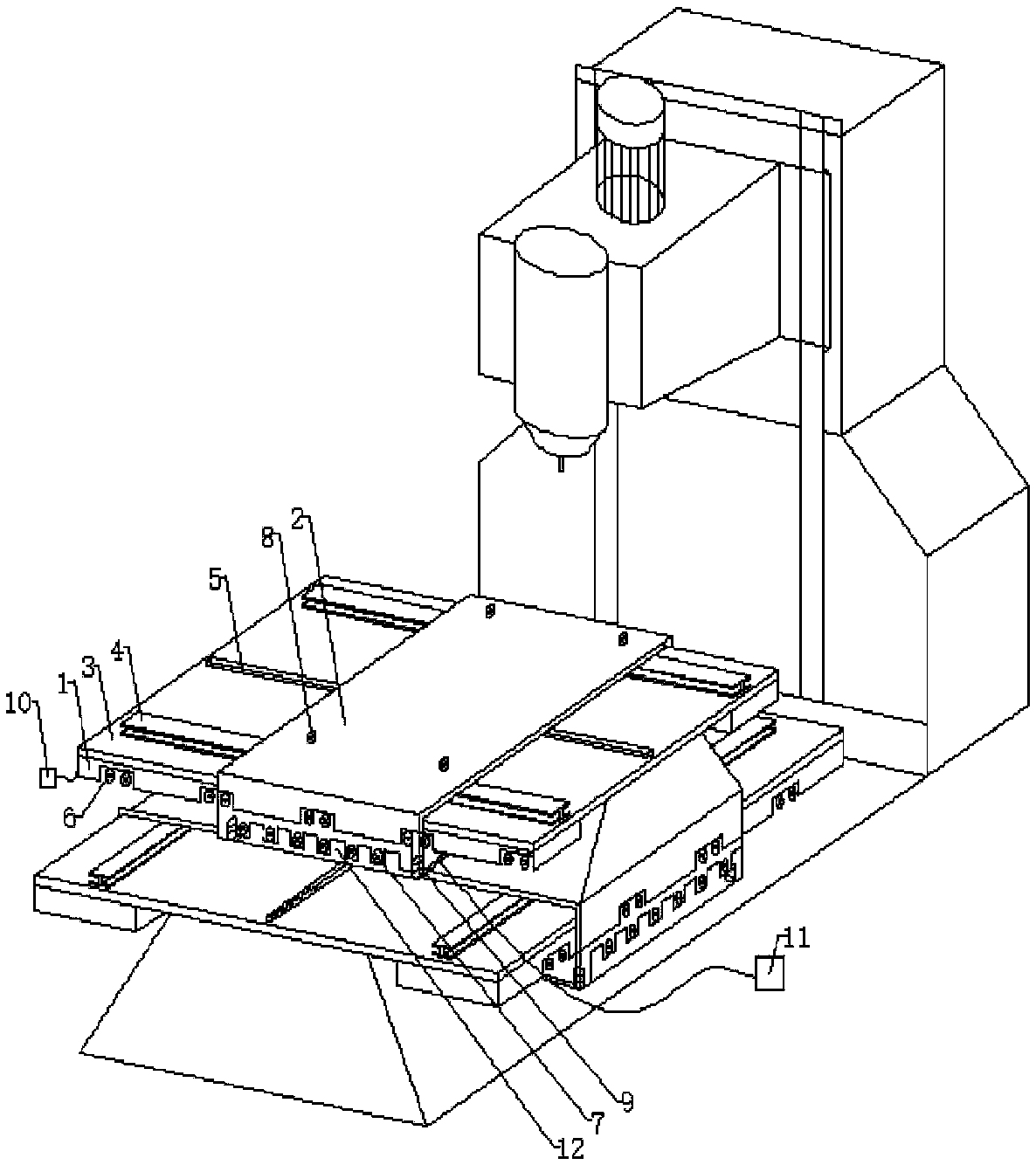

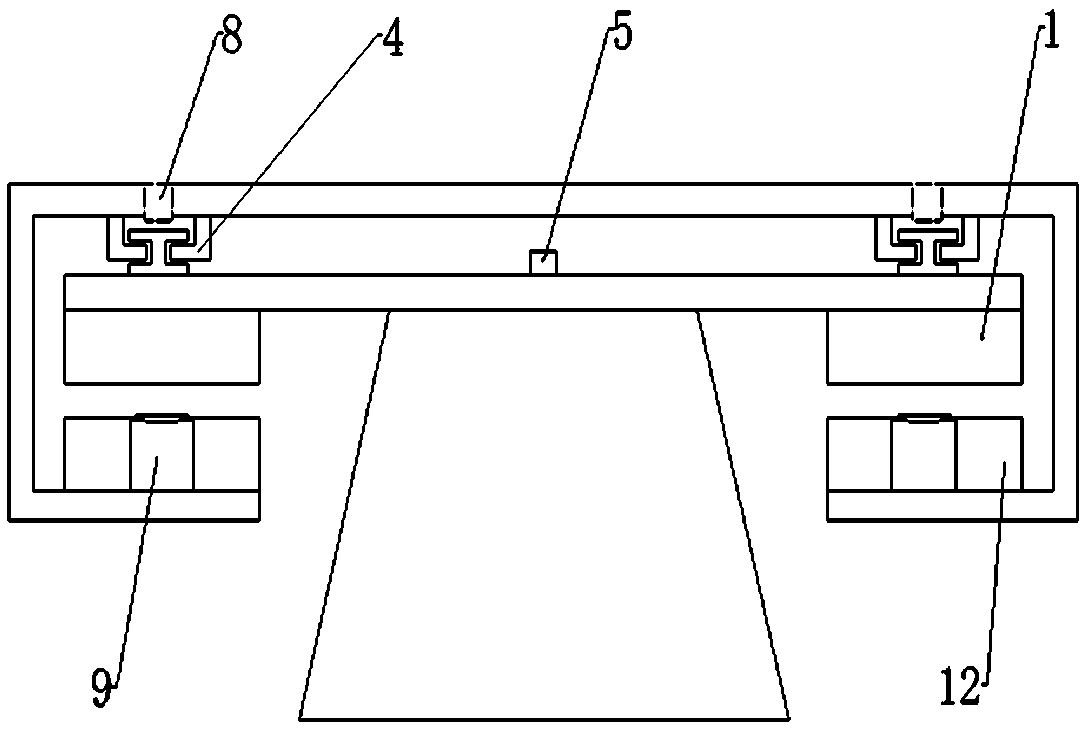

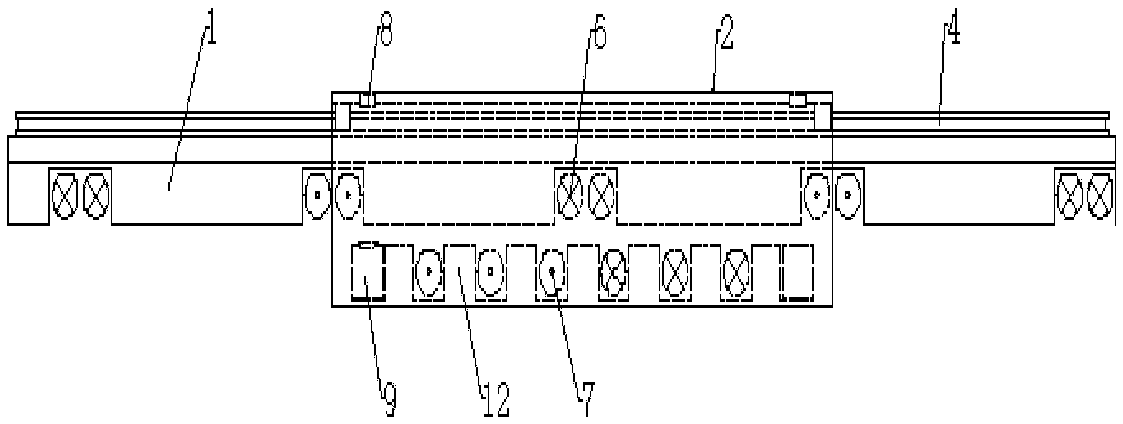

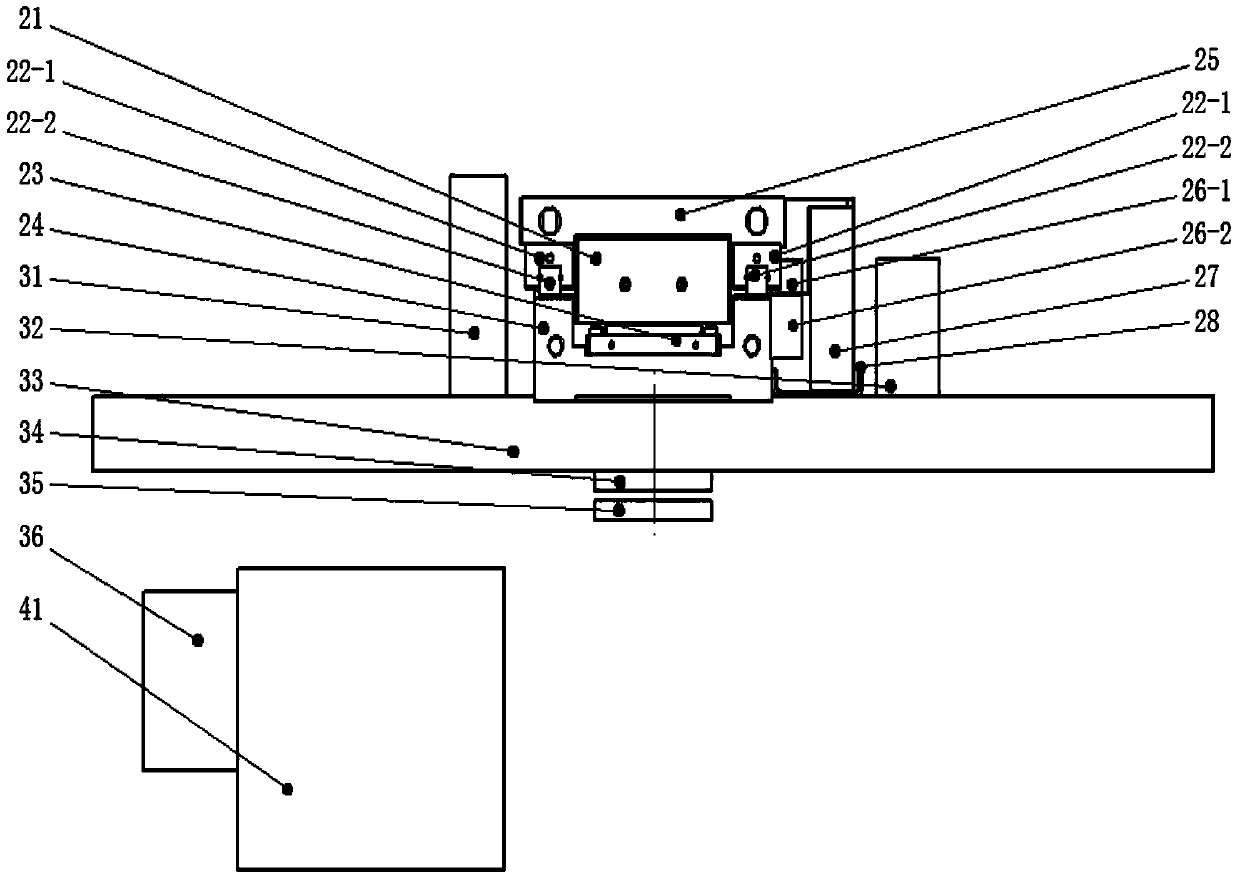

Magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for vertical machining center

InactiveCN105500032ASimple platform structureImprove reliabilityFeeding apparatusLarge fixed membersStatorControl system

The invention provides a magnetic levitation motion stage provided with controllable excitation linear synchronous motors and used for a vertical machining center. The magnetic levitation motion stage is characterized in that the magnetic levitation motion stage comprises a motion stage, a base, the controllable excitation linear synchronous motors, a levitation control system and a motion control system. The magnetic levitation motion stage has the advantages and effects that the electromagnetic thrust force is changed by adjusting the current of armature windings; the magnetic levitation forces are the unilateral magnetic pull generated between excitation magnetic poles on stators and rotor iron cores of the linear synchronous motors and are adjusted by adjusting the exciting current; the motion stage depends on the magnetic levitation forces generated by the two motors to operate and has the capacity of direct automatic levitation.

Owner:SHENYANG POLYTECHNIC UNIV

Driving and connecting device for rotary drilling rig power head pile casing

ActiveCN102678042AAchieve direct driveSimple structureConstructionsRotary drillingElectrical and Electronics engineering

The invention relates to a connecting device which is required for connecting a pile casing when a rotary drilling rig power head is in construction for stratum easy to collapse. A driving and connecting device provided by the invention consists of a power head connecting shaft, a connecting body, pin shafts, a stop pin, a split pin and a pile casing driver. The lower end of the power head connecting shaft is connected with the upper end of the connecting body through 8 pin shafts which are uniformly distributed along the periphery direction, and the stop pin and the split pin limit axial float of the 8 pin shafts. The lower end of the connecting body is connected with the pile casing driver through 2 pin shafts. The power head directly drive the pile casing through the connecting body and the pile casing driver when in rotation and pressurization. The connecting body in the device consists of two parts; the upper and lower parts of the connecting body are respectively welded on an intermediate ring plate; an external ring arranged at the upper part of the connecting body is a ring plate; an internal ring arranged at the upper part of the connecting body are 8 arc-shaped plates which are uniformly distributed along the periphery direction; the external plate and the internal plates are welded on the intermediate ring plate to form 8 grooves for connection with the power head connecting shaft; the lower part of the connecting body are two arc-shaped plates which are intermediately provided with a shaft sleeve in a welding way; and the two arc-shaped plates are symmetrically welded on the intermediate ring plate for connection with the pile casing driver. With the help of the connecting body, the pin shafts, the stop pin and the split pin, the connecting structure provided by the invention effectively realize the drive of the power head on the pile casing.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

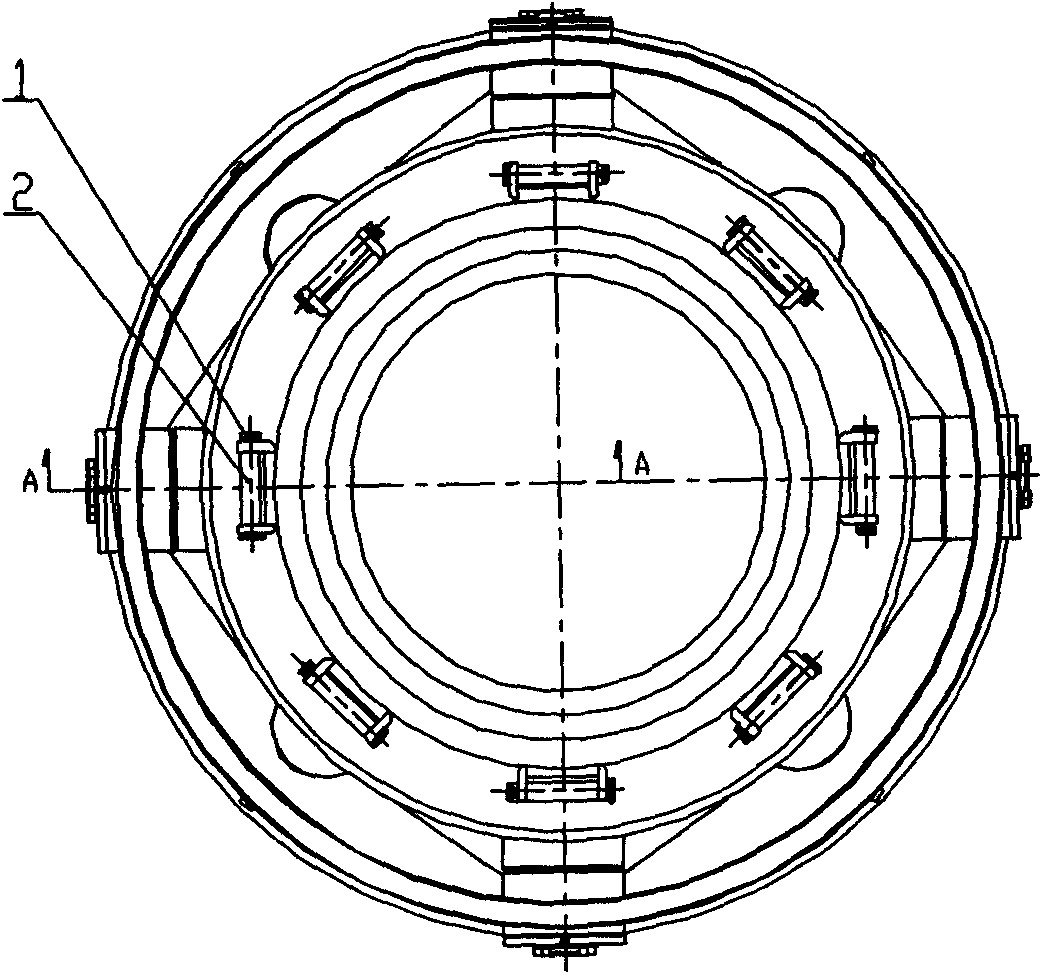

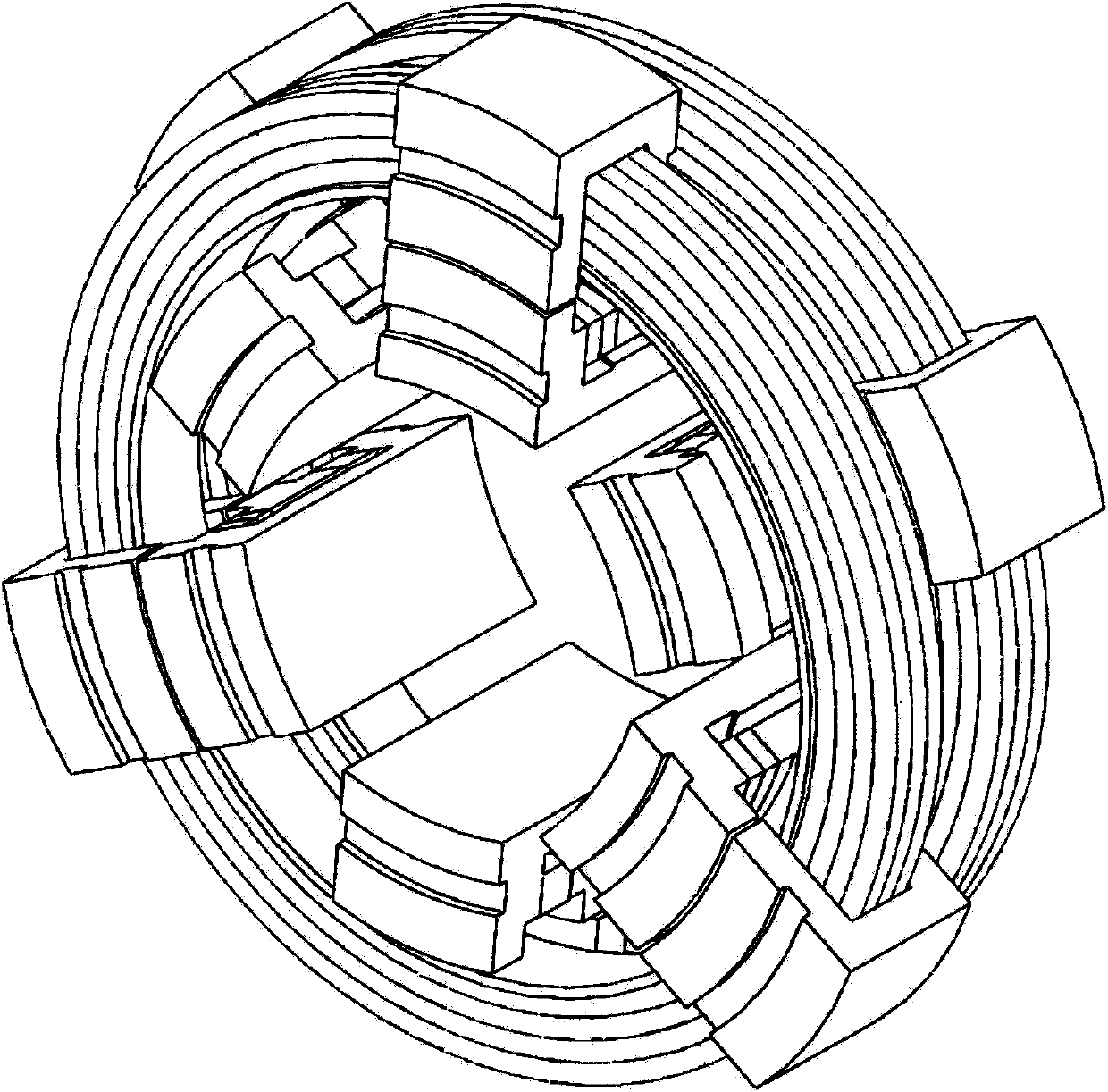

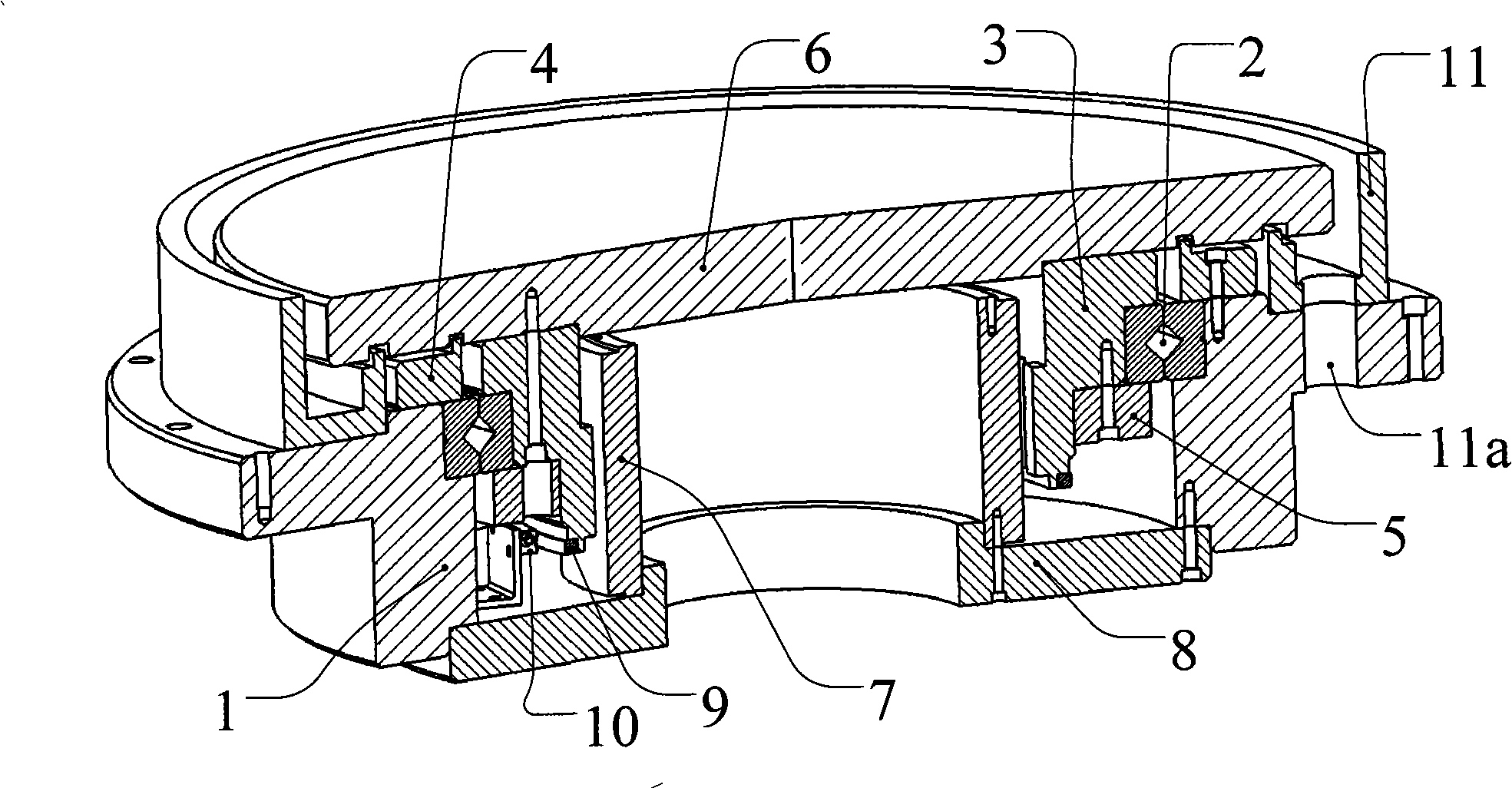

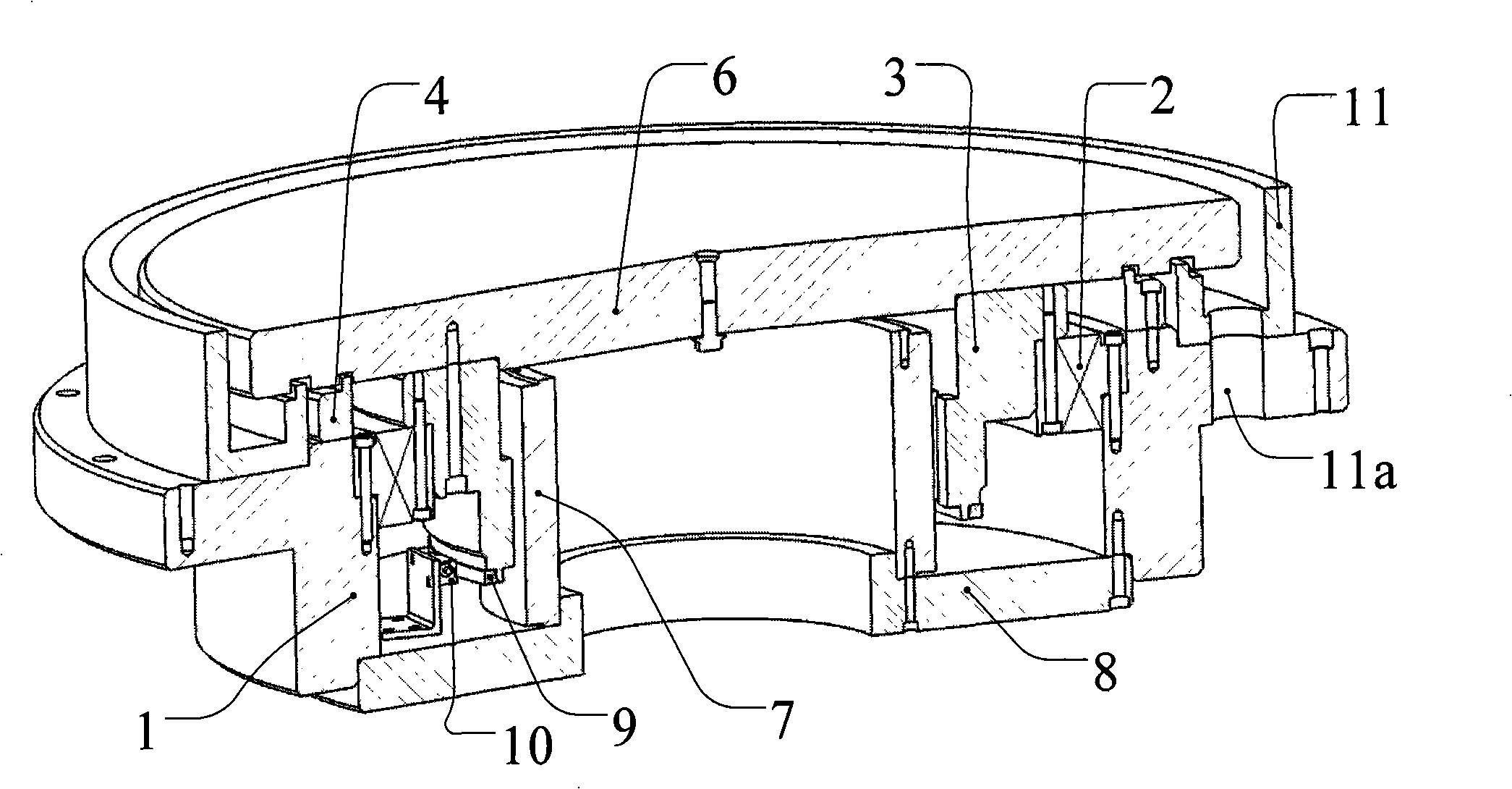

Transverse flux permanent magnet or magnetic reluctance permanent magnet motor of annular box structure

InactiveCN103795158AStructural solutionHigh mechanical strengthMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse fluxElectrical polarity

The invention discloses a transverse flux permanent magnet or magnetic reluctance permanent magnet motor of an annular box structure. The motor is manufactured with a stator phase ring body and a rotor phase ring body as basic components, and an electromagnetism switching mode that iron cores of the stator phase ring body and iron cores of the rotor phase ring body are grouped in an odd and even mode is created. The inside of a left annular box, the inside of a middle annular box and the inside of a right annular box are respectively provided with one odd circumferential array iron core, one even circumferential array iron core and two 1 / 2 phase windings in series connection through the stator phase ring body. The iron cores of the rotor phase ring body are divided into the following two kinds: one kind of the iron cores serves as permanent magnet motors, a permanent magnet is embedded between a left magnetic pole and a middle magnetic pole of each odd iron core, a non-magnetic steel structure body is embedded between the middle magnetic pole and a right magnetic pole of each odd iron core, and vice versa; one kind of the iron cores serves as magnetic reluctance permanent magnet motors, a leftwards middle magnetic pole is embedded in each odd iron core, a non-magnetic steel structure body is embedded between each middle magnetic pole and the corresponding right magnetic pole, a rightward middle magnetic pole is embedded in each even iron core, a non-magnetic steel structure body is embedded between each left magnetic pole and the corresponding middle magnetic pole, and vice versa; the polarity directions of the permanent magnets embedded in the odd iron cores and even iron cores or the polarity directions of the stacked body of the magnetic reluctance permanent magnet materials of the leftward middle magnetic poles and the rightward middle magnetic poles are the same. The stator phase ring body and the rotor phase ring body are coaxially sleeved and are assembled in a segmented mode in the axial direction. The motor has universality.

Owner:王新

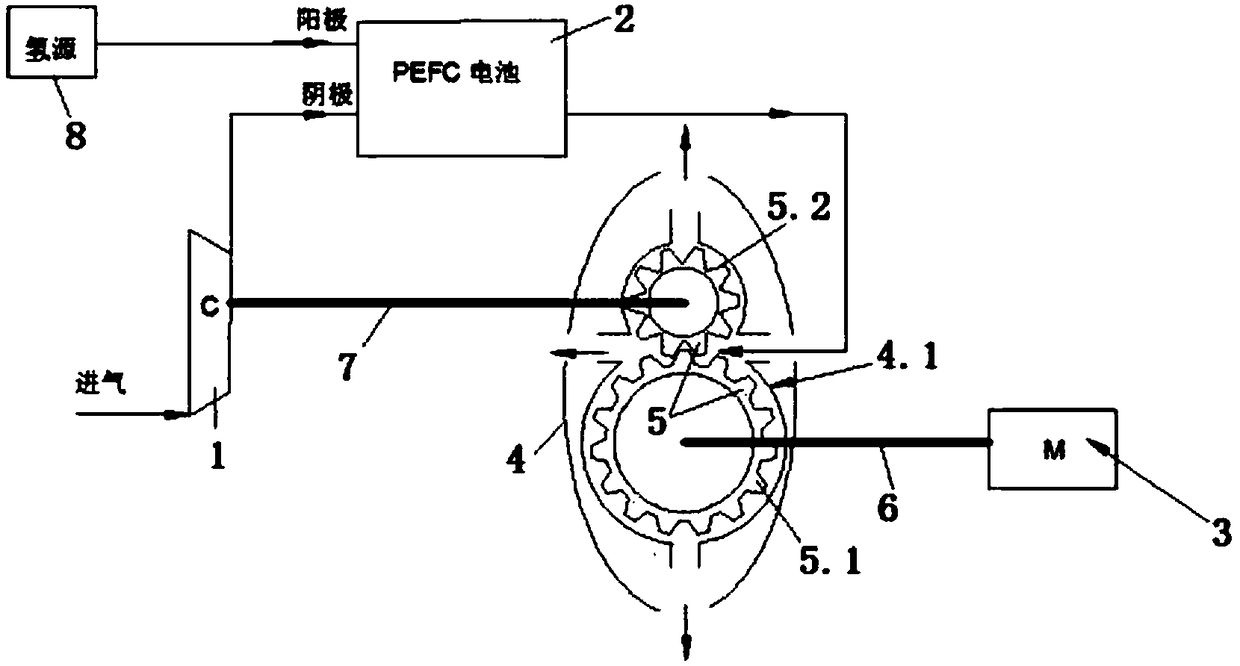

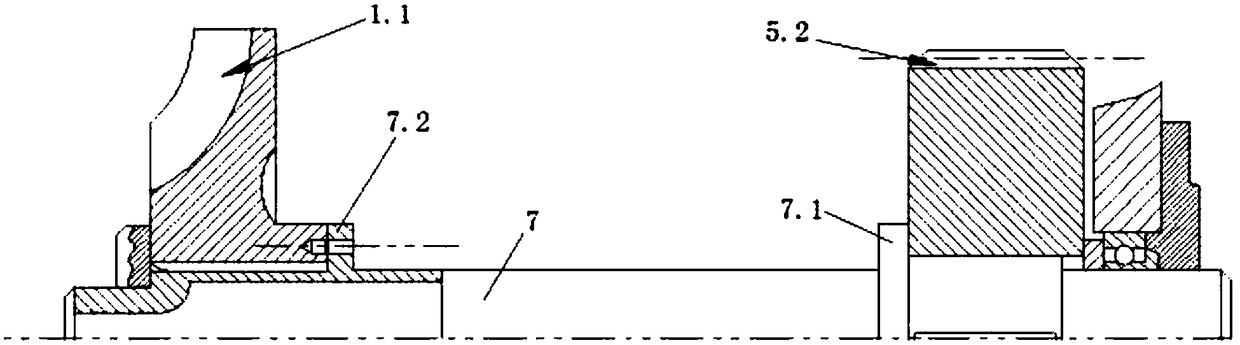

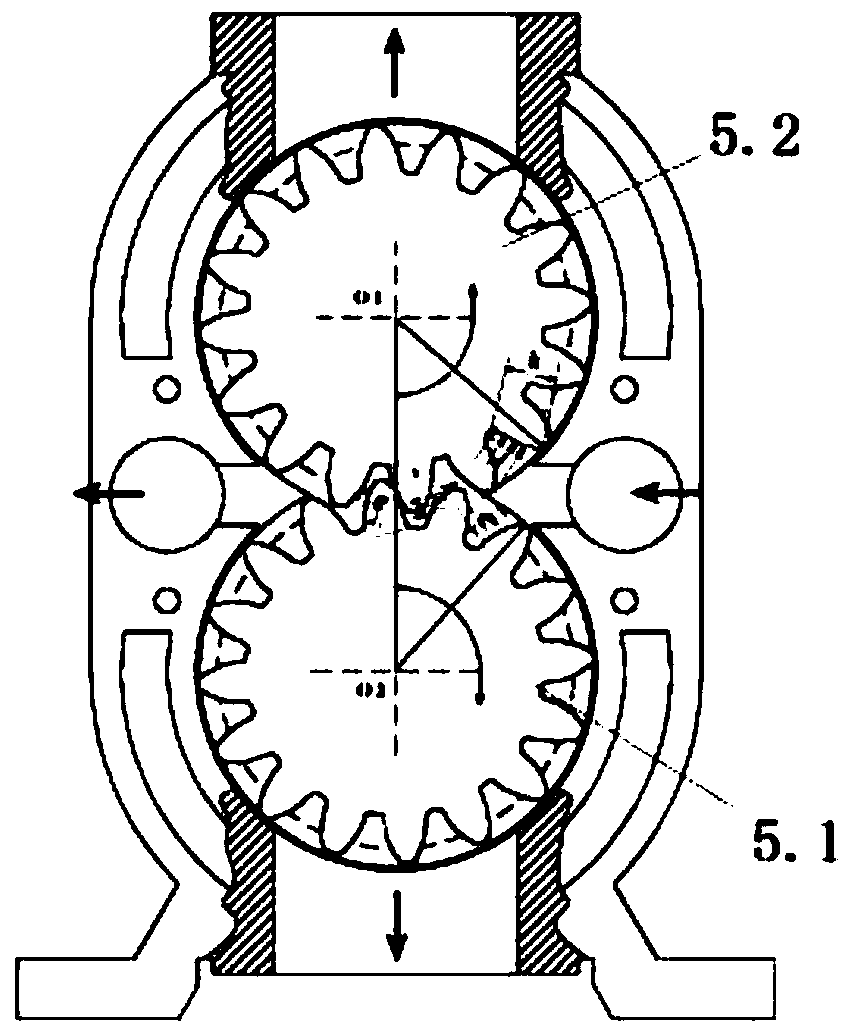

Gas compressor with high-pressure ratio for fuel cell system and energy recycling turbine device

ActiveCN108590771AReduce power consumptionLow powerEngine of intermeshing engagement typePump installationsImpellerAxial compressor

The invention discloses a gas compressor with a high-pressure ratio for a fuel cell system and an energy recycling turbine device. The gas compressor comprises a gas compressor body, a fuel cell, an electromotor, an energy recycling turbine and a hydrogen source, wherein an input end of the gas compressor body communicates with the atmosphere; an anode input end of the fuel cell is connected withthe hydrogen source through a pipeline; a cathode input end of the fuel cell is connected with the gas compressor body through a pipeline; a cathode output end of the fuel cell is connected with the energy recycling turbine through a pipeline; a transmission gear group is arranged in the energy recycling turbine; a driving gear of the transmission gear group is connected with an output end of theelectromotor through a first shaft; and a driven gear of the transmission gear group is connected with gas compressor impellers of the gas compressor body through a second shaft. According to the gascompressor with the high-pressure ratio for the fuel cell system and the energy recycling turbine device disclosed by the invention, the electromotor and the turbine are arranged aside the gas compressor, and energy discharged from an air exhaust system of the fuel cell is recycled by utilizing the turbine so as to drive the gas compressor, and therefore, power, consumed by driving the gas compressor, of the electromotor is effectively reduced, and the comprehensive efficiency of the fuel cell is effectively improved.

Owner:NAVAL UNIV OF ENG PLA

A two-wheel-leg-track compound mobile mechanism

ActiveCN108791548BImprove mobile efficiencyAchieve direct driveEndless track vehiclesTerrainDrive shaft

The invention relates to the technical field of specialized robots, in particular to a two-wheel-leg-caterpillar band compound type movement mechanism. The two-wheel-leg-caterpillar band compound typemovement mechanism comprises a movement seat body, walking wheels, swing leg drive mechanisms and swing leg assemblies. The two walking wheels are installed at the left end and the right end of the movement seat body. Walking wheel drive motors are arranged in the walking wheels. The swing leg assemblies are arranged on the front side and the rear side of the movement seat body. The two swing legdrive mechanisms are arranged on the movement seat body. The swing leg assemblies on the two sides of the movement seat body are driven by the different swing leg drive mechanisms to swing. The swingleg assemblies located on the same side of the movement seat body are connected through a swing leg drive shaft. The swing leg drive shafts are driven by the swing leg drive mechanisms to rotate anddrive the swing leg assemblies to swing. The swing leg assemblies are provided with caterpillar bands. When the walking wheels make contact with the ground to rotate, the caterpillar bands leave the ground, and when the caterpillar bands make contact with the ground to rotate, the walking wheels leave the ground. The problems that an existing robot movement mechanism is poor in maneuvering flexibility, low in movement efficiency and the like on a complex terrain are solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Ring structured travelling wave type contactless liquid medium ultrasonic wave electric machine

InactiveCN100492865CExtend your lifeSimple processPiezoelectric/electrostriction/magnetostriction machinesLiquid mediumTransformer

This invention relates to a non-contacted supersonic motor including a stator, a rotor, a reversible drive circuit and a rotation speed following control device, in which, the stator is a ring post, the outside of which is set with ring piezoelectric ceramic plates and electrodes, in which, the reversible drive circuit includes a DC supply, a square wave generator, a frequency dividing phase shifter, a power amplified circuit and a transformer boosting circuit, in which, the rotation control device includes a control signal interface circuit, a controller and a motor vibration test circuit, which includes an integral phase shift circuit, a proportion amplified circuit, a subtraction circuit and a discriminating circuit.

Owner:TIANJIN UNIV

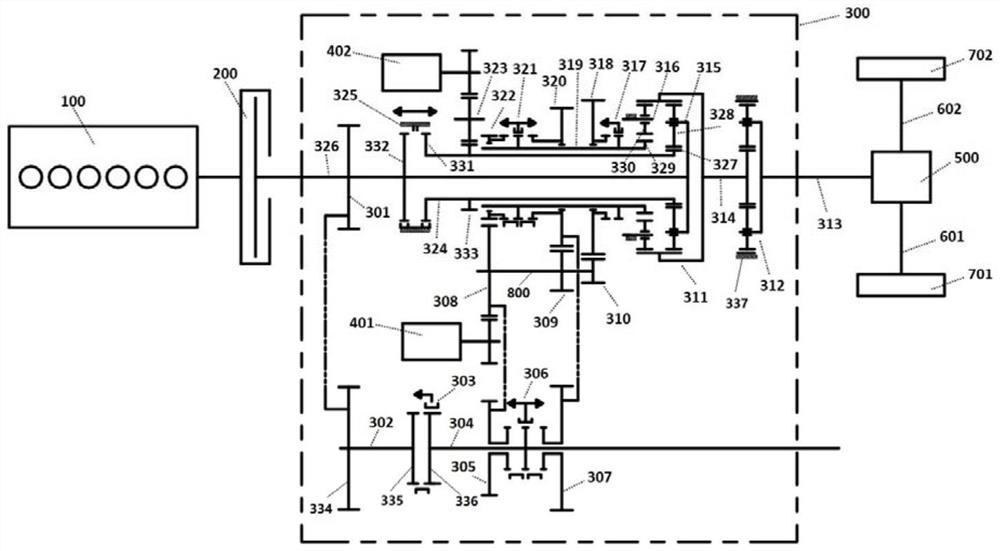

Three-gear parallel shaft type double-motor three-planet-row hybrid power system

PendingCN112224006ASmall sizeReduce peak torqueHybrid vehiclesGas pressure propulsion mountingElectric machineHybrid powertrain

The invention discloses a three-gear parallel shaft type double-motor three-planet-row hybrid power system. The system comprises an engine, a flexible connector, a shell, a center shaft, a first hollow shaft, a second hollow shaft, an output front shaft, an output rear shaft, a first planet row, a second planet row and a third planet row. The center shaft, the first hollow shaft, the second hollowshaft, the output front shaft, the first planet row, the second planet row, the third planet row, the first motor and the second motor are all arranged in the shell, the first hollow shaft is sleevedwith the center shaft, and the first hollow shaft is sleeved with the second hollow shaft. The system aims to solve the problems that a motor in an existing hybrid power assembly system is low in maximum rotating speed, large in peak torque and high in motor cost; and the axial length is large, the requirement for the arrangement space is high, and the vehicle model adaptability is poor are solved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Direct driving type rotary transverse moving device

ActiveCN103744431ASimple structureLow costPosition/direction controlElectric power transmissionMoving parts

The invention provides a direct driving type rotary transverse moving device, which comprises a rotary moving part, a transverse moving part and a signal transmission control part, wherein a wireless electric power transmission unit is used for supplying electricity to a linear motor driving controller, and in addition, position feedback units of the transverse moving part are respectively positioned on a rotary table top and rotate along with the rotation of a rotary table, so the linear motor cannot be wound by a power supplying power supply wire in the rotating process of the rotary table or cannot be wound by a feedback data wire. In addition, the device adopts a wireless network for realizing the communication between the linear motor driving controller and a main control system, and the winding of various kinds of cables is further avoided, so the complete direct driving of the linear motor without any winding on the rotary table top is realized, and good application prospects are realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Treadle -type power water purification device

PendingCN111594419AAchieve direct driveHigh power transmission efficiencyPositive displacement pump componentsFlexible member pumpsDiaphragm pumpStructural engineering

The invention relates to a treadle-type power water purification device. The device comprises a purification mechanism and a treadle-type chain wheel mechanism, wherein the purification mechanism comprises a crankshaft and at least two diaphragm pump assemblies connected with the crankshaft, piston rods of the diaphragm pump assemblies are connected with rod journals of the crankshaft, the rod journals connected with the adjacent diaphragm pump assemblies are opposite, water inlets of the diaphragm pump assemblies are connected with a sewage tank through one-way valves, water outlets of the diaphragm pump assemblies are connected with an inlet of a filter through one-way valves, a water outlet of the filter is connected with a clean water tank, and the crankshaft is in transmission connection with the treadle-type chain wheel mechanism. According to the water purification device, the novel diaphragm pump assemblies are adopted, power can be directly transferred into the diaphragm pumpassemblies, so that direct transmission of power is realized, and the power transmission efficiency and the water purification efficiency are improved.

Owner:CHANGZHOU TECHNICIAN COLLEGE JIANGSU PROVINCE

A Mechanical Flow Instantaneous Control Valve

ActiveCN106195392BMeet needsAchieve direct driveOperating means/releasing devices for valvesWater/sewage treatment apparatusImpellerGear drive

The invention discloses a mechanical flow instant control valve. A flow meter is used for metering flow and driving an impeller, a clutch and a trigger gear to rotate. When the set flow is reached, the trigger gear triggers a reset gear to move, then a driving gear is driven to move, and the driving gear and a transfer gear are engaged, so that power of a motor is transferred to the driving gear through the transfer gear. A piston rod connected to the driving gear drives a piston to move in a valve body along with the driving gear at the moment, and regeneration is achieved. According to the mechanical flow instant control valve, the pure mechanical structure principle is used for achieving the purpose of flow instant triggering regeneration; and the mechanical structure is reliable, stable in performance and low in cost, the demands of a user can be completely met, and a gap in the current market is filled up.

Owner:NANJING FOBRITE ENVIRONMENTAL TECH

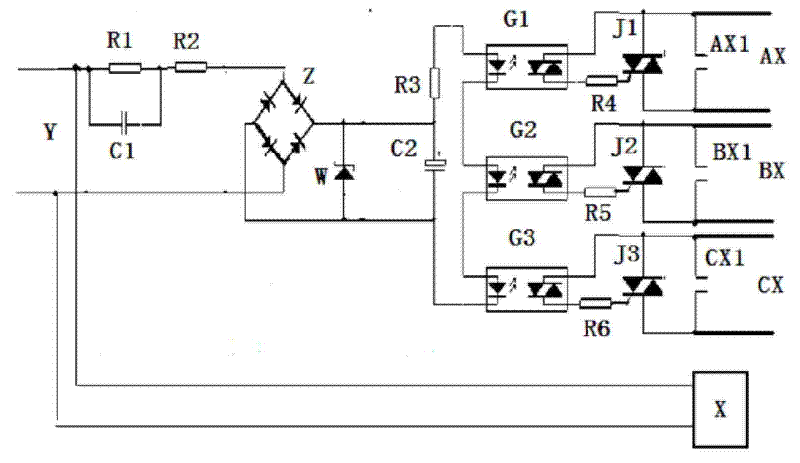

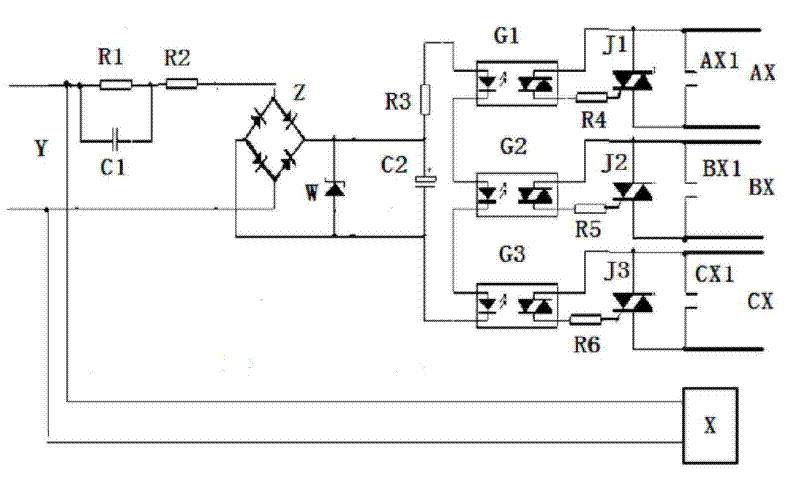

Passive switch drive controller for hybrid AC contactor based on opto-coupler

The invention relates to a passive switch drive controller for a hybrid AC contactor based on an opto-coupler, comprising a resistor (R1), a capacitor (C1), a resistor (R2), a rectifier bridge (Z), a voltage regulator tube (W), a capacitor (C2), a resistor (R3), an opto-coupler (G3), a resistor (R4), a resistor (R5), a resistor (R6), a bidirectional thyristor (J1), a bidirectional thyristor (J2) and a bidirectional thyristor (J3). The characteristics of the thyristors are sufficiently utilized; a control circuit adopts the opto-coupler to realize separation of an excitation power supply of the contactor and electricity of a three-phase main circuit and unifiedly provides a switch signal controlled by the opto-coupler for a three-phase bidirectional thyristor; and a power supply and a current transformer are not required for configuration specially, so that the hybrid AC contactor based on opto-coupling separation and direct drive of switch control is realized. The passive switch drivecontroller not only realizes non-arc starting and disjunction, but also has the characteristics of simple control circuit, small volume, low cost, high performance index, strong universality, safety,reliability and the like.

Owner:FUZHOU UNIV

Integrated outer rotor type direct drive polishing machine turntable

ActiveCN101554710BPrecision Rotary SupportAchieve direct drivePolishing machinesSemiconductor/solid-state device manufacturingGratingElectric machine

The invention relates to the technical field of polishing units, in particular to an integrated outer rotor type direct drive polishing machine turntable device. An inner ring of a supporting bearing is fixedly arranged on a rotor shaft disk; an outer ring of the supporting bearing is fixedly arranged in a bearing seat; a polishing disk is arranged on the rotor shaft disk; the supporting bearing supplies precise rotational support for the rotor shaft disk and the polishing disk; a direct drive motor stator is arranged inside the rotor shaft disk through a supporting disk; a circle grating is arranged at the lower end of the rotor shaft disk; and a reading head is arranged on the supporting disk and used for finishing speed and position feedback control of the turntable. The rotor disk integrates the rotor of a direct motor, realizes direct drive to the polishing disk by the direct drive motor, leads the turntable to be compact in structure and high in precision, and can be widely applied to precise polishing units.

Owner:HWATSING TECH

Hub switching structure

InactiveCN111376706AAchieve direct driveReduce the numberMotor depositionEngineeringStructural engineering

The invention provides a hub switching structure. The hub switching structure comprises a tire connecting piece, a rotating flange, a bearing assembly, a flange supporting shaft and a driving unit, wherein the flange supporting shaft is internally provided with an accommodating space, and the driving unit is installed in the accommodating space; an output shaft of the driving unit is fixedly connected with the rotating flange so as to drive the rotating flange to rotate around the flange supporting shaft; and the tire connecting piece is fixedly connected with the rotating flange. According tothe hub switching structure provided by the invention, the driving unit can directly drive wheels to rotate, and the hub switching structure can adapt to the wheels with different diameters.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Linear platform using compound bending vibration type biped linear ultrasonic vibrator

ActiveCN102324867BAchieve direct driveHigh positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesEngineeringUltrasound

The invention relates to a linear platform using a compound bending vibration type biped linear ultrasonic vibrator, belonging to the technical field of piezoelectric ultrasound drive. The problems of complex structure, low positioning accuracy and the like existing in the traditional linear platform driven by an electromagnetic motor are solved. The linear platform provided by the invention comprises a vibrator, two linear guide rails, two rotors, two baffle plates, a platform, a pedestal, two positioning frames, a prepressing beam, a plate spring and prepressing screws, wherein two linear guide rails are arranged on the upper surface of the pedestal in parallel, and each linear guide rail is provided with one rotor; one side end of each rotor in the direction of movement is fixedly connected with one baffle pate, and the other side end of each rotor in the direction of movement is fixedly connected with the other baffle pate; the platform is fixedly connected with the upper end faces of the two baffle plates; and the prepressing beam is fixed on the pedestal through the two positioning frames, is higher than the rotors and is located between the two rotors. The linear platform provided by the invention adopts an ultrasonic vibrator.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com