Direct driving type rotary transverse moving device

A translation device and direct-drive technology, applied in position/direction control, non-electric variable control, instruments, etc., can solve problems such as feedback or control signal cable winding, easy wear, limited stability and reliability, etc. , to achieve the effect of simple structure, avoiding winding and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, and do not have any limiting effect on it.

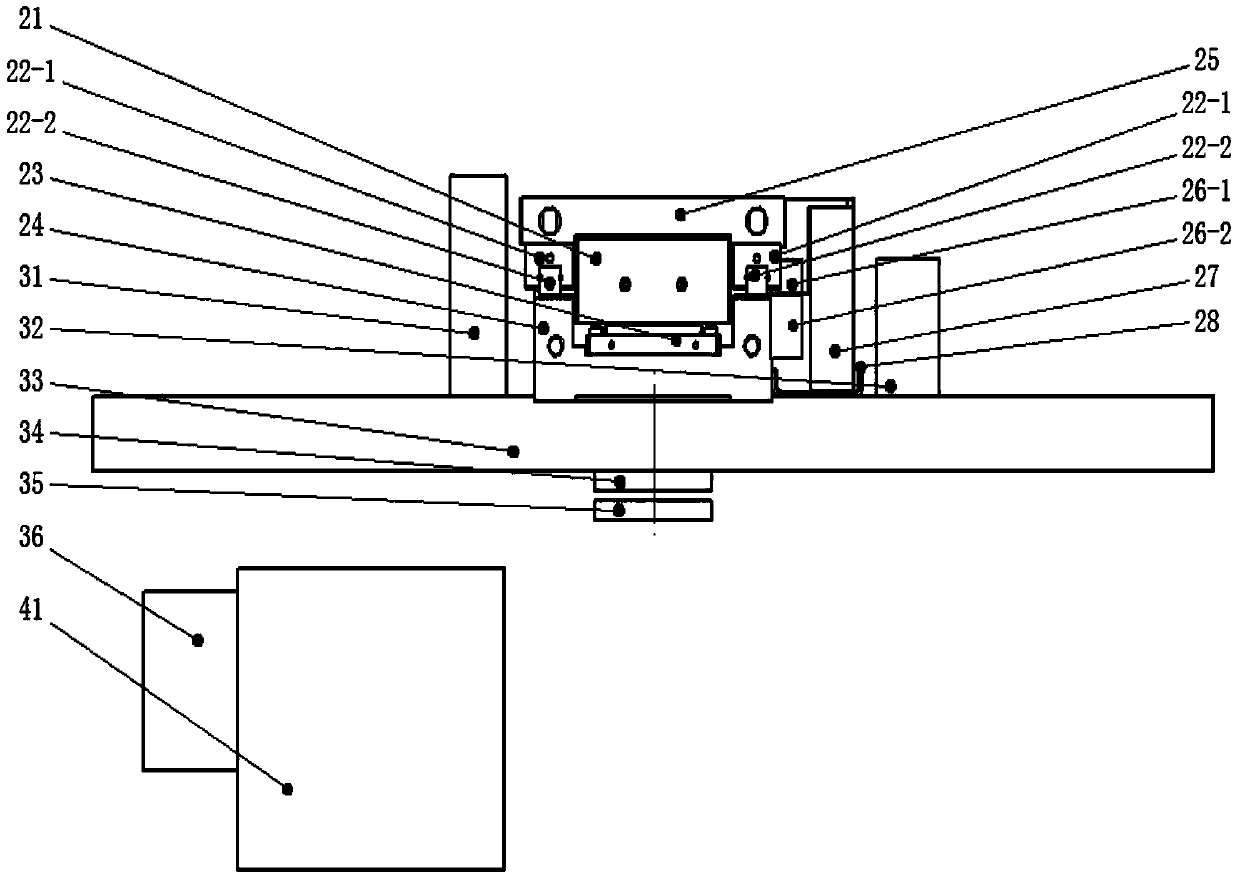

[0025] figure 1 The reference signs in are: linear motor mover 21, slider 22-1, guide rail 22-2, linear motor stator 23, base 24, translation platform 25, displacement feedback sensor moving head 26-1, displacement feedback sensor static ruler 26-2, drag chain 27, drag chain box 28, wireless network transceiver rotating end 31, linear motor drive controller 32, turntable 33, wireless power supply rotor 34, wireless power supply stator 35, wireless network transceiver fixed end 36, General control system 41.

[0026] The direct-drive rotary translation device in this embodiment is as figure 1 As shown, it includes the rotary motion part, the translational motion part and the signal transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com