Drum extrusion type washing machine

A washing machine, squeeze-type technology, applied in the field of washing machines, can solve the problems of low washing capacity, clothing wear, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

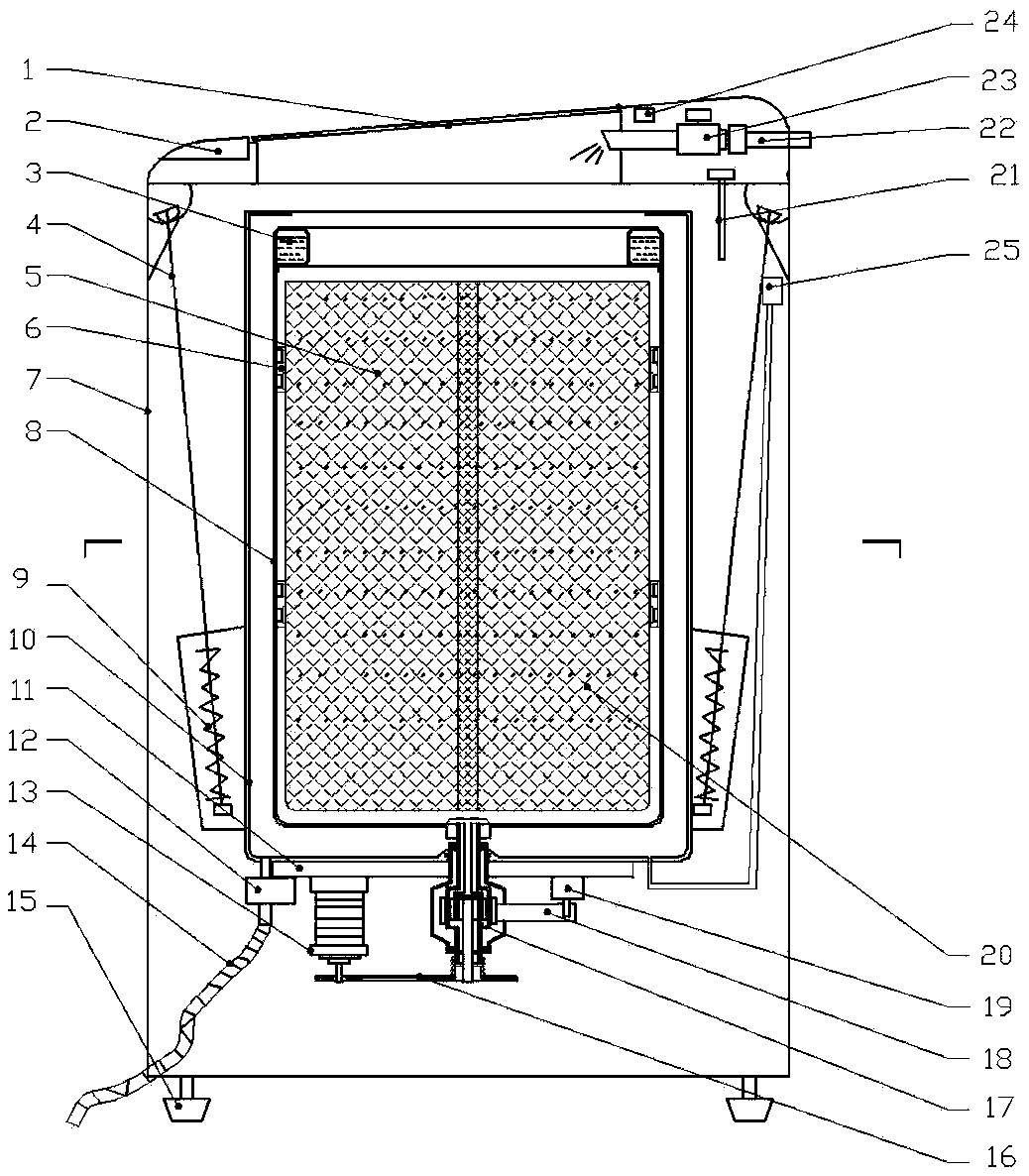

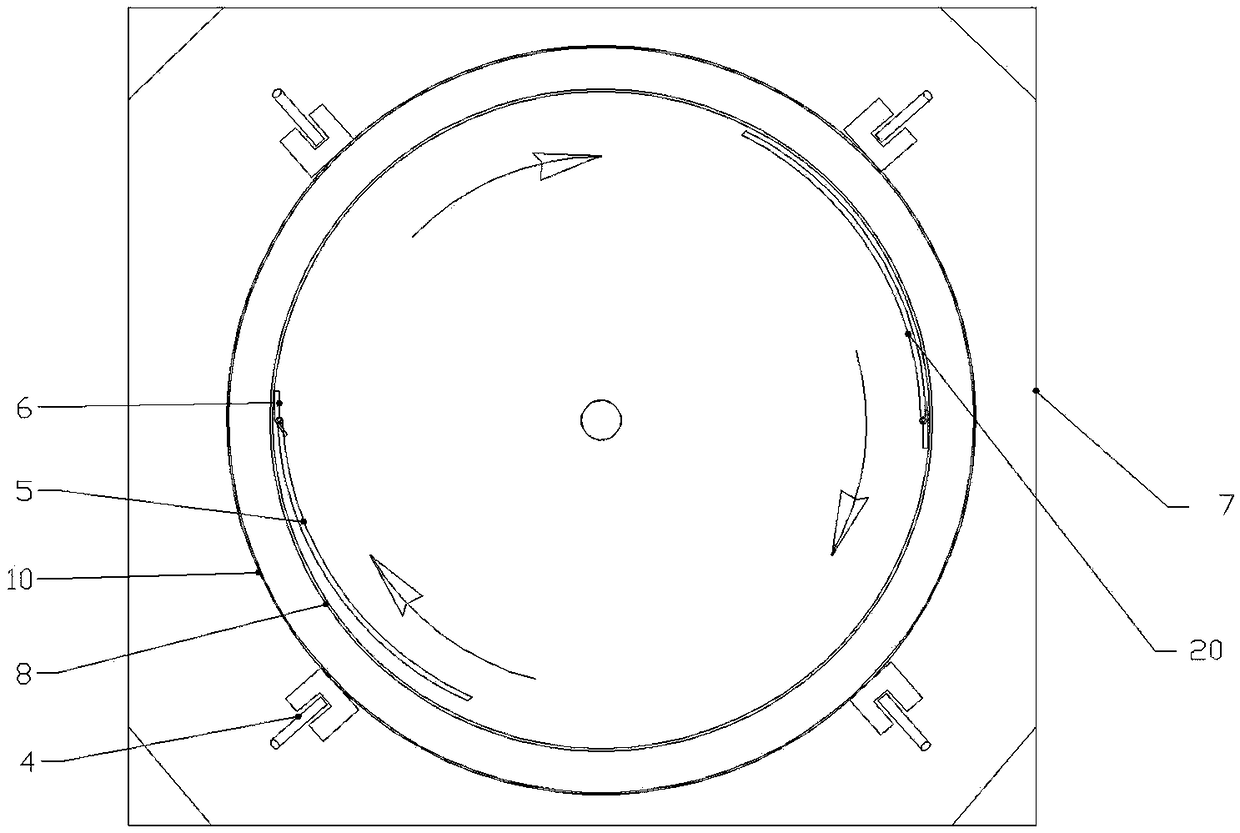

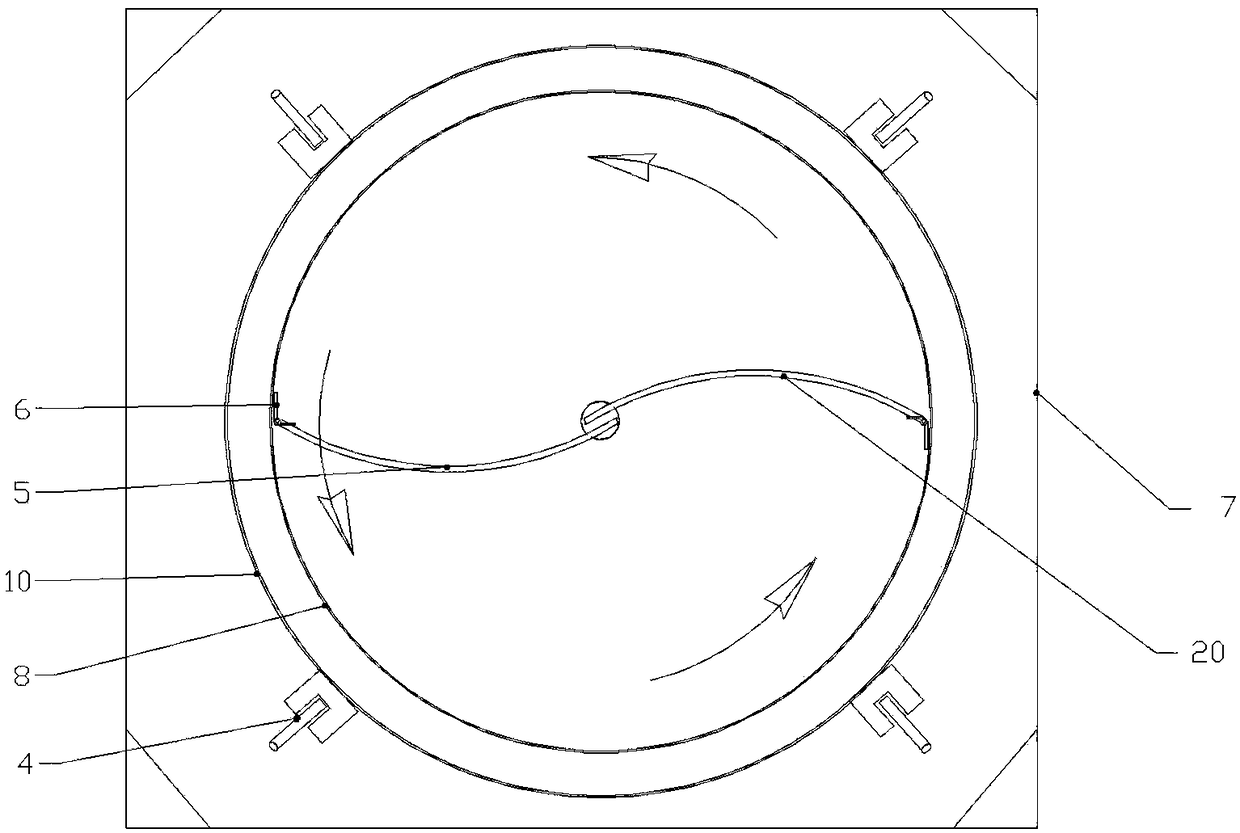

[0018] Such as figure 1 As shown, the rotary drum extrusion washing machine of the present invention mainly includes a casing, a shock absorber, a water tank, a dehydration bucket, an extrusion device, an electric control device, a water supply and discharge device, a driving device and other components.

[0019] The shell includes a washing machine upper cover 1, a box body 7, and a cuboid box body composed of feet 15. The upper cover 1 is convenient for putting in and taking out clothes, and the feet 17 adjust the level and support of the whole machine. The box body 7 is suspended by a shock absorbing device. Bucket 10, electric control device 2 is installed on the front top, and water supply solenoid valve 23, loam cake opening sensor 24, shake sensor 21, liquid level sensor are installed on the rear top;

[0020] The shock absorbing device is composed of four pull rods 4 with the same structure and with shock absorbing springs 9. One end of the pull rods 4 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com