A Mechanical Flow Instantaneous Control Valve

A control valve and mechanical technology, which is applied in the direction of mechanical equipment, valve details, valve devices, etc., can solve problems such as the inability to realize flow instant regeneration, and achieve the effects of low cost, stable performance, and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

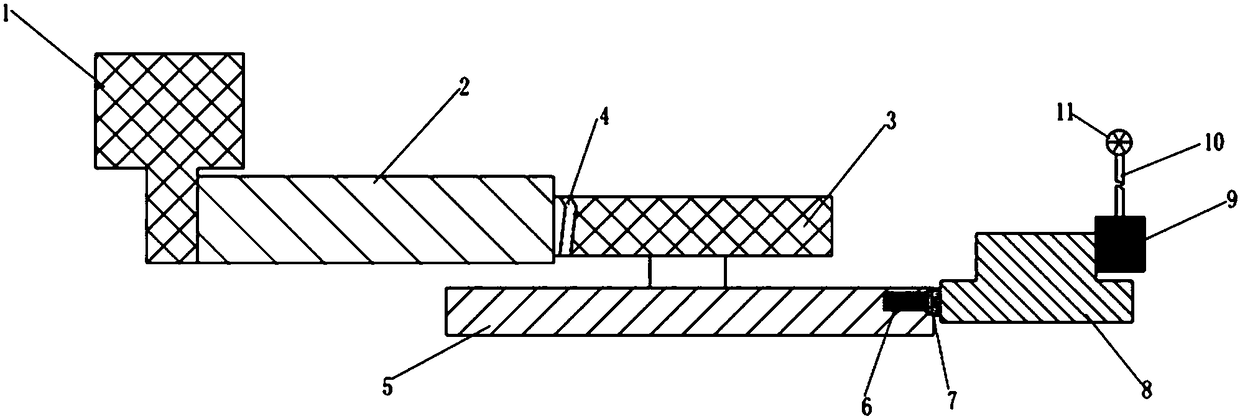

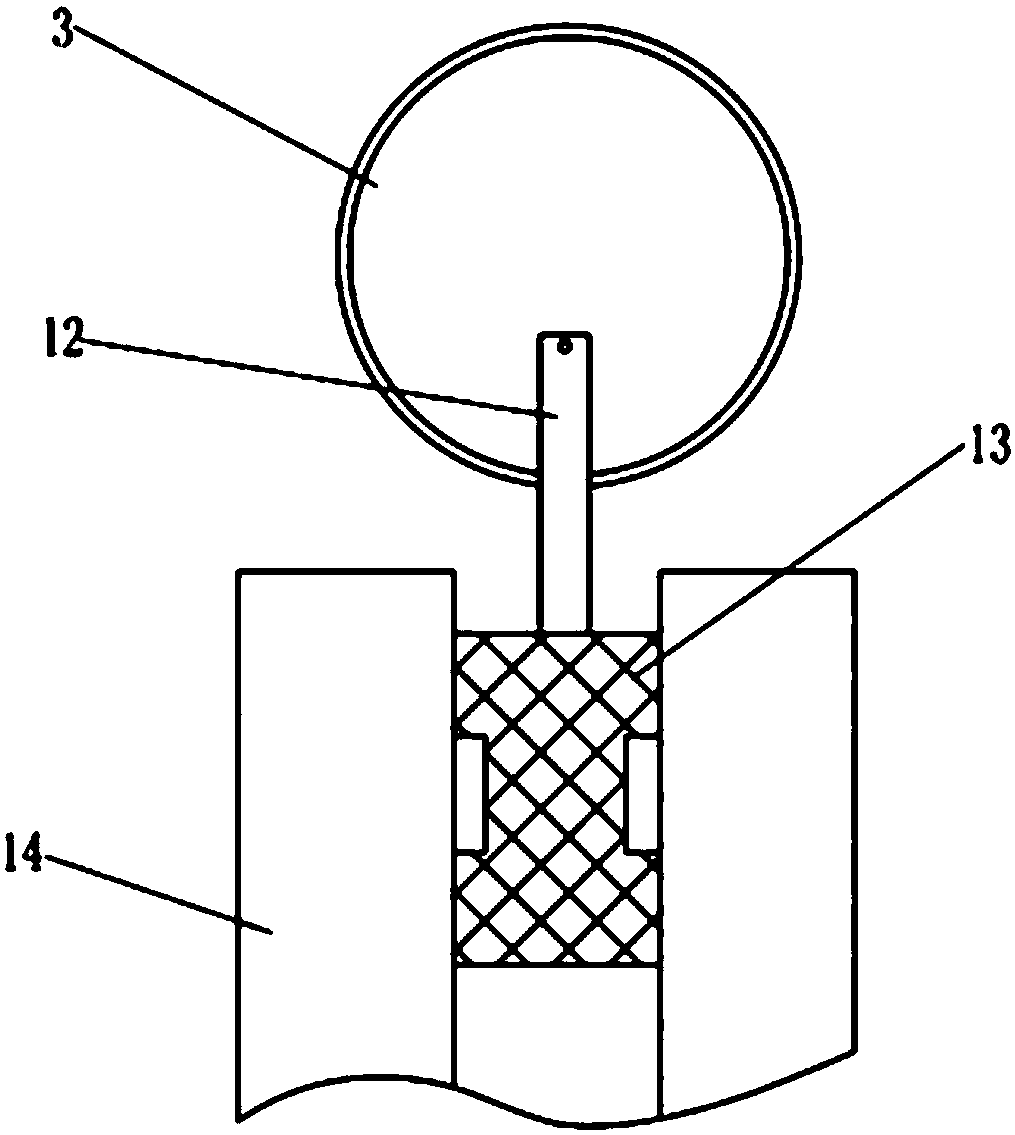

[0012] The present invention will be further explained below in conjunction with the drawings.

[0013] Such as figure 1 As shown, the motor 1 and the transmission gear 2 mesh with each other, the transmission gear 2 and the drive gear 3 mesh with each other, but the drive gear 3 has a gap 4, in the normal operating state of the control valve, the drive gear 3 is due to the gap 4 When the transmission gear 2 is disengaged, the motor 1 only drives the transmission gear 2 to rotate. The user first needs to set the regeneration flow rate of the softening control valve. When the user uses water, the water flows through the flow meter 11 and pushes the impeller of the flow meter 11 to rotate. When the flow meter 11 realizes the measurement, it also drives the flexible shaft 10 to rotate. The flexible shaft 10 is respectively connected with the flow meter 11 and a one-way clutch 9. The rotation of the impeller drives the flexible shaft 10, and the flexible shaft 10 transmits torque to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com