Integrated outer rotor type direct drive polishing machine turntable

An external rotor, polishing machine technology, applied in surface polishing machine tools, grinding/polishing equipment, electrical components, etc., can solve the problems of uncompact structure, low rotation accuracy, insufficient bearing capacity, etc. The effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

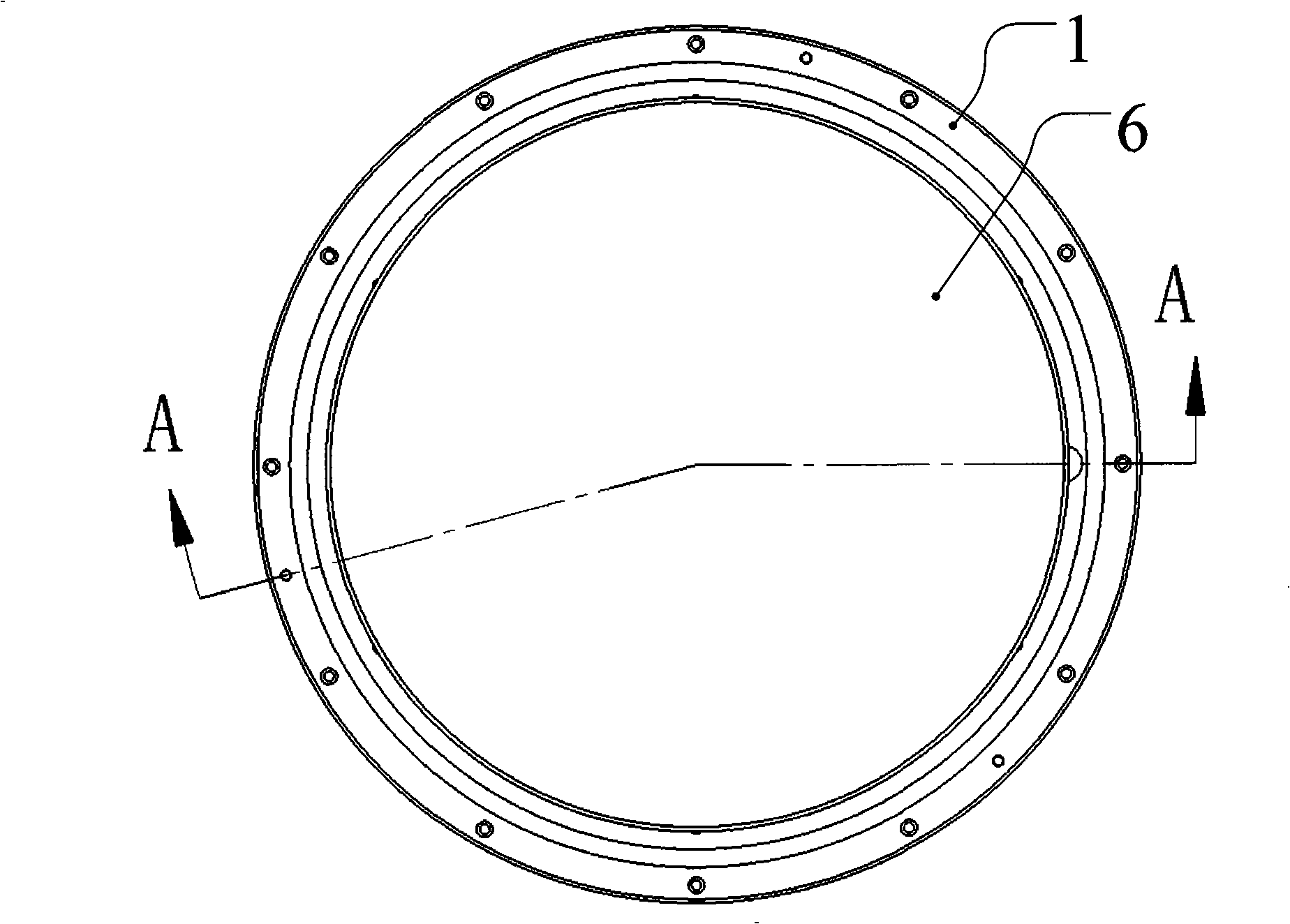

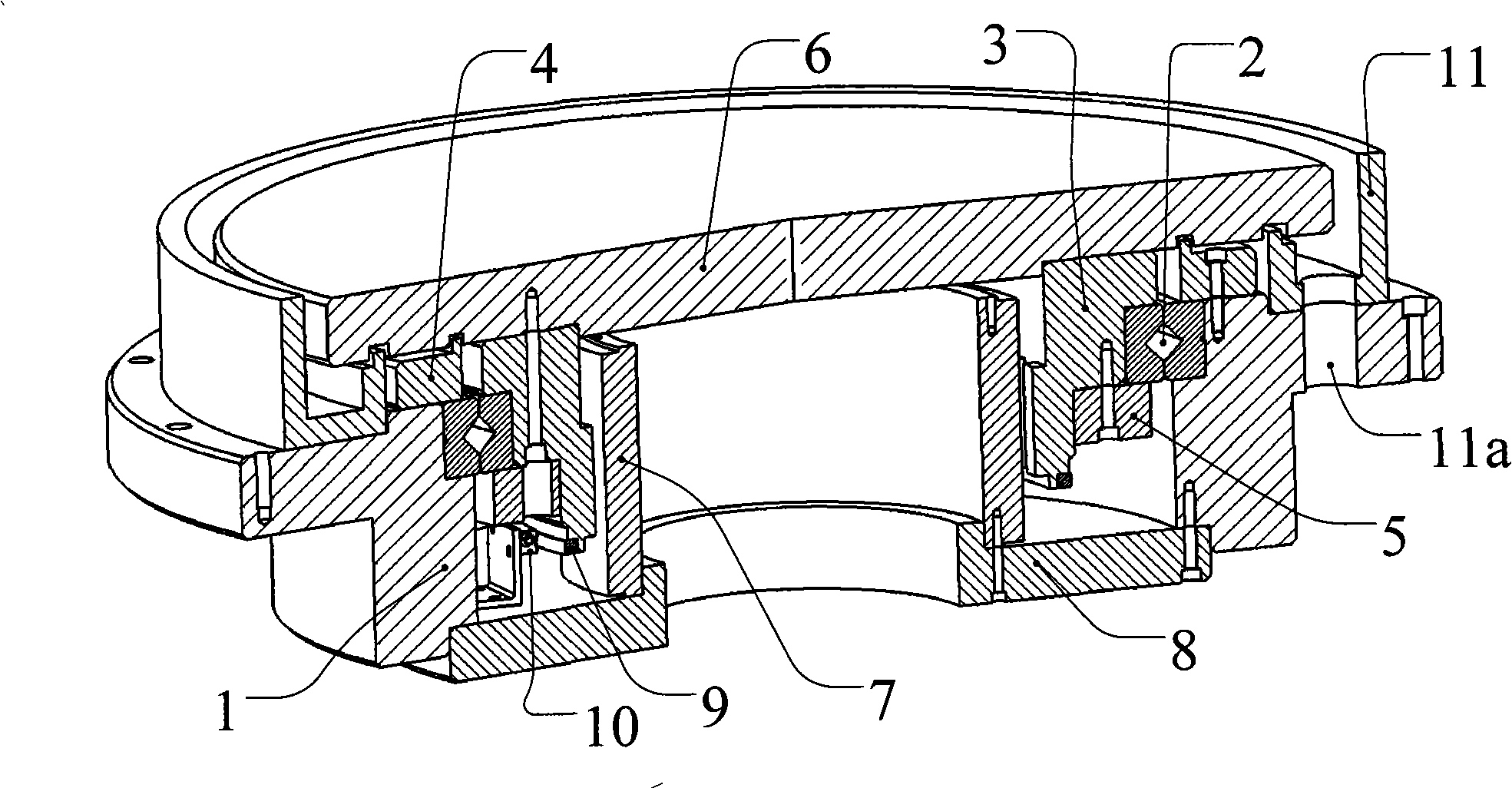

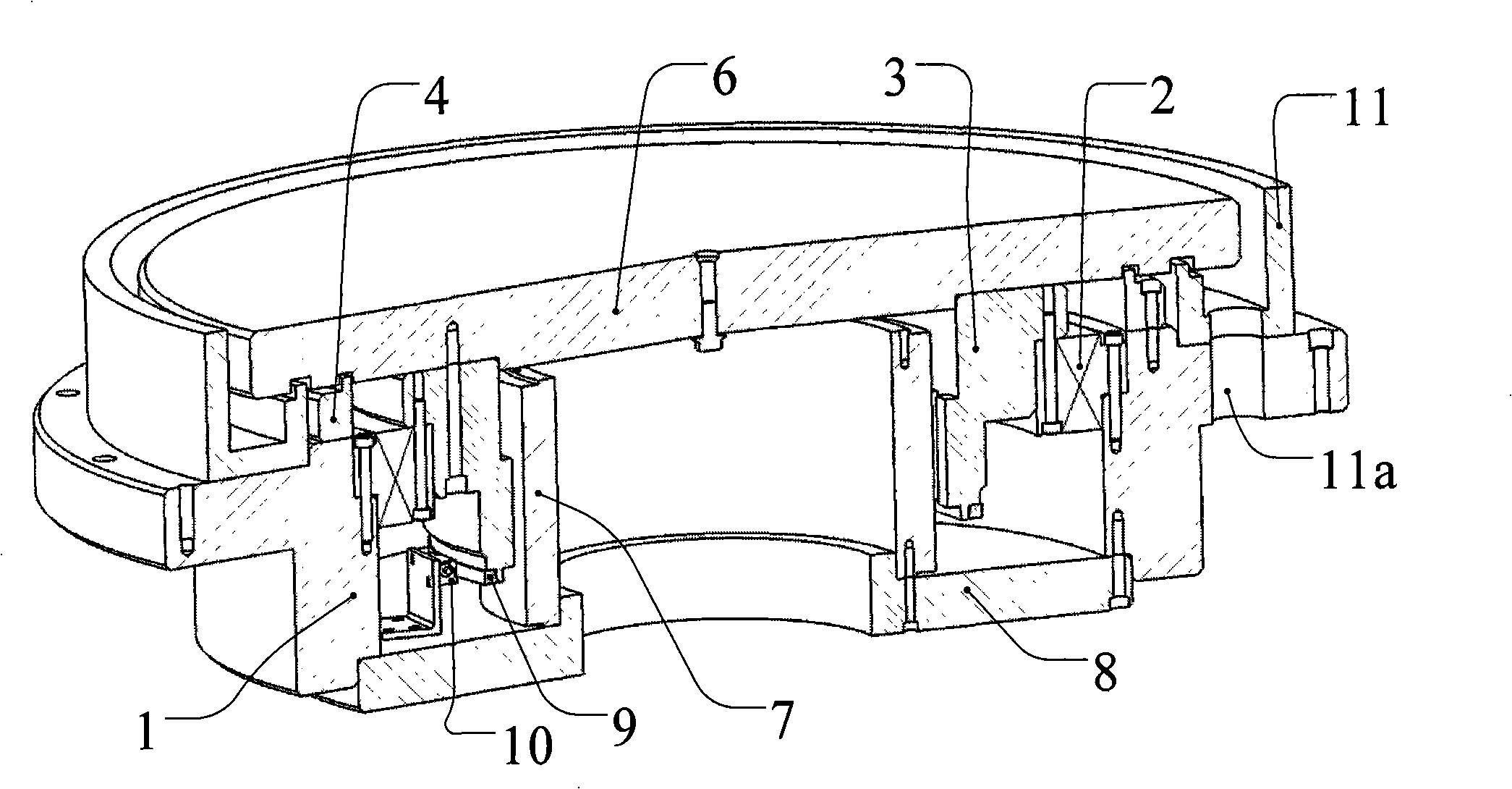

[0018] The present invention provides a turntable of an integrated outer rotor type direct-drive polishing machine. The specific implementation of the present invention will be described below with reference to the accompanying drawings.

[0019] The principle of the present invention is: the support bearing 2 is a crossed roller bearing, a double-row thrust angular contact ball bearing or a three-row cylindrical roller combined bearing, which can carry relatively large axial, radial and bending moment loads; the rotor shaft disk 3 The direct drive motor stator 7 is integrated, which is not only the rotating support of the polishing disc 6, but also the rotor of the direct drive motor, realizing the direct drive motor directly driving the polishing disc 6 to rotate; providing speed and position feedback control through the reading head 10 and the circular grating 9 ; The liquid flows down from the outer edge of the polishing disc 6 directly into the sump 11, and then is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com