Linear platform using compound bending vibration type biped linear ultrasonic vibrator

A linear ultrasonic and bending vibration technology, applied in the field of linear platforms, can solve the problems of low positioning accuracy and complex structure, and achieve the effects of high positioning accuracy, simplified mechanism, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

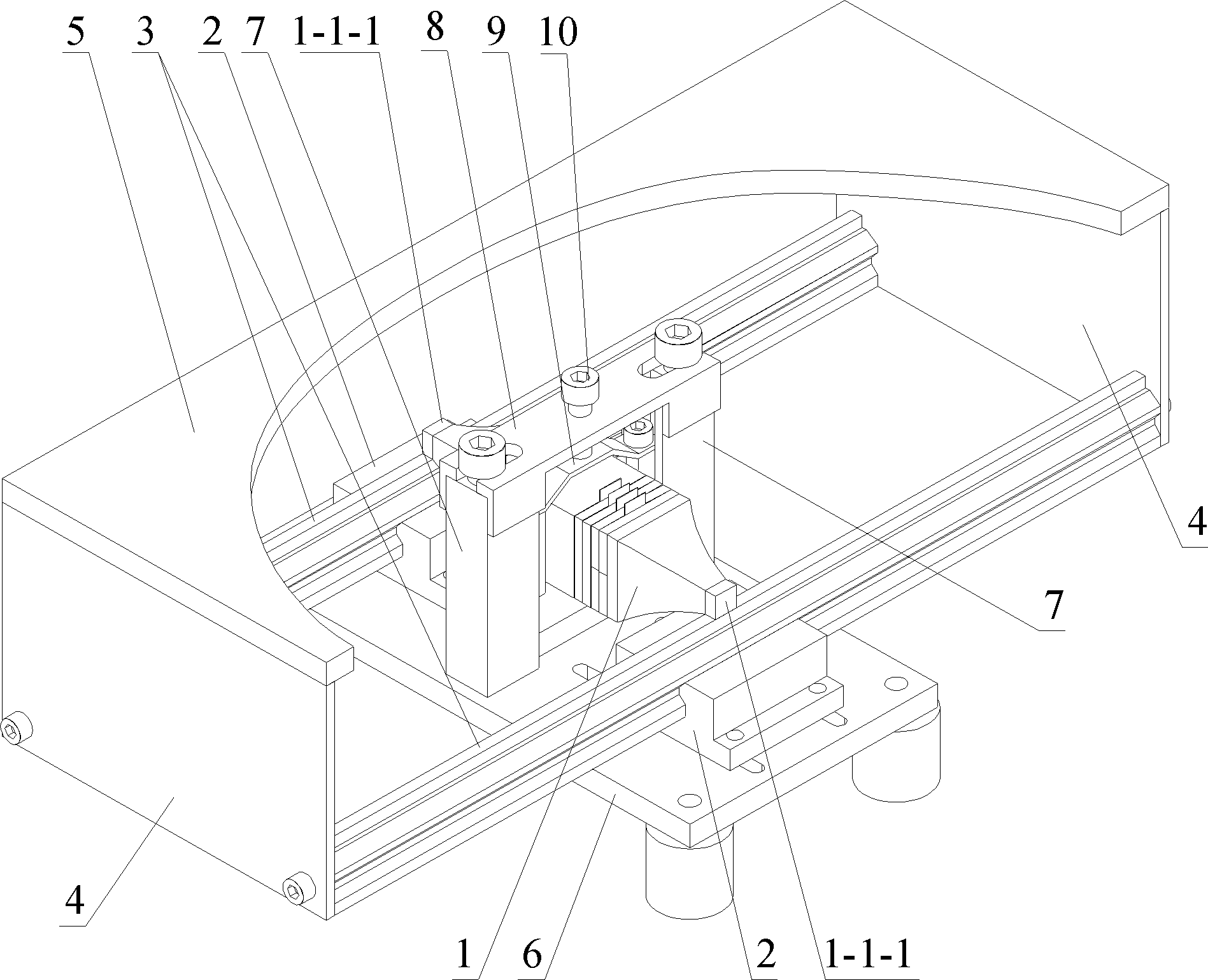

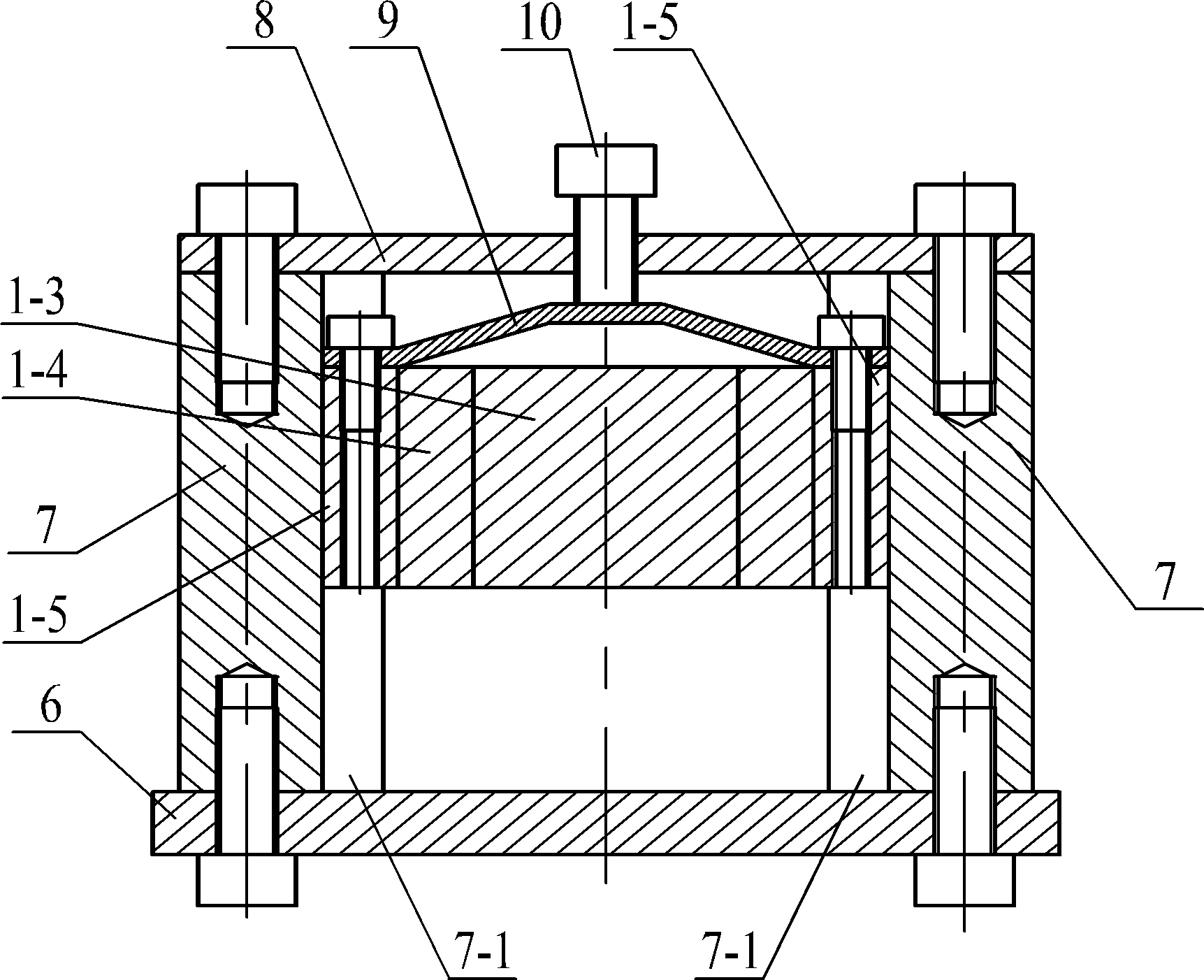

[0029] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, the linear platform using the compound bending vibration biped linear ultrasonic vibrator described in this embodiment, it includes a vibrator 1, two linear guide rails 2, two movers 3, two baffles 4, a platform 5, a base Seat 6, two positioning frames 7, preload beam 8, leaf spring 9 and preload screw 10,

[0030] Two linear guide rails 2 are arranged in parallel on the upper surface of the base 6, each linear guide rail 2 is provided with a mover 3, and one side end of the two mover 3 along the moving direction is fixedly connected with a baffle plate 4, The other ends of the two movers 3 along the moving direction are fixedly connected to the other baffle 4, and the platform 5 is fixedly connected to the upper end surfaces of the two baffles 4,

[0031] The pre-compression beam 8 is fixed on the base 6 through two positioning frames 7, the pre-compression beam...

specific Embodiment approach 2

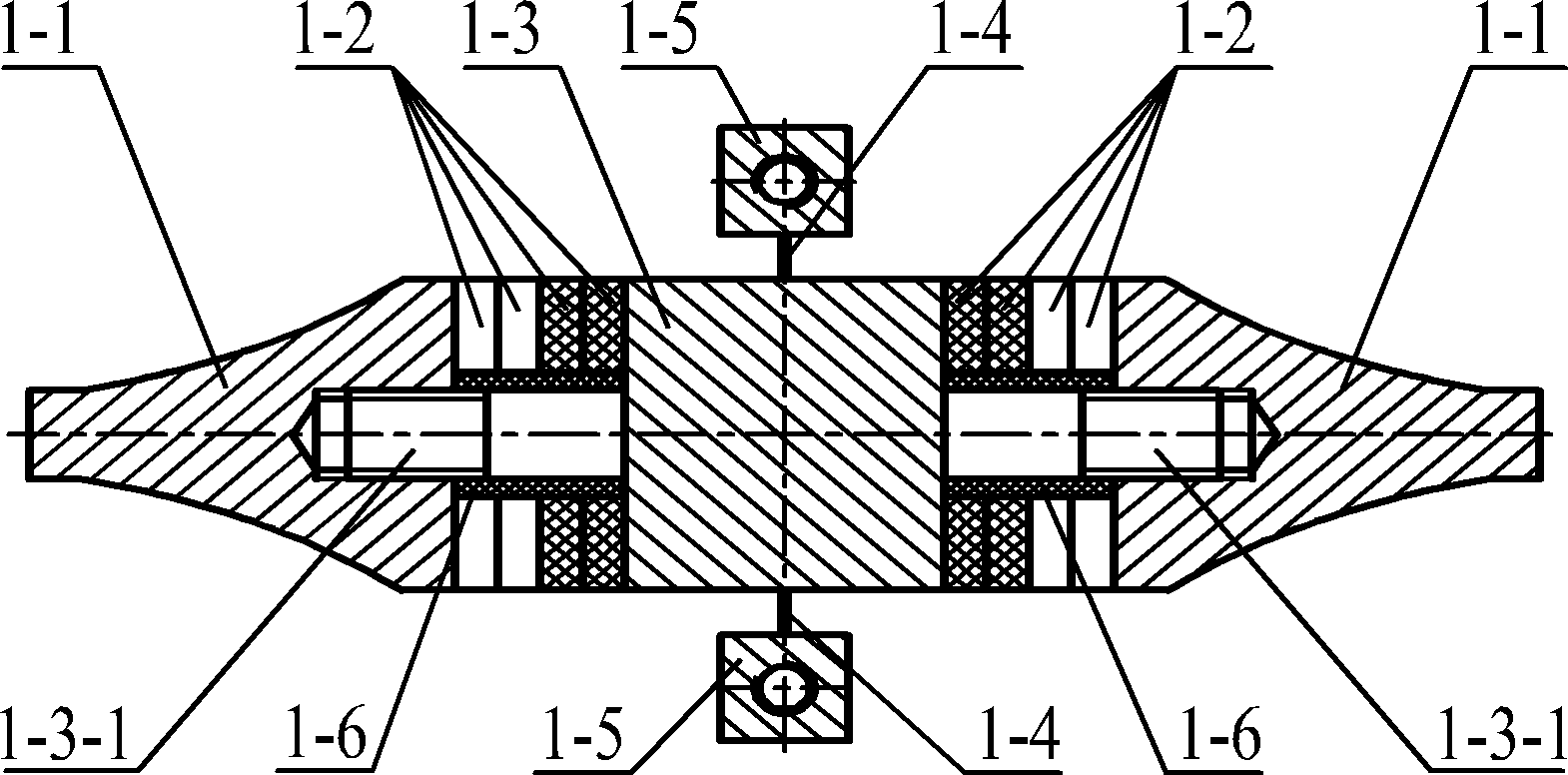

[0036] Specific implementation mode two: the following combination Figure 3 to Figure 7 Describe this embodiment, this embodiment is a further description of Embodiment 1, the vibrator 1 also includes two end caps 1-1, eight bending vibration piezoelectric ceramic sheets 1-2, flanges 1-3, two a thin-walled beam 1-4, two insulating sleeves 1-6, eight electrode sheets 1-7 and two friction sheets 1-8,

[0037] The two mounting seats 1-5 are arranged symmetrically on both sides of the flange 1-3, and each mounting seat 1-5 is fixedly connected to the flange 1-3 through a thin-walled beam 1-4.

[0038] A stud 1-3-1 is set in the center of the two end faces of the flange 1-3, and each stud 1-3-1 is covered with four pieces of bending vibration piezoelectric ceramic sheets 1-2, and the stud 1-3-1 An insulating sleeve 1-6 is arranged between 3-1 and the socket surfaces of the four bending vibration piezoelectric ceramic sheets 1-2, and between the end face of the flange 1-3 and the ...

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The cross-section of the bending vibration piezoelectric ceramic sheet 1-2 is square or circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com