High-frequency in-situ imaging fatigue tester

A fatigue testing machine and testing machine technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc., to achieve the effects of high reliability, high-speed response, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

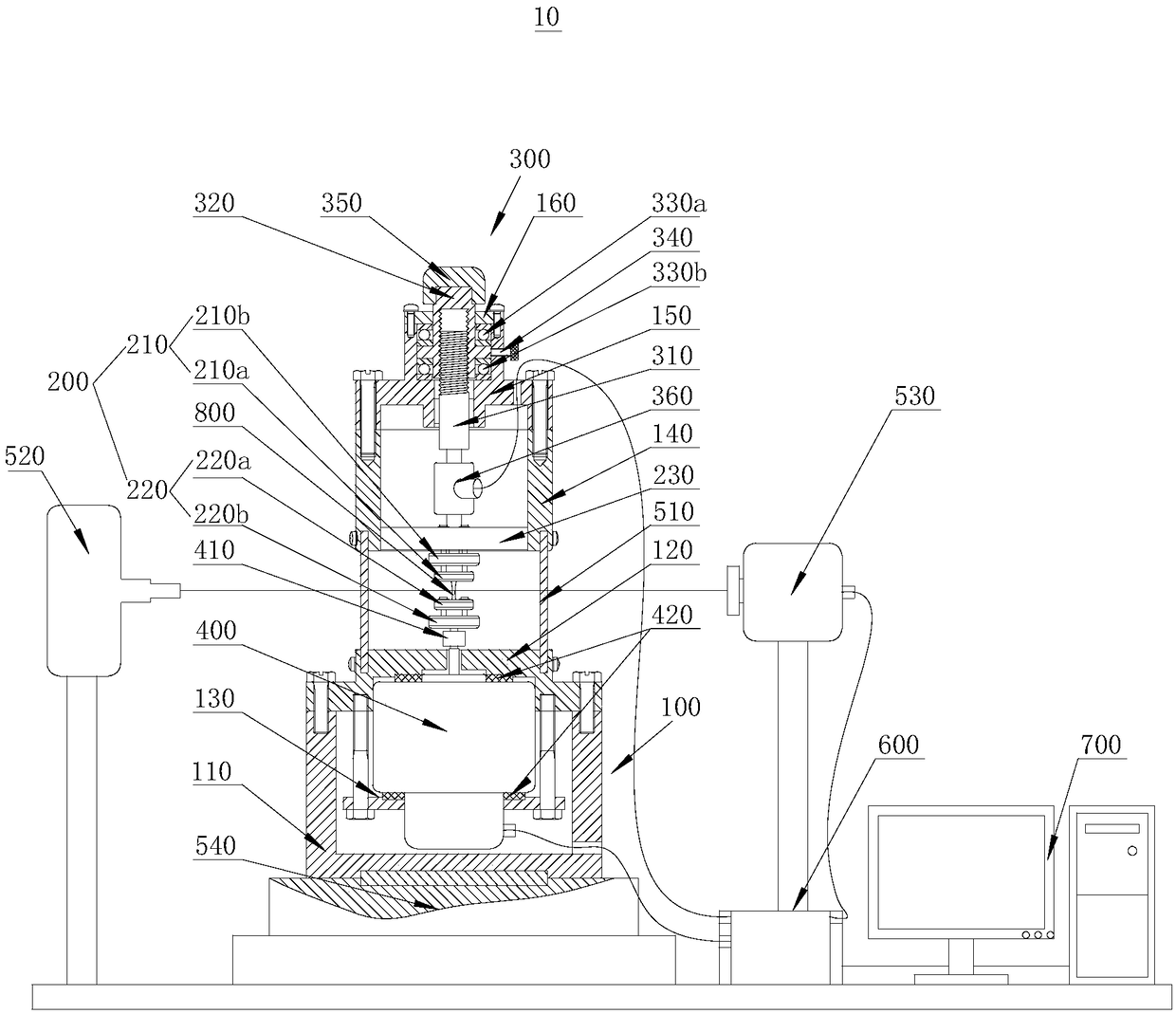

[0030] See attached figure 1 , a high-frequency in-situ imaging fatigue testing machine 10 provided by an embodiment of the present invention includes: a testing machine body 100 , a sample clamping mechanism 200 , a preset force loading mechanism 300 and a voice coil motor 400 .

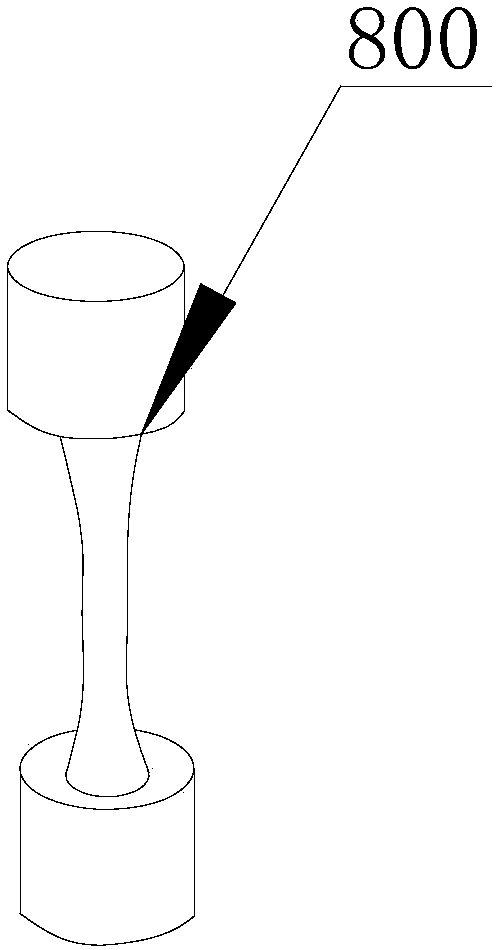

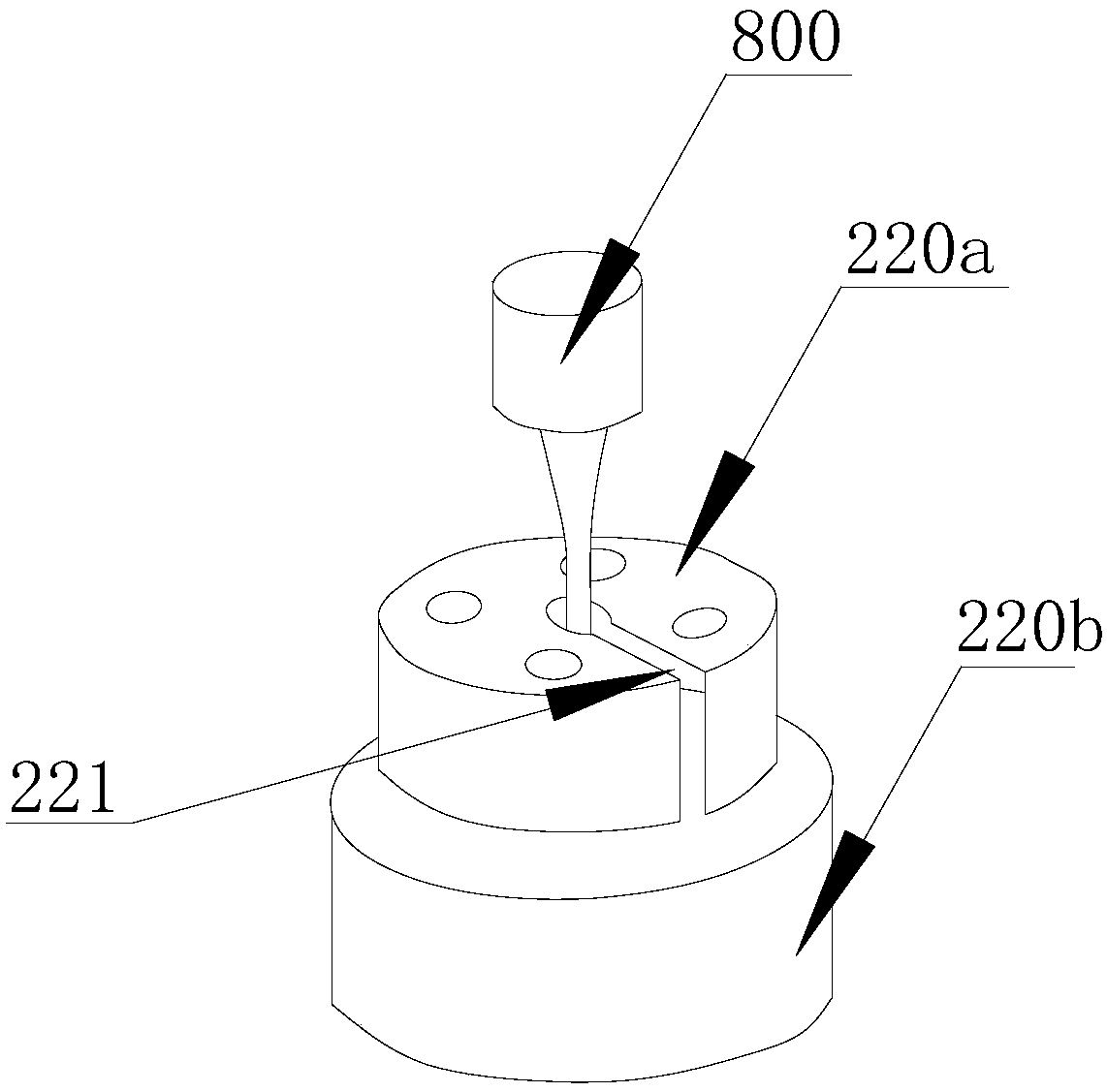

[0031] Wherein, the sample clamping mechanism 200 is used to clamp and fix the sample 800 , and the sample clamping mechanism 200 includes a first clamping assembly 210 and a second clamping assembly 220 which are oppositely arranged. The preset force loading mechanism 300 is disposed on the side of the first clamping assembly 210 of the sample clamping mechanism 200 , and is used to apply a preset tensile force to the sample 800 . The voice coil motor 400 is fixedly connected to the testing machine body 100 , and the actuating shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com