Patents

Literature

60results about How to "Improve transmission stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

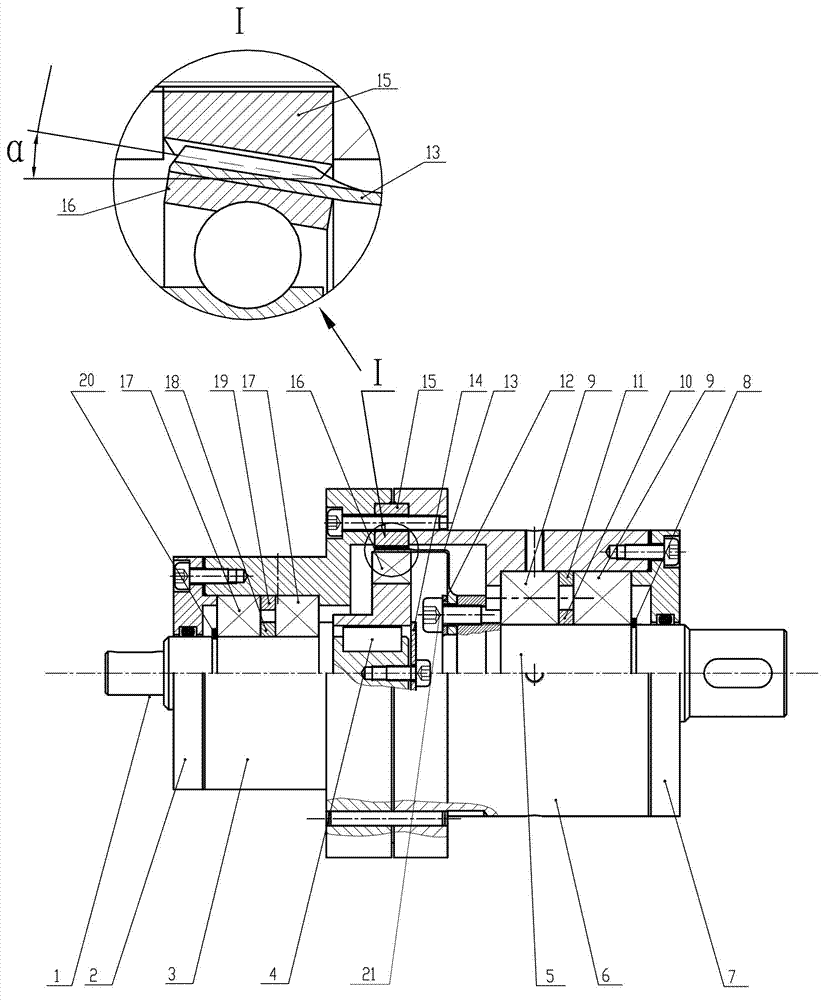

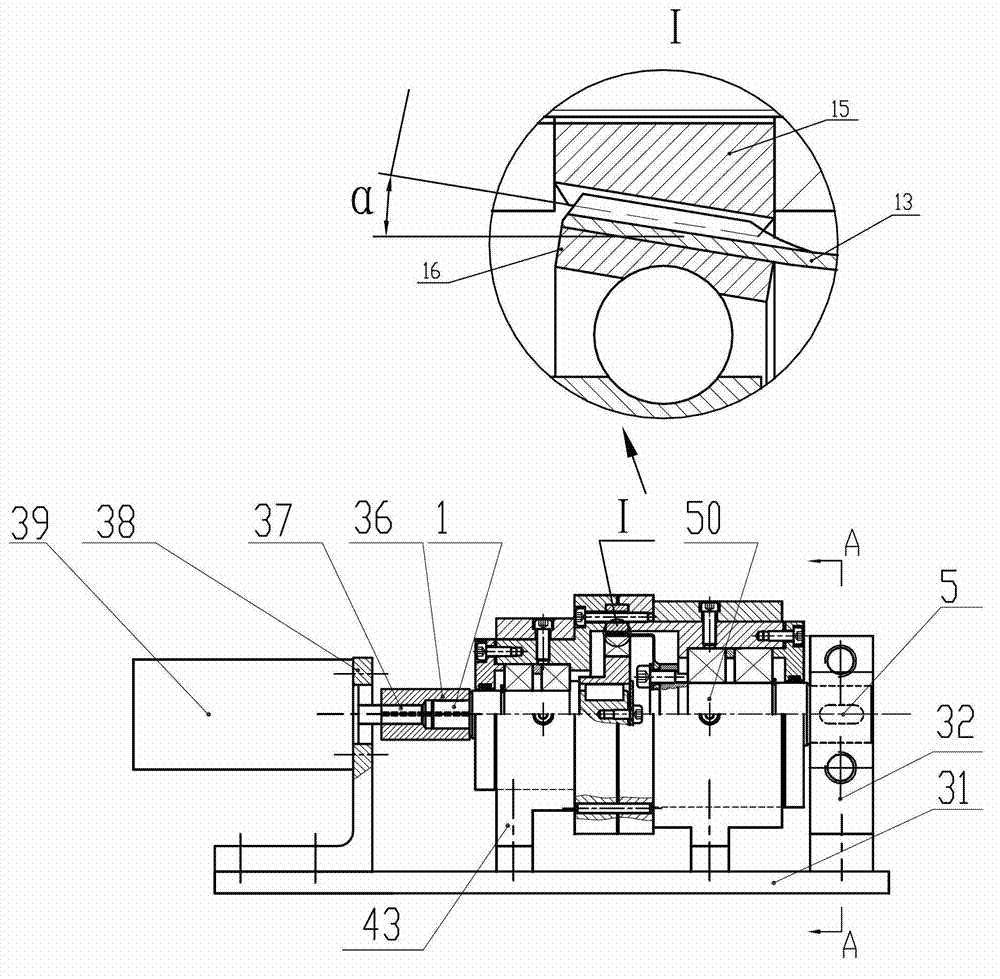

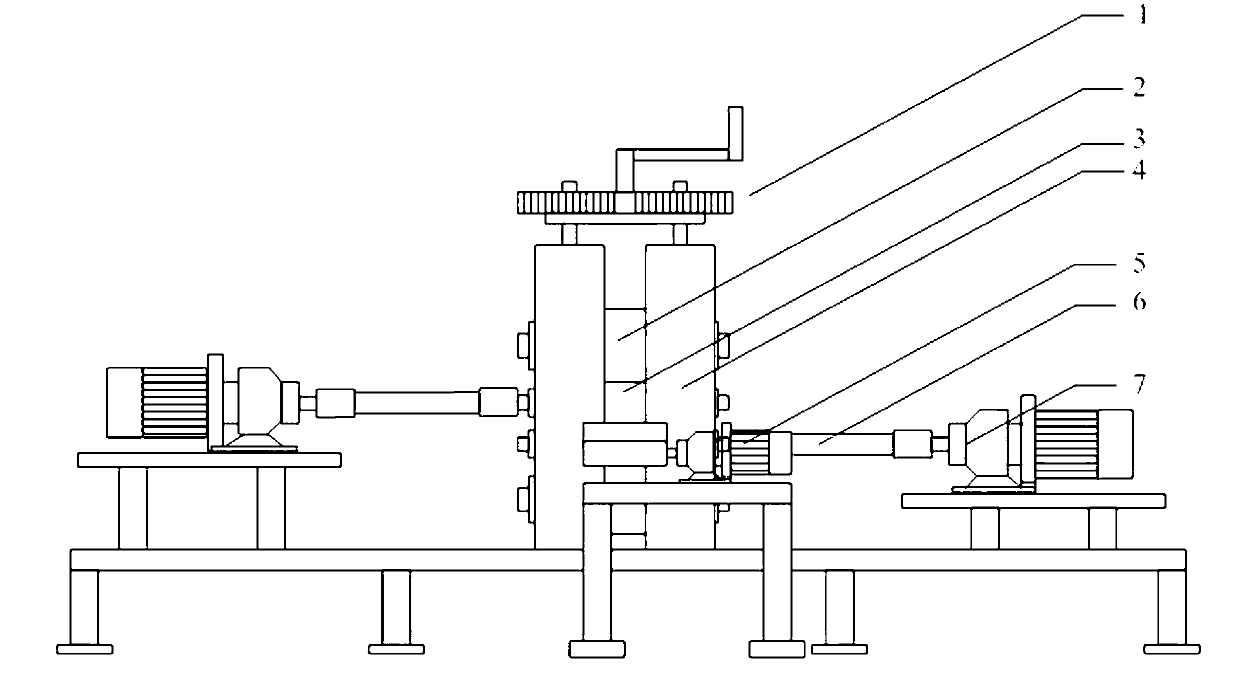

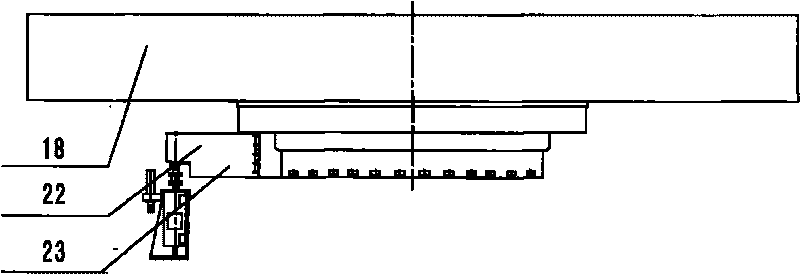

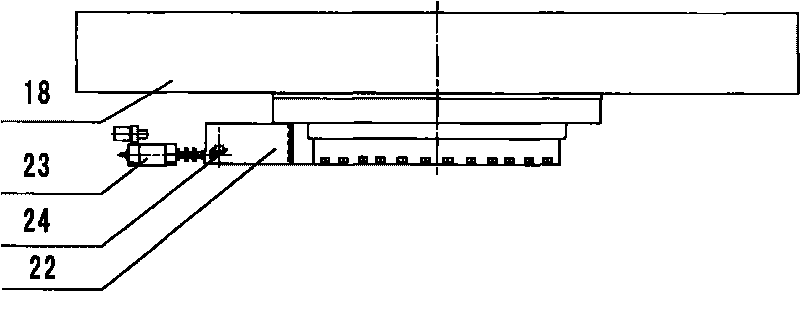

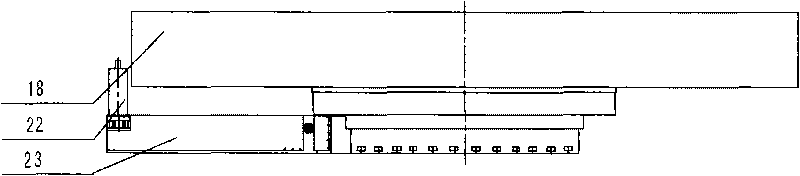

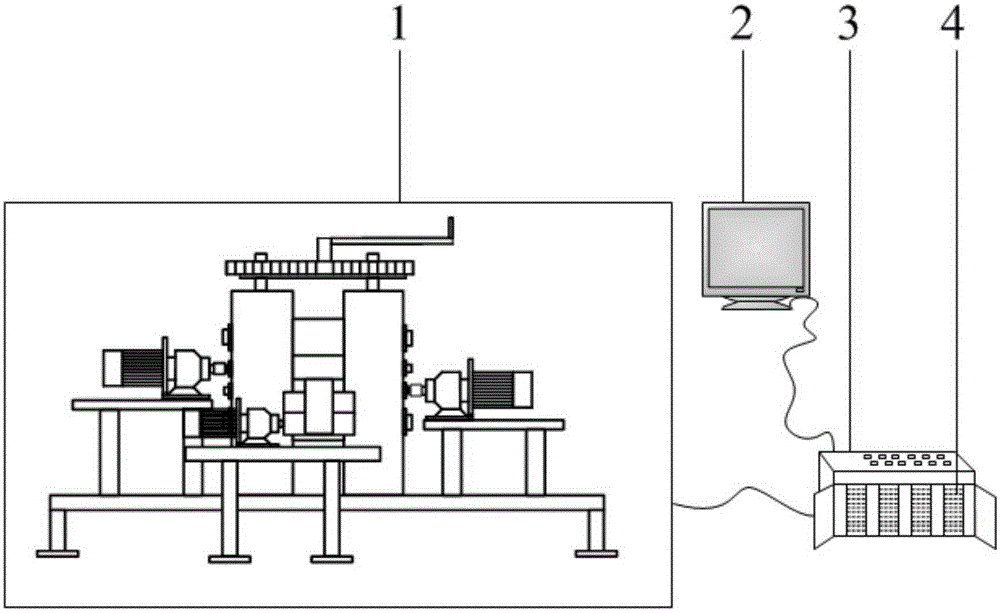

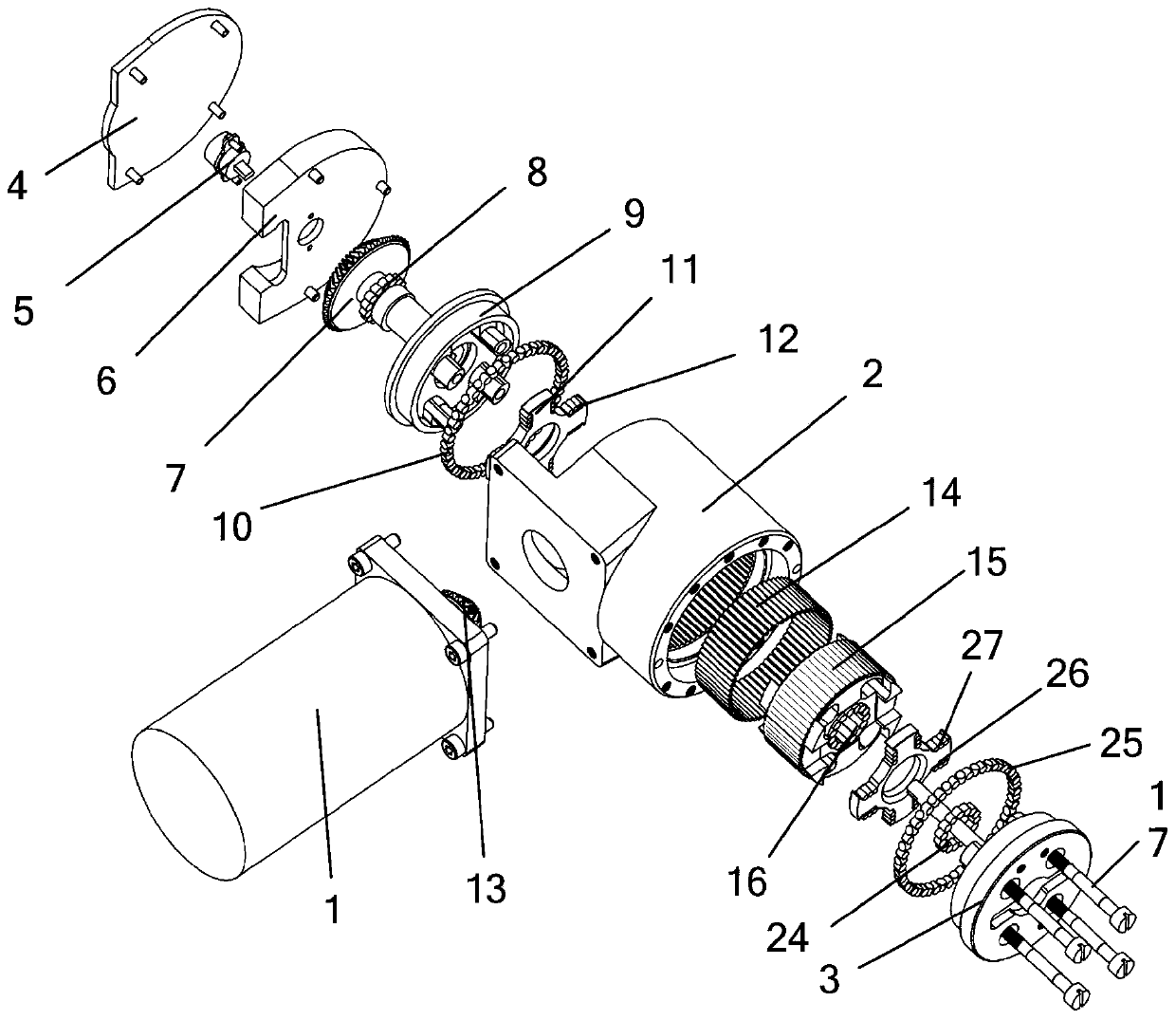

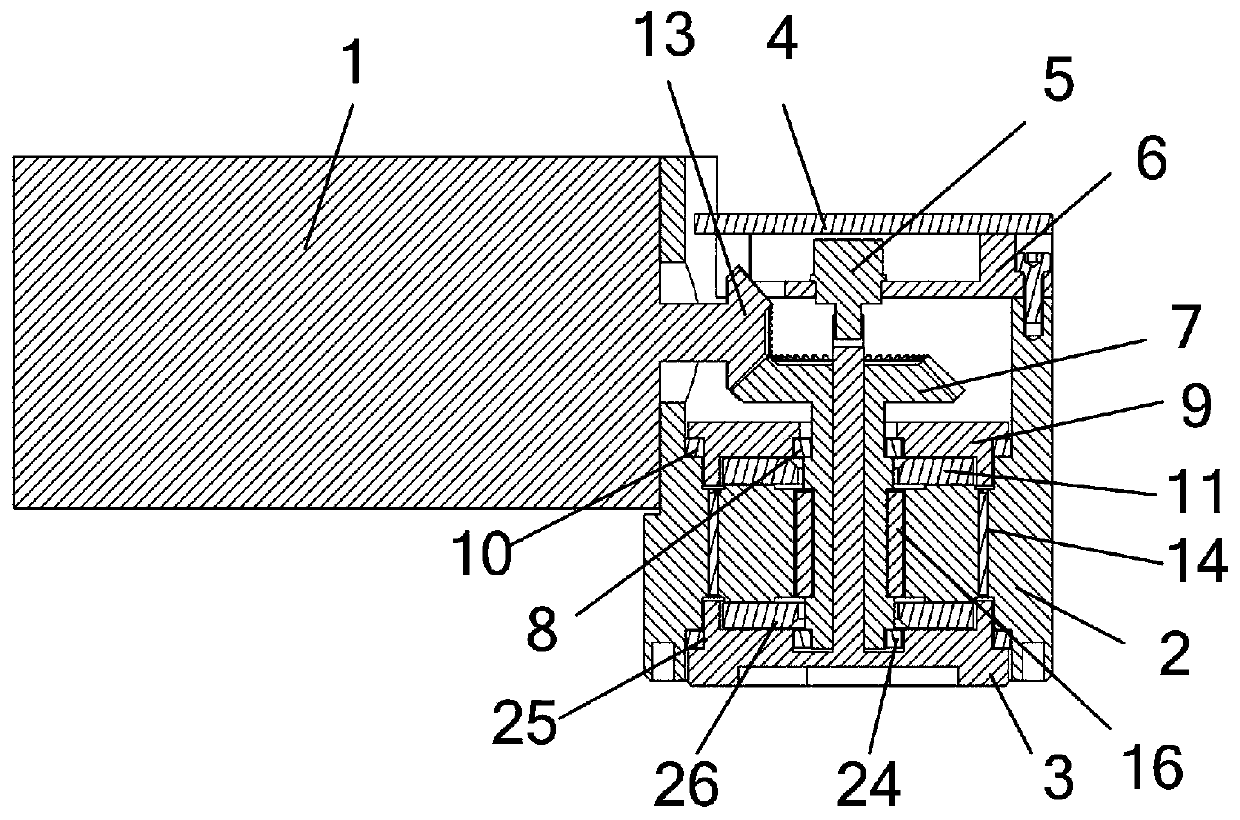

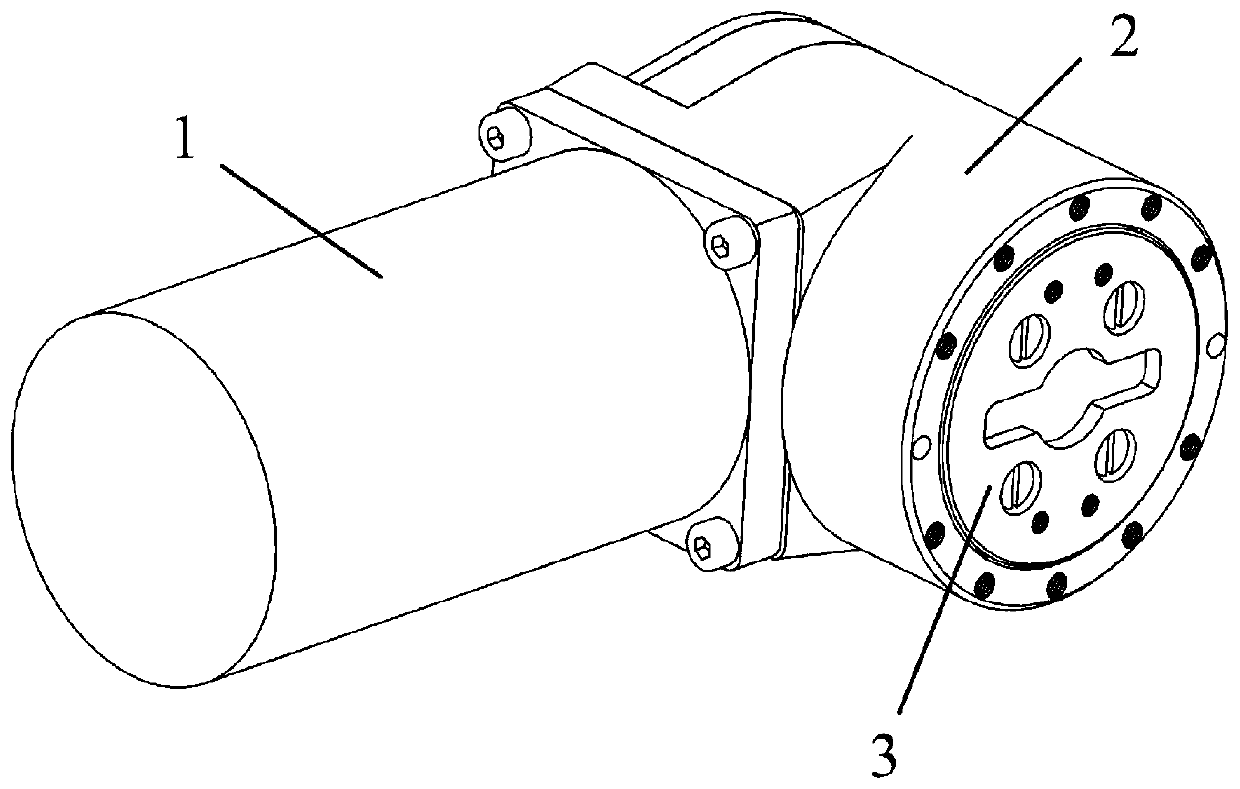

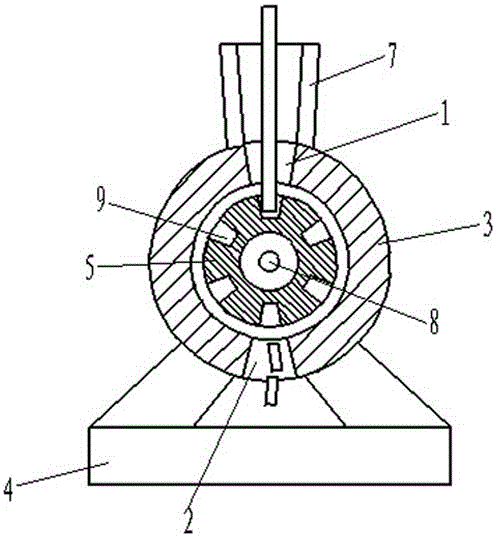

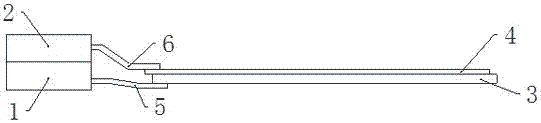

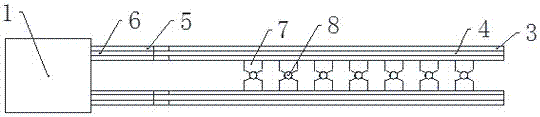

Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

ActiveCN102777546AEasy meshImprove transmission stiffnessMachine gearing/transmission testingToothed gearingsDiameter ratioEngineering

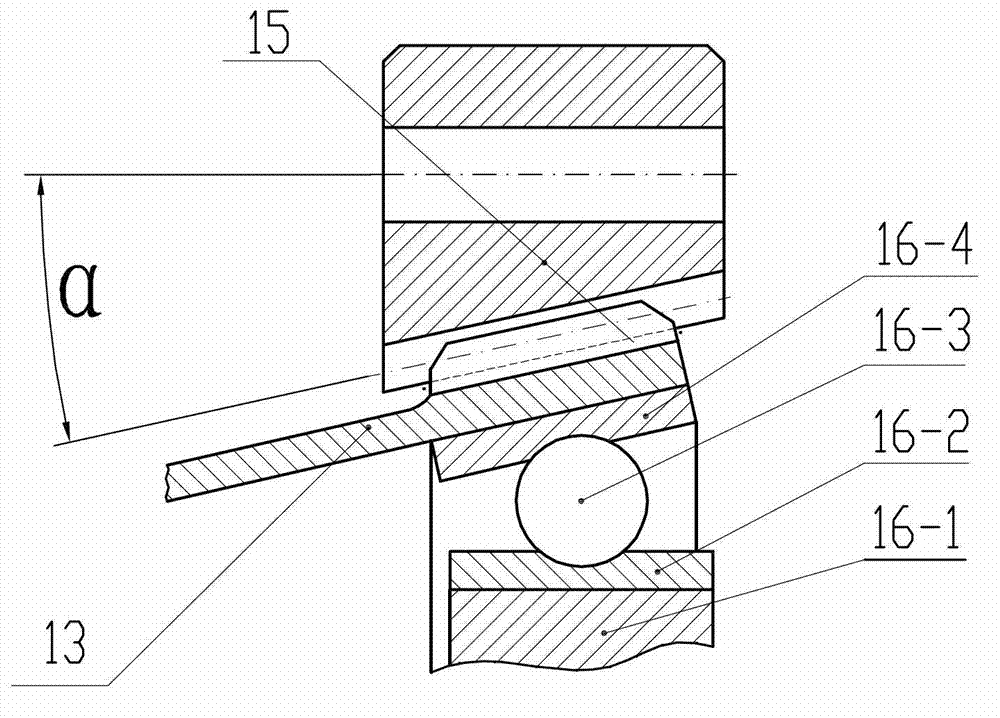

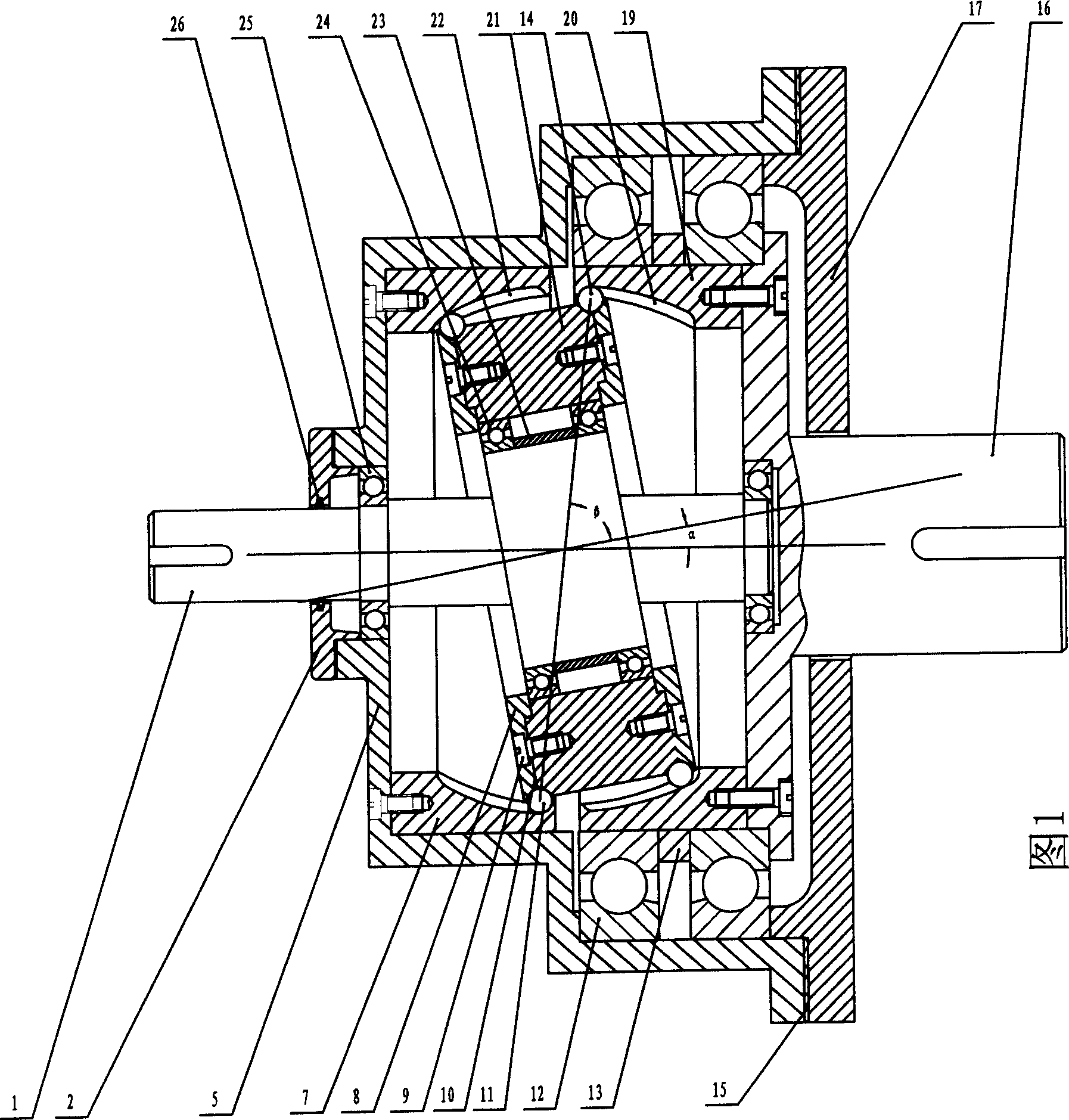

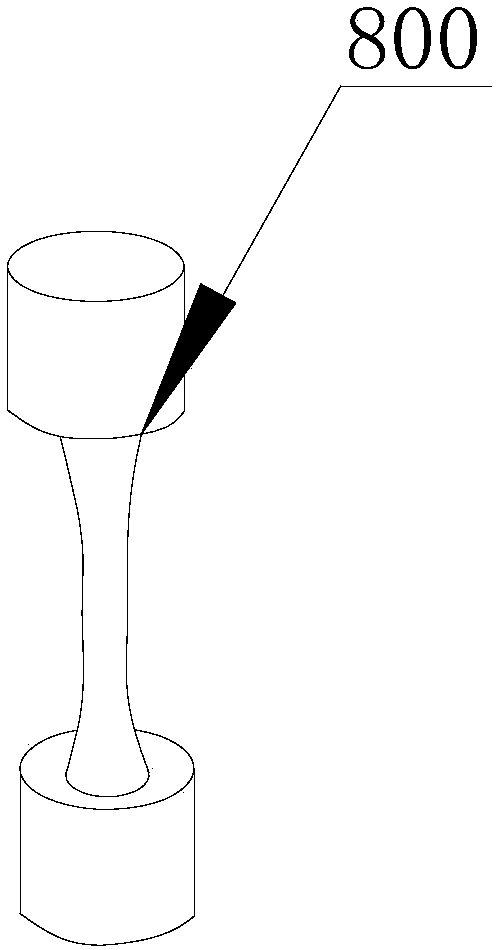

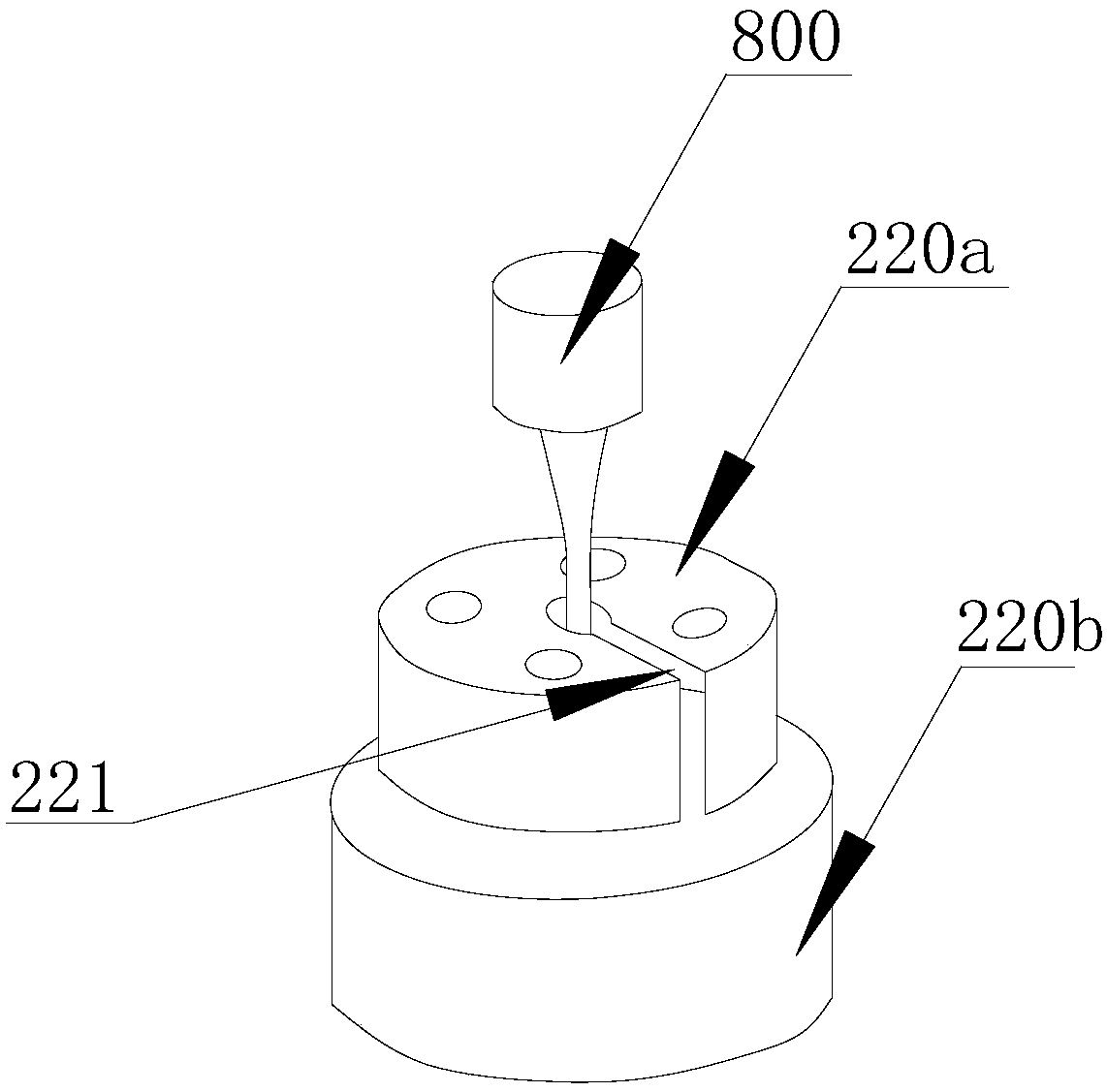

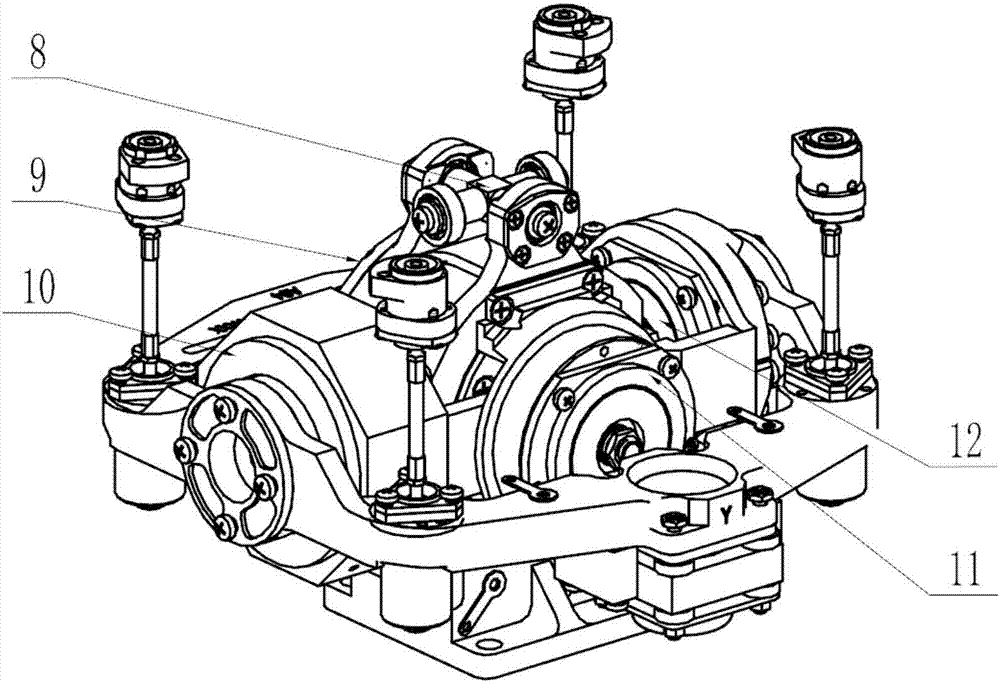

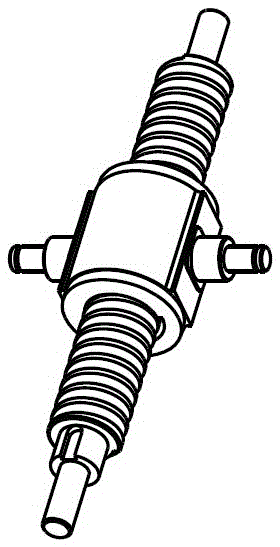

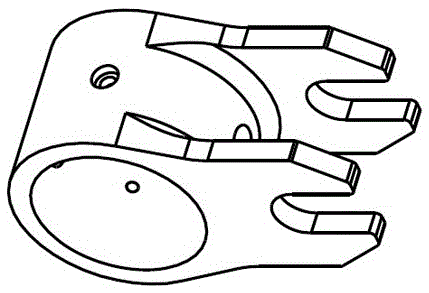

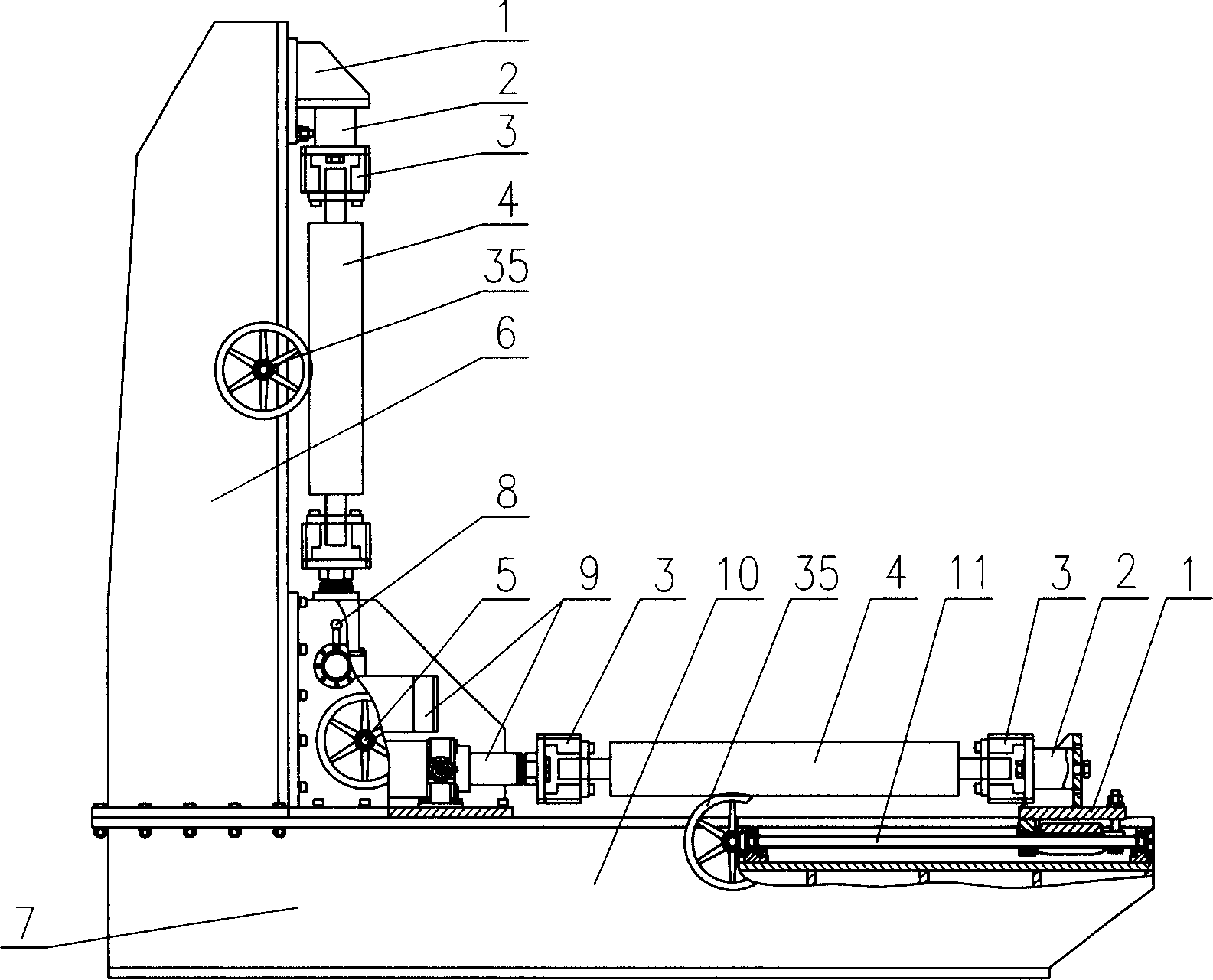

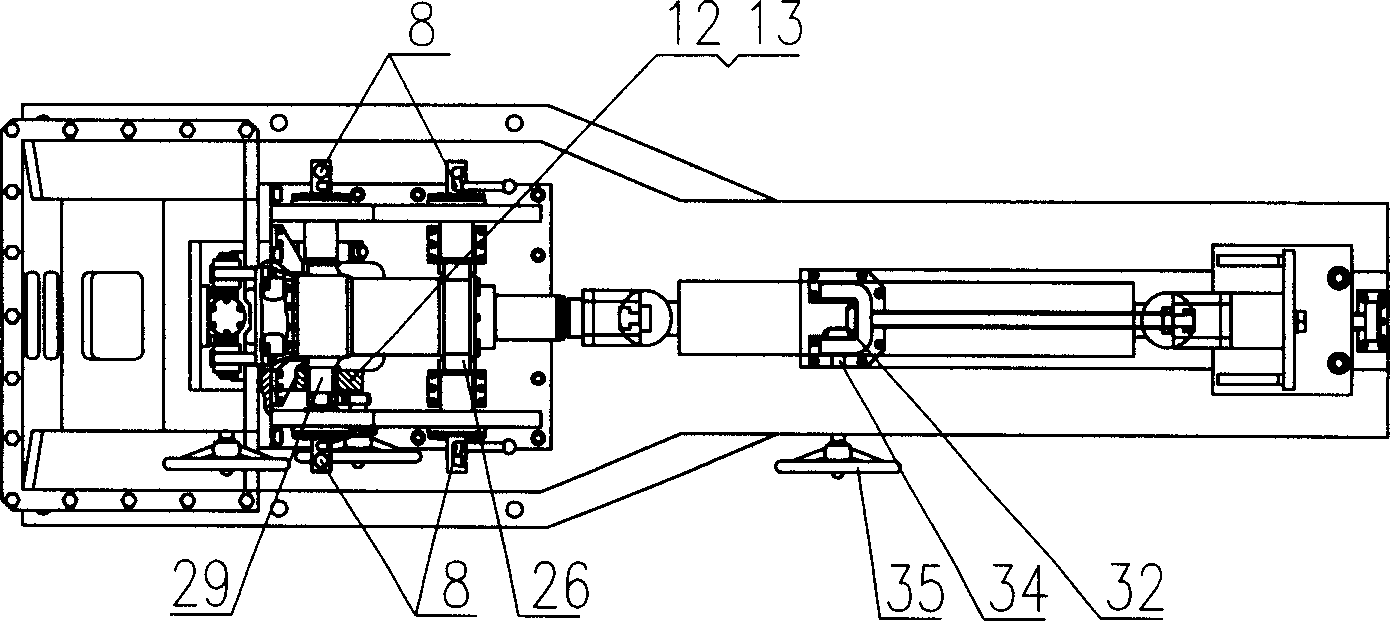

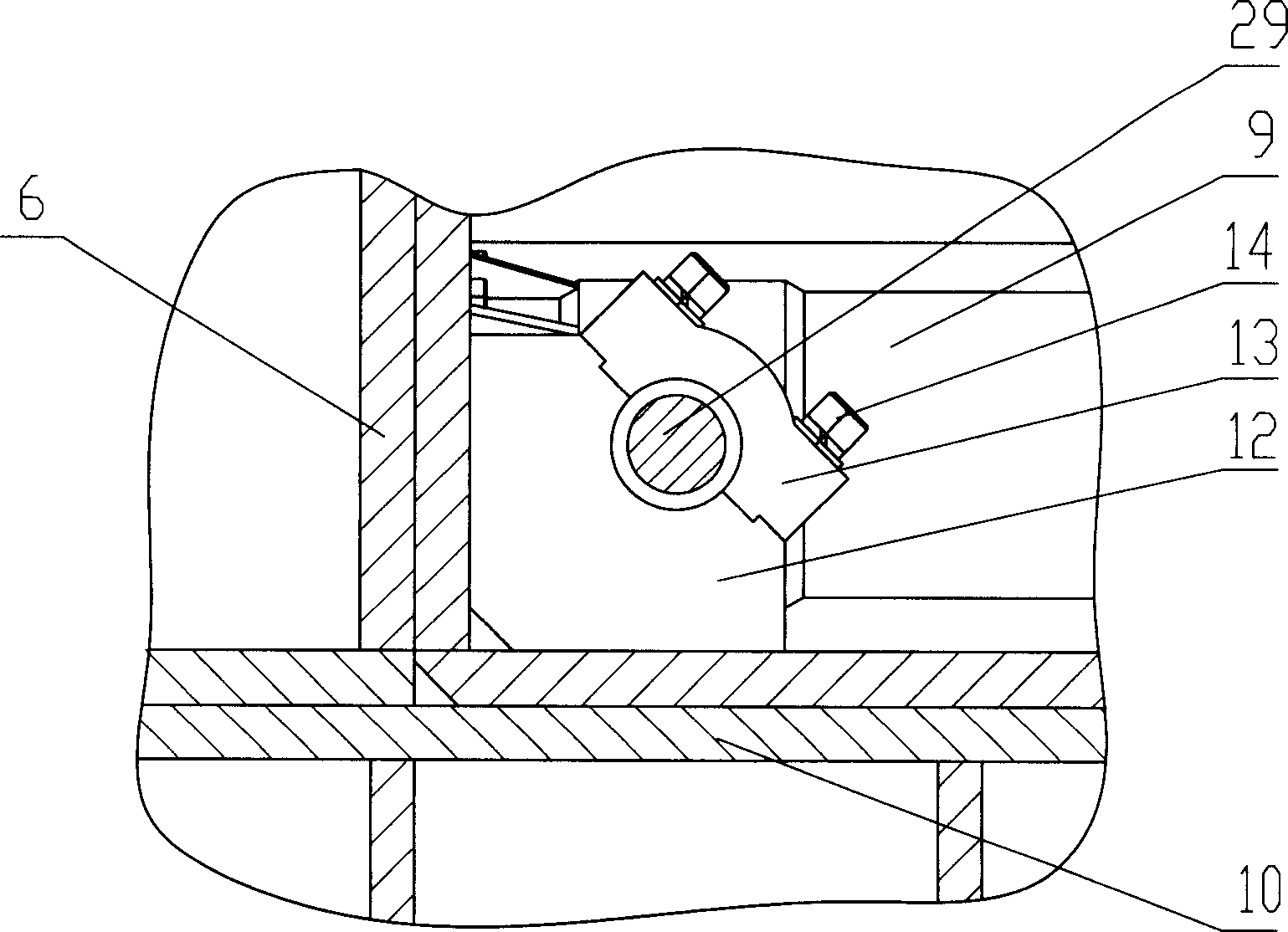

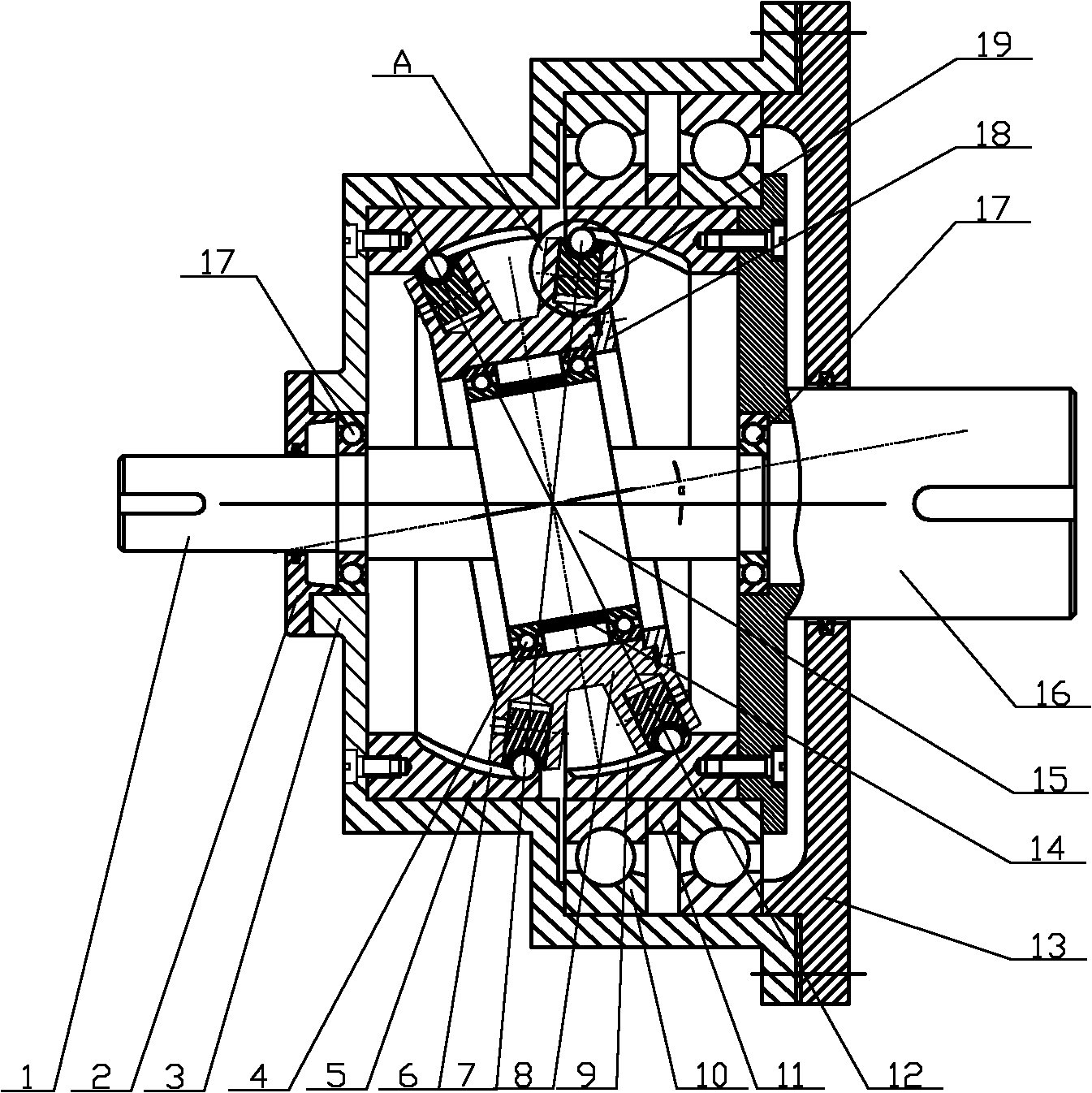

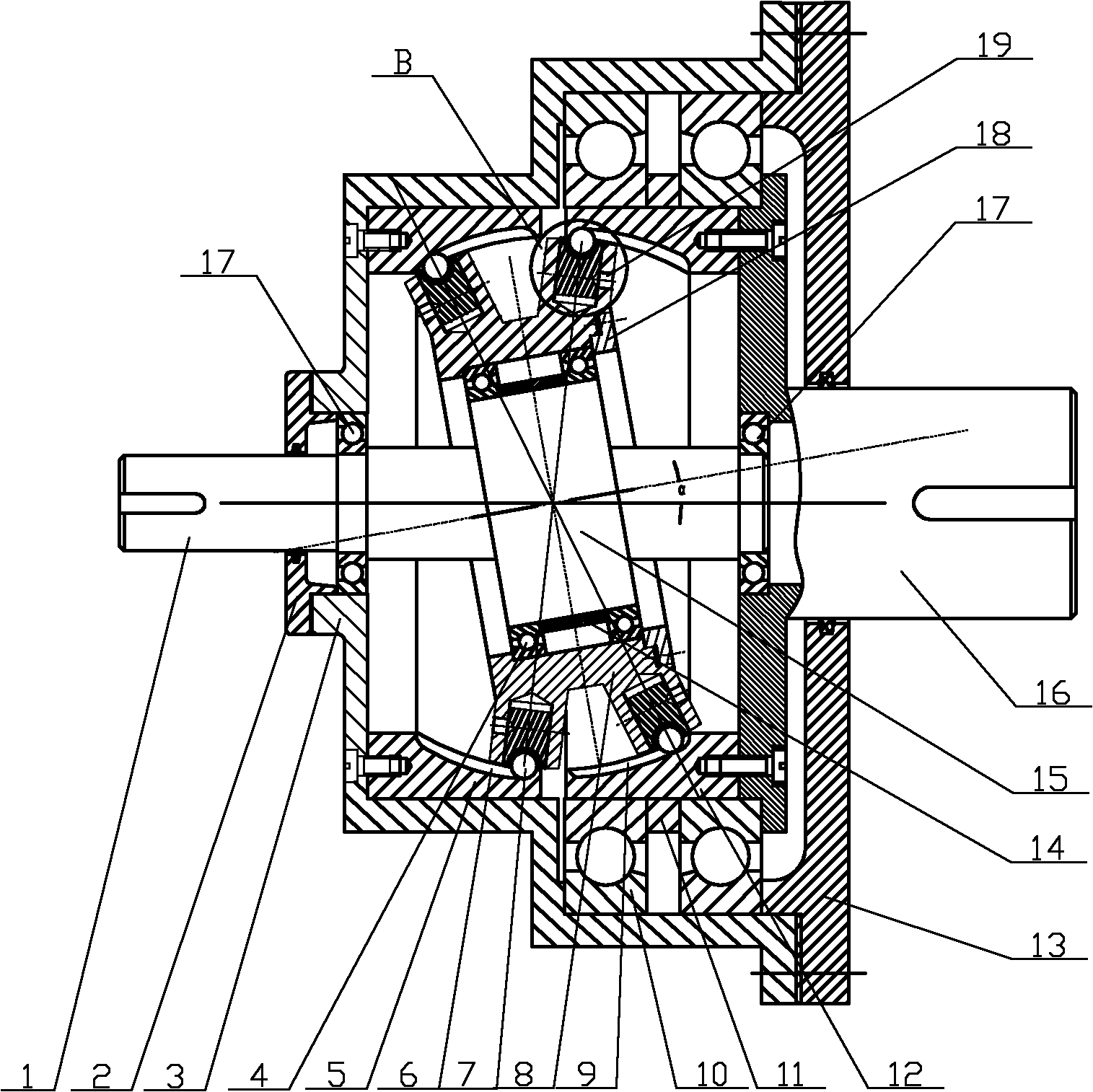

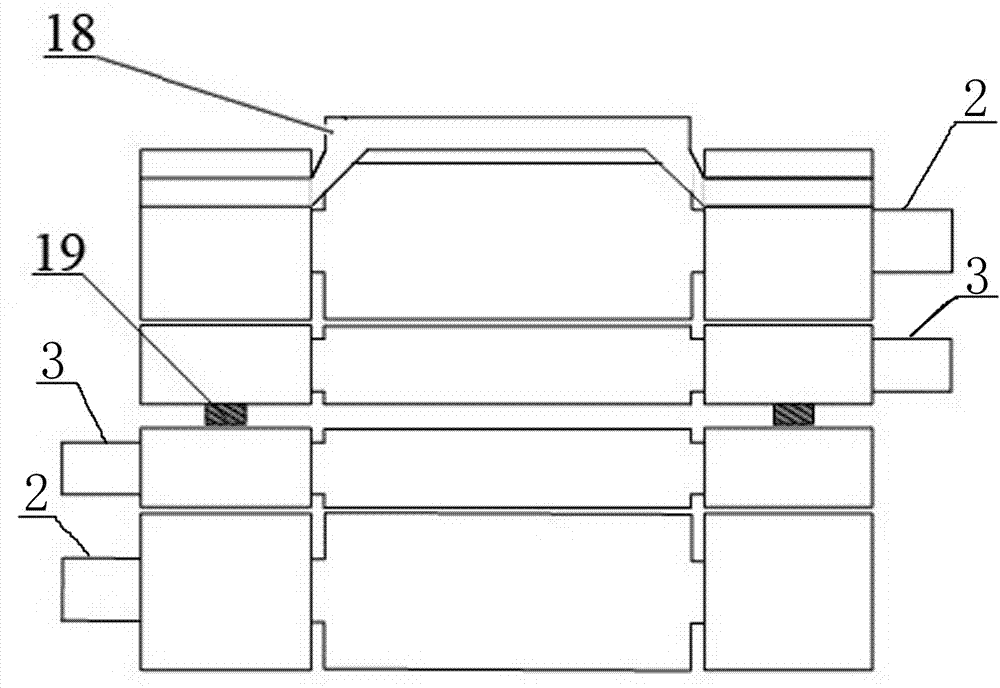

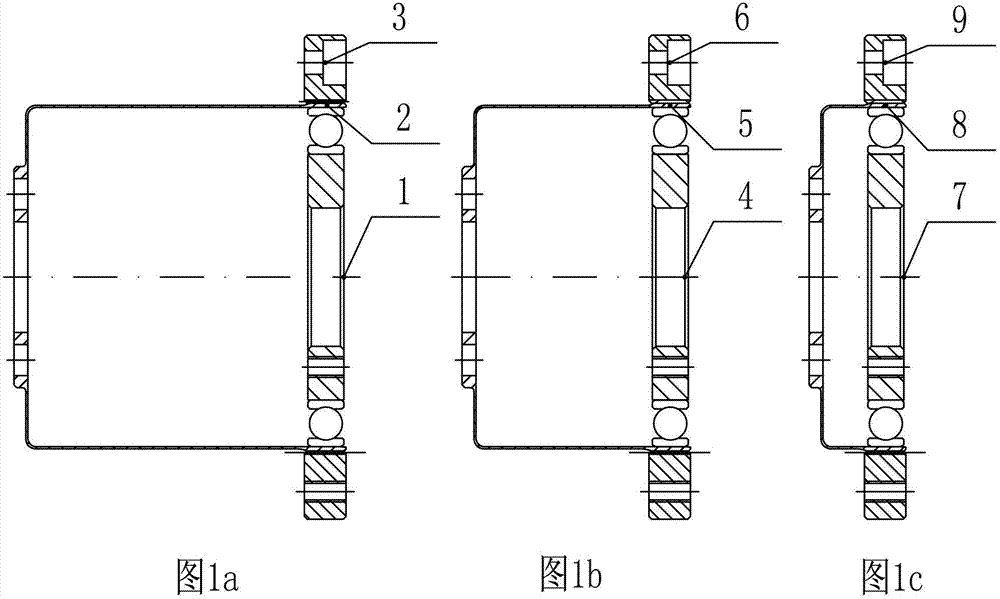

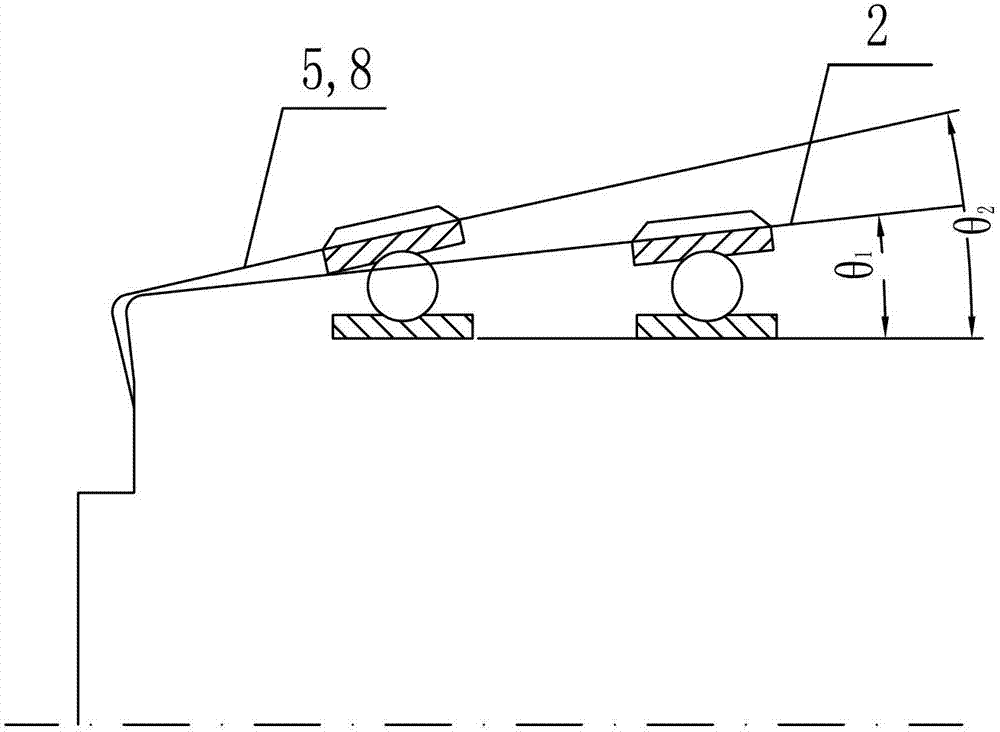

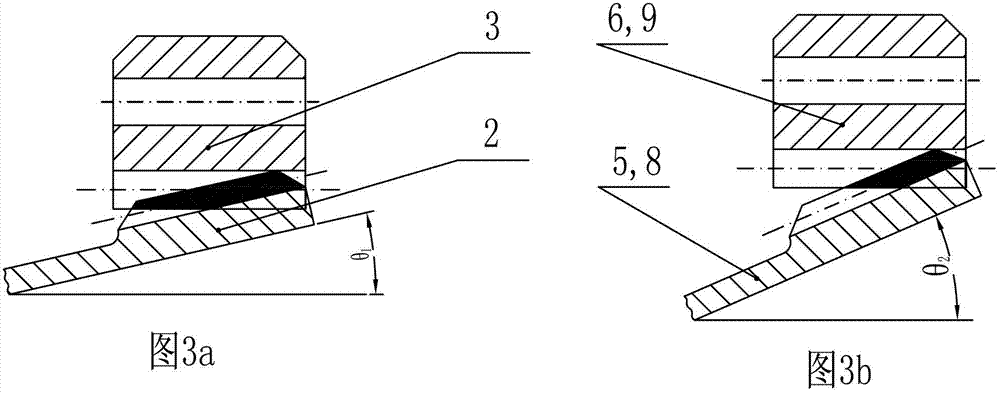

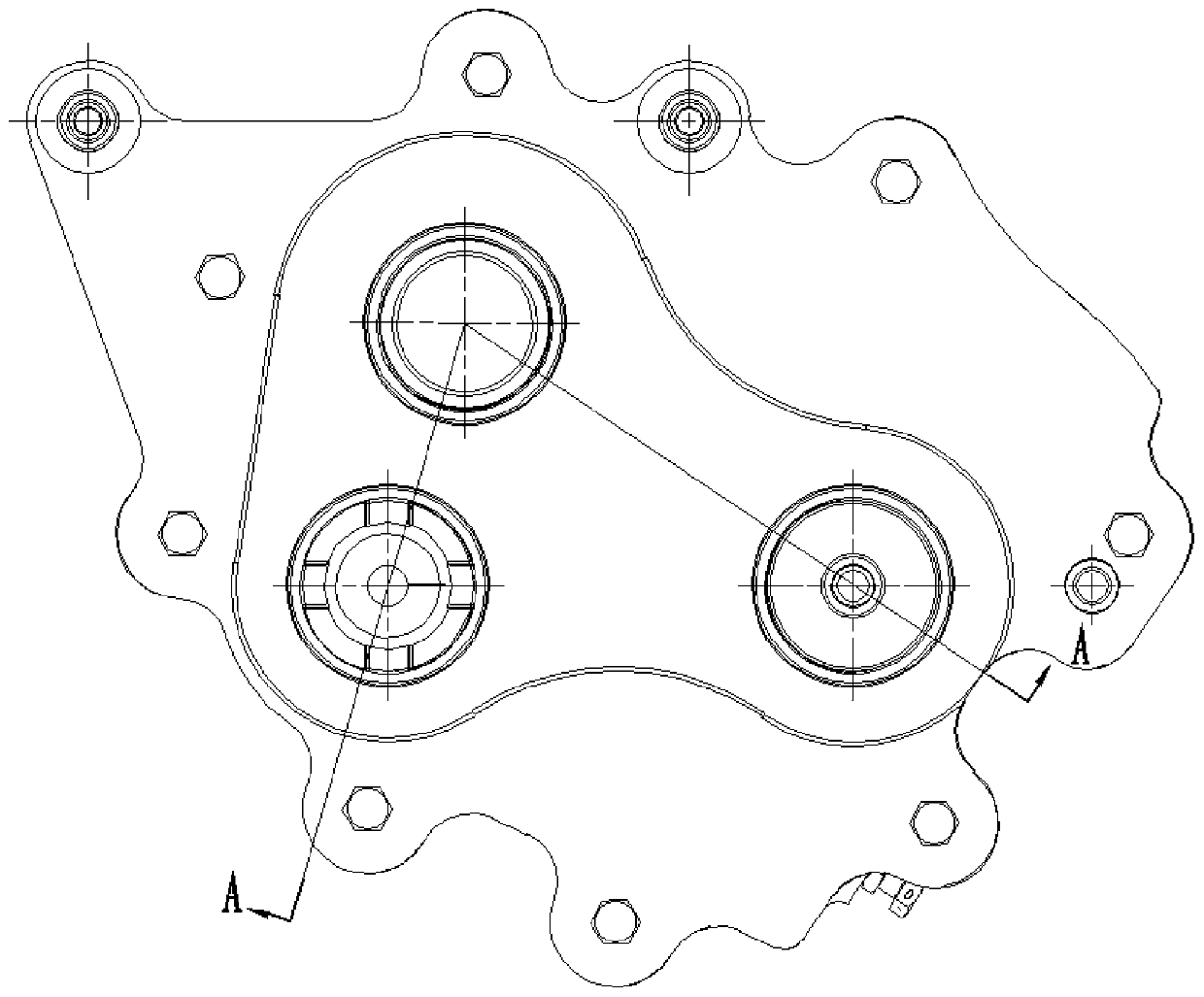

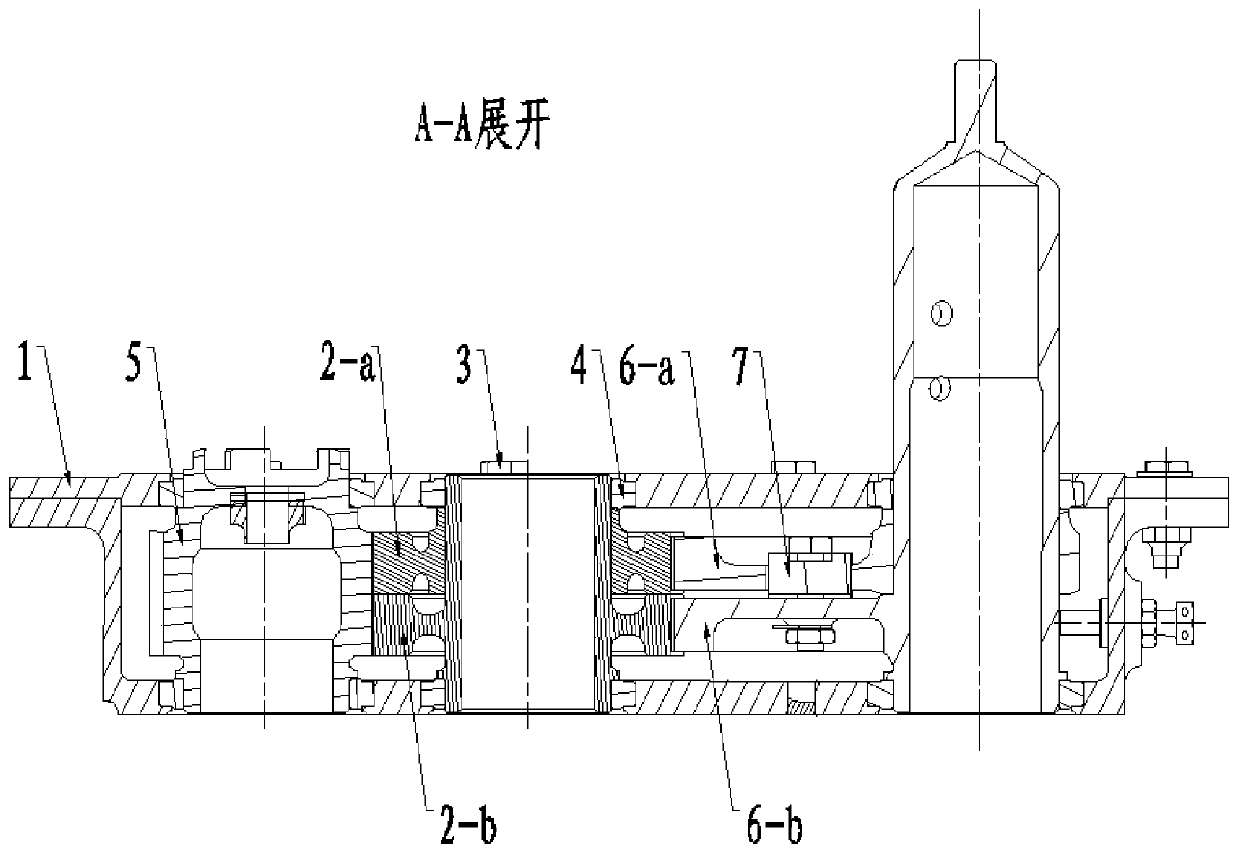

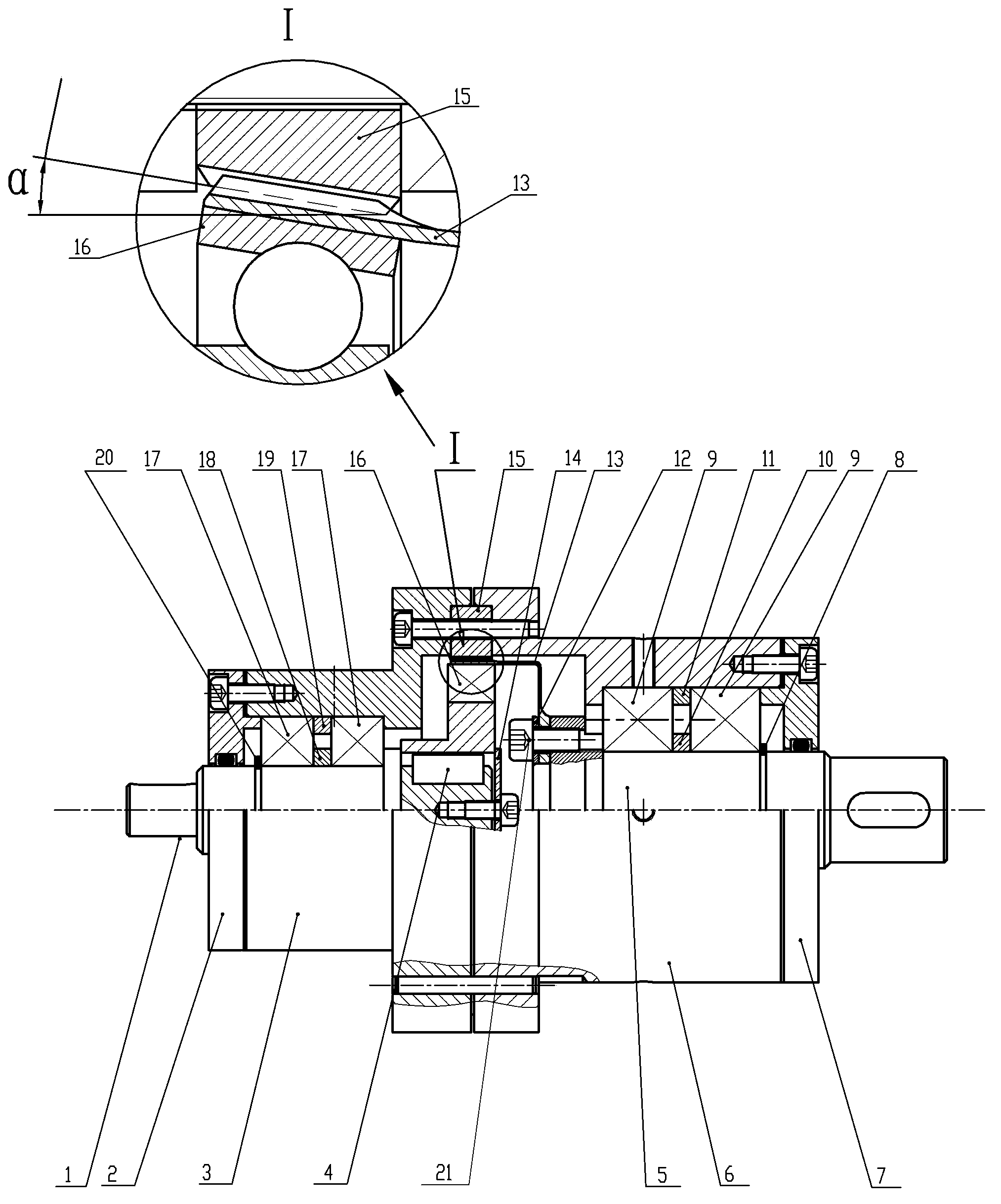

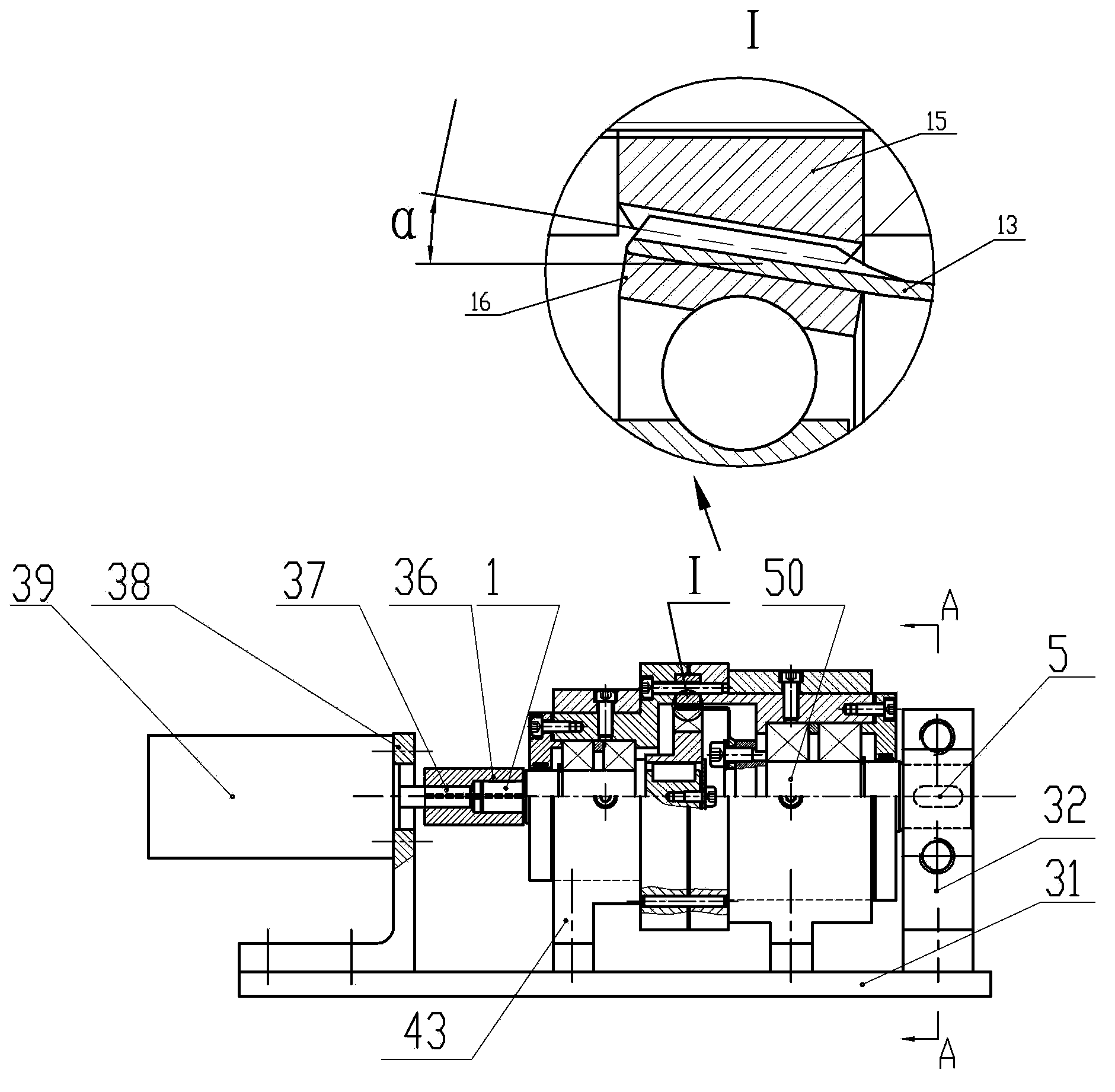

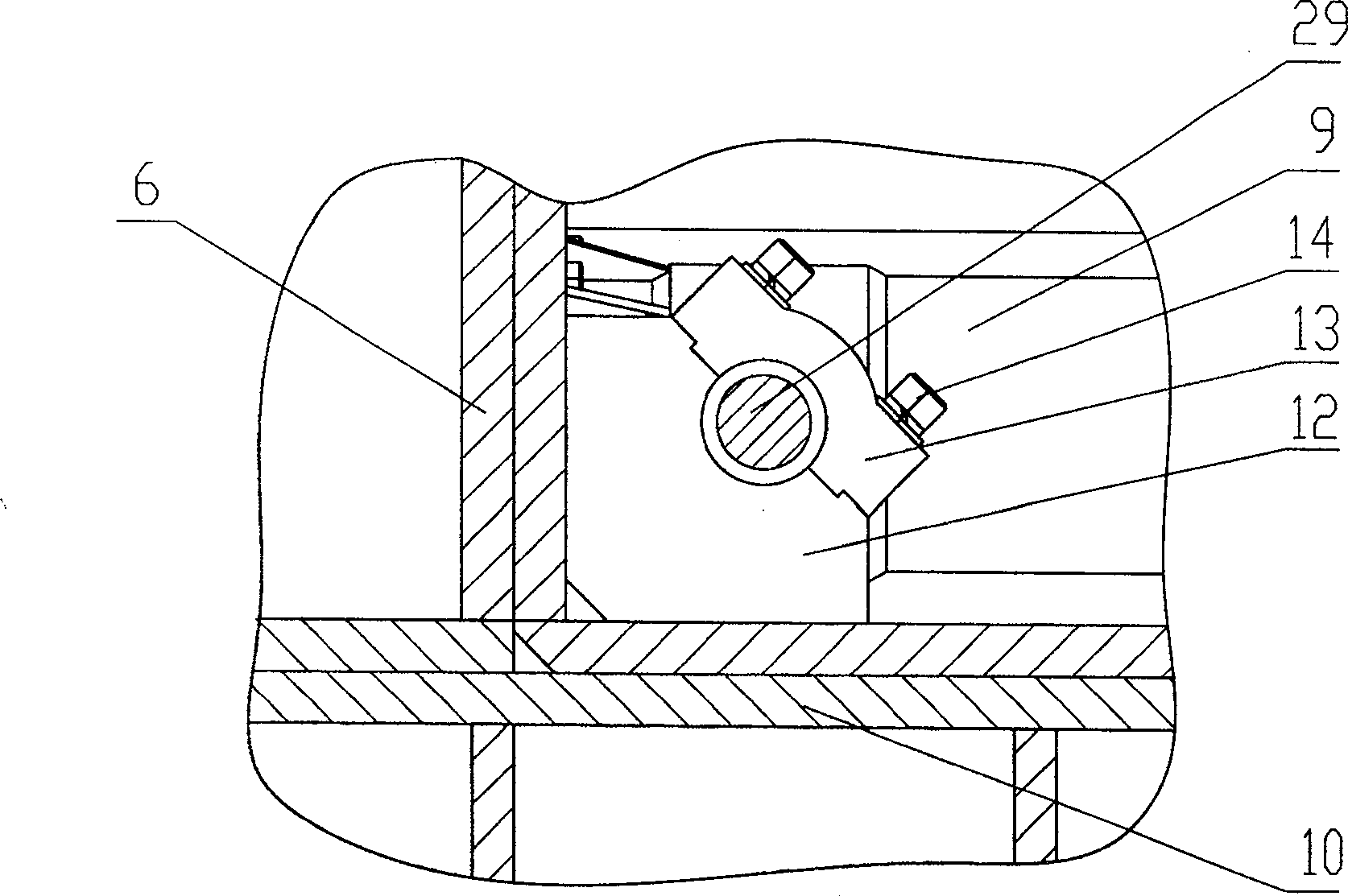

The invention discloses a short tube flexible gear harmonic reducer of a rigid wheel tooth dip angle and a transmission rigidity testing device thereof, and relates to the technical field of harmonic reducers. According to the invention, the deflection of the flexible wheel gear teeth is caused by the reduction of the axial size of the short tube flexible gear harmonic reducer, so as to realize the reduction of the surface area between the rigid wheel gear teeth and the flexible wheel gear teeth, and to realize the lowering of the transmission rigidity; the problem of complicated operating process of the existing harmonic drive rigidity experiment testing device is solved; and the length diameter ratio of a soft wheel is 1 / 4 to 3 / 5 of a short tube wheel, the inner wheel of the rigid wheel with a dip angle is the wheel teeth with the dip angle alpha along the rigid wheel axial direction, and the deflection direction and the field angle direction of the soft wheel on a long shaft are coincident. The transmission rigidity testing device of the short tube flexible gear harmonic reducer implements current control namely torque control through a computer and a servo driver, and the harmonic drive output end realizes continuous loading unloading; and the harmonic drive rigidity of the short tube soft wheel is obtained, and the transmission rigidity is serially, rapidly accurately obtained.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

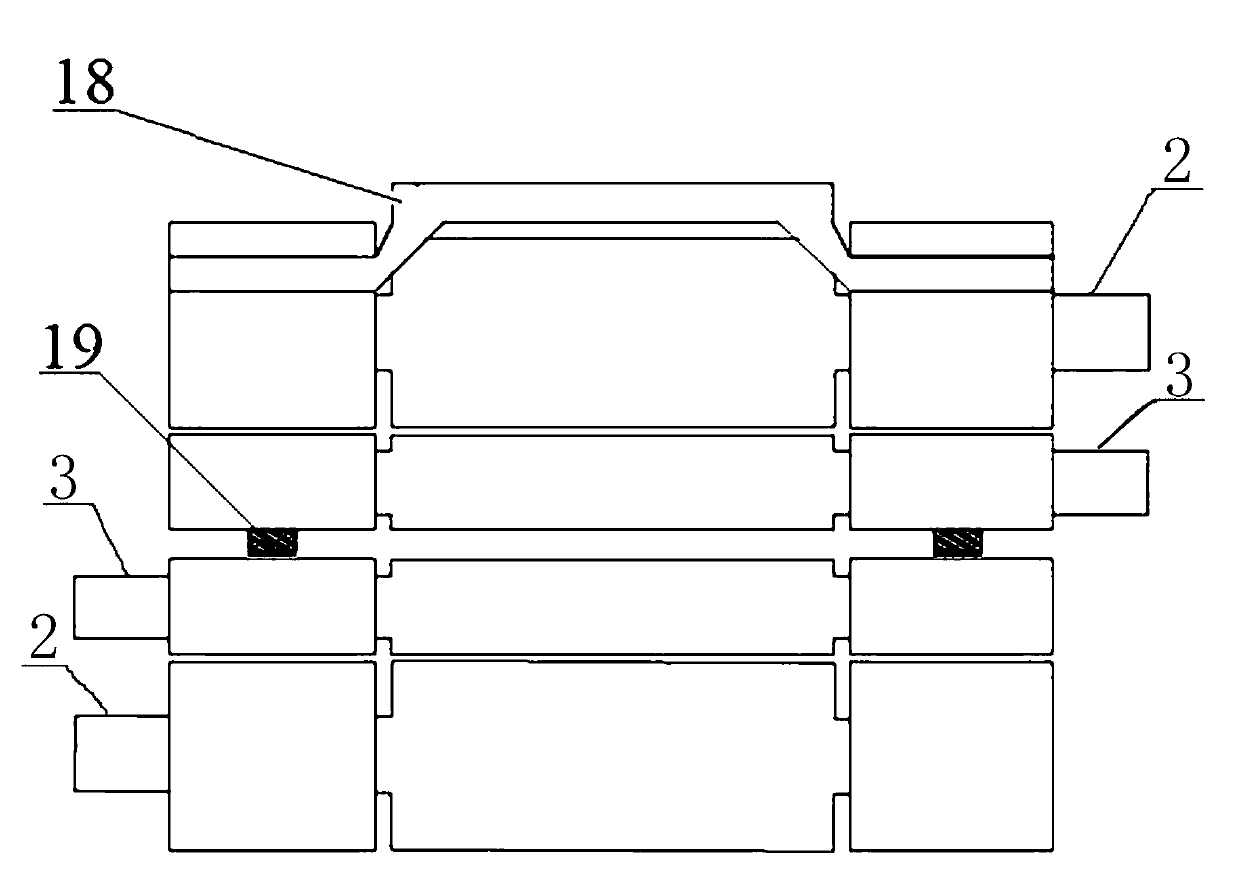

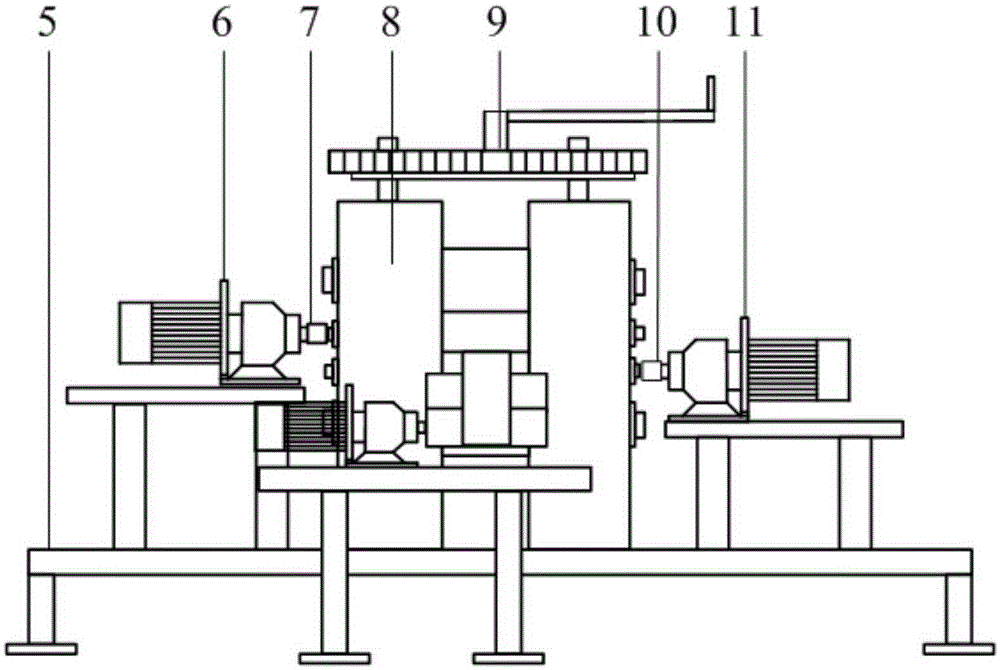

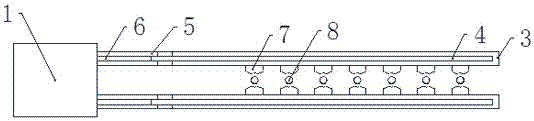

Multifunctional rolling mill for producing thin metal straps and ultra-thin metal straps

ActiveCN102989765AIncrease the diameterImprove transmission stiffnessMetal rolling stand detailsMetal rolling arrangementsThin metalAlloy

The invention relates to a multifunctional rolling mill for producing thin metal straps and ultra-thin metal straps and belongs to the field of metal rolling devices. The multifunctional rolling mill comprises a pressing-down device, a memorial archway, a base, a roll system, a roll gap adjusting device, a main transmission motor and a tension motor. The memorial archway is fixed on the base through a bolt, the pressing-down device is fixed on the memorial archway through a pressing-down lead screw, the roll system is placed in the memorial archway, a bearing seat limits horizontal movement of the roll system, the roll system can vertically slide in a memorial archway window, the roll gap adjusting device uplifts a spring through the pressing-down lead screw and a balance beam to be connected with the memorial archway, the main transmission motor is connected with the roll system through a universal spindle, the tension motor is fixed on the base through a bolt, and the roll system adopts a four-roller vertical distributing mode, a two-roller vertical distributing mode or a two-roller horizontal distributing mode. The multifunctional rolling mill can be used for rolling liquid, powdery and particle-shaped ultra-thin metal and alloy strap materials and has a continuously variable function, a stepless adjusting function and a function of optionally selecting transmission speed ratio of vertical rollers.

Owner:NORTHEASTERN UNIV

A transmission

ActiveCN103363027AImprove transmission stiffnessAvoid constraintsPortable liftingToothed gearingsTooth segmentEngineering

Owner:WITTENSTEIN GROUP

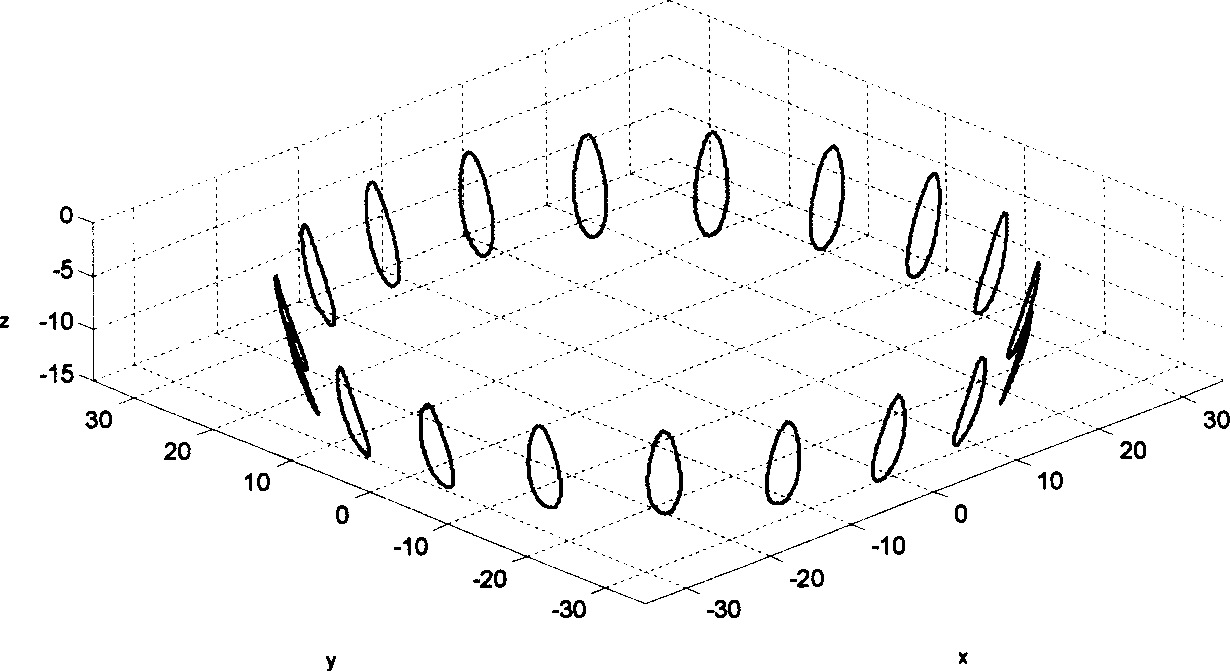

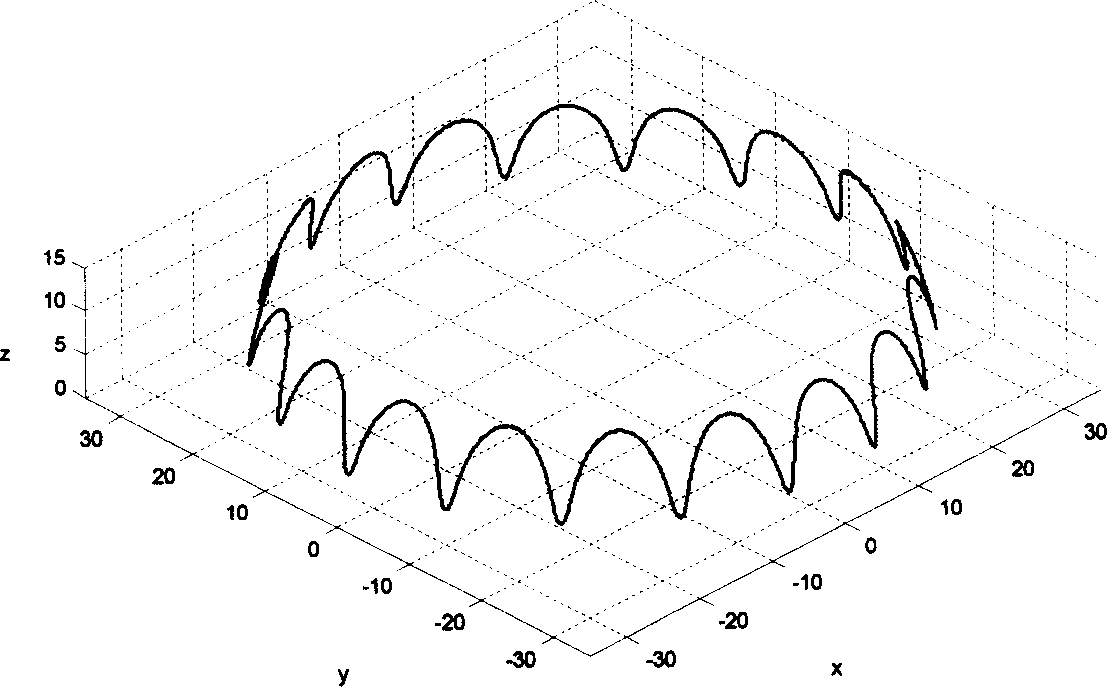

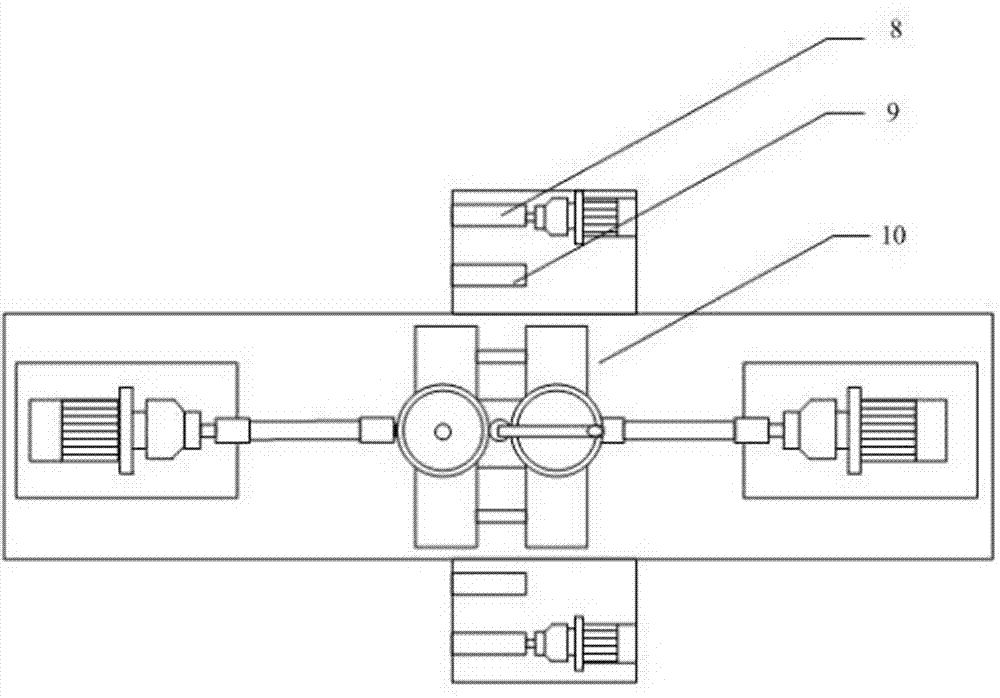

Transmission device of having nutation oscillating tooth

The invention discloses a nutation loose-teeth driving device, which comprises the input and the output shafts: the offset shaft sect is connected with the nutatoin disk throuth the bearing; the end face of the disk toward the input shaft is engaged with the fixing disk through the sphere loose-teeth of the first steel ball group along the circumferential direction; the fixing disk is fixed on the base; the other end of face of the dial toward the output shaft is engaged with the turning disk through the sphere loose-teeth of the second steel ball group along the circumferential direction; the bearing is between the turning disk and the base. The invention makes use of the roller assistant steel ball as the medium to engage with the loose-teeth between the fixing disks and the planetary turning disks. The invention is suitable for the precise driving devices.

Owner:DALIAN JIAOTONG UNIVERSITY

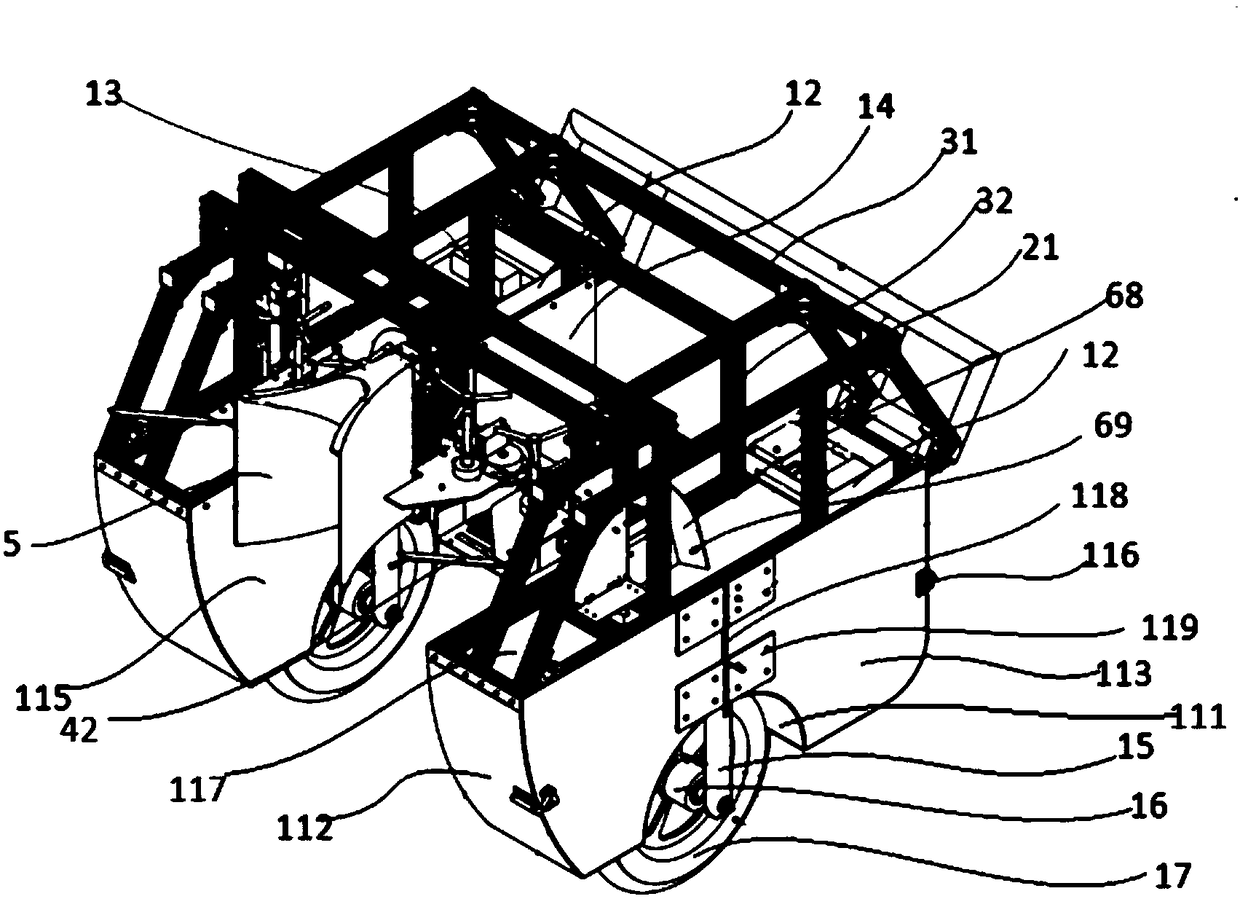

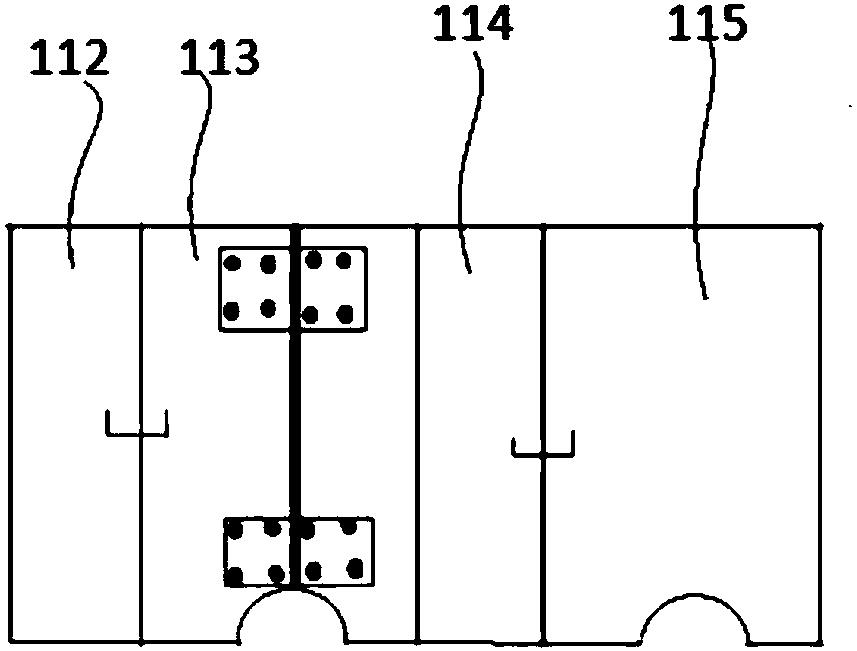

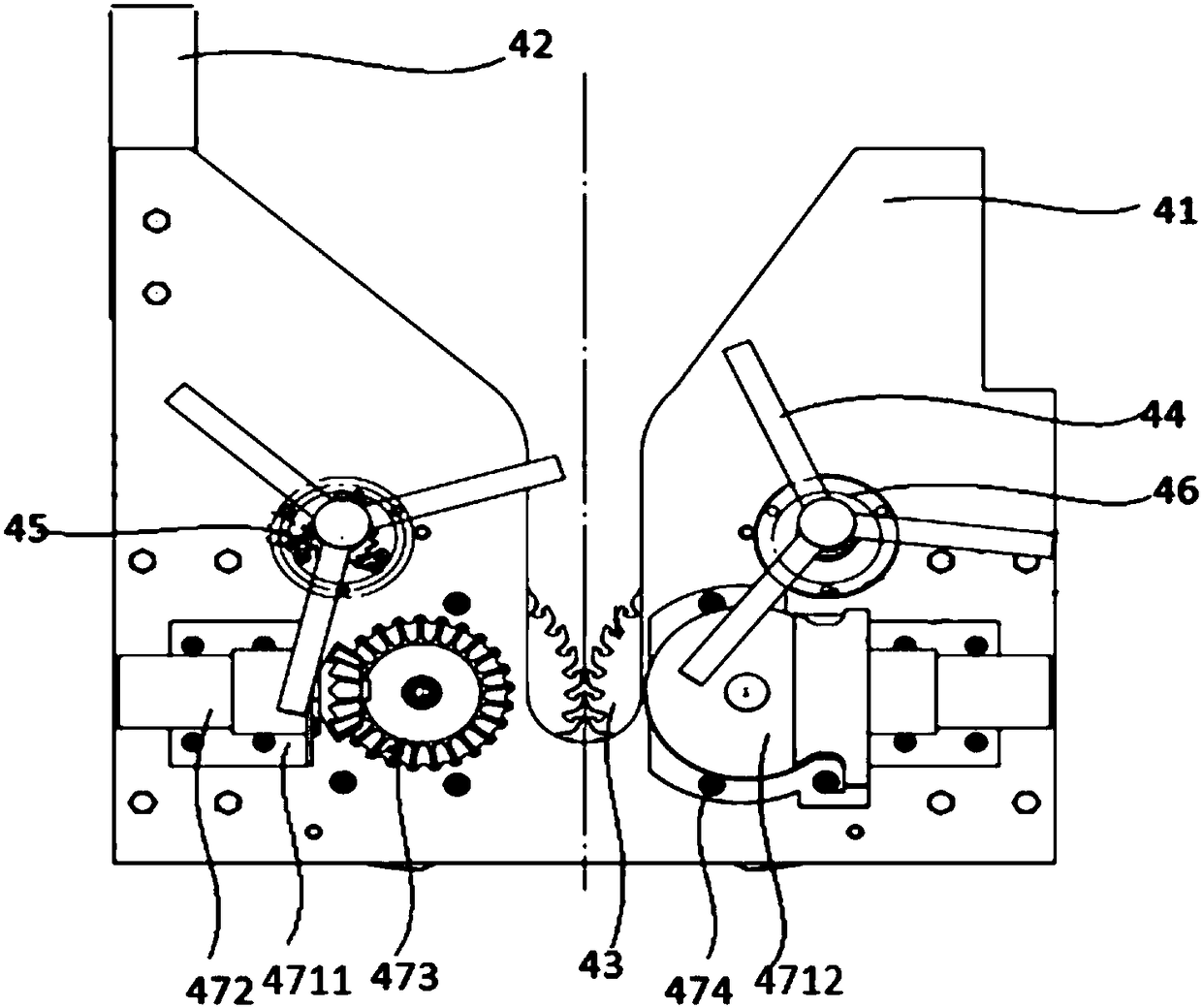

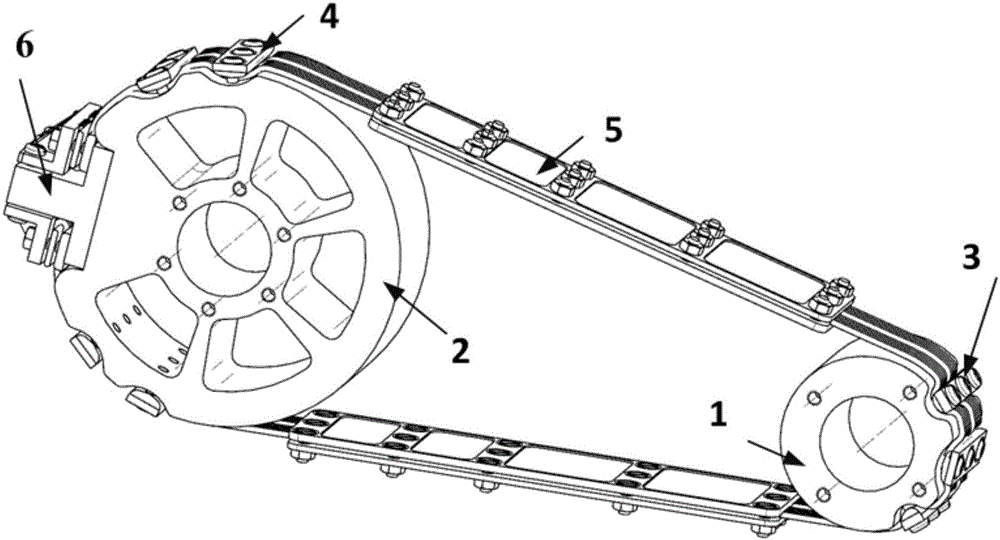

Rapid pineapple harvester

InactiveCN108207318AGood accuracy retentionGood synchronizationPicking devicesAgricultural engineering

The invention discloses a rapid pineapple harvester. The rapid pineapple harvester mainly comprises a first collection module, a second collection module, a connection module, a cutting module, a leafpressing block and a lifting mechanism. The first collection module is connected with the second collection module through the connection module. The cutting module is used for cutting off stems of pineapples. The leaf pressing block is used for pressing down leaves of the pineapples. The lifting mechanism is used for adjusting the height of the cutting module. The rapid pineapple harvester has the advantages of capability of accurately harvesting the complete pineapples at a high speed, simple and reliable structure, simplicity and convenience in operation, low cost, high practicability andwide application range.

Owner:CHONGQING UNIV

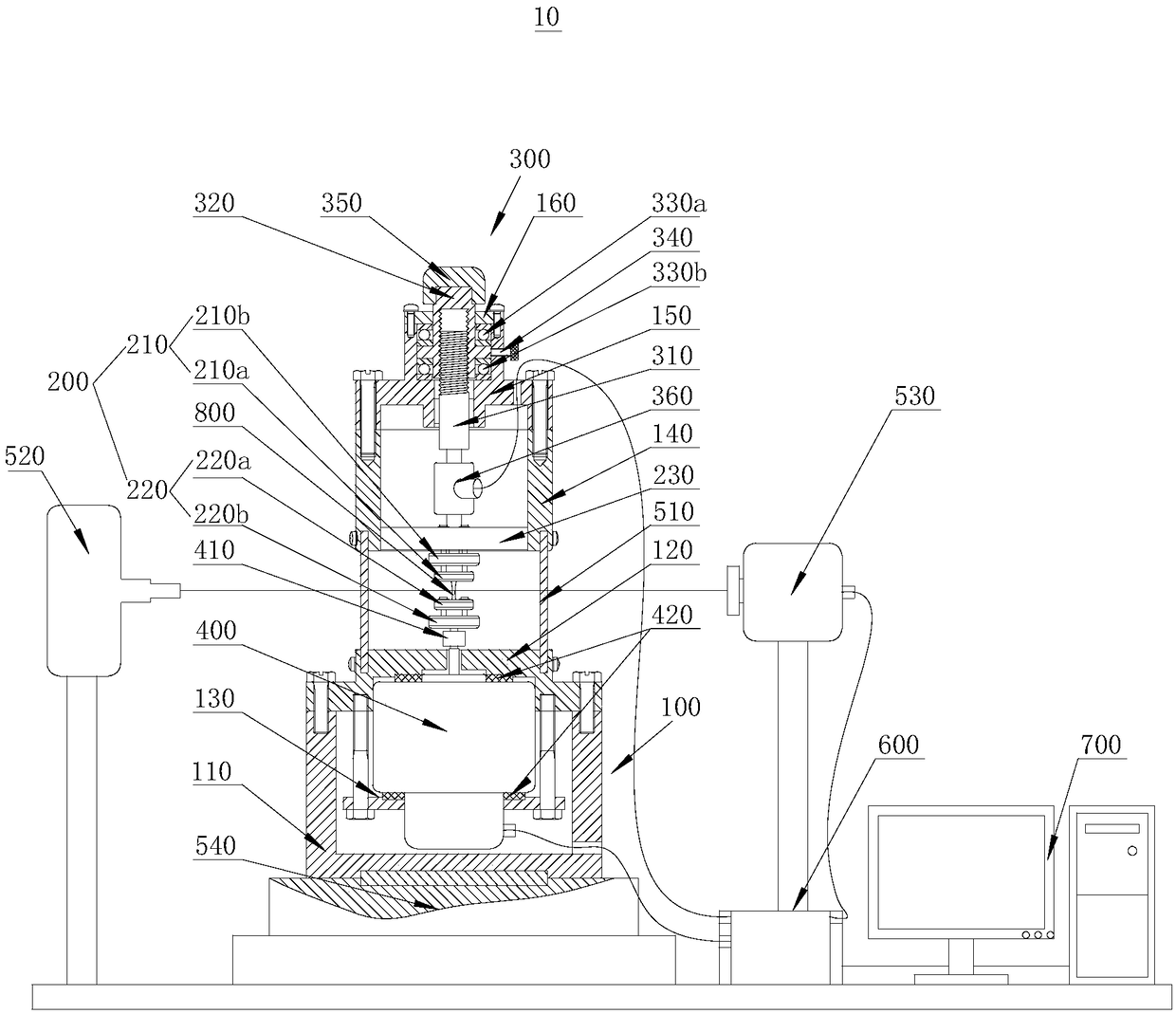

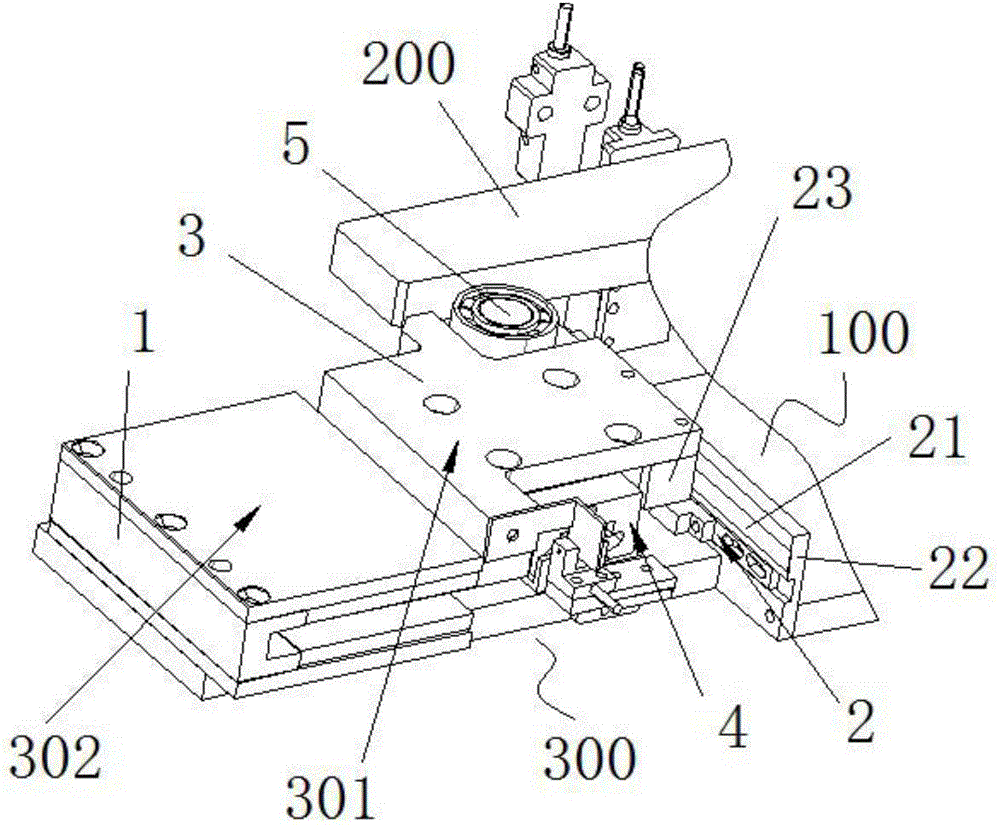

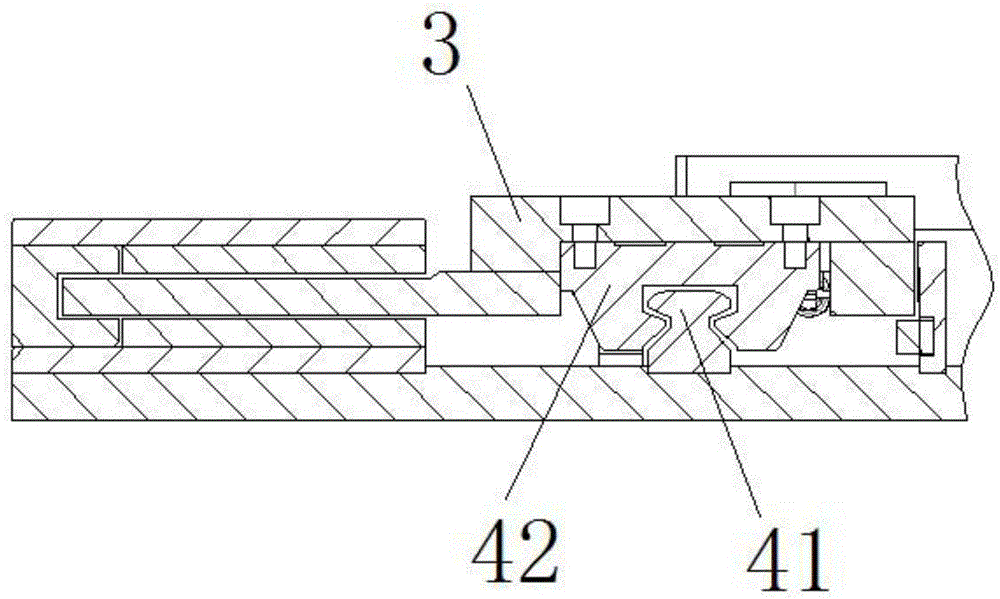

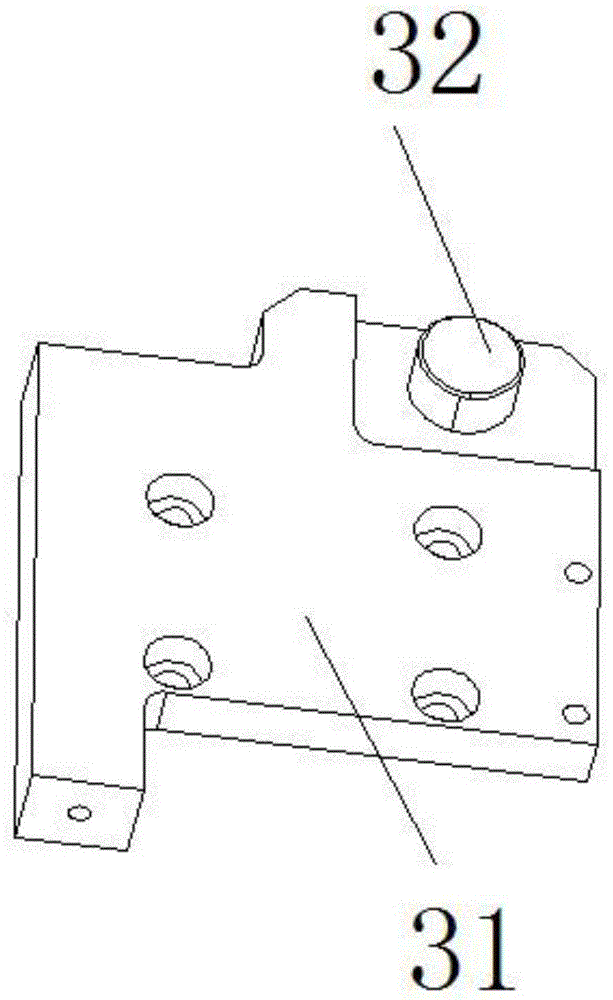

High-frequency in-situ imaging fatigue tester

PendingCN108562506AHigh frequencyHigh precisionMaterial strength using repeated/pulsating forcesMaterial analysis by transmitting radiationFatigue damageHigh energy

The invention relates to the technical field of material testing and particularly relates to a high-frequency in-situ imaging fatigue tester. The tester comprises a tester body, a test sample clampingmechanism, a preset force loading mechanism and a voice coil motor, wherein the test sample clamping mechanism is used for clamping and fixing a test sample, and the test sample clamping mechanism comprises a first clamping assembly and a second clamping assembly which are arranged oppositely; the preset force loading mechanism is arranged at one side of the first clamping assembly of the test sample clamping mechanism and is used for applying preset tension and pressure to the test sample; and the voice coil motor is fixedly connected to the tester body, and a moving shaft of the voice coilmotor is connected to the second clamping assembly. The voice coil motor is utilized for realizing high-frequency actuation to perform high-frequency fatigue on the test sample, and high-energy X-raysare utilized for performing three-dimensional imaging on fatigue damage inside materials, thereby researching the high-cycle and even ultra-high-cycle fatigue failure mechanism of the materials.

Owner:SOUTHWEST JIAOTONG UNIV

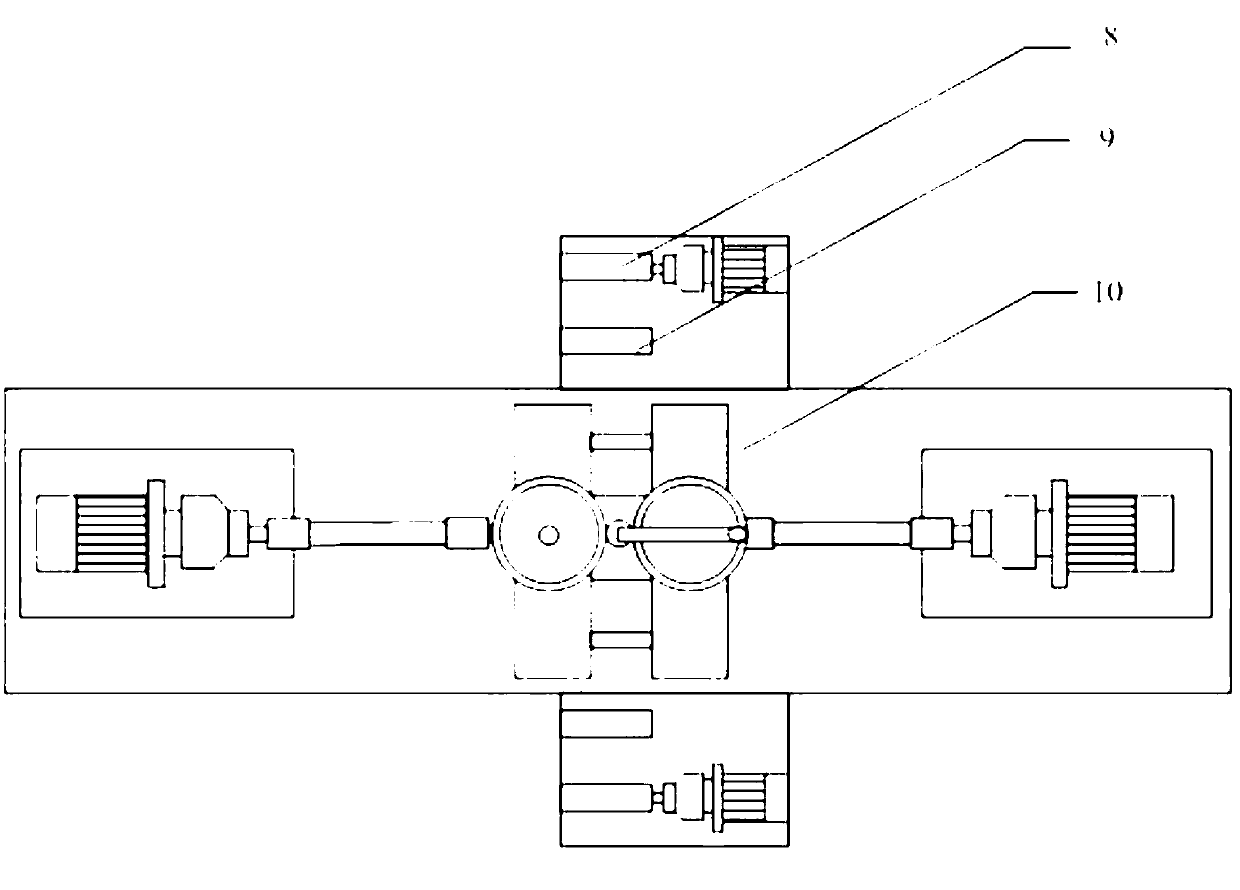

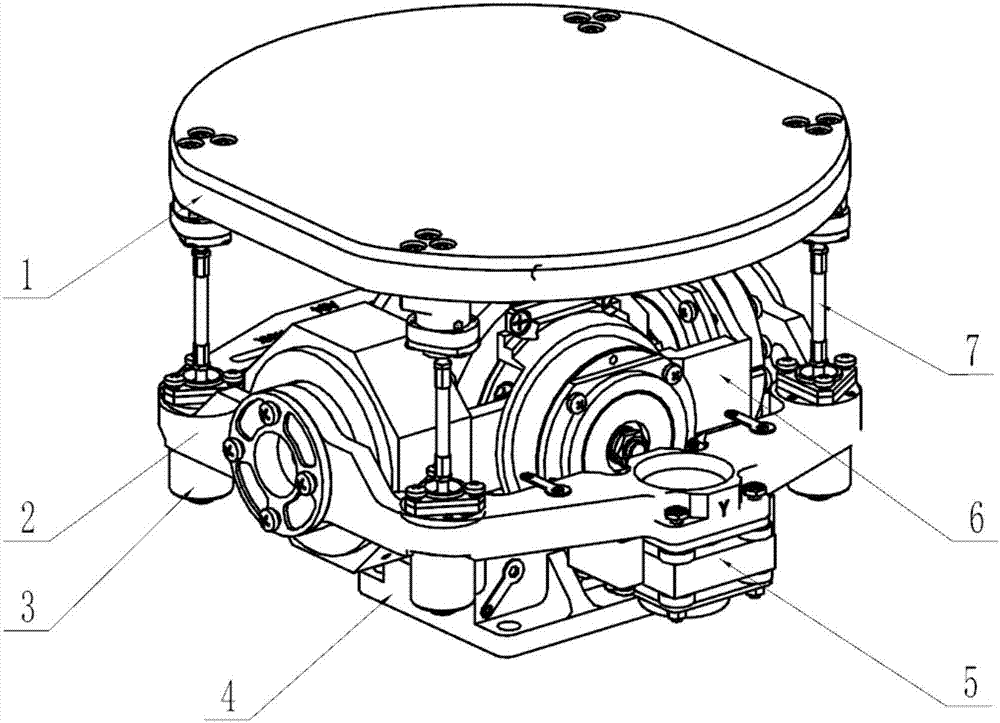

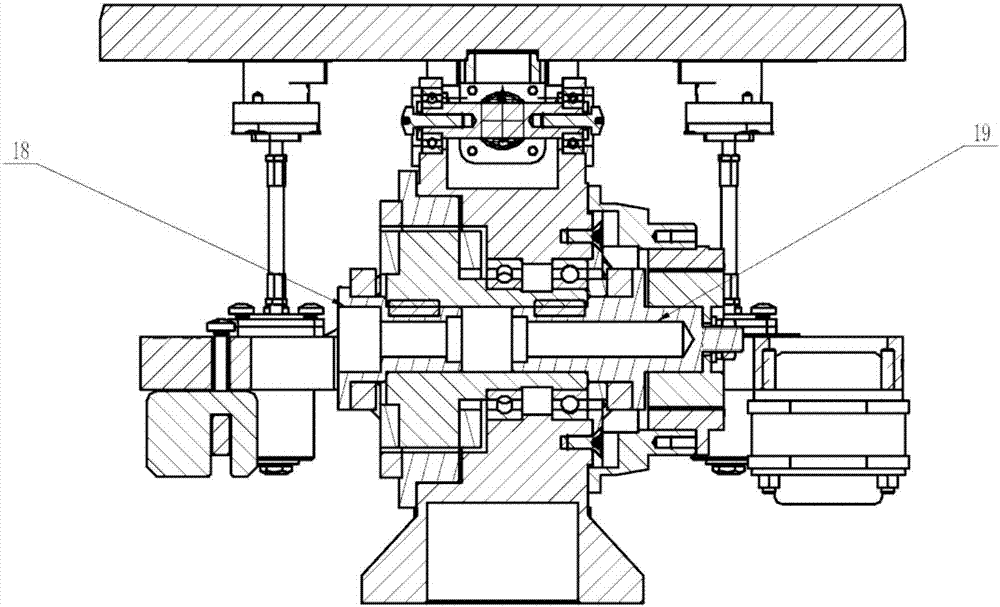

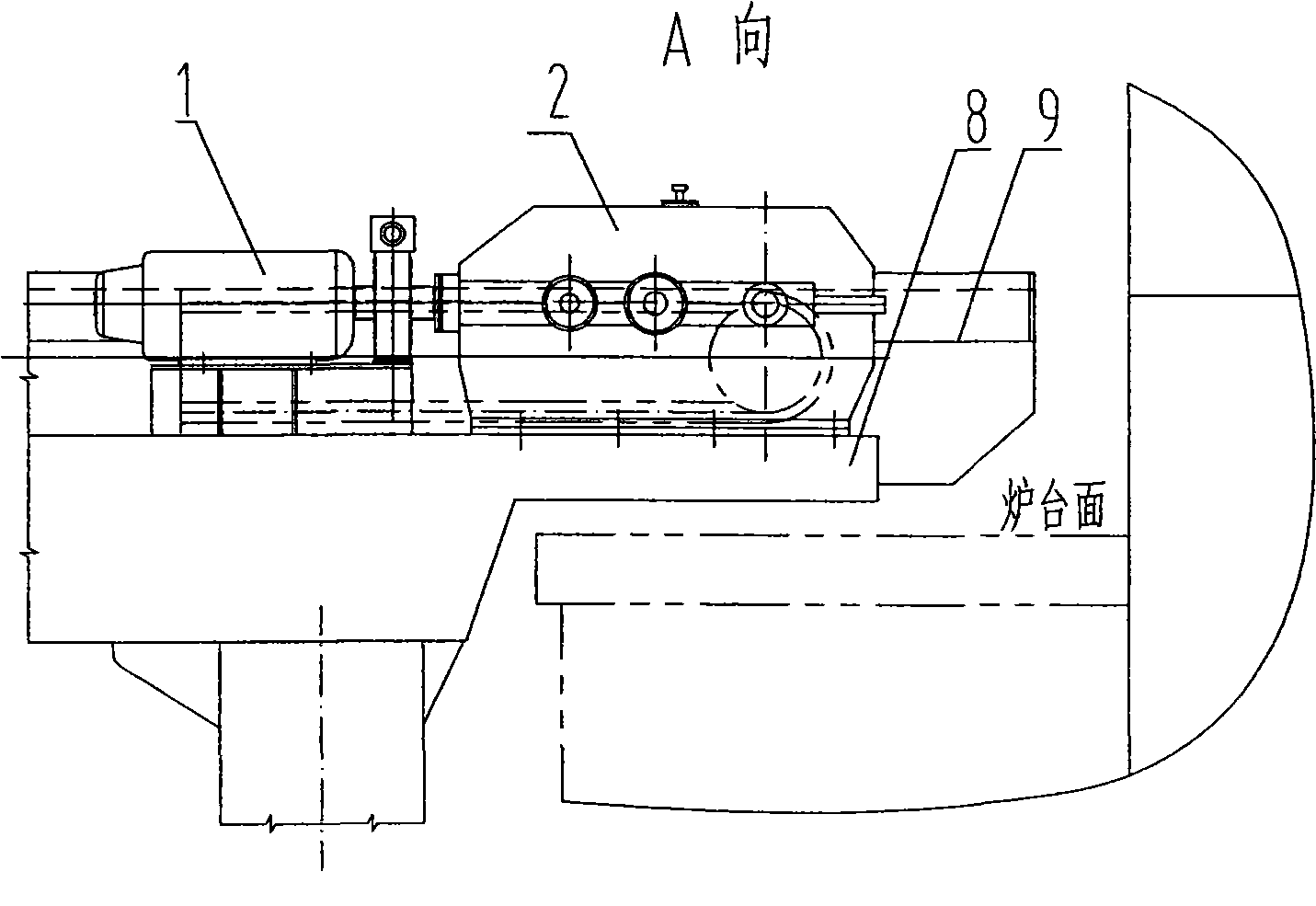

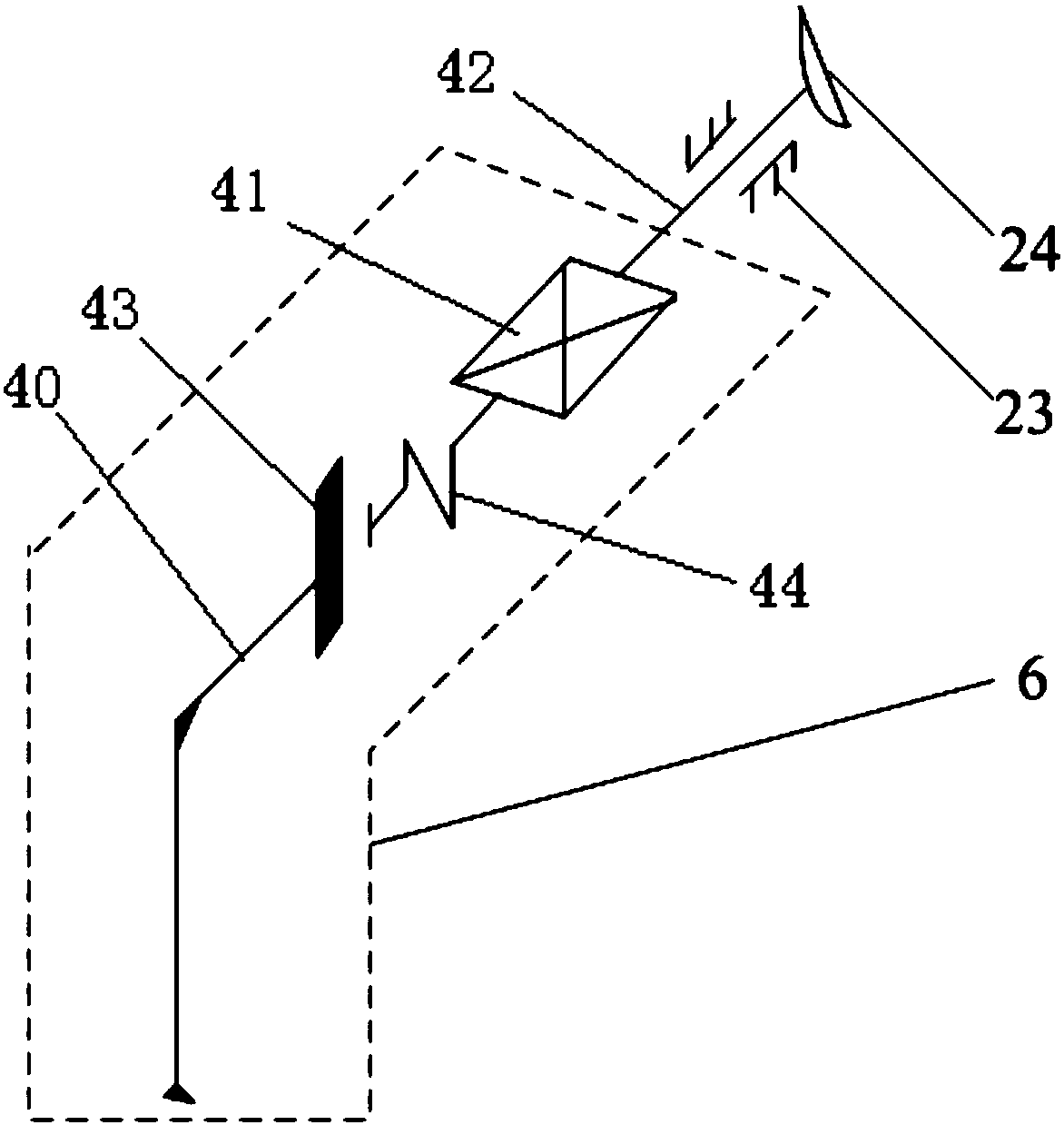

High bandwidth antenna servo control stable platform

The invention discloses a high bandwidth antenna servo control stable platform, and is aimed at providing a stable platform which is high in transmission stiffness and low in frictional resistance and can realize scan tracking of a same-caliber antenna. The stable platform is realized via the following technical solution: two push-pull connecting rod assemblies (7) are symmetric to a gyro assembly (5) and connected to a frame, a pitching drive motor (9) with a pitching rotary transformer (11) is fixedly connected to the middle part of two side azimuth drive motors via a pitching drive frame (6) fixedly connected with the two side azimuth drive motors (10), an azimuth drive frame (2) and the pitching drive frame are connected to an antenna feeder load upper frame (1) by the push-pull connecting rod assemblies to form a parallelogram mechanism of double frames and four push-pull rods, the lengths of the push-pull connecting rod assemblies (7) are adjusted via threads of a bulb (15), movement of two degrees of freedom of azimuth and pitching of the antenna feeder load upper frame is driven, the kinetic energy is transferred to the upper load frame, and the drive frame thus drives the load frame.

Owner:10TH RES INST OF CETC

Marble high-precision movement platform

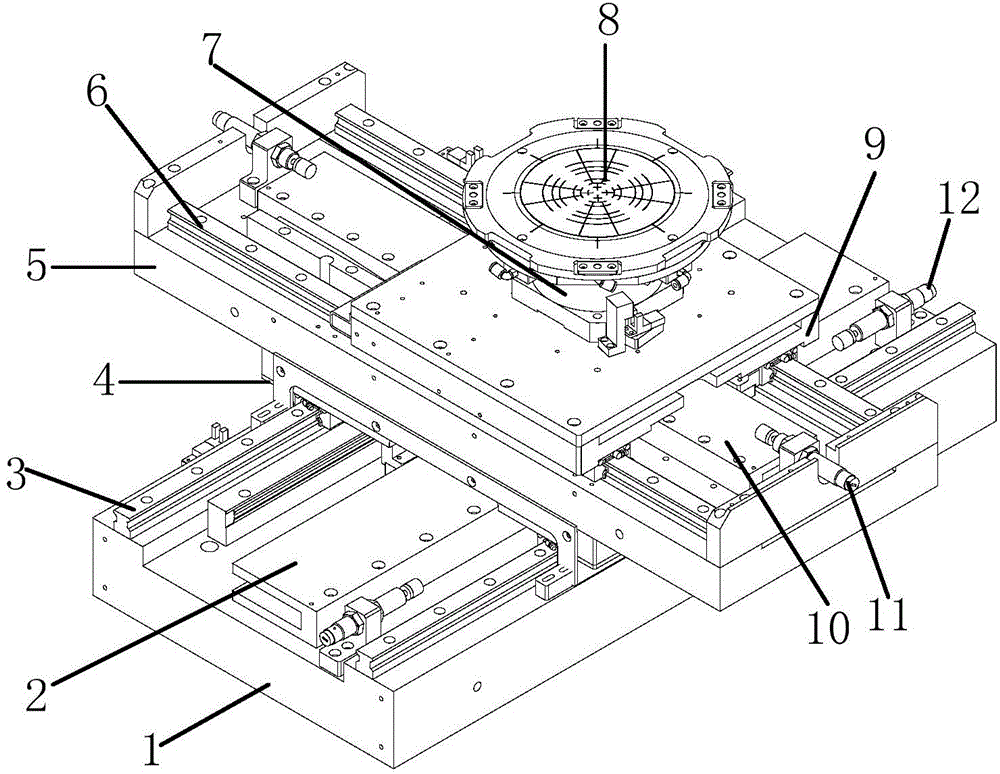

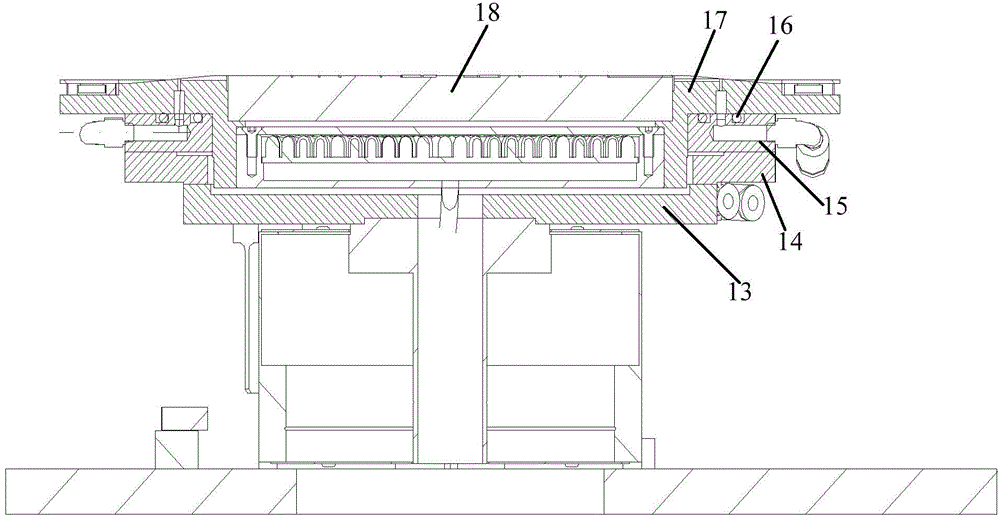

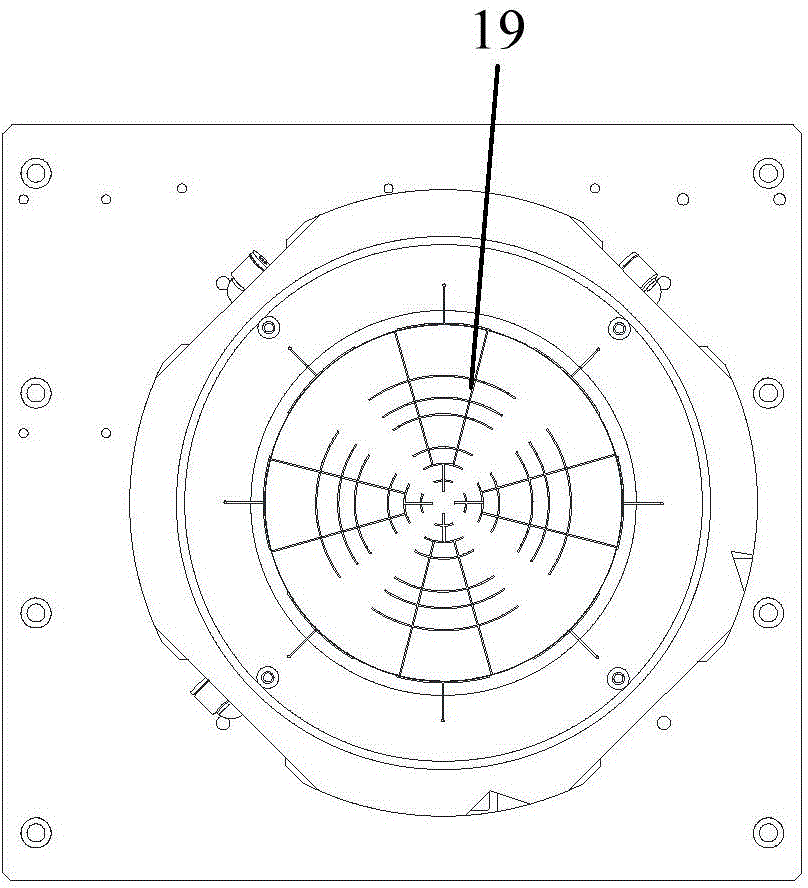

ActiveCN104362228AGuaranteed stabilityReduce shockSemiconductor/solid-state device manufacturingSemiconductor devicesModular designEngineering

The invention relates to a marble high-precision movement platform. An X-axis linear guide rail and an X-axis linear motor are arranged on an X-axis marble base, an X-axis connecting plate is arranged on the X-axis linear guide rail, the X-axis linear motor and the X-axis connecting plate are in driving connection, and the X-axis connecting plate is controlled to move along the X-axis linear guide rail. A Y-axis linear guide rail and a Y-axis linear motor are arranged on a Y-axis marble base, a Y-axis connecting plate is arranged on the Y-axis linear guide rail, the Y-axis linear motor and the Y-axis connecting plate are in driving connection, and the Y-axis connecting plate is controlled to move along the Y-axis linear guide rail. The Y-axis marble base is connected with the X-axis connecting plate, and an included angle of 90 degrees is formed between the Y-axis linear guide rail and the X-axis linear guide rail. A quartz carrying table is arranged on a rotary DD motor, and the rotary DD motor is arranged on the Y-axis connecting plate. Movement is quiet, noise is low, an X-axis platform and a Y-axis platform can be dismounted, matching is convenient, and the modular design requirement is met.

Owner:SUZHOU DELPHI LASER +1

Gear box of heavy CNC vertical turning machine

The invention discloses a gear box of a heavy CNC vertical turning machine, which comprises a motor base, a gear box body, an intermediate shaft in the box body, an intermediate gear which is arranged on the intermediate shaft and a power input mechanism which is arranged between the intermediate shaft and the motor. The box body on the intermediate shaft section is stretched downwards, the box body on the motor base section moves synchronously, and the two sections of the box body are transversely jointed to form a step-shaped lower box body; and the lower end of the intermediate shaft is lengthened to reach into the lower box body, and the intermediate gear arranged on the intermediate shaft moves downwards to drive the power input mechanism arranged between the intermediate shaft and the motor base to move into the lower box body. The gear box of the heavy CNC vertical turning machine has the advantages of high precision, high transmission efficiency, high transmission rigidity, simple and compact structure, low manufacturing cost, low noise, high reliability and high driving force, can enable a worktable to realize a minimum speed of 0.15r / min, a maximum rotating speed of 125r / min and a torque of 1,000 kN.m, can be provided with a 50-160kW motor and has the capability of driving a ultra-large vertical lathe worktable with a bearable load of 1,000 tons.

Owner:齐重数控装备股份有限公司

Ultra-thin strap combined forming rolling mill with different speed ratios capable of being adjusted online and continuously

ActiveCN105170651AImprove surface qualityReduce torsional vibrationRoll mill control devicesMetal rolling arrangementsHuman–machine interfaceControl system

Disclosed is an ultra-thin strap combined forming rolling mill with the different speed ratios capable of being adjusted online and continuously. The ultra-thin strap combined forming rolling mill comprises a rolling mill master control part and a rolling mill mechanical part. A rolling mill control system human-computer interface is arranged in a master control computer. Input fields and output fields for speed setting of an upper working roller and a lower working roller, and an input field and an output field for adjustment step size setting of the different speed ratios are arranged on the human-computer interface. The master control computer is connected with an operation platform through a programmable logic controller (PLC). A rolling forward starting switch, a rolling backward starting switch and a different speed ratio adjusting switch are arranged on the operation platform. The different speed ratios can be increased or decreased by a different speed ratio adjustment step size online through the different speed ratio adjusting switch. When asymmetrical rolling of an ultra-thin strap is conducted through the ultra-thin strap combined forming rolling mill, the different speed ratios can be arranged to be infinitely variable and can be set to be an arbitrary value in theory. Due to the fact that the limit of the minimum rolling thickness of the synchronous rolling is overcome by the asymmetrical rolling and the thinness rolling capacity is stronger, the selection range of the diameter of the working rollers of the ultra-thin strap combined forming rolling mill can be broadened, accordingly, the occurrence of torsional vibration phenomena of the rollers is effectively reduced, and the surface quality of the ultra-thin strap is improved.

Owner:NORTHEASTERN UNIV LIAONING

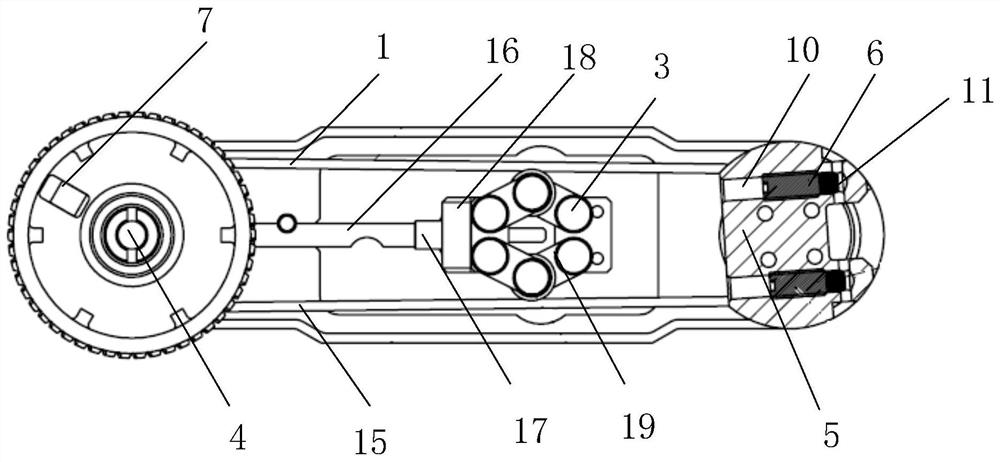

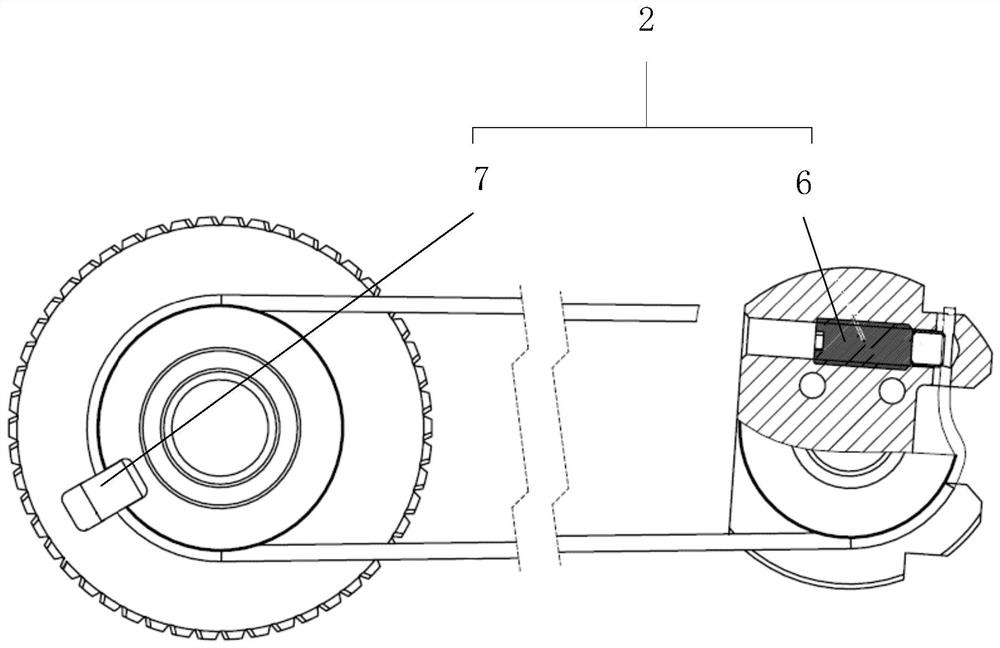

Cycloidal-pin wheel speed reduction type electric steering engine

ActiveCN111075912AHigh torqueLarge bending momentMechanical energy handlingGearing detailsControl theoryCycloid

The invention provides a cycloidal-pin wheel speed reduction type electric steering engine. The cycloidal-pin wheel speed reduction type electric steering engine comprises a servo motor, a servo motorbevel gear, a shell, an eccentric shaft, a rear end cover, a first crossed roller bearing assembly, a second crossed roller bearing assembly, a first cycloidal gear support, a second cycloidal gear support, a first cycloidal gear support roller assembly, a second cycloidal gear support roller assembly, a roller pin assembly, a cycloidal gear, a flange and an axial locking part, wherein the eccentric shaft, the rear end cover, the first crossed roller bearing assembly, the second crossed roller bearing assembly, the first cycloidal gear support, the second cycloidal gear support, the first cycloidal gear support roller assembly, the second cycloidal gear support roller assembly, the roller pin assembly, the cycloidal gear, the flange and the axial locking part are arranged in the shell. According to the technical scheme, the first cycloidal gear support cooperates with the cycloidal gear and the rear end cover, and the second cycloidal gear support cooperates with the cycloidal gear and the flange, so that the hinge moment and bending moment bearing capacity of the steering engine are remarkably improved, and the steering engine has the advantages of being high in rigidity and precision and simple and compact in structure; and the electric steering engine can realize high-bearing and high-precision operation in a narrow space.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Alignment mechanism and exposure machine with same

ActiveCN104678721AGuaranteed accuracyGuaranteed stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingControl system

The invention discloses an alignment mechanism. The alignment mechanism comprises a base assembly, an alignment bracket and an angle adjustment device, wherein the angle adjustment device is arranged on the base assembly and comprises a pushing device and a first driving device; the first driving device is used for driving the pushing device to horizontally move and comprises a linear motor assembly and a grating assembly; the grating assembly comprises a grating ruler, a mounting bracket and a grating ruler reading head; the grating ruler reading head is connected with the pushing device and is arranged parallel to the movement direction of the pushing device, the mounting bracket is connected with the base assembly, and the grating ruler is arranged on the mounting bracket. The invention further discloses an exposure machine. The exposure machine comprises an exposure machine main body, a light source device, a control system and the alignment mechanism, wherein the alignment mechanism is mounted on the exposure machine main body. The mounting position of the exposure machine is automatically regulated through the alignment mechanism; the alignment mechanism is simple in structure, good in stability and high in regulation precision.

Owner:浙江欧视电科技有限公司

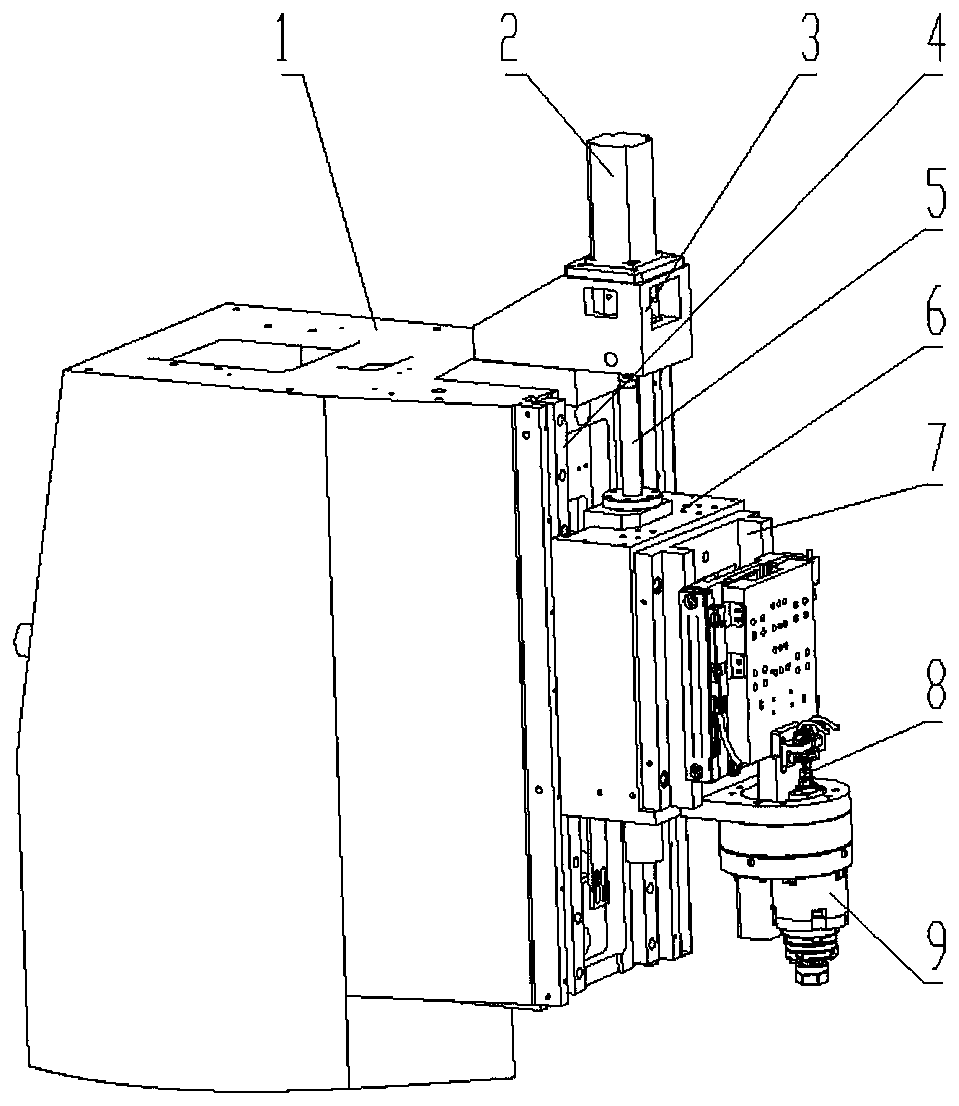

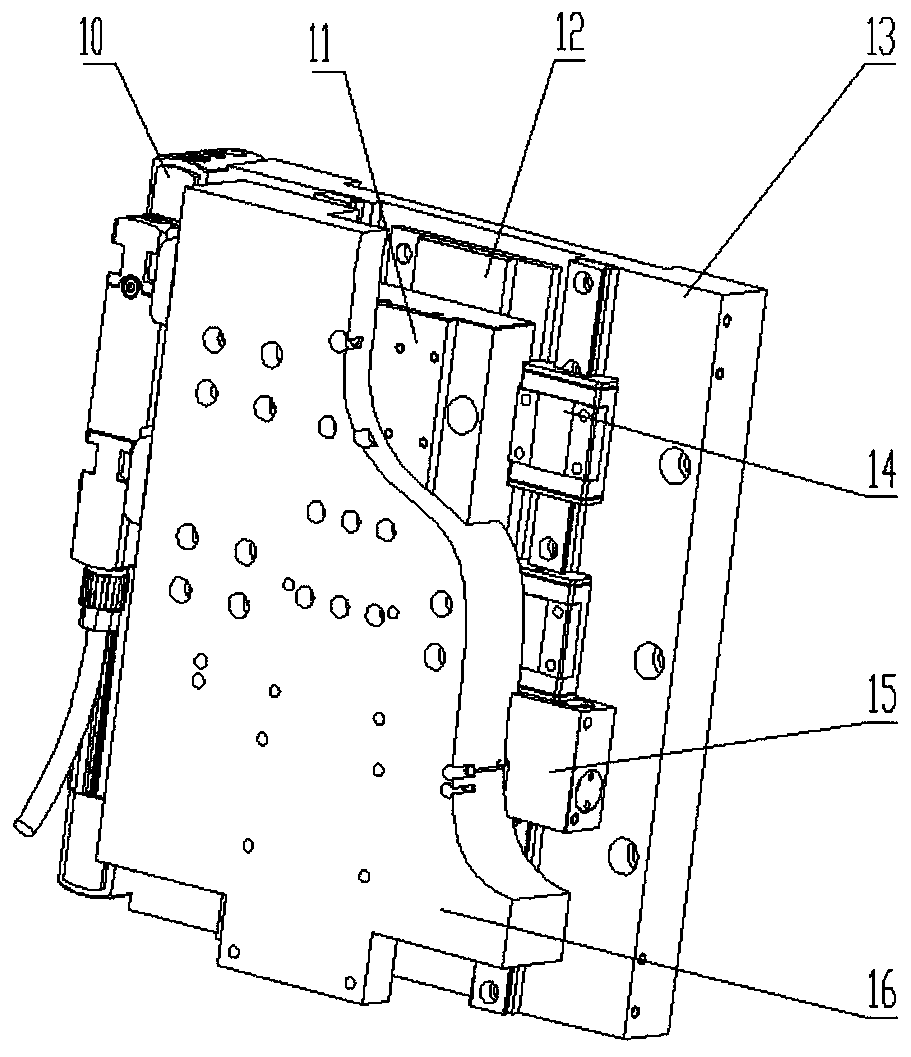

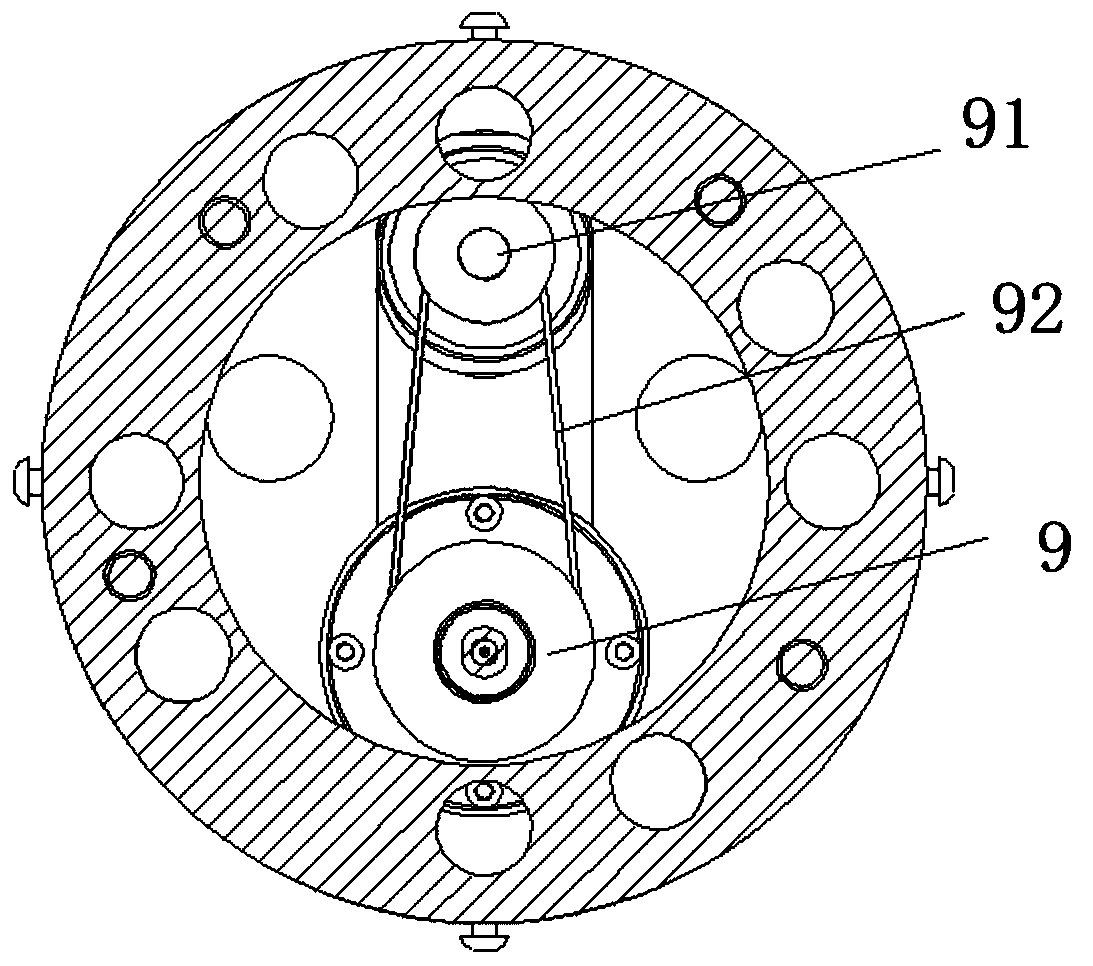

Dual-purpose main shaft in Electric Discharge Machining machine tool

PendingCN110814456AImprove practicalityMeet processing needsElectrical-based auxillary apparatusElectric dischargeElectric machine

The invention discloses a dual-purpose main shaft in an Electric Discharge Machining machine tool. The dual-purpose main shaft is characterized by comprising a main shaft system and a linear motor system, wherein the main shaft system is arranged on a stand column of the Electric Discharge Machining machine tool and involves a Z-axis servo motor, a ball screw, a Z-axis sliding seat and an R shaft,the linear motor system involves a linear motor and an electrode wire clamping mechanism, an electric motor is connected with the electrode wire clamping mechanism, a motor stator is fixed on a mounting plate, and the mounting plate is fixedly mounted on the Z-axis sliding seat. According to the dual-purpose main shaft in the Electric Discharge Machining machine tool, under the condition that a common Electric Discharge Machining main machine structure is not changed, the linear motor is combined to the servo motor drive, and the transformation cost is small, the machining requirements of a large-depth-diameter-ratio micro-hole, a narrow slit and a narrow groove can be met, the large-weight and large-area electrode machining task requirements can be met.

Owner:北京市电加工研究所有限公司

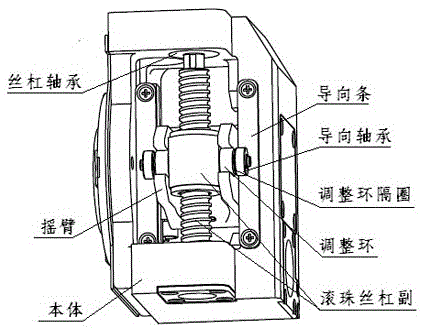

High-rigidity transmission mechanism

The invention discloses a high-rigidity transmission mechanism. The high-rigidity transmission mechanism comprises a mechanism body, screw bearings, a ball screw pair, rocker arms, adjusting rings, adjusting ring spacing collars, guide bearings, and guide strips. The ball screw pair does circular motion, in the moving process, a ball nut can only do vertical translation due to existing of the guide bearings, supporting arms extending from the two ends of the ball nut are connected with rocker arm shifting forks through the adjusting rings, and accordingly, the vertical translation of the nut is converted into circular motion of the rocker arms. Force produced through load torque can be uniformly distributed through the two supporting arm structures of the ball nut, deformation of the rocker arms is decreased, and the rigidity is improved; the outer ends of the supporting arms of the ball nut are provided with the guide bearings to make contact with the guide strips, self rotating of the ball nut is limited, and the gap in the ball screw pair is eliminated; meanwhile, the inner circle and the outer circle of each adjusting ring are in interference fit so that the clearance can be eliminated; and the adjusting rings and the rocker arms are made of a stainless steel material and subjected to heat treatment so that the hardness and abrasion resistance of the surfaces of the adjusting rings and the surfaces of the rocker arms can be improved.

Owner:SHANGHAI XINYUE METER FACTORY

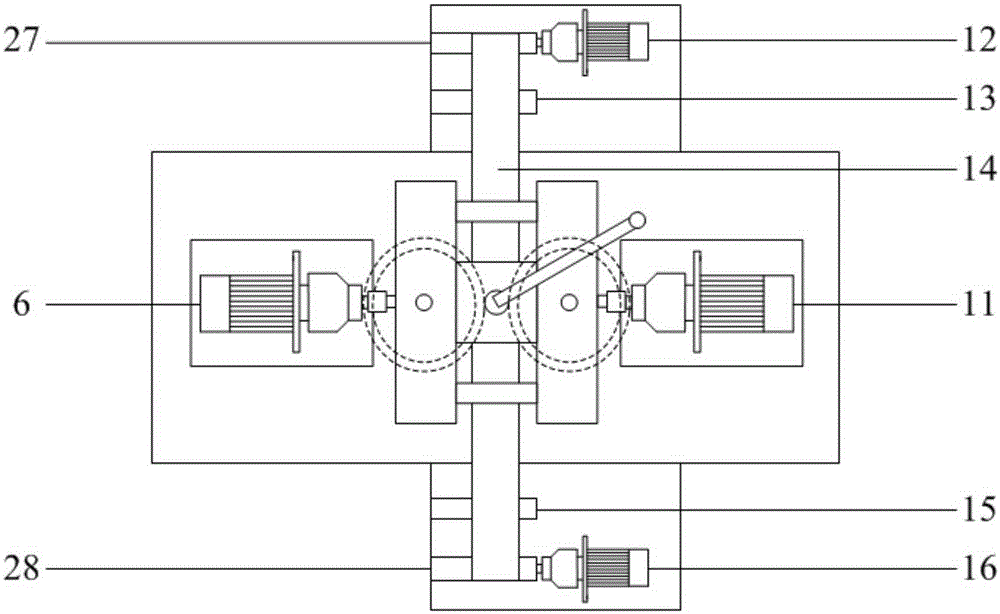

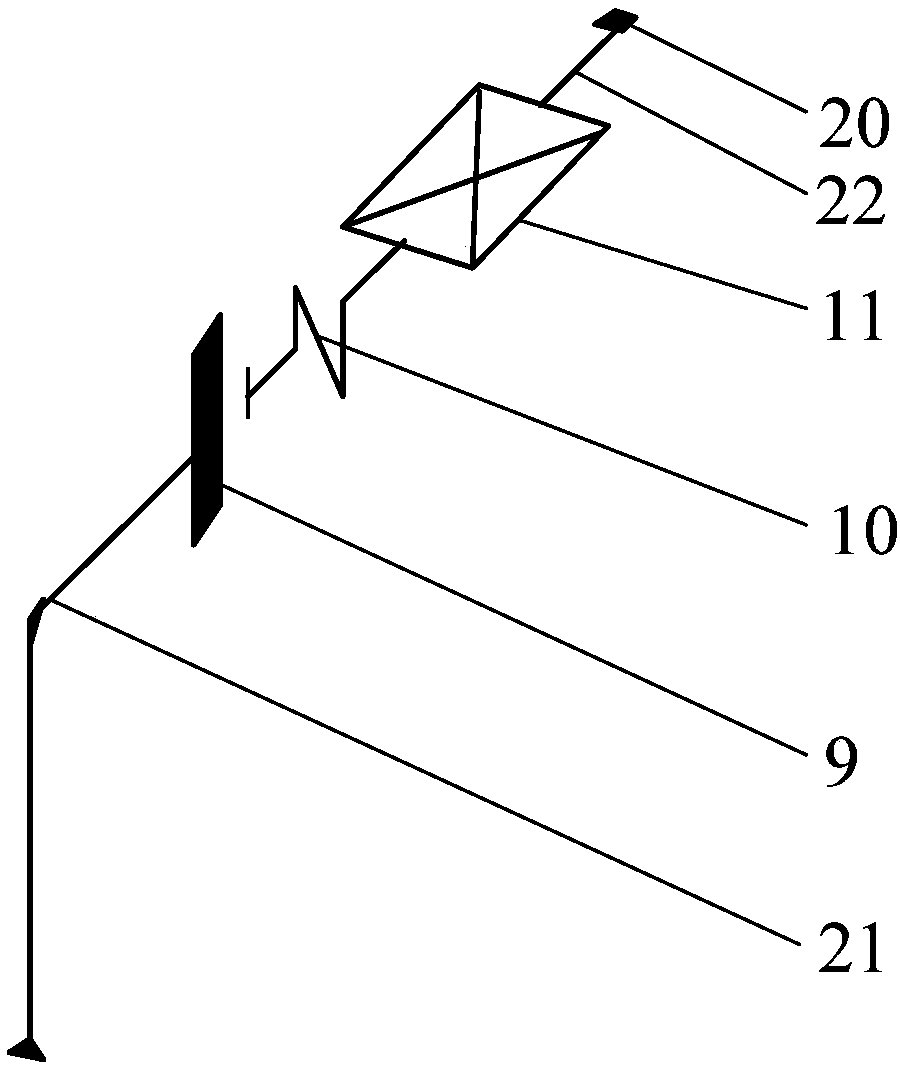

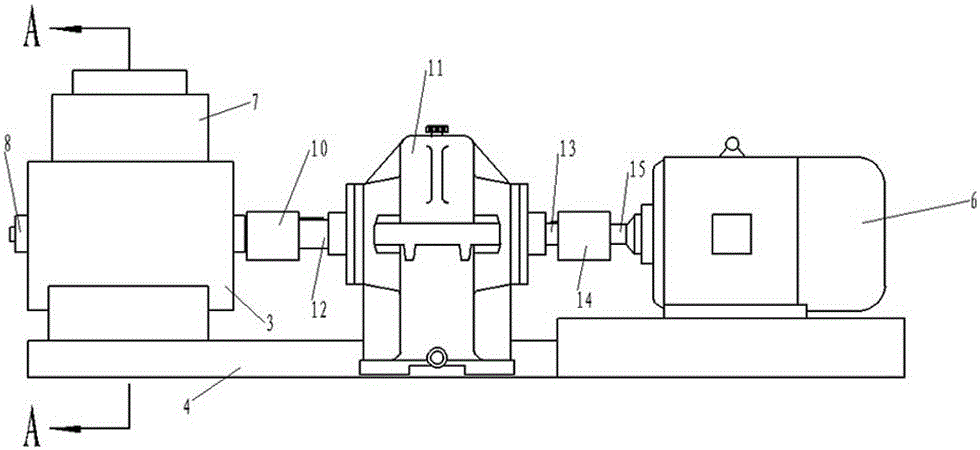

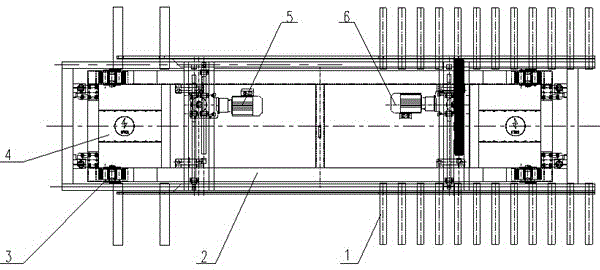

Bi-directional electromechanical actuation type test-bed for damper

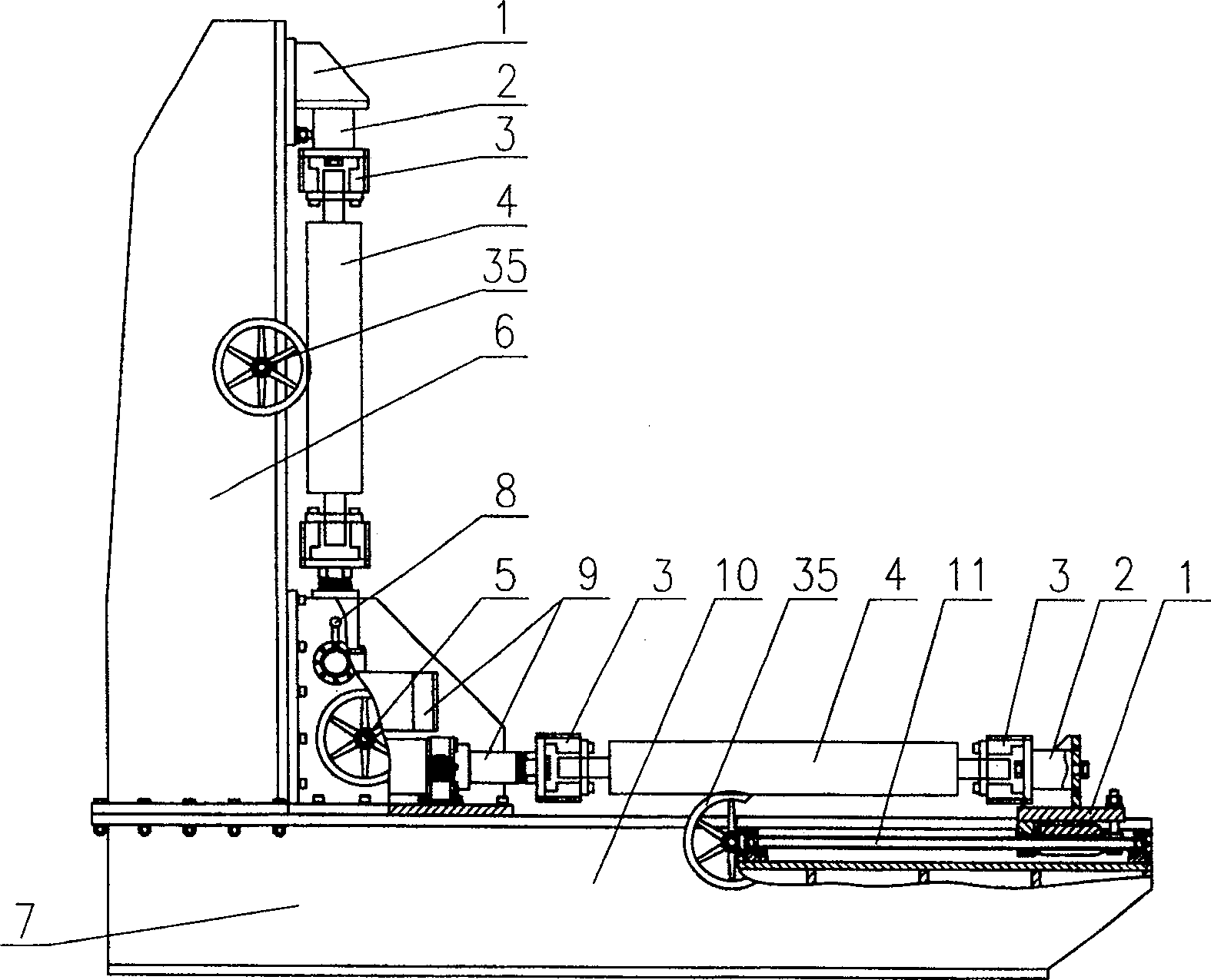

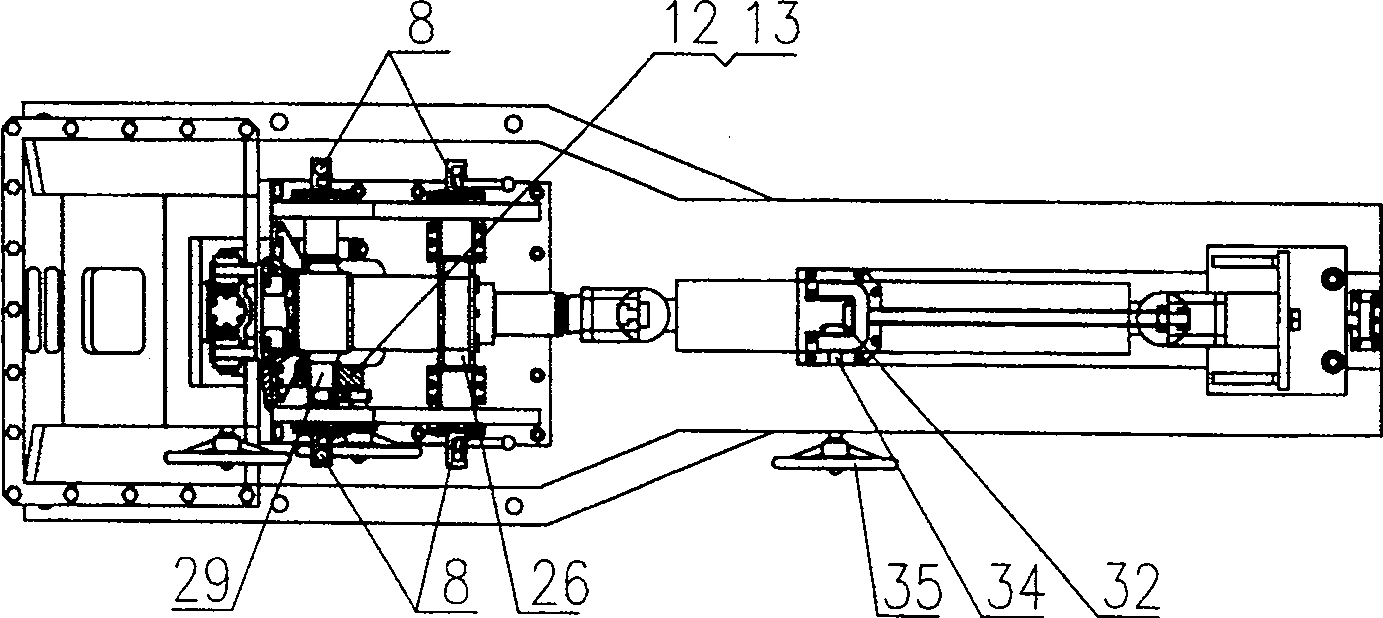

InactiveCN1727867AAdaptableEasy to install and debugVehicle suspension/damping testingLocking mechanismEngineering

A test bed of vibration absorber in two way electromechanical actuating type consists of í‹ LíŒ shaped body base formed by rigid ¿C connecting base with vertical column ; electromechanical actuator formed by power mechanism , driving mechanism and executing mechanism ; turnover mechanism on body base for rotating said actuator on lead vertical surface , locking mechanism on base and vertical column for locking said actuator and counter force seat on both base and vertical column .

Owner:SOUTHWEST JIAOTONG UNIV

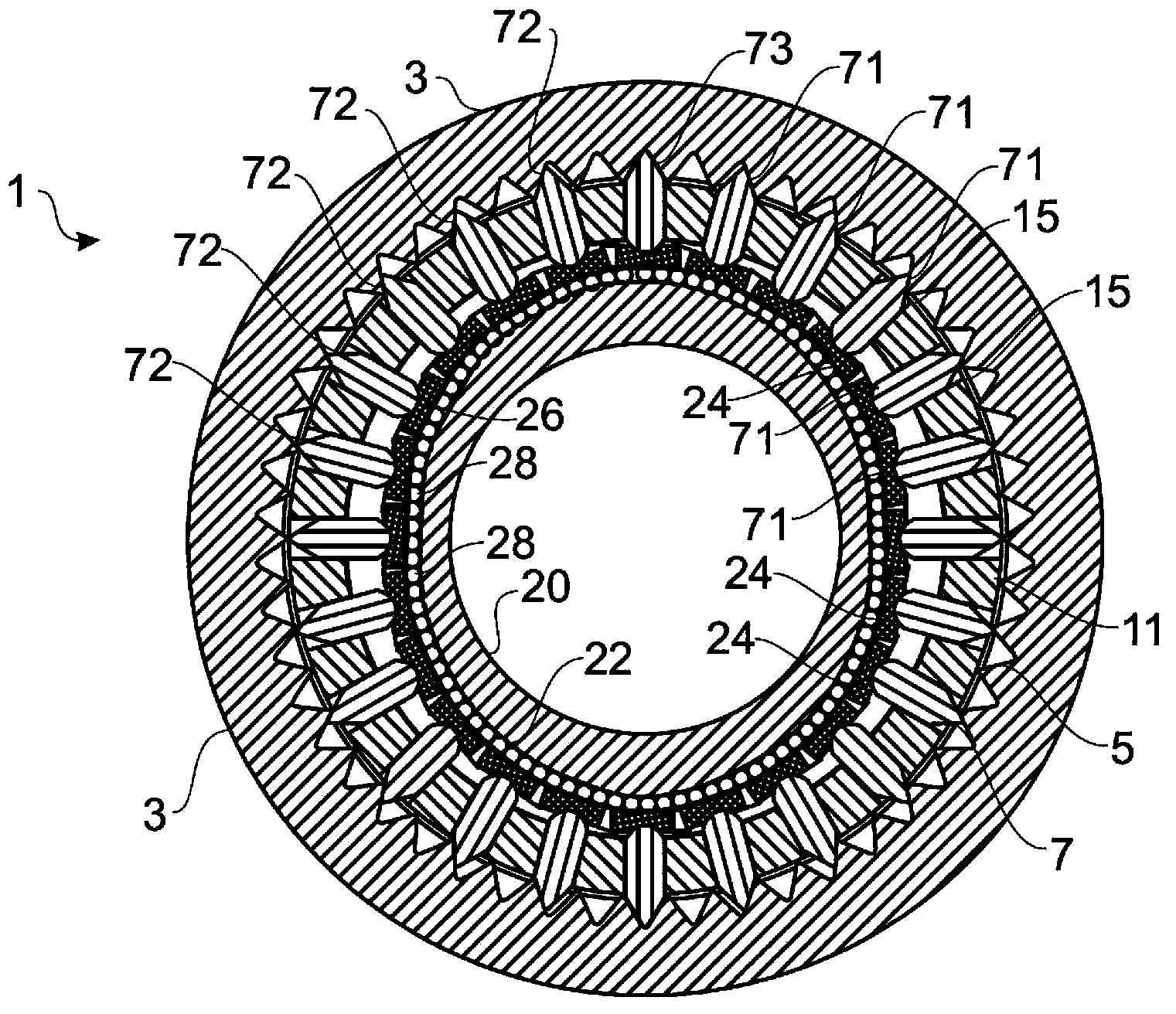

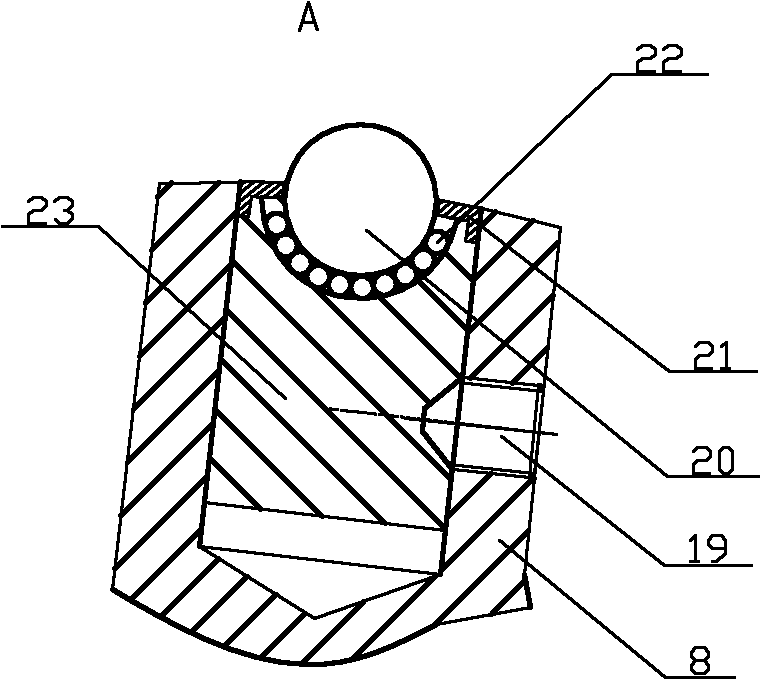

Nutation oscillating-tooth speed reducer

InactiveCN102080706AHigh transmission precisionReduce volumeGearboxesToothed gearingsLow noiseNutation

The invention belongs to speed reducers, and specifically relates to a nutation oscillating-tooth speed reducer. The nutation oscillating-tooth speed reducer is characterized in that a bull-eye type nutation-disc oscillating-tooth transmission mechanism comprises a nutation disc, a nutation bearing, a bearing sleeve, an end cover, bull-eye type round-ball rolling pair sets, a fixed disc tooth slot and a rotating disc tooth slot; each bull-eye type round-ball rolling pair set is formed by arraying a plurality of bull-eye type round-ball rolling pairs; and each bull-eye type round-ball rolling pair consists of a round ball, a round ball check ring, a rolling ball and an oscillating-tooth main body. The speed reducer is reasonable, novel and special in design, has a compact structure, can solve the problem that the similar speed reducer has a complex structure, large volume and low transmission efficiency, and also can prevent the defect of top cutting generated when the transmission ratio is great; and simultaneously, the speed reducer has the characteristics of high transmission precision, high transmission rigidity, high transmission efficiency, low noise, big transmission ratio, long service life, few parts, small volume, light weight, convenience for installment, manufacturing and maintenance, good bearing capability, no need of output mechanisms, and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

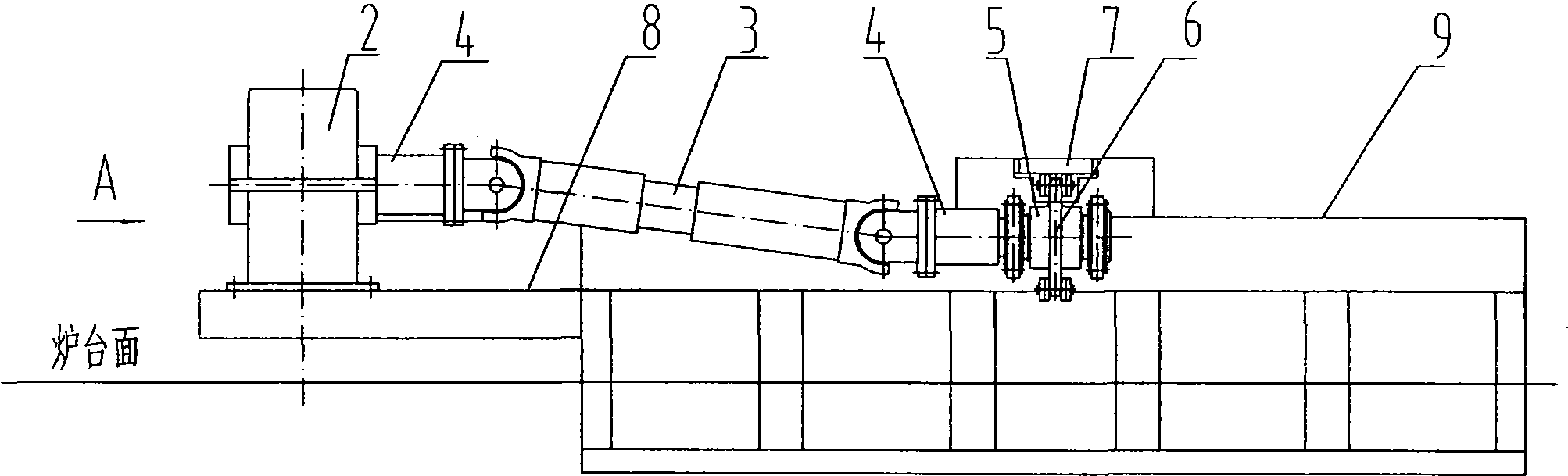

Coal-charging transmission gear for tamping coke oven

The invention relates to a coal charging driving device for a tamping coke oven, which relates to a device special for the tamping coke oven. In the prior art, because the driving link of the driving device for the damping coke oven is long, the weight of the mechanism is heavy and the driving rigidity is poor, the stability of coal cakes in the coal charging process becomes poor. The coal charging and driving device of the invention uses a motor to drive a chain wheel shaft by a speed reducer through a middle driving system, the chain wheel shaft drives a chain wheel, and then the chain wheel drives a closed loop chain provided with a coal supporting plate. The middle driving system is connected with a universal joint by the speed reducer through a coupling flange, and the other end of the universal joint is connected with the chain wheel shaft through the coupling flange. Compared with the prior art, the coal charging driving device lightens the weight of the mechanism and improves the driving rigidity and the stability of the coal cakes in the coal delivering process because the speed reducer is directly connected with the chain wheel shaft through the universal joint.

Owner:TAIYUAN HEAVY IND

Intelligent patrol robot execution mechanism of high-voltage distribution room

PendingCN108258603AImprove transmission efficiencyHigh positioning accuracyProgramme-controlled manipulatorSwitchgearTransfer switchControl engineering

The present invention relates to the field of patrol robots, and especially to an intelligent patrol robot execution mechanism of a high-voltage distribution room. The mechanism comprises a lifting fork mechanism, an opening button execution unit, a transfer switch rotation unit and a polar column short-circuit unit, each unit is arranged on a lifting platform at the upper end of the lifting forkmechanism, the opening button execution unit is provided with a first drive rod configured to press an opening button, the transfer switch rotation unit is provided with an inner concave mold, the inner concave mold has two degrees of freedom of movement and rotation, the polar column short-circuit unit comprises a protective cover pulling mechanism, a protective cover insertion mechanism and a plugging rotation joint, the protective cover pulling mechanism and the protective cover insertion mechanism are fixedly connected with the plugging rotation joint, a five-protection lock protective cover is pulled out by employing the protective cover pulling mechanism, and a standby polar column short-circuit cover is inserted into the polar column position of a high-voltage control cabinet through the protective cover insertion mechanism after the five-protection lock protective cover is pulled out. The intelligent patrol robot execution mechanism of the high-voltage distribution room can greatly improve the patrol efficiency and can effectively reduce the fault hidden troubles.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

High-speed metal plate shearing machine

The invention discloses a high-speed metal plate shearing machine which comprises a shell, a machine seat, a shearing rotor and a motor, wherein the shell is provided with a material feeding opening and a material discharging opening; the shearing rotor is matched with the inner side of the shell; the shell is fixedly connected with the machine seat; the motor is fixedly connected with the machine seat; the feeding opening is provided with a hopper. The high-speed metal plate shearing machine has the beneficial effects that the driving rigidity is high, device power is strong, soft aluminium plates can be sheared, high-strength iron plates also can be sheared easily, the plates at the feeding opening can be prevented from being burst forth to hurt people by using the hopper, and the safety is further improved.

Owner:NANTONG CHENGTAI MAGNETIC MATERIAL TECH CO LTD

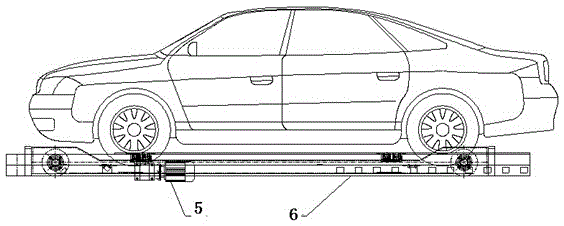

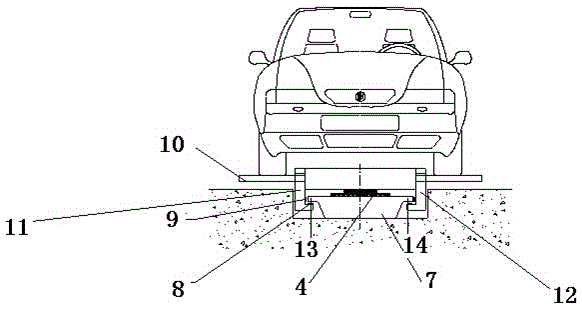

Magnetic suspension intelligent carrier

InactiveCN105110019AImprove protectionRun fastNon-mechanical conveyorsAutomotive engineeringElectromagnet

The invention discloses a magnetic suspension intelligent carrier which comprises a steel structure unit. The steel structure unit comprises outer carrier frames, an inner carrier frame, a braking auxiliary wheel, a linear motor, a front wheel centering system, a rear wheel centering system, a guide rail, suspending electromagnets, guide electromagnets and a vehicle carrying frame. The vehicle carrying frame is used for fixing vehicles. The lower portion of the vehicle carrying frame is connected with a left hanging device and a right hanging frame. The cross section of the left hanging device and the cross section of the right hanging device are in an L type, and the guide electromagnets are arranged on the inner side of the vertical wall face of the L-type cross section of the left hanging device and the inner side of the vertical wall face of the L-type cross section of the right hanging device respectively. The suspending electromagnets are arranged on the upper surface of the horizontal wall face of the L-type cross section of the left hanging device and the upper surface of the horizontal wall face of the L-type cross section of the right hanging device respectively. The front wheel centering system and the rear wheel centering system are used for enabling the vehicles to be placed in the center of the magnetic suspension intelligent carrier.

Owner:SHANGHAI HYTONE PARKING EQUIP CO LTD

Multifunctional rolling mill for producing thin metal straps and ultra-thin metal straps

ActiveCN102989765BIncrease the diameterImprove transmission stiffnessMetal rolling stand detailsMetal rolling arrangementsThin metalAlloy

Owner:NORTHEASTERN UNIV LIAONING

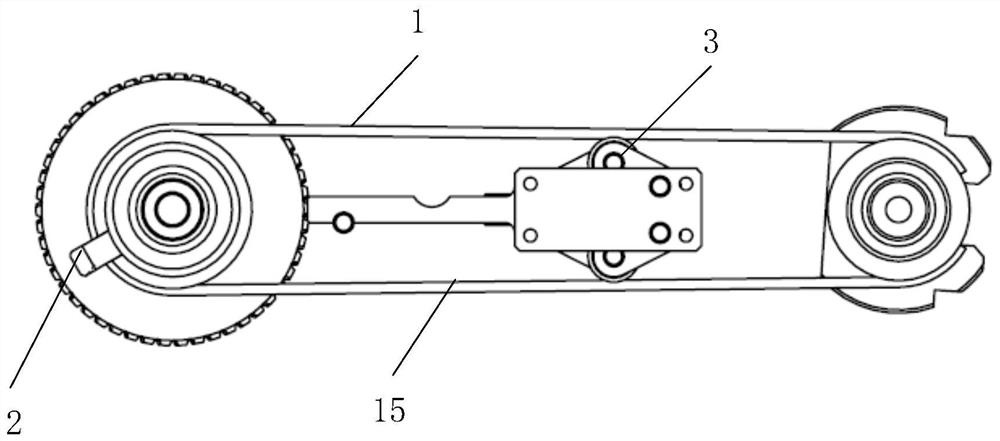

Rope transmission mechanism and rope transmission mechanism of manipulator

ActiveCN113043259AIncrease the selected diameterEasy maintenanceProgramme-controlled manipulatorEngineeringWire rope

The invention provides a rope transmission mechanism. The rope transmission mechanism comprises a steel wire rope, a connecting device and a tensioning device, wherein the steel wire rope is sequentially wound on a driving wheel and a driven wheel in a certain direction and forms a steel wire ring; the driving wheel pulls the driven wheel to rotate through the steel wire rope; the connecting device comprises a driving wheel connecting device and driven wheel connecting devices; the driving wheel connecting device is arranged on the driving wheel and connects the driving wheel and the steel wire rope; the driven wheel connecting devices are arranged on the driven wheel and connect the driven wheel and the steel wire rope; and the tensioning device is arranged between the driving wheel and the driven wheel and connected with the steel wire rope and is used for tensioning the steel wire rope. According to the single-rope transmission in the embodiment of the invention, on the premise of a narrow installation space, the space utilization rate is increased, and the selected diameter of the rope is increased, so that the transmission rigidity is improved. The continuous tensioning mechanism is convenient to adjust, the upper section and the lower section of the steel wire rope are effectively and synchronously tensioned, and movement coordination and force transmission stability are guaranteed.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

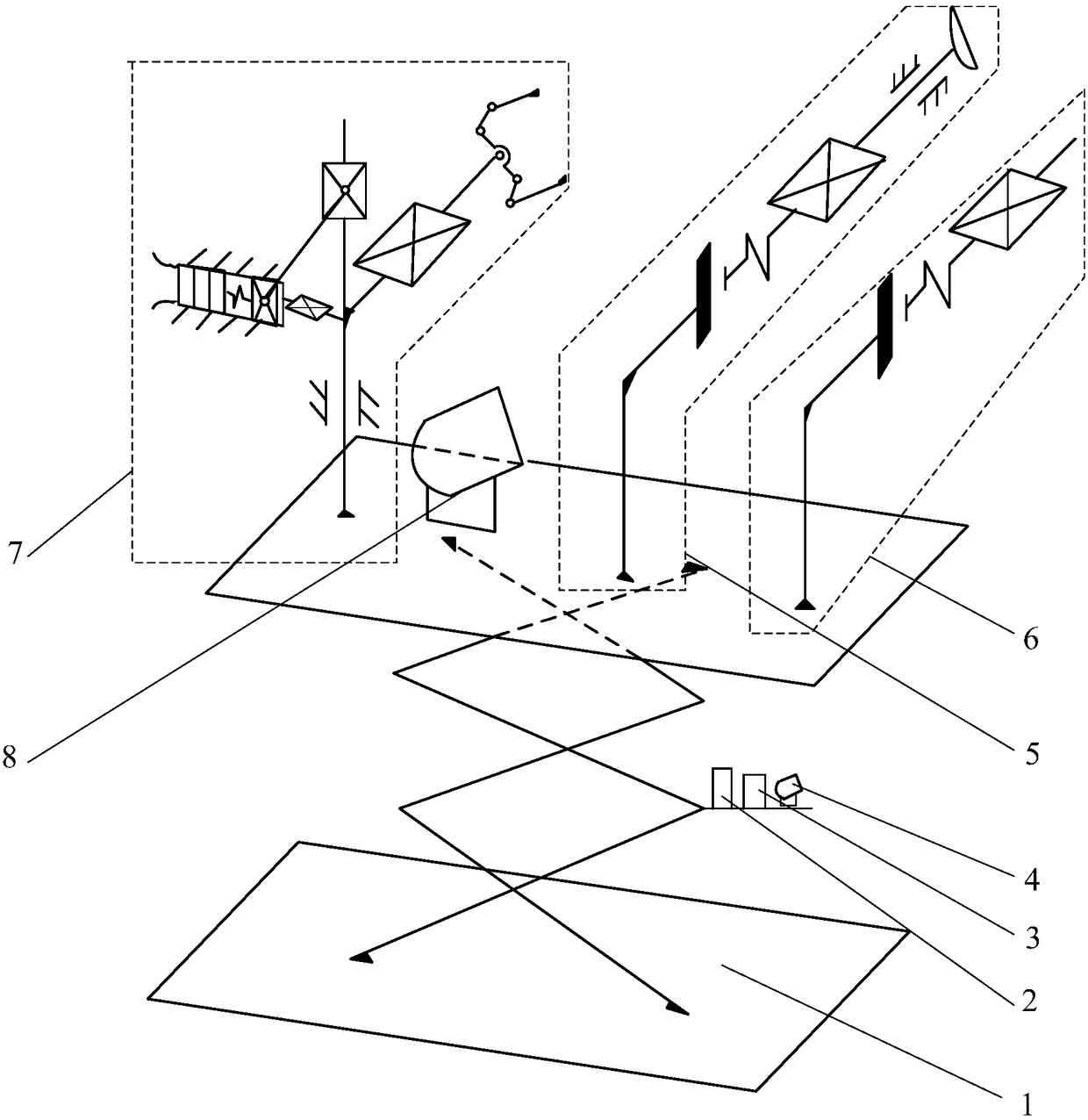

Long-distance, heavy-load and parallel-axis type precision 2:1 transmission mechanism

ActiveCN106545626ALow elongationImprove transmission stiffnessRopes and cables for vehicles/pulleyGearingEngineeringProcessing cost

The invention discloses a long-distance, heavy-load and parallel-axis type precision 2:1 transmission mechanism. The mechanism mainly comprises an input shaft, an output shaft, a flexible transmission part, a pre-tensioning pressing block, an end part fixing block, etc., wherein the input shaft is parallel to the output shaft and is connected with the output shaft through a flexible transmission part; two ends of the flexible transmission part are fixed to the output shaft; an intermediate part of the flexible transmission part is fixed to the input shaft; the input shaft in rotating can drive the flexible transmission part, and the flexible transmission part can synchronously pull the output shaft to rotate; as the input shaft and the output shaft of the whole mechanism are correspondingly connected with a driving end and a load end of an limited cornering device, the parallel 2-1 transmission of the driving end and the load under the long-distance and heavy-load condition can be achieved. The mechanism has the characteristics of being high in transmission accuracy, high in transmission rigidity, simple in structure, convenient to dismount and mount, low in processing cost, and easy to construct; the problem that the long-distance, heavy-load and parallel-axis type precision 2:1 transmission is hard to achieve by a traditional transmission mode can be solved.

Owner:西安应用光学研究所

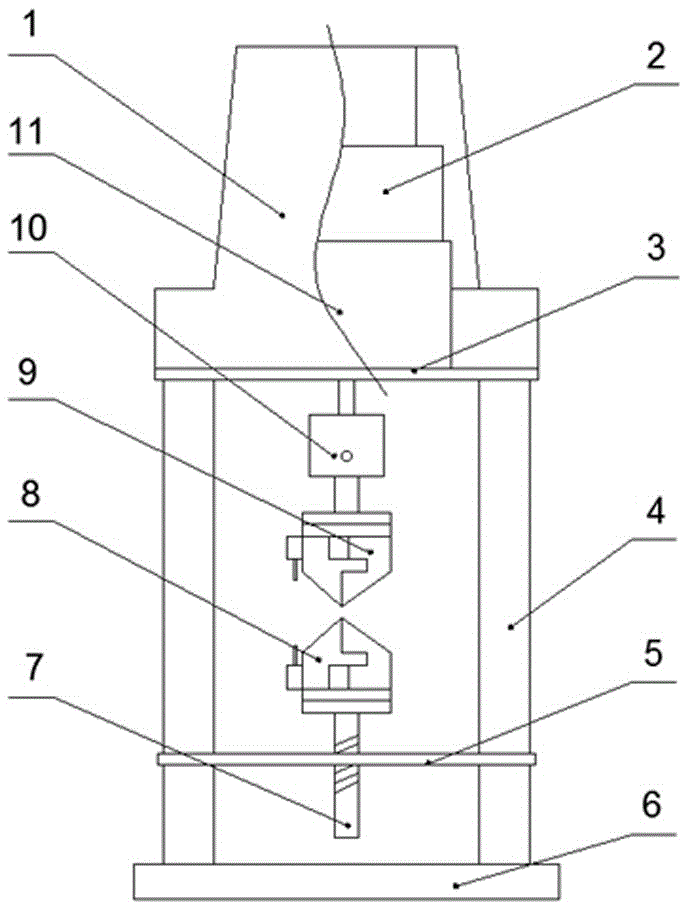

Fatigue testing machine

InactiveCN106769565AHigh precisionImprove transmission stiffnessMaterial strength using repeated/pulsating forcesFatigue testingAutomotive engineering

The invention discloses a fatigue testing machine. A mechanical part of the fatigue testing machine comprises a motor cover, a voice coil motor, a fixture, an upper support plate, a motor support plate, an intermediate plate, vertical columns and a bottom plate. The voice coil motor is used as a power source. The fatigue testing machine has the characteristics of high precision, high response speed, high transmission stiffness, smooth thrust, high reliability, no limitation of travel length and long life. The two vertical columns are used as main supports so that the structure is simple. Raw materials are saved in production and a cost is reduced.

Owner:郭洪

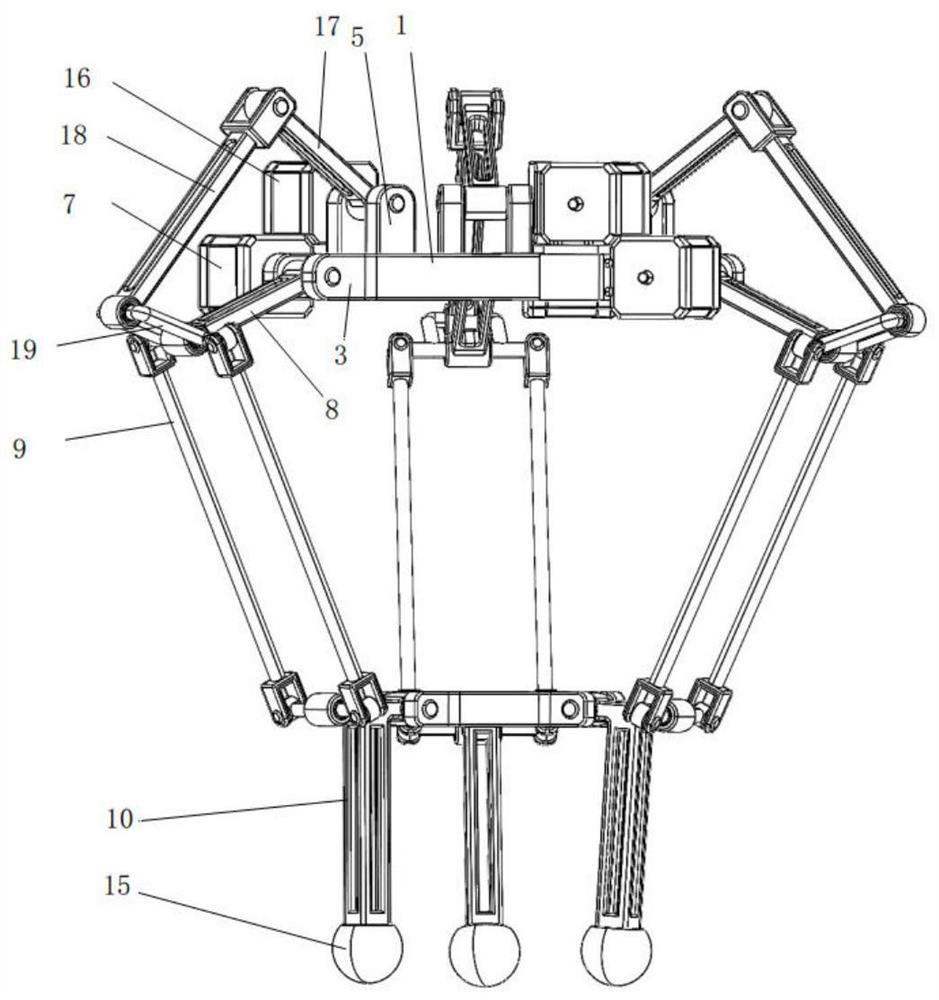

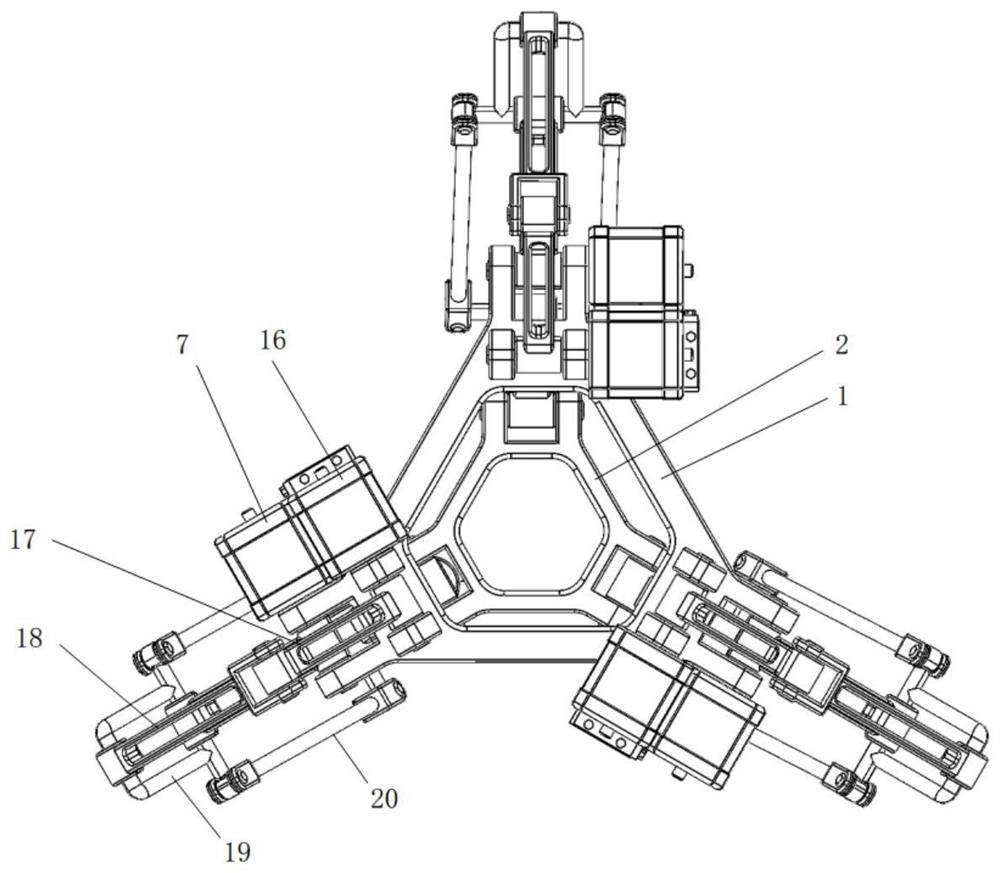

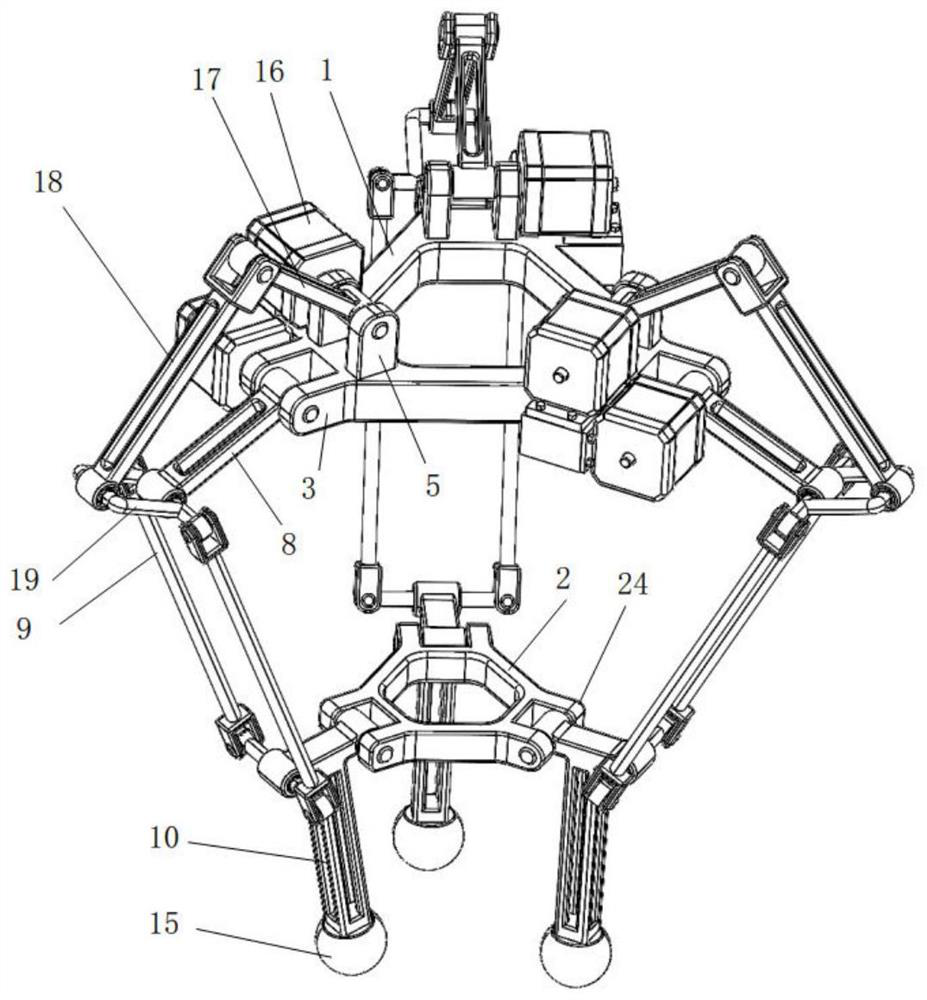

Logistics sorting robot with embedded mechanical claw

PendingCN113146589AFast sortingStructural symmetryProgramme-controlled manipulatorGripping headsLogistics managementEngineering

The invention discloses a logistics sorting robot with an embedded mechanical claw. The logistics sorting robot comprises a fixed platform, driving branch chains and a moving platform; the driving branch chains are arranged on the fixed platform, the driving branch chains comprise the first driving branch chain, the second driving branch chain and the third driving branch chain, and the first driving branch chain, the second driving branch chain and the third driving branch chain are evenly distributed on the fixed platform in the circumferential direction; the fixed platform serves as a supporting platform to grab, carry and release objects to be sorted; and the moving platform is arranged on the driving branch chains, and the moving platform is connected to the first driving branch chain, the second driving branch chain and the third driving branch chain at the same time so as to assist and coordinate a driving transmission part to grab, carry and release the objects to be sorted. The logistics sorting robot is symmetrical in structure, simple in structure, easy to assemble, high in rigidity, low in manufacturing cost, wide in application range, large in load capacity and high in logistics sorting speed, and modular production is easy to achieve.

Owner:江苏天东智特科技有限公司

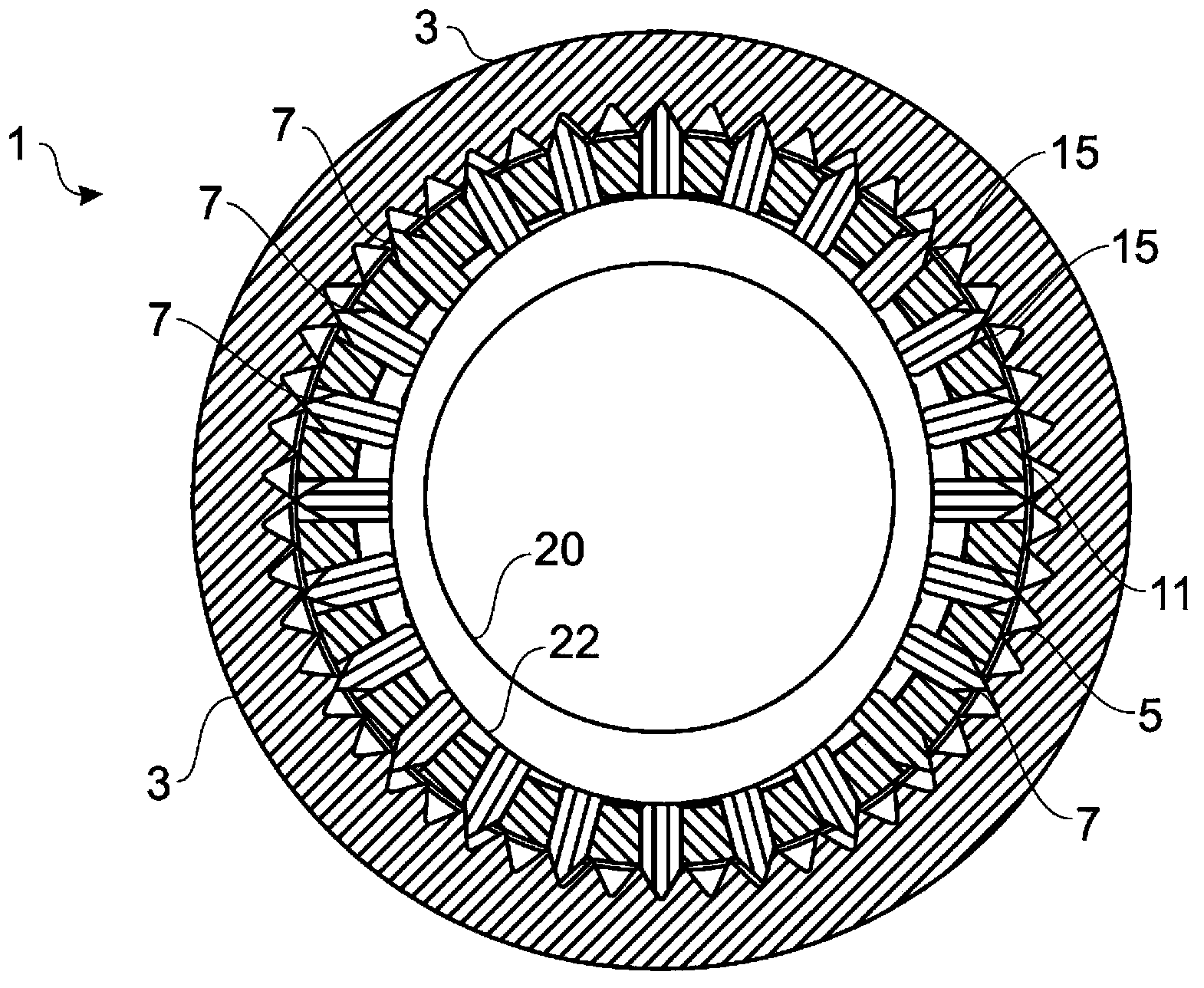

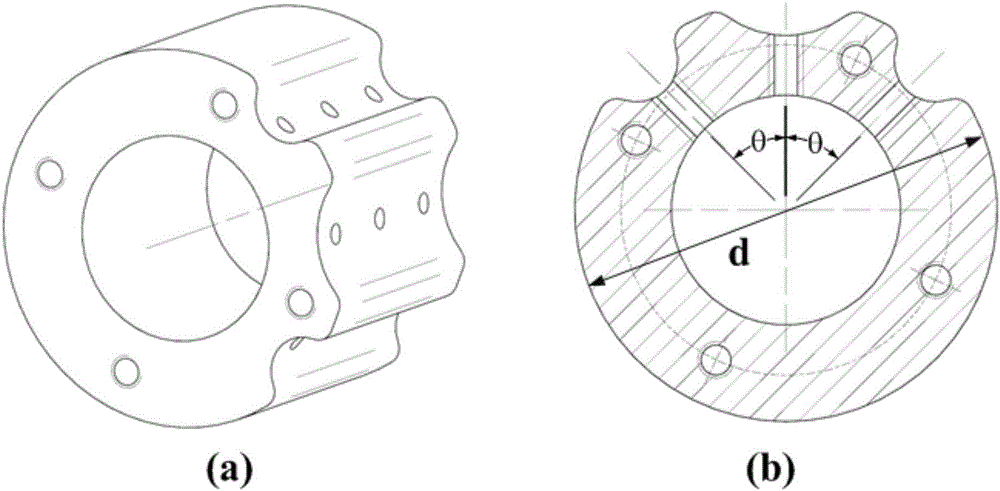

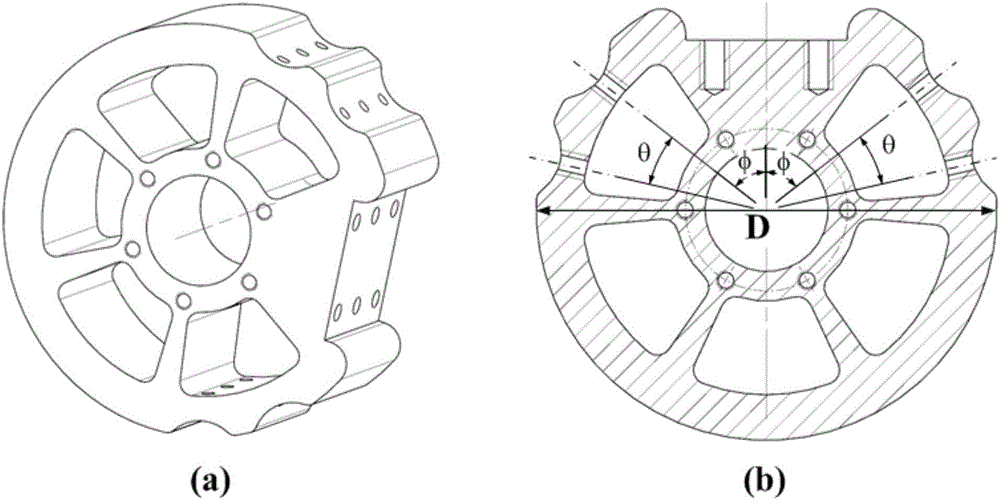

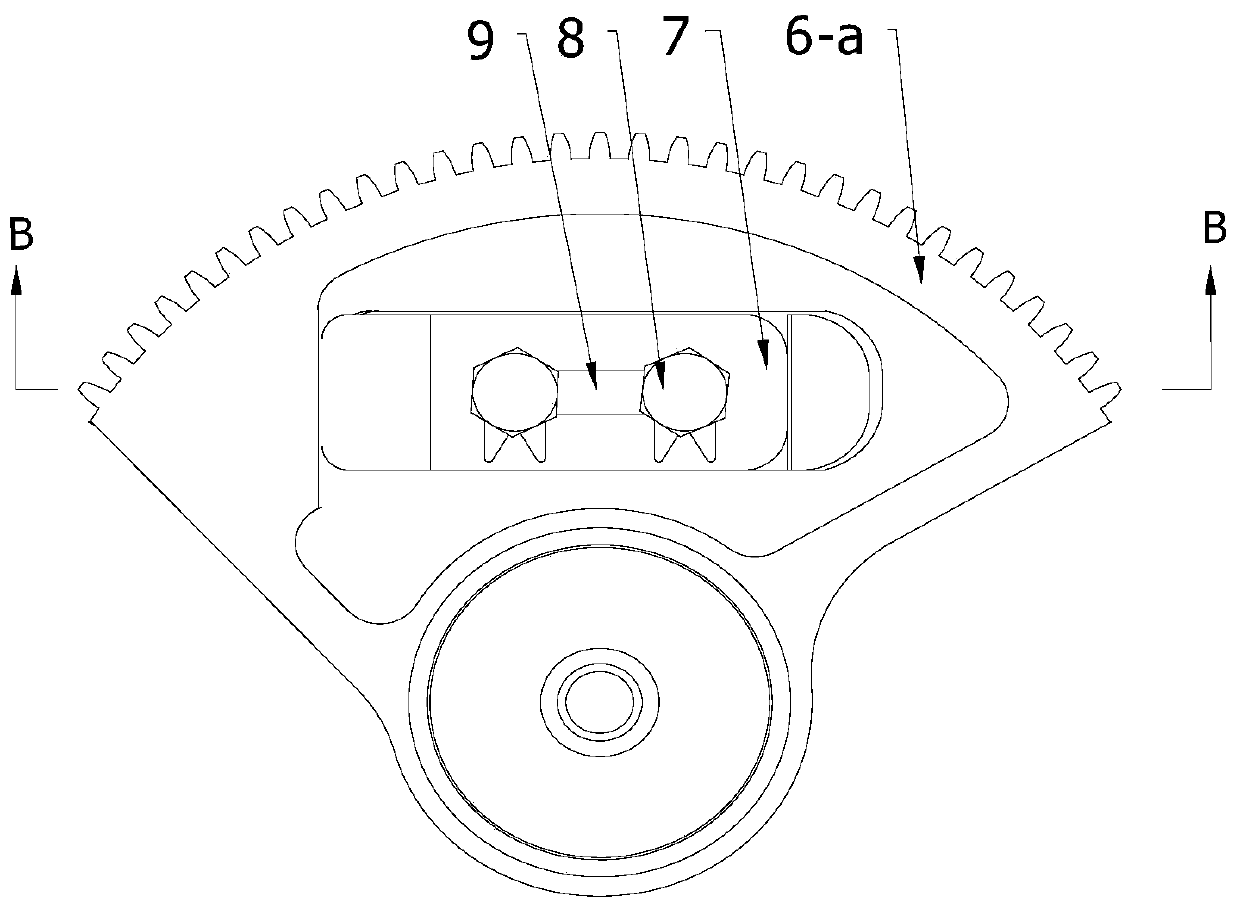

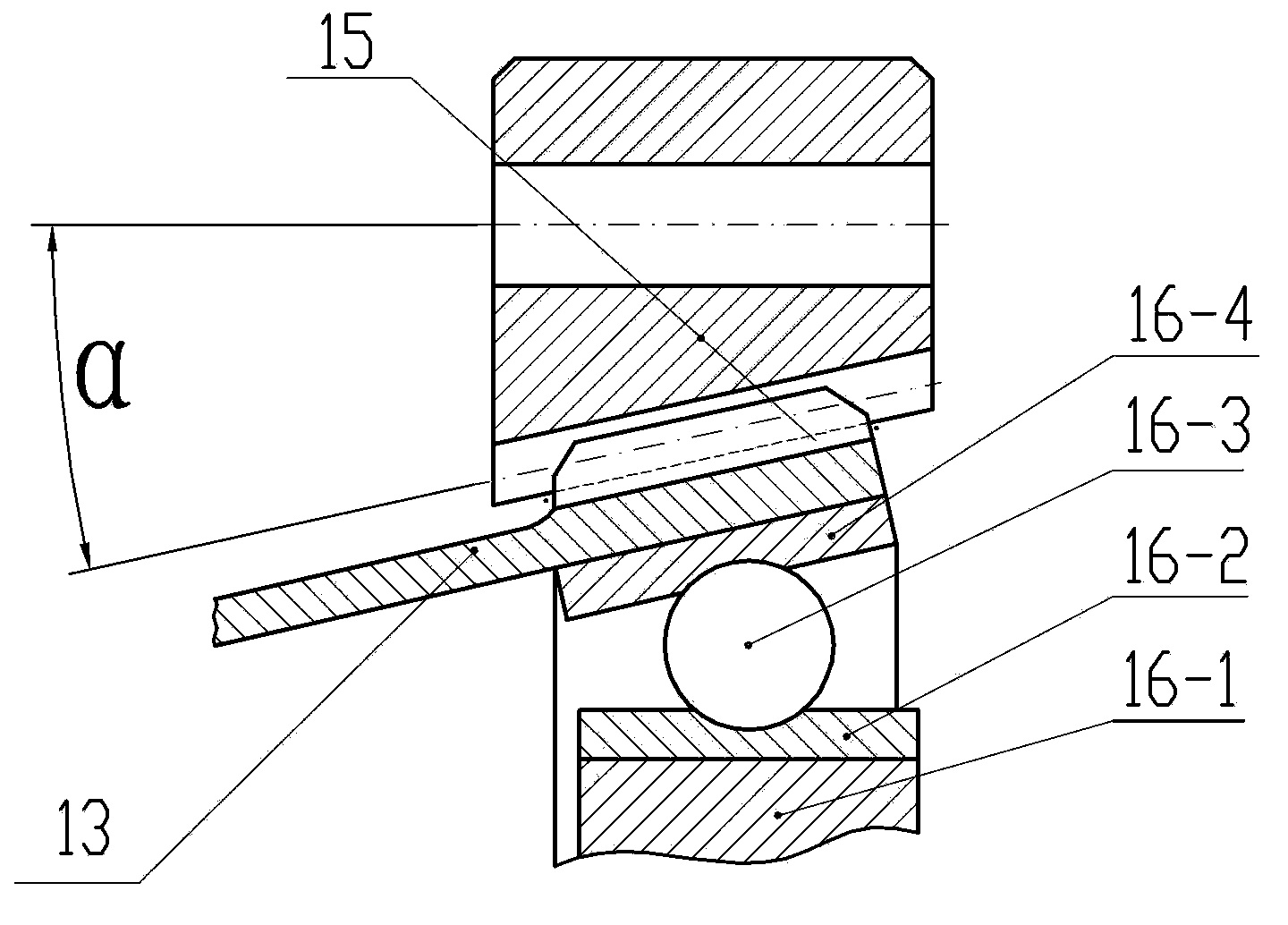

Rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and machining process thereof

Provided are a rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and a machining process thereof. Inner teeth of the rigid gear are gear teeth with an inclination angle alpha, the inclination direction of the inclination angle alpha is consistent with the field angle theta2 at the position of a long shaft of the flexible gear, and the inclination angle alpha is 0.1 degree to 2 degrees. Top ends of two tooth profile curve line sections of the outer tooth profile of the flexible gear are connected through a tooth top straight line section. Each tooth profile curve line section is formed by connecting upper circular radius and lower circular radius in smooth transition mode. The harmonic speed reducer comprises the rigid gear, the flexible gear and a wave generator. The ratio of the length and the inner diameter of the flexible gear is smaller than 1. The flexible gear and the rigid gear in the short-tube flexible-wheel harmonic speed reducer are both machined through a slow-feeding wire cutting off machine. The gear teeth of the flexible gear and the gear teeth of the rigid gear are meshed in the certain inclination angle. The total contact area of the meshing teeth pair is increased by 15% compared with the condition where no inclination angle exists. Overlapping ratio of the harmonic gears is improved, and harmonic transmission rigidity is improved.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

Multistage-transmission speed-reduction clearance-elimination gear box for airplanes and clearance-elimination method

PendingCN111059251ASave spaceImprove transmission stabilityPortable liftingGearing detailsGear wheelControl engineering

The invention relates to a multistage-transmission speed-reduction clearance-elimination gear box for airplanes. The gear box comprises a gear box body, a clearance-elimination cushion block, bolts, nuts, a driving gear, an intermediate gear set and a driven gear set, wherein the driving gear, the intermediate gear set and the driven gear set are sequentially meshed for transmission; the driven gear set comprises a driven gear thin gear and a driven gear thin gear shaft; the driven gear thin gear sleeves the driven gear thin gear shaft; a rectangular notch is formed in a hub web plate of the driven gear thin gear; a lug is arranged on a web plate of the driven gear thin gear thin gear shaft; the driven gear thin gear passes through the rectangular notch, one side of the lug is arranged ina gap with the rectangular notch, and the other side is pressed against the clearance-elimination cushion block embedded in the rectangular notch; a contact surface of the clearance-elimination cushion block with the rectangular notch is arranged to be an inclined surface flaring outwards; and the bolts penetrate through the clearance-elimination cushion block and the driven gear thin gear shaft and are pressed against the nuts. The invention relates to a clearance elimination method of the multistage-transmission speed-reduction clearance-elimination gear box for airplanes, and tooth staggering clearance is adjusted by screwing nuts for a plurality of times, so that operation is convenient, the structure is simple, and maintenance is convenient.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

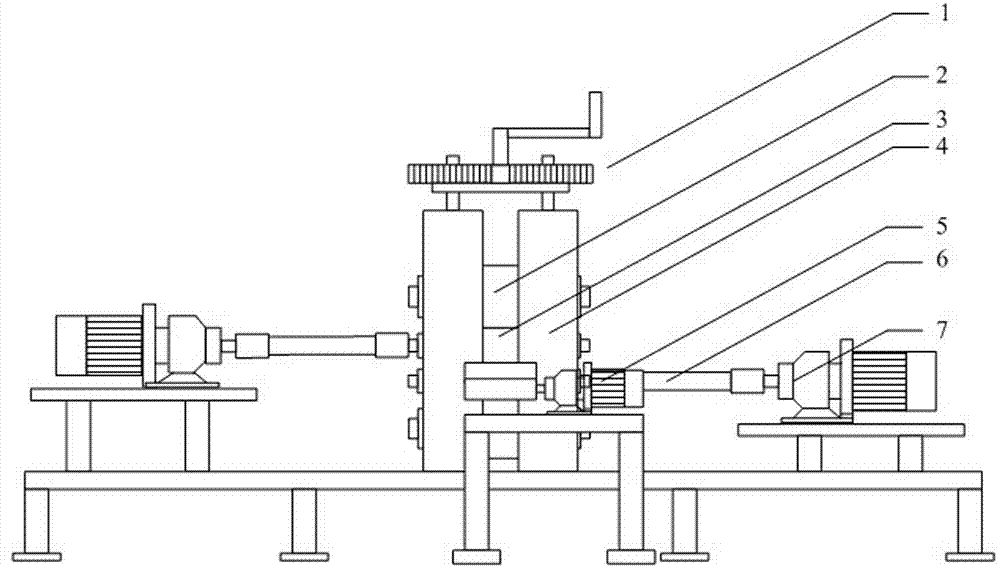

Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

ActiveCN102777546BEasy meshImprove transmission stiffnessMachine gearing/transmission testingToothed gearingsExperimental testingReduction drive

The invention discloses a short tube flexible gear harmonic reducer of a rigid wheel tooth dip angle and a transmission rigidity testing device thereof, and relates to the technical field of harmonic reducers. According to the invention, the deflection of the flexible wheel gear teeth is caused by the reduction of the axial size of the short tube flexible gear harmonic reducer, so as to realize the reduction of the surface area between the rigid wheel gear teeth and the flexible wheel gear teeth, and to realize the lowering of the transmission rigidity; the problem of complicated operating process of the existing harmonic drive rigidity experiment testing device is solved; and the length diameter ratio of a soft wheel is 1 / 4 to 3 / 5 of a short tube wheel, the inner wheel of the rigid wheel with a dip angle is the wheel teeth with the dip angle alpha along the rigid wheel axial direction, and the deflection direction and the field angle direction of the soft wheel on a long shaft are coincident. The transmission rigidity testing device of the short tube flexible gear harmonic reducer implements current control namely torque control through a computer and a servo driver, and the harmonic drive output end realizes continuous loading unloading; and the harmonic drive rigidity of the short tube soft wheel is obtained, and the transmission rigidity is serially, rapidly accurately obtained.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

Bi-directional electromechanical actuation type test-bed for damper

InactiveCN100504336CAdaptableEasy to install and debugVehicle suspension/damping testingLow noiseVertical plane

The invention discloses a two-way electromechanical actuation type shock absorber test bench, the base (7) of which is an "L"-shaped base (7) rigidly connected by a base (10) and a column (6), a power mechanism, The transmission mechanism and the executive mechanism are an integrated electromechanical actuator (9), and a steering mechanism for driving the electromechanical actuator (9) to rotate in the vertical plane is arranged on the base (7), and the base (10) and the column (6) respectively has a locking mechanism (8) for locking the electromechanical actuator (9), and an adjustable reaction force seat (1) is respectively installed on the base (10) and the column (6). It has the advantages of good dynamic performance, high working precision, wide test range, strong adaptability, low energy consumption, low noise, no pollution, quick and convenient operation, etc.

Owner:SOUTHWEST JIAOTONG UNIV

Active clamping delivery mechanism

InactiveCN107234478AAchieving Active GrippingAvoid sliding contactMetal working apparatusConveyor partsLinear motorSliding contact

The invention aims to provide an active clamping delivery mechanism comprising a main driving device, an auxiliary driving device, a pair of main sliding rails arranged symmetrically, main attachments connected to the main sliding rails and the main driving device, gripping jaws, and auxiliary attachments connected to the gripping jaws and the auxiliary driving device; the gripping jaws are movably connected to the auxiliary attachments movably, and arranged on the main sliding rails; the gripping jaws are arranged between the two main sliding rails symmetrically; and at least one of the two gripping jaws arranged symmetrically is movably arranged on the main sliding rail, and can only do rectilinear motion in the direction toward or opposite to the gripping jaw symmetrical to the gripping jaw movably arranged on the sliding rail. According to the active clamping delivery mechanism provided by the invention, the gripping jaws are driven by linear motors, so that the purpose of active clamping of the gripping jaws is achieved, the sliding contact between the gripping jaws and workpieces is avoided, and the surface quality of the workpieces is ensured; the sliding rails can be driven by the linear motors directly, and the dynamic response performance, positioning accuracy, transmission stiffness and transmission efficiency of a system are improved; and the running noise is reduced.

Owner:SUZHOU BEARING FACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com