Intelligent patrol robot execution mechanism of high-voltage distribution room

A technology of intelligent inspection and high-voltage power distribution, which is applied in the field of inspection robots, can solve the problems of inability to find equipment thermal defects, inability to detect equipment and instruments, and high labor intensity, achieving fast speed, high positioning accuracy, and accuracy retention Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

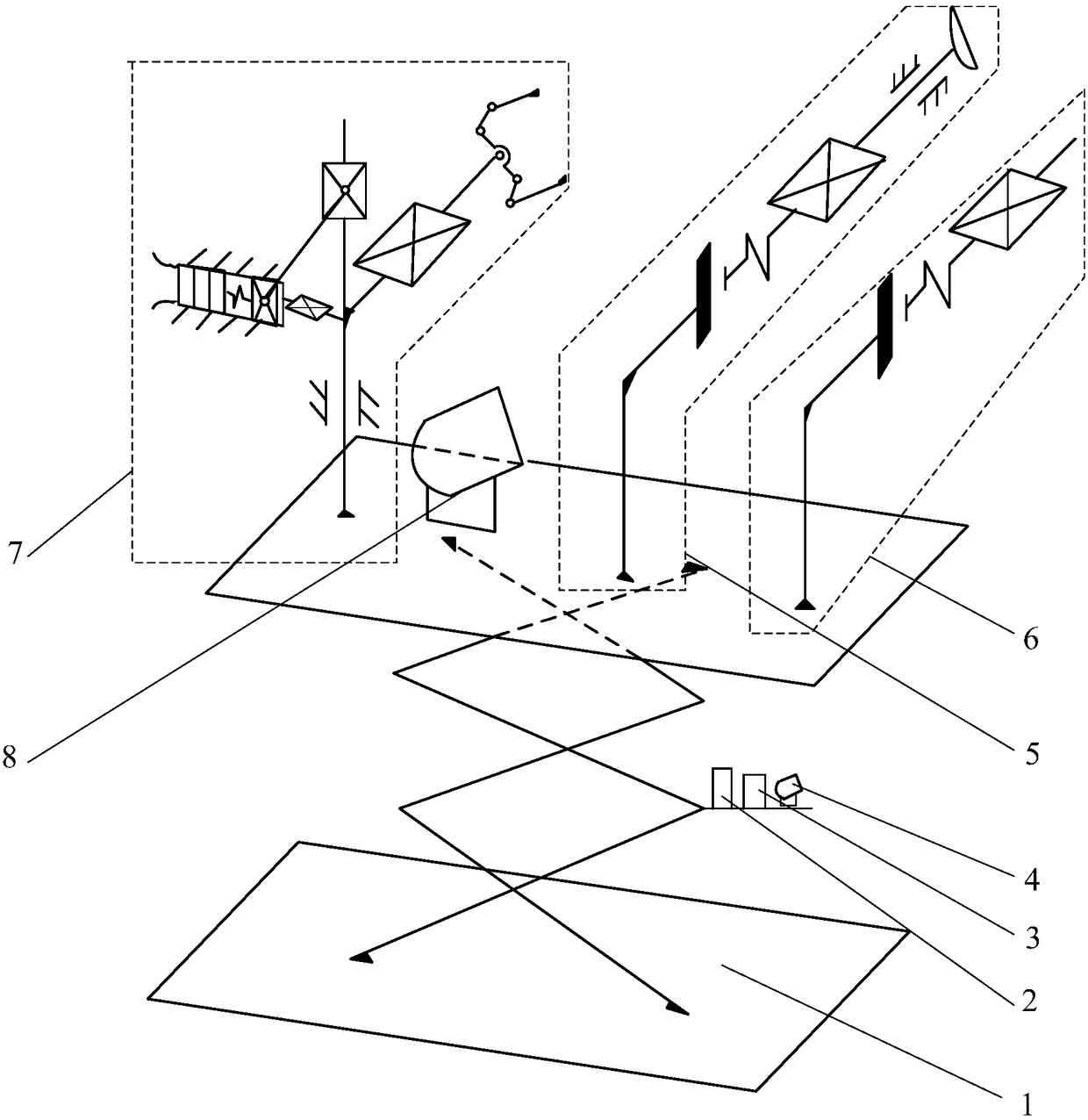

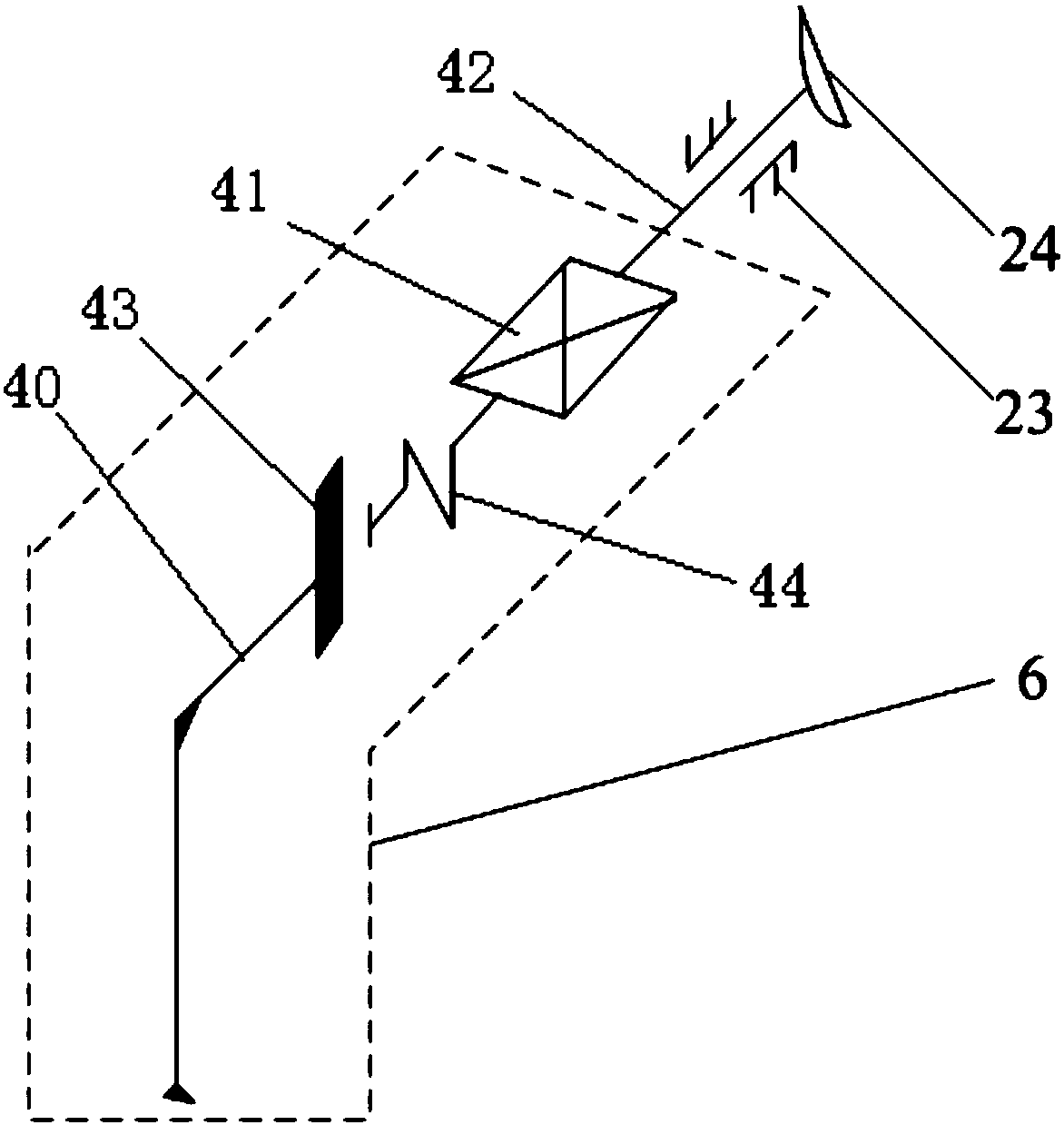

[0031] Such as figure 1 As shown, the present invention includes a lifting scissors mechanism 1, an opening button execution unit 6, a changeover switch rotation unit 5 and a pole shorting unit 7, and a lifting platform is arranged on the lifting scissors mechanism 1, and the switching The switch rotation unit 5, the opening button execution unit 6 and the pole short-circuit unit 7 are all arranged on the lifting platform.

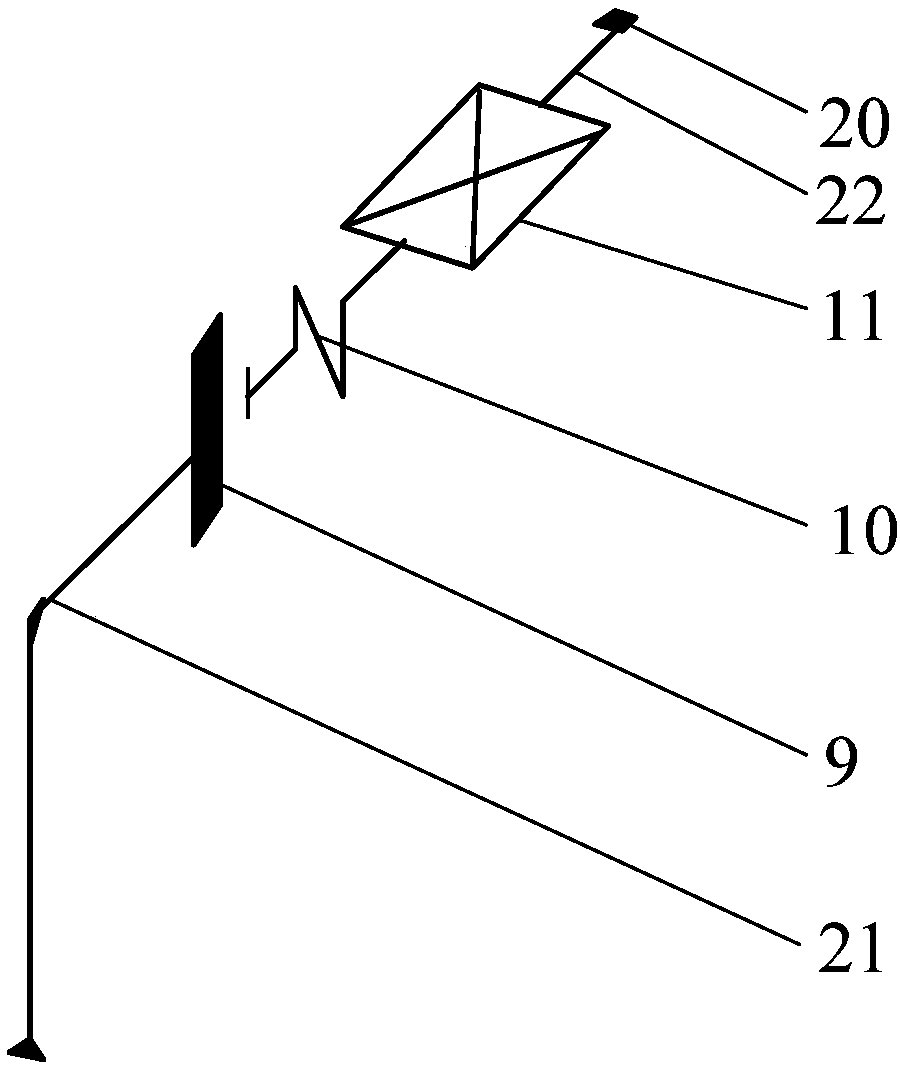

[0032] The opening button execution unit 6 is used to press the opening button of the high voltage power distribution room. Such as figure 2 As shown, the opening button execution unit 6 includes a first fixed rod 21, a first driving mechanism 11 and a first driving rod 22, and the first fixed rod 21 is fixed on the lifting platform of the lifting scissor mechanism 1 Above, the first drive mechanism 11 is fixed on the first fixed rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com