Gear box of heavy CNC vertical turning machine

A digitally controlled vertical gearbox technology, which is applied to large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of easy oil immersion, poor heat dissipation of motors, etc., and achieve low manufacturing cost, large driving force, The effect of high transmission stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

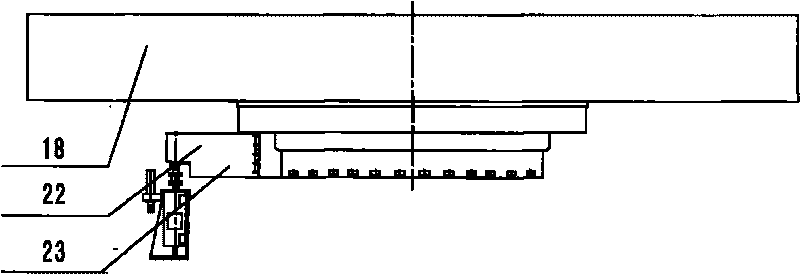

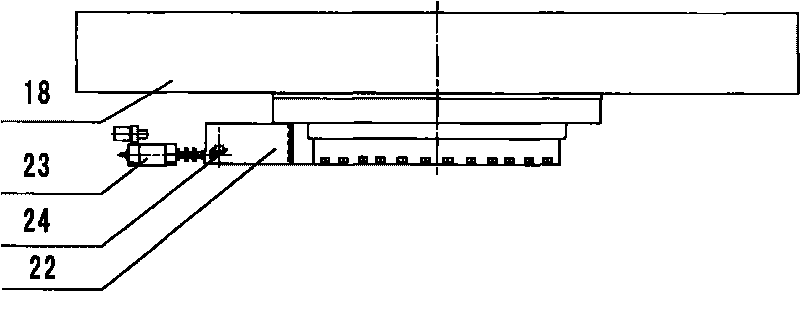

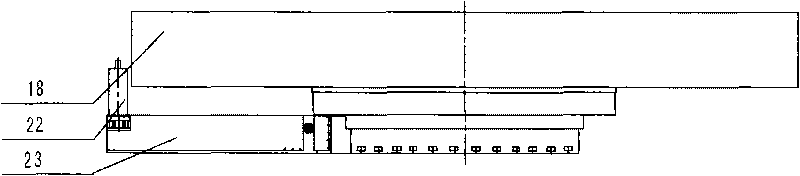

[0027] like Figure 4 As shown, the design includes the motor base 2, the box body 22 of the gearbox, the intermediate shaft in the box body 22, the intermediate gear mounted on the intermediate shaft, and the power input mechanism between the intermediate shaft and the motor 23, the intermediate shaft section The box body 22 of the motor seat 2 is stretched downward, and the box body 22 of the second section of the motor seat moves down synchronously. The intermediate gear on the intermediate shaft moves down, drives the power input mechanism between it and the motor base 2 and moves into the lower casing 4, and the height of the lower casing 4 is determined according to the height of the motor.

[0028] The intermediate shaft in this example is the upper case III shaft 9, and the lower end is connected with a lower case III shaft 7 through a spline coupling sleeve 8, and the input gear on the lower case III shaft 7 is connected with the power input mechanism between it and t...

example 2

[0030] The power output mechanism between the upper box III shaft 9 and the workbench base 11 is; the upper box III shaft 9 transmits power to the large ring gear through the output gear, IV shaft 10, V shaft 13, and VI shaft 15 in the workbench 17. 16. After the hydraulically controlled mechanical two-speed shift, it is transmitted to the workbench base 11.

[0031] The hydraulic mechanical two-speed transmission structure is driven by the shifting hydraulic cylinder 21 to move the shift fork 19 and the joint 12 to move up and down, respectively combined with the two-speed kinematic chain to realize two-speed transmission. When the joint 12 stops in the middle, it is in neutral. Used in conjunction with the C-axis, the gear shift position of the shift fork 19 is provided with a gear travel switch 20, and is provided with an in-position signal display device. See Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com