High-speed metal plate shearing machine

A metal plate and shearing machine technology, applied in the field of mechanical equipment, can solve the problems of reduced production efficiency, prolonged melting and forging time, inconvenient transportation, etc., and achieves the effects of strong equipment power, improved safety performance, and high transmission rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

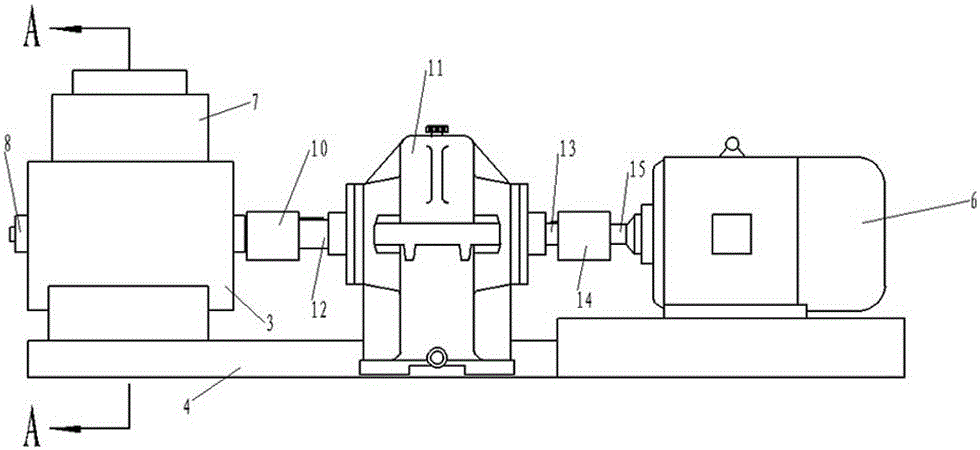

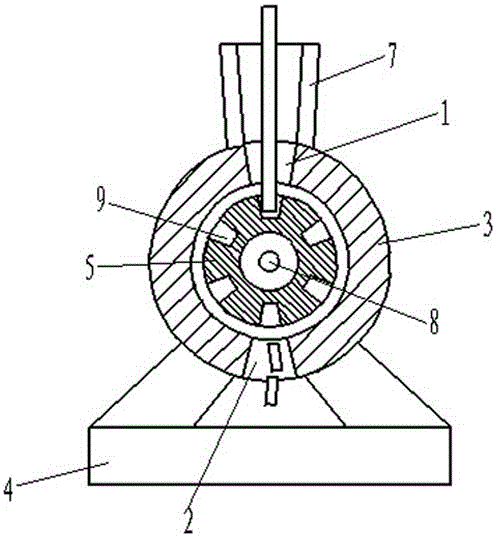

[0011] figure 1 , figure 2 Markings in: feed port 1, discharge port 2, casing 3, machine base 4, shearing rotor 5, motor 6, hopper 7, drive shaft 8, card slot 9, first coupling 10, reducer 11. Output shaft 12, input shaft 13, second coupling 14, motor shaft 15.

[0012] A high-speed shearing machine for sheet metal parts, including a casing 3 with a feed port 1 and a discharge port 2, a machine base 4, a shearing rotor 5, and a motor 6. The shearing rotor 5 matches the inner wall of the casing 3, The casing 3 is fixedly connected with the machine base 4 , and the motor 6 is fixedly connected with the machine base 4 . The feeding port 1 is provided with a hopper 7 . Adding the hopper 7 can increase the safety performance, and avoid the metal plates other than the feeding port 1 from popping up and hurting people due to the strong shear forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com