Whole-core conveyer belt tooth-shaped joint cutter

A conveyor belt and cutting machine technology, applied in metal processing and other directions, can solve the problems of difficult cutting and low efficiency, and achieve the effects of improving efficiency, expanding scope, and improving quality and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

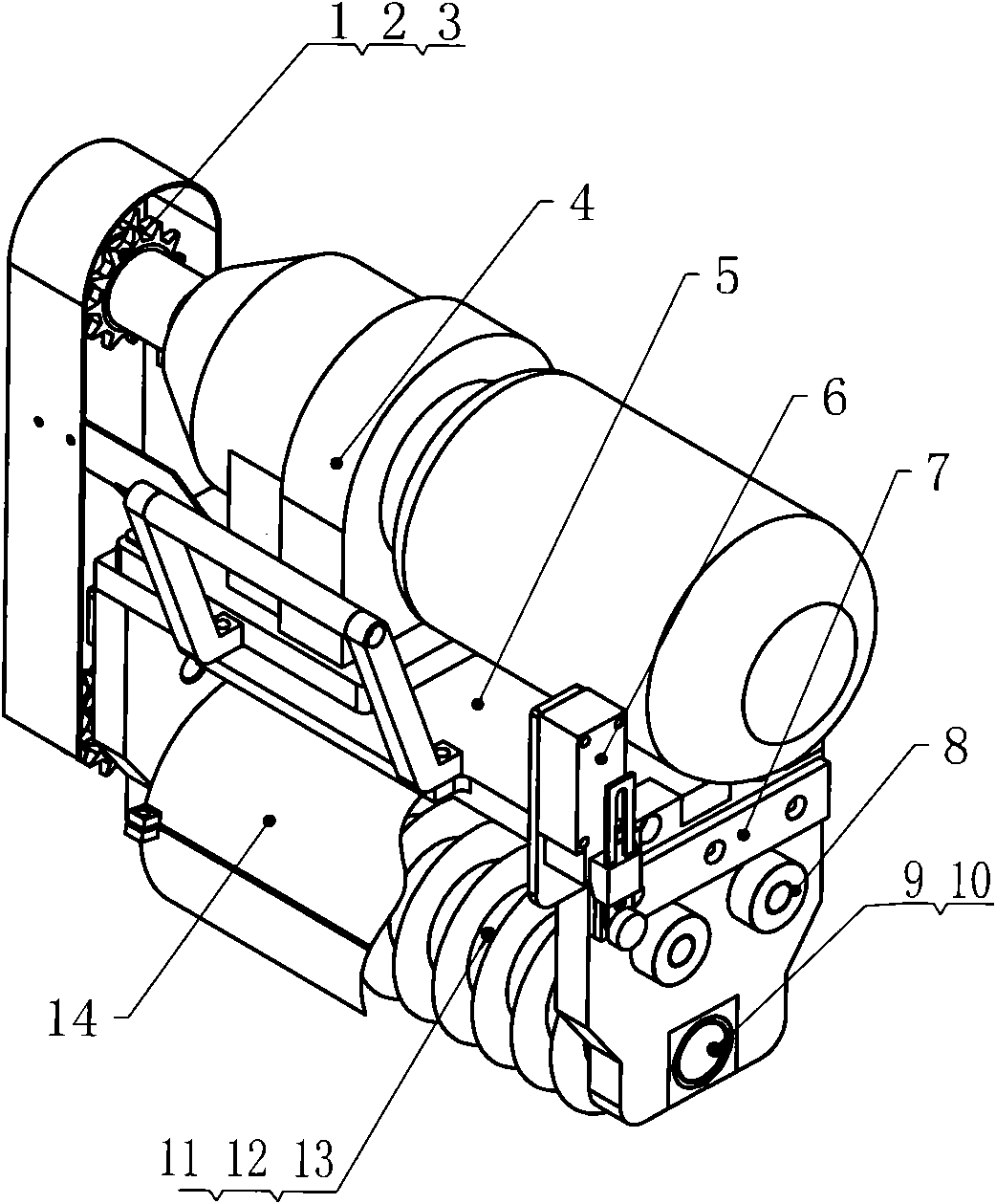

[0020] see figure 1 , this is the entire tool post assembly 15, the geared motor 4 is fixed on the tool post frame, the sprocket 2 at the output end of the geared motor 4 on the top is connected with the sprocket at the end of the main shaft 9 below through the chain 1, and the sprocket cover is used at the same time 3 fixed as a protective safety cover. The main shaft 9 is horizontally assembled on the bearing seat 10 of the frame. On the rotatable main shaft 9, fixed disk blades 11, spacer sleeves 12 and rubber spacers 13 are arranged at intervals successively. If this is combined as a disk blade 11, then According to different requirements of users, disc blades 11 are combined into 5-15 groups, that is to say, a group of blades has 5-15 horizontally parallel disc blades 11 and corresponding spacers 12 and rubber spacers 13, discs Blade 11 can once just be cut into 5-15 tooth racks to whole core conveyer belt, even scope is bigger.

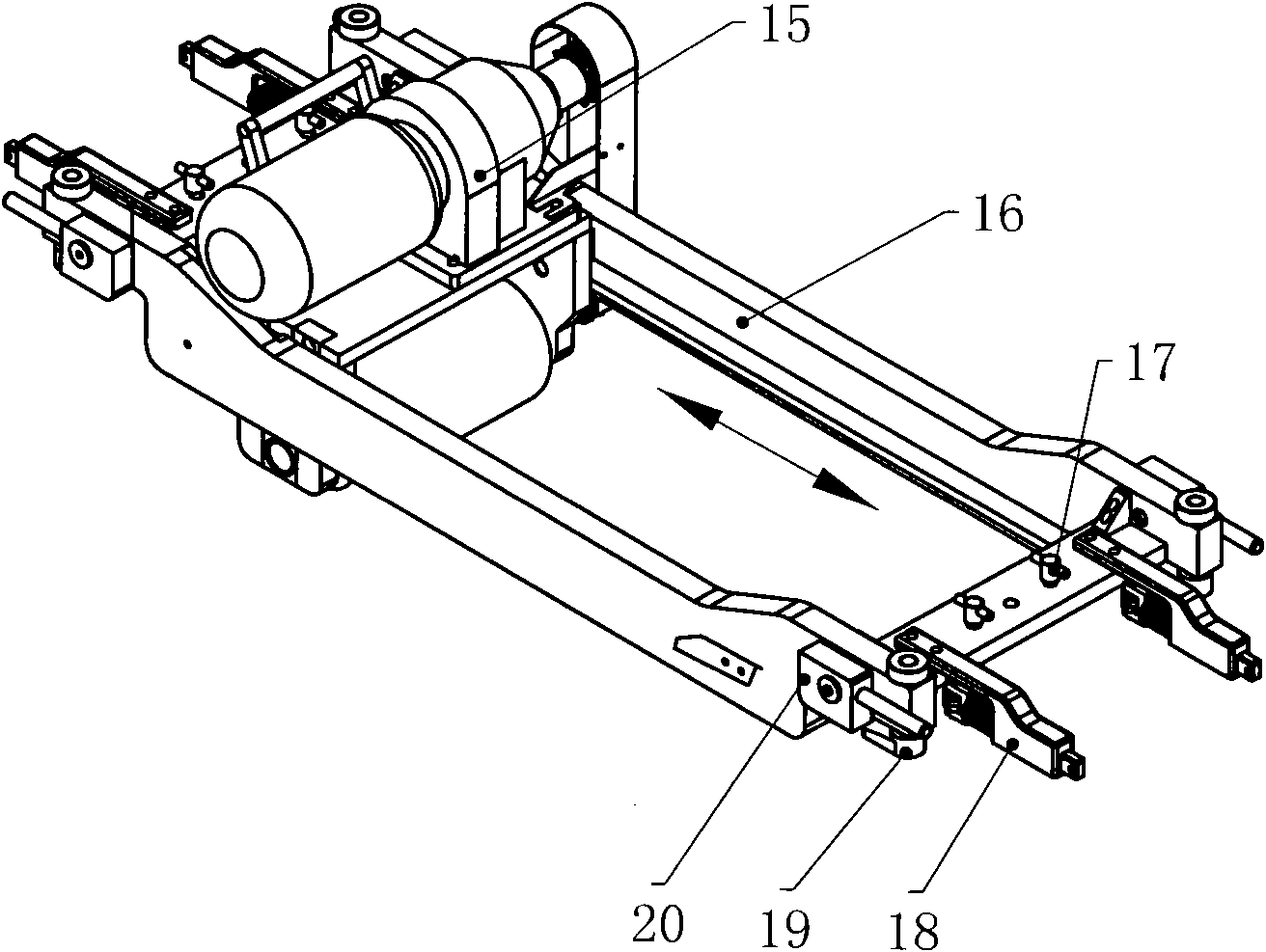

[0021] see figure 2 ,Yes figure 1 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com