A chipless cutting machine

A cutting machine and cutting device technology, used in metal processing and other directions, can solve problems such as low efficiency, burrs at the incision, vibration, etc., and achieve the effect of improving cutting accuracy, reducing labor intensity, and avoiding sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

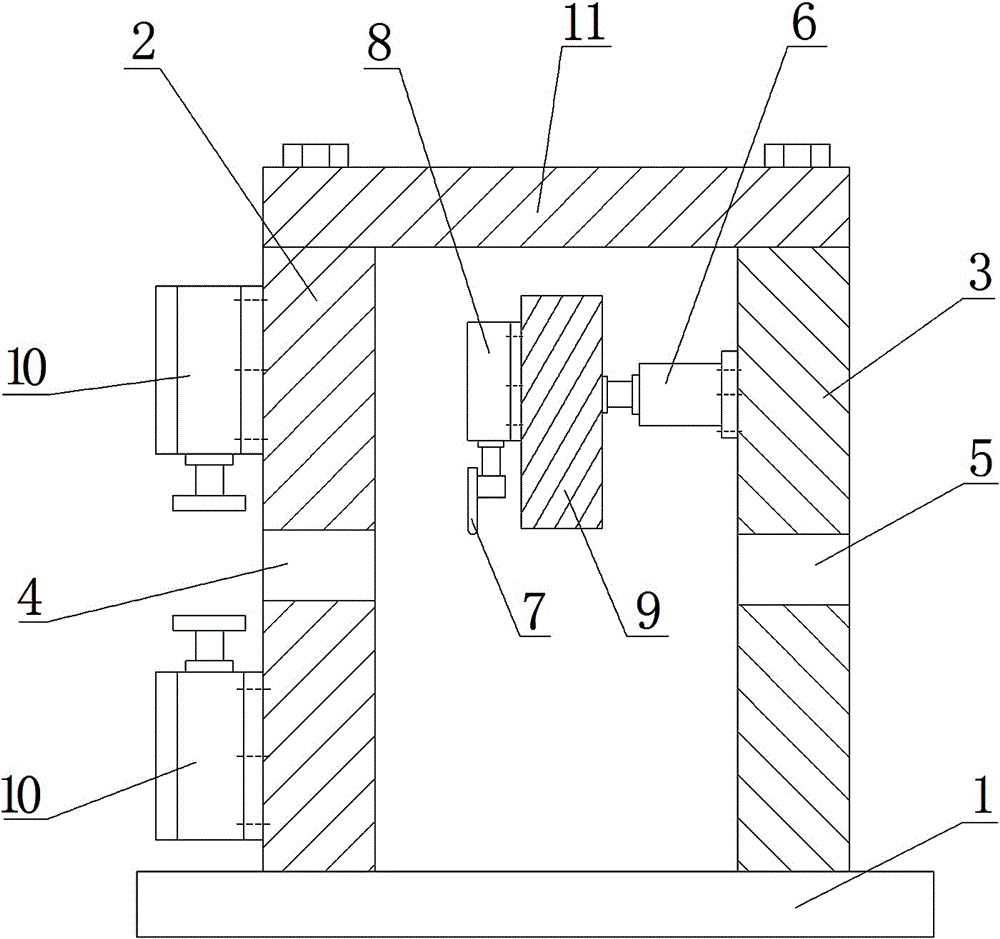

[0013] Such as figure 1 As shown, a chipless cutting machine includes a base 1, a clamping device, a cutting device, a fixed block A2 and a fixed block B3 arranged at both ends of the base 1, and the side walls of the fixed block A2 and the fixed block B3 are A guide hole a4 and a guide hole b5 are respectively provided, and the finished PE pipe removed from the traction mechanism passes through the guide hole b5 into the guide hole a4. The side wall of fixed block B3 is provided with the cutting device that is positioned at the guide hole b5 top, and described cutting device is arranged between fixed block A2 and fixed block B3, and cutting device consists of rotary cylinder 6, cutter 7, cylinder A8 and rotating disk 9 components, the rotary cylinder 6 is perpendicular to the fixed block B3 and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com