Long-distance, heavy-load and parallel-axis type precision 2:1 transmission mechanism

A transmission mechanism and large load technology, applied in the field of transmission, can solve the problems that it is difficult to meet the high transmission rigidity requirements of the servo system, it is not suitable for equipment with limited rotation angles, and the weight is only a few hundred grams, etc. It achieves simple structure, low processing cost, The effect of improving transmission stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Describe the present invention below in conjunction with specific embodiment:

[0033] The purpose of the present invention is to provide a long-distance large-load parallel shaft precision 2:1 transmission mechanism, which can meet the requirements of 2:1 transmission between the drive end and the load end of the limited-rotation-angle equipment on the one hand, and meet the requirements of the limited-rotation-angle equipment on the other hand. The drive end and the load end are under the condition of long distance and large load, for example, the distance between the transmission shaft and the reflector axis reaches 176mm, and the weight of the reflector reaches 19Kg, which requires high rigidity and high precision transmission.

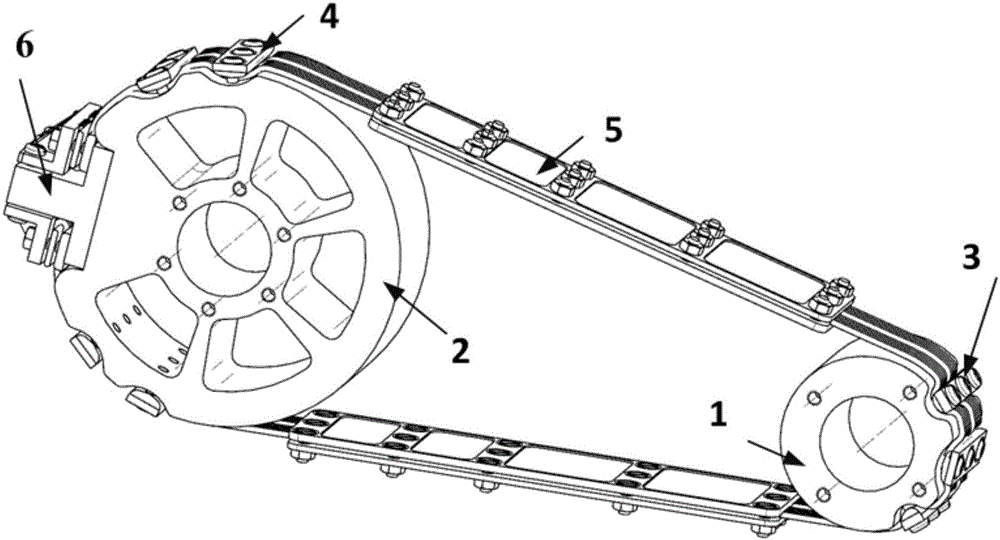

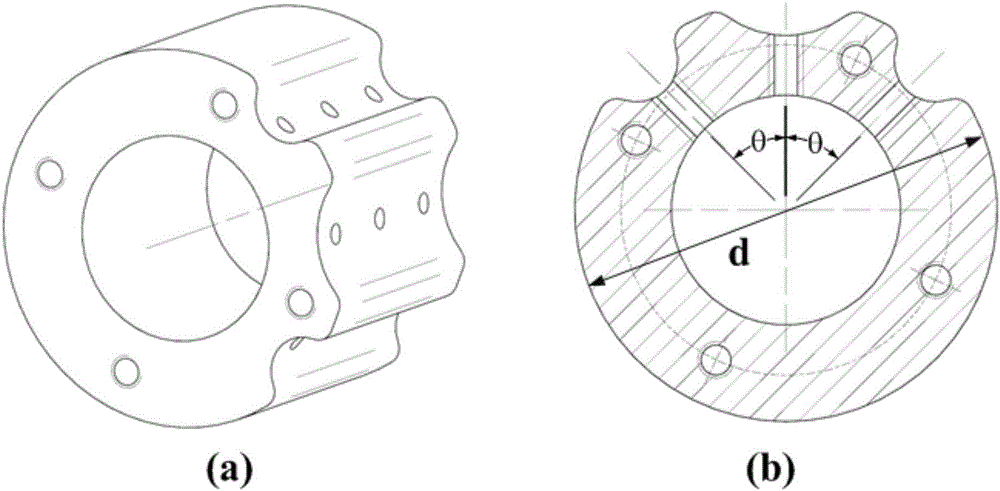

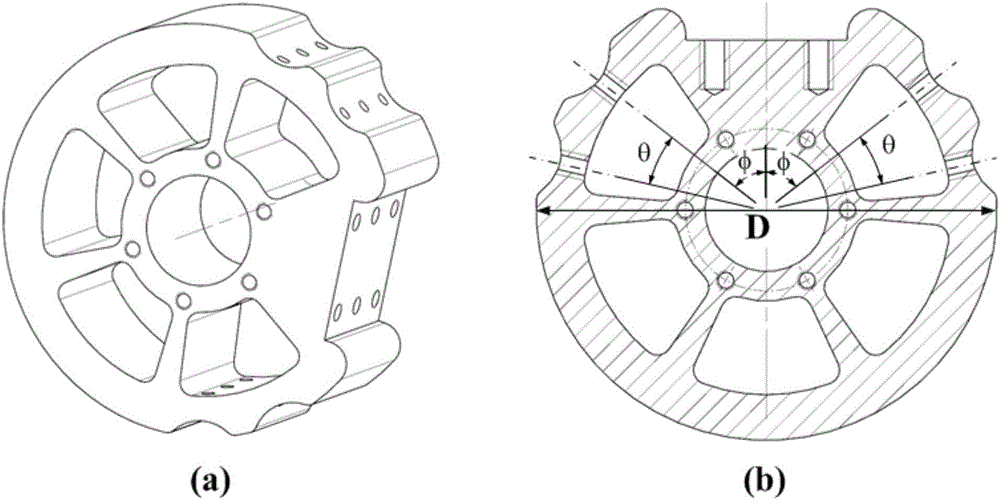

[0034] Such as figure 1 As shown, the long-distance and large-load parallel shaft precision 2:1 transmission mechanism is composed of an input shaft, an output shaft, a flexible transmission part, a pre-tightened pressure block, and a T-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com