Patents

Literature

215results about How to "Reduce torsional vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

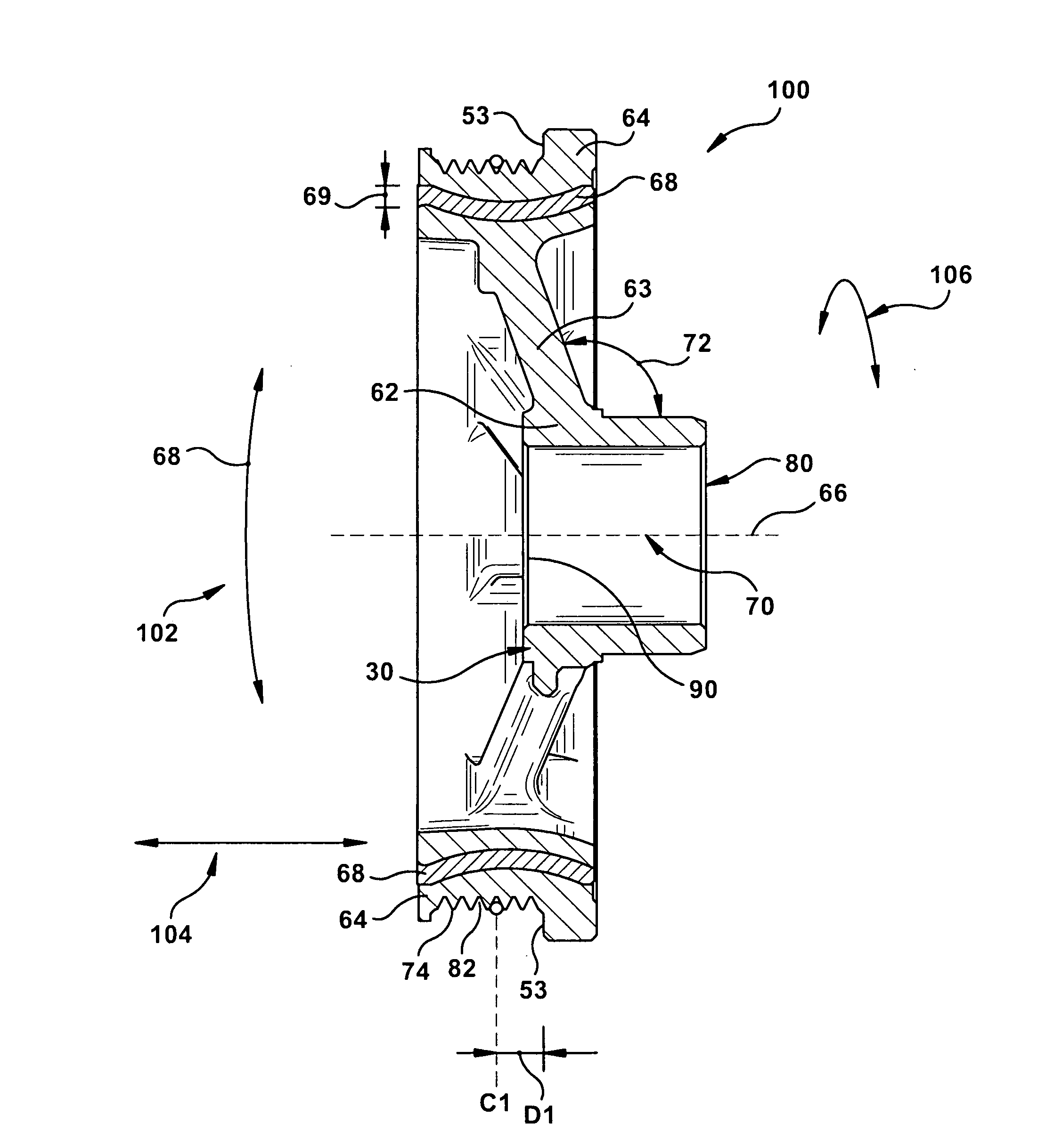

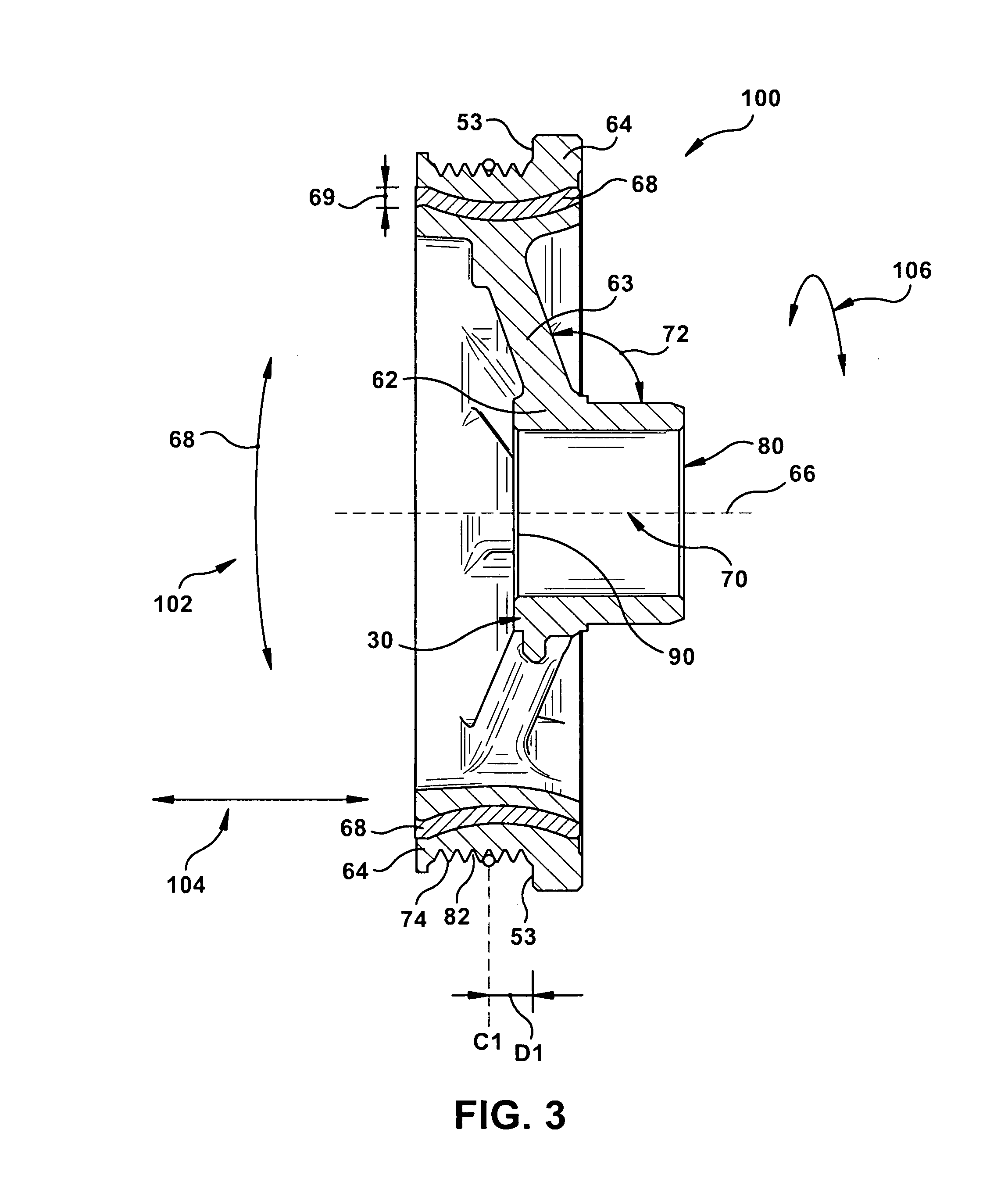

Decoupler with tuned damping and methods associated therewith

ActiveUS20130217524A1Reduce torsional vibrationImprove fatigue lifeAuxillary drivesRotating vibration suppressionEngineeringDamping torque

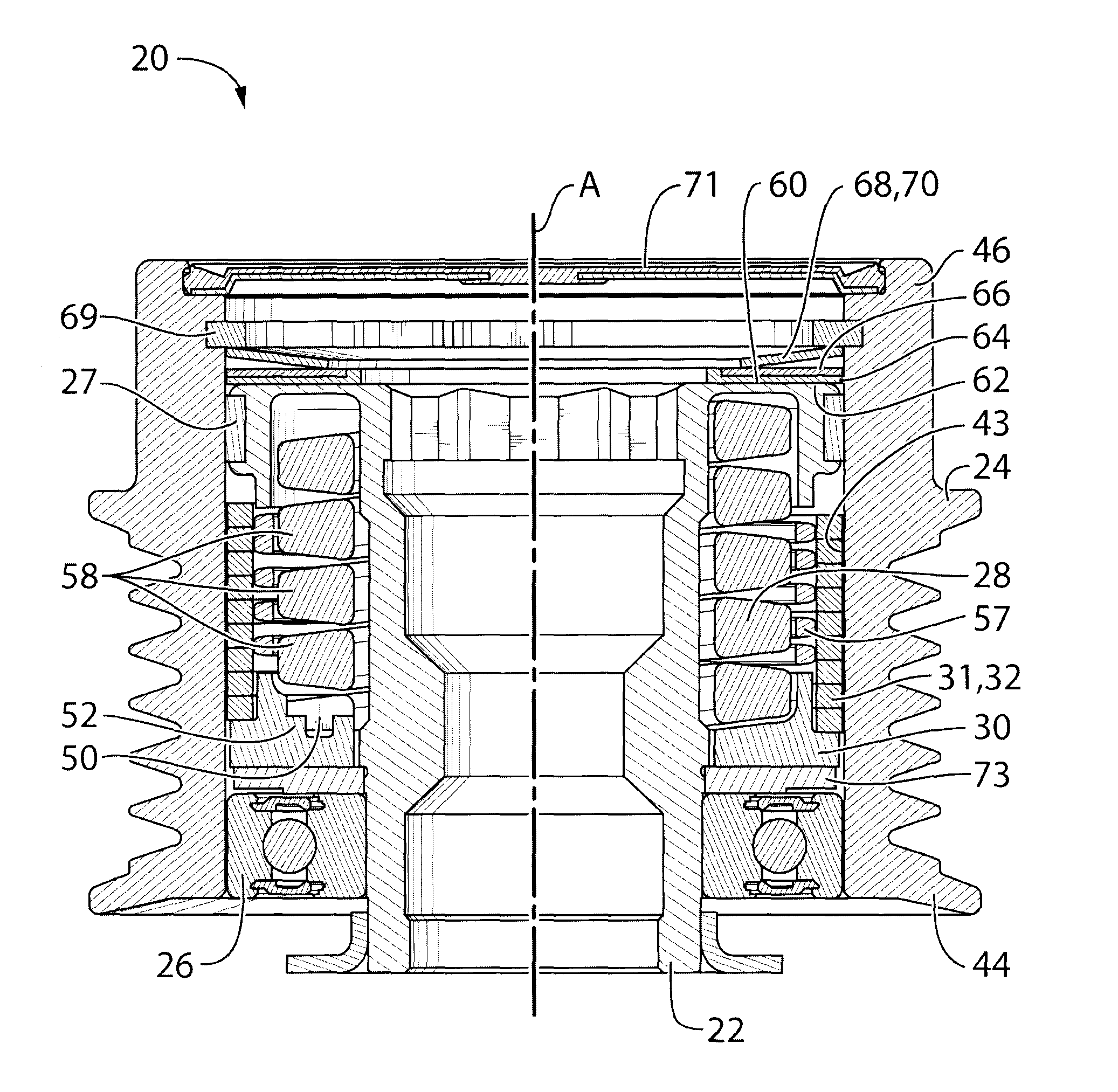

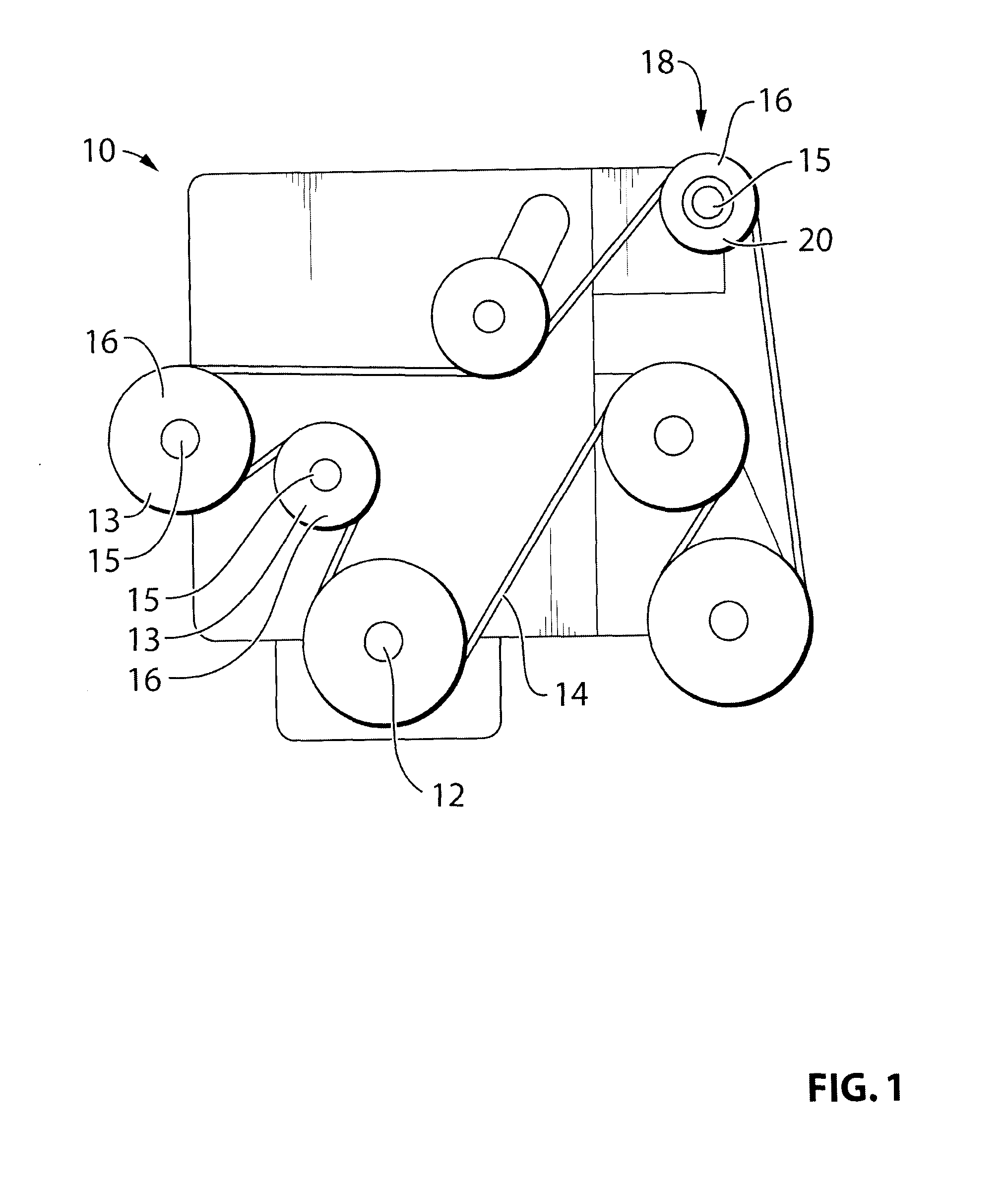

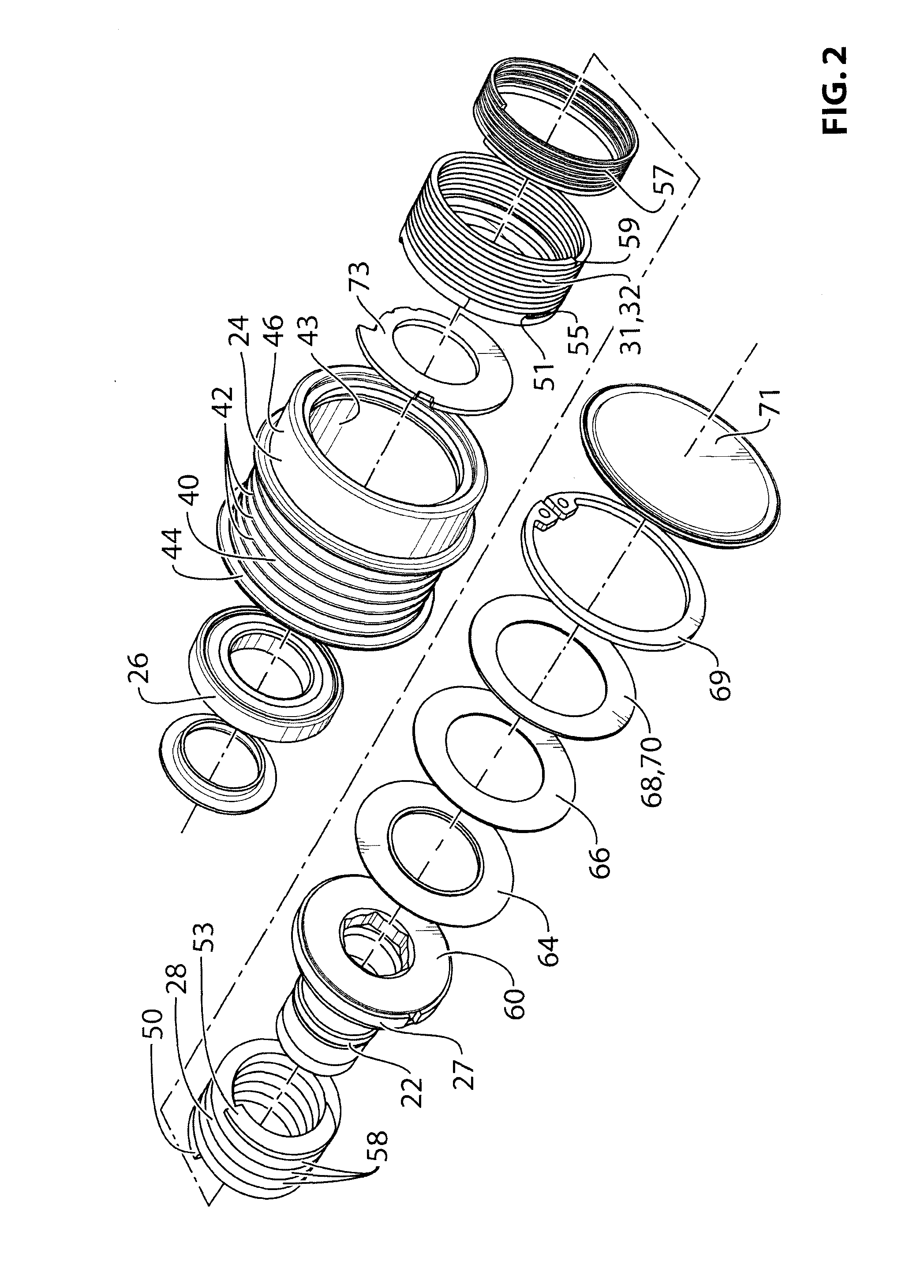

In an aspect, the invention relates to a decoupler that is positionable between a shaft (eg. for an alternator) and an endless power transmitting element (eg. a belt) on an engine. The decoupler includes a hub that mounts to the shaft, and a pulley that engages the endless power transmitting element, an isolation spring between the hub and the shaft. The decoupler provides at least a selected damping torque between the hub and the pulley.

Owner:LITENS AUTOMOTIVE INC

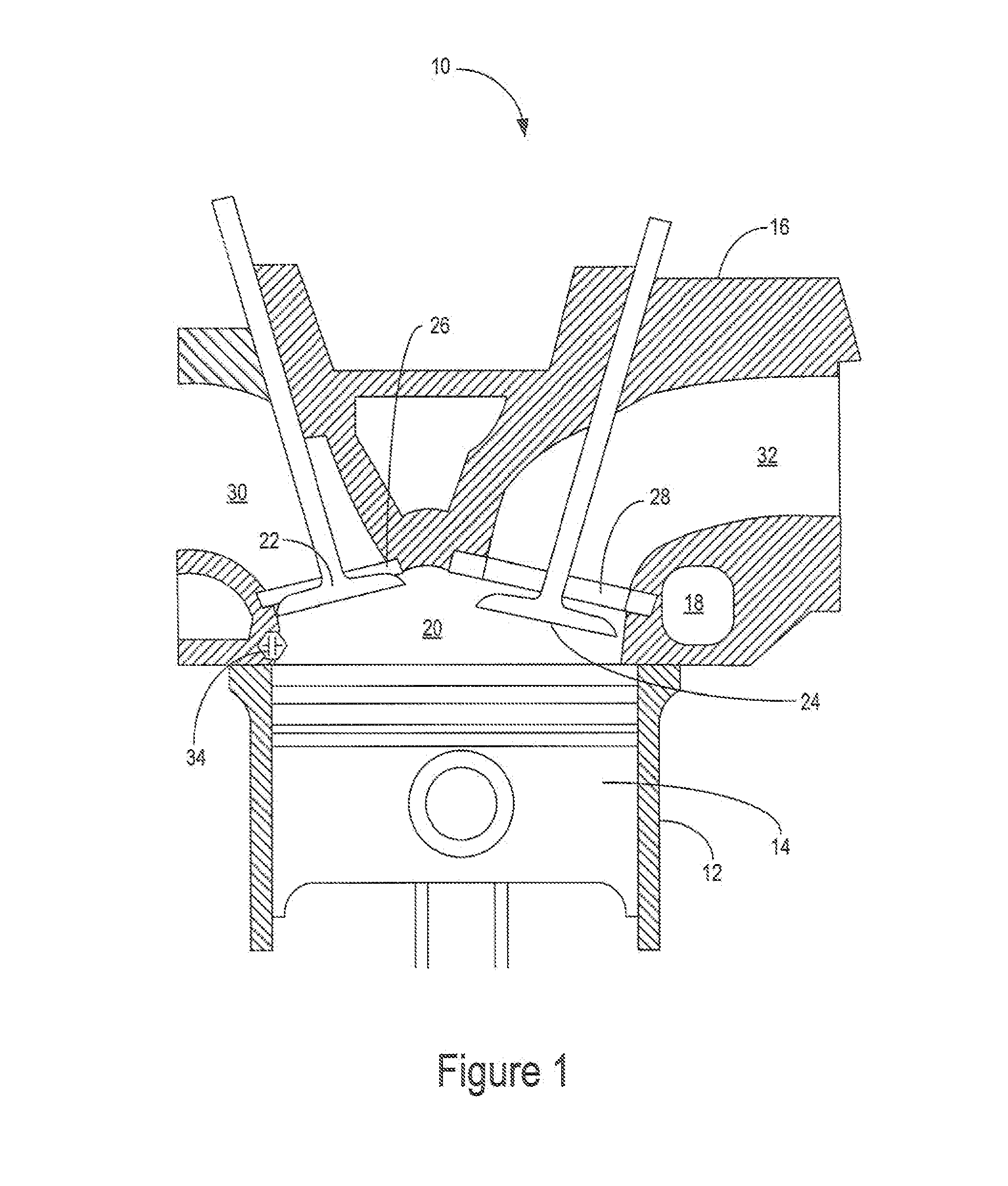

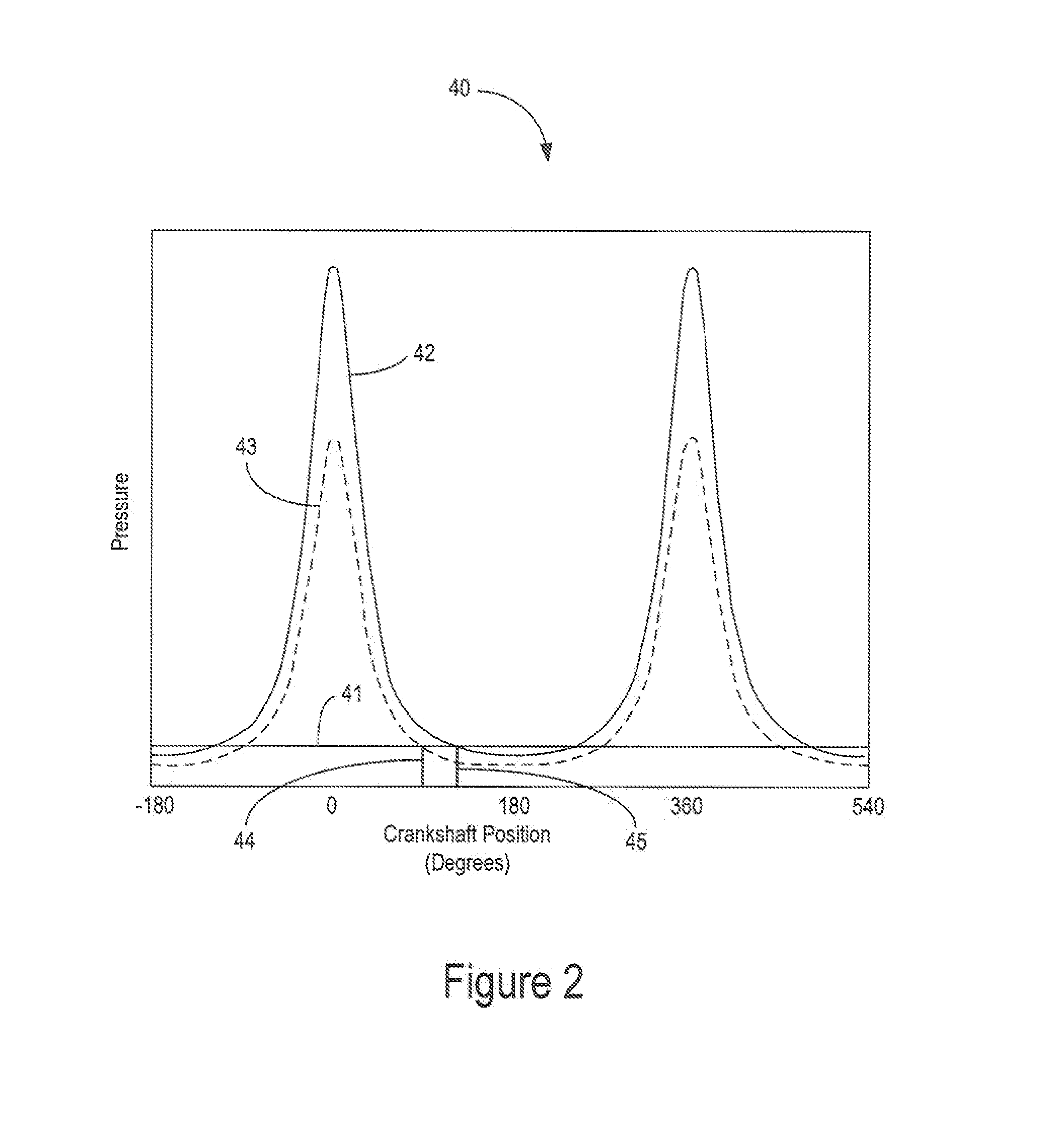

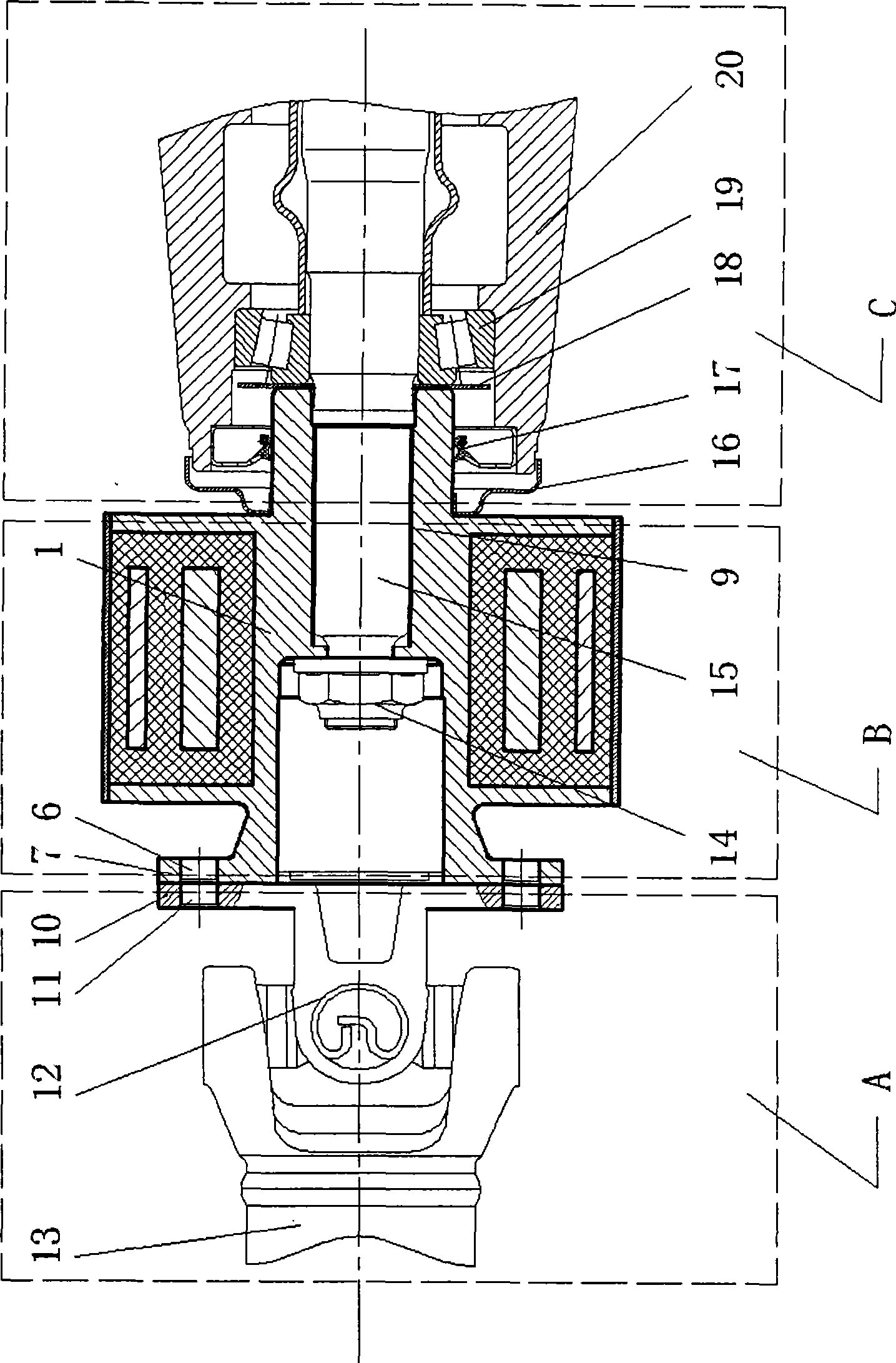

Systems and Methods to Control Torsional Vibration in an Internal Combustion Engine with Cylinder Deactivation

InactiveUS20090007877A1Reduce torsional vibrationVibration minimizationNon-rotating vibration suppressionEngine controllersPistonExternal combustion engine

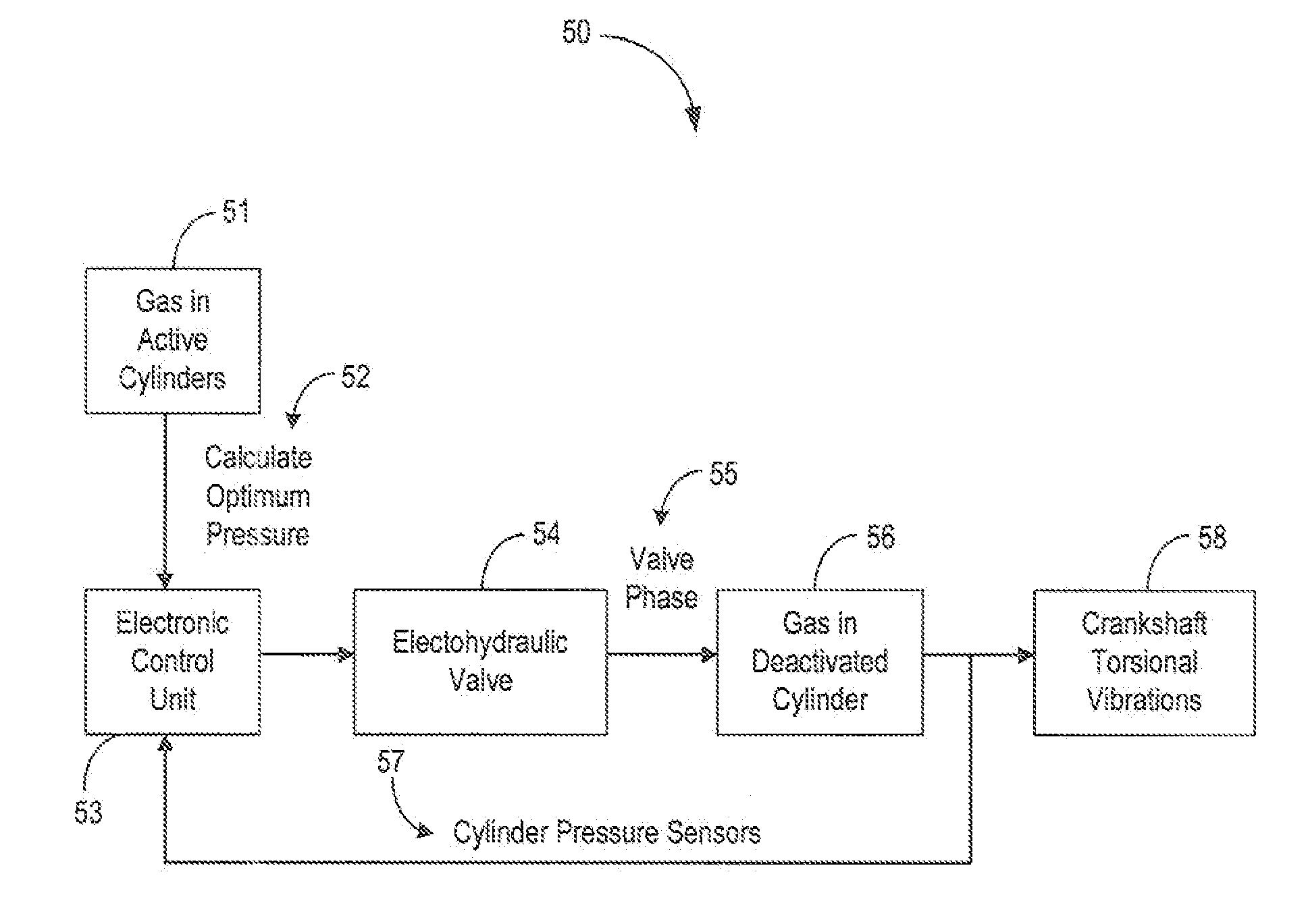

The present disclosure utilizes deactivated cylinders in a variable displacement engine to control the torsional vibration of a crankshaft. In a deactivated mode, deactivated cylinders are compressed and expanded by a reciprocating piston, but they are doing no net work and still causing an oscillating torque on the crankshaft. The present disclosure utilizes this oscillating torque to counter torque from the active cylinders. This is done through controlling the gas pressure in the deactivated cylinders by using intake and exhaust values to equalize the pressure between the cylinder and ports. The optimum gas pressure in deactivated cylinders to minimize total torque fluctuations is approximately one-half that of the active cylinders. A closed control loop adjusts gas pressure in the deactivated cylinders to cancel out torque from the active cylinders.

Owner:CHRYSLER GROUP LLC

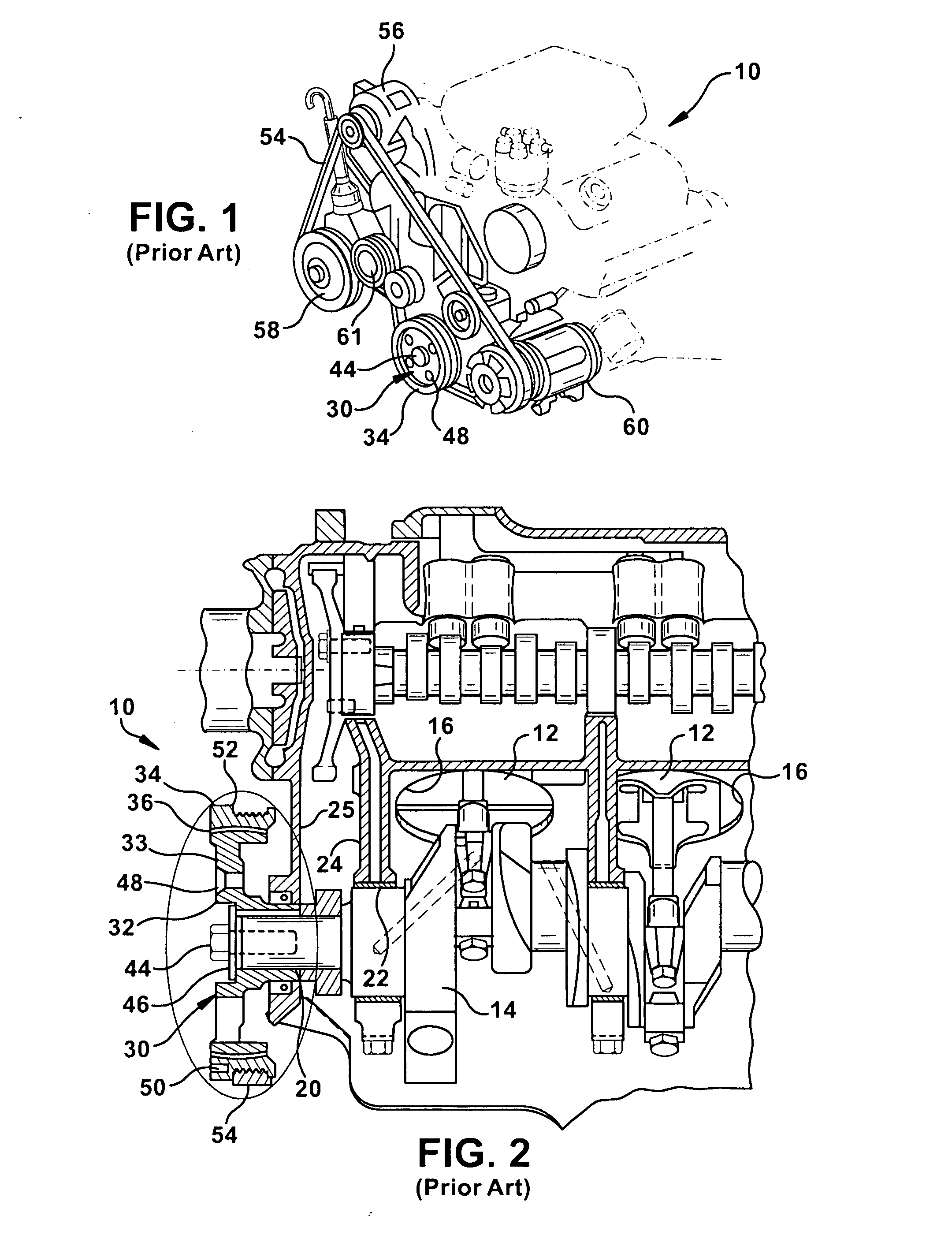

Single mass dual mode crankshaft damper with tuned hub

InactiveUS20090145261A1Cost effectiveReduce torsional vibrationRotating vibration suppressionSpringsElastomerDual mode

A damper for attachment to a crankshaft of an engine is provided. The damper has a hub member, an inertia member spaced radially outward from the hub member and an elastomer positioned between the hub member and the inertia member. The hub member has an opening for attachment to the crankshaft and extends at an angle away from the opening such that the inertia member is offset from the opening of the hub member. The offset inertia member prevents amplification of noise from the crankshaft. The elastomer has a curvature to improve dampening of bending vibrations.

Owner:METALDYNE LLC

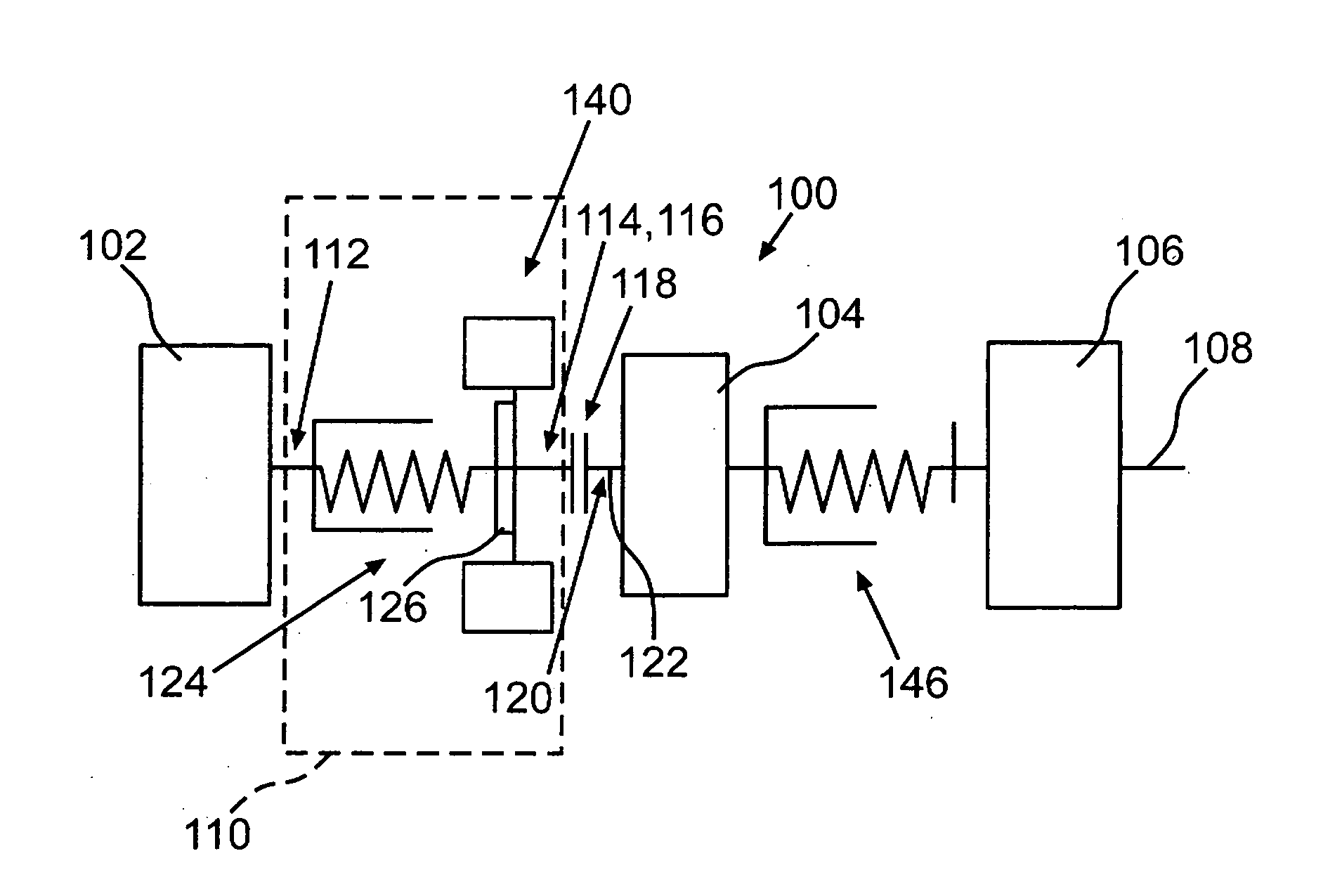

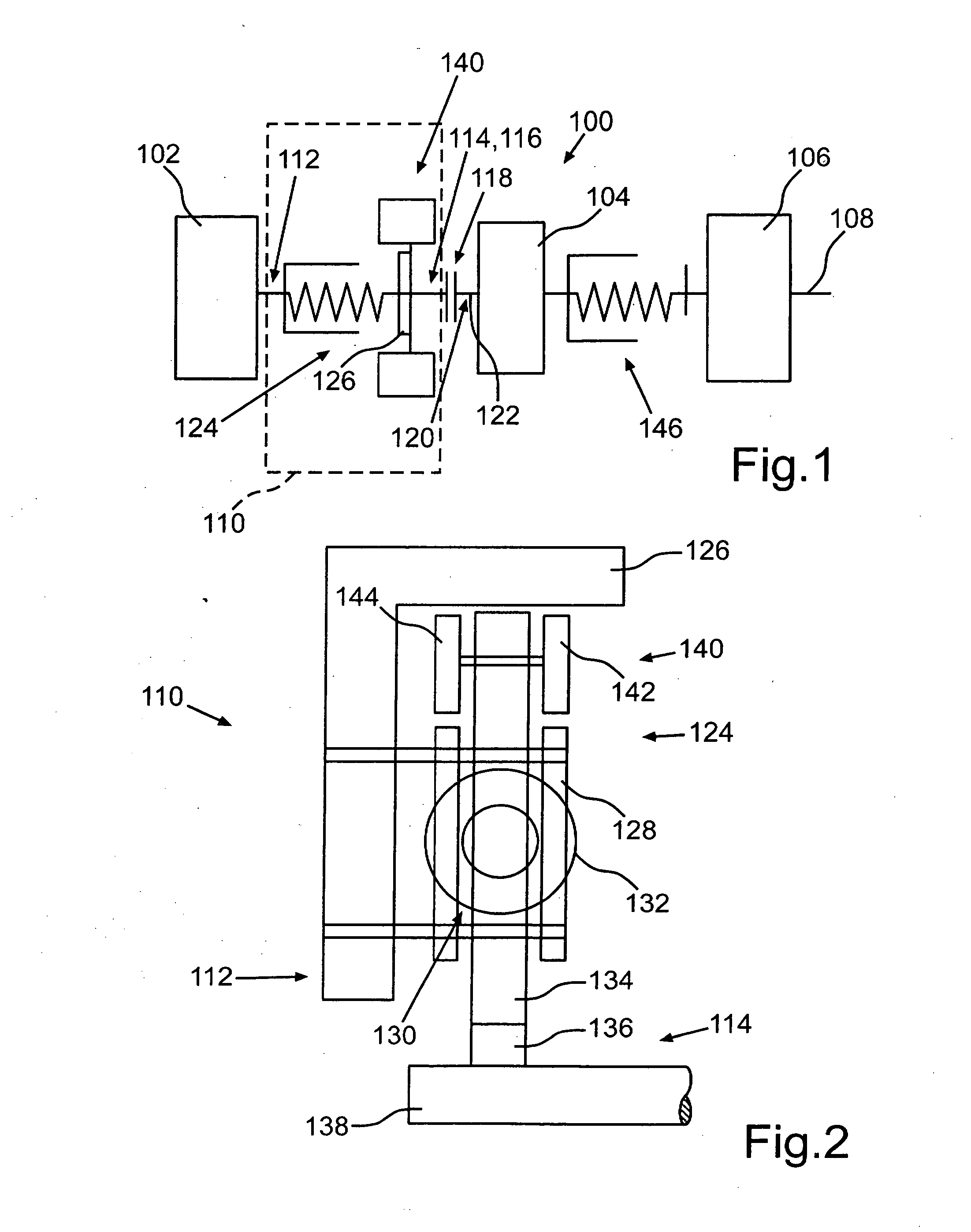

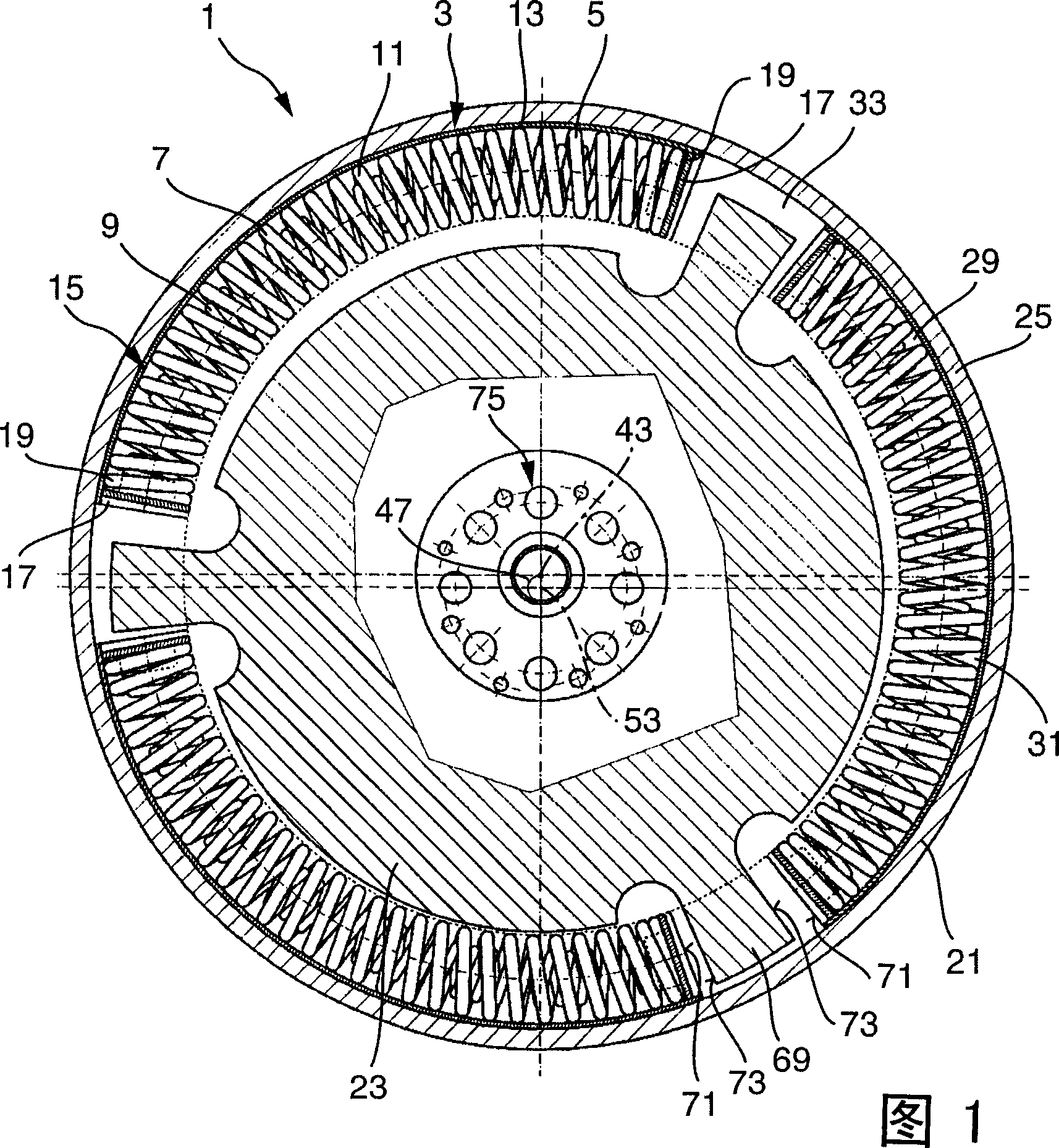

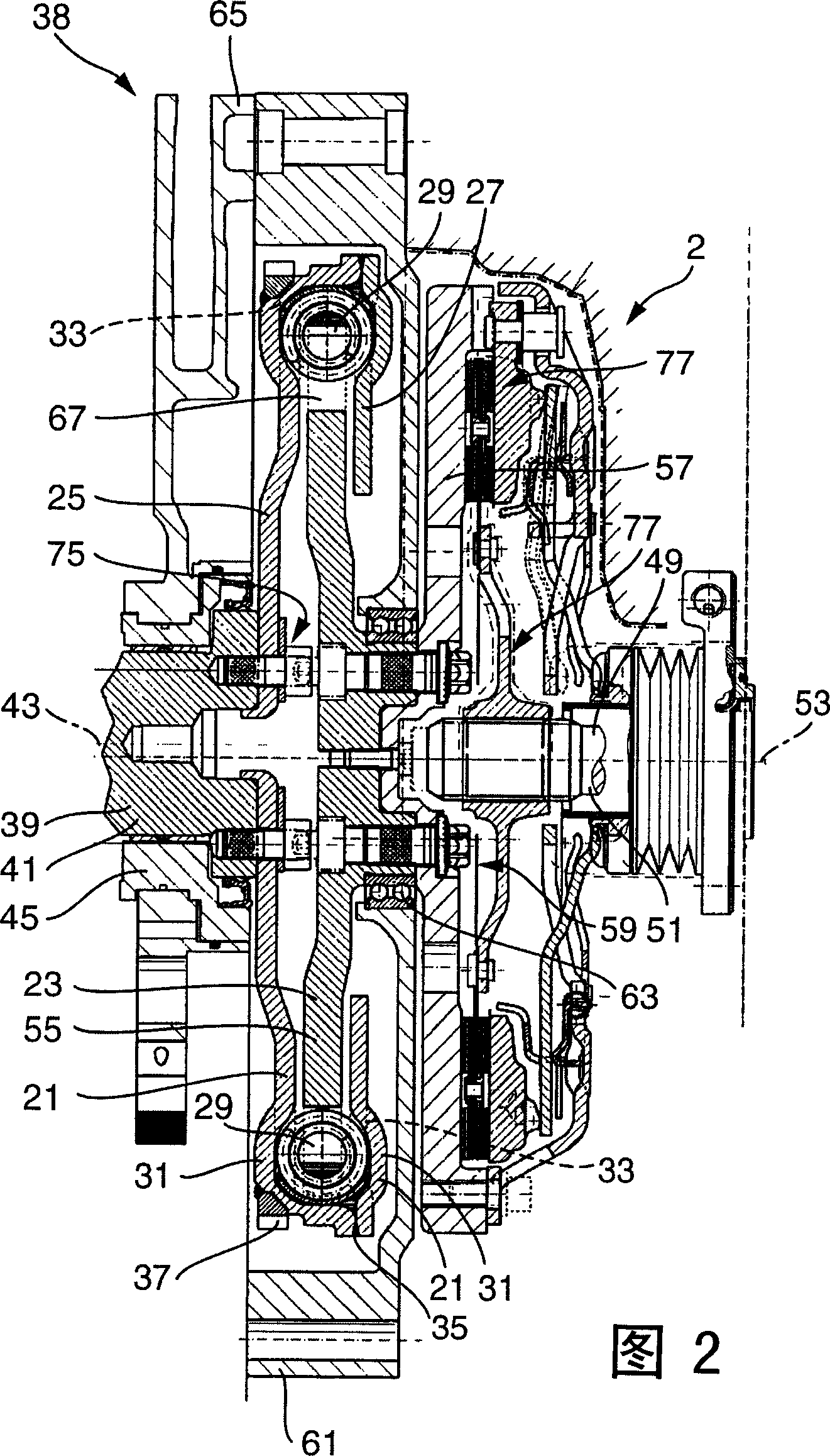

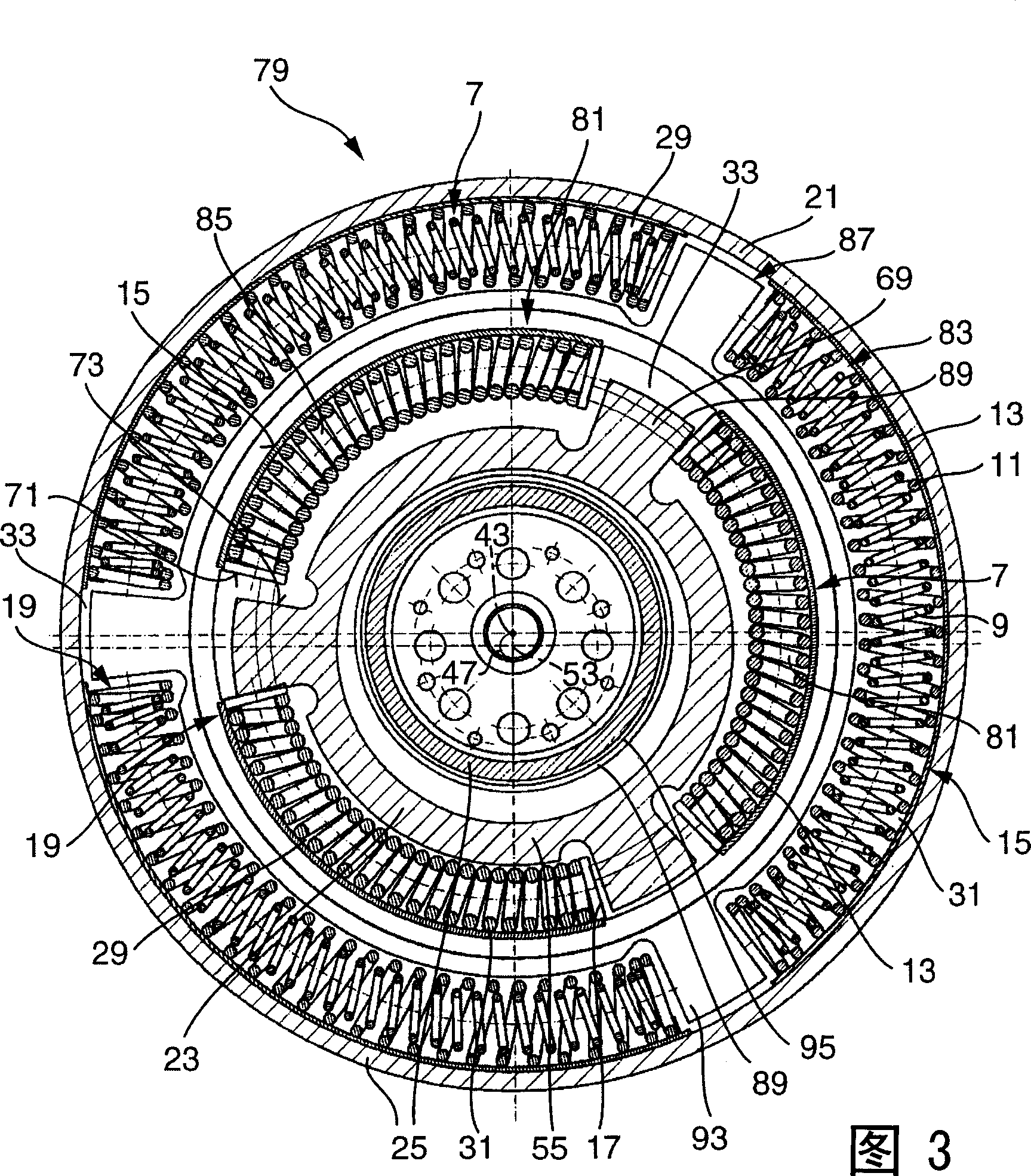

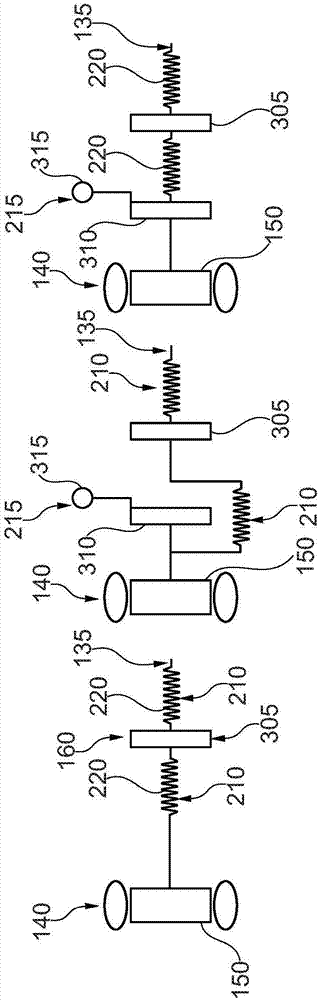

Hybrid drive train with torsional vibration damper

ActiveUS20120055283A1Reduce hummingLarge effective radiusRotating vibration suppressionGearingLow speedExternal combustion engine

In a hybrid drive train with torsional vibration dampers of a hybrid motor vehicle, including an internal combustion engine, an electric machine, a clutch and a transmission, a first spring damping system is arranged between the internal combustion engine and the electric machine and a second spring damping system is arranged between the electric machine and the transmission, each damping system being provided with an arrangement of springs and a centrifugal pendulum for reducing humming noises in a hybrid drive train in the low speed driving range of the hybrid motor vehicle.

Owner:DAIMLER AG

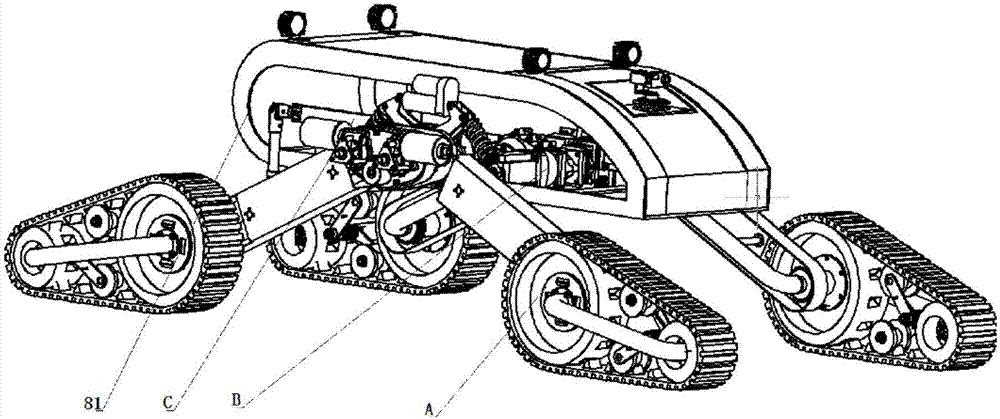

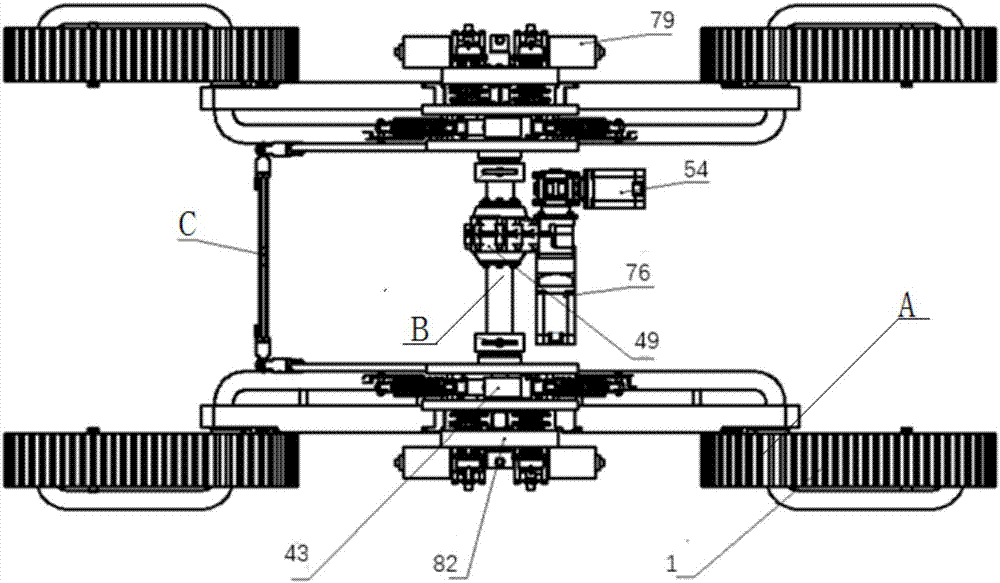

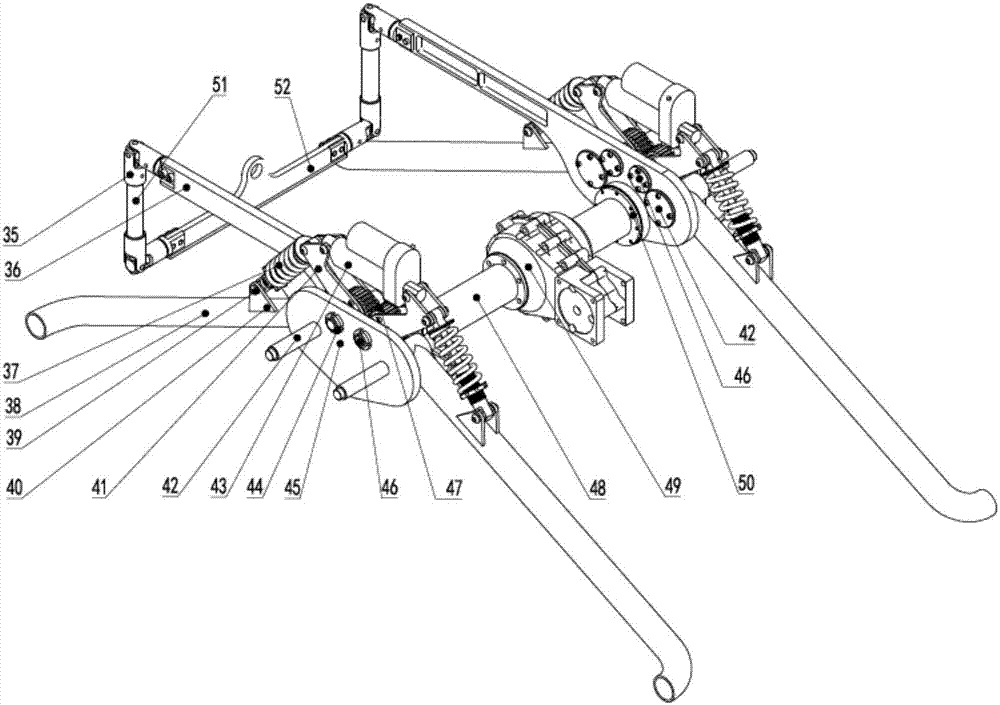

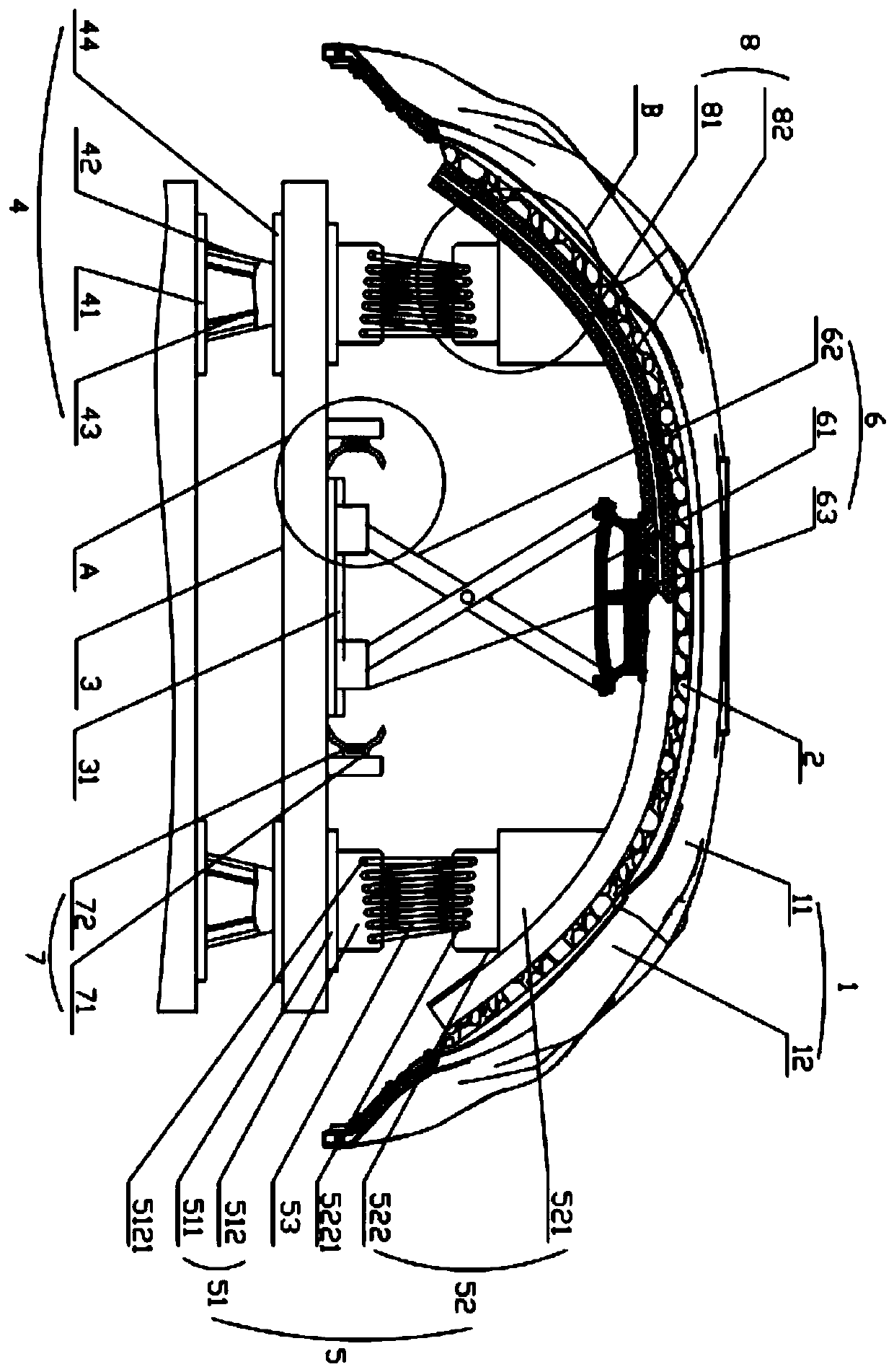

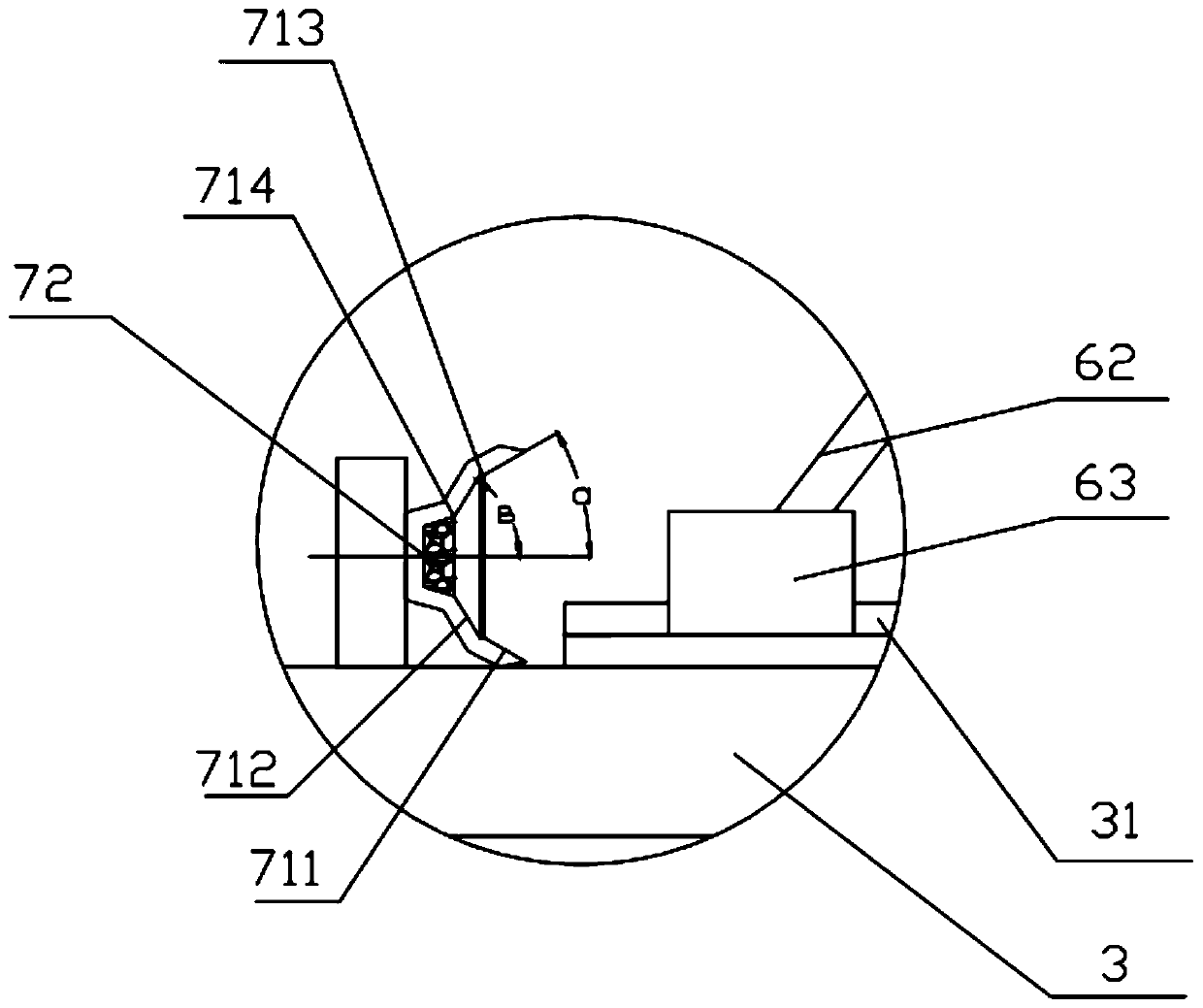

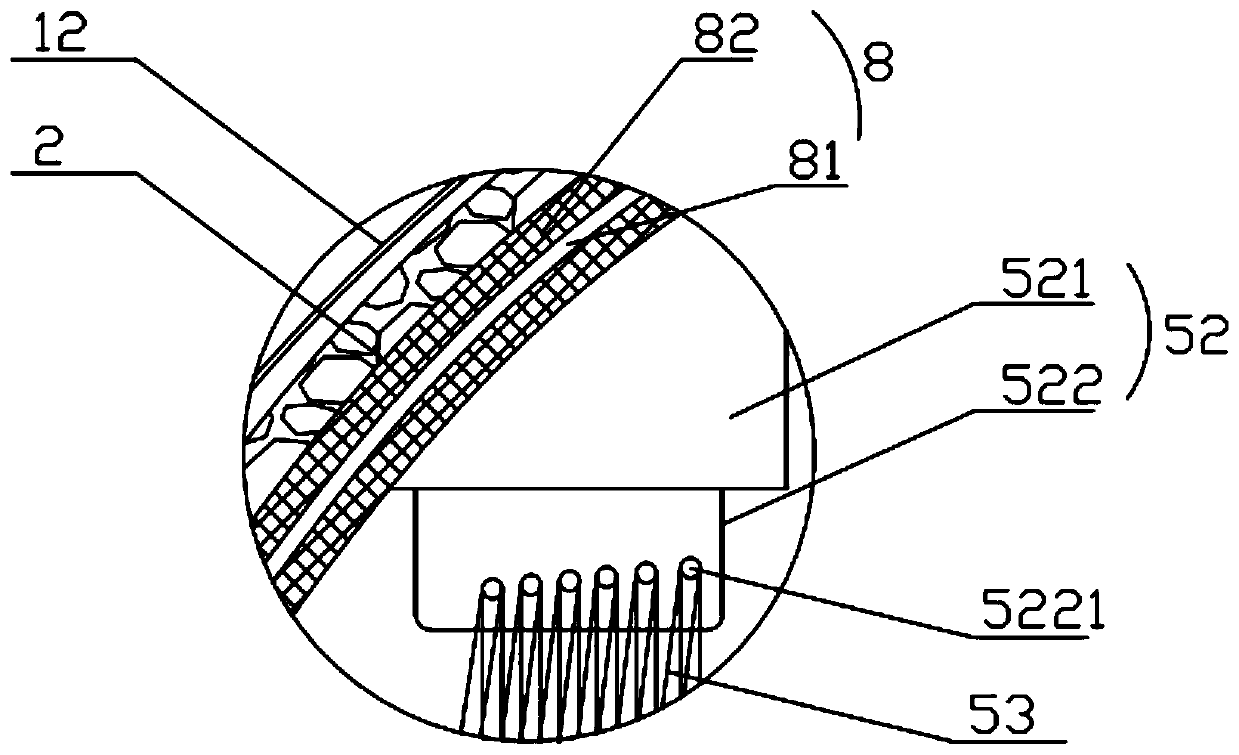

Improved structure of step-and-track-composite-type movable robot travelling system

ActiveCN107953937AEasy to adapt to different road conditionsImprove walking stabilityEndless track vehiclesDrive motorRoad surface

The invention relates to an improved structure of a step-and-track-composite-type movable robot travelling system. According to the improved structure of the step-and-track-composite-type movable robot travelling system, a balance rocker arm hanger bracket of which the two sides are symmetrical is configured on an H-shaped chassis, and a work platform is placed at three fixing points of the balance rocker arm hanger bracket; a driving steering assembly driven by a linear travelling driving motor (54) and a steering travelling driving motor (76) is configured on the balance rocker arm hanger bracket and located on an H-shaped chassis outer bridge shell cross rod, and four supporting legs of the balance rocker arm hanger bracket are configured with joint track assemblies capable of achievingposture adjustment. According to the improved structure of the step-and-track-composite-type movable robot travelling system, the adaptability to a complex annular road surface is very high, and theflexible posture regulation and stable posture keeping capacity is achieved; the attaching profile modeling capacity of uneven complex ground automatic adaption is achieved, and disturbance of the uneven road surface on a vehicle is reduced; the weight loading capacity of the movable work platform is improved, and the stairway-climbing and obstacle crossing capacity is achieved; and through the four-wheel-driving mode, the vehicle cross-country capacity is improved, spot turn can be achieved, and the maneuverability is high.

Owner:北京履坦科技有限公司

Torsional vibration reducing device

ActiveUS20170234401A1Suppresses torque fluctuationsReduce vibrationRotating vibration suppressionCouplingEngineering

A torsional vibration reducing device includes: a rotating body; an inertial body; a coupling member configured to transmit the torque to the rotating body and to the inertial body; and a first coupling portion and a second coupling portion, which are separately provided to either the rotating body or the inertial body The first coupling portion engages with the coupling member so as to: restrict movement of the coupling member in a rotational direction of the rotating body; and allow movement of the coupling member in a radial direction of the rotating body. The second coupling portion engages with the coupling member such that when the rotating body and the inertial body rotate relative to each other, a contact portion of the coupling member with respect to the first coupling portion moves in the radial direction of the rotating body.

Owner:TOYOTA JIDOSHA KK

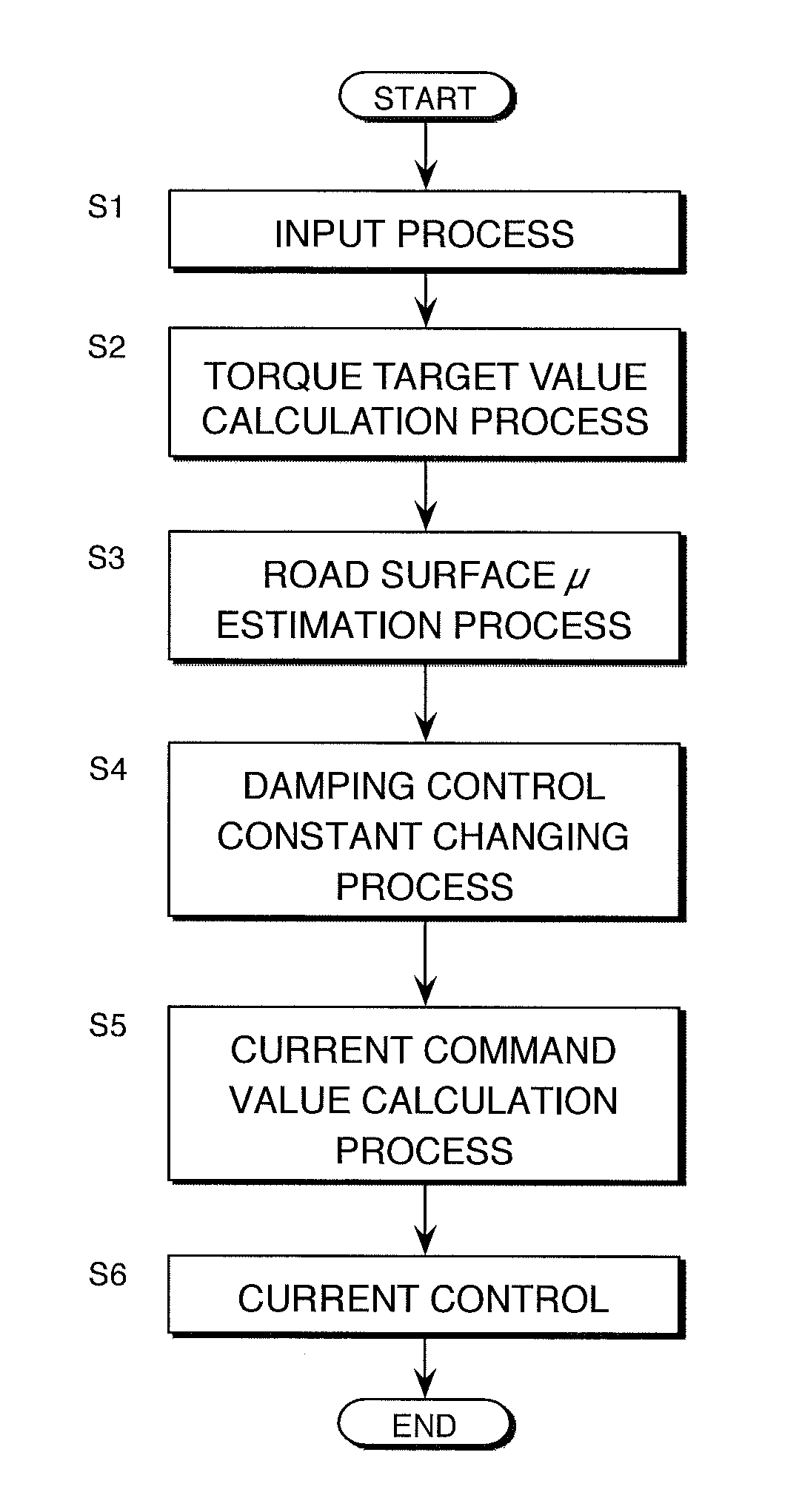

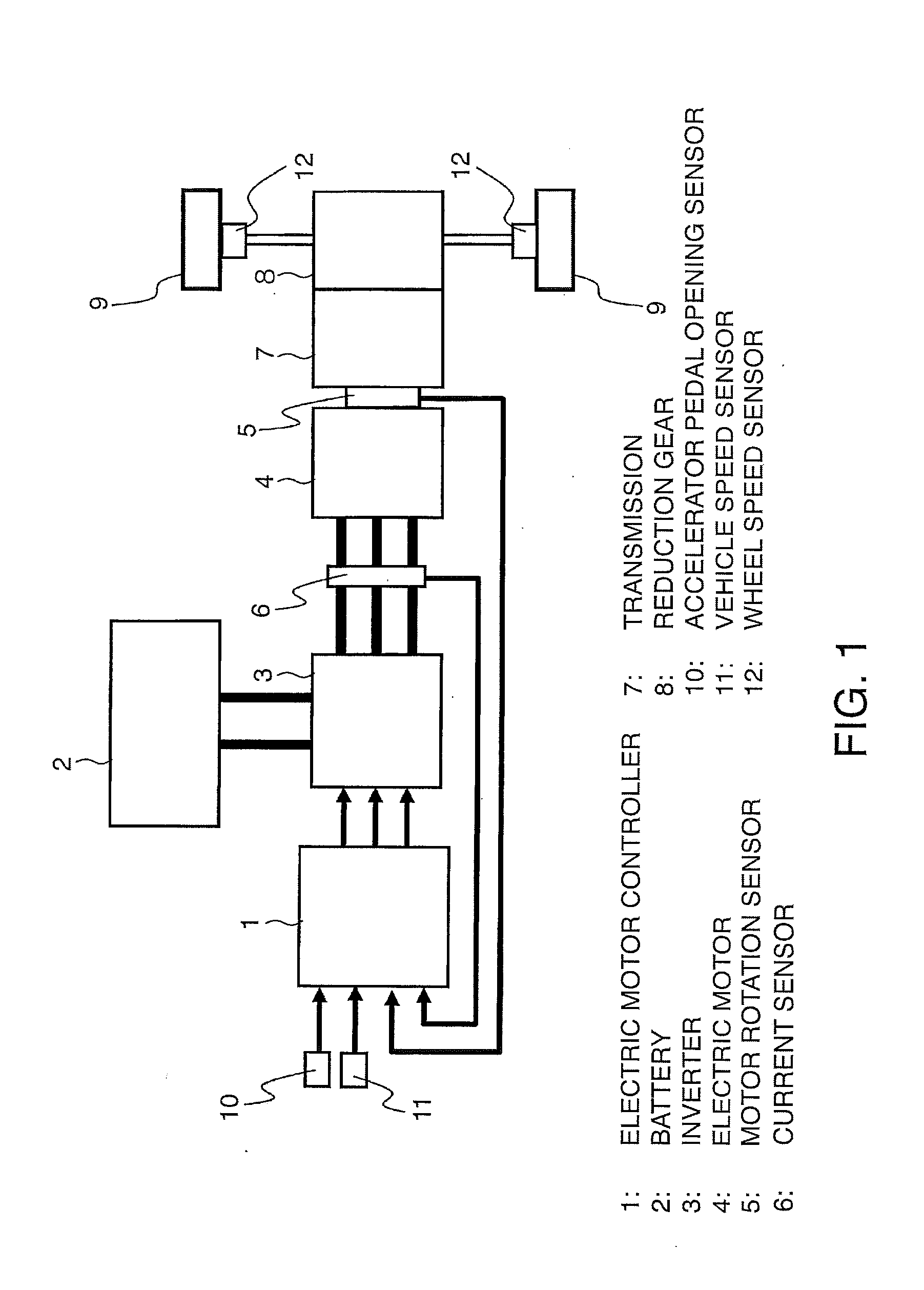

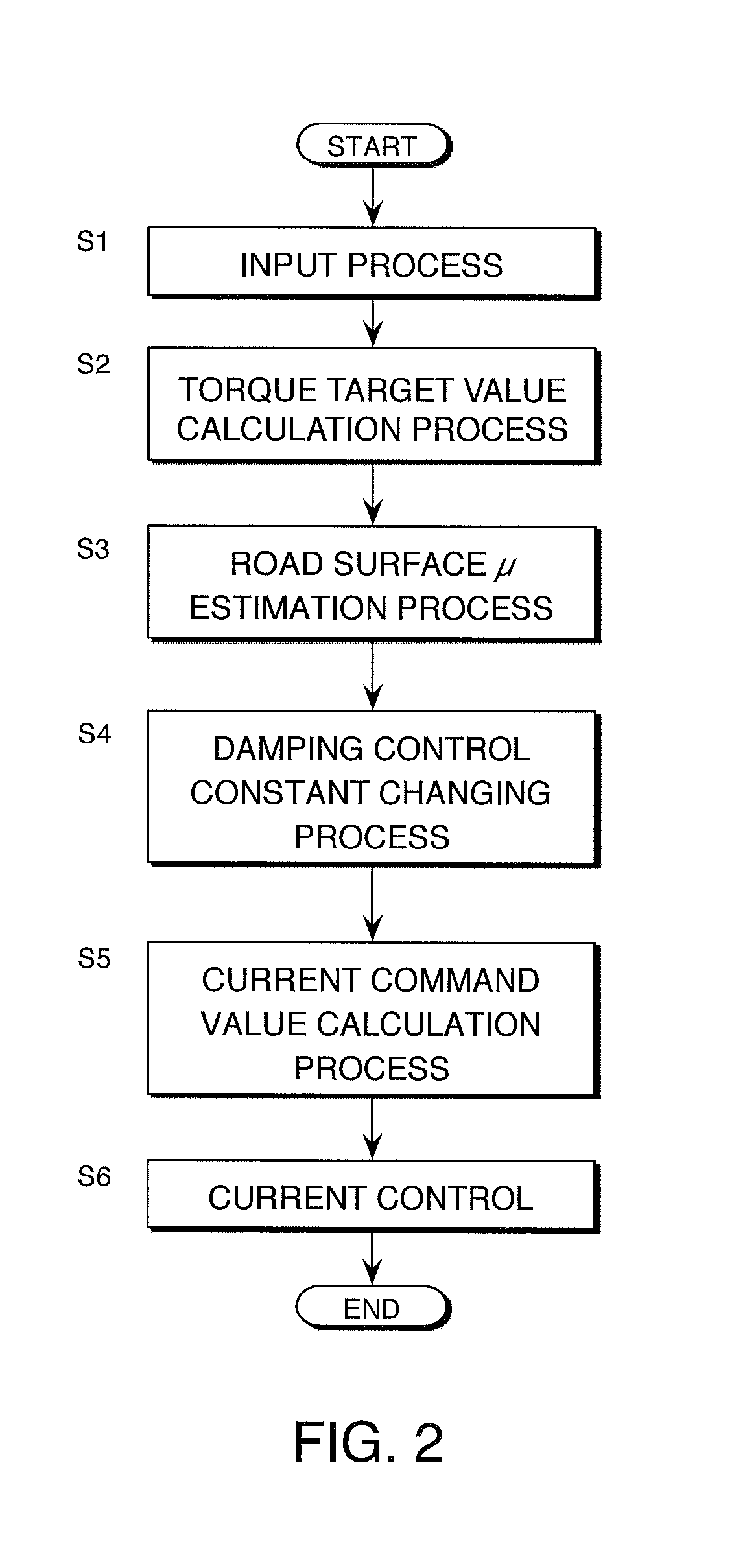

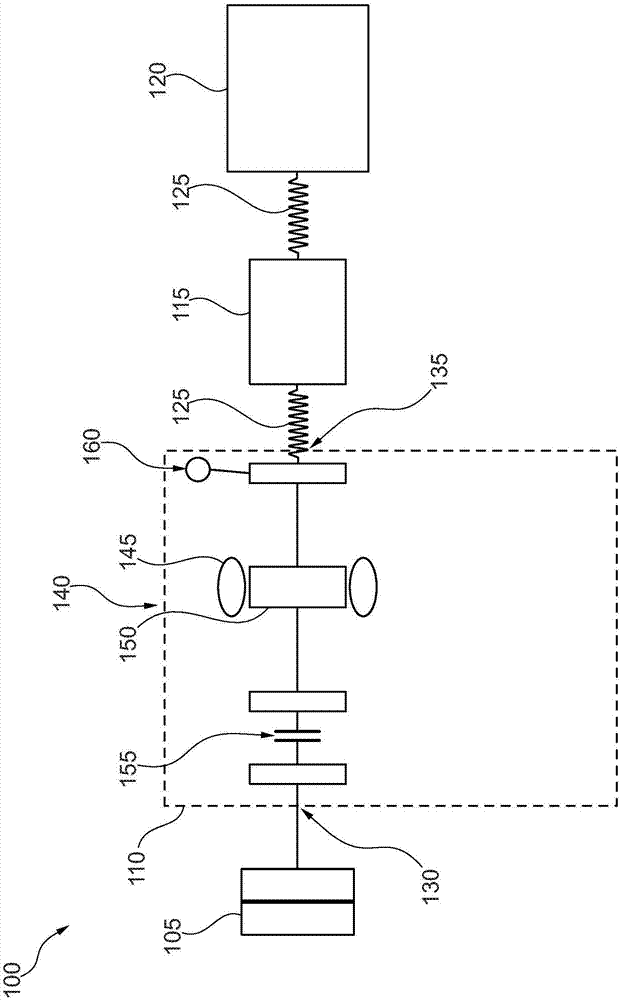

Damping control device and damping control method for vehicle using electric motor

InactiveUS20150012160A1Sufficient control effectReduce torsional vibrationDigital data processing detailsVehicular energy storageTorsional vibrationControl theory

A damping control method of a vehicle using an electric motor for suppressing vibration of the vehicle using the electric motor as a power source includes setting a drive torque target value based on vehicle information of the vehicle, and performing filter processing on the drive torque target value using a damping filter having a characteristic of removing or reducing a frequency component equivalent to torsional vibration of a vehicle drive system based on a vehicle information of the vehicle and an external disturbance suppression filter for suppressing external disturbance, the damping filter calculating a first torque target value and having a characteristic Gm(s) / Gp(s) configured by a model Gp(s) of a transfer characteristic of a torque input to the vehicle and a motor rotation speed and an ideal model Gm(s) of the transfer characteristic of the torque input and the motor rotation speed set in advance.

Owner:NISSAN MOTOR CO LTD

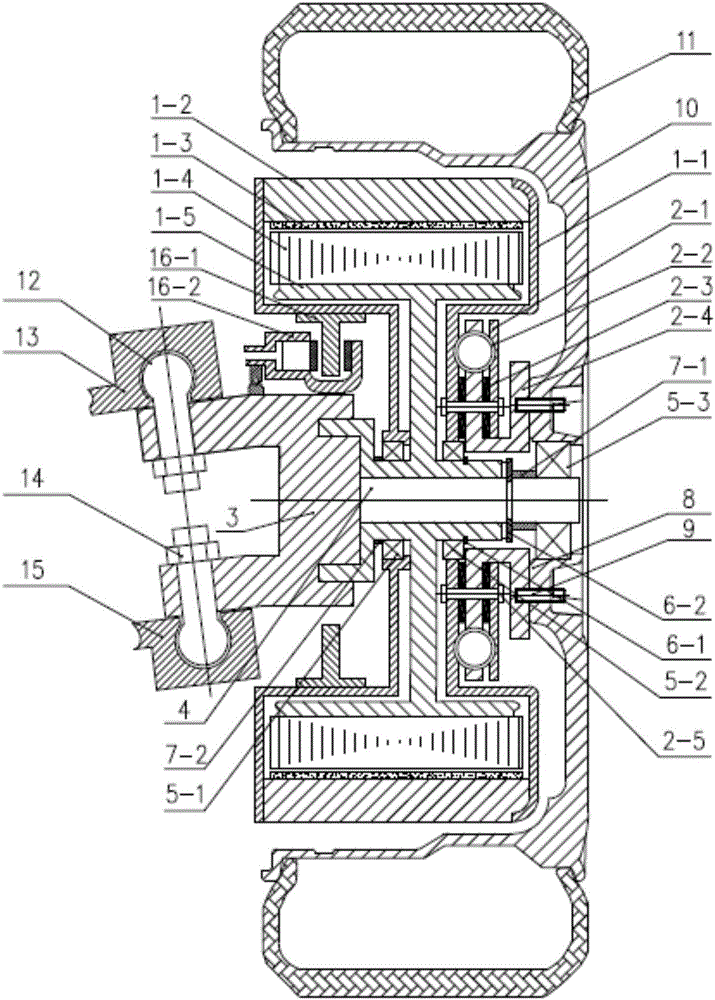

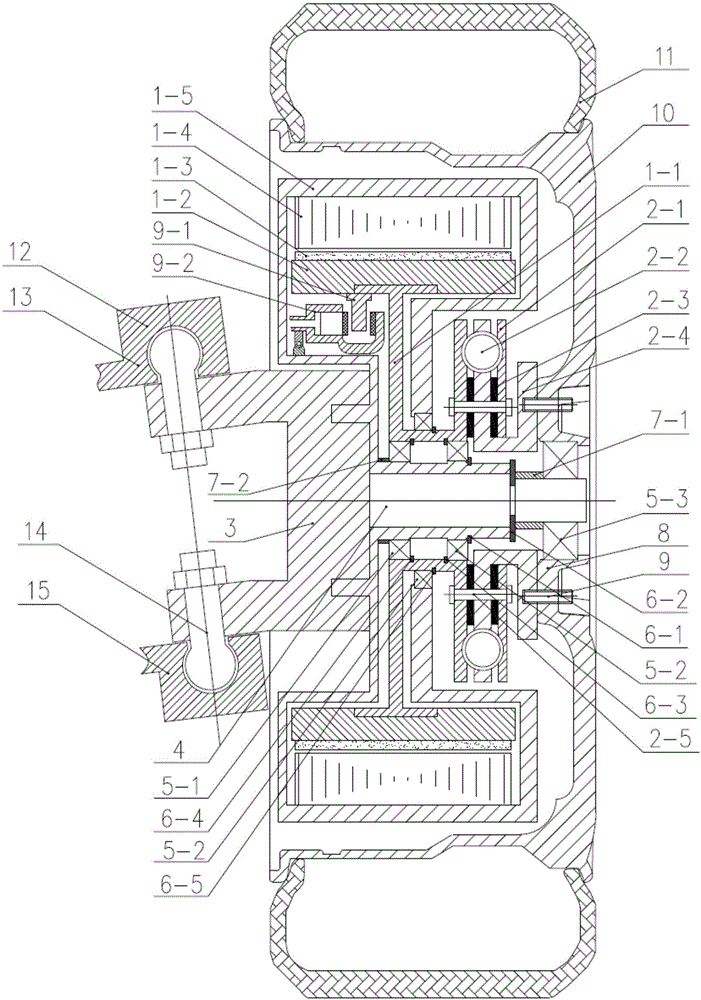

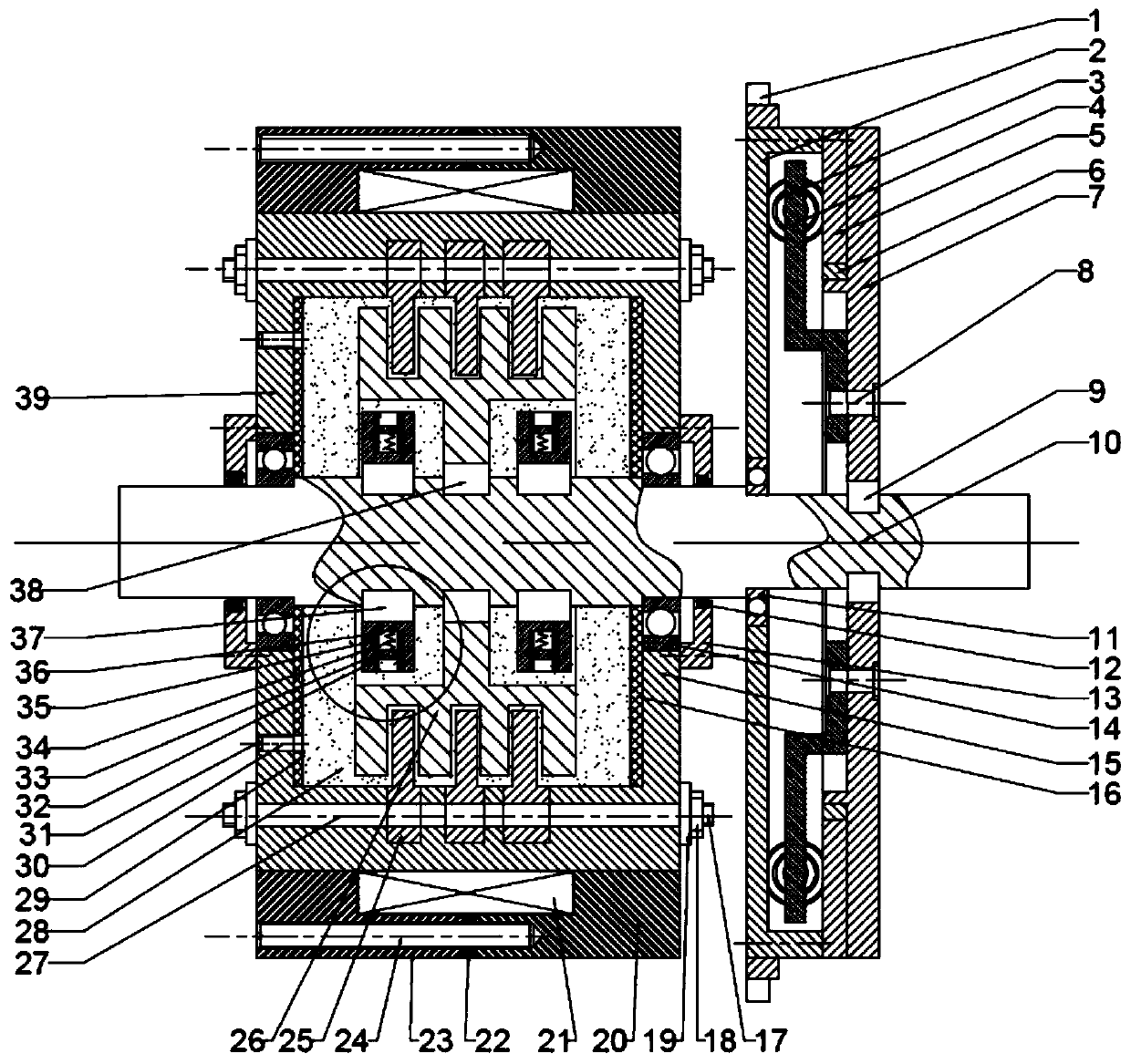

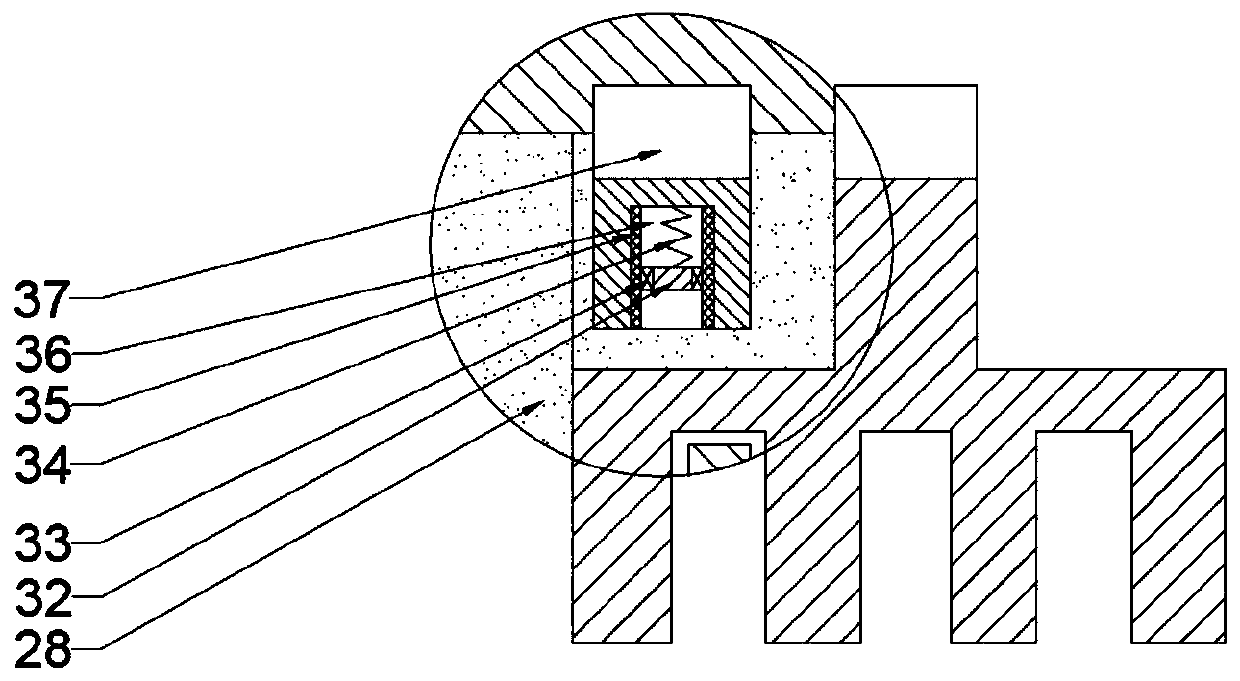

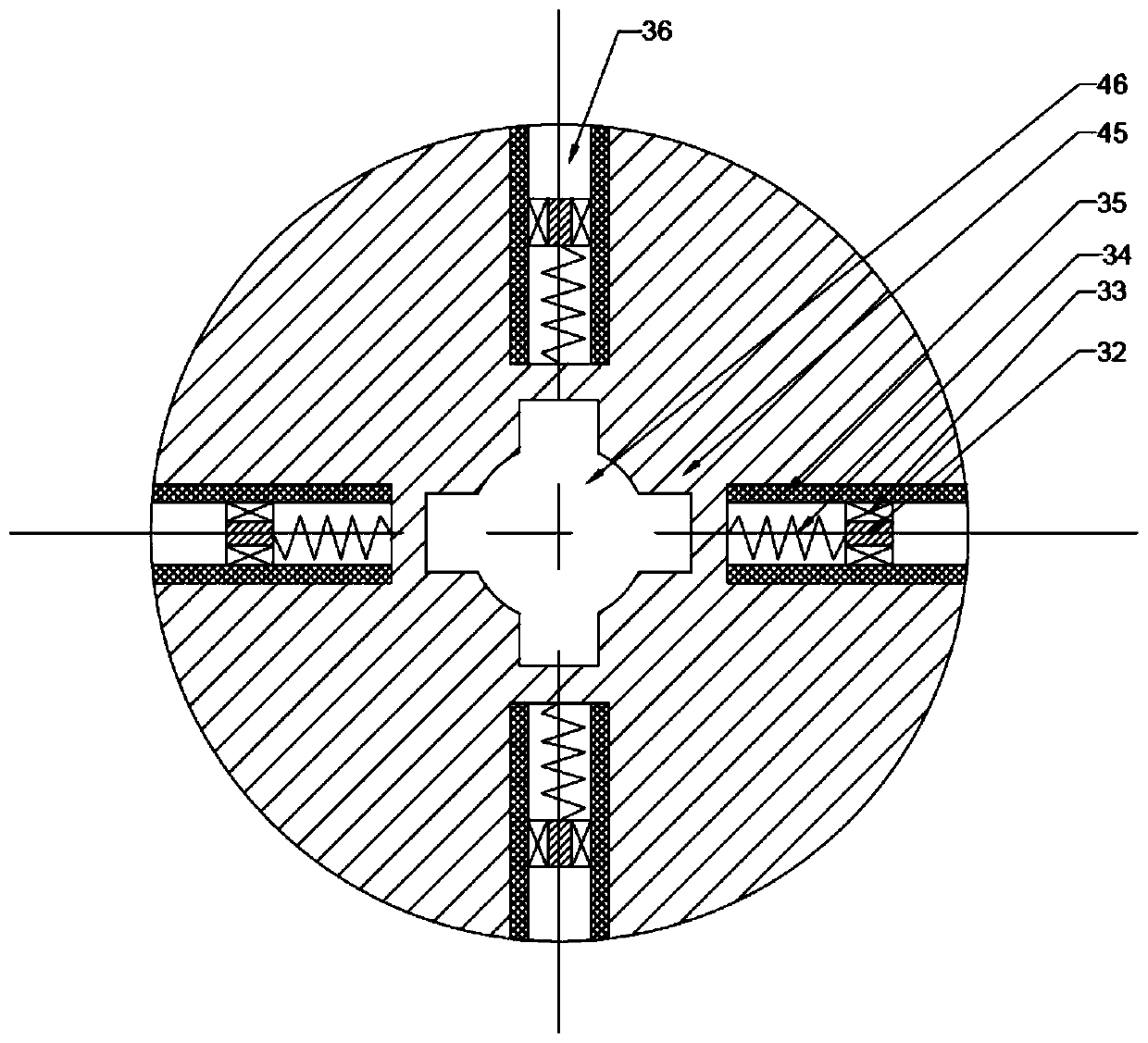

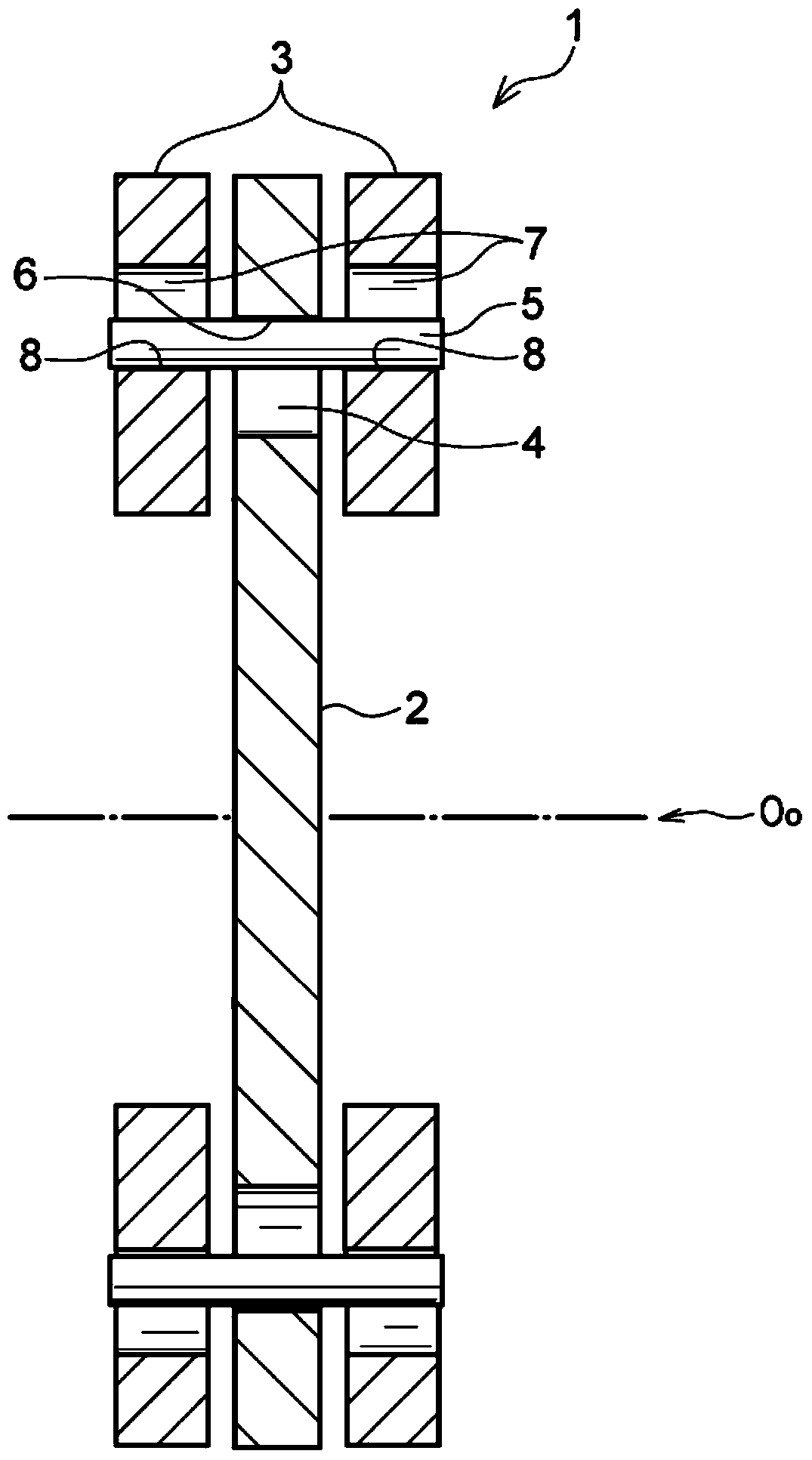

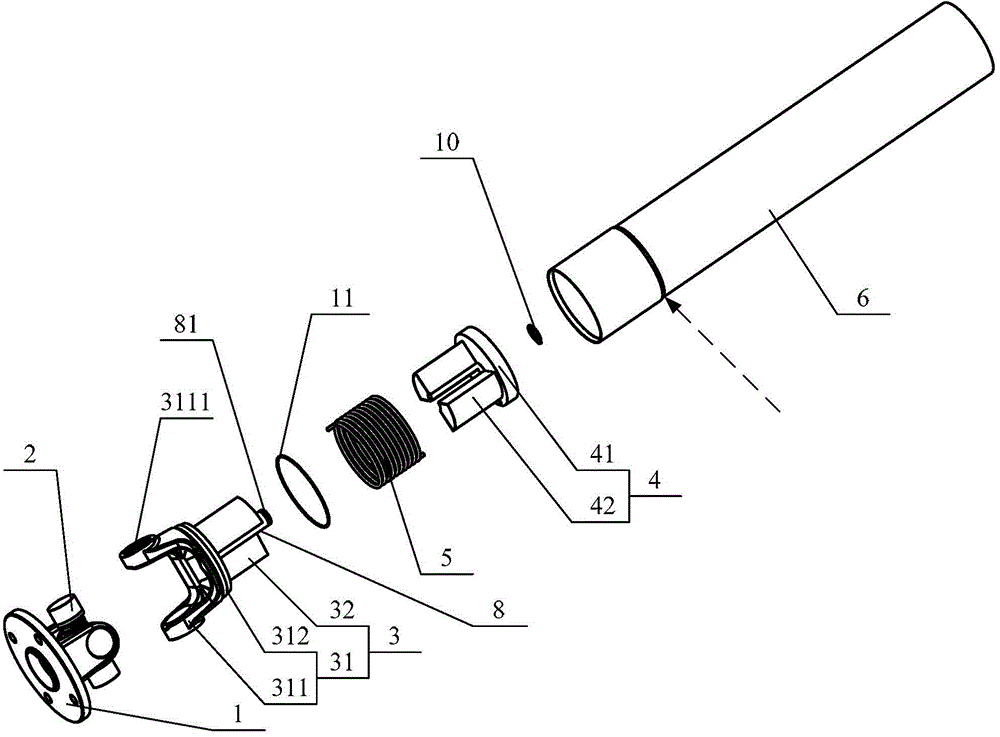

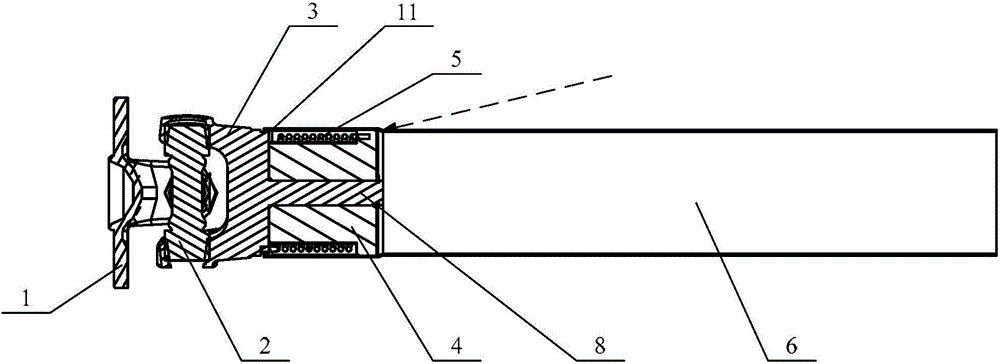

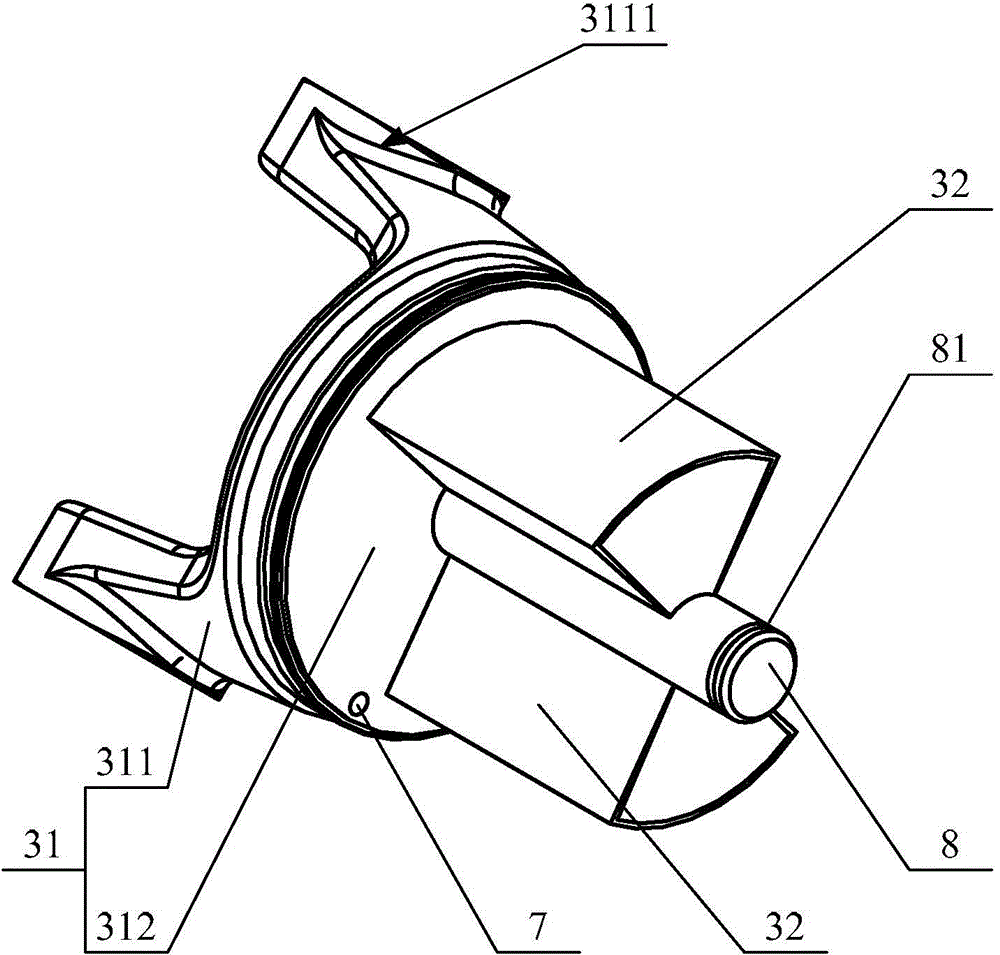

Hub electric driving system with torsion vibration attenuation function

InactiveCN106364310ASmooth rideReduce torque rippleMotor depositionMechanical energy handlingElectricityVibration attenuation

The invention discloses a hub electric driving system with a torsion vibration attenuation function. The hub electric driving system with the torsion vibration attenuation function comprises a hub motor, a torsion vibration attenuation device, a brake, a hub and the like. The torsion vibration attenuation device is composed of a rotor supporting frame, elastic elements, a driven disc, a driven disc hub and damping fins. The rotor supporting frame, the driven disc hub and the driven disc are each provided with peripherally distributed rectangular window holes with the elastic elements. The rotor supporting frame is connected with a hub motor rotor. The driven disc hub is provided with a notch corresponding to a rivet spacer bush and connected with the hub through bolts. The driven disc and the rotor supporting frame are riveted together through rivets and clamp the driven disc hub and the vibration attenuation damping fins on two sides. The brake is a disc brake. A brake disc is installed on the rotor supporting frame and rotates along with the rotor supporting frame. A brake caliper is installed on a suspension knuckle arm. Due to the arrangement of the torsion vibration attenuation device, the torque pulsation from the hub motor can be effectively attenuated, the inherent characteristics of the system can be adjusted, and the purpose of improving the dynamic characteristics of the hub electric driving system is realized.

Owner:SHANDONG UNIV OF TECH

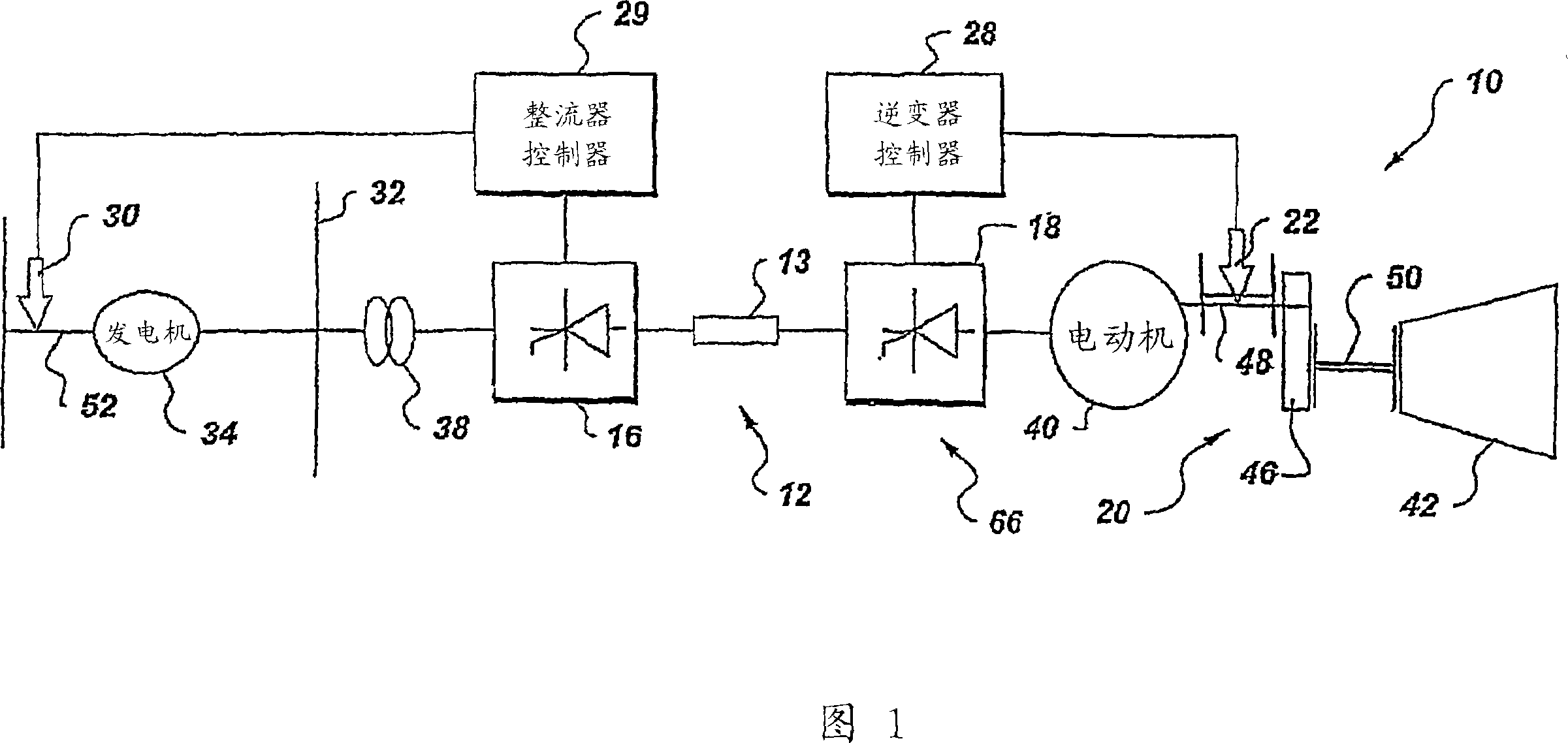

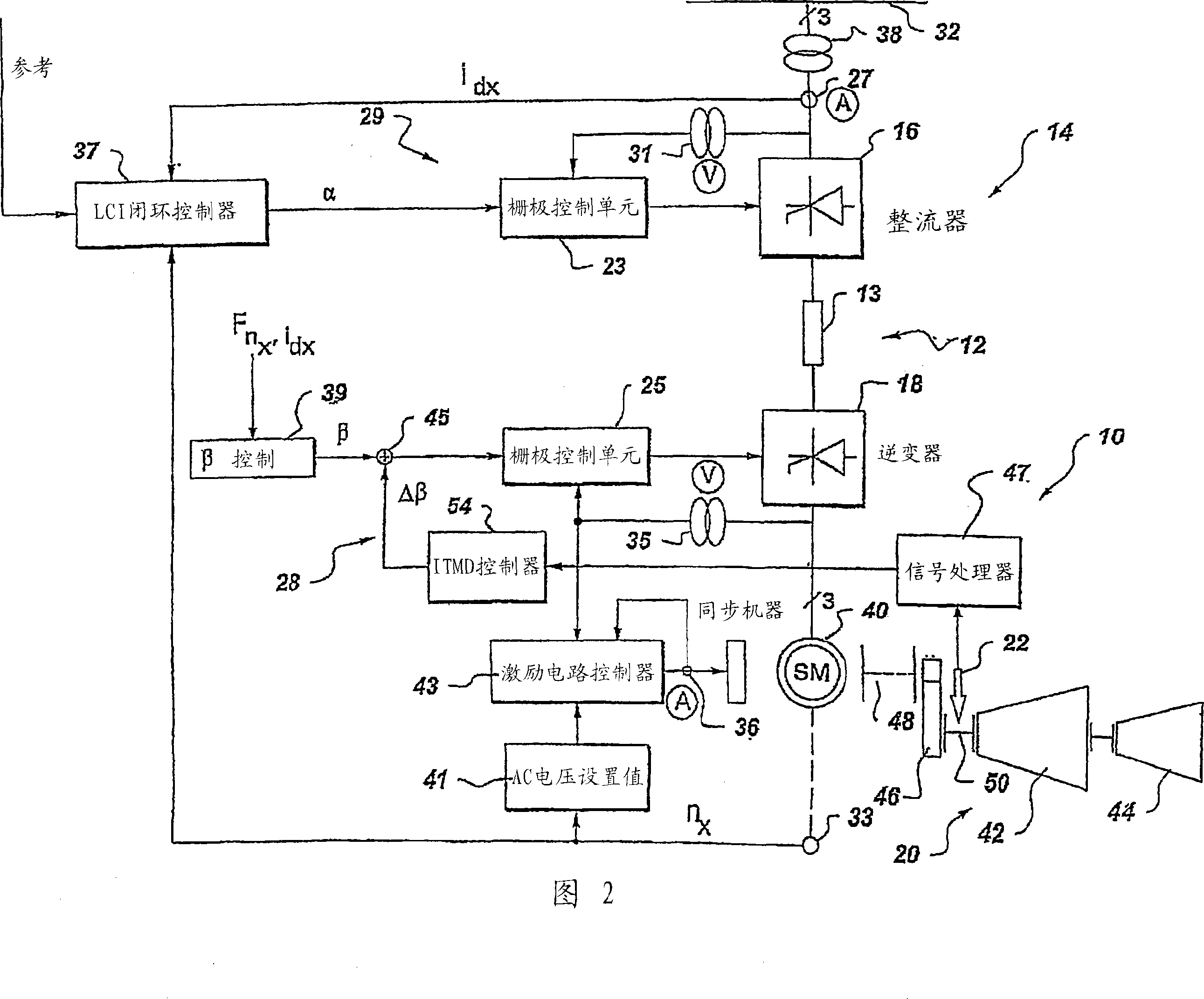

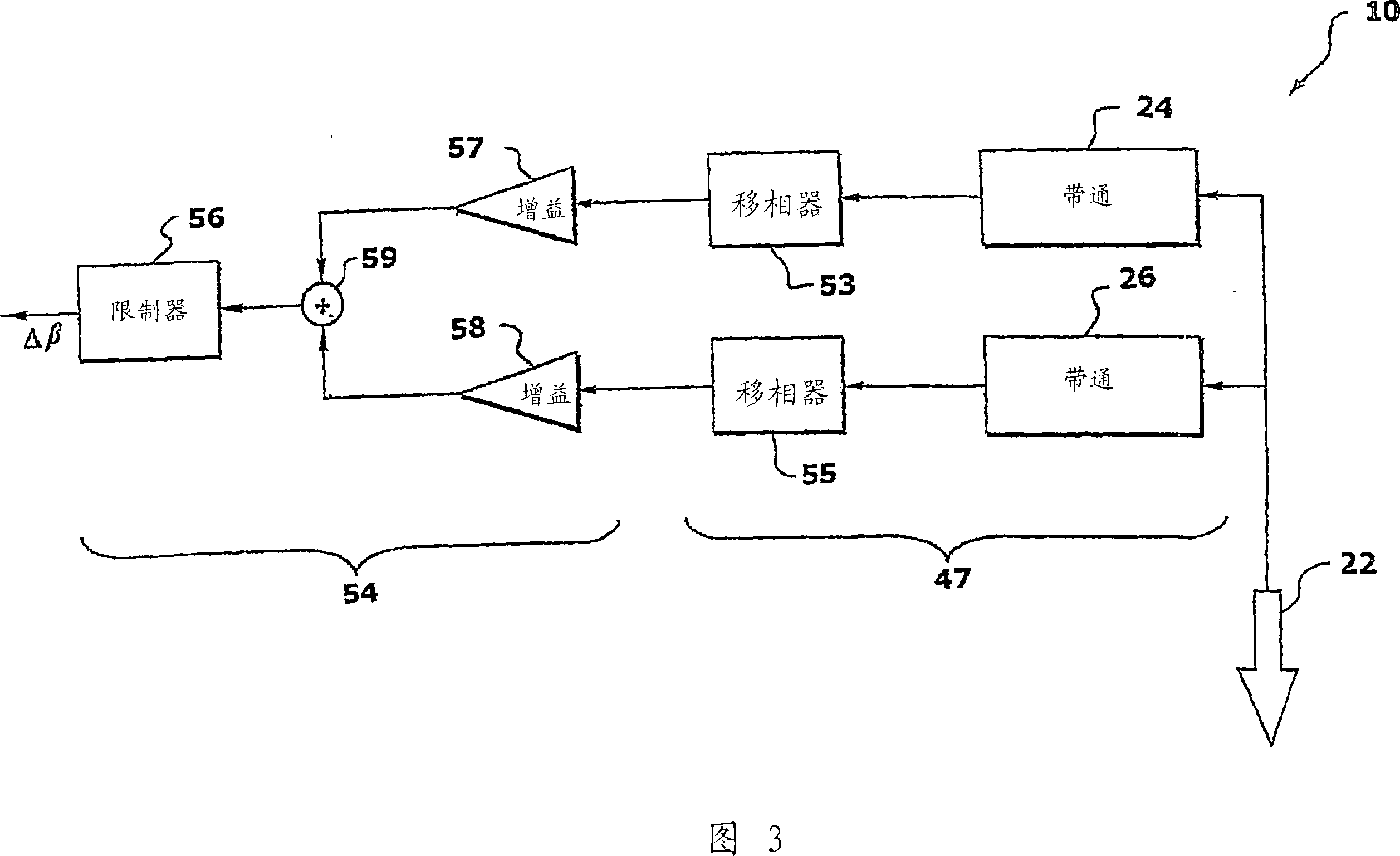

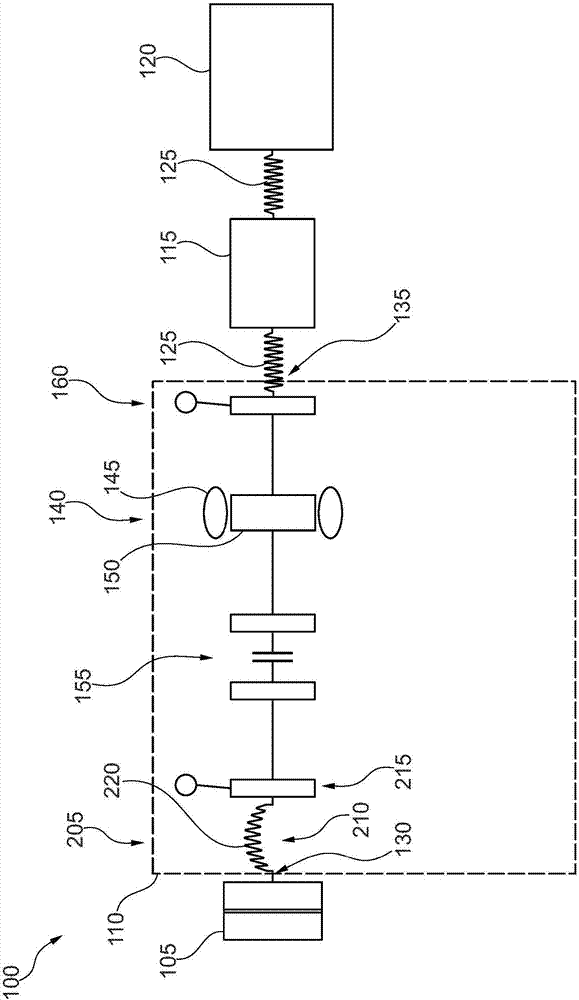

Integrated torsional mode damping system and method

InactiveCN101164225AReduce torsional vibrationElectric motor controlElectric devicesInductorTorsional vibration

An integrated torsional mode damping method for a current source converter comprising a rectifier, an inverter and a DC link inductor coupled between the rectifier and inverter, the method comprising: sensing a signal representative of torque on a shaft coupled to the inverter or rectifier; using the sensed signal to detect the presence of torsional vibrations on the shaft; and by regulating real power via the corresponding inverter or rectifier to reduce the torsional vibration.

Owner:GENERAL ELECTRIC CO

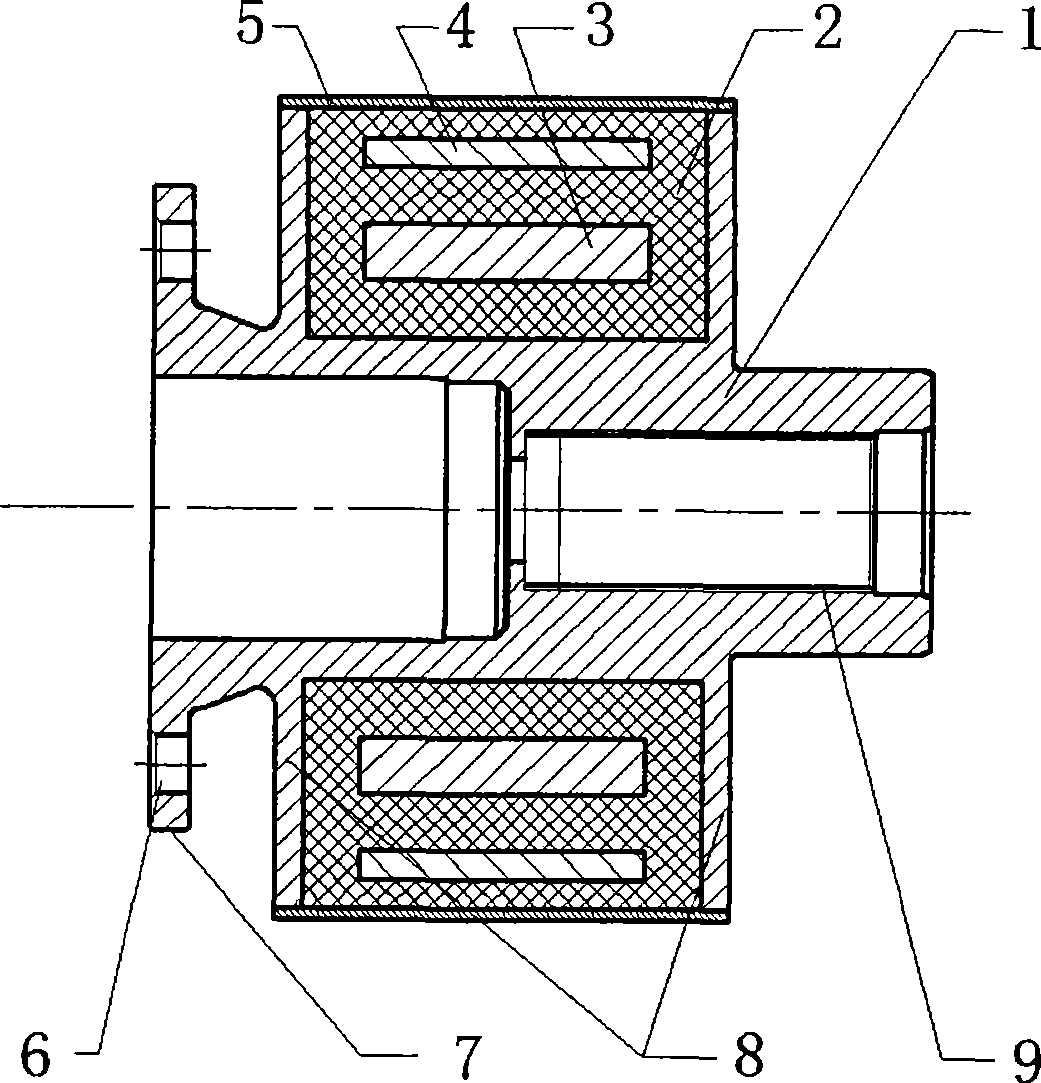

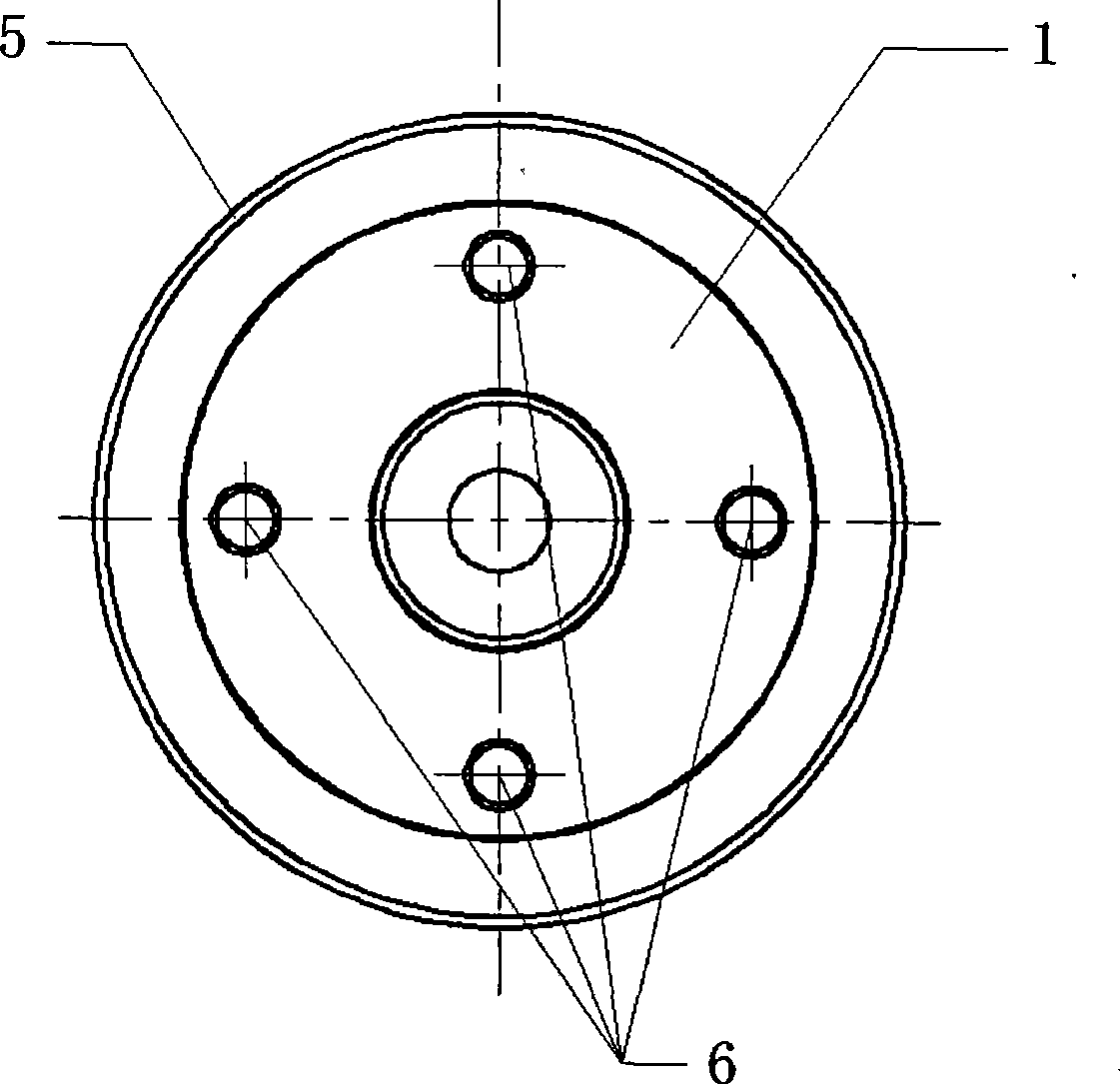

Torsion vibration damper used for main reducing gear

InactiveCN101476612AReduce torsional vibrationImprove torsional vibrationVibration suppression adjustmentsPeak valueCar manufacturing

The invention relates to a torsional vibration absorber for a main decelerator, and belongs to the technical field of automobile manufacturing. A vibration absorber substrate has a tubular structure, the front end of the vibration absorber substrate is provided with a flange which is provided with a flange connection hole, an inner hole of the vibration absorber substrate is a stepped hole, a spline is arranged in one end of a minor diameter of the stepped hole, the front and the back outside the vibration absorber substrate are provided with an axial limit plate respectively, and a rubber layer is placed between the front axial limit plate and the back axial limit plate. Fixed outer rings are sleeved outside the rubber layer, the front axial limit plate and the back axial limit plate. A first quality loop and a second quality loop are wrapped in the rubber layer from inside to outside. Through adjusting shape and amount of the inner quality loops of the vibration absorber, parameters of rubber, and the like, the vibration absorber restrains torsional vibration peak values under a plurality of frequencies, replaces a shaft end flange or a similar structure at an input shaft of the main decelerator, connects a universal joint at an output end of a transmission shaft and the input shaft of the main decelerator to transfer force, has little alteration on the structure of a vehicle, and is convenient to mount and use.

Owner:TSINGHUA UNIV

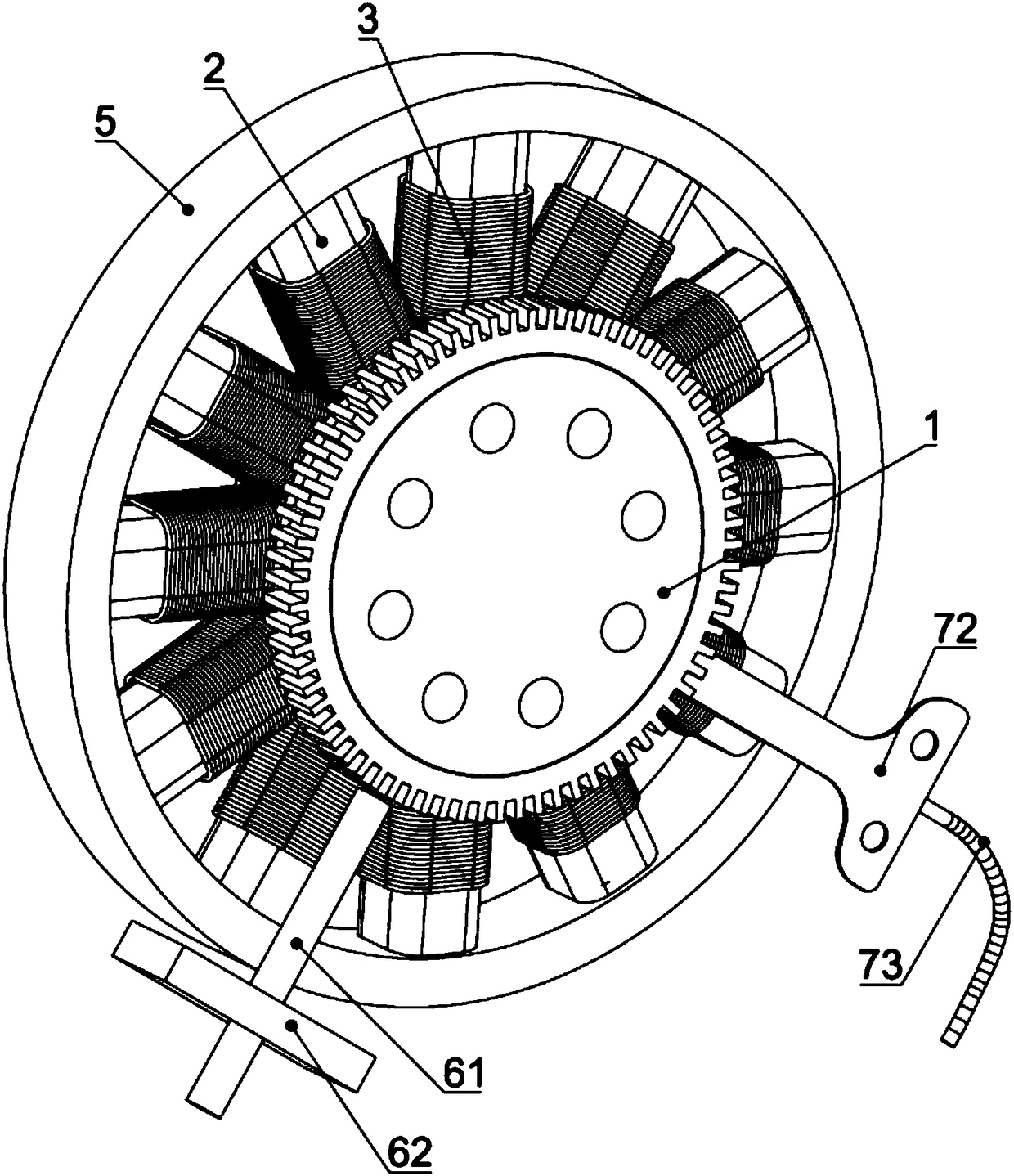

Magnetorheological fluid-based semi-active control variable inertia dual-mass flywheel

ActiveCN109944906AChanging magnetic forceChange viscosityRotating vibration suppressionNon-rotating vibration suppressionMagnetic currentSemi active

The invention relates to a magnetorheological fluid-based semi-active control variable inertia dual-mass flywheel, and aims to solve the problems of uncontrollable damping and small adjustable dampingrange of the existing dual-mass flywheel. The magnetorheological fluid-based semi-active control variable inertia dual-mass flywheel comprises a primary flywheel assembly, a secondary flywheel assembly, an excitation device, a damping liquid chamber assembly, a magnetorheological fluid, an inner rotor, two variable inertia discs and two arc-shaped springs; the primary flywheel assembly is supported on each of a second flywheel connecting shaft and the secondary flywheel assembly; the secondary flywheel assembly is matched with the second flywheel connecting shaft; a force transferring plate is in rigid connection with a second flywheel; the two arc-shaped springs are symmetrically mounted in two arc-shaped grooves of the primary flywheel assembly; the inner rotor and the two variable inertia discs are matched with the second flywheel connecting shaft; damping plates are matched with damping clamping grooves in a damping liquid chamber shell to form a plurality of layers of fluid gaps;an upper damping liquid chamber shell is connected with a lower damping liquid chamber shell through shell extending plates at cross sections; and the excitation device is fixed to the outer side ofthe damping liquid chamber shell.

Owner:JILIN UNIV

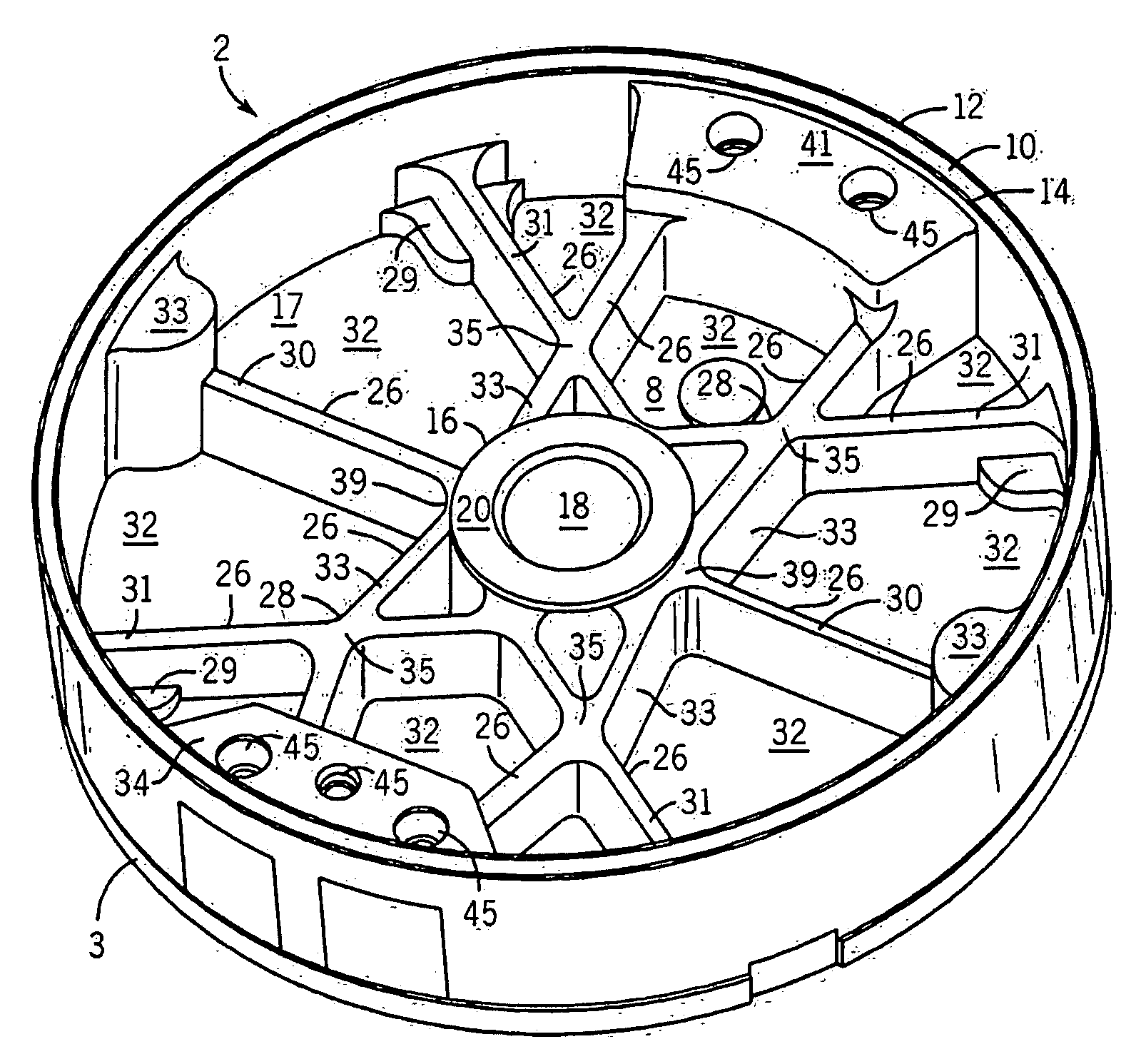

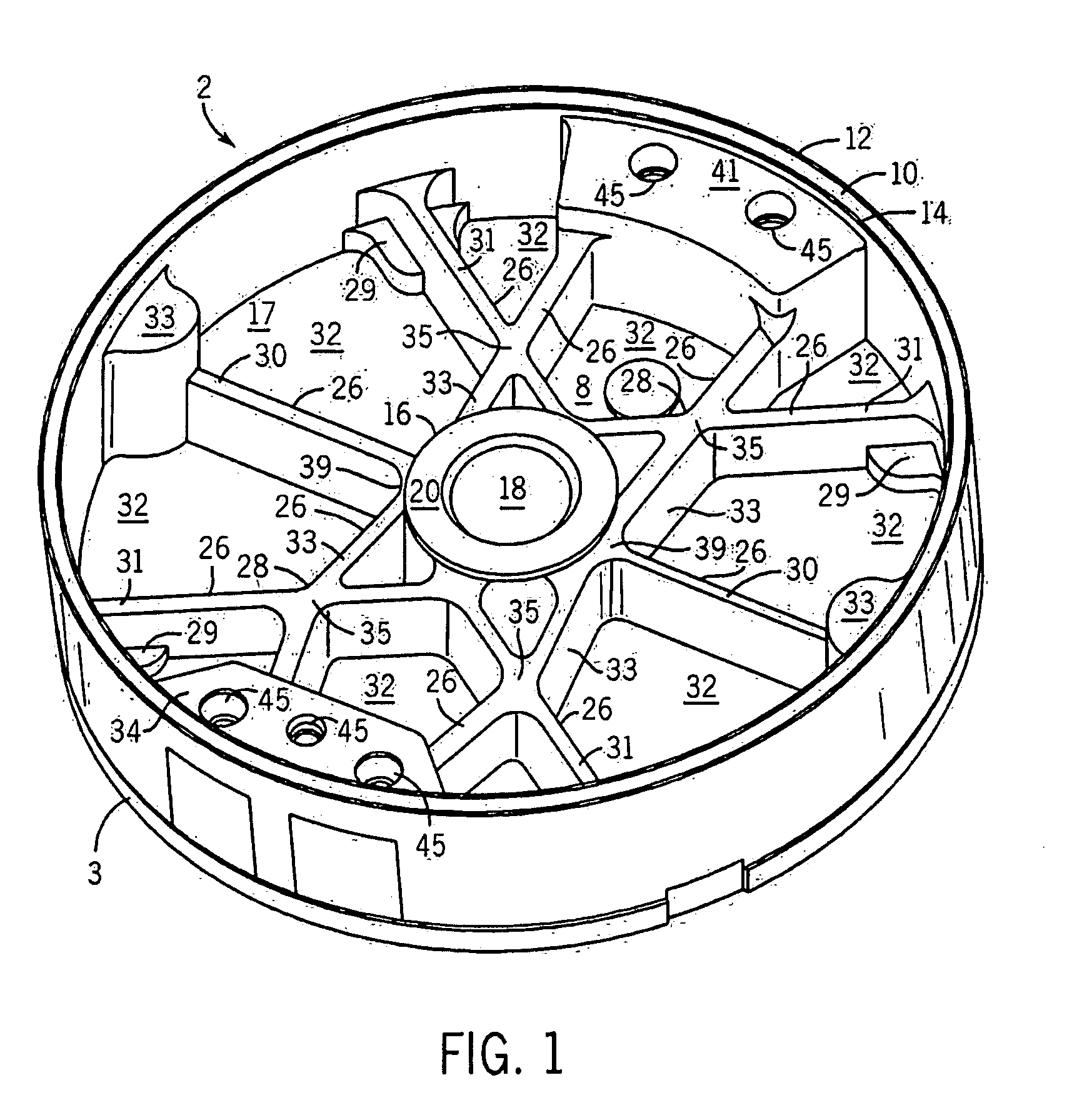

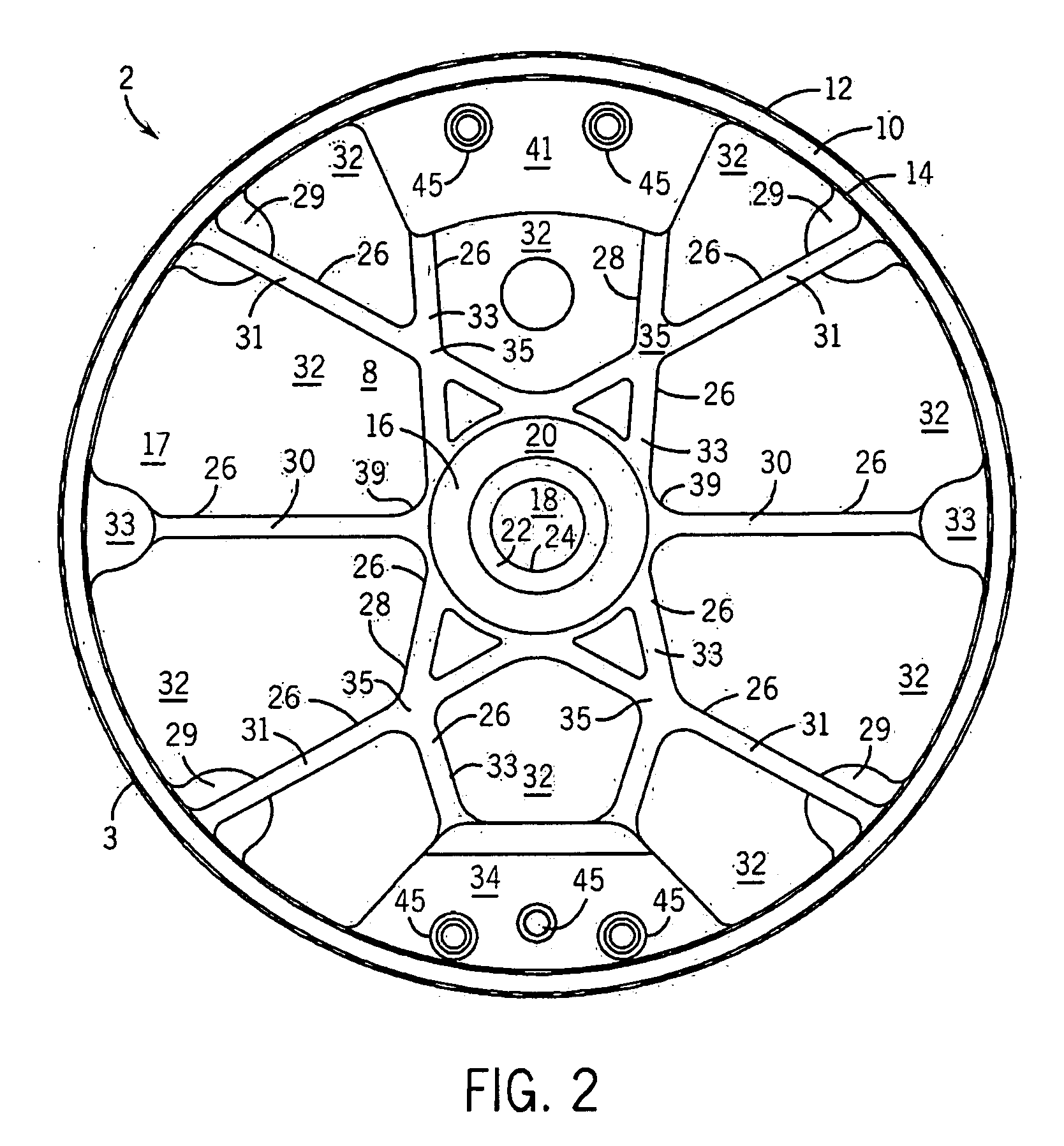

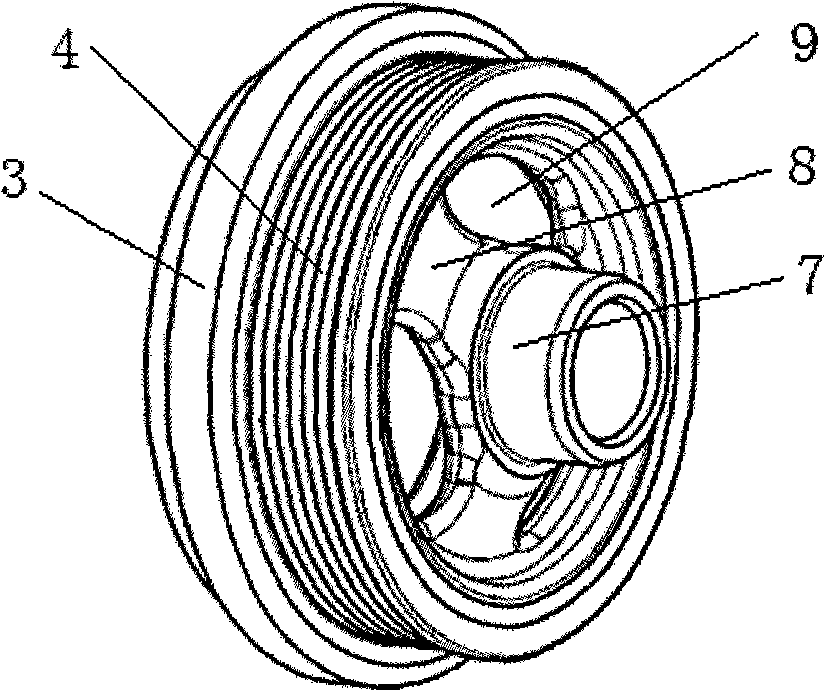

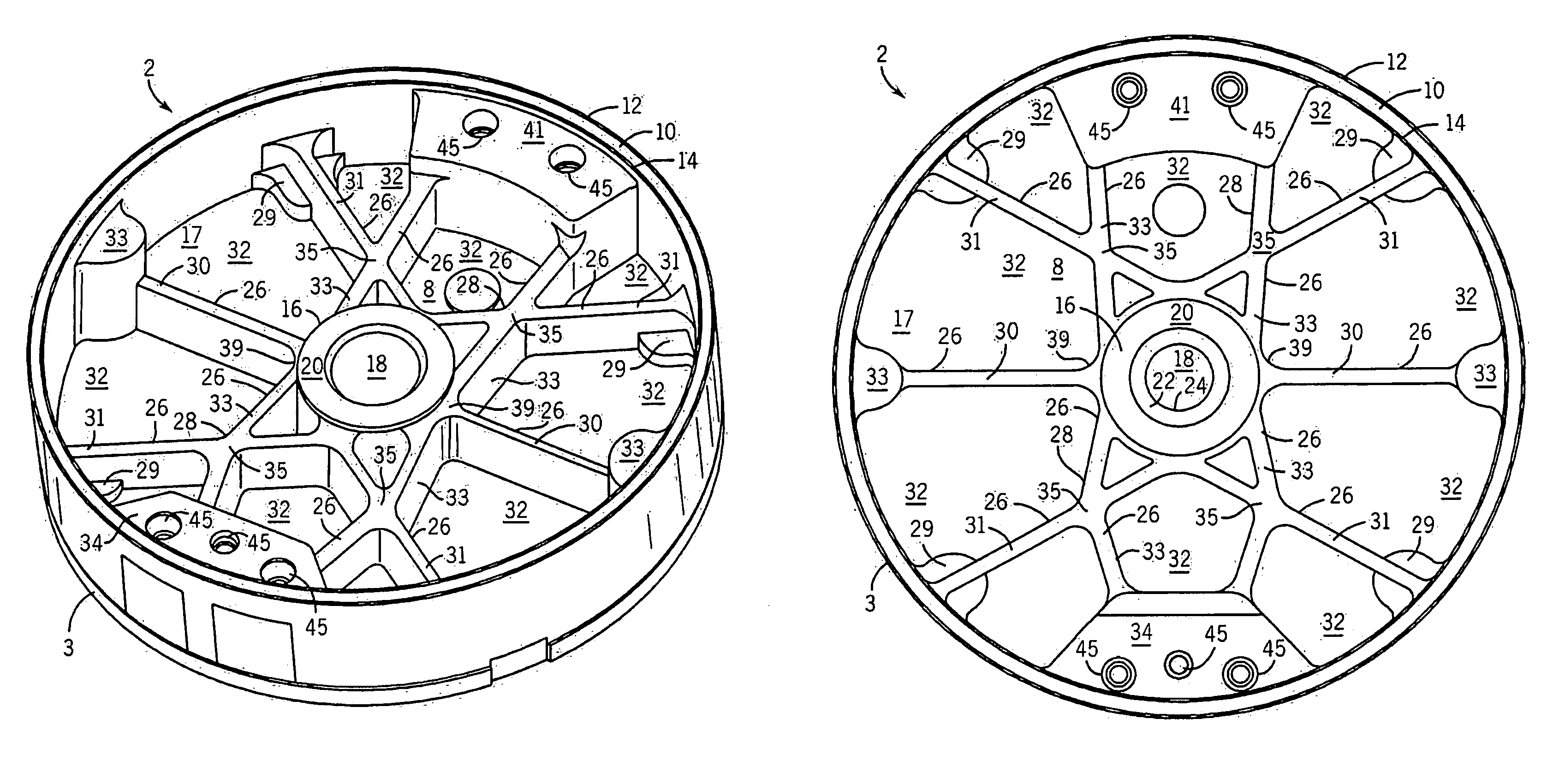

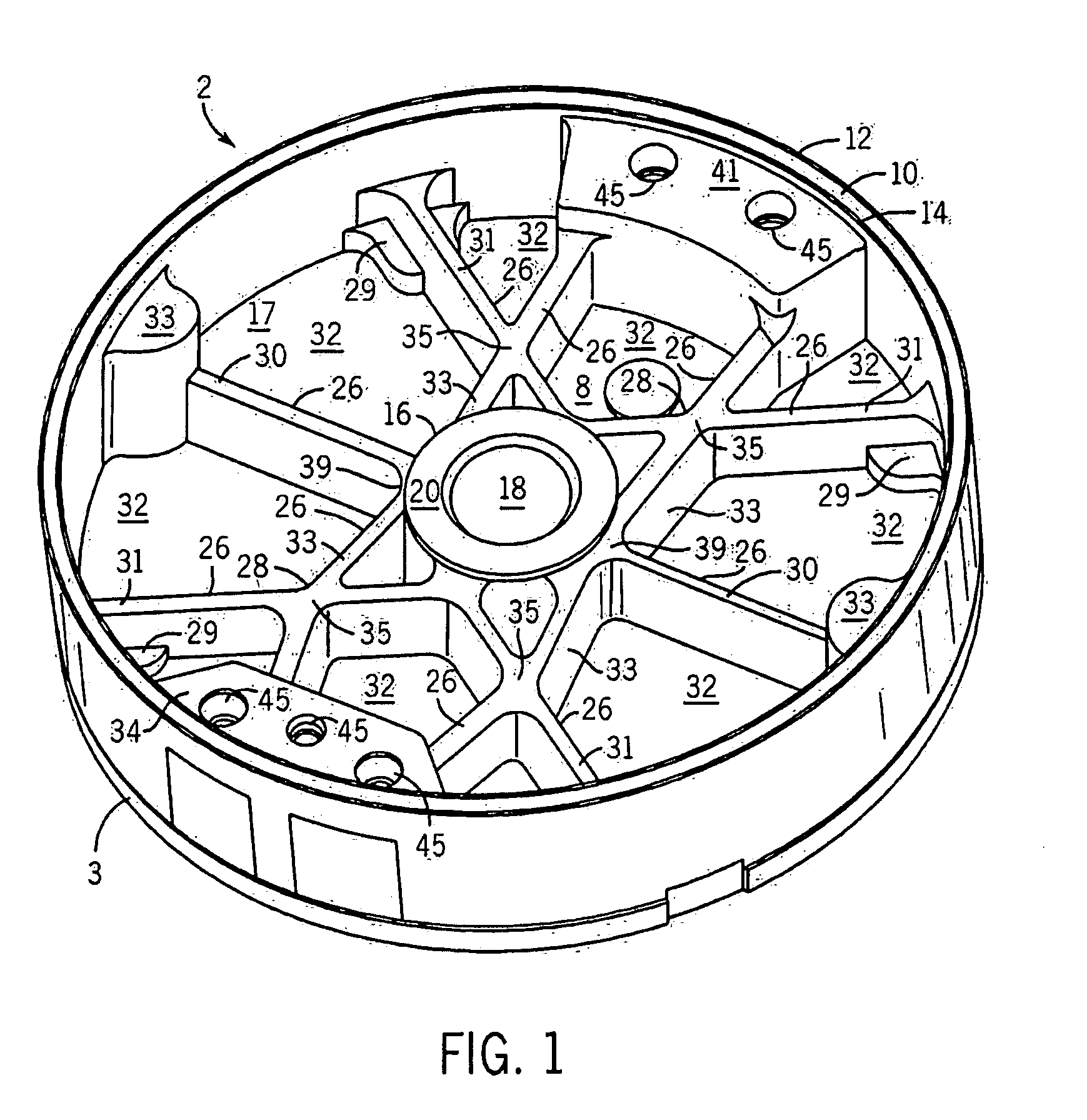

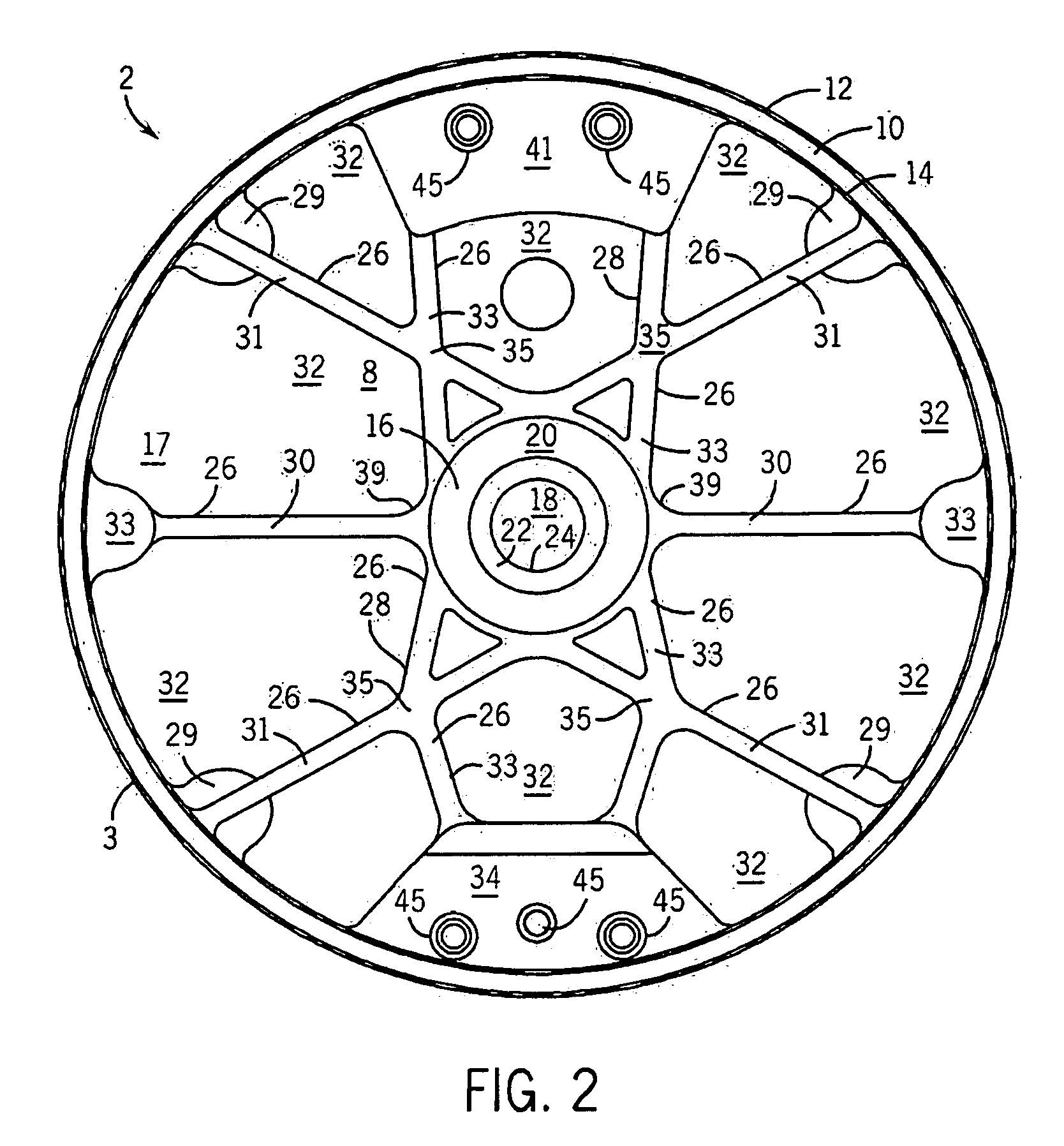

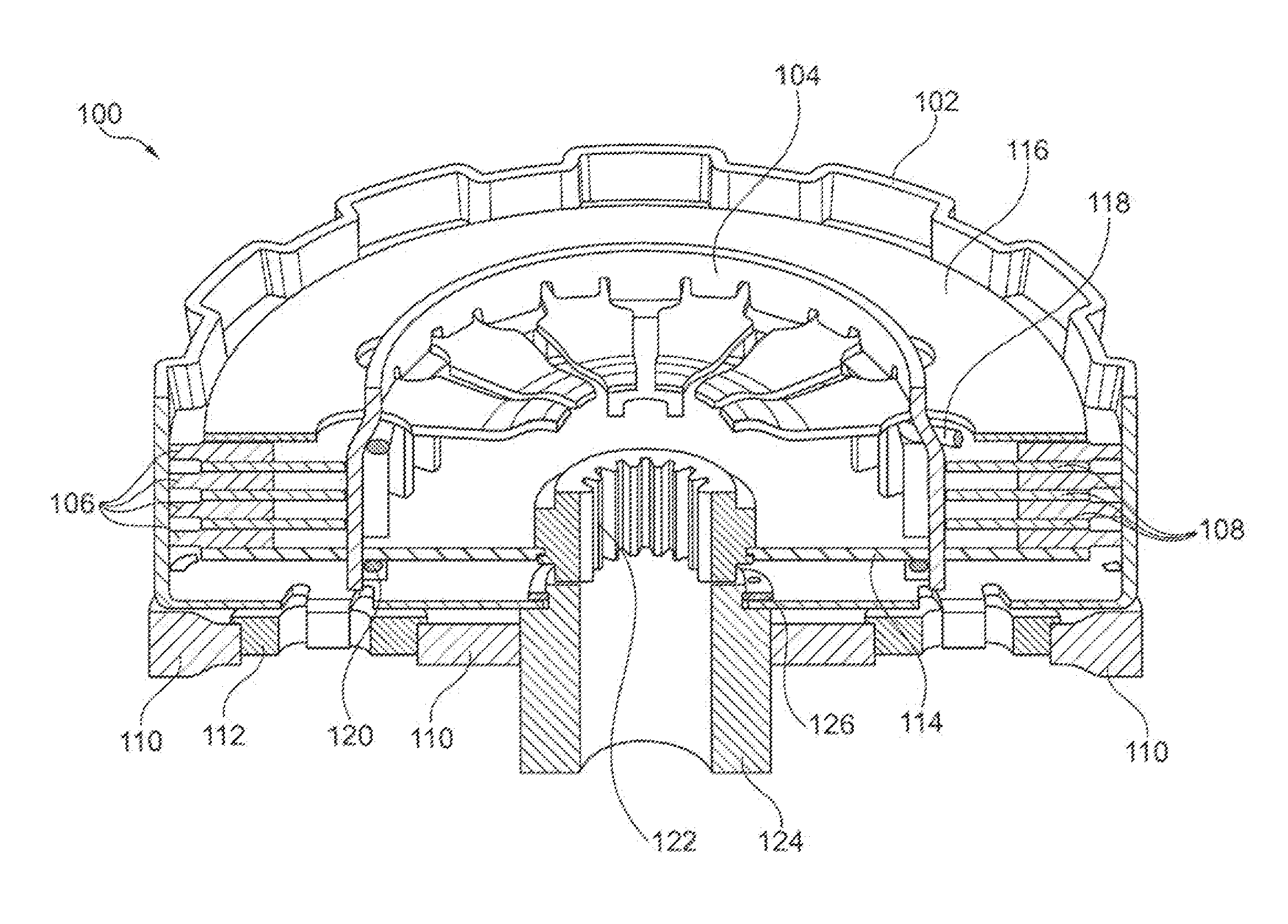

Flywheel Assembly

ActiveUS20090120401A1Reduces and eliminates axial vibrationReduce torsional vibrationCoolant flow controlGearingInternal combustion engineFlywheel

A system for a flywheel assembly for use in conjunction with an internal combustion engine is disclosed. The flywheel assembly includes a flywheel in rotational association with a crankshaft of the internal combustion engine. The flywheel assembly further includes a cooling fan mounted over the flywheel, and capable of rotation therewith. The cooling fan and the flywheel are secured in a constant axial position relative to the crankshaft by virtue of a drive-cup and a retaining nut. Further, the flywheel includes a plurality of integrally formed, intersecting support ribs, for providing excellent dynamic stiffening (e.g., damping) capabilities to the flywheel assembly for substantially reducing and / or eliminating radiated noise.

Owner:KOHLER CO

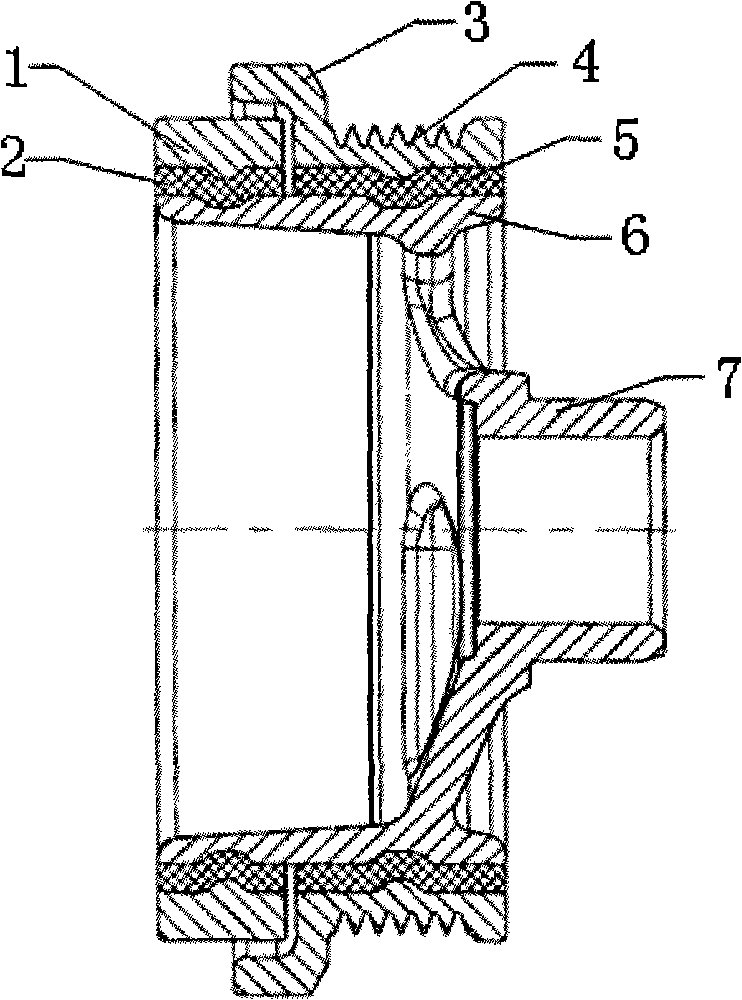

Vibration damper assembly

InactiveCN101886685AReduce vibrationReduce noiseInertia force compensationRubber ringTorsional vibration

The invention discloses a vibration damper assembly, which comprises a shock absorber mounting shaft, a spoke and a hub. A belt wheel having the function of an inertia disc is arranged outside the hub through a second-stage rubber ring, and is provided with a second-stage inertia ring. The shock absorber assembly is characterized in that the front end of the hub is connected in parallel with a first-stage rubber ring and a first-stage inertia ring. In order to eliminate the vibration caused by first-order vibration frequency of a crank, the first-stage rubber ring and a first-stage inertia ring form a torsional vibration damper consistent with the first-order vibration frequency of the crank. The first-stage inertia ring is arranged in the second-stage inertia ring. Because parallelly-connected two-stage vibration damper is adopted, and two stages of inertia rings are used, the working frequency of the vibrator damper is effectively reduced, the hardness of the rubber can be controlled in a certain range, and the service life of the crank of an engine is improved and the vibration and noise of the engine are reduced under the action of the vibration damper consisting of the two stages of inertia rings.

Owner:CHERY AUTOMOBILE CO LTD

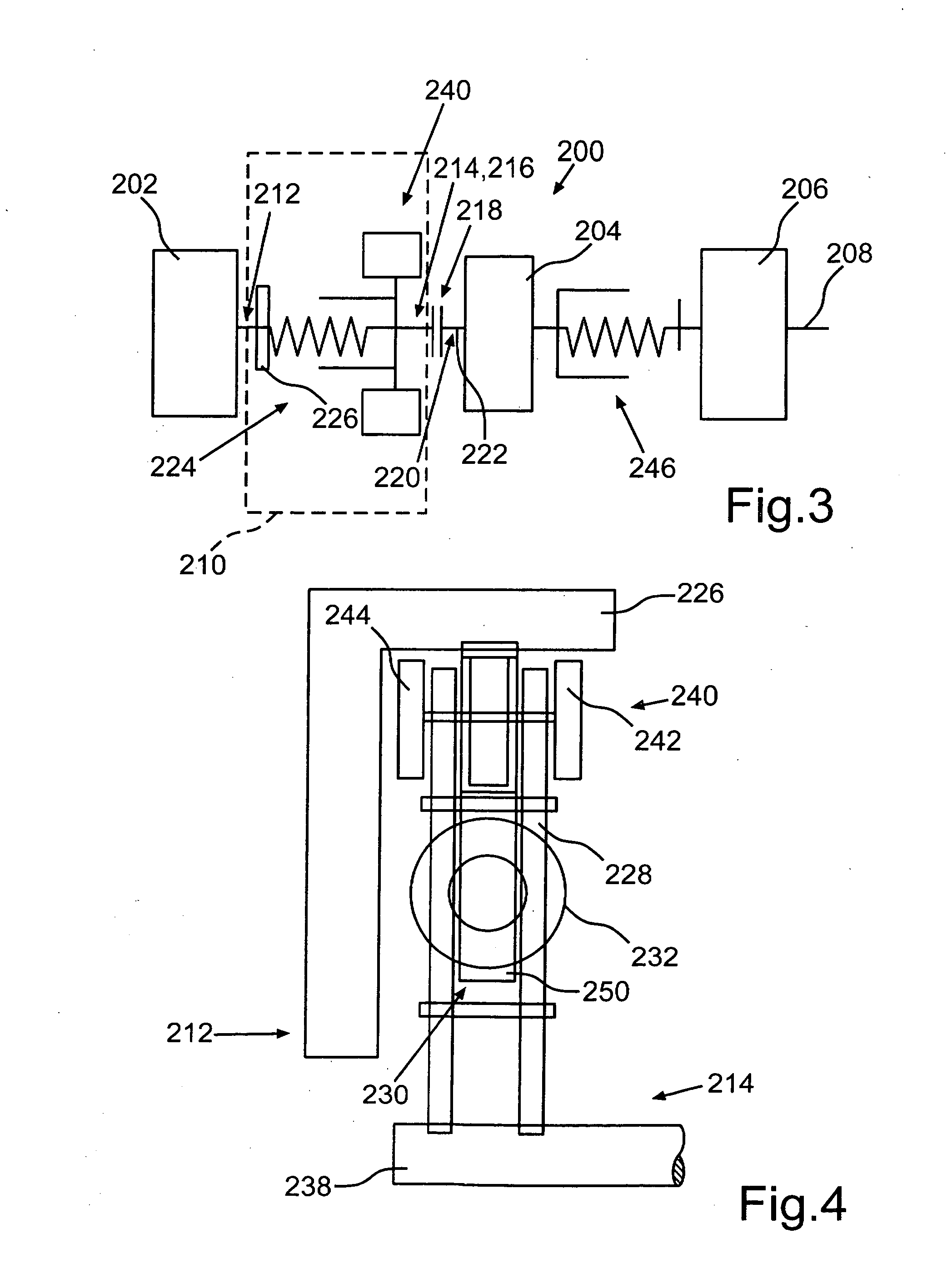

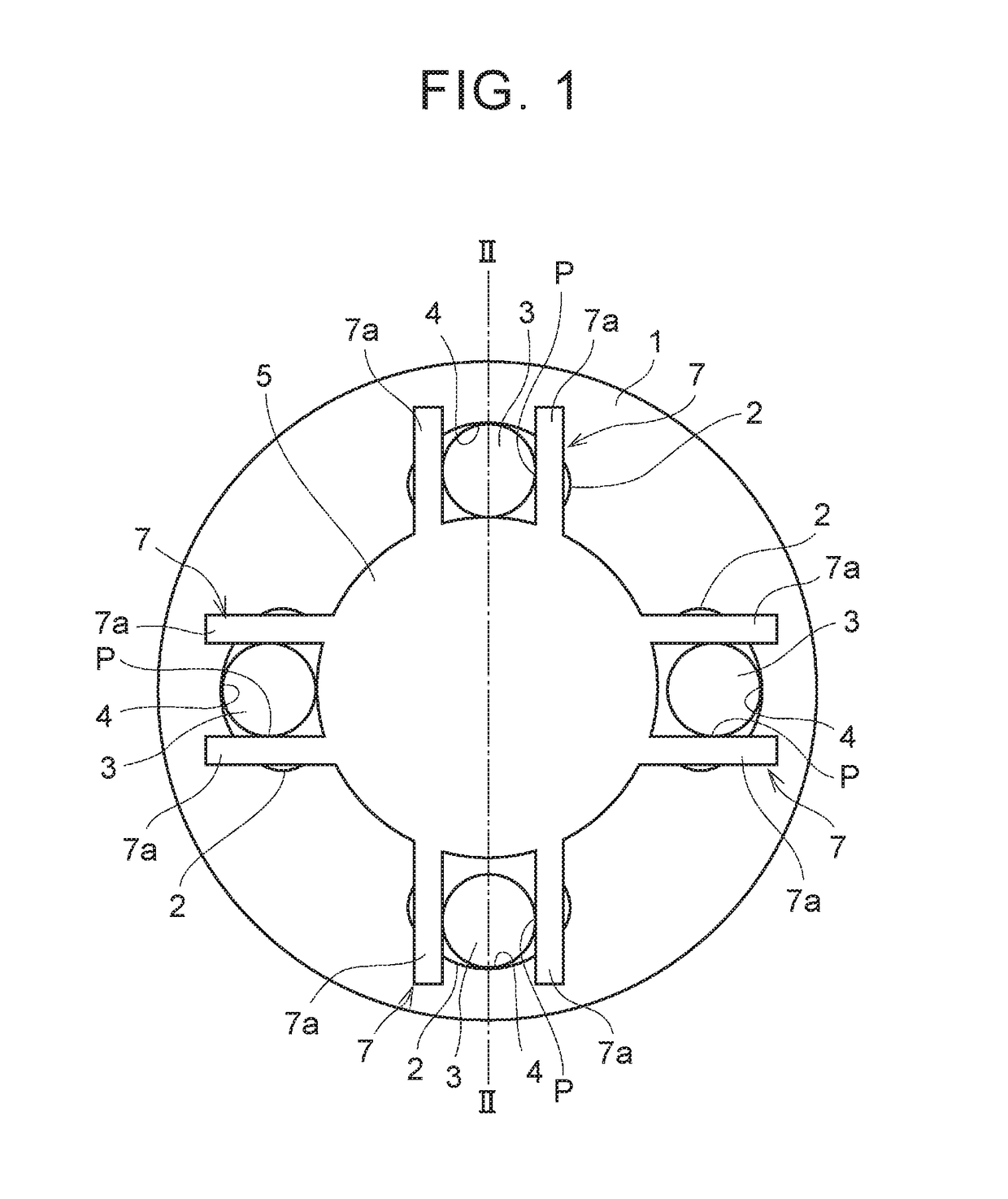

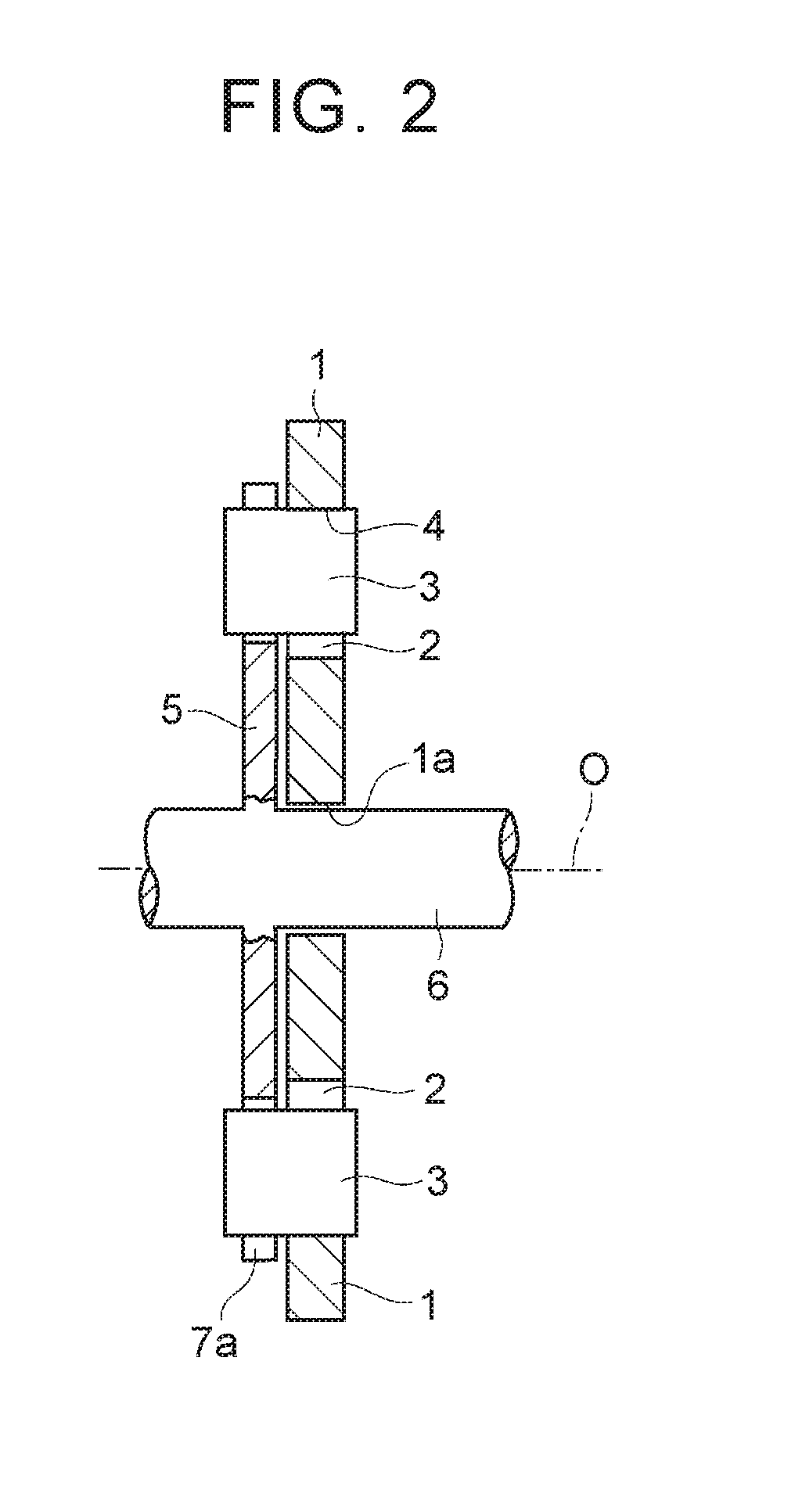

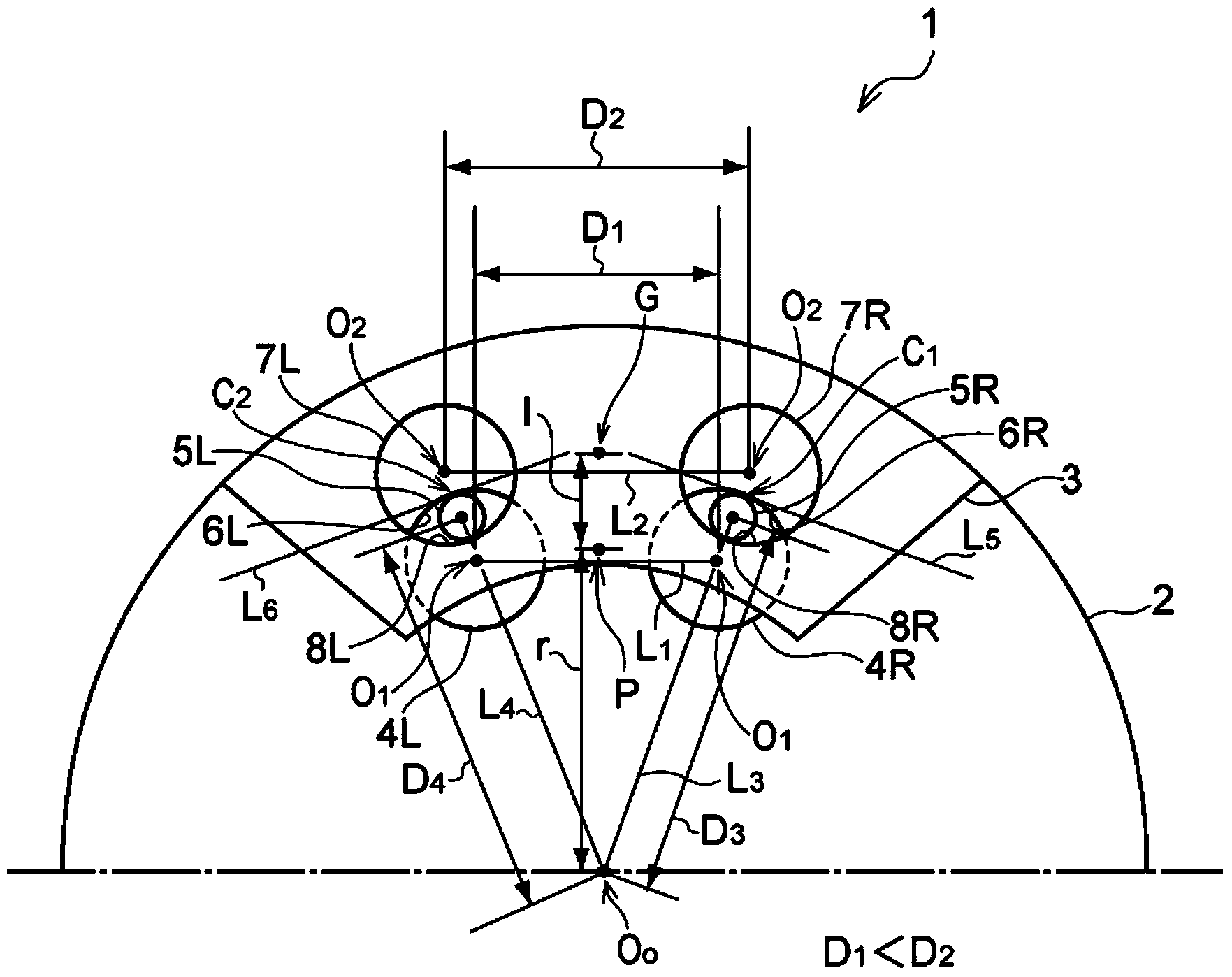

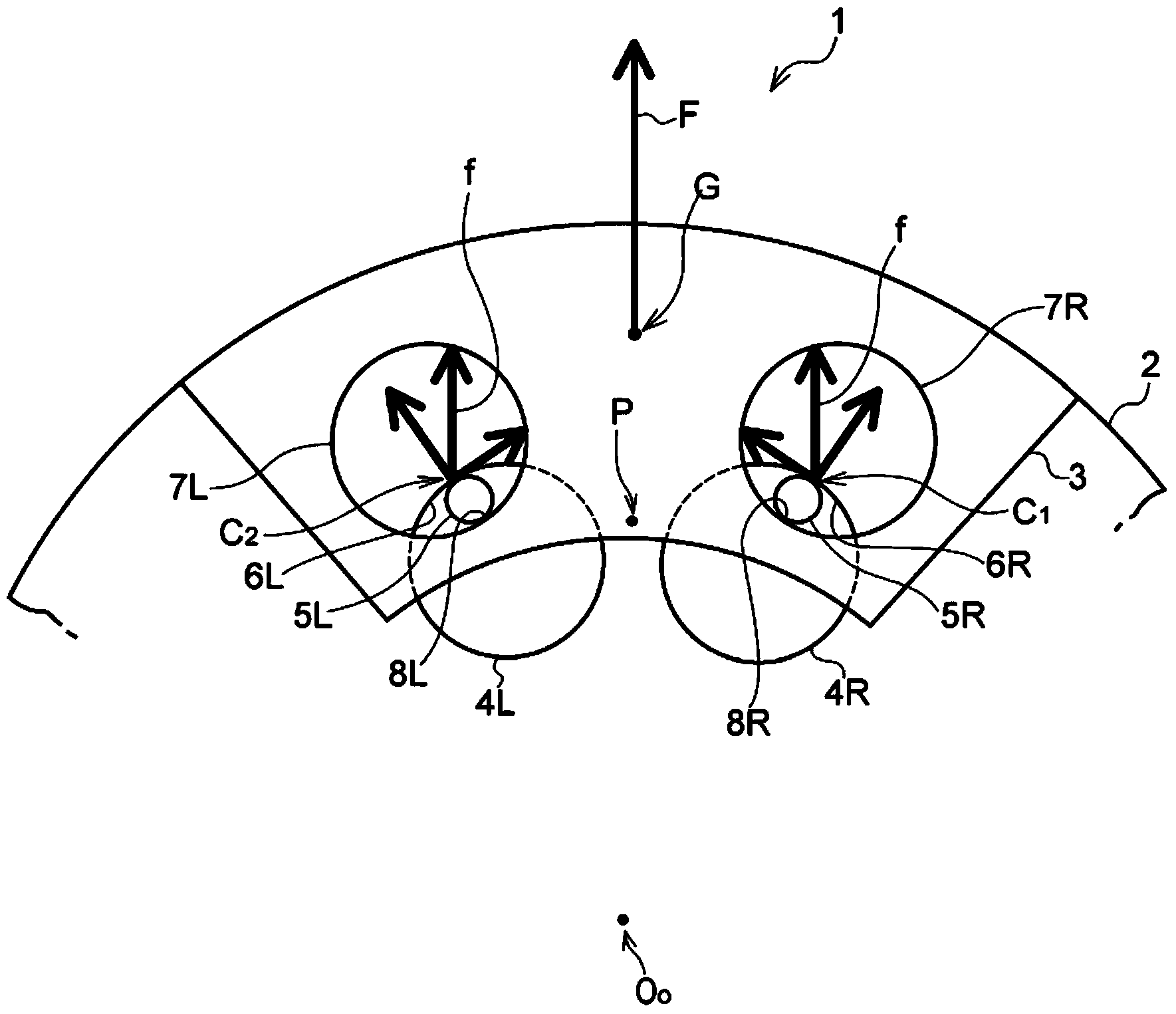

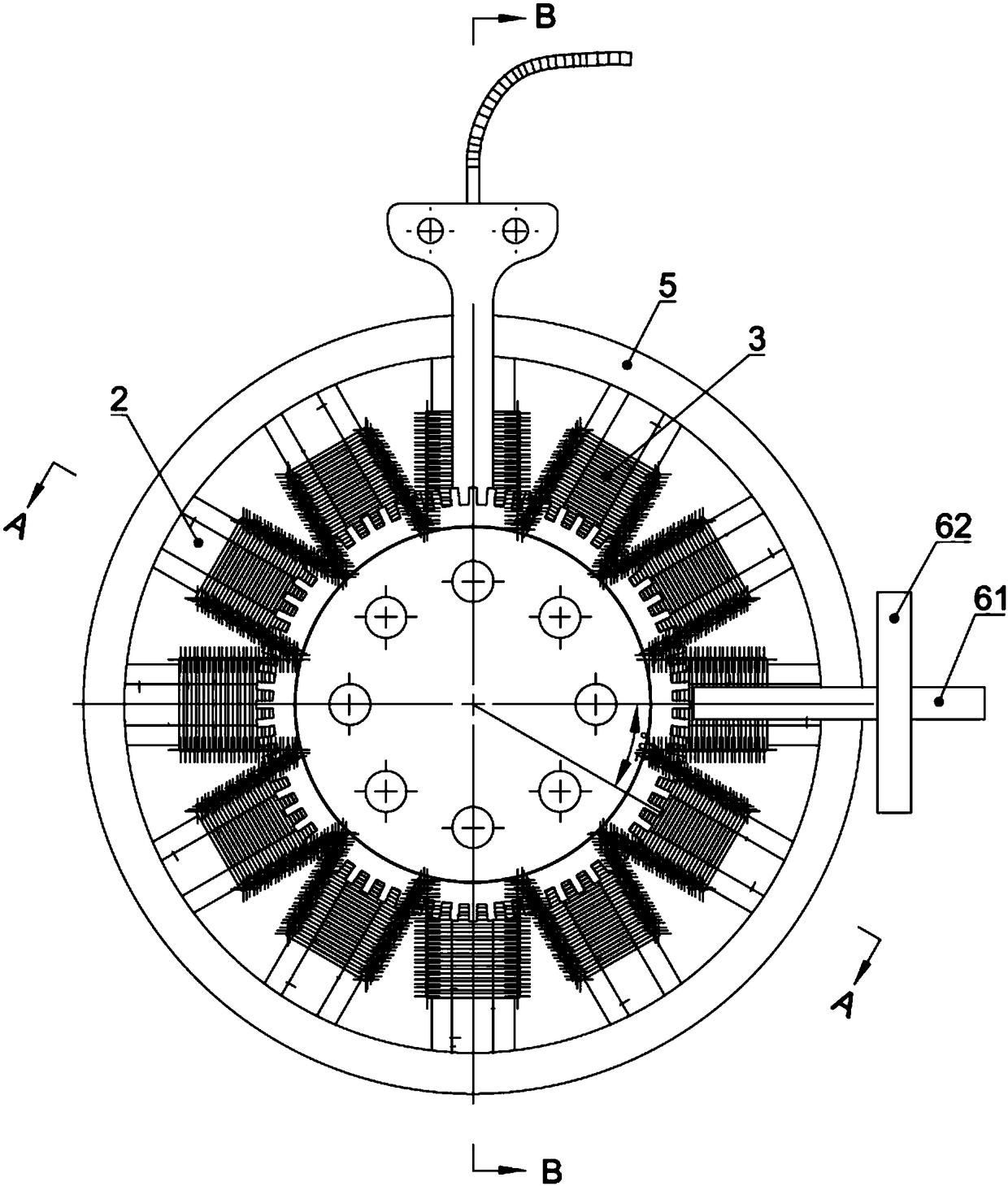

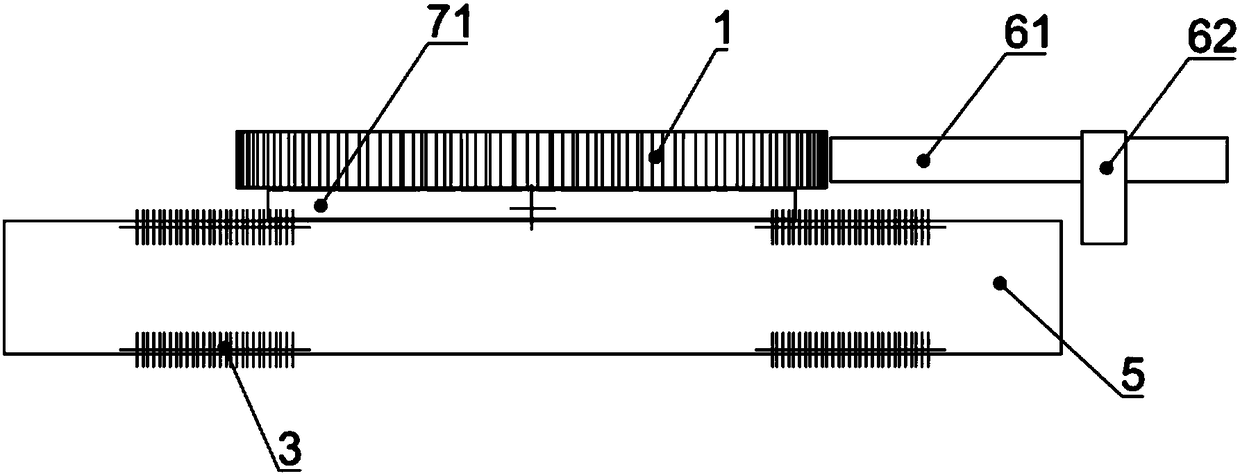

Torsional oscillation damping device

InactiveCN104081082AReduce torsional vibrationRotating vibration suppressionFluid gearingsReciprocating motionEngineering

Provided is a torsional oscillation damping device with which space for a mass that moves in a reciprocating manner can be maintained and the oscillation-damping effect can be improved. This torsional oscillation damping device, wherein a mass (3) is attached to a rotating body (2) by means of two support pins (5R, 5L), is equipped with: two first hollow parts (4), which are formed in the rotating body (2) at positions corresponding to the support pins (5R, 5L), and into which the support pins (5R, 5L) are inserted; and two second hollow parts (7), which are formed in the mass (3) at positions opposing the first hollow parts (4), and into which the support pins (5R, 5L) are inserted. The portions of the inner circumferential edges of the first hollow parts (4) which are to the outside in the radial direction of the rotating body (2) are guide surfaces (6R, 6L), and the portions of the inner circumferential edges of the second hollow parts (7) which are to the inside in the radial direction of the rotating body (2) are attachment surfaces (8R, 8L). The guide surfaces (6R, 6L) and the attachment surfaces (8R, 8L) are formed as concave curved surfaces, with the distance (D1) between the centers of curvature (O1) of the guide surfaces (6R, 6L) being shorter than the distance (D2) between the centers of curvature (O2) of the attachment surfaces (8R, 8L).

Owner:TOYOTA JIDOSHA KK

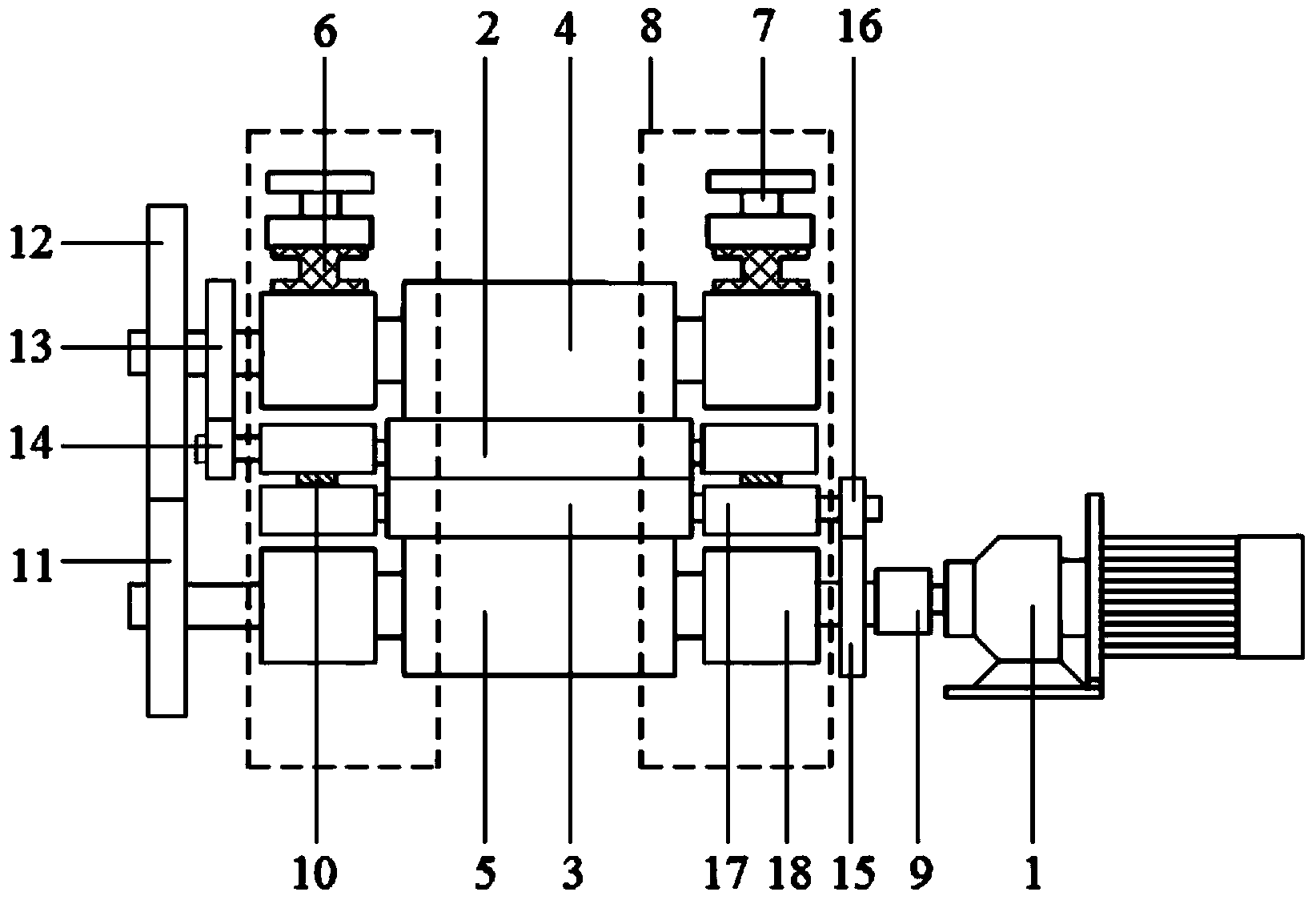

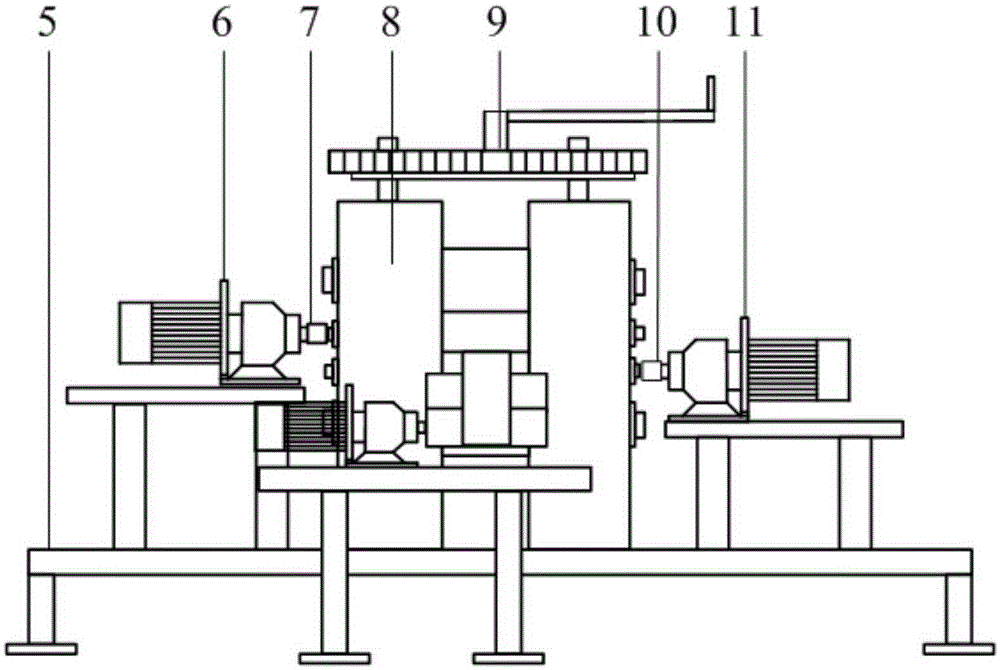

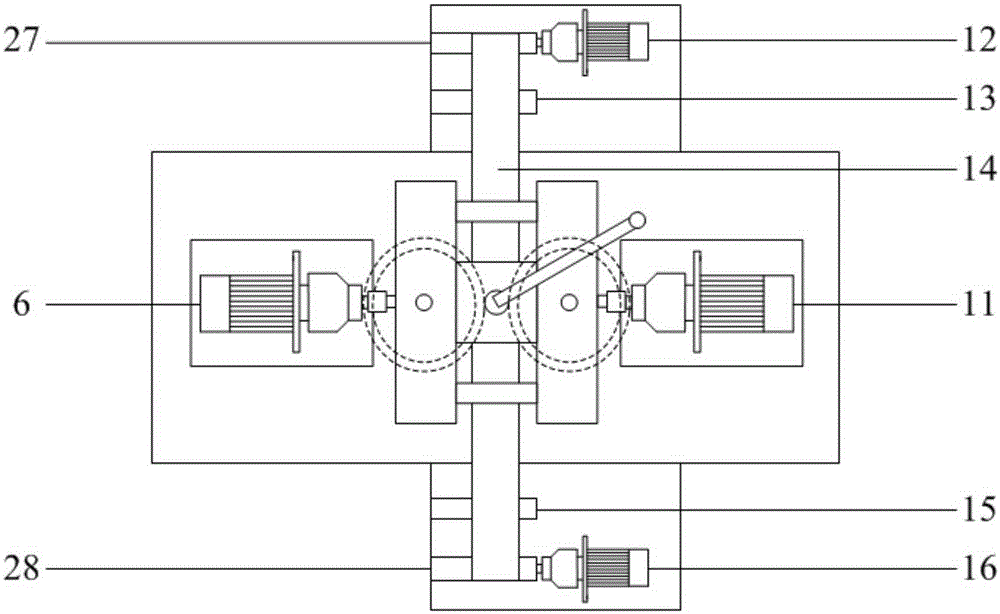

Ultrathin strip rolling mill adopting support roller transmission and rolling method of ultrathin strip rolling mill

ActiveCN104043648AMin limit thicknessStrong rolling capacityMetal rolling stand detailsMetal rolling arrangementsCouplingStrip mill

An ultrathin strip rolling mill adopting support roller transmission and a rolling method of the ultrathin strip rolling mill belong to the technical field of plate and strip rolling. A main transmission motor of the ultrathin strip rolling mill directly drives a support roller by a coupler; the support rollers are driven by first opening gear banks; work rollers and the support rollers are driven by a second opening gear bank and a third opening gear bank; tension motors are positioned at front and rear sides of the rolling mill; a rolled piece penetrates through roller seams and is connected with a reel; the rolling method comprises the steps of preparing two types of first opening gear banks, wherein multiple sets of first type of gear banks are arranged, all sets of the first type of gear banks are different in gear ratio and are used for asynchronous rolling, and the second type of gear banks are same in tooth number and are used for synchronous rolling; selecting one type of gear banks for mounting according to process needs, and applying a rolling force by a pressing device, applying a tension by the tension motors, and starting the main transmission motor, thus finishing the first rolling process rolling. The proper first opening gear banks can be replaced and mounted by multiple times according to the process needs, and the next rolling process rolling is performed till the rolled piece achieves a target thickness.

Owner:NORTHEASTERN UNIV

Flywheel assembly

ActiveUS8714051B2Reduces and eliminates axial vibrationReduce torsional vibrationCoolant flow controlGearingEngineeringFlywheel

Owner:KOHLER CO

Telescopic step-by-step layered buffering vehicle bumper

ActiveCN111002934AImprove cushioning performanceAvoid secondary collisionBumpersAutomotive engineeringCoil spring

The invention discloses a telescopic step-by-step layered buffering vehicle bumper, and belongs to the field of vehicle bumpers. The bumper comprises a bumper shell assembly, an energy absorption block, a bumper beam, a bumper support, a first-stage buffer mechanism, a second-stage buffer mechanism, a valve base assembly and a bearing plate. The primary buffer mechanism comprises a first support,a second support and a plurality of spiral springs; the first-stage buffer mechanism can ensure that the bumper absorbs energy during torsional vibration rotation. Therefore, overlarge torsional vibration and impact amplitude in impact are attenuated; a common amplitude value of a resonance region in impact is inhibited and a large torque is transmitted; even if the collision direction of the external force is uncertain, when the vehicle bumper is collided, multi-stage buffering can be carried out through the two-stage buffering mechanism, that is to say, the two-stage buffer mechanism can convert the vertical impact load into the horizontal transverse impact load, and can buffer the horizontal transverse impact load to play an important role in improving the impact energy absorption effect, improving the vehicle collision safety and protecting pedestrians.

Owner:南昌华翔汽车内外饰件有限公司

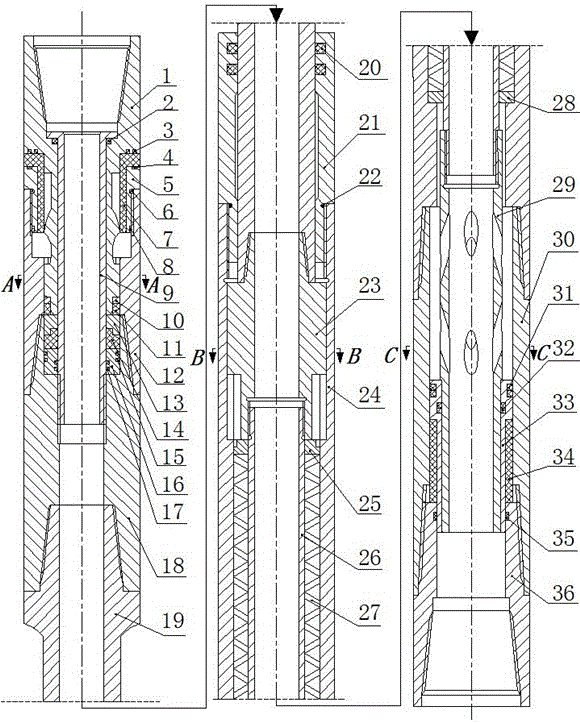

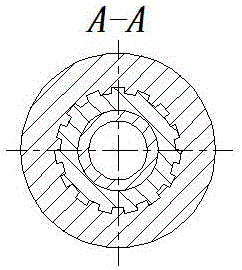

Novel hydraulic oscillator with energy gathering and damping functions

ActiveCN106014317AReduce horizontalReduce torsional vibrationDrilling rodsVibration devicesWell drillingDamping function

The invention relates to a novel hydraulic oscillator with energy gathering and damping functions. The novel hydraulic oscillator is fixedly mounted in the position close to a drill bit and comprises a damping assembly, a transmission assembly and an oscillating assembly. The oscillating assembly is mounted at the front end of the transmission assembly. The damping assembly is mounted at the rear end of the transmission assembly. Vibration generated on an upper tool by the oscillator during operating is absorbed through multiple stages of vibration absorption rings; bit pressure and torque are transmitted through a disk spring and splines, and the disk spring and the splines are connected in series. When flowing through a flow guide pipe, drilling fluid flows into a pressure chamber through flow guide holes in the circumference of the flow guide pipe and then flows back to a central flow channel, pressure pulsation of the drilling fluid fluctuates, and the oscillating assembly generates an oscillating effect. The novel hydraulic oscillator with the energy gathering and damping functions can generate the oscillating frequency of a certain range to reduce friction drag borne by a drilling tool in the rock breaking process of the drill bit, automatically absorb vibration and reduce the influence of the oscillating assembly on the upper drilling tool during operating, so that the well drilling efficiency is improved.

Owner:江苏弘业检测技术有限公司

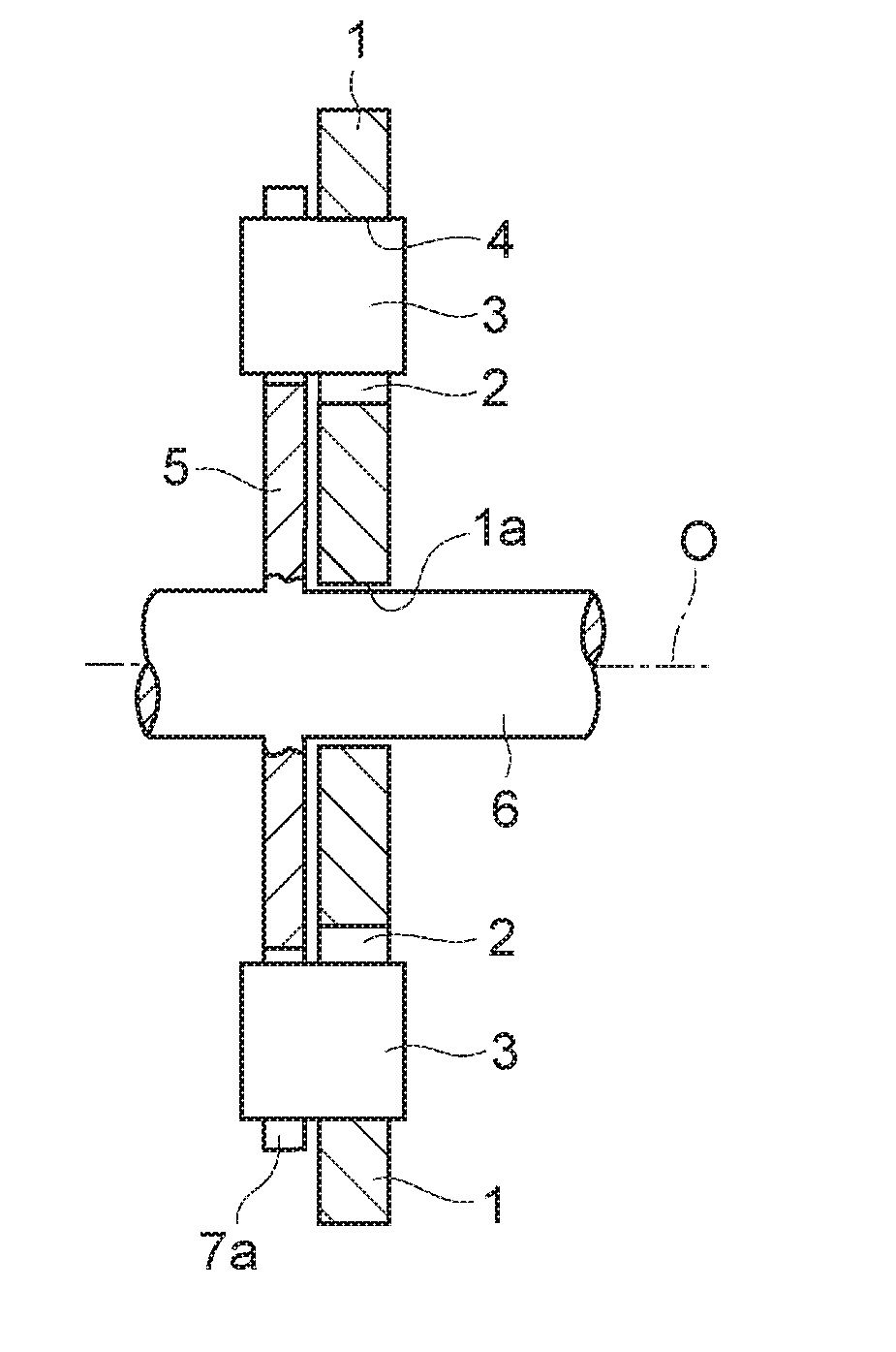

Device for coupling two shafts having an axial offset

InactiveCN1746524ASignificant radial forceReduce torsional vibrationRotating vibration suppressionYielding couplingEngineeringMechanical engineering

The invention relates to a device used to couple in a first axis and a second axis, wherein the axes have displaced axial lines and are arranged parallel in axial direction; the device is provided with at least one first rotating mass allocated for the first axis and at least one second rotating mass allocated for the second axis; in order to transmit torque, the device is also provided with at least one first stop surface coupled in the first axis and a second stop surface coupled in the second axis; moreover, the stop surfaces contact each other during transmitting torque; the first stop surface is fixed relative to a position in the radial direction of the first axis, while the second stop surface is fixed relative to a position in the radial direction of the second axis.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Transmission shaft and automobile applying transmission shaft

ActiveCN104653646APlay a shock absorbing roleReduce torsional vibrationYielding couplingDrive shaftButt joint

Owner:GREAT WALL MOTOR CO LTD

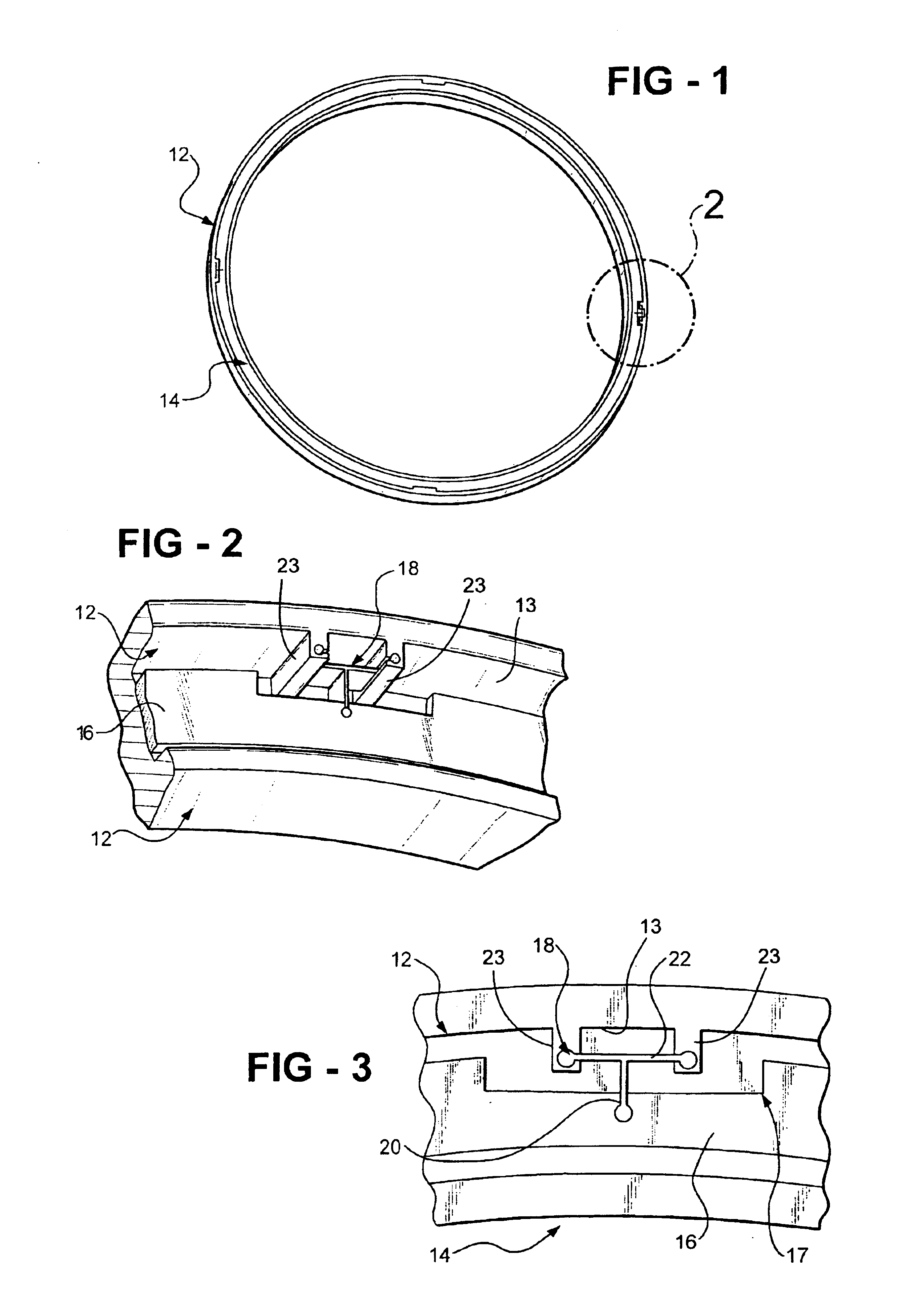

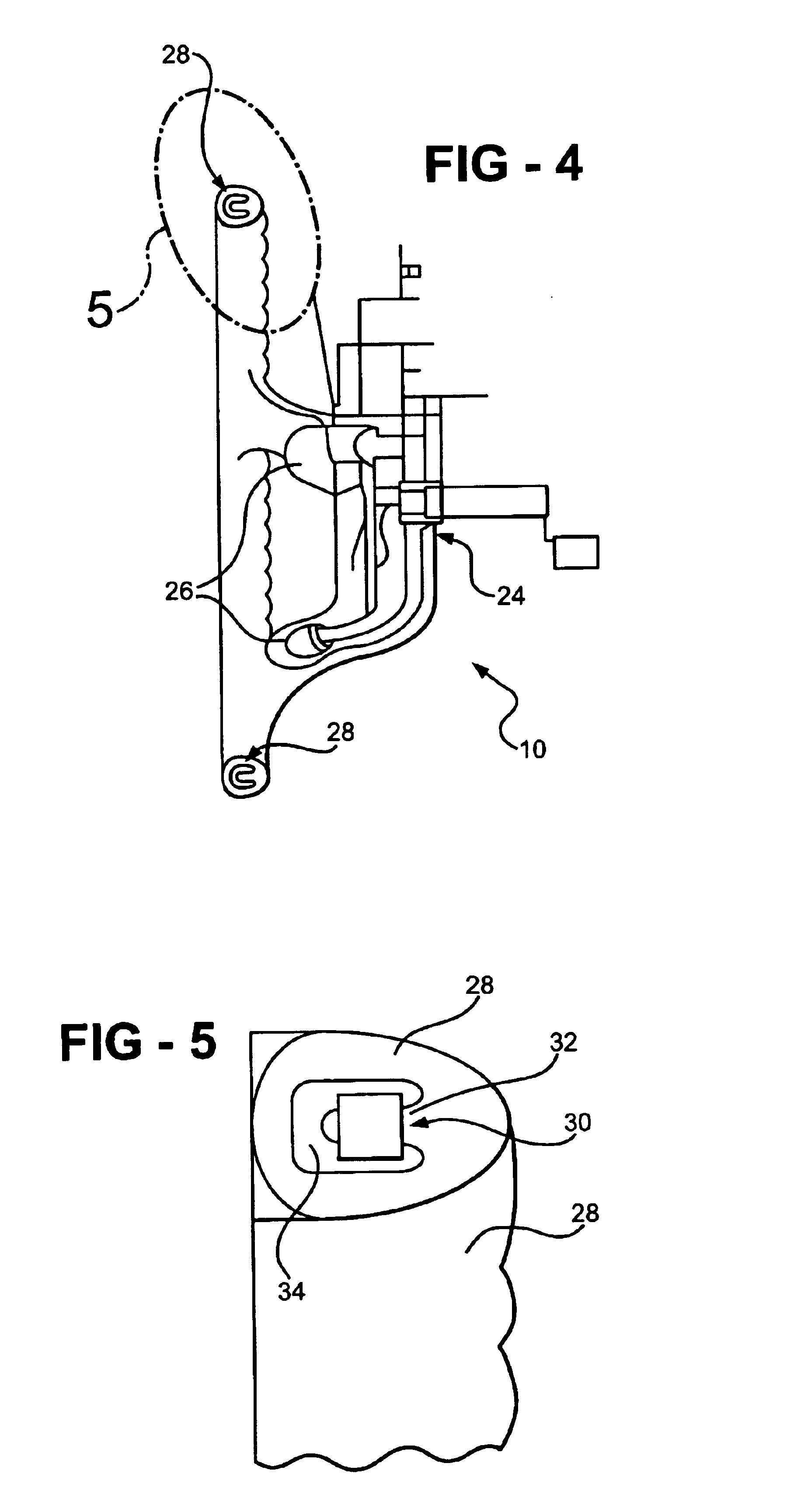

Steering wheel dynamic absorber assembly

InactiveUS6976403B2High vibration sensitivityLow costControlling membersRotating vibration suppressionSteering wheelEngineering

An assembly operable to be used with a steering wheel of a vehicle and to suppress a vibration transmitted to the steering wheel includes a plurality of support flexures and an inertial ring attached to the support flexures. The support flexures are operable to be attached to the steering wheel and the support flexures and the inertial ring are tuned to suppress a vibration at a predetermined band of frequencies. The support flexures and the inertial ring are positioned in an annular cavity formed in the rim.

Owner:GM GLOBAL TECH OPERATIONS LLC

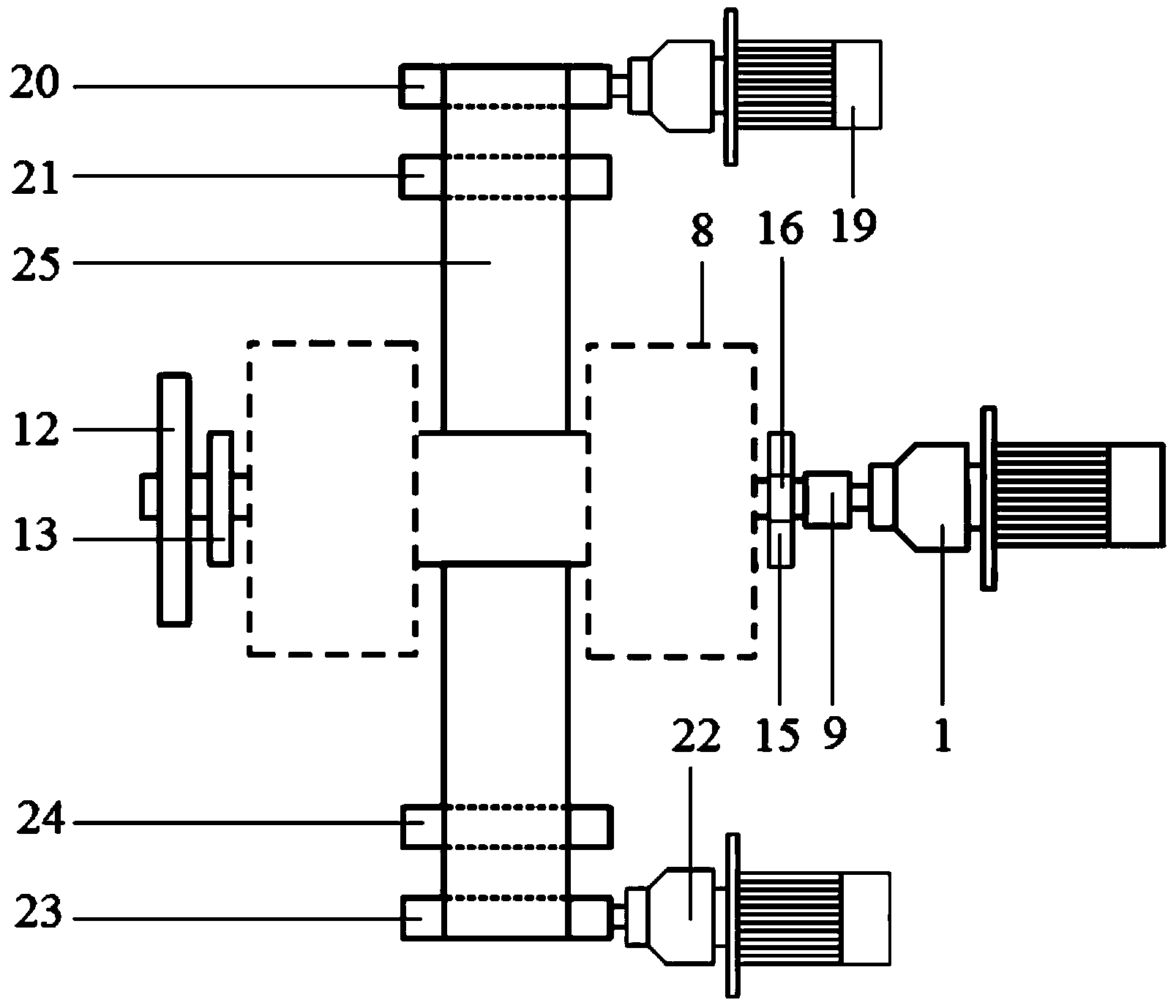

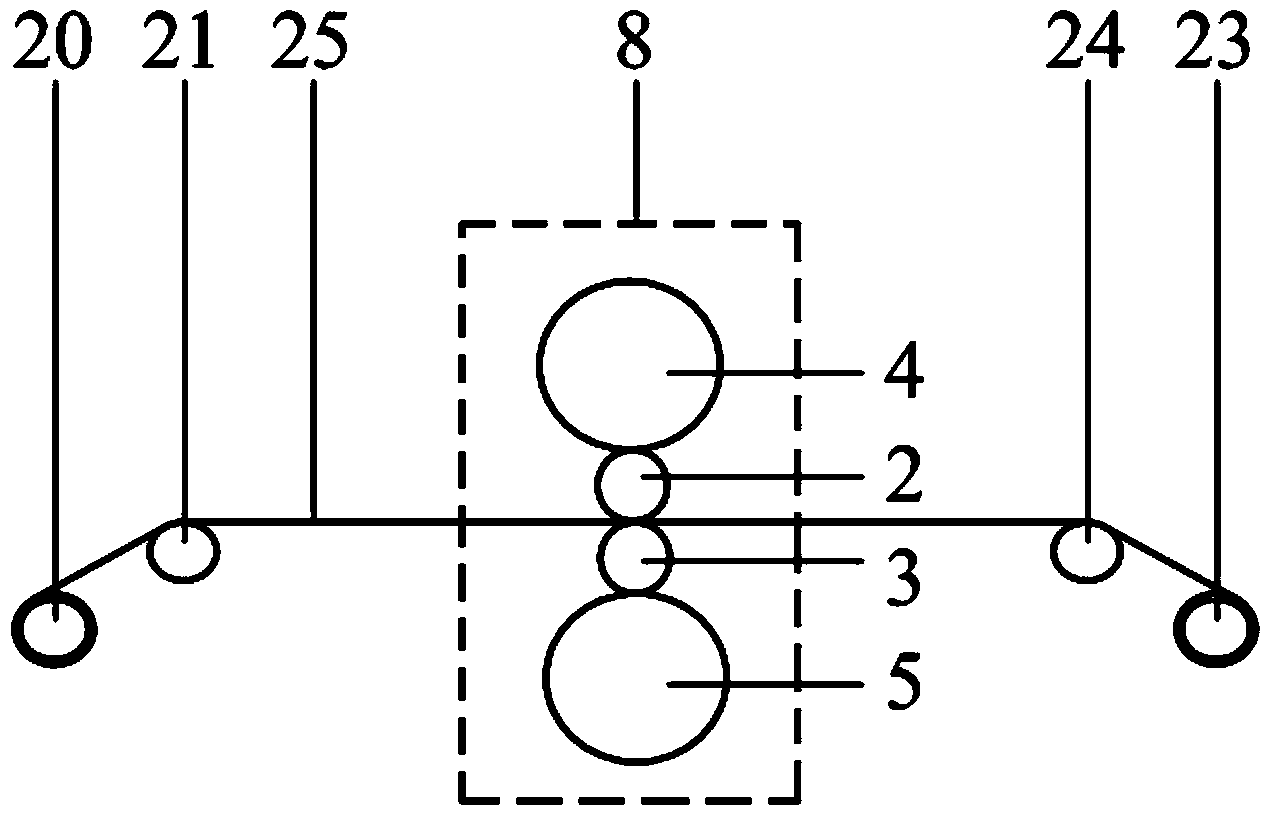

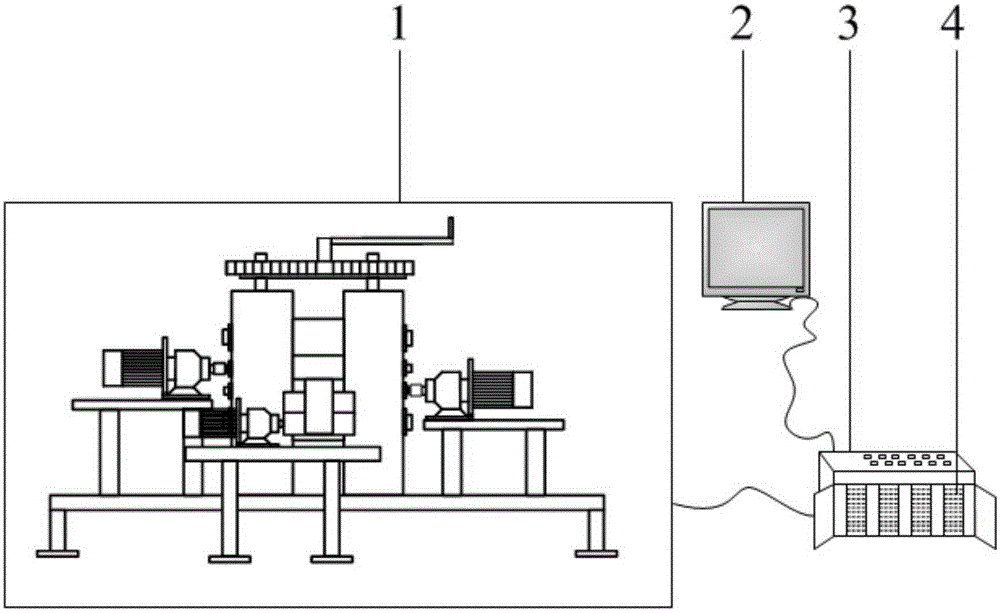

Ultra-thin strap combined forming rolling mill with different speed ratios capable of being adjusted online and continuously

ActiveCN105170651AImprove surface qualityReduce torsional vibrationRoll mill control devicesMetal rolling arrangementsHuman–machine interfaceControl system

Disclosed is an ultra-thin strap combined forming rolling mill with the different speed ratios capable of being adjusted online and continuously. The ultra-thin strap combined forming rolling mill comprises a rolling mill master control part and a rolling mill mechanical part. A rolling mill control system human-computer interface is arranged in a master control computer. Input fields and output fields for speed setting of an upper working roller and a lower working roller, and an input field and an output field for adjustment step size setting of the different speed ratios are arranged on the human-computer interface. The master control computer is connected with an operation platform through a programmable logic controller (PLC). A rolling forward starting switch, a rolling backward starting switch and a different speed ratio adjusting switch are arranged on the operation platform. The different speed ratios can be increased or decreased by a different speed ratio adjustment step size online through the different speed ratio adjusting switch. When asymmetrical rolling of an ultra-thin strap is conducted through the ultra-thin strap combined forming rolling mill, the different speed ratios can be arranged to be infinitely variable and can be set to be an arbitrary value in theory. Due to the fact that the limit of the minimum rolling thickness of the synchronous rolling is overcome by the asymmetrical rolling and the thinness rolling capacity is stronger, the selection range of the diameter of the working rollers of the ultra-thin strap combined forming rolling mill can be broadened, accordingly, the occurrence of torsional vibration phenomena of the rollers is effectively reduced, and the surface quality of the ultra-thin strap is improved.

Owner:NORTHEASTERN UNIV LIAONING

Crankshaft vibration reducer and control method of crankshaft vibration reducer

ActiveCN108167386ACounteract and reduce torsional vibrationReduce torsional vibrationRotating vibration suppressionVibration dampersReciprocating motionReducer

The invention relates to the technical field of vehicle torsional vibration dampers, and discloses a crankshaft vibration reducer. The crankshaft vibration reducer comprises a tooth disc module, a cylindrical piece, an electromagnetic coil and an electromagnetic module, wherein the tooth disc module is connected to a crankshaft; the cylindrical piece is peripherally arranged on the tooth disc module with the center of the tooth disc module as center; the electromagnetic coil is wound on the outer wall of the cylindrical piece; and the electromagnetic module is arranged in the cylindrical piece, and can perform a reciprocating motion along the cylindrical piece. The crankshaft vibration reducer solves the problems of complicated structure, high cost, high control difficulty, difficult latermaintenance and liquid leakage in a vibration reducer in the prior art. The invention further provides a control method of the crankshaft vibration reducer; the crankshaft vibration reducer is adopted; the crankshaft drives the tooth disc module and the electromagnetic module to rotate; and a current value in the electromagnetic coil under corresponding rotating speed is controlled according to the rotating speed.

Owner:WEICHAI POWER CO LTD

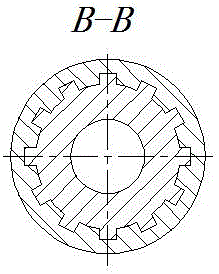

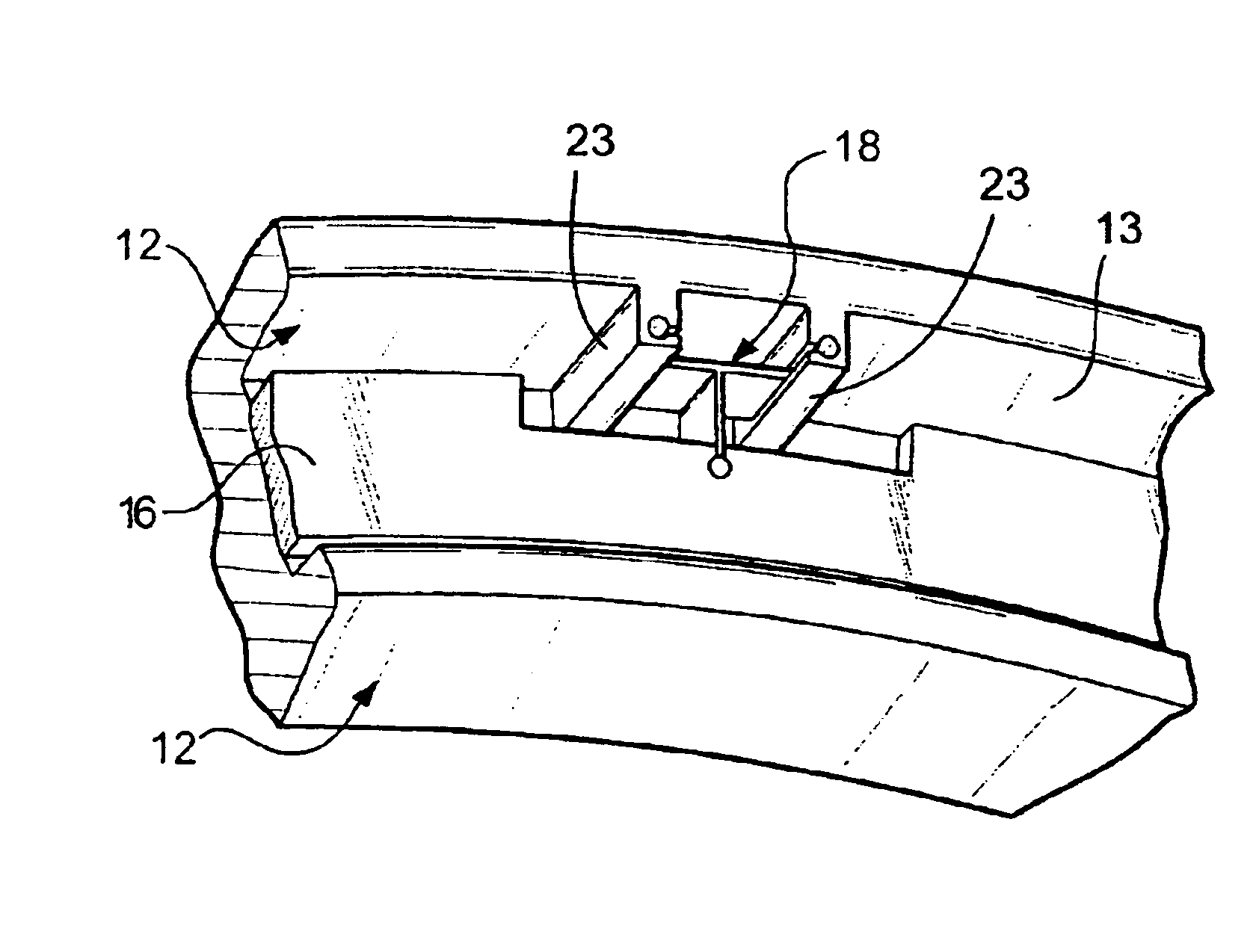

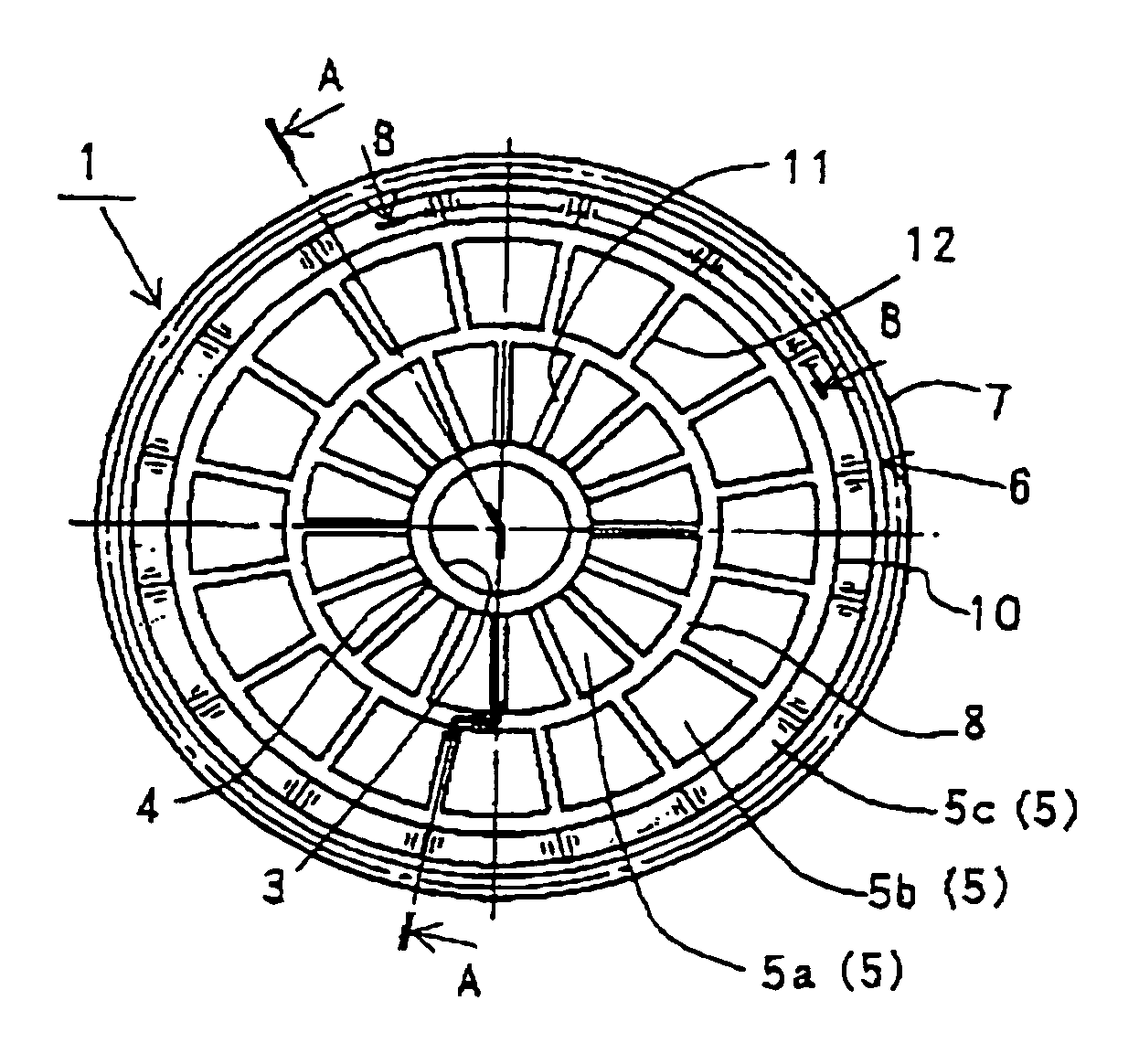

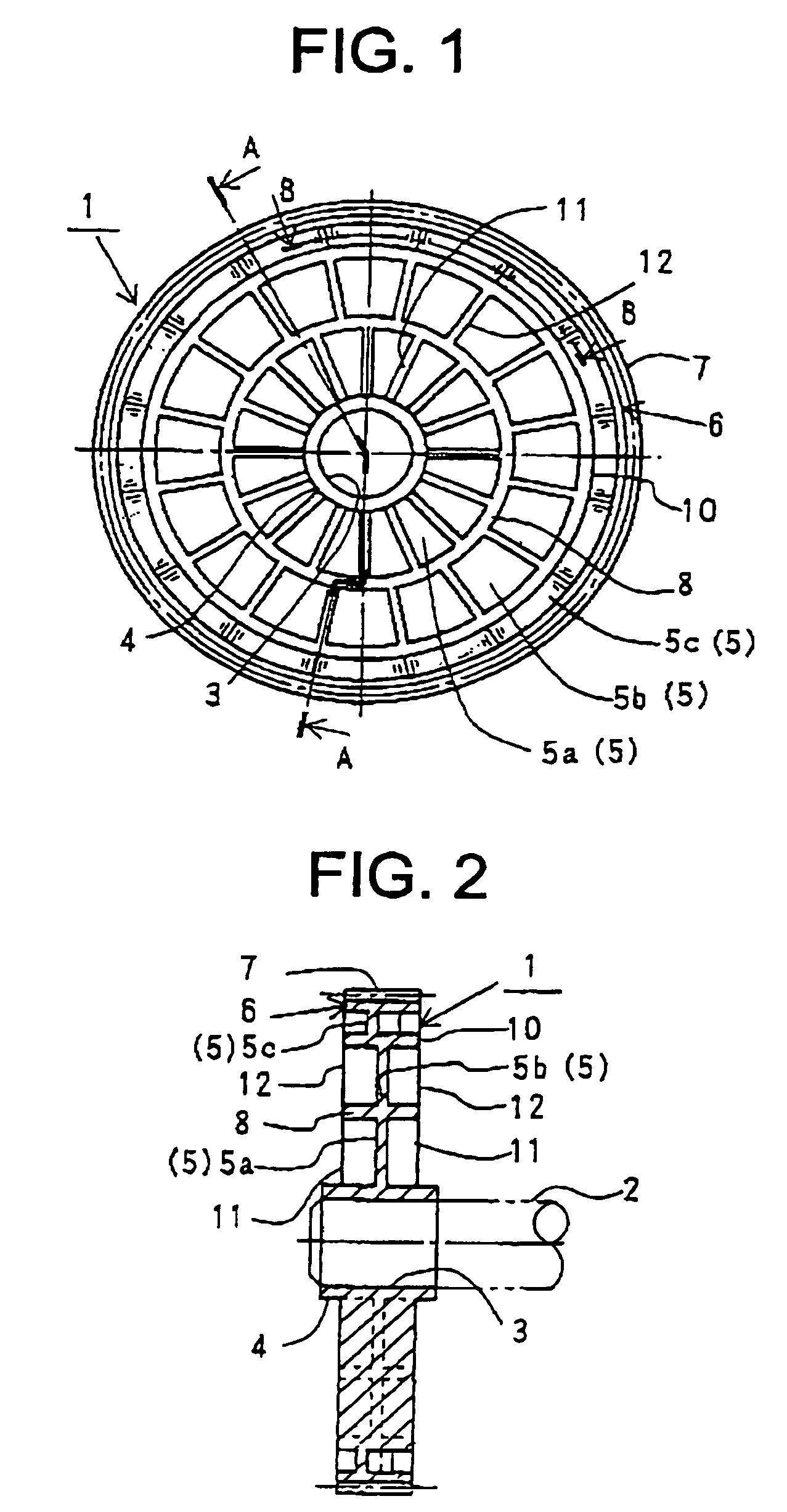

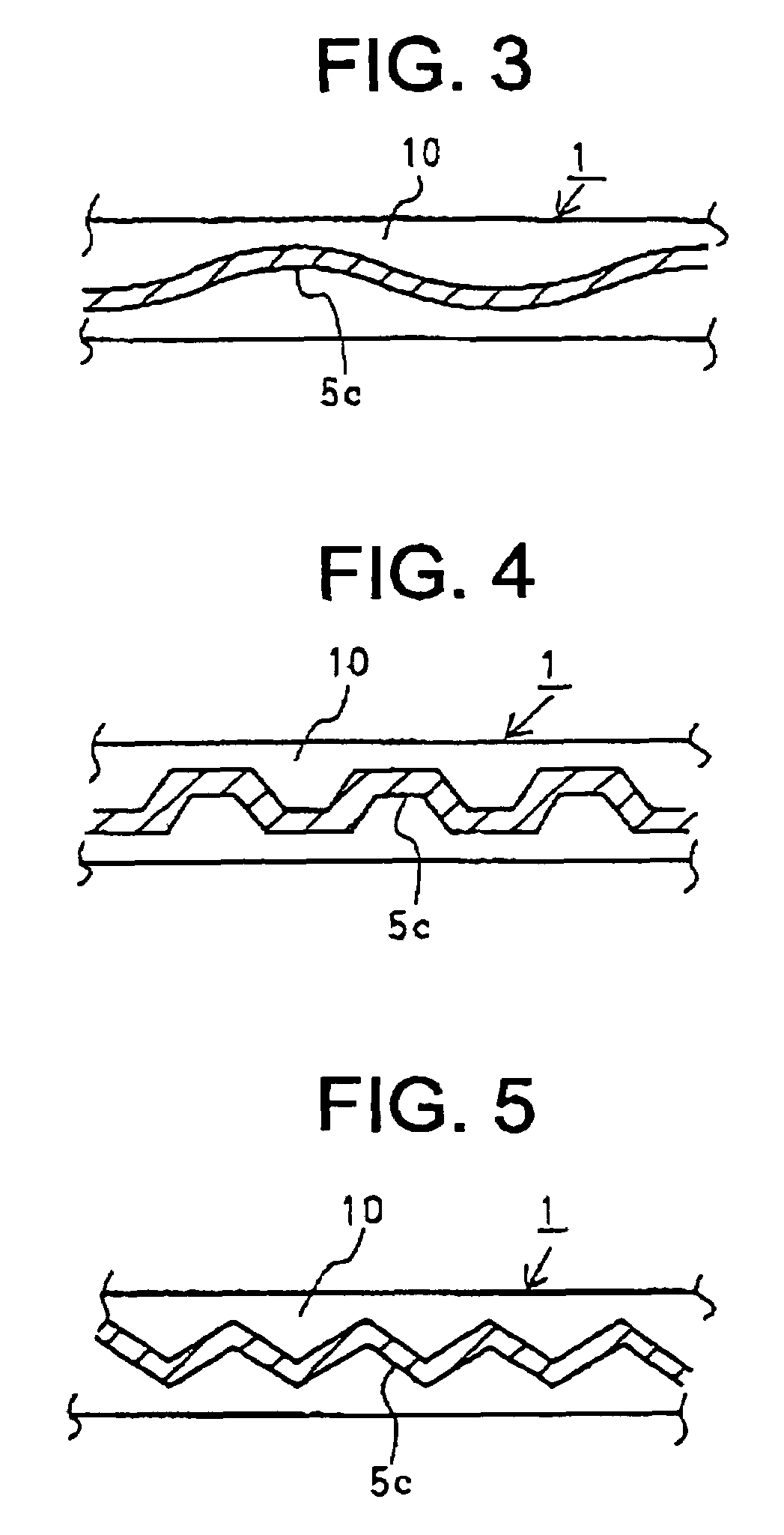

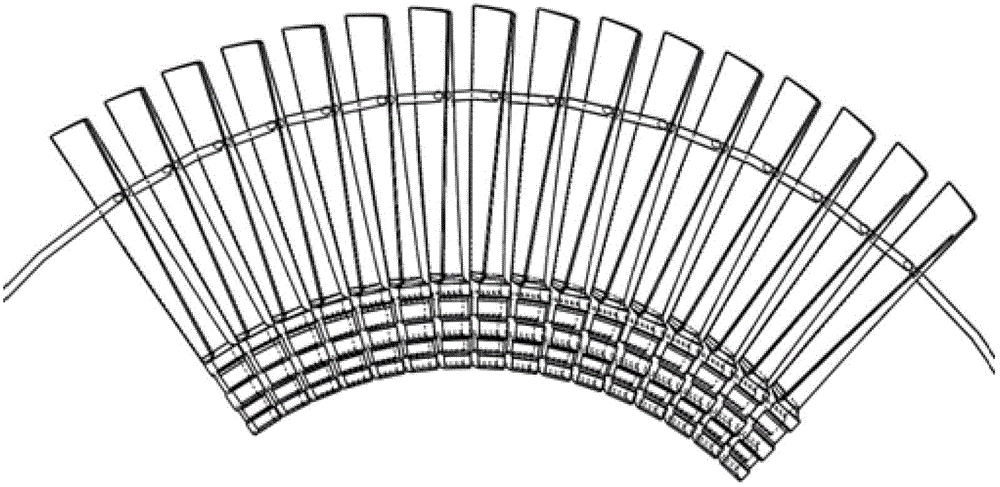

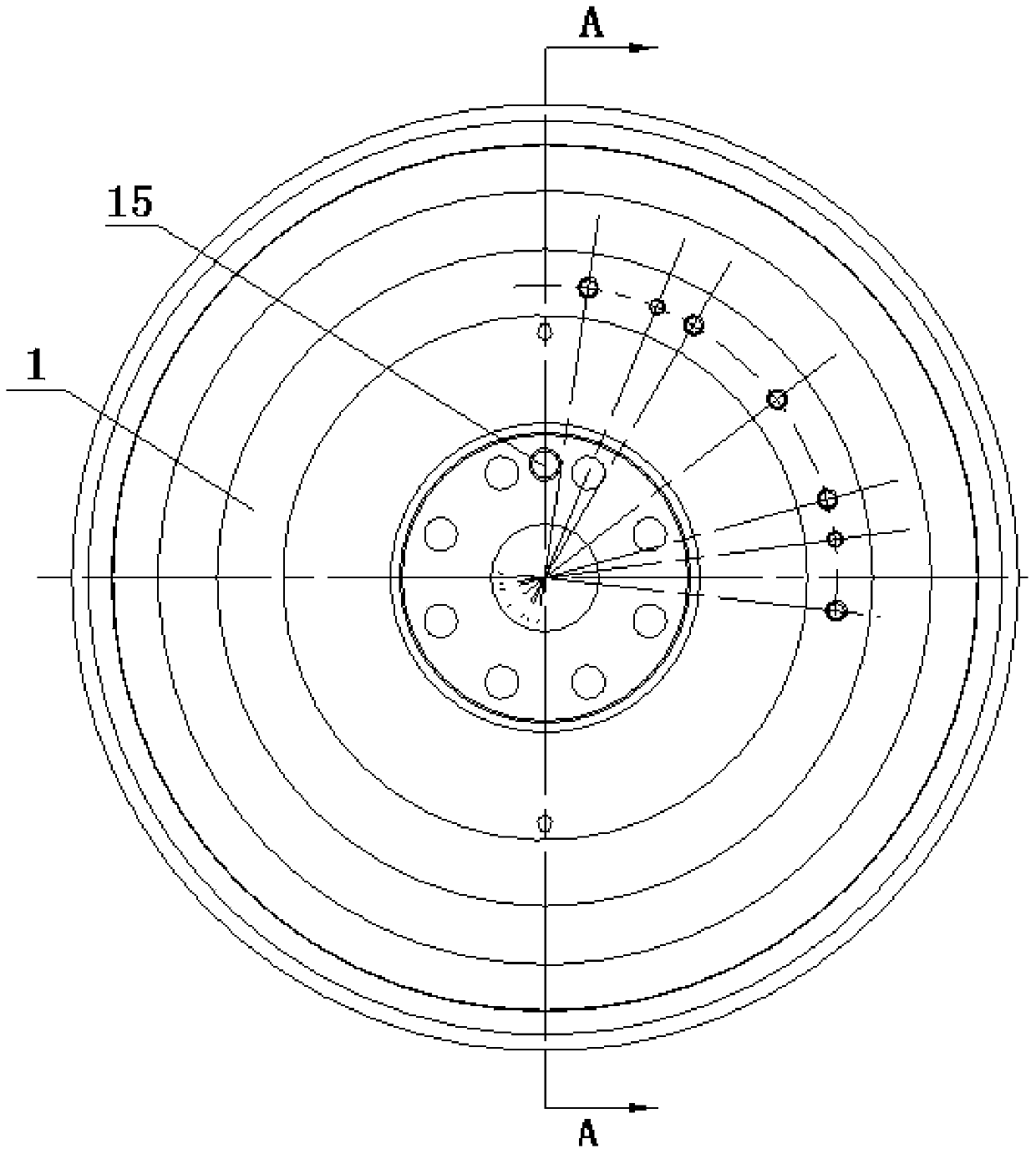

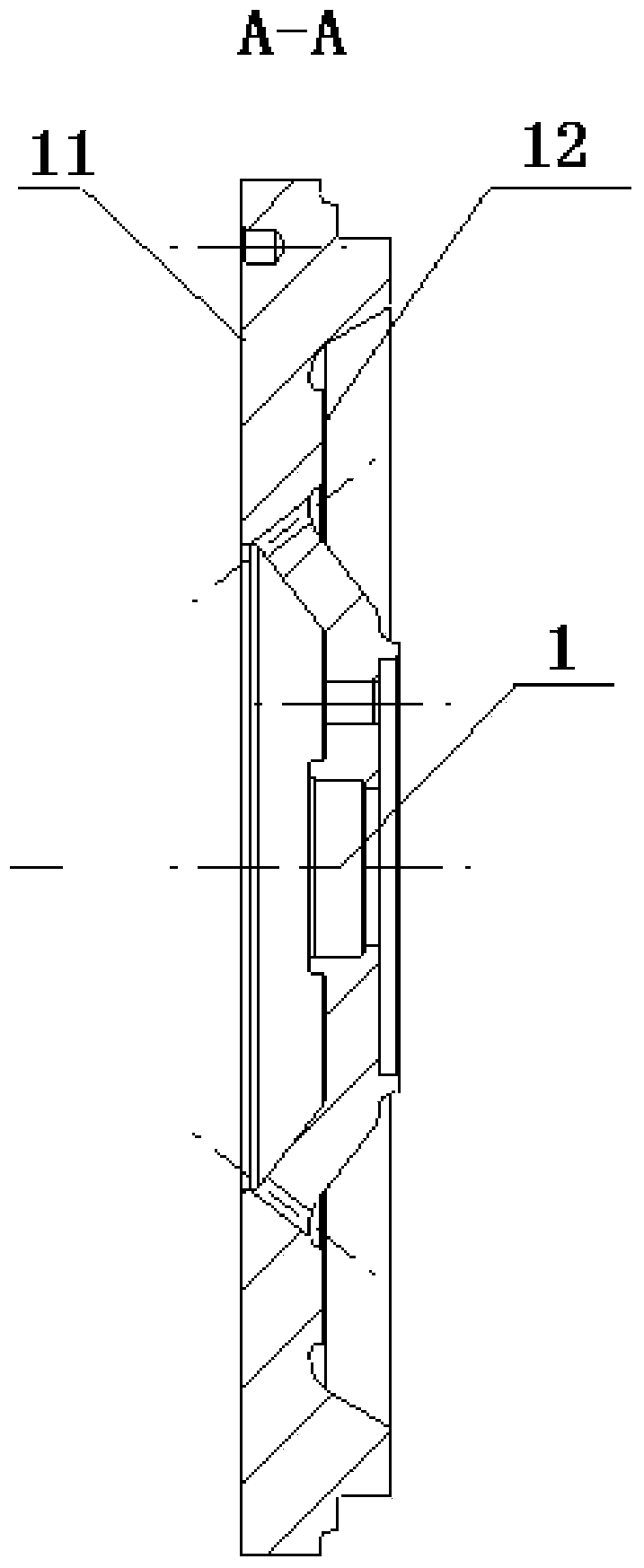

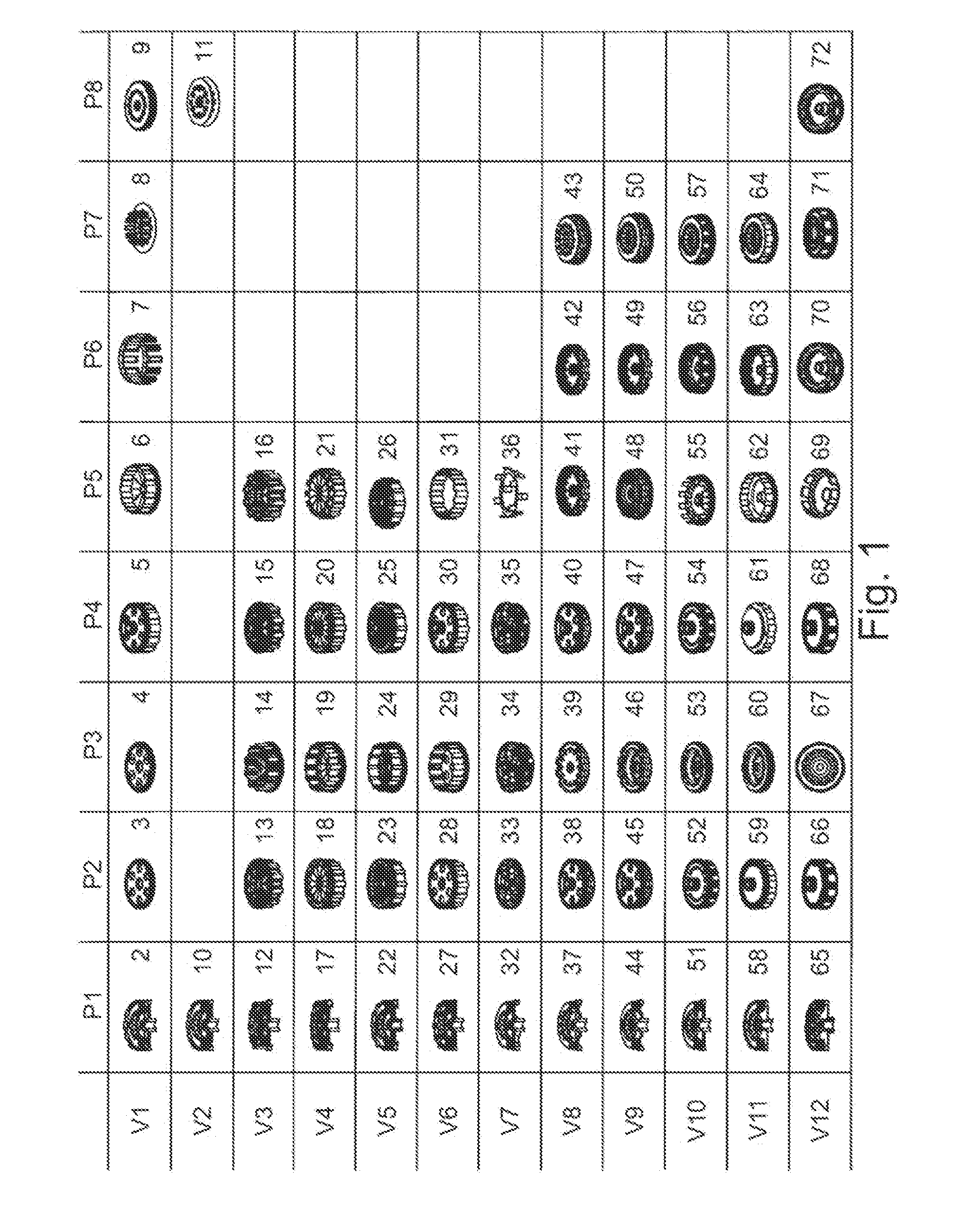

Gear made of resin, image-forming device, and rotation-transmitting means made of resin

InactiveUS7036393B2Improve rigidityMaintain accuracyPortable liftingElectrographic process apparatusEngineering

A gear 1 made of a resin includes webs 5 (5a and 5b) formed so that the rigidity of the web is increased by a first circumferential rib 8, a second circumferential rib 10, first diametrical ribs 11 and second diametrical ribs 12, and the circumferential sectional shape of the outermost web 5c is a corrugated shape, whereby the rigidity of the outermost web 5c is increased. As a result, it is possible to increase the rigidity of the outermost web 5c without increasing of the thickness of the outermost web 5c; to form a toothed portion 6 with a high accuracy; to reduce the deformation (for example, the amount of displacement of the toothed portion 6 and a shaft-supporting portion 4 in a rotating direction) due to an external force; and to enhance the rotation-transmitting accuracy. In this gear 1, a vibration and a noise due to the vibration can be reduced by increasing the rigidity of the web.

Owner:ENPLAS CORP

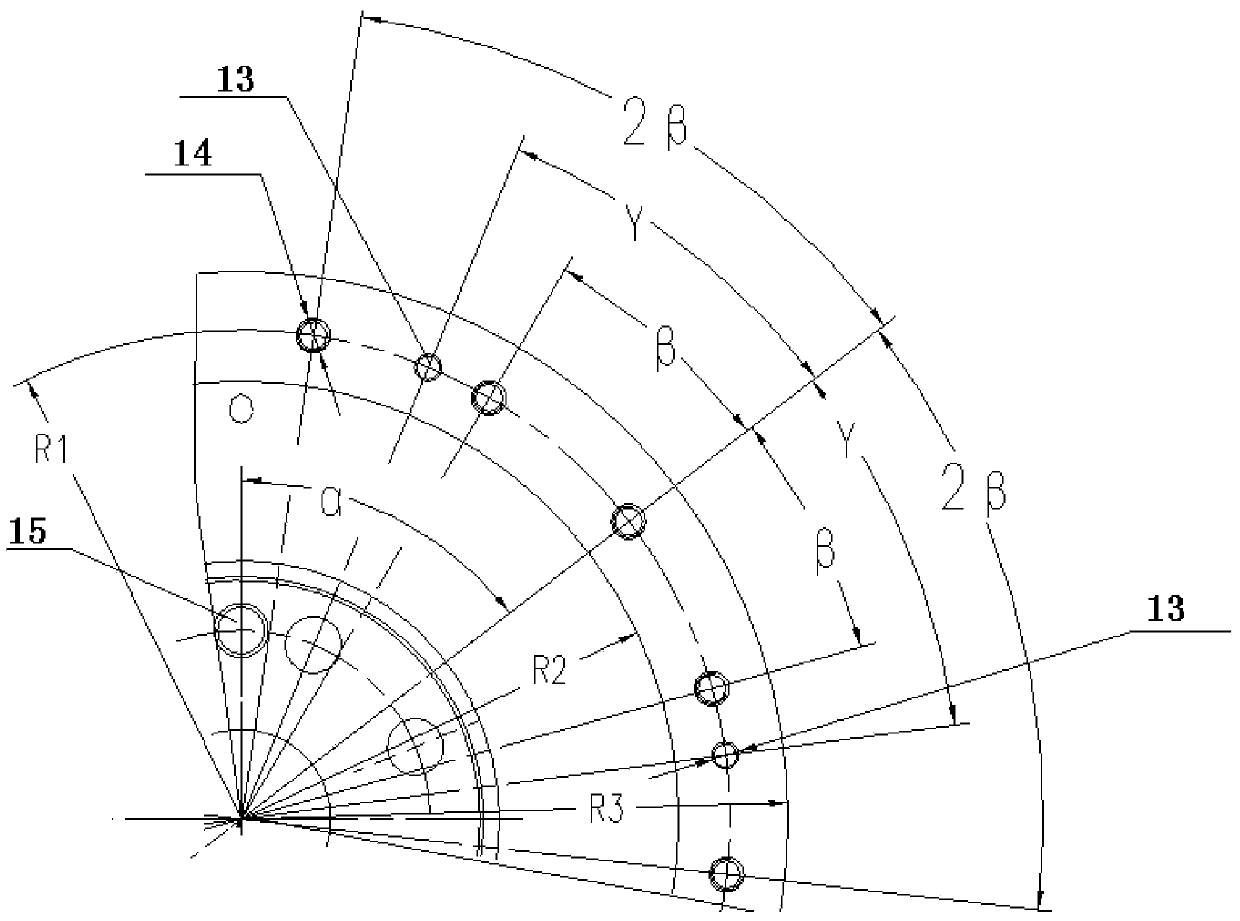

Half-section type free lacing wire structure of turbine blade with top tangent circle

InactiveCN102720543AReduce vibrationReduce axial vibrationBlade accessoriesMachines/enginesSteam turbine bladeEngineering

The invention provides a half-section type free lacing wire structure of a turbine blade with a top tangent circle, wherein the cross section of a part of the half-section type free lacing wire structure cooperating with a lacing wire hole of the turbine blade is shaped as follows: tangent circles are arranged on circular top and bottom parts respectively; and the height of each tangent circle is less than or equal to 20% the circular semi-diameter. A lacing wire of the half-section type free lacing wire structure has good sectional property which is beneficial to the bending of the lacing wire; two contact points exist between the lacing wire structure and the blade; through the adding of the contact points between the lacing wire and the blade, the total frictional force can be increased, so that the damping is increased and the vibration of the blade is decreased; and additionally, the lacing wire not only can decrease the vibration of a blade assembly along the radial direction and the peripheral direction, but also can effectively decrease the axial vibration and the torsion vibration of the blade assembly.

Owner:XI AN JIAOTONG UNIV

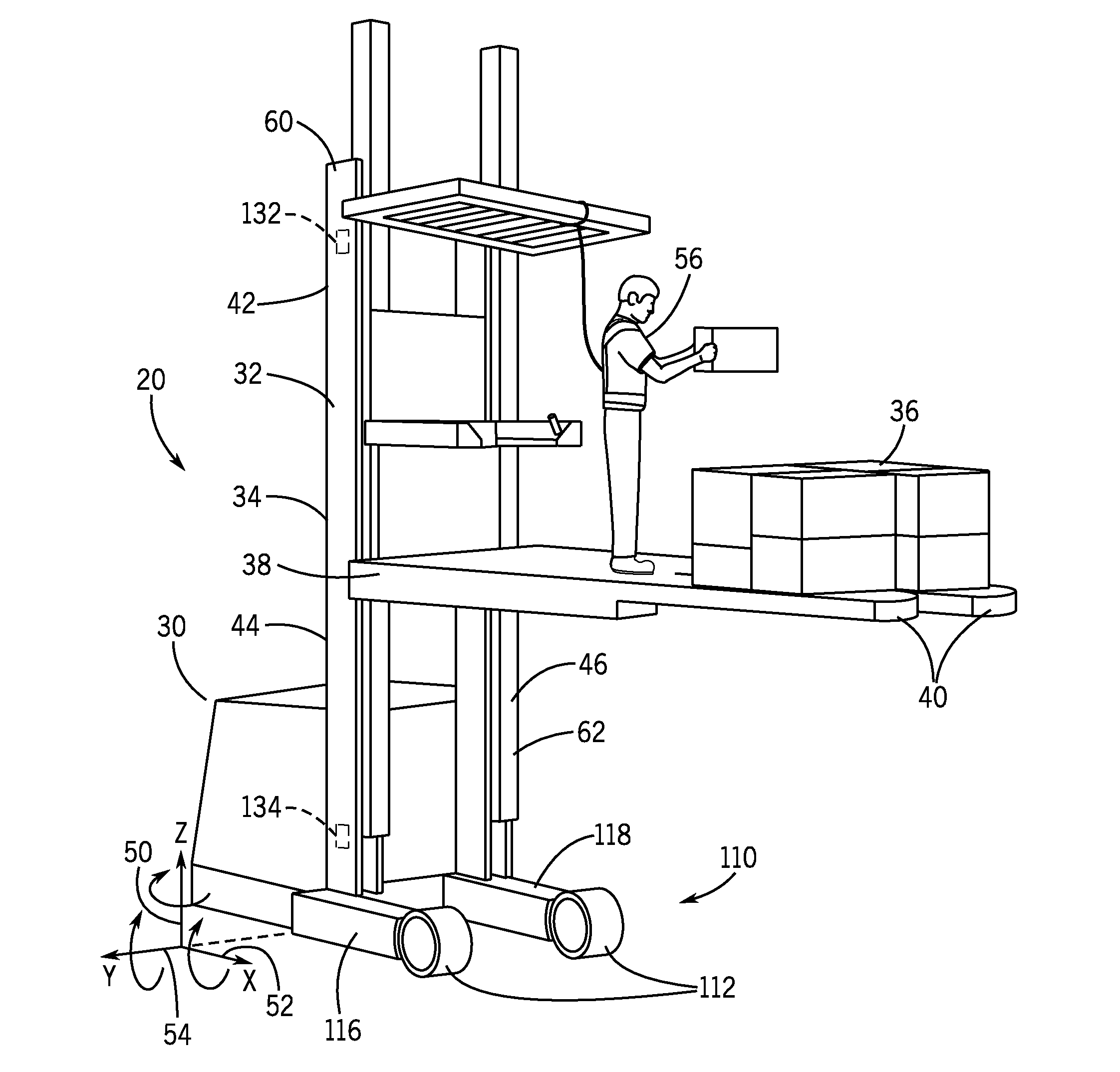

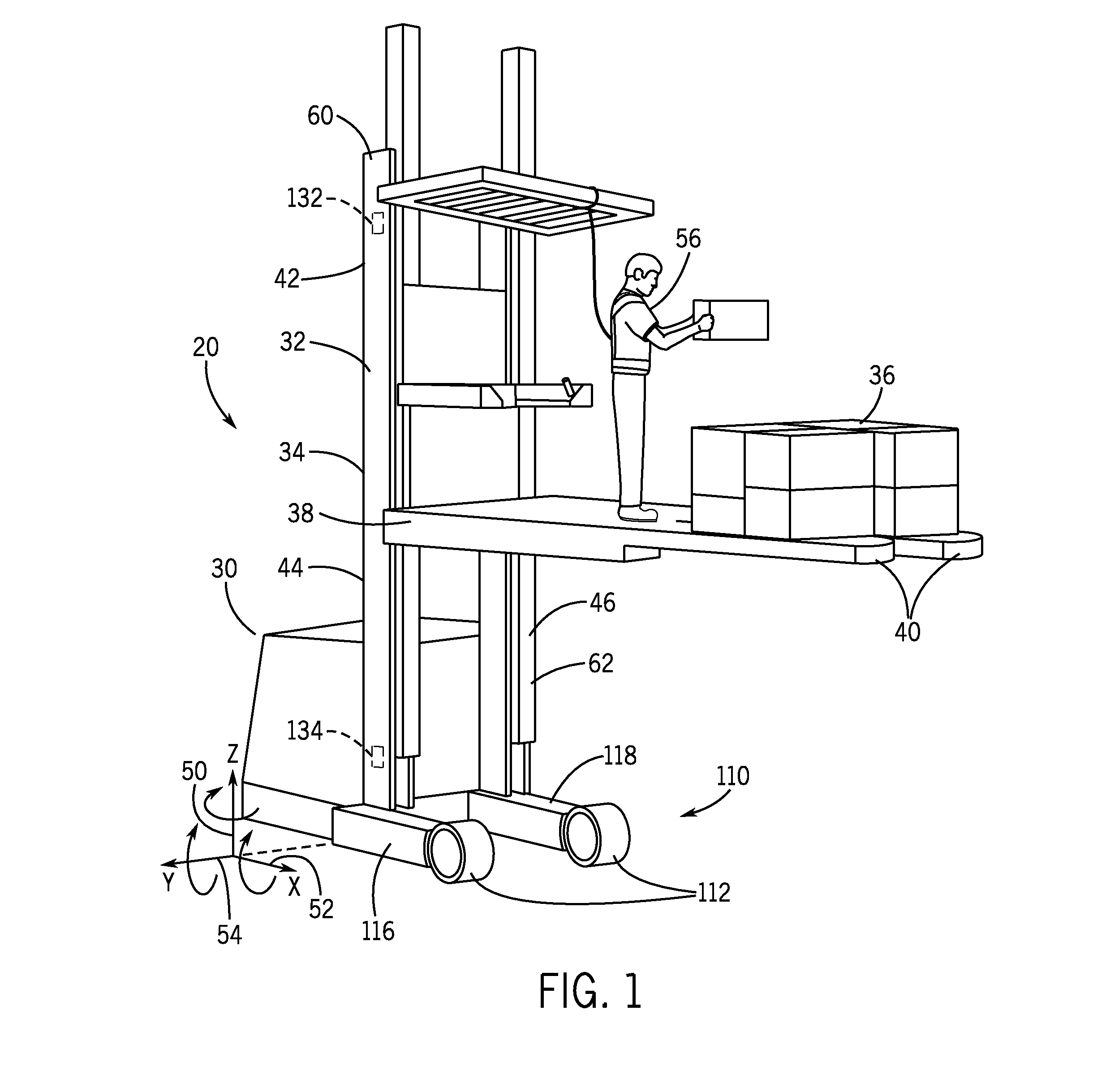

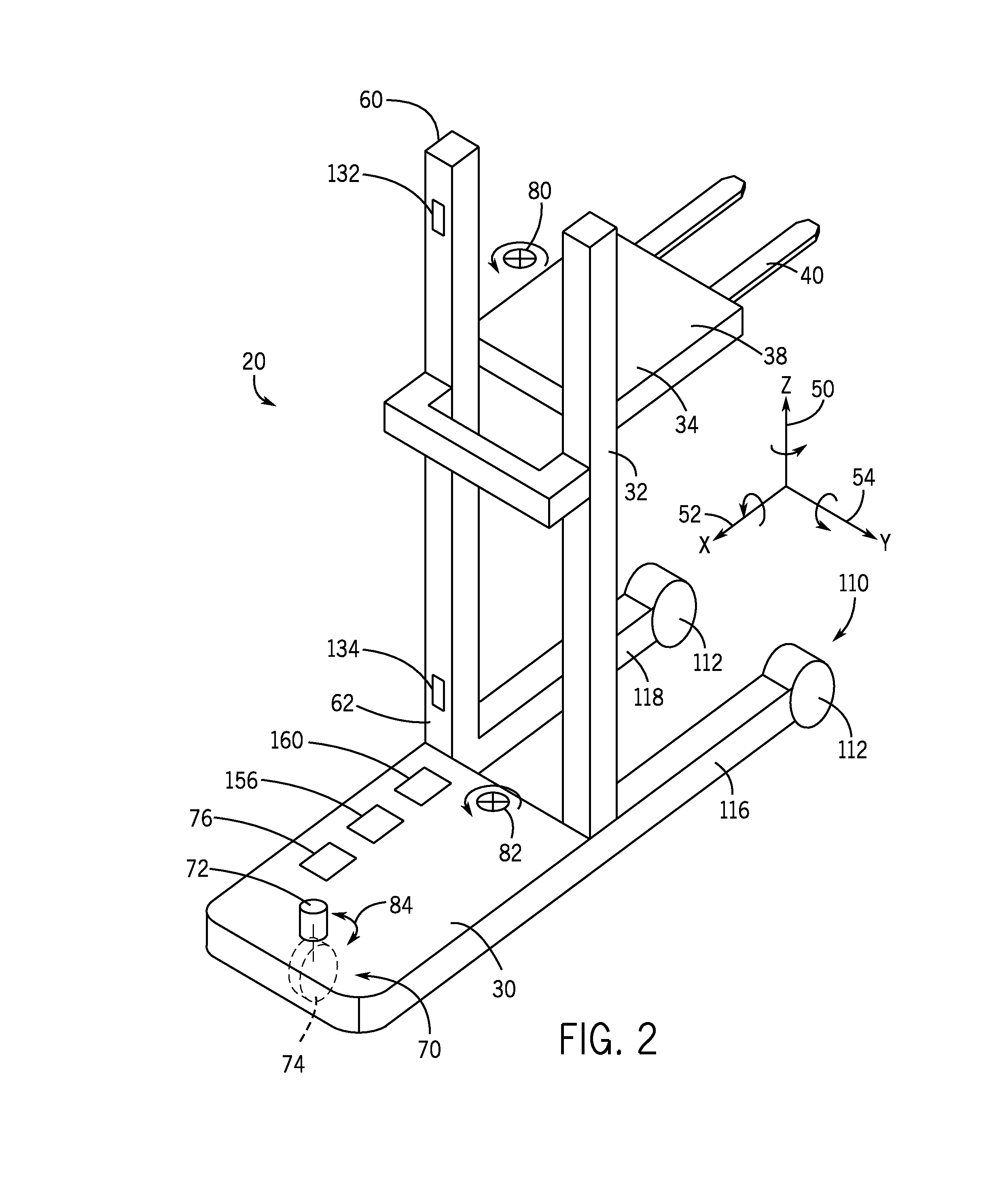

Vibration control systems and methods for industrial lift trucks

ActiveUS20140216853A1Improved vibration controlReduce and eliminate vibrating motionAnalogue computers for trafficSteering initiationsDrive wheelVibration control

A lift truck includes systems and methods for improved vibration control. A corrective yaw input mechanism reduces or eliminates torsional vibration motion of the lift truck about the Z-axis. Some embodiments may include, alone or in combination, drive wheel control and load wheel control.

Owner:RAYMOND LTD

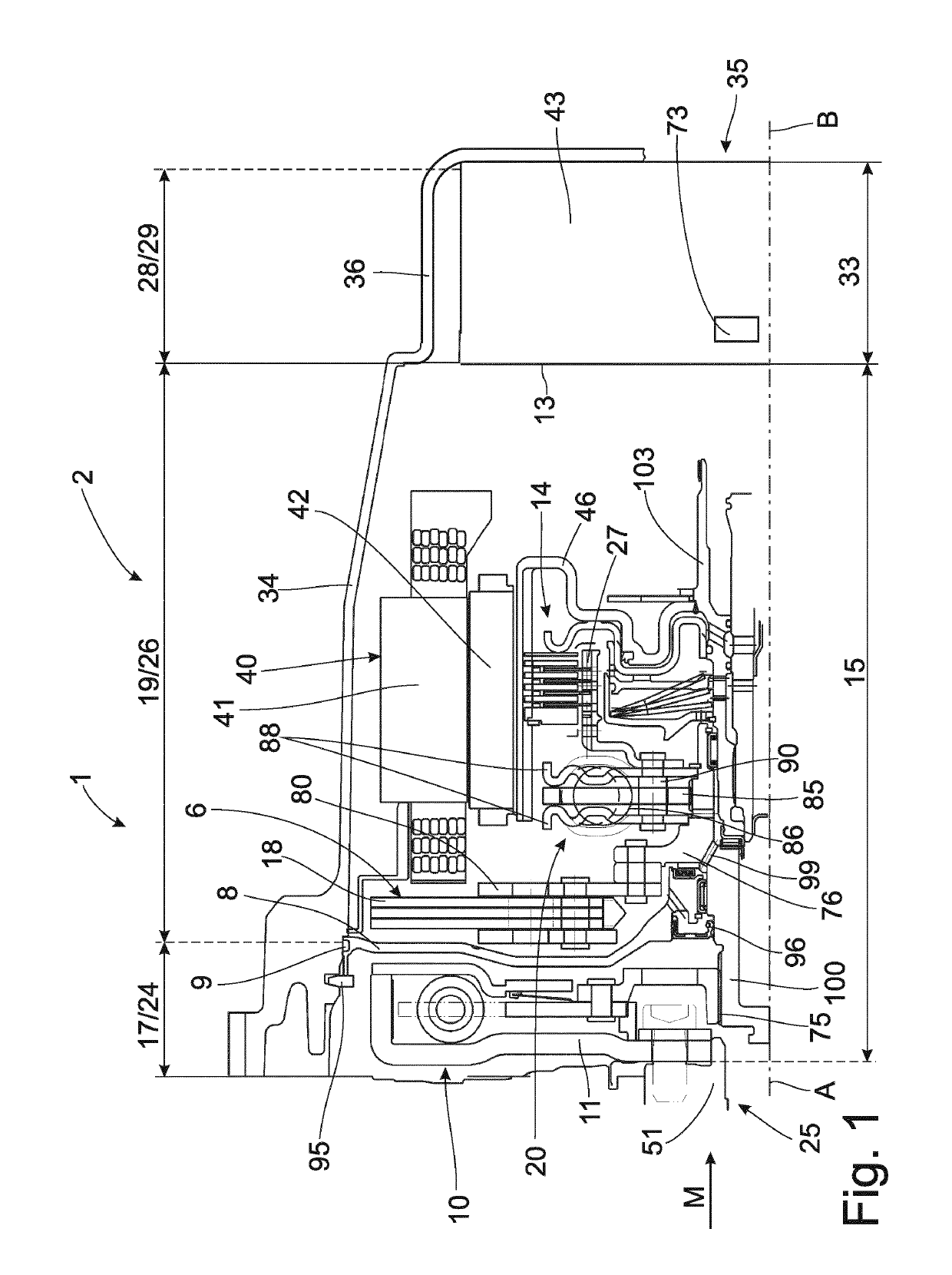

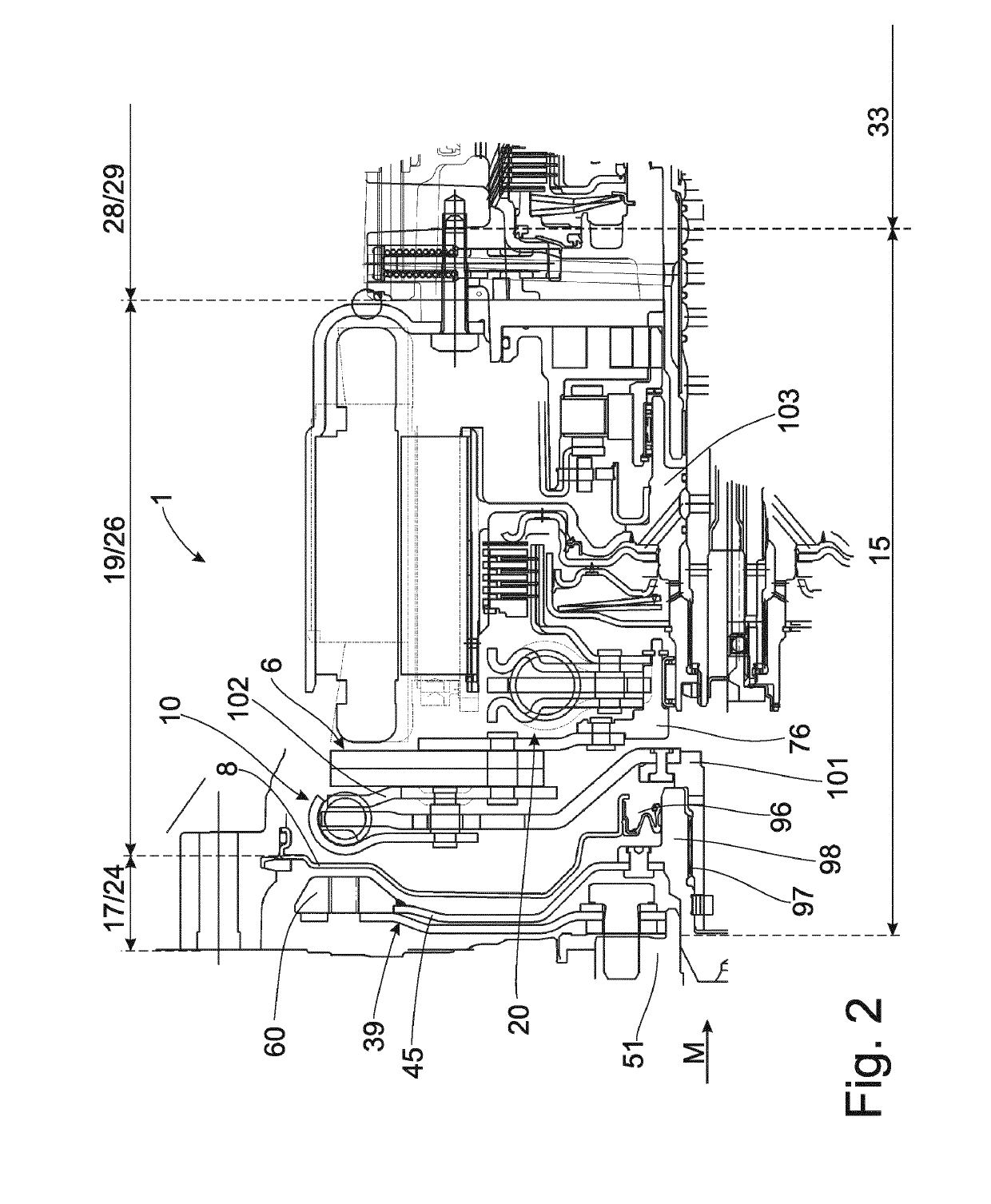

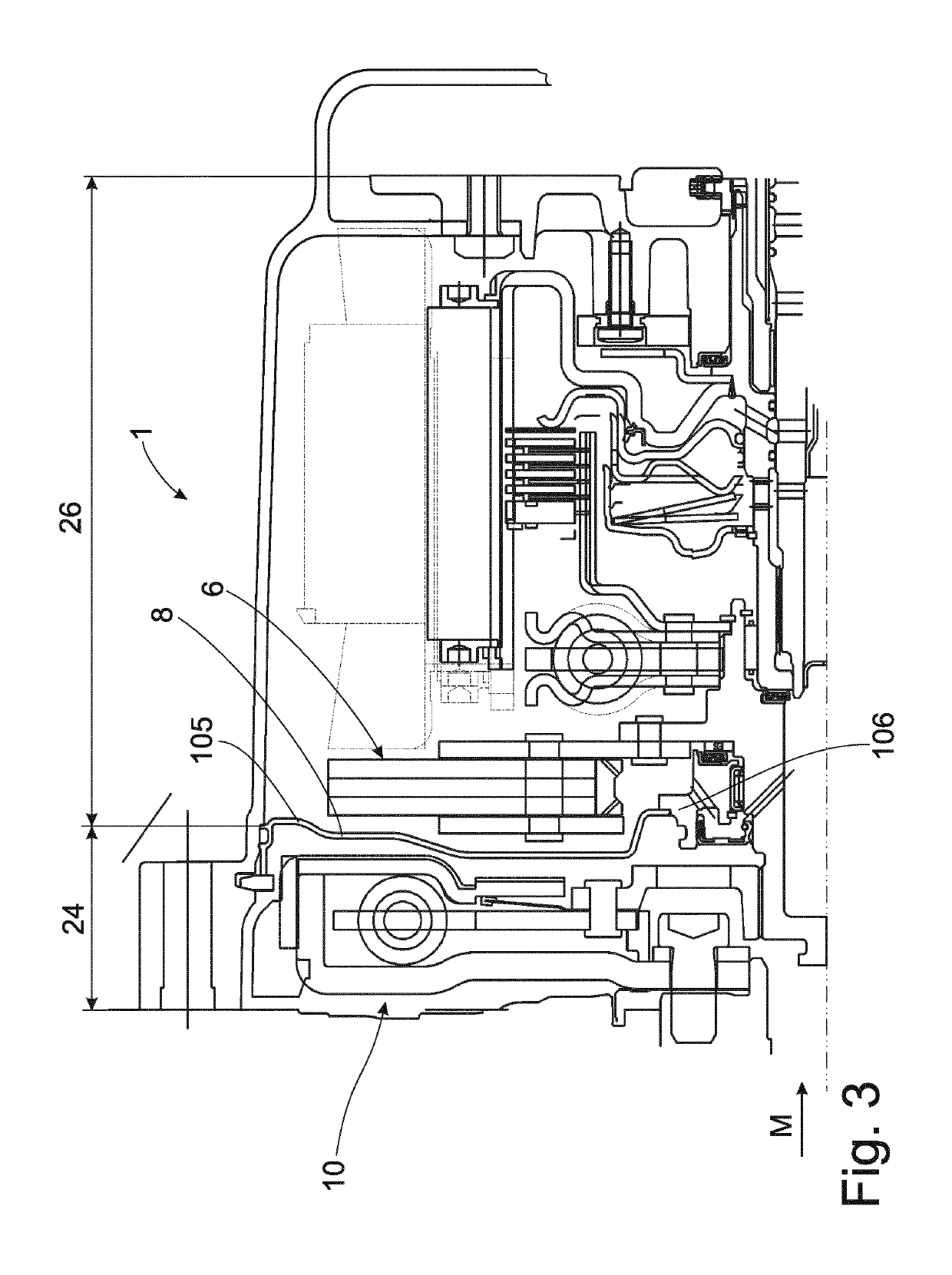

Torque-Transmission Device

ActiveUS20190226550A1Reduce torsional vibrationGuaranteed economic efficiencyHybrid vehiclesRotating vibration suppressionPowertrainTorque transmission

A torque transmission device for a powertrain of a motor vehicle has an input area and an output area. A torque path runs from the input area to the output area. A torsional vibration damping unit is positioned first, followed by a gear unit, along the torque path between the input area and the output area. The torsional vibration damping unit provides a first spatial area and an adjoining second spatial area along the torque path, and the gear unit provides an adjoining third spatial area.

Owner:ZF FRIEDRICHSHAFEN AG

Flywheel and gear ring component

The invention discloses a flywheel and gear ring component. The flywheel and gear ring component comprises a flywheel, a gear ring and a counterweight, wherein the rear end surface of the flywheel is a mounting combined surface of a clutch; the front end surface of the flywheel is a counterweight mounting surface; the flywheel is provided with a counterweight mounting and positioning pin hole and a counterweight mounting threaded hole; the counterweight is arranged on the flywheel by a bolt, and is positioned with the flywheel through a positioning pin. The flywheel and gear ring component is simple and reasonable in structure; the size and the number of the balancing blocks on a crank shaft are greatly reduced by distributing balancing blocks to the flywheel; the market requirements of miniaturization and lightweight of an engine are met; meanwhile, the manufacturing and the machining of the crank shaft are facilitated; the production cost of the crank shaft is reduced; the torsional vibration caused by the dynamic unbalance of a crank shaft system is reduced by the flywheel and gear ring component and the overall balancing process of the crank system, and service lives of a bearing bush and related parts are prolonged.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hybrid module for motor vehicle

ActiveCN107110235ASmall sizeCompact structureHybrid vehiclesYielding couplingDrive wheelExternal combustion engine

The invention relates to a hybrid module for a motor vehicle power train, comprising an input side for connecting to an internal combustion engine, an output side for connecting to a drive wheel, an electric drive motor comprising a stator and a rotor and a torque transfer device is arranged between the rotor and the output side. Said transfer device is designed to reduce rotational irregularity.

Owner:SCHAEFFLER TECH AG & CO KG

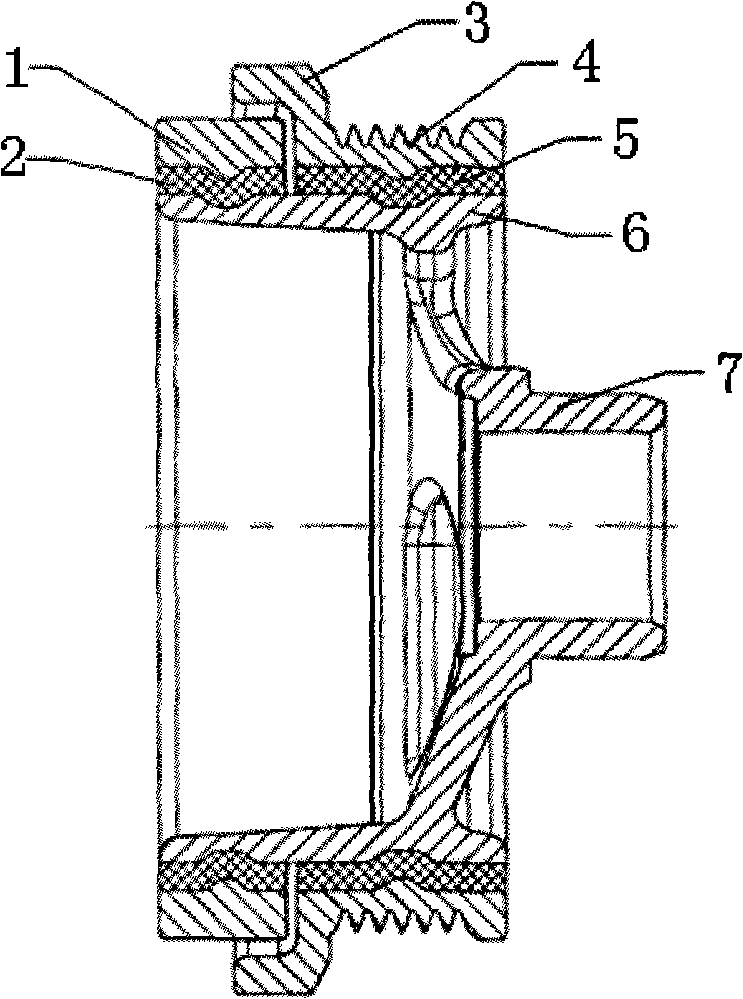

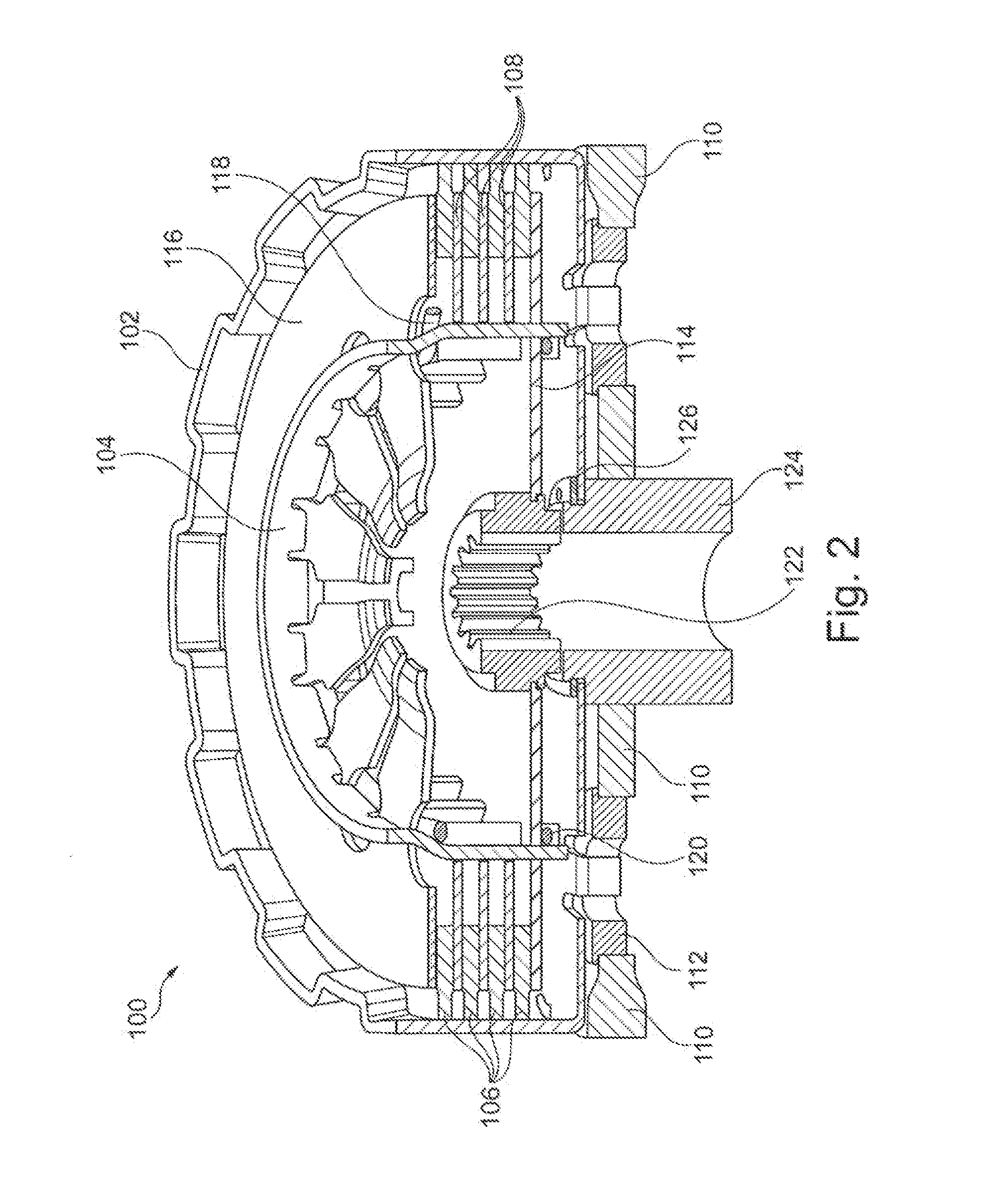

Wet clutch for a motorcycle

ActiveUS20140102846A1Circumference smallLow production costFriction clutchesInterengaging clutchesEngineeringClutch

A wet clutch for a motorcycle having an outer basket having a first toothing as the input side of the wet clutch, an inner basket which is coaxial to the outer basket having a second toothing as the output side of the wet clutch, first frictional elements which are torsionally connected to the outer basket, second frictional elements which are torsionally connected to the inner basket, the first and second frictional elements being situated axially alternating between the inner basket and the outer basket, and a clamping element to compress the first and second frictional elements axially in order to produce a torsional connection between the input side and the output side. The inner basket and / or the outer basket can essentially be produced from one or more sheet metal parts.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com