Device for coupling two shafts having an axial offset

An axis and crankshaft technology, applied in the field of devices coupling a first shaft and a second shaft, can solve problems such as radial force, and achieve the effects of compensating for axis misalignment, small weight, and high damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

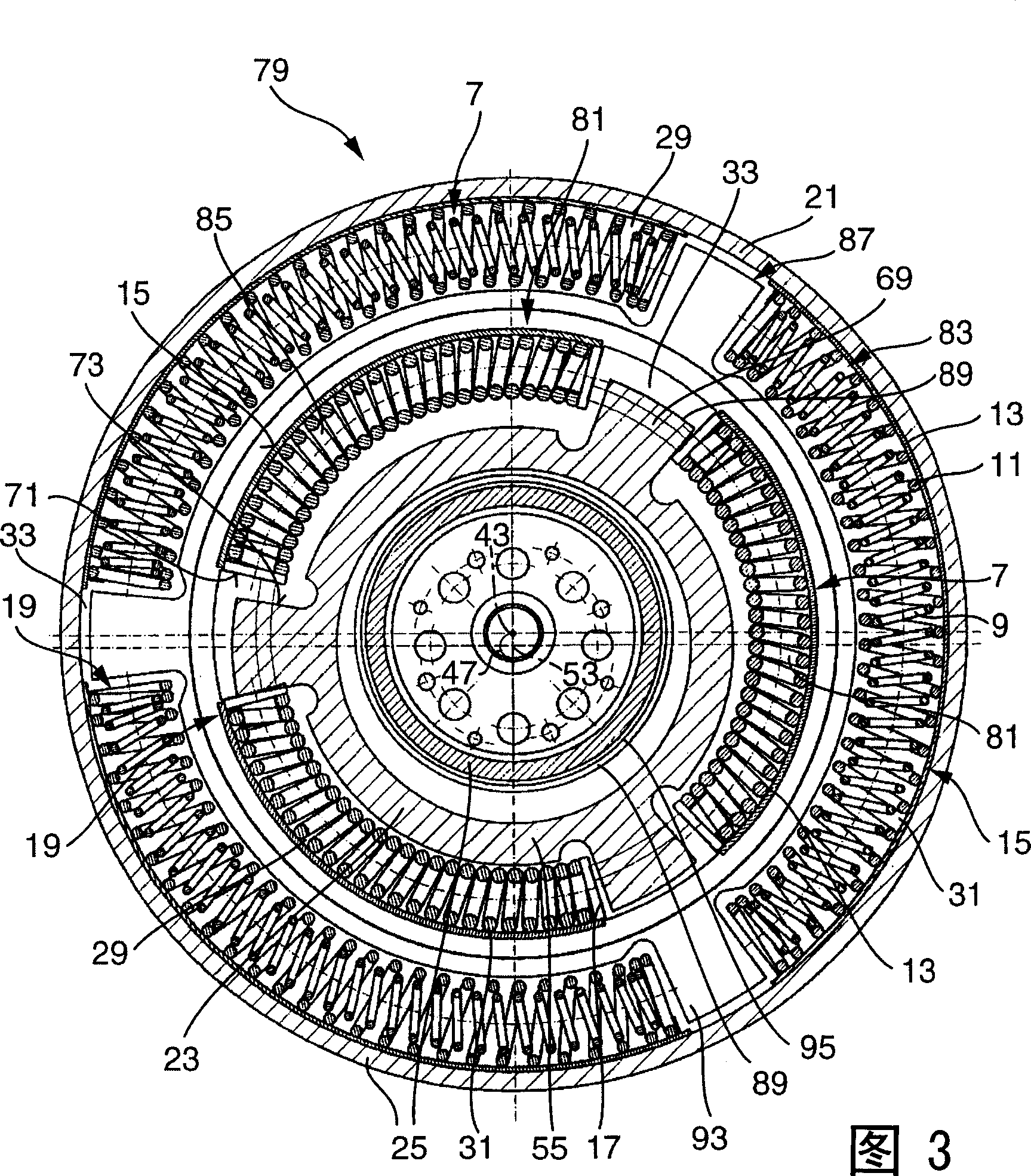

[0036] Identical or functionally similar parts are provided with the same reference numerals in the following description of the figures.

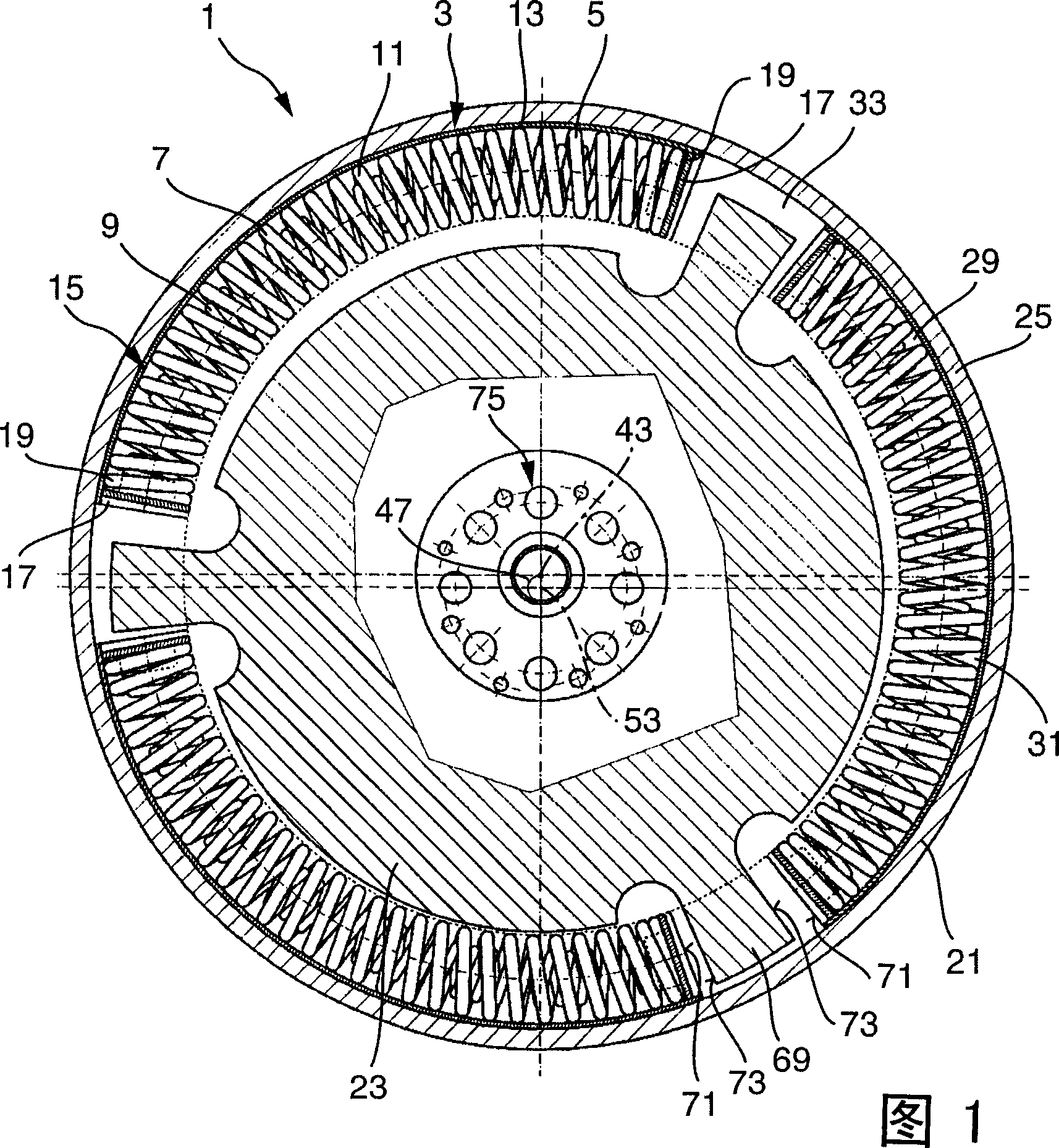

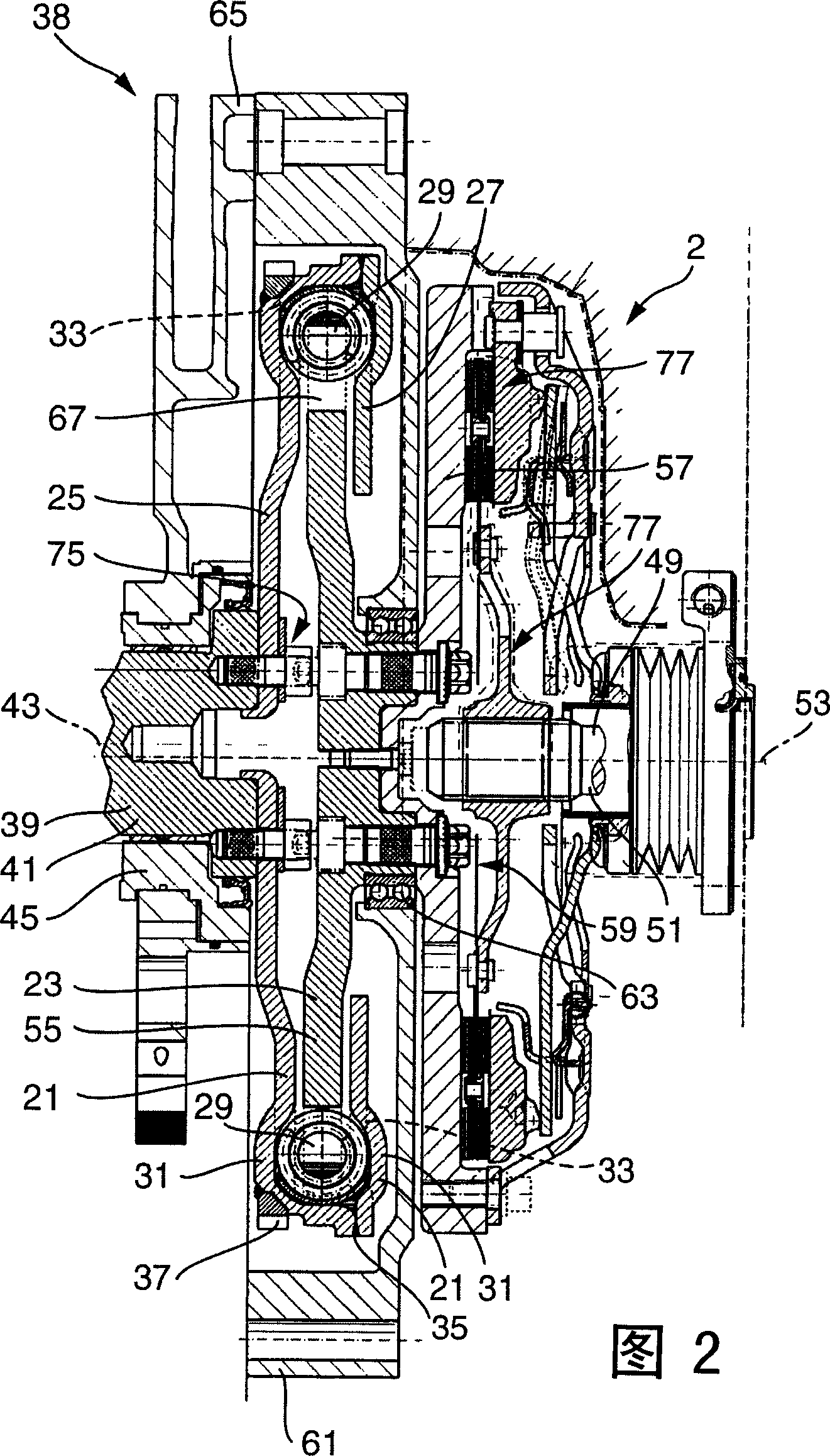

[0037]FIG. 1 shows a cross-sectional view of a device 1 for coupling two shafts with a torsional vibration damper 3 having a curved spring damper 5 . FIG. 2 shows a longitudinal section through the device 1 shown in FIG. 1 with a flanged dry clutch 2 . Dry clutches are well known and are used for coupling or decoupling two shafts, therefore, they are only described in this application to the extent necessary to understand the invention. 1 and 2 will be referred to simultaneously below.

[0038] The arc spring damper 5 has three arc spring units 7 arranged on a radius. Each arc spring unit has an inner arc spring 9 and an outer arc spring 11 . Also can each only be provided with an arc spring when needed. In order to absorb the centrifugal force occurring on the outer arc spring 11, each arc spring unit 7 of the arc spring damper 5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com