Half-section type free lacing wire structure of turbine blade with top tangent circle

A technology for steam turbine blades and loosening ties, which is applied in the directions of blade supporting elements, mechanical equipment, engine elements, etc., can solve problems such as high machining accuracy, difficulty in guaranteeing, and reducing blade dynamic stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

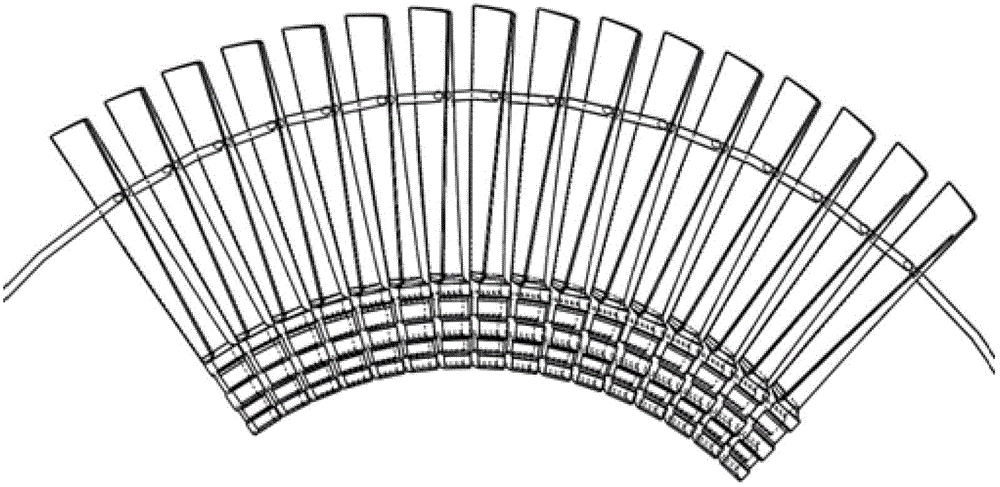

[0030] see figure 1 , Figure 2a and Figure 2b As shown, the ties are drilled around 70% of the blade height of the steam turbine moving blade. The diameter of the ties in the project is generally about Φ10-15mm, and the ties are straight holes.

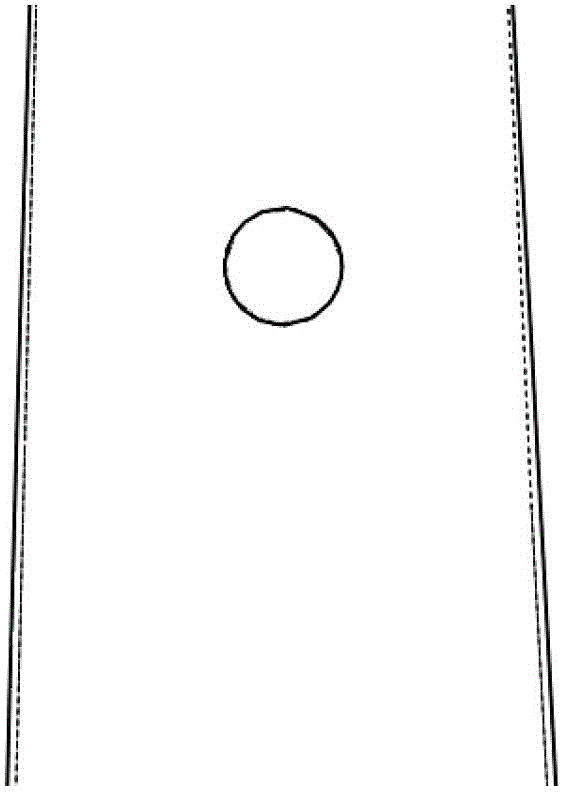

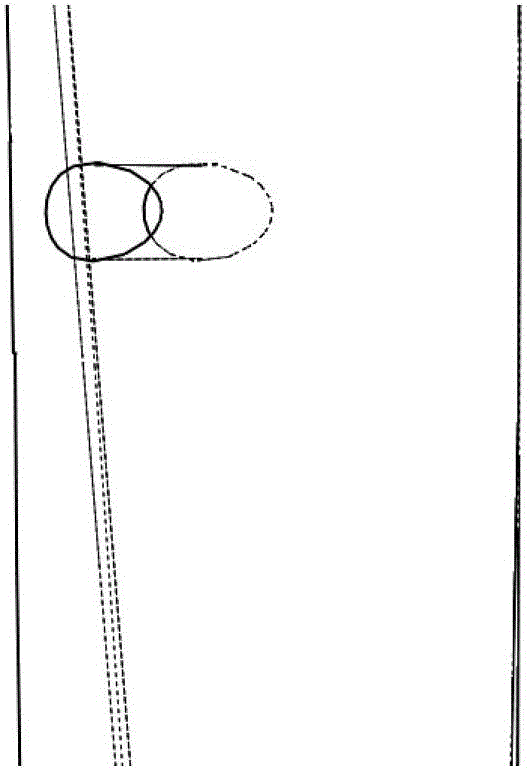

[0031] see Figure 3a and Figure 3b As shown, the tie bar of the present invention is designed as a half-section, and the top and bottom are cut into circles, and are divided into multiple sections at the same time. A certain gap 10 is maintained between each section. The specific value of the gap 10 depends on the safety of the tie bar work, usually about It is 17-22mm. The diameter of the tendon is generally about 0.5mm smaller than the diameter of the tendon hole, and a gap of 0.25mm is maintained at the top and bottom. This is mainly to ensure that the blade can be inserted into the tendon smoothly.

[0032] see Figure 4 , when the ties are installed, firstly push the ties to fill the gaps between all the blades, then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com