Patents

Literature

63results about How to "Reduce axial vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic and static pressure composite gas bearing with internal pi shaped air wedge groove

InactiveCN101691879AImprove bearing capacityImprove reliabilityBearing componentsBearingsCouplingGas supply

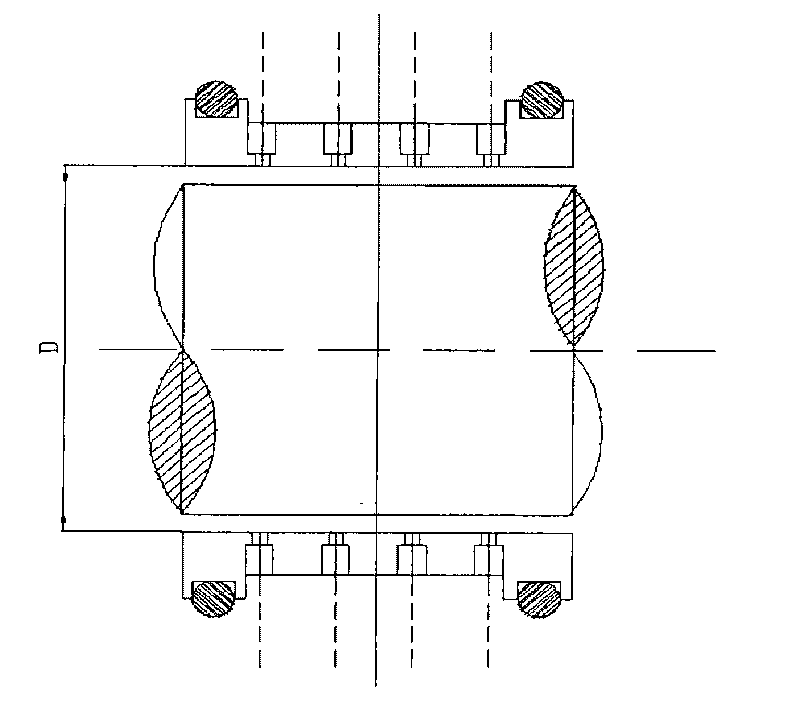

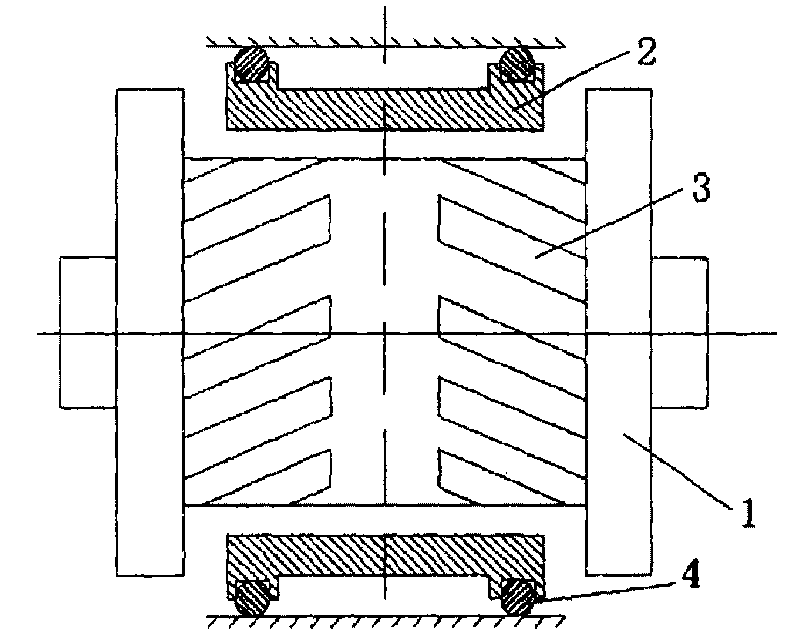

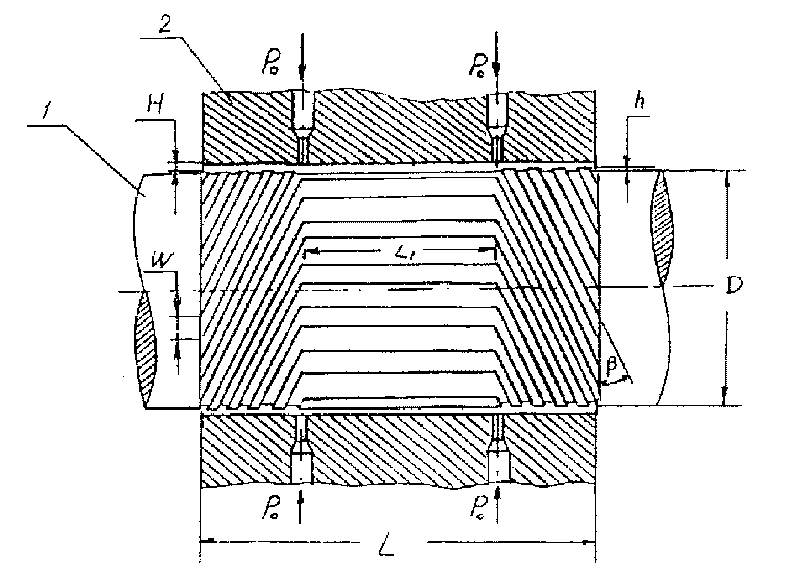

The invention provides a dynamic and static pressure composite gas bearing with an internal pi shaped air wedge groove, which relates to bearing technology, and belongs to a gas bearing with a novel structural form for supporting an ultrahigh speed rotary machine. The gas bearing is structurally characterized in that the inner surface of the bearing adopts pi shaped air wedge groove design, dynamic and static pressure composite design, and dynamic and static pressure design of a thrust surface; the thrust surface adopts spiral pressurizing groove design; and the inner surface and the thrust surface are provided with a static pressure gas supply hole respectively. The gas bearing overcomes the defects of the coupling and mutual interference between static pressure and dynamic pressure, overcomes the defect that the dynamic pressure effects at two ends of the bearing are inconsistent, not only remarkably improves the bearing capacity and rotating speed of the bearing, but also greatly reduces the axial and transverse vibration of a rotor journal, and improves the stability and reliability of a rotor system. Therefore, the gas bearing has the advantages of simple structure, high bearing capacity, stable operation and high reliability, and further widens the application range of the gas bearing.

Owner:DALIAN UNIV OF TECH

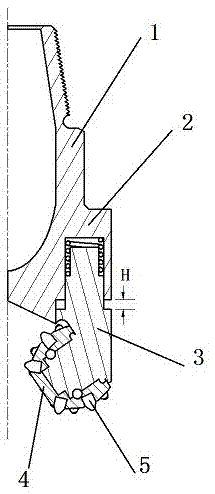

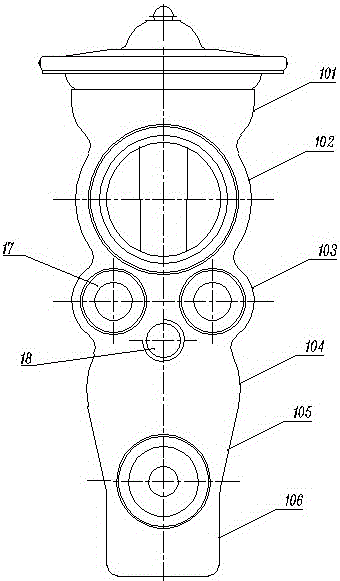

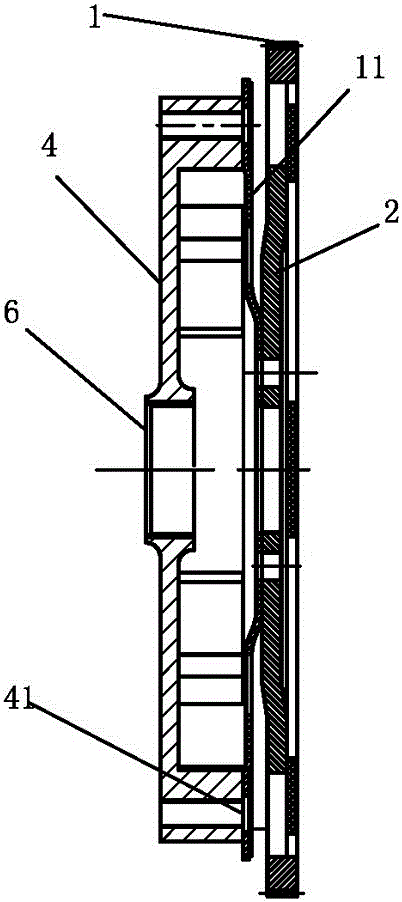

Axial vibration resistance type mechanical sealing device

ActiveCN104179974AChange natural frequencyEliminate axial vibrationEngine sealsShock absorbersAxial vibrationPerpendicular direction

An axial vibration resistance type mechanism sealing device comprises a sealing pair formed by contacting a moving ring with a static ring, wherein the perpendicular direction of the sealing end surface of the moving ring and the static ring is defined as the axial direction. The axial vibration resistance type mechanism sealing device is characterized in that the moving ring is arranged in a moving ring seat, the static ring is arranged in a static ring seat, and the moving ring seat and the static ring seat are fixedly connected onto a base; the mechanical sealing device further comprises a spring vibrator system consisting of an elastic assembly and a vibrator, the elastic assembly is connected with the moving ring seat and the vibrator, and the vibrator only has the axial freedom degree; and the static ring and the static ring seat are in flexible connection, the static ring only has the axial freedom degree, the moving ring is fixedly connected onto the moving ring seat, or, the moving ring and the moving ring seat are in flexible connection, the moving ring only has the axial freedom degree, and the static ring is fixedly connected onto the static ring seat.

Owner:ZHEJIANG UNIV OF TECH

Bearing and spindle motor

Owner:LG INNOTEK CO LTD

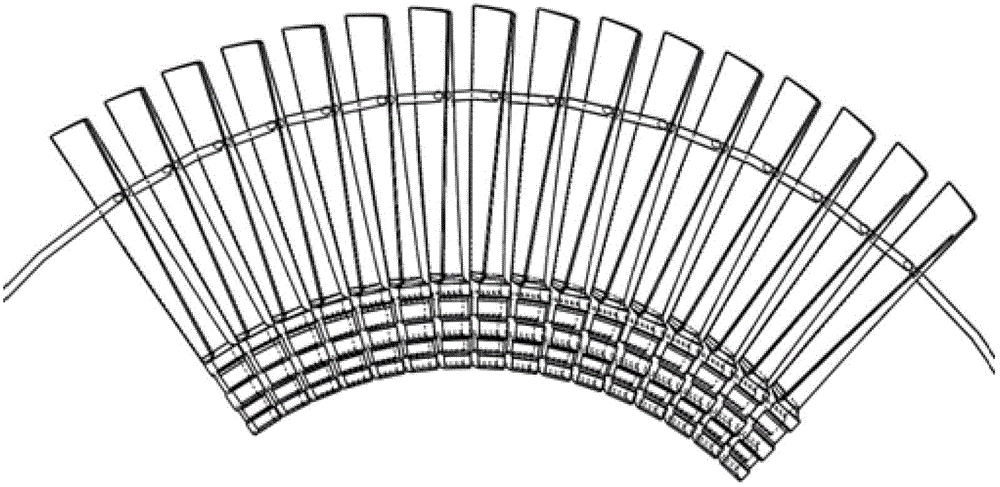

Half-section type free lacing wire structure of turbine blade with top tangent circle

InactiveCN102720543AReduce vibrationReduce axial vibrationBlade accessoriesMachines/enginesSteam turbine bladeEngineering

The invention provides a half-section type free lacing wire structure of a turbine blade with a top tangent circle, wherein the cross section of a part of the half-section type free lacing wire structure cooperating with a lacing wire hole of the turbine blade is shaped as follows: tangent circles are arranged on circular top and bottom parts respectively; and the height of each tangent circle is less than or equal to 20% the circular semi-diameter. A lacing wire of the half-section type free lacing wire structure has good sectional property which is beneficial to the bending of the lacing wire; two contact points exist between the lacing wire structure and the blade; through the adding of the contact points between the lacing wire and the blade, the total frictional force can be increased, so that the damping is increased and the vibration of the blade is decreased; and additionally, the lacing wire not only can decrease the vibration of a blade assembly along the radial direction and the peripheral direction, but also can effectively decrease the axial vibration and the torsion vibration of the blade assembly.

Owner:XI AN JIAOTONG UNIV

Nickel-molybdenum intermediate alloy preparation method for smelting TA10 cast ingot

The invention provides a nickel-molybdenum intermediate alloy preparation method for smelting a TA10 cast ingot. The nickel-molybdenum intermediate alloy preparation method comprises the following steps: respectively turning a pure nickel rod and a molybdenum rod into scrap materials, and heating and drying the scrap materials; adding dried master batch nickel scraps into a crucible of a medium-frequency induction furnace; meanwhile, adding molybdenum scraps into a secondary charging hopper in the medium-frequency induction furnace; vacuumizing the medium-frequency induction furnace to 0.6Pa-0.1Pa and starting to heat and smelt; raising the temperature to 1800-1900 DEG C and keeping the heat for 15-20 minutes; observing that when the smelting rate of the master batch nickel scraps is more than 45%, starting to add the molybdenum scraps; inflating argon to carry out gas protection; continually raising the temperature to guarantee that the temperature reaches 1900 DEG C and keeping the temperature for 20-30 minutes to sufficiently float impurities in smelting liquid up to the surface of a smelting tank; and finally, pouring the smelting liquid into a fixed die and cooling to the room temperature to obtain the product. According to the nickel-molybdenum intermediate alloy preparation method, pure nickel and pure molybdenum are directly prepared into an intermediate alloy; the smelting point of the nickel-molybdenum alloy is reduced and various disadvantages of a traditional manner of adding the intermediate alloy in the process of smelting the TA10 cast ingot are made up.

Owner:CHEN YAN BAOJI METAL MATERIALS

Diamond drill bit suitable for hard stratum drilling

PendingCN110145240AReduce the amplitudeImprove roundnessDrill bitsConstructionsWorking lifeDrill bit

The invention discloses a diamond drill bit suitable for hard stratum drilling, and belongs to the field of drilling. The drill bit comprises a drill bit body, a plurality of blades which extend fromthe drill bit body or are fixed to the drill bit body, water holes or nozzles. The blades are provided with scraping cutting teeth. At least one blade extends to form a strengthening base at the circumferential position of the drill bit, wherein the strengthening bases are provided with scraping cutting teeth. According to the technology, local strengthening of a cutting structure can be achieved,the hard stratum drilling work life is prolonged, and meanwhile premature failures of the cutting teeth due to vibration in the drill bit hard stratum drilling process can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Vibration reduction device of engine cooling water pipe and vehicle

ActiveCN102705627AReduce transmissionReduce axial vibrationPipe elementsMachines/enginesWater pipeEngineering

The embodiment of the invention provides a vibration reduction device of an engine cooling water pipe and a vehicle, and relates to the field of mechanical vibration reduction devices. The vibration reduction device is used for reducing vibration of an engine and propagation of liquid pulsation produced by a water pump from axial and radial directions to a vehicle body through the cooling water pipe. The vibration reduction device of the engine cooling water pipe comprises a shell, a movable vibration reduction pipe is arranged in the shell in the axial direction, a second vibration reduction ring is sleeved outside the vibration reduction pipe, a first vibration reduction ring is arranged at one end in the shell in a sealing mode, and the first vibration reduction ring is thinner than the second vibration reduction ring. According to the embodiment, the vibration reduction device is applied in the field of manufacturing of automobiles.

Owner:长城汽车股份有限公司平湖分公司

Steel structure roof and mounting method thereof

ActiveCN107700736AAvoid position shiftThe locked position does not changeBuilding roofsBuilding material handlingSteel columnsScrew thread

Owner:江西佳慧钢结构工程有限公司

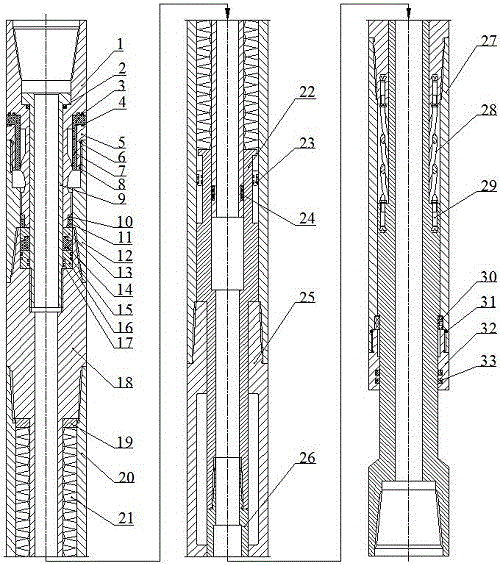

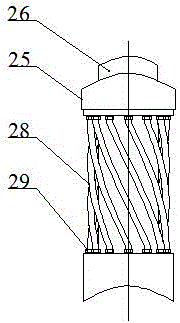

Anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping

ActiveCN106567681AExtend your lifeAvoid drill stickingDrilling rodsDrilling casingsEngineeringDrill bit

The invention discloses an anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping to solve the problem that the rock breaking efficiency is low due to clamping and slipping in the drilling process. According to the main technical scheme, an upper connector, an upper shell, an adapter and a lower shell are sequentially connected through a thread; a compression spring is mounted on a compression spring guide rod, the low end of the compression spring guide rod pushes an anti-falling connector to enable a mandrel to stretch, and the anti-falling connector is connected with a mandrel thread and axially positioned through an adapter shaft shoulder; a steel wire rope system is arranged in a left-rotation mode, the upper and lower ends of the steel wire rope system are separately fixed to the lower end of the adapter and fixed into a circular groove in the upper end of a mandrel boss, the upper and lower ends of steel wire ropes are mounted by 30-40 degrees in an inclined mode, and the steel wire ropes are in a tensional state initially; during work, drilling pressure is transferred to the mandrel through the compression spring, and torque is transferred to the mandrel through the steel wire rope system; and when the mandrel rotates backwards, the steel wire rope system retracts to enable the mandrel to compress the compression spring to axially retract so as to decrease the cutting depth of a drill bit, and the drill bit is in a rock mass in the whole process.

Owner:沛县昌运机械制造有限公司

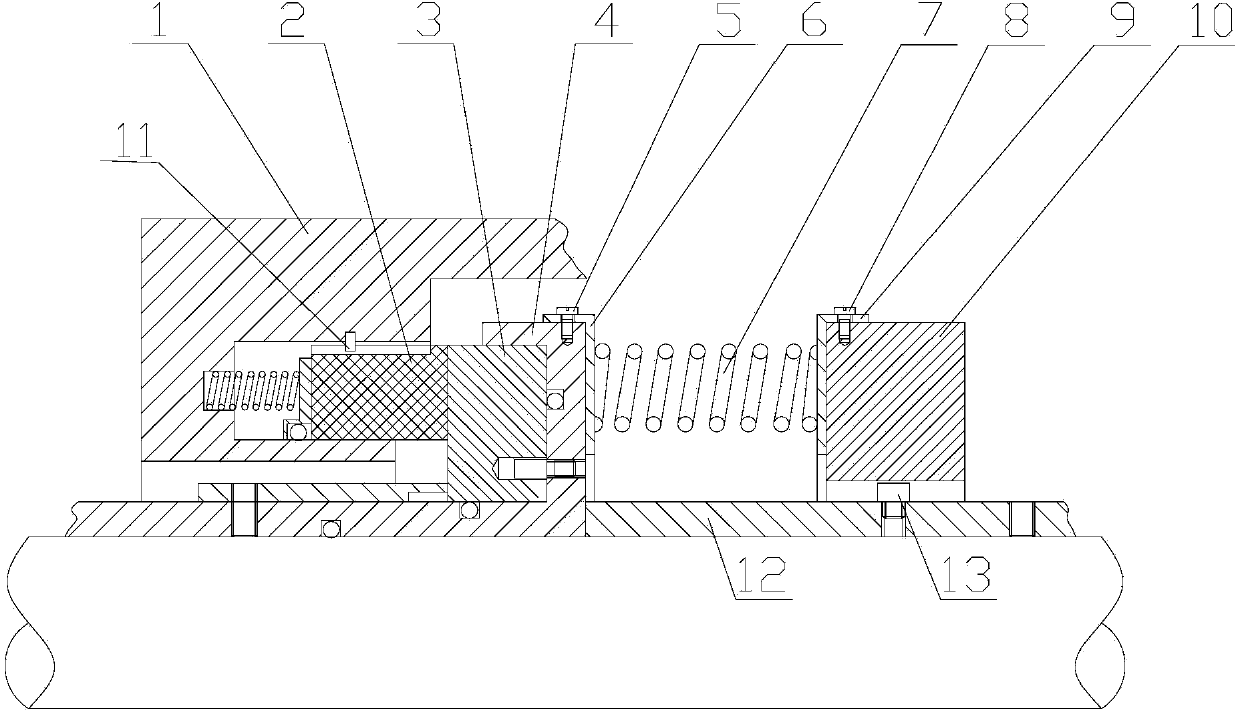

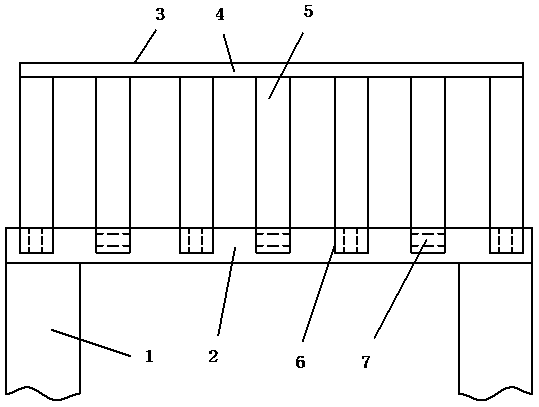

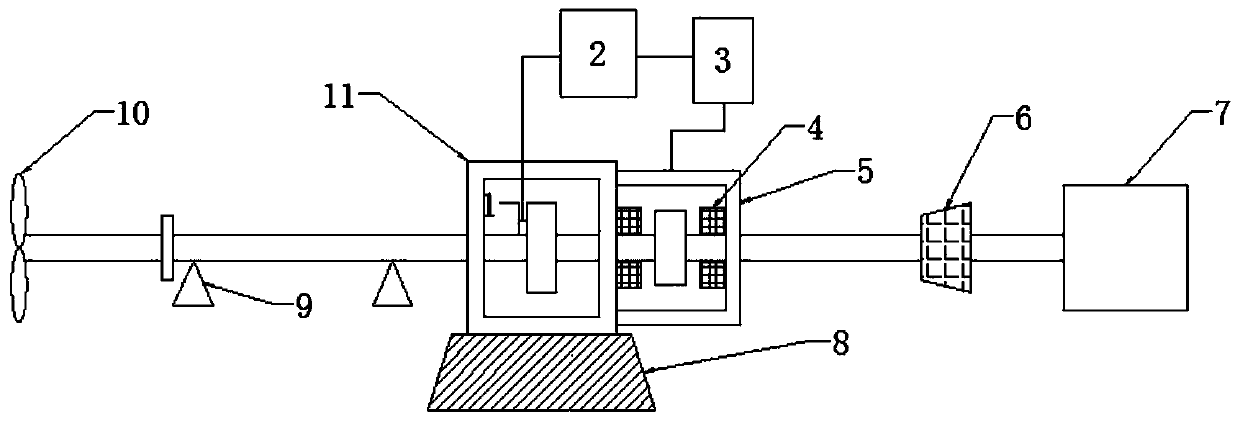

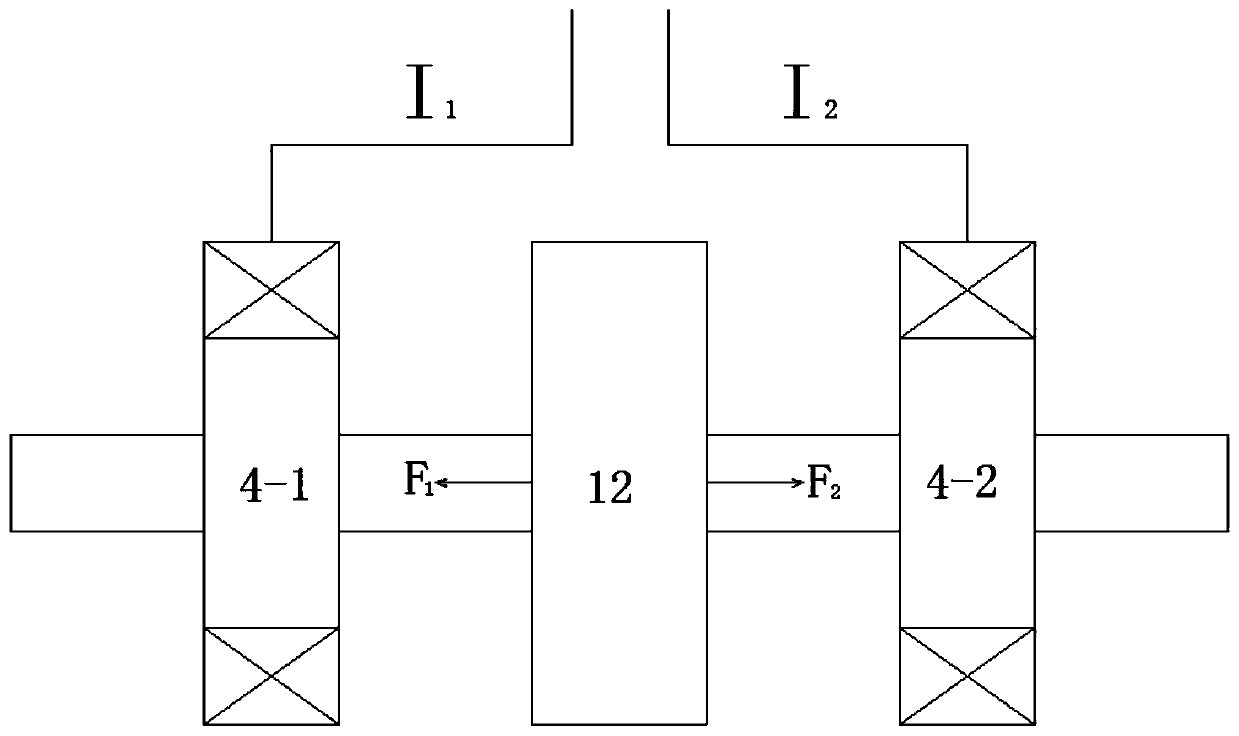

Two-way active electromagnetic control system for vibration of marine propulsion shafting

PendingCN109739275AReasonable structureReduce axial vibrationMechanical oscillations controlPropulsion power plantsTransmitted powerPower transmission

The invention discloses a two-way active electromagnetic control system for vibration of marine propulsion shafting. The control system is installed on the marine propulsion shafting. The marine propulsion shafting comprises an elastic coupling, a marine power device, a bearing base, a radial bearing, propellers and a thrust bearing; the above components are axially distributed along the thrust shafting, the thrust bearing is located on the bearing base for transmitting power in the marine power device to the propellers; the control system comprises a two-way active electromagnetic control assembly, the two-way active electromagnetic control assembly is mounted on the base of the thrust bearing for applying axial force in both directions according to the axial vibration, thereby reducing axial vibration caused during operation of the shafting. According to the control system in the invention, a force is applied by a two-way active electromagnetic controller mounted on the base of the thrust bearing, the unique performance of the two-way active electromagnetic controller can meet unique requirements of the propellers and is effective in controlling the shafting excitation without wear during operation, and the maintenance cost is low.

Owner:WUHAN UNIV OF TECH

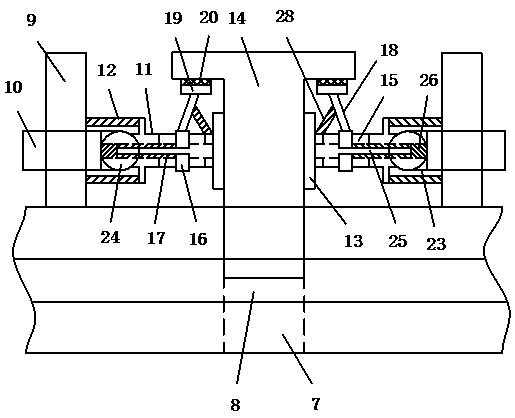

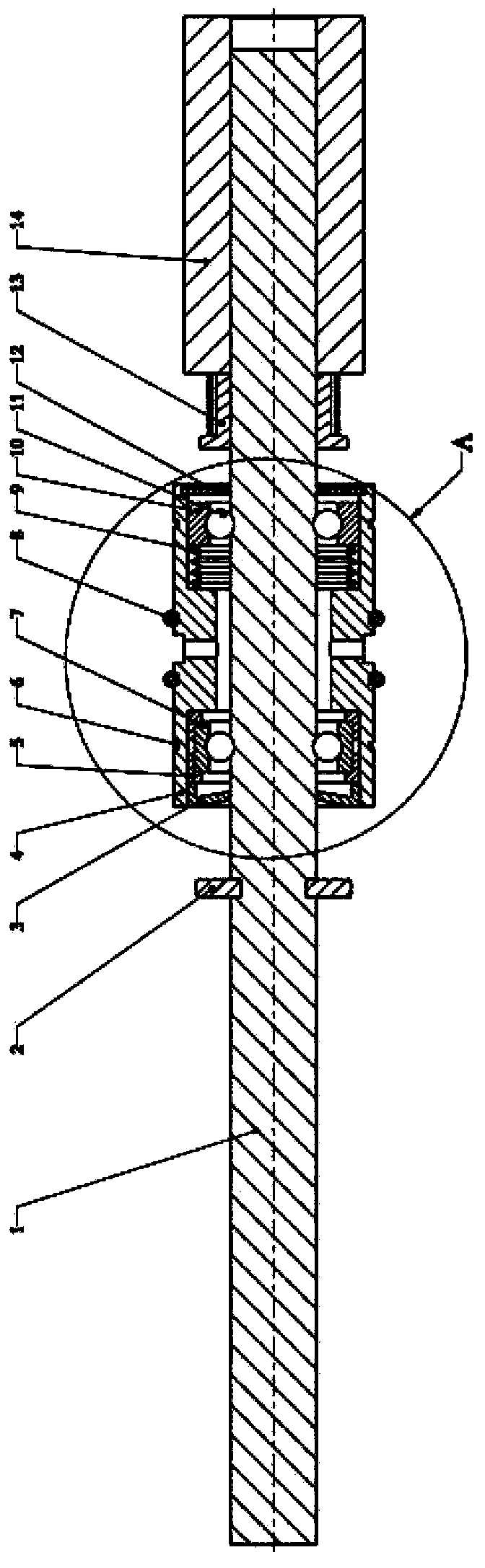

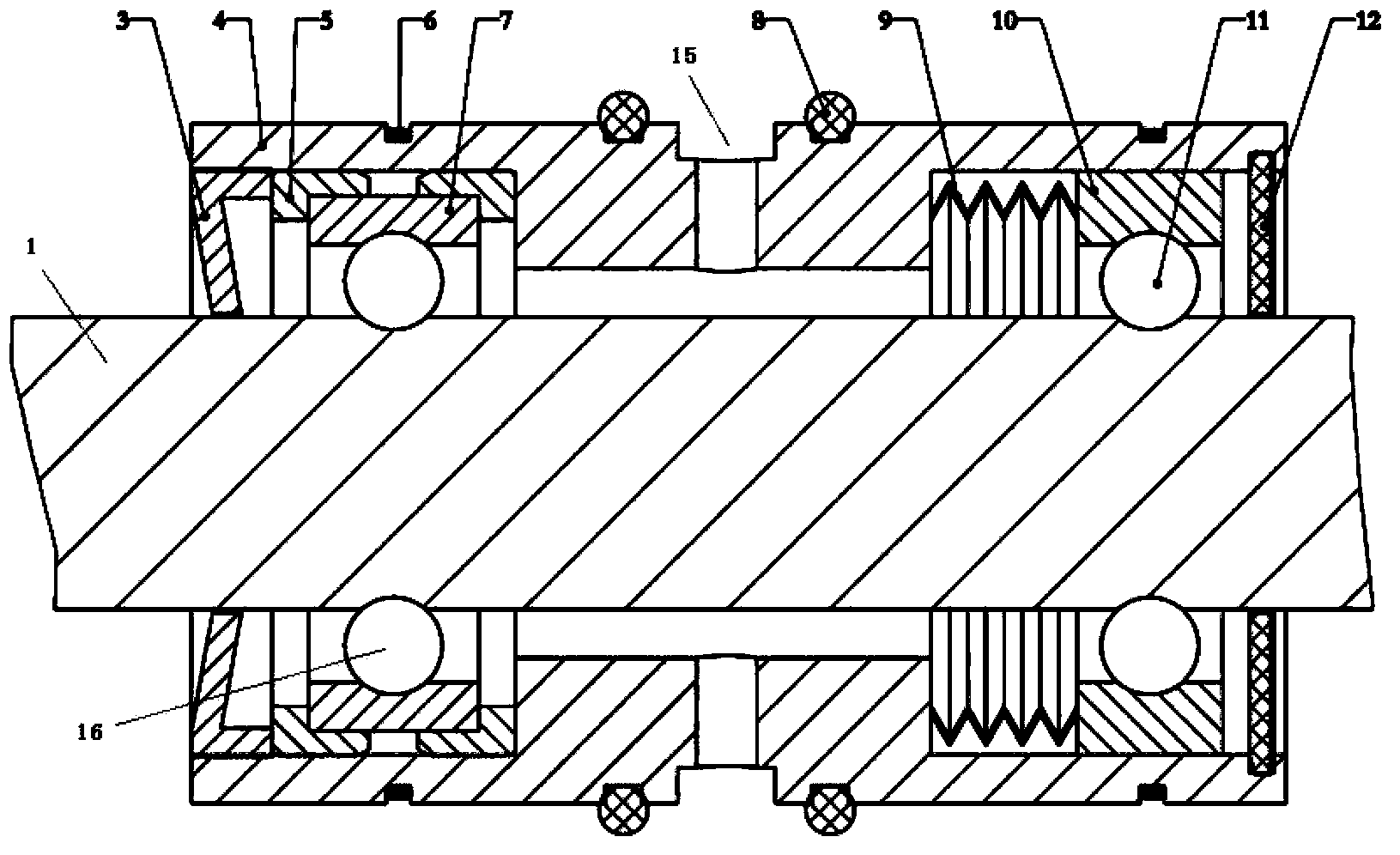

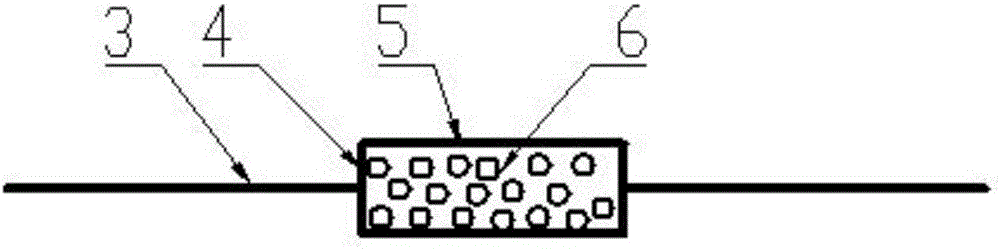

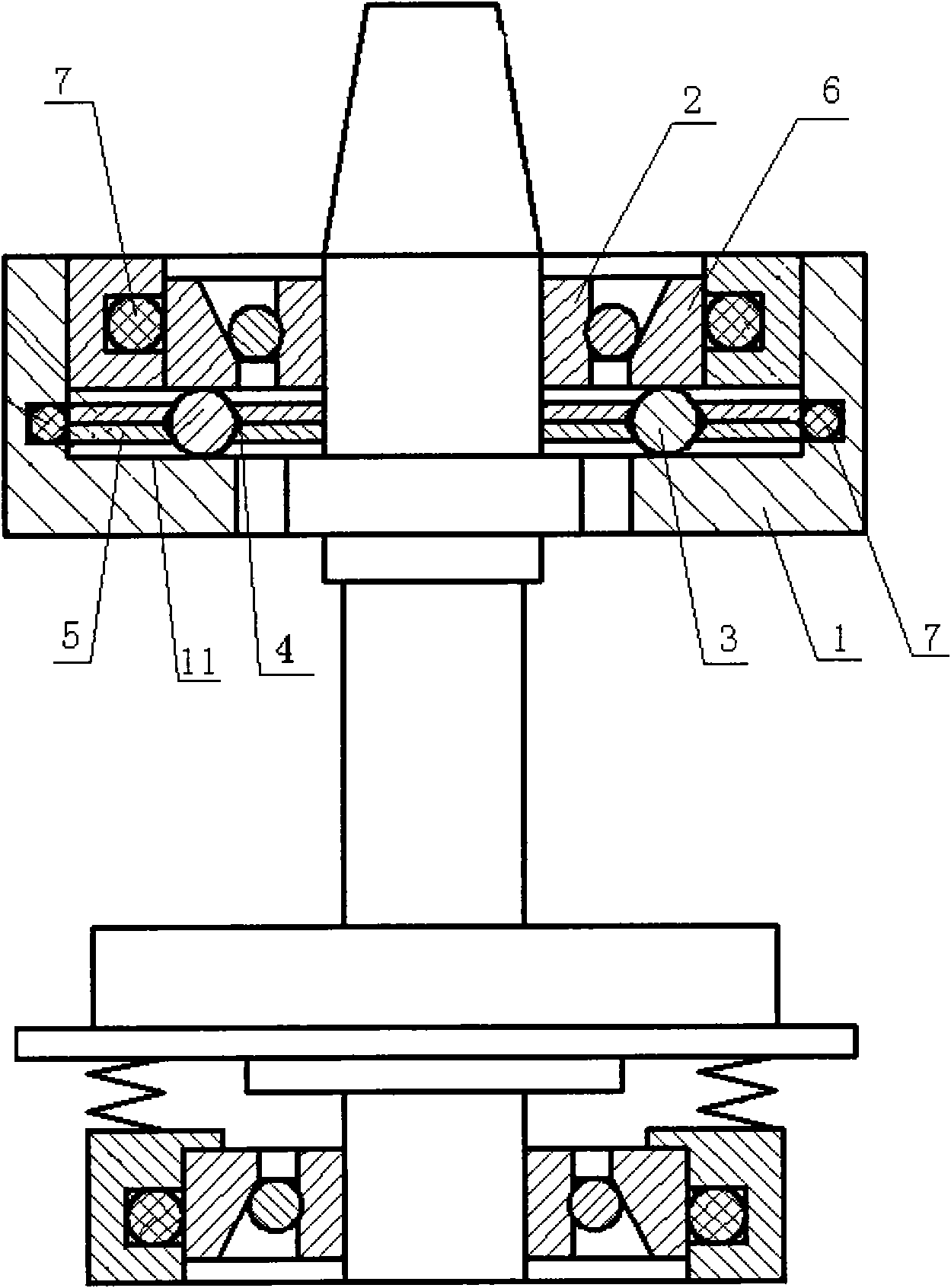

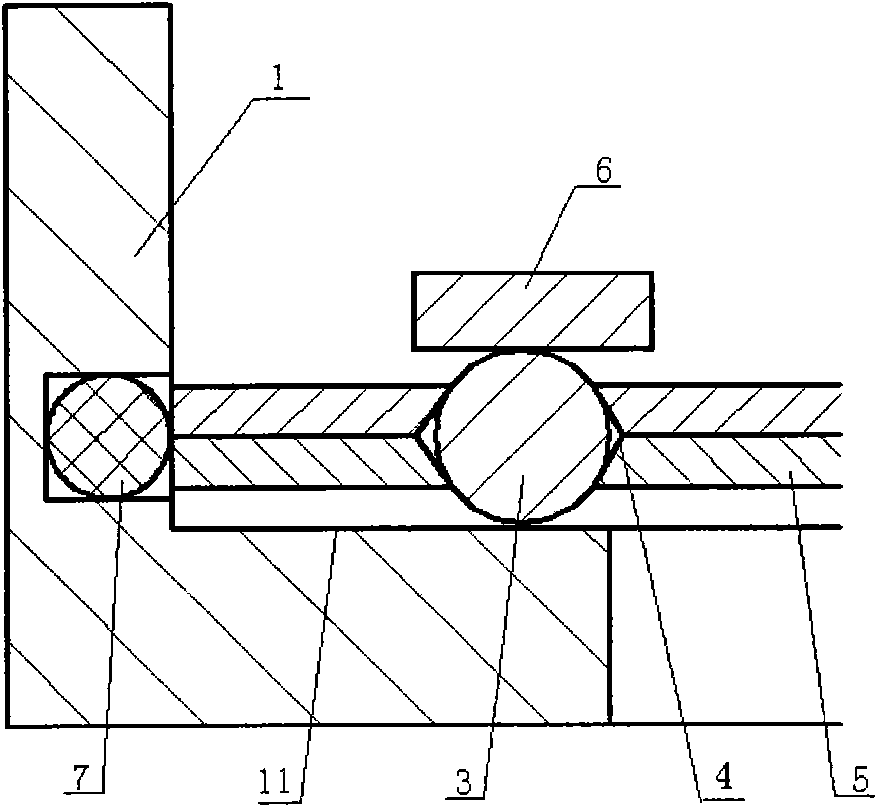

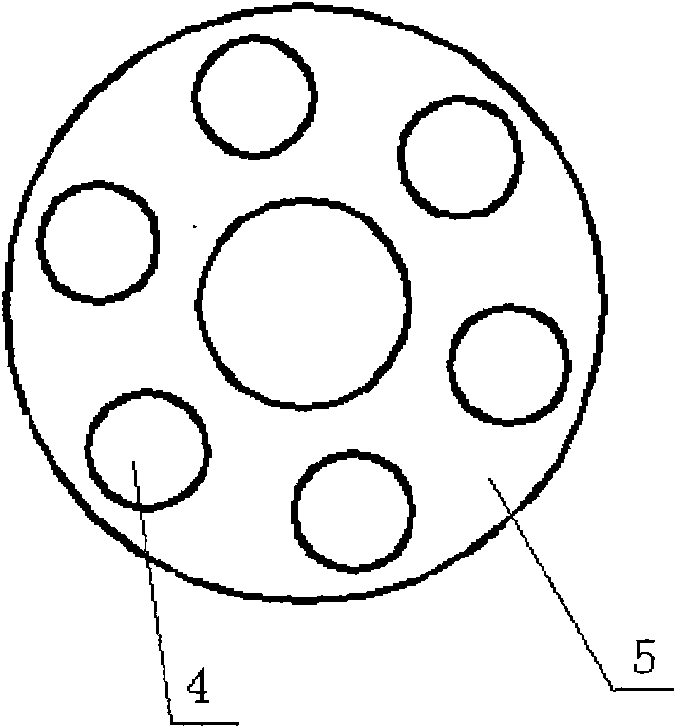

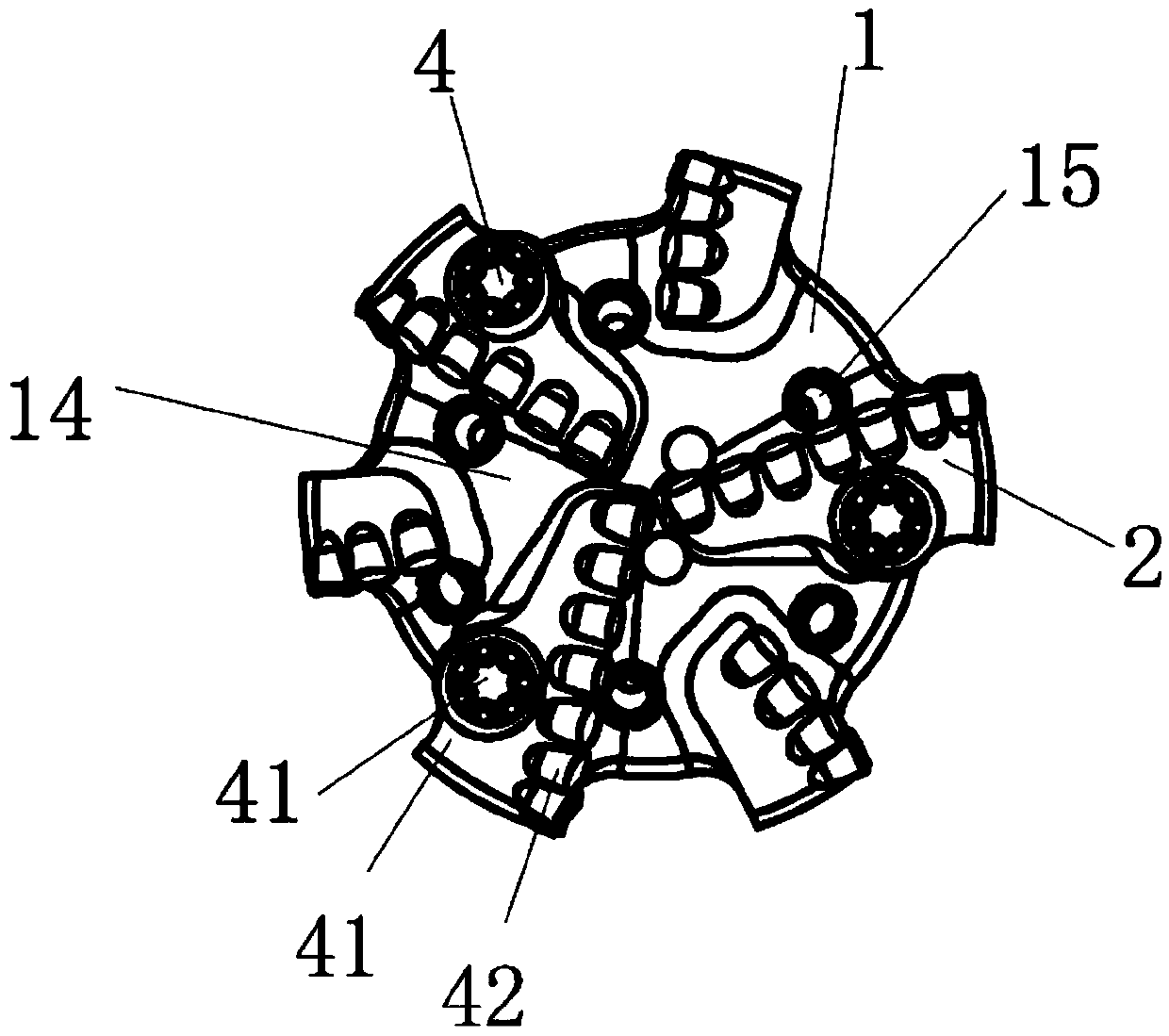

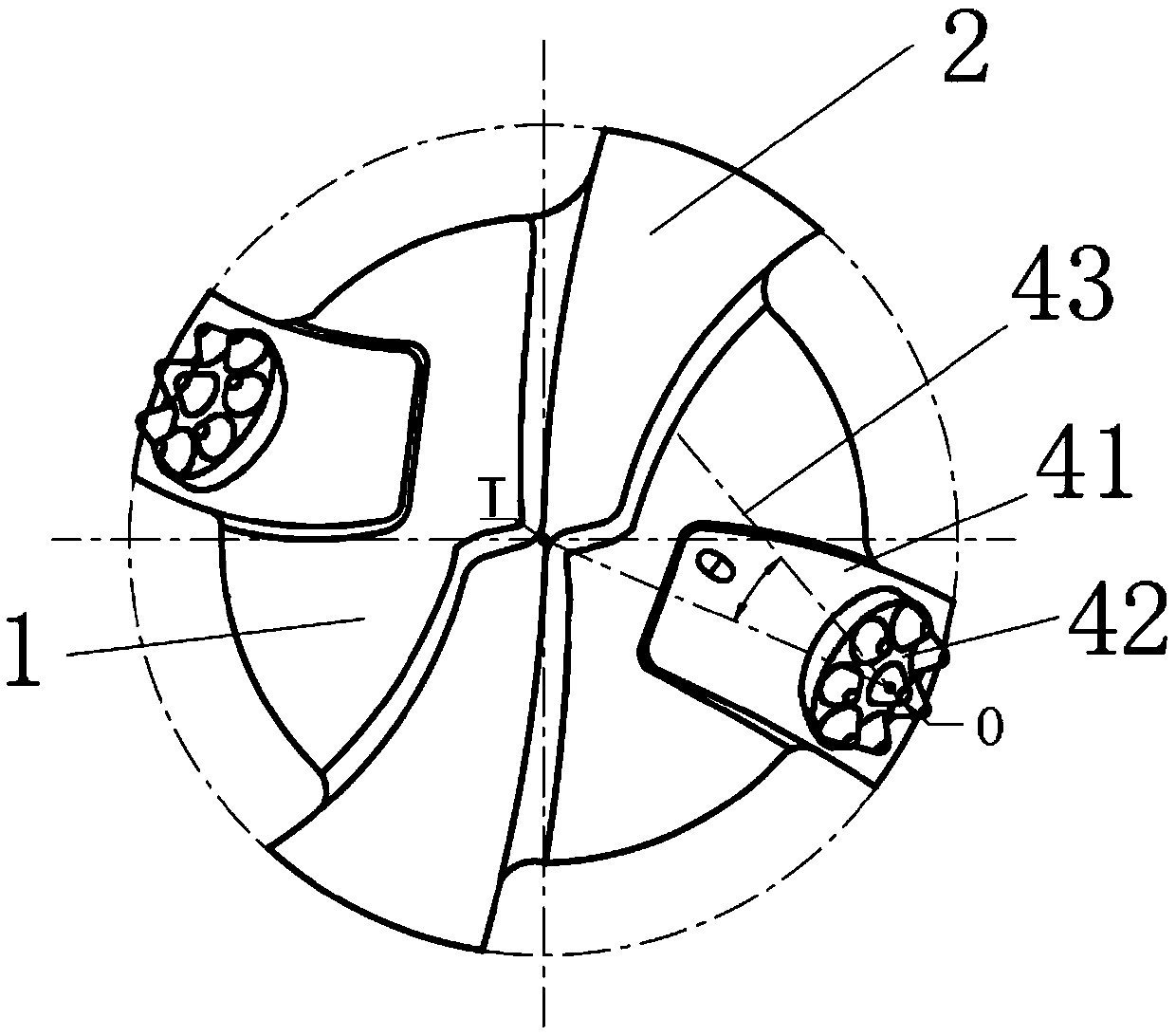

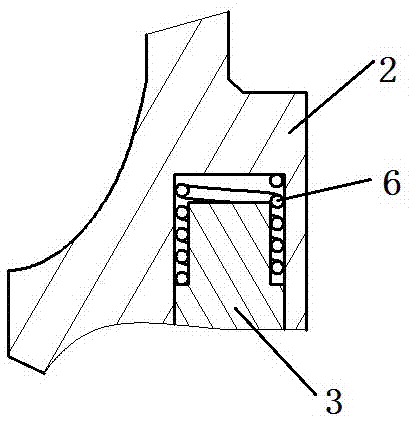

High-speed elastic damping false twister spindle based on sensor technology

ActiveCN103409868AReduce radial and axial vibrationsEliminate axial playTextiles and paperYarnExternal circuit

The invention discloses a high-speed elastic damping false twister spindle based on the sensor technology. The high-speed elastic damping false twister spindle based on the sensor technology comprises a mandrel, two sets of steel balls which are arranged on the radial outer side of the mandrel, and a big outer ring which is used for fixing the steel balls on the mandrel, wherein a small outer ring is arranged between each set of steel balls and the big outer ring, all the steel balls are fixed in the big outer ring through the small outer rings, a spring is arranged between one small outer ring and the big outer ring in the axial direction, and the spring axially and tightly presses the small outer rings. Due to the facts that the small outer rings are arranged between the steel balls and the big outer ring, plastic damping sleeves are arranged between the small outer rings and the big outer ring in an embedded mode to reduce radial vibration and axial vibration, and the spring which is arranged between the small outer ring and the big outer ring in a connected mode is arranged in the axial direction to eliminate the axial clearance, stable working of the high-speed elastic damping false twister spindle is ensured, and stability of spinning products is ensured. Due to the fact that a vibration sensor is in cooperation with an external circuit to carry out real-time online detection on vibration parameters of a false twister, the faults of the high-speed elastic damping false twister spindle can be predicted, and the spinning technology can also be adjusted according to the vibration parameters to achieve optimization of quality of yarn.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

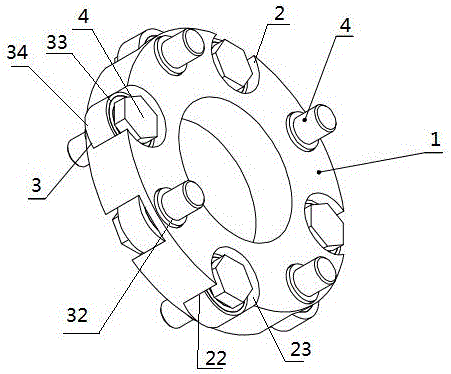

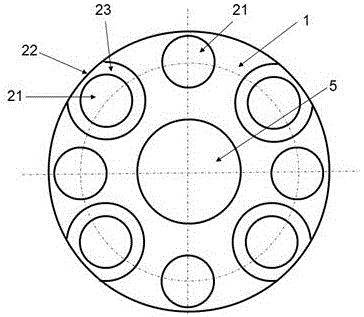

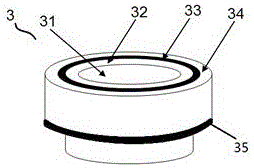

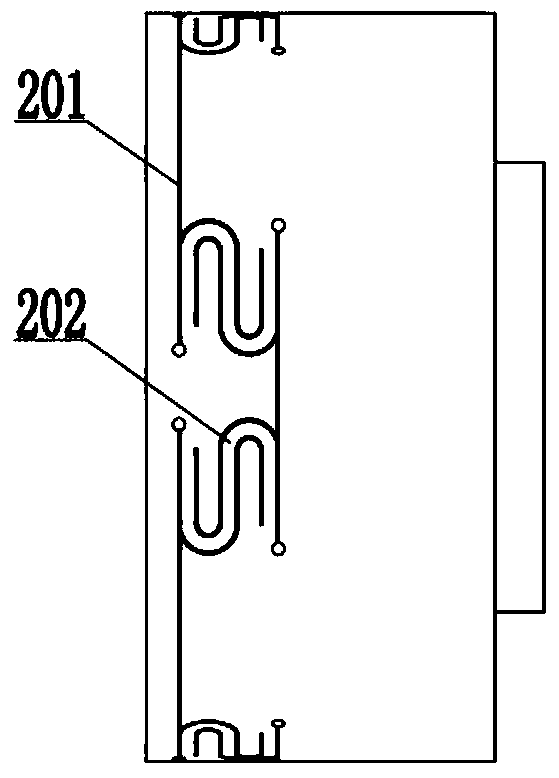

Vibration and noise reduction flange

PendingCN106050946ACut off the delivery pathReduce axial displacementNon-rotating vibration suppressionCouplings for rigid shaftsAxial displacementEngineering

The invention discloses a flange. The flange comprises a flange plate and a first connecting unit, wherein the flange plate comprises a flange hole formed in the center of a circle and at least one connecting groove, the first connecting unit is positioned in the connecting groove and is used for connecting a first element to one side surface of the flange plate, the first connecting unit comprises a bolt and a shock absorber which is positioned on the outer side of the bolt, the shock absorber is used for reducing axial displacement and axial vibration, and additionally, a noise transmission path can be cut off, so that the noise amplitude is reduced.

Owner:NINGBO HAITONG AUTO PARTS

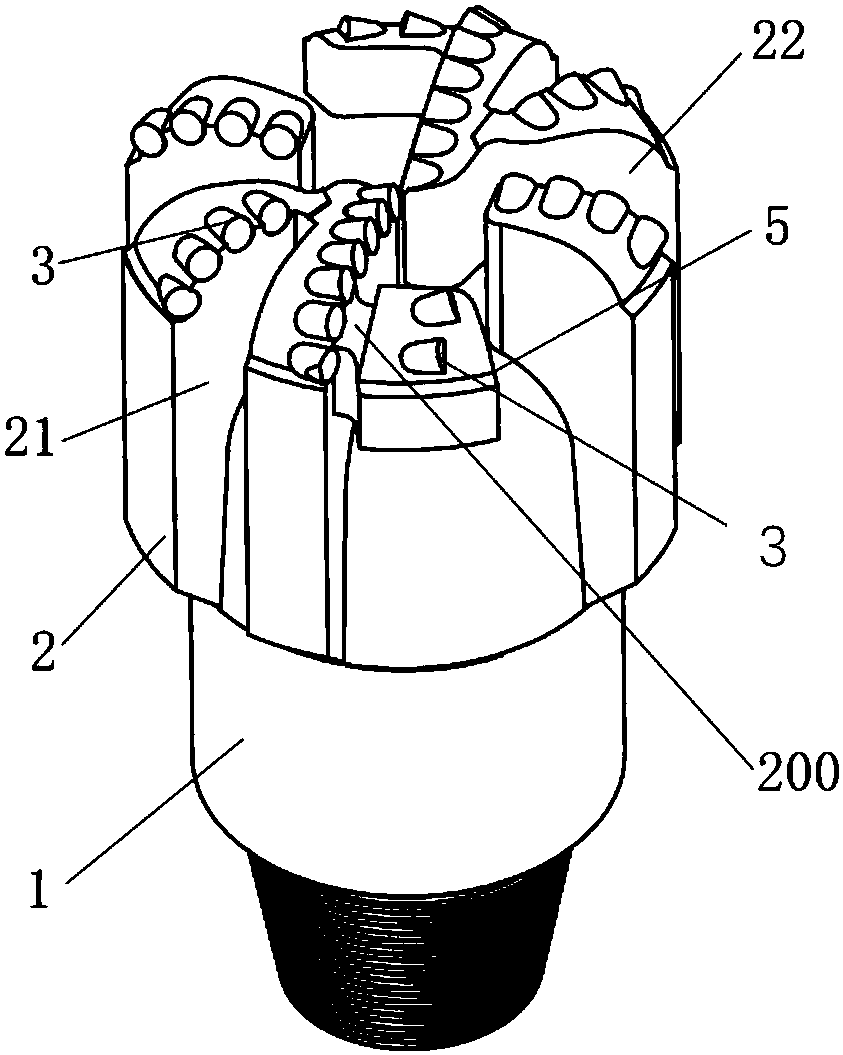

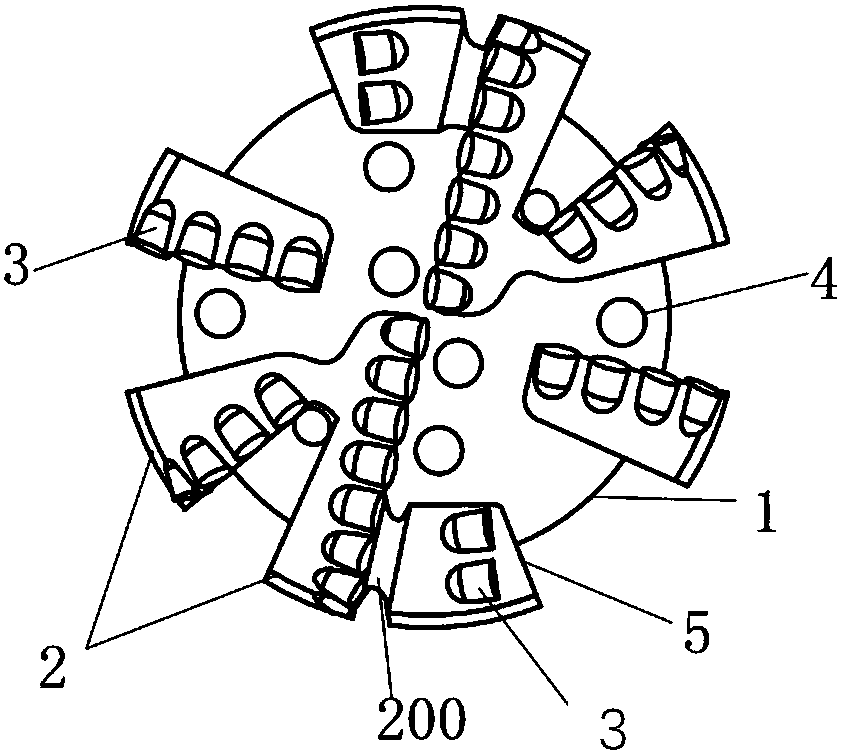

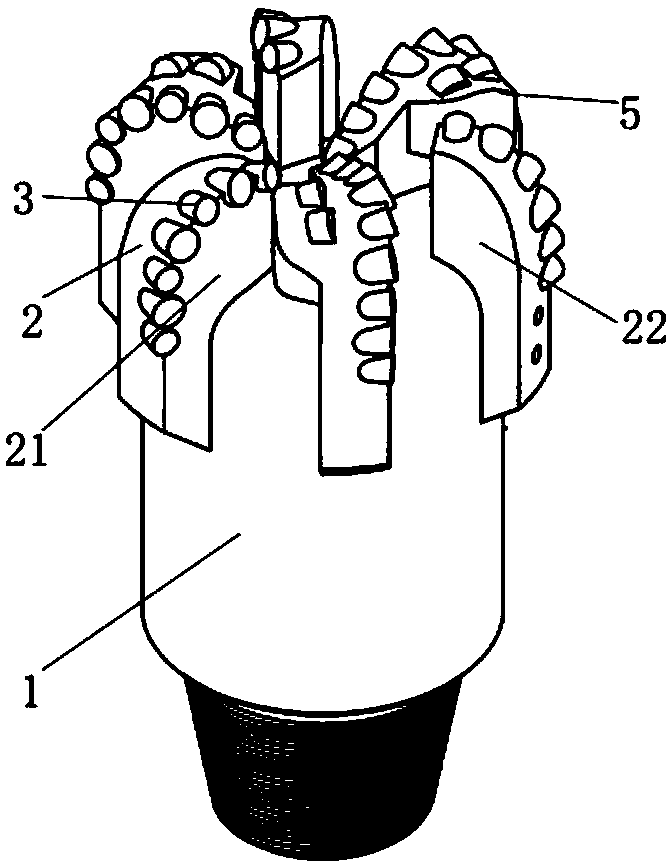

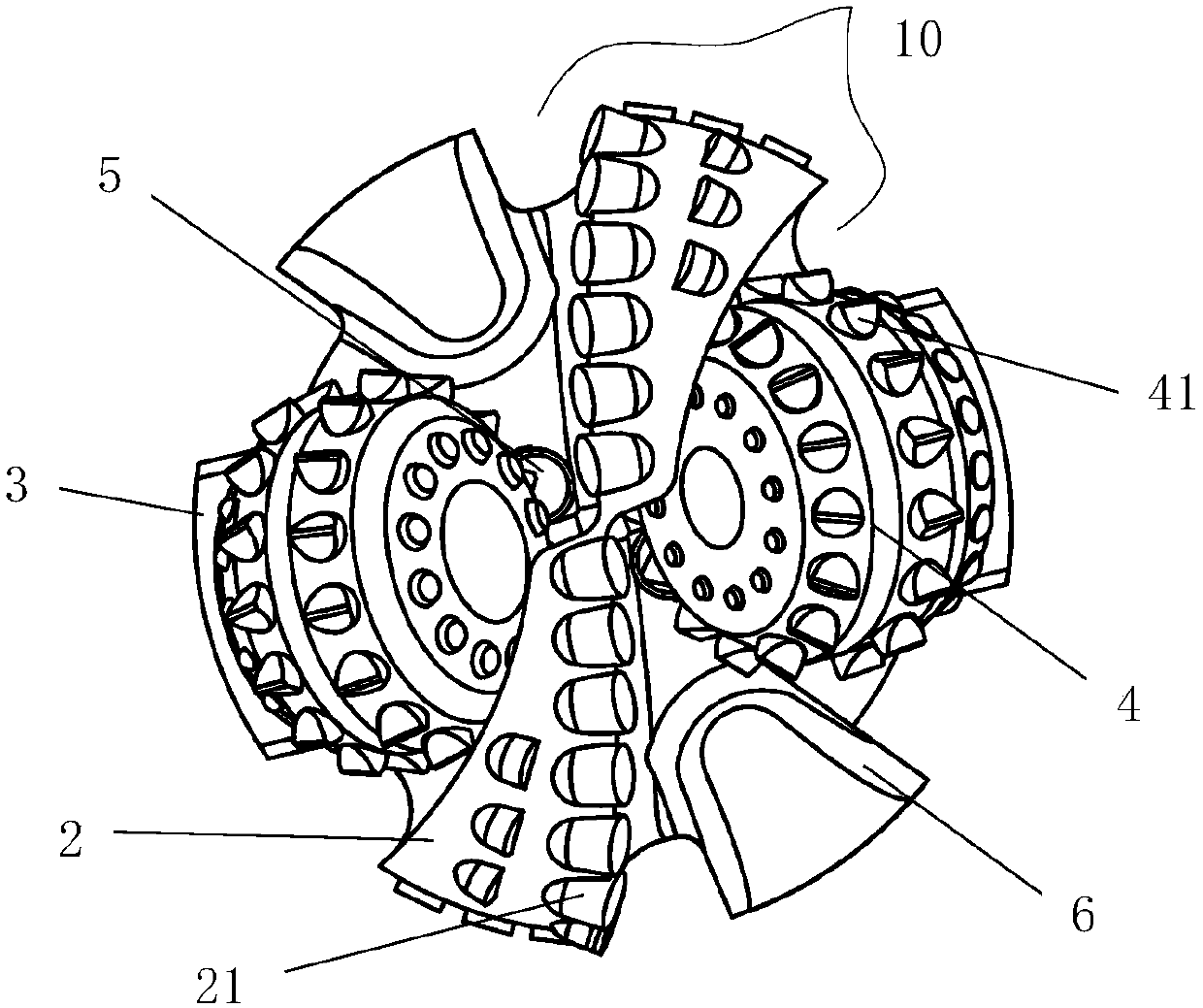

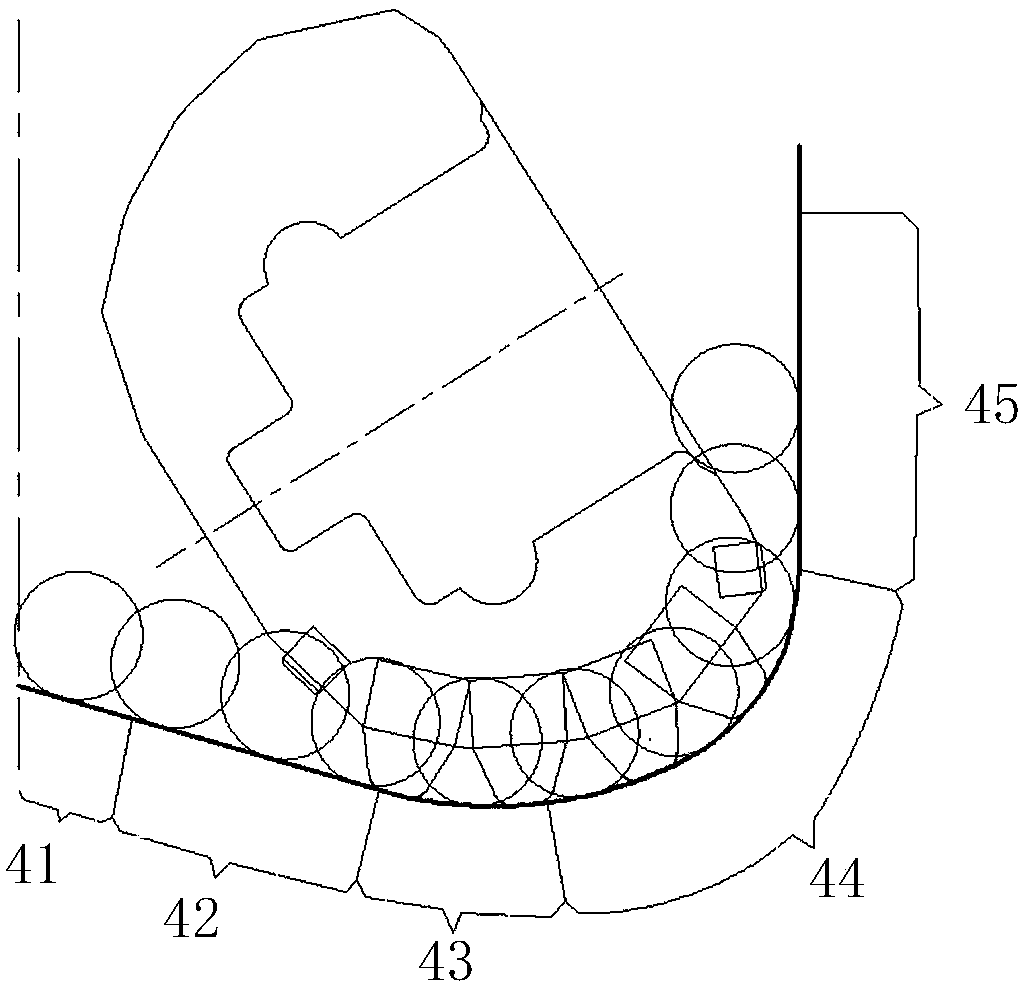

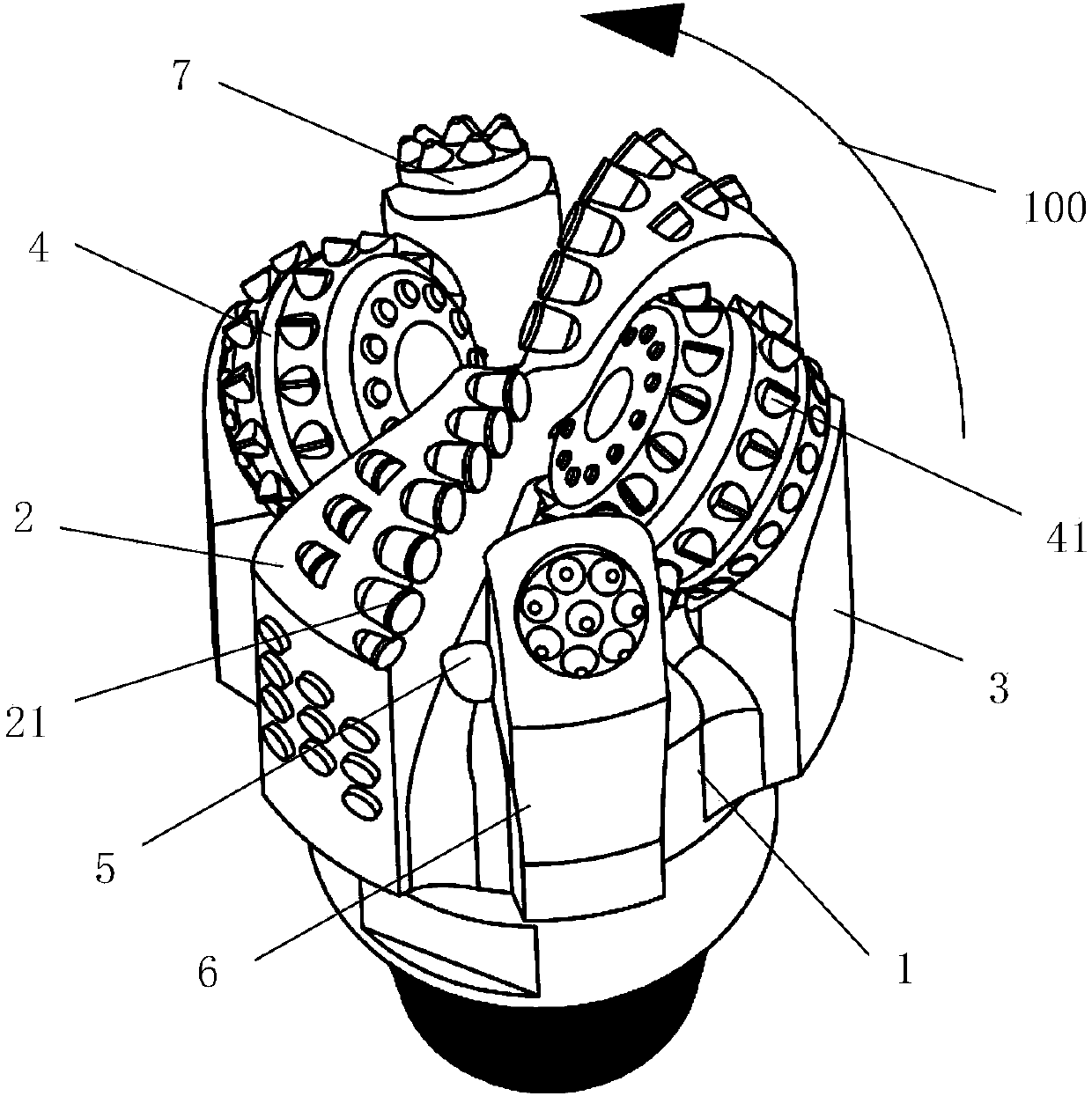

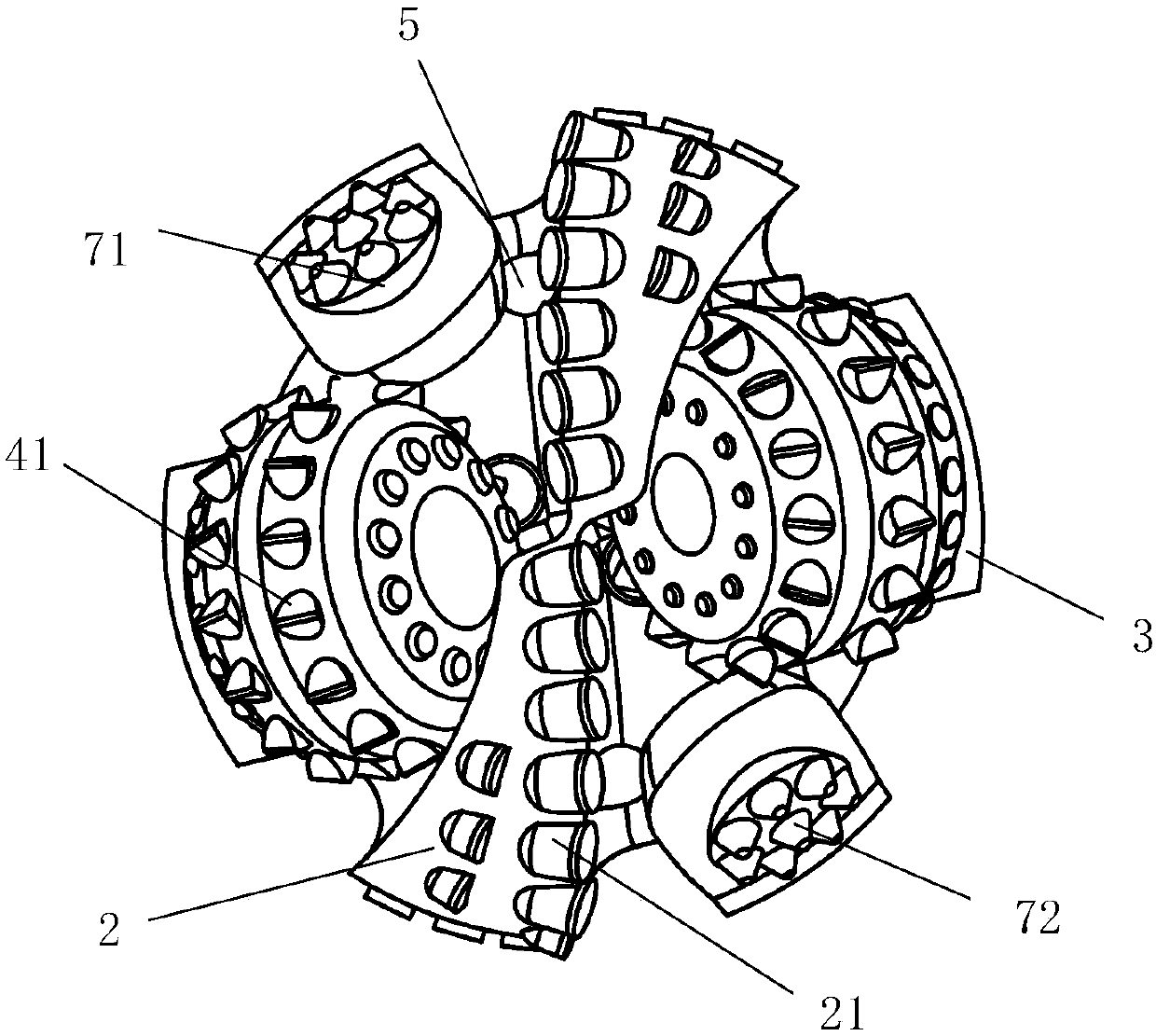

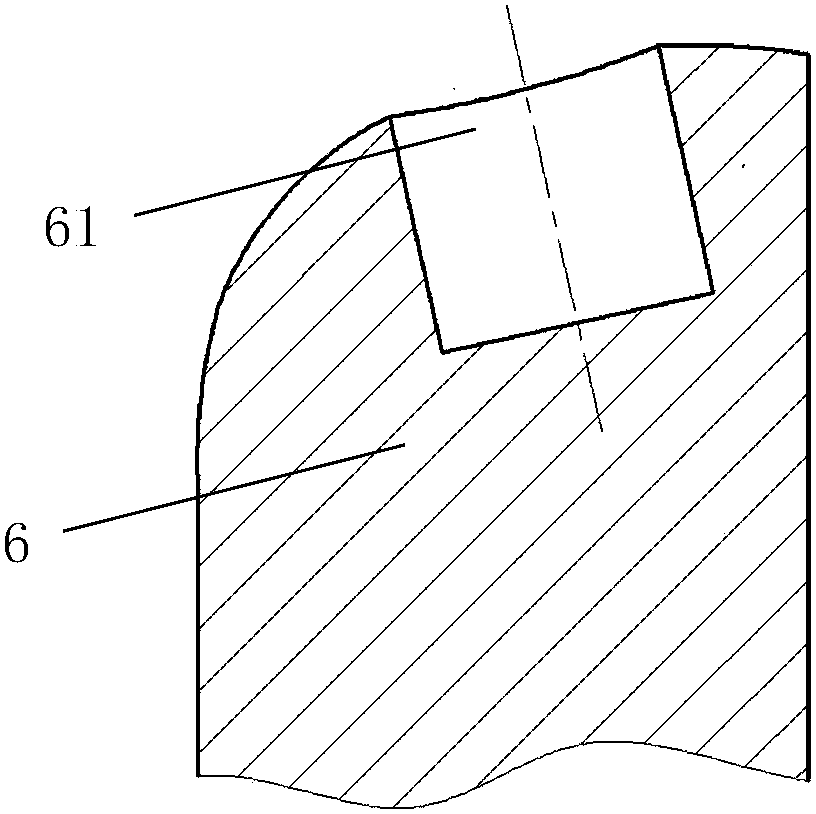

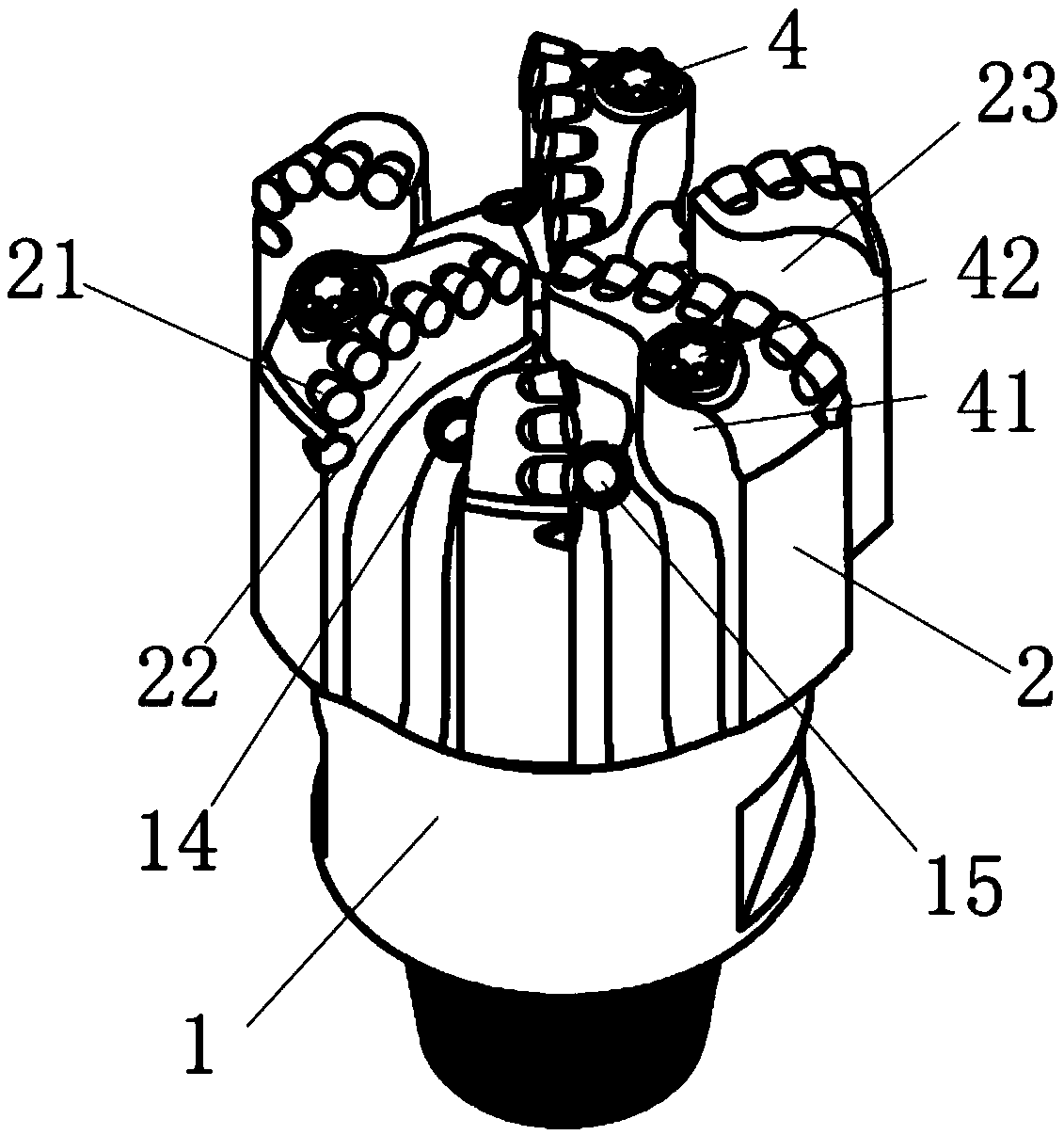

Composite diamond drill bit with fixed buffer structure

PendingCN110359852AReduce axial vibrationReduce spanEarth drilling toolsDrill bitsPetroleum engineeringDrill bit

The invention discloses a composite diamond drill bit with a fixed buffer structure, and belongs to the field of drilling. The drill bit mainly comprises a drill bit body, multiple cutter wings and atleast two tooth palms extending from the drill bit body or fixed on the drill bit body, and at least two tooth wheels consisting of tooth wheel bodies and teeth, water holes or nozzles; the tooth wheels are rotationally connected with the tooth palms; and scraping teeth are arranged on the cutter wings. For any two adjacent tooth wheels, in the rotating direction of the drill bit, front tooth wheels are on the front side, and back tooth wheels are on the back side; at least one cutter wing is arranged in areas before the back tooth wheels and behind the front tooth wheels; a buffer base extending from the drill bit body or fixed on the drill bit body is arranged between the at last one cutter wing and the front tooth wheels; and a fixed buffer element is arranged on the buffer base. The drill bit can obviously reduce the impact vibration in the guide drilling process, reduces the impact failure of the scraping teeth, and improves the continuous drilling capacity.

Owner:SOUTHWEST PETROLEUM UNIV +1

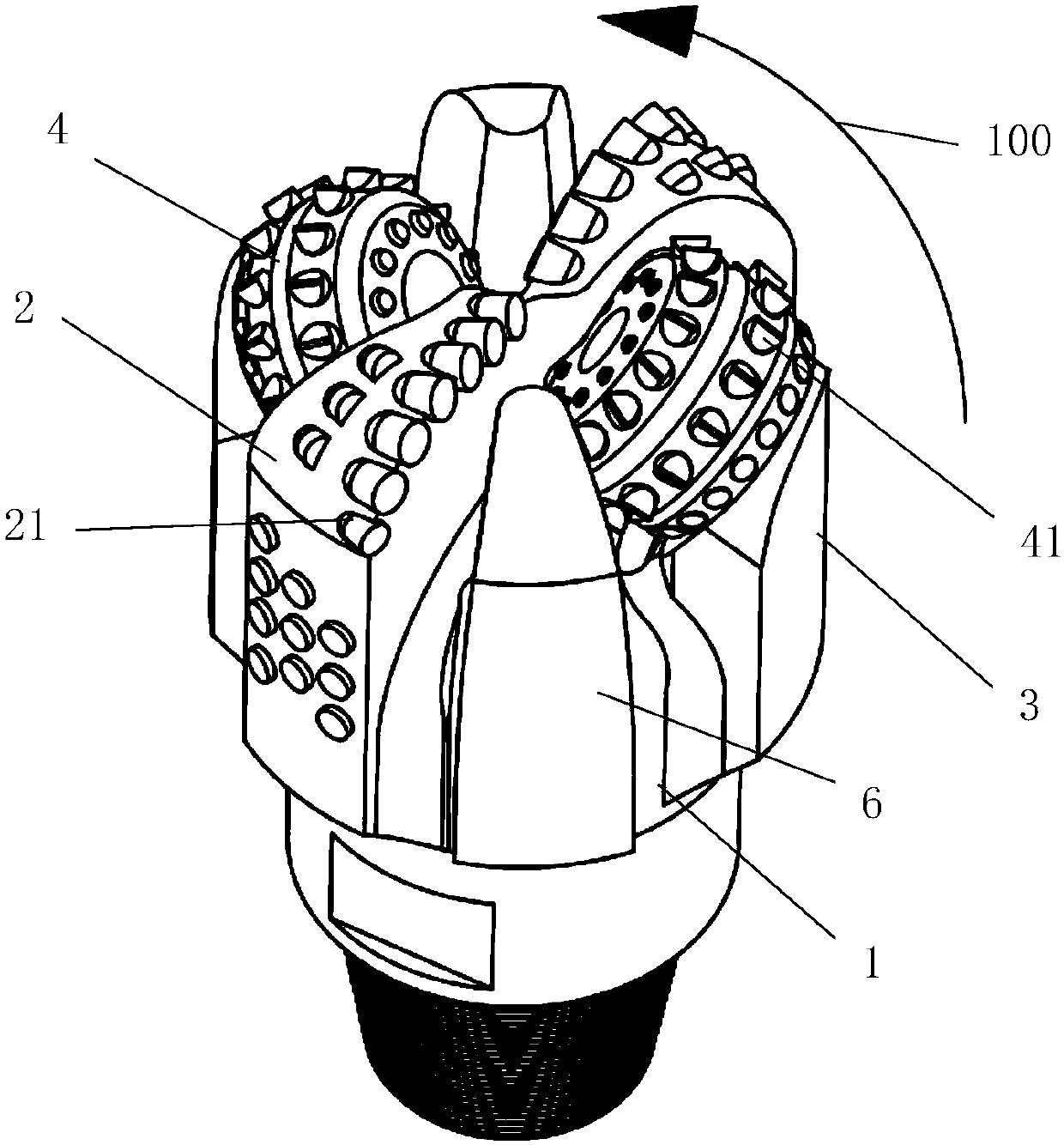

Combined type diamond bit with rotary buffer structure

PendingCN110359856AExtend working lifeUniform wearEarth drilling toolsDrill bitsEngineeringDrill bit

The invention discloses a combined type diamond bit with a rotary buffer structure, and belongs to the field of drilling. The bit mainly comprises a bit body, multiple blades and at least two tooth palms extending from the bit body or fixed to the bit body, at least two tooth wheels composed of tooth wheel bodies and teeth, water holes or nozzles; the tooth wheels are rotatably connected with thetooth palms, scraping teeth are arranged on the blades, for any two adjacent tooth wheels, in the rotating direction of the bit, the tooth wheel with the circumferential position close to the front isthe front tooth wheel, the tooth wheel with the circumferential position close to the back is the rear tooth wheel, at least one blade is arranged on the area in front of the rear tooth wheel and behind the front tooth wheel, a buffer base extending from the bit body or fixed to the bit body is arranged between at least one blade and the front tooth wheel, and a rotary buffer element is arrangedon the buffer base. According to the bit, the impact vibration of the bit in the guide drilling process can be obviously reduced, impact failures of the scraping teeth can be reduced, and the continuous drilling capacity of the bit can be improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

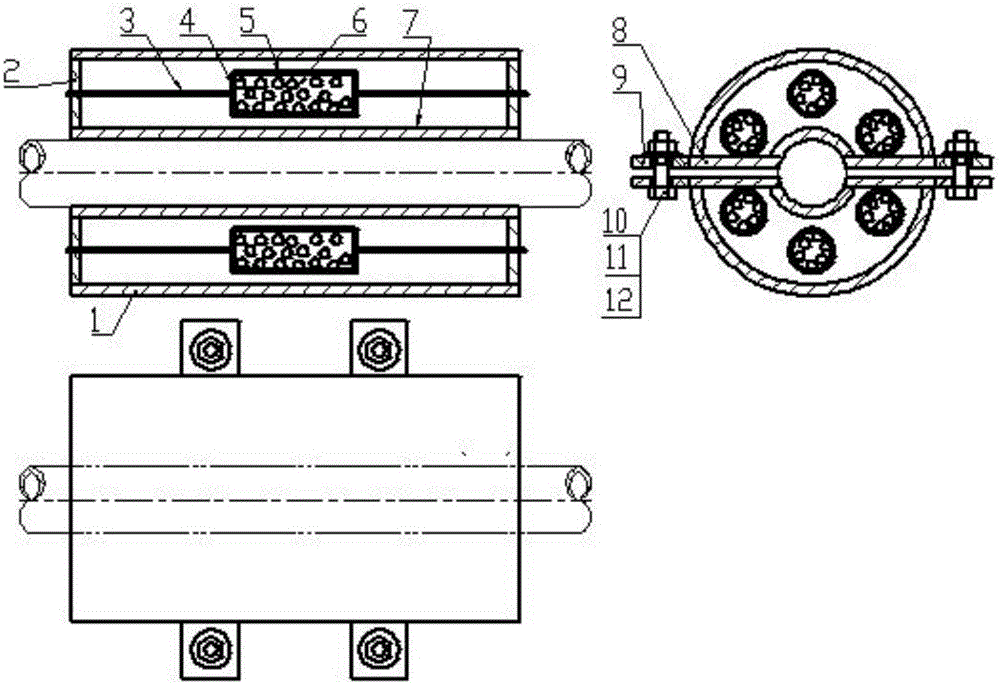

Multidirectional vibration damping device for fluid conveying pipeline

ActiveCN106678485AReduce vibrationGood vibration dampingPipe elementsShock absorbersVibration attenuationSteel ball

The invention discloses a multidirectional vibration damping device for a fluid conveying pipeline. The multidirectional vibration damping device comprises two parts which are the same in structure. Each part comprises an outer shell, an end cover A, minitype absorbers, an inner shell, a cover plate and a connecting plate, wherein the multiple minitype absorbers are arranged in an inner cavity of the outer shell; each minitype absorber comprises steel wires, end covers B, a cylinder and steel balls, wherein the end covers B are welded to the cylinder, the steel balls are arranged in the cylinder, and the two steel wires are welded to the two end covers B respectively; the steel wires are welded to the end cover A so that the end cover A, the outer shell and the inner shell can be welded into a whole; the cover plate seals an inner cavity formed by the end cover A, the inner shell and the outer shell and is welded to the end cover A, the inner shell and the outer shell into a whole; and the connecting plate and the cover plate are a whole. The inner shells of the two parts of the multidirectional vibration damping device are tightly attached to the outer wall of the pipeline, the connecting plates are fastened together by thread fastening pieces, and vibration attenuation for the pipeline is achieved. The multidirectional vibration damping device is simple in structure, convenient to use, capable of reducing radial vibration and axial vibration of the pipeline and suitable for space pipeline vibration attenuation.

Owner:HT METALFORMING EQUIP MFG

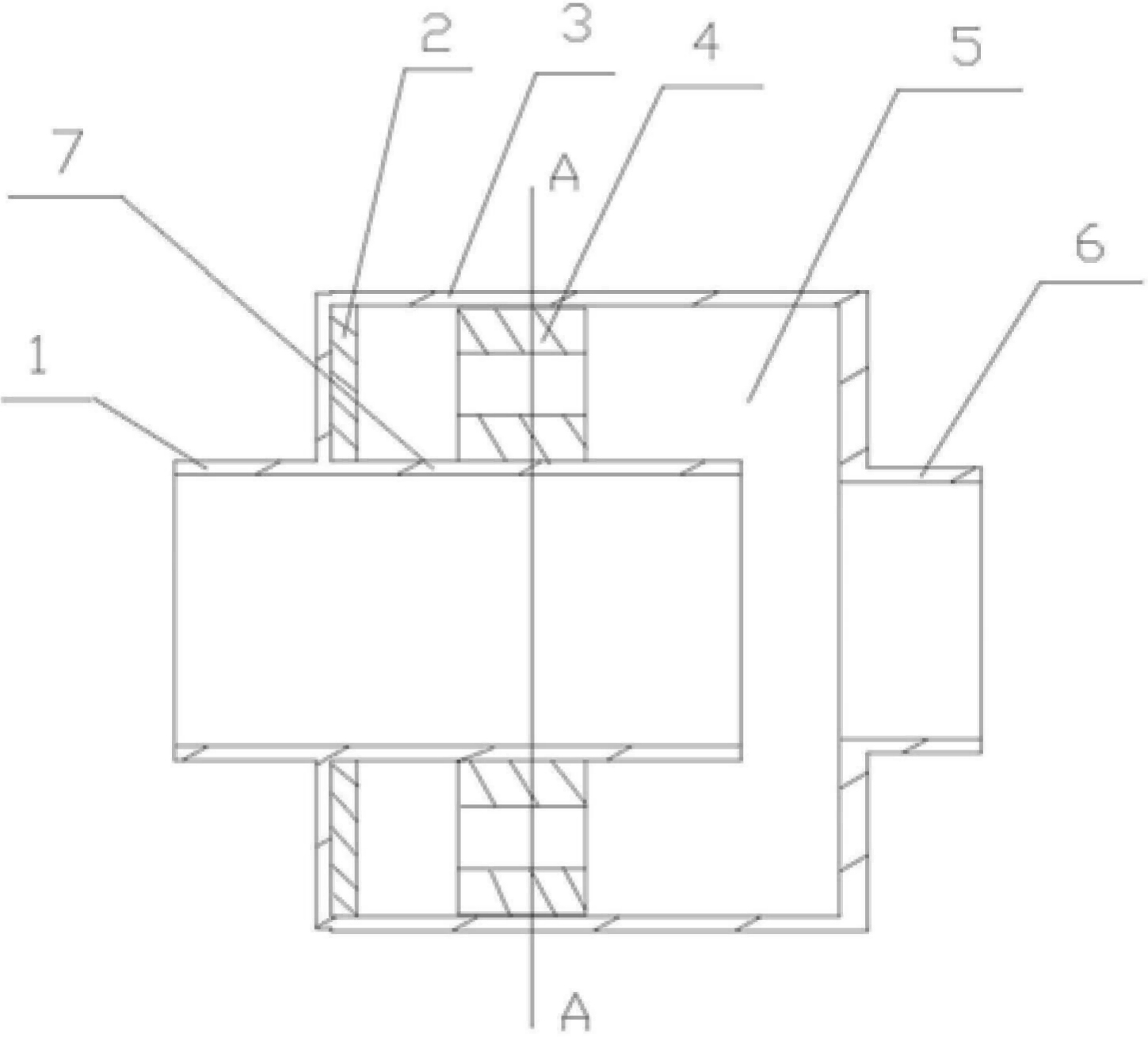

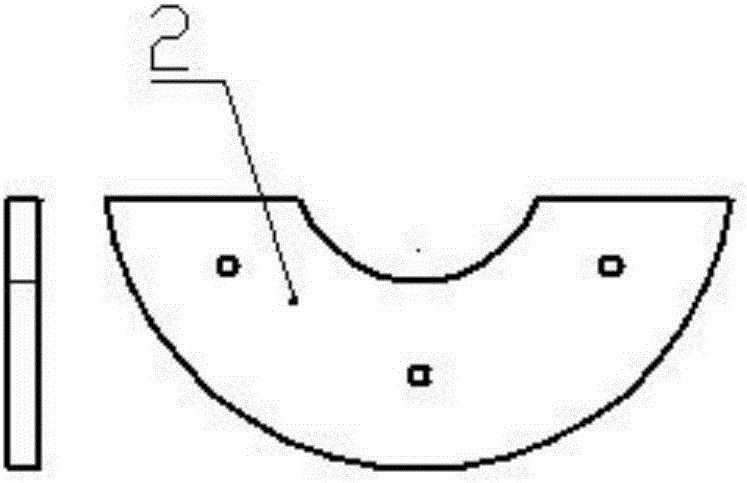

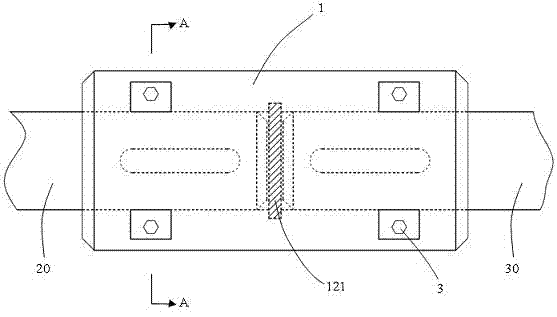

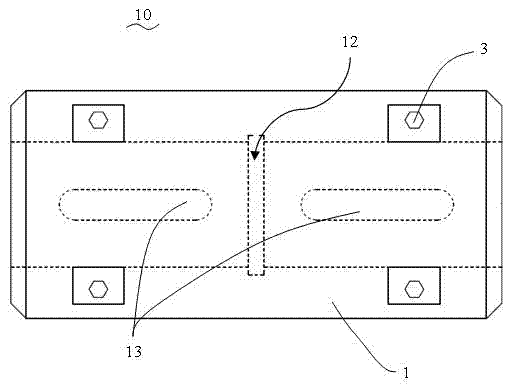

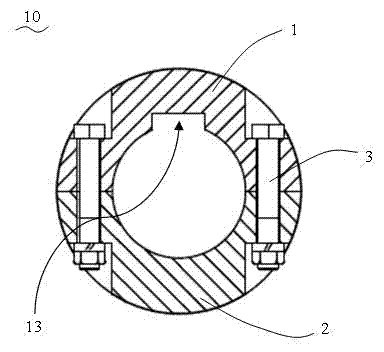

Coupler for clamping shell

InactiveCN102829094AReduce axial vibrationExtended service lifeCouplings for rigid shaftsEngineeringRotational molding

The invention provides a coupler for a clamping shell, which comprises a first clamping shell, a second clamping shell and a bolt, wherein the first clamping shell and the second clamping shell are divided along an axial direction and are buckled with each other; four first through holes are arranged on the first clamping shell; four second through holes are arranged on the second clamping shell; the first through holes and the second through holes are continuously communicated with each other; the bolt continuously passes through the first through holes and the second through holes, so as to fixedly buckle and hold the first clamping shell and the second clamping shell; semicircular grooves which are buckled with each other are respectively arranged on inner walls of the first clamping shell and the second clamping shell, so as to form a continuous circular groove; and an elastic gasket is embedded in the circular groove. Through such a structure, the axial vibration generated between a driving shaft and a driven shaft is reduced, the service life of the coupler for the clamping shell is prolonged and the service life of rotational molding equipment is also prolonged.

Owner:无锡市华润环保设备有限公司

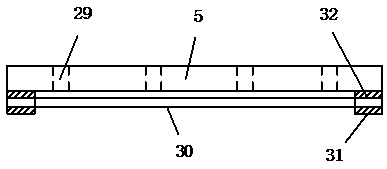

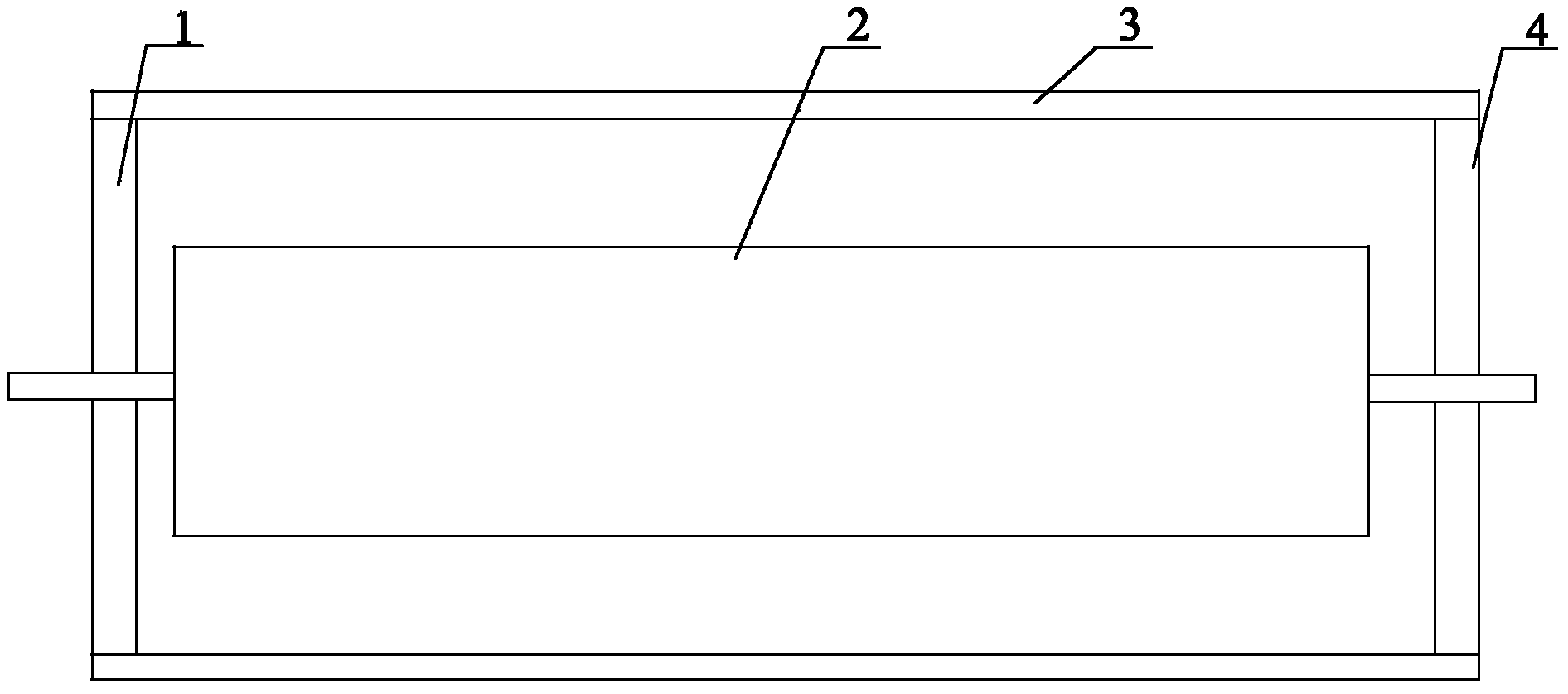

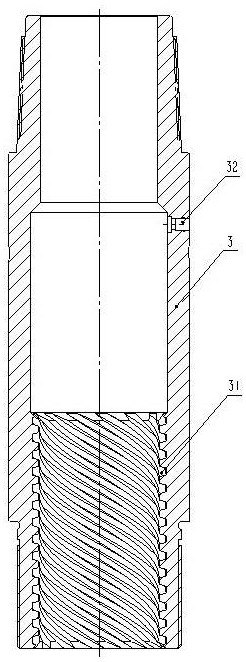

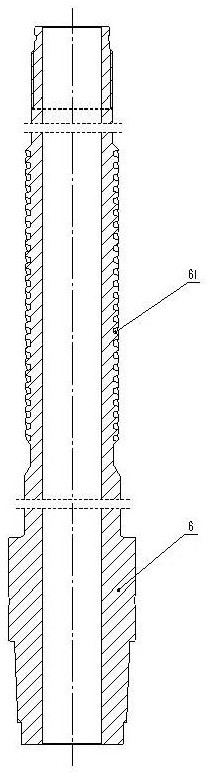

Fixing device for optical fiber hydrophone

InactiveCN103438979AImprove acoustic sensitivityReduce axial vibrationVibration measurement in fluidHydrophoneElastic vibration

The invention relates to a fixing device for an optical fiber hydrophone. The fixing device for the optical fiber hydrophone is composed of an optical fiber hydrophone protection outer shell, a front portion encapsulating component and a rear portion encapsulating component. The fixing device for the optical fiber hydrophone is characterized in that the front portion encapsulating component and the rear portion encapsulating component are fixed at the two ends of the optical fiber hydrophone respectively, and then the front portion encapsulating component and the rear portion encapsulating component are further fixed on the optical fiber hydrophone protection outer shell respectively. According to the fixing device for the optical fiber hydrophone, the optical fiber hydrophone is made not to make direct contact with the optical fiber hydrophone protection outer shell through the elastic vibration reducing front portion encapsulating component and the elastic vibration reducing rear portion encapsulating component, therefore, when the optical fiber hydrophone works, axial vibration and axial acceleration which are transmitted when the optical fiber hydrophone drag linear array is in a moving state can be reduced through the elastic vibration reducing front portion encapsulating component and the elastic vibration reducing rear portion encapsulating component, and thus the sound sensitivity of the optical hydrophone can be improved.

Owner:武汉普惠海洋光电技术有限公司

Bearing component of molecular pump

ActiveCN101608637AReduce feverReduce contact areaPump componentsAxial flow pumpsEngineeringMechanical engineering

Owner:KYKY TECH

Low-torque diamond drill bit

PendingCN110145238AProne to damageLimit eatingEarth drilling toolsConstructionsSpray nozzleHigh torque

The invention discloses a low-torque diamond drill bit, and belongs to the field of drilling. The low-torque diamond drill bit comprises a drill bit body, multiple blades which stretch from the drillbit body or are fixed to the drill bit body, water holes or spray nozzles and passageways. At least one blade is provided with hanging cutting teeth, at least one blade is only provided with a normalwheel unit, or bases and / or a base stretching from the blade are / is arranged at the front end and / or the rear end of the at least one blade, and normal wheel units are arranged on the bases. The working torque of the drill bit under complex working conditions can be remarkably reduced, overloading or premature failure, caused by too high torque of the drill bit, of the drill bit and matching toolsis reduced, the working stability of the drill bit is improved, and the service life of the drill bit is prolonged. Especially, during directional drilling, by means of the low-torque PDC drill bit,the adjusting time of tool surfaces during directional sliding drilling can be shortened.

Owner:SOUTHWEST PETROLEUM UNIV +1

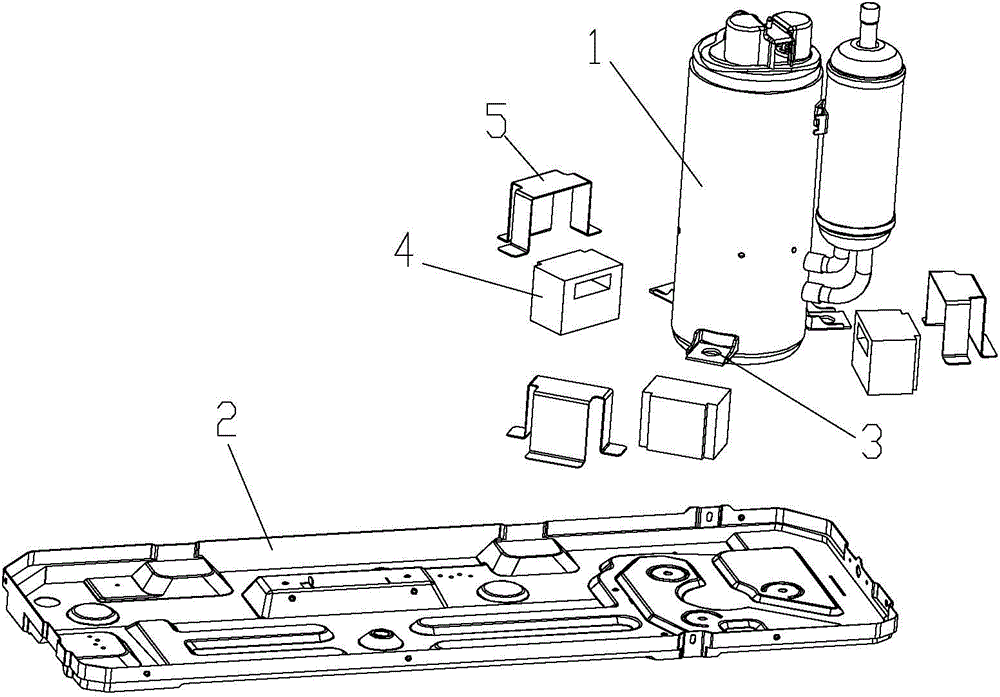

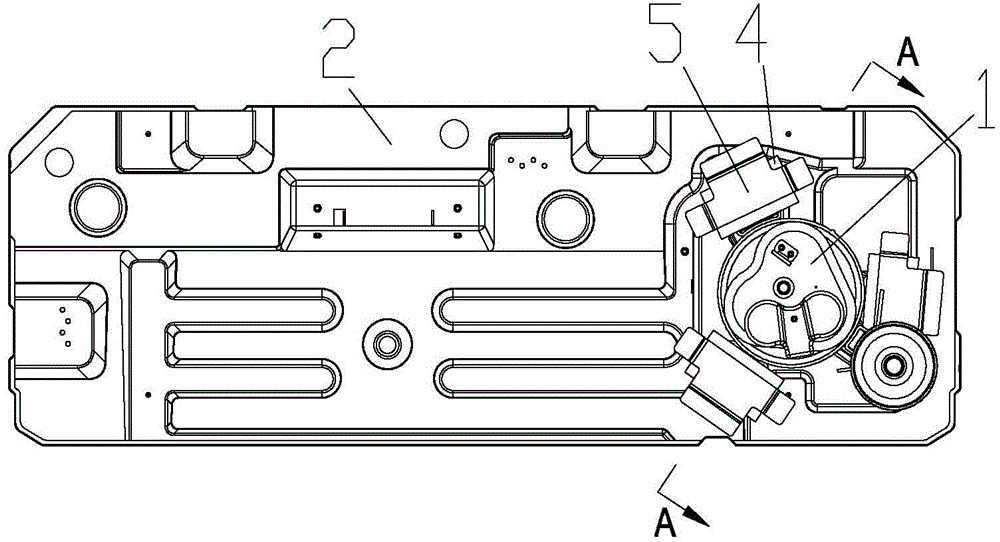

Vibration attenuation mounting structure and compressor with same

InactiveCN105020803AReduce axial vibrationReduce vibrationLighting and heating apparatusAir conditioning systemsVibration attenuationStructural engineering

The invention provides a vibration attenuation mounting structure and a compressor with the same. The vibration attenuation mounting structure is used for mounting a piece to be fixed on a bottom tray and comprises foundation feet connected with the piece to be fixed, crash pads in inserted fit with the foundation feet and fixing pieces used for fixing the crash pads on the bottom tray. The foundation feet and the fixing pieces are arranged away from the ground in a spaced mode. According to the technical scheme, the foundation feet are inserted in the crash pads, and the crash pads attenuate the axial vibration and tangential vibration of the piece to be fixed.

Owner:GREE ELECTRIC APPLIANCES INC

Novel tricone bit

The invention relates to a novel tricone bit which comprises three palms and cones arranged at the lower ends of the palms. The three palms form a drill bit body through welding. The novel tricone bit is characterized in that at least one palm which is movable in the axial direction exists, and each palm is composed of fixed jaws and a movable bearing. After the scheme is adopted, bit pressure among the three cones can be distributed again according to formation conditions; axial vibration of the bit is reduced, and the stability of the bit is improved; due to the fact that the cones move in the axial direction, impacting rock breaking can be generated, the rock breaking efficiency of the bit is improved, the complex cones are decomposed into the fixed jaws and the movable bearings, and the novel tricone bit is convenient to manufacture and low in cost.

Owner:SOUTHWEST PETROLEUM UNIV

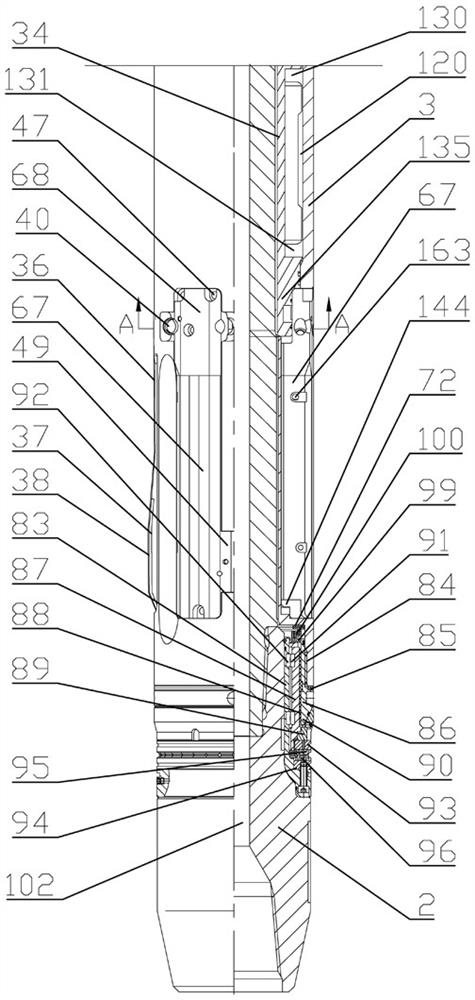

Constant-pressure and constant-torque tool for well drilling

PendingCN113863873AAchieve a soft landingAvoid impact damageDrilling rodsDrilling casingsWell drillingUpper joint

The invention discloses a constant-pressure and constant-torque tool for fluid well drilling. The constant-pressure and constant-torque tool comprises an upper joint, an upper shell, a middle shell, a lower shell, a lower joint, a compensation joint, a mandrel, a limiting baffle ring, a piston, a nut, a first disc spring group, a second disc spring group and a third disc spring group, the mandrel is provided with an inner through hole, a mandrel bypass hole and a limiting step, the first disc spring group and the second disc spring group are mounted in the upper shell, the third disc spring group is mounted in the compensation joint, a multi-head thread groove and an oil injection hole are formed in the middle shell, a multi-head thread groove is formed in the outer portion of the lower joint, a combined sealing groove and an oil injection hole are formed in the lower shell, and a combined sealing groove is formed in the piston. The multi-head thread groove of the middle shell is engaged with the multi-head thread groove of the lower joint, so that compression torsion replacement is achieved, the energy storage function of the disc spring groups is combined, the purpose of constant pressure and constant torque is achieved, the tool is compact in structure and powerful in function, different drilling tools can be protected according to different mounting positions, and the purpose of stable drilling is achieved.

Owner:成都阿斯贝瑞科技有限公司

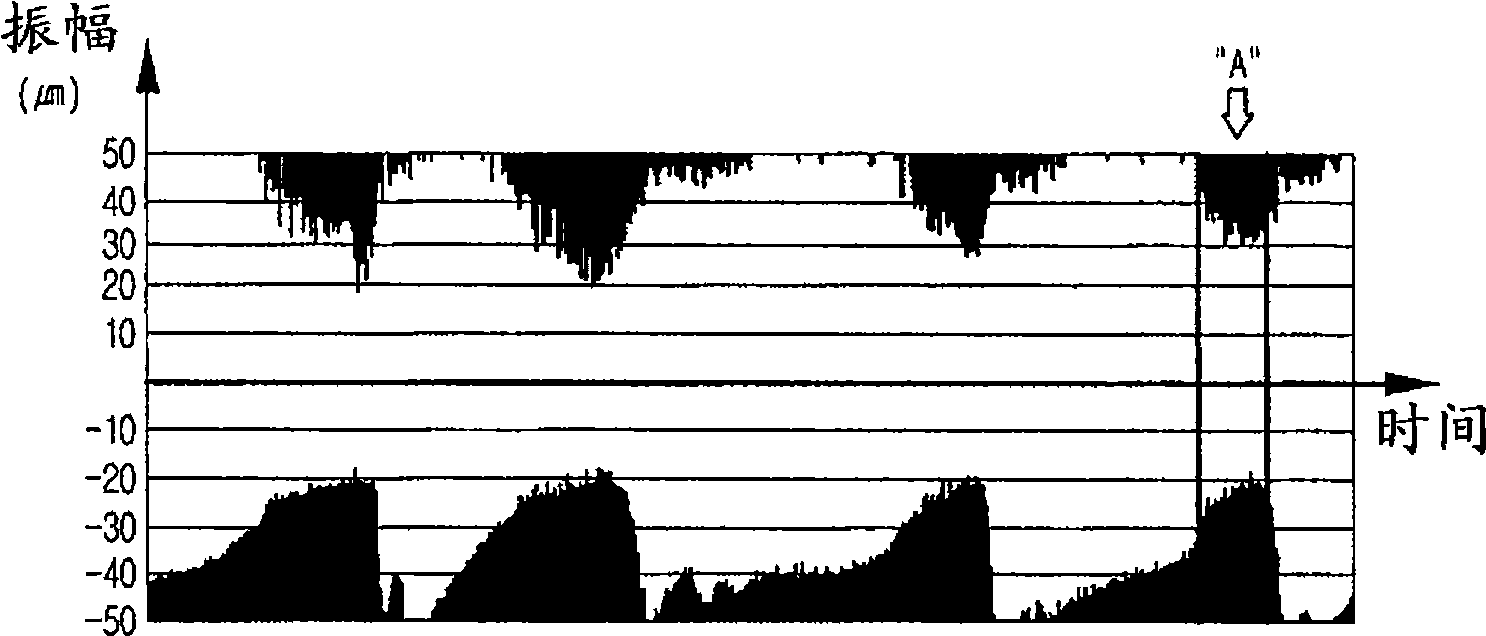

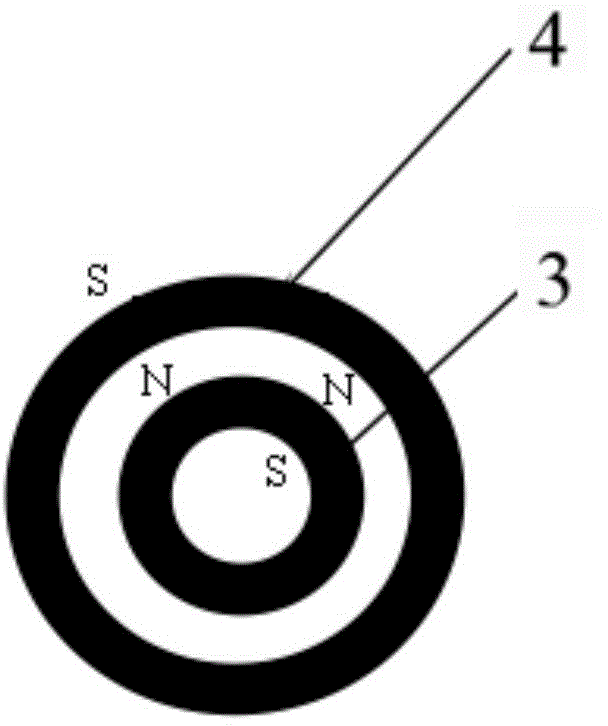

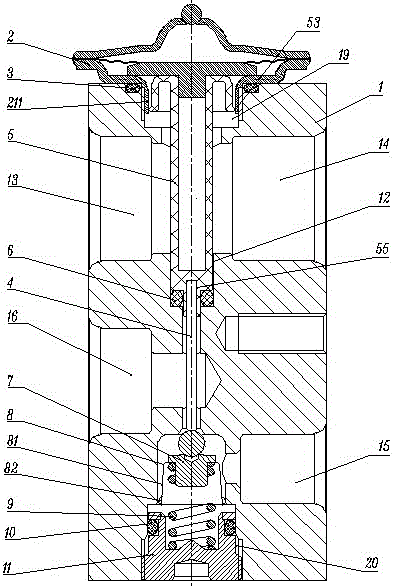

Method for reducing axial vibration of electric spindle of spinning machine

InactiveCN104313739AReduce vibrationReduce axial vibrationTextiles and paperElectric machineElectrical polarity

The invention relates to a method for reducing the axial vibration of an electric spindle of a spinning machine. The shaft extension of a rotating shaft of a motor rotor directly serves as a spindle blade which is inserted into a spindle foot; magnetic steel is inlaid on the outer side of the middle part of the spindle blade inserted into the spindle foot; a magnetic ring having the same polarity with the magnetic steel is arranged on the inner part of the spindle foot and opposite to the magnetic steel inlaid on the spindle blade; the magnetic ring and the magnetic steel are mutually staggered axially; the magnetic ring is closer to the motor rotor than the magnetic steel. According to the principle that the same magnetic polarity repels, the corresponding parts of the spindle blade and the spindle foot do not contact. By the method, the axial vibration of the spindle blade can be reduced, and the whole stability is enhanced.

Owner:DONGHUA UNIV

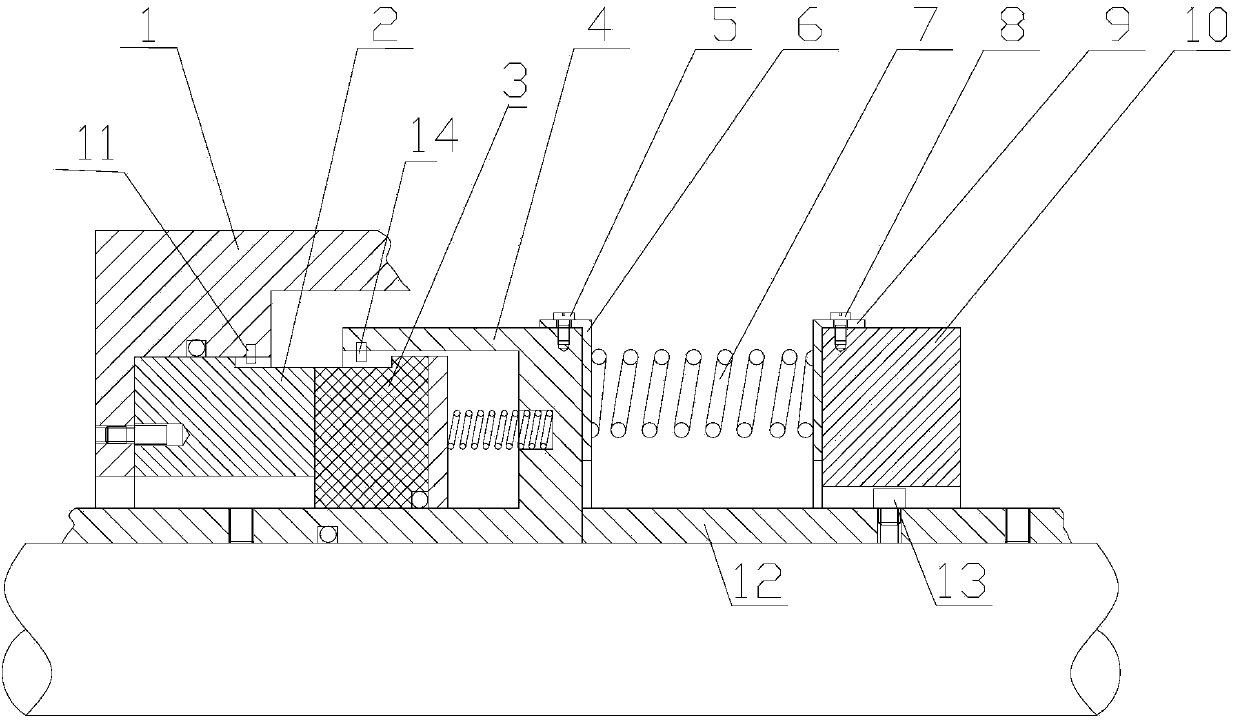

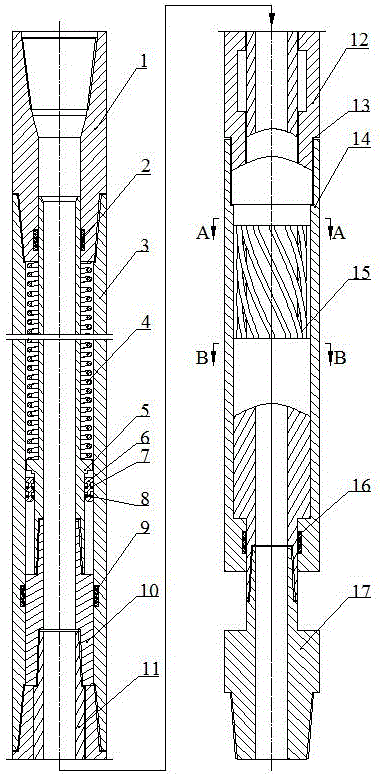

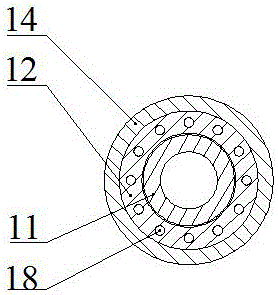

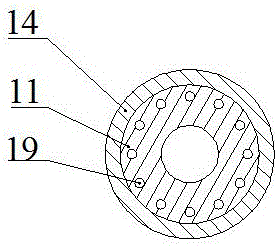

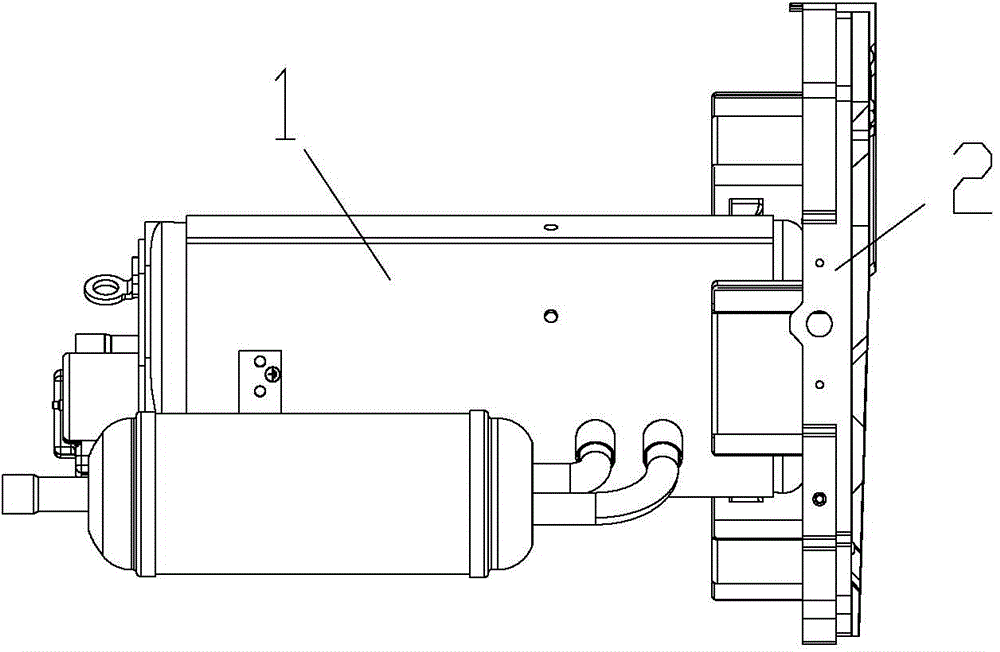

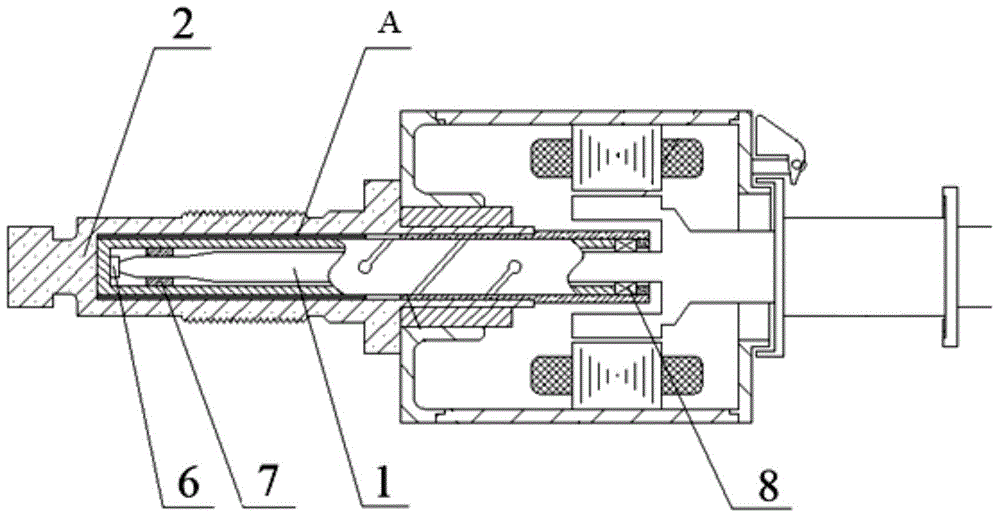

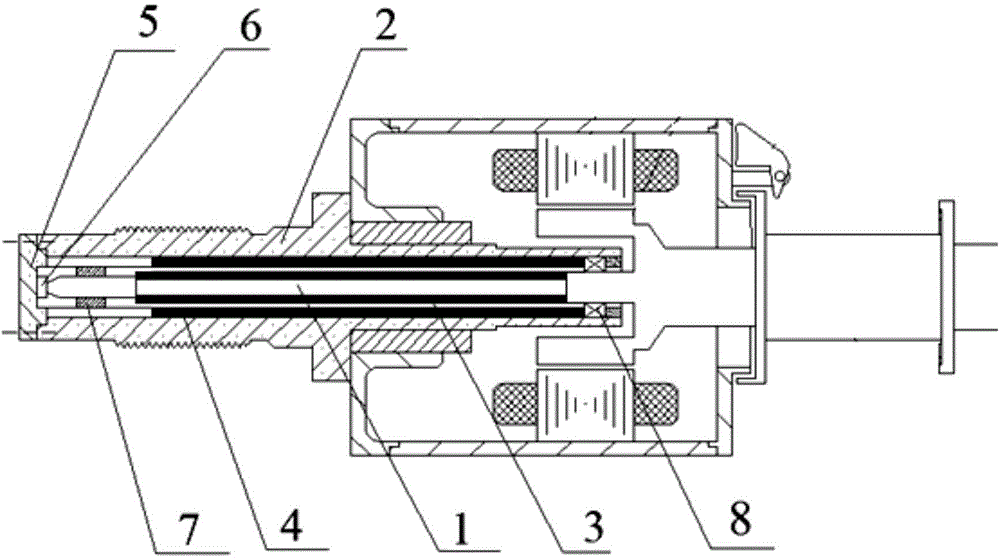

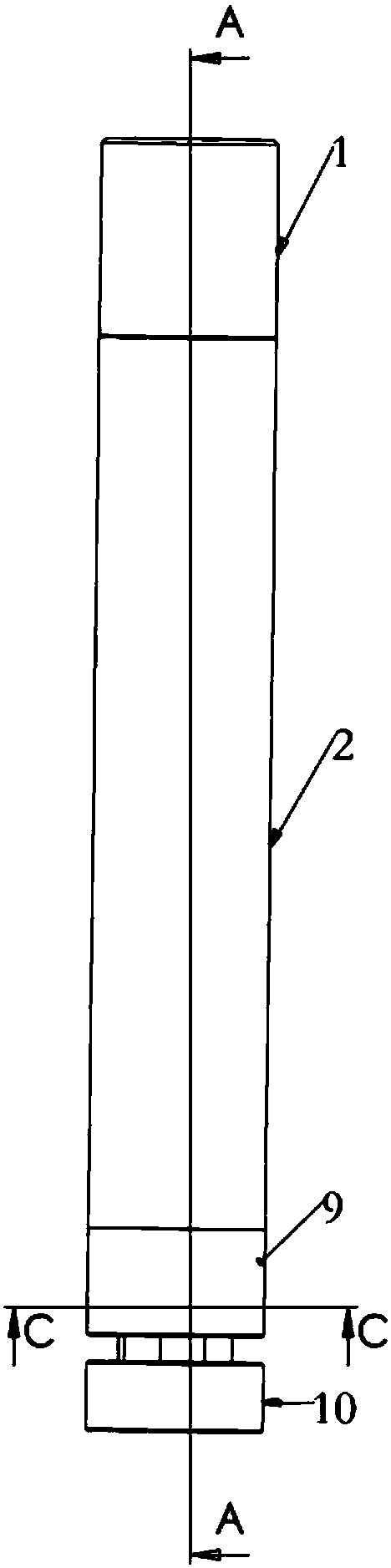

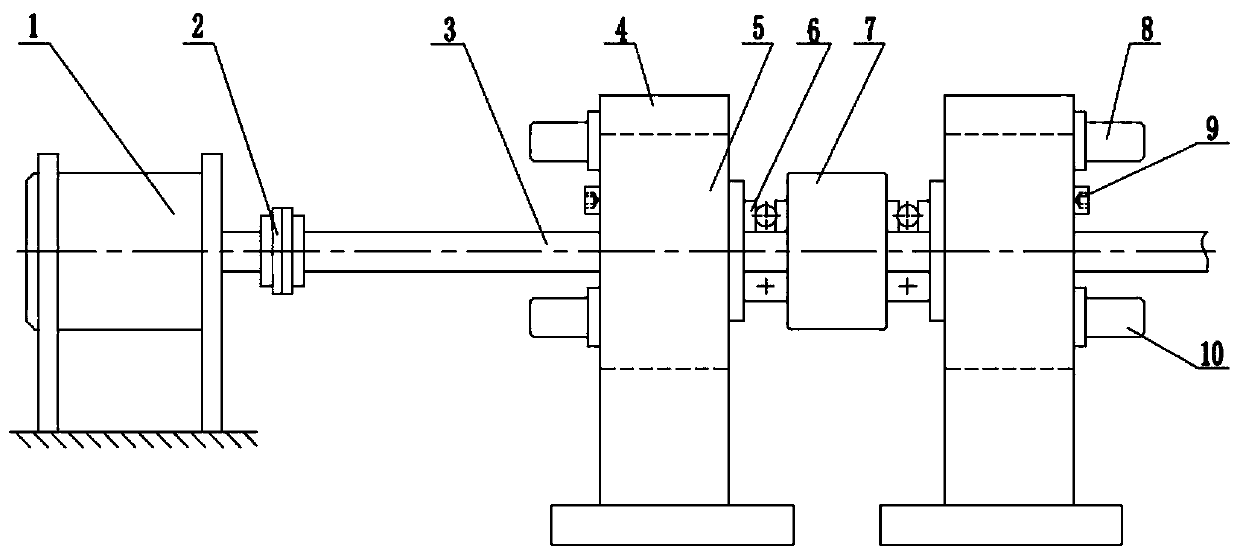

Hydraulic drilling and pressing device

ActiveCN109386242AReduce axial vibrationIncrease drilling speedDrilling rodsDrilling casingsPressure transmissionUpper joint

The invention provides a hydraulic drilling and pressing device, which comprises an upper joint connected with a drill rod; an outer cylinder, one end of the outer cylinder is connected with an upperjoint, a support, an elastic piece and a cylinder body are arranged in the outer cylinder, the elastic piece is arranged between the support and the cylinder body, when the support compresses the elastic piece under different pressures, the lower end of the support seat enters different parts of the stepped hole of the cylinder body so as to transmit different drilling pressures; and a lower jointassembly connected with the drill bit and provided with a torque transmission mechanism, which on the one hand provides connection with the outer cylinder and transmits torque through the torque transmission mechanism, and on the other hand transmits drilling pressure coming from the cylinder body to the drill bit through an internally arranged flow passage. The hydraulic drilling and pressing device can improve the transmitted drilling pressure value, realize the multi-stage adjustment of the one-stroke drilling pressure, improve the drilling pressure transmission efficiency, reduce the axial vibration of the drill bit and solve the drag pressure problem in the horizontal well.

Owner:CHINA PETROLEUM & CHEM CORP +1

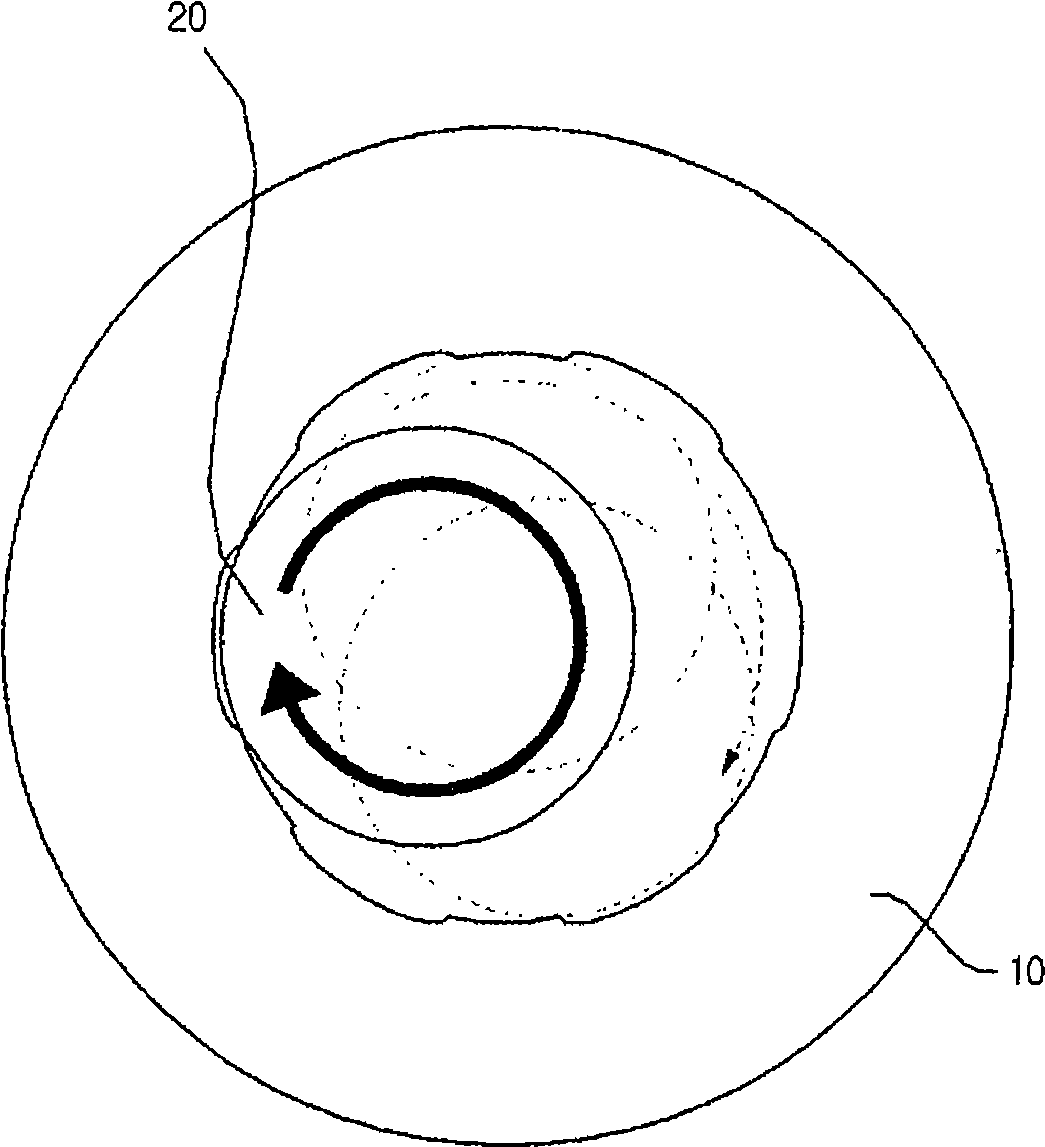

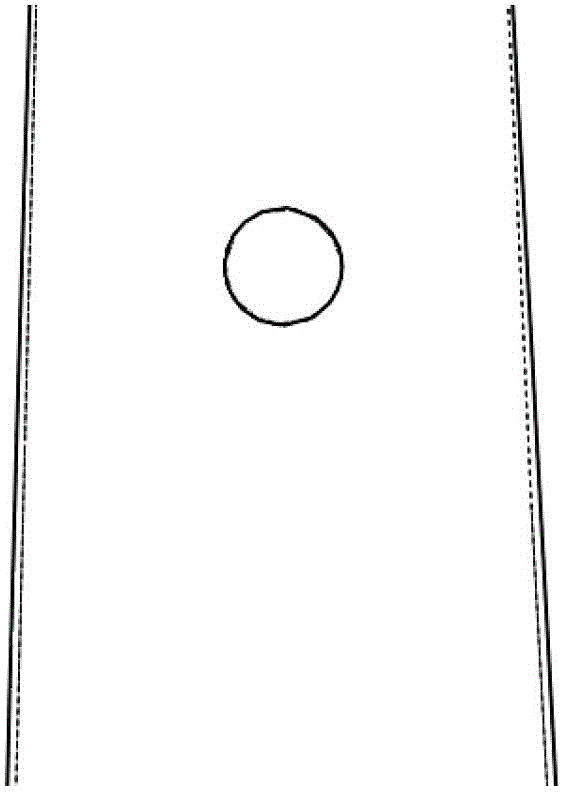

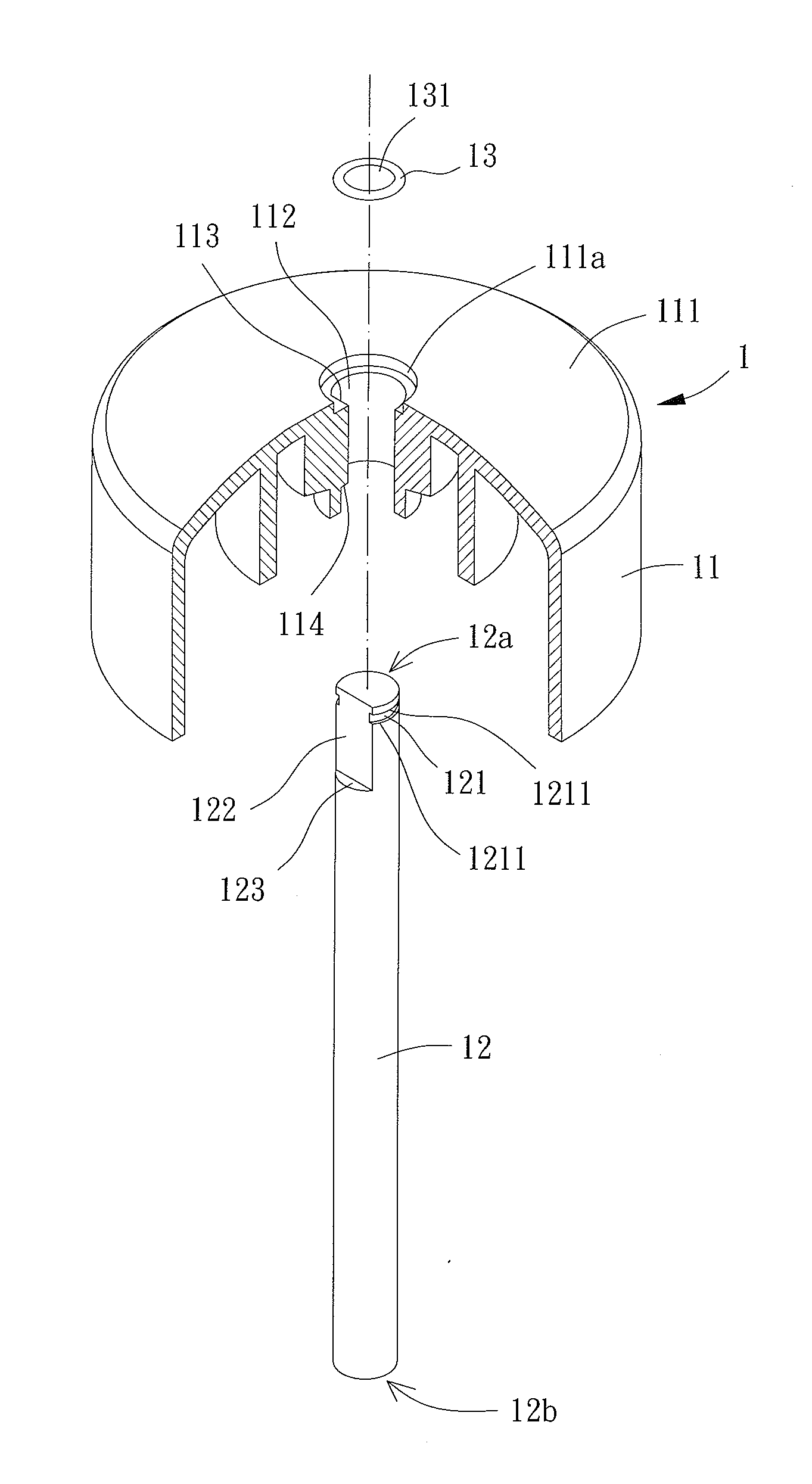

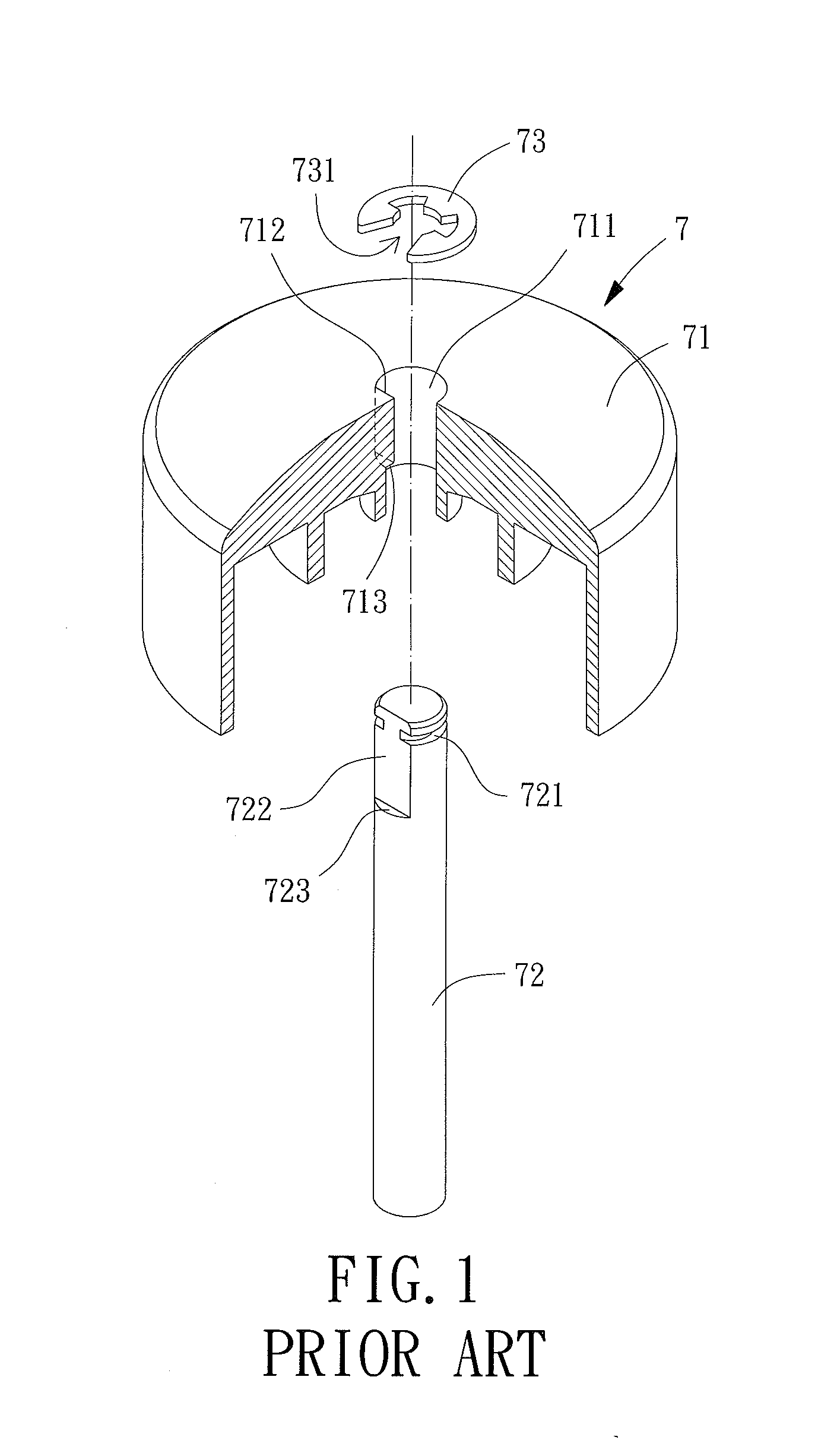

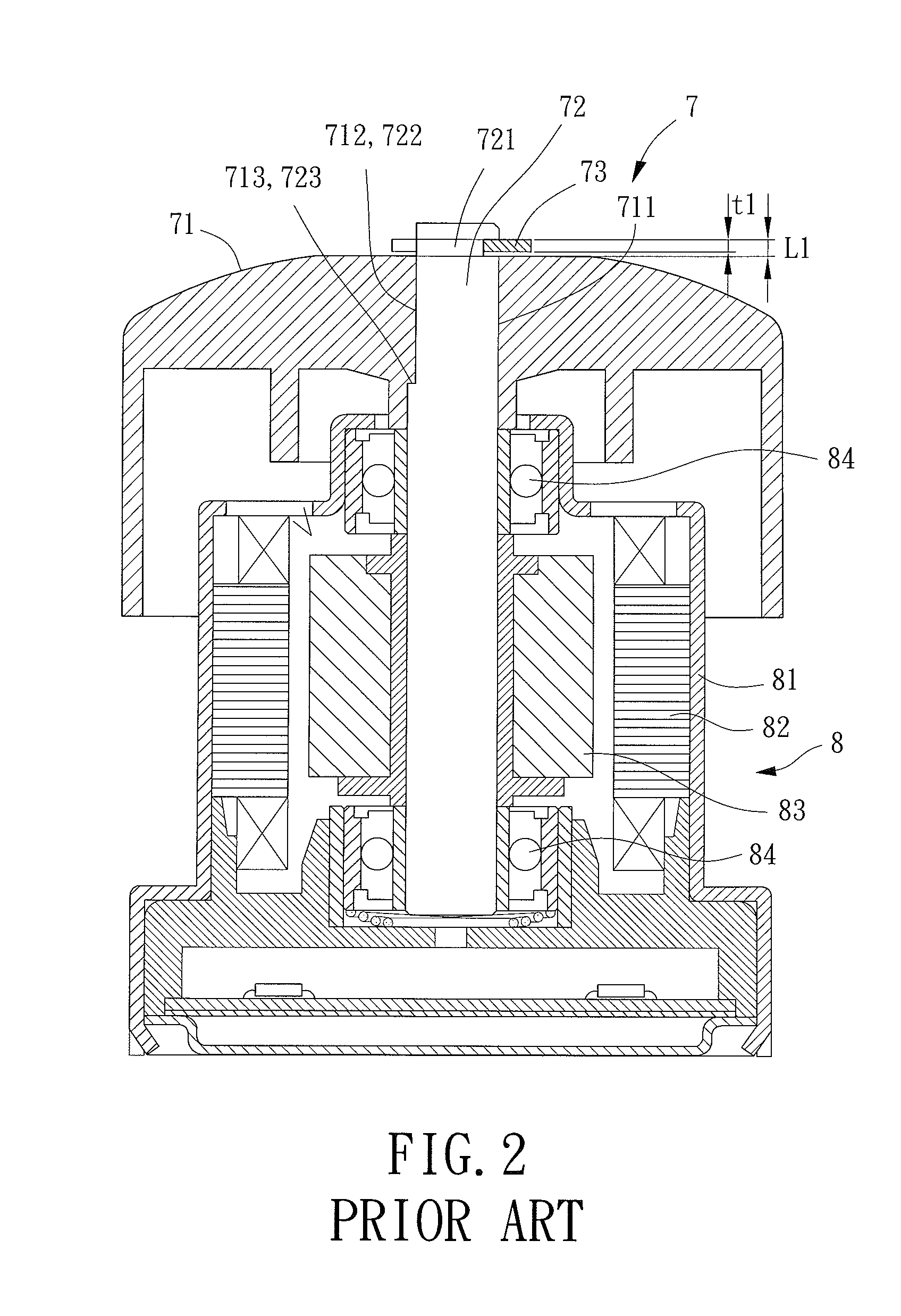

Rotor for Motor

InactiveUS20120062079A1Reduce axial vibrationPrevent leakagePump componentsMechanical energy handlingAxial vibrationElectric motor

A rotor for a motor includes a hub having a through-hole. A shaft extends through the through-hole and includes an outer periphery having a reduced section, wherein the reduced section has two end walls in an axial direction of the motor. The engaging member includes a hole through which the shaft extends. The engaging member is tightly engaged with the reduced section while tightly pressing against the two end walls of the reduced section. The engaging member is a resilient, continuous annular member free of grooves and notches. When the rotor is mounted in a motor, axial vibration of the hub relative to the shaft is reduced, and leakage of lubricating oil in the bearings of the motor is prevented.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Double-damping thermal expansion valve with effect of reducing vibration and noise

PendingCN106839540AReduce radial vibrationReduce axial vibrationMechanical apparatusFluid circulation arrangementThermal expansionSteel ball

The invention discloses a double-damping thermal expansion valve with the effect of reducing vibration and noise. The double-damping thermal expansion valve comprises a valve body, a power head, an O-shaped valve, an ejecting needle, an ejecting rod sleeve, a ball seat part, a damping clamp, springs and adjusting caps, wherein spherical column-pin convex bags protruding outwards are arranged on the outer side surfaces of the lower parts of column pins under the damping clamp and are in elastic and sliding contact with step hole walls of the upper parts of adjusting-cap installing holes, so that the radial vibration of a ball seat is reduced; the ejecting rod sleeve is a mushroom-shaped nylon member; and arc-shaped convex ribs are arranged at the lower parts of four flanges of the ejecting rod sleeve and are contacted with the inner hole walls of a lower cover of the power head, axial vibration of the ball seat is reduced, the interference of vibration fields of refrigerant airflow and a car on a steel-ball valve core is reduced, and the purpose of eliminating vibration and noise in operation of an air-conditioning system of the car is achieved. In addition, the valve body is formed by machining a novel aluminum profile of which redundant materials are removed under the premise of guaranteeing enough wall thickness of all holes, so that the use amount of the materials is reduced and the cost of a product is reduced.

Owner:NINGBO SONGYING AUTOMOBILE PARTS

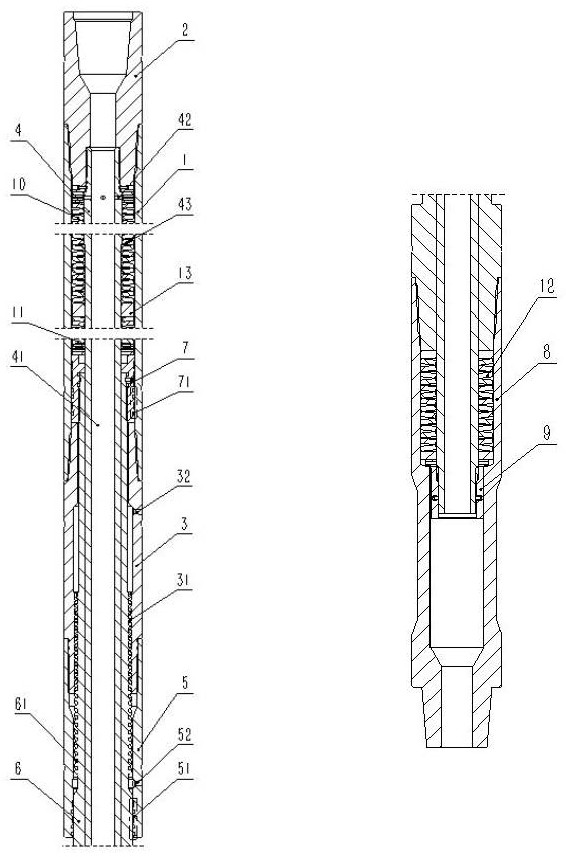

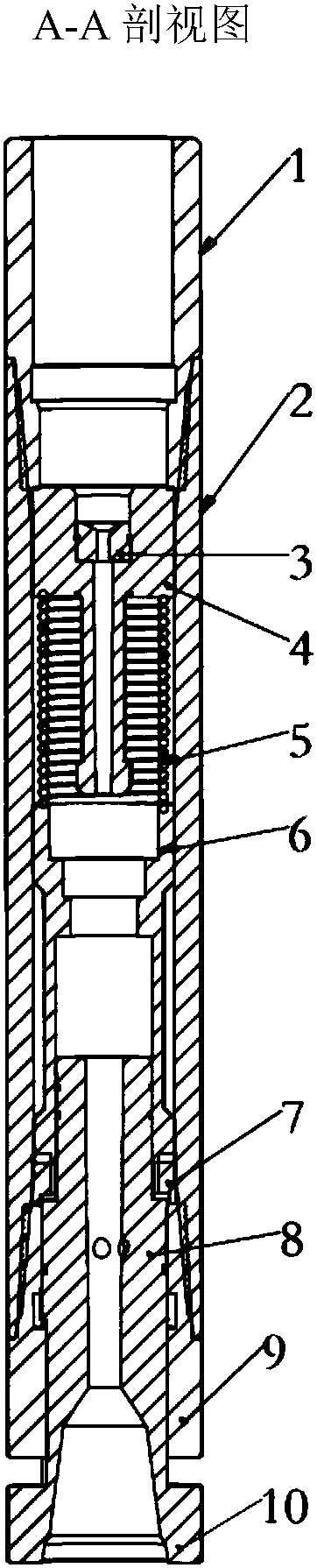

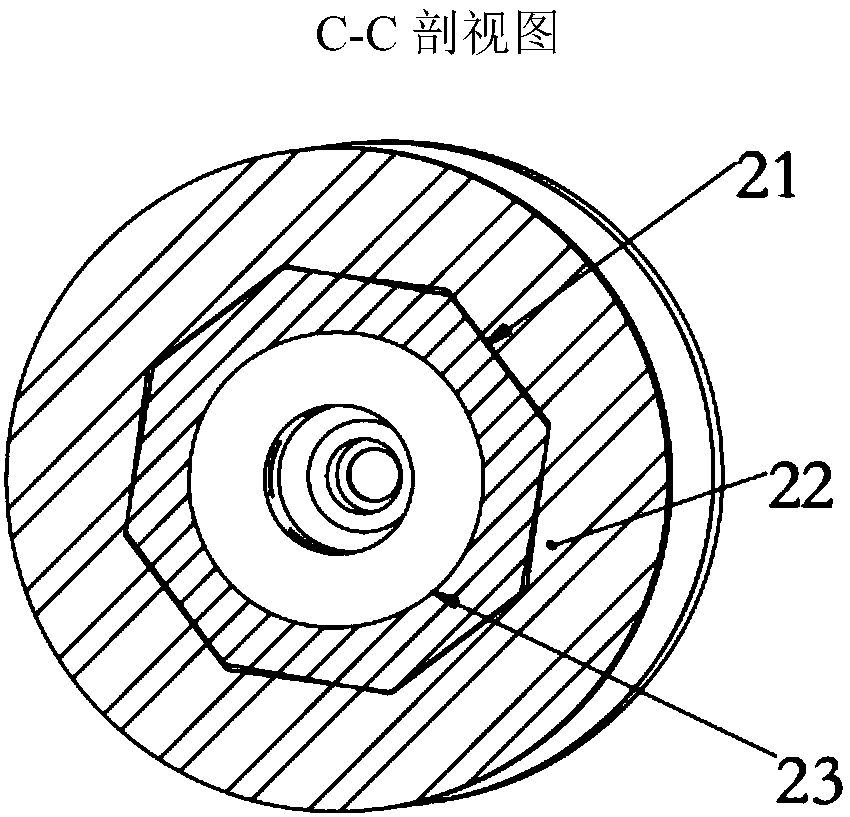

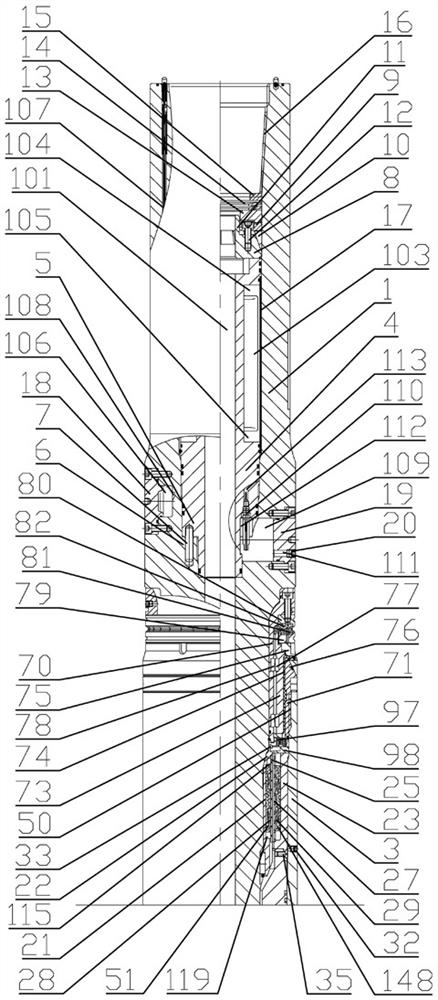

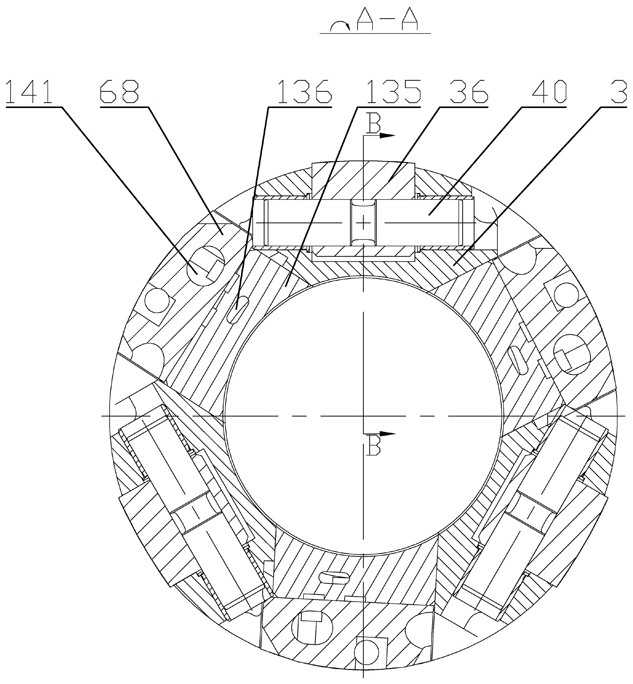

Underground rotary guiding device

The invention relates to the technical field of petroleum drilling and production, in particular to an underground rotary guiding device. The device comprises a mandrel, a lower connector, a non-rotary outer barrel, an upper electronic bin assembly, a lower electronic bin assembly, a rotary transformer assembly, an upper bearing assembly, a lower bearing assembly and a hydraulic driving device. The device disclosed by the invention is reasonable and compact in structure, power electricity and data signals in a two-way communication module or an MWD system can be transmitted downwards through the upper electronic bin assembly, axial vibration and swing of the device are reduced through the upper bearing assembly and the lower bearing assembly, a lower communication module transmits the power electricity and the data signals to the hydraulic driving device, so that the lower connector is always located at a predetermined well track, the directional and sliding directing requirements of the device are reduced, the hydraulic driving device feeds back a moving state signal to the ground upwards for an operator to operate, the vertical drilling technology is practically applied, the speed increasing effect is remarkable, the safety and reliability of the system are improved, the circuit complexity and the system loss are reduced, and the transmission efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anti-stagnation tool based on flexible rods

InactiveCN106050154AReduce axial and torsional vibrationsExtend your lifeDrilling rodsDrilling casingsPetroleumDrill bit

The invention discloses an anti-stagnation tool based on flexible rods and belongs to the field of drilling of ultra-deep petroleum wells. By the adoption of the anti-stagnation tool based on the flexible rods, the problem that the rock breaking efficiency is lowered due to the fact that a drill bit gets stuck or slides in the drilling process is solved. According to the main technical scheme, a vibration reduction assembly, an upper shell, a middle shell and a lower shell are connected in sequence through threads; the lower end of a combined disc spring pushes an anti-falling pipe to make a central pipe stretch, and the anti-falling pipe is positioned in the axial direction through an upper connector shaft shoulder of the middle shell; a flexible rod system rotates leftwards, and the upper end and the lower end of the flexible rod system are fixed in circular grooves in the lower end of the middle shell and the upper end of a central pipe boss correspondingly; the flexible rods are installed in the way that the upper ends and the lower ends of the flexible rods are inclined by 30-40 degrees and are in the stretching state initially; during operation, the drilling pressure is transmitted to the central pipe through the combined disc spring, and the torque is transmitted to the central pipe through the flexible rod system; and when the central pipe rotates reversely, the flexible rod system contracts, the combined disc spring is compressed by the central pipe to contract in the axial direction to reduce the cutting depth of the drill bit, and the drill bit is in a rock stratum all the time in the whole process.

Owner:SOUTHWEST PETROLEUM UNIV

Damping device for axial vibration damping and noise reduction of shafting

ActiveCN110939680AReduce axial vibrationSave installation spaceSpringsNon-rotating vibration suppressionVibration controlElectric machinery

The invention discloses a damping device for axial vibration damping and noise reduction of a shafting. The damping device mainly comprises a damper main body and a bearing seat. According to the damping device, a stepping motor drives a rotating shaft to rotate, the rotating shaft is provided with a thrust plate, the axial vibration of the rotating shaft can be transmitted to the damper main bodythrough the thrust plate, hydraulic oil in a gap of the damper main body is subjected to extrusion, an oil film damping effect is formed, so that the axial vibration of the rotating shaft is reducedor weakened, and the damping device belongs to the technical field of vibration control. Two sets of damper assemblies are arranged on the left side and the right side of the thrust plate and are usedfor transmitting and absorbing vibration in the left direction and the right direction respectively. The damping device can be widely applied to the mechanical field with axial vibration, and has theadvantages of excellent vibration damping effect, compact structure and small installation space.

Owner:BEIJING UNIV OF CHEM TECH

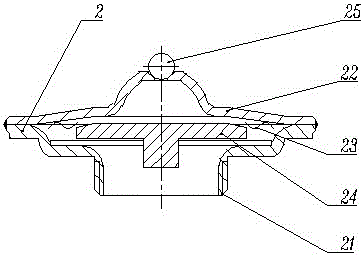

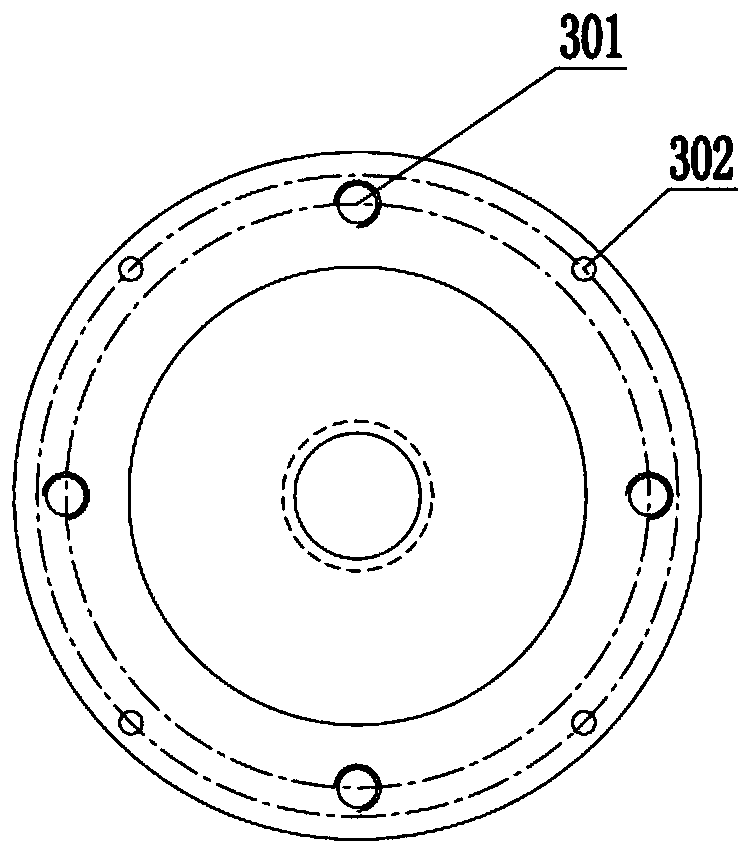

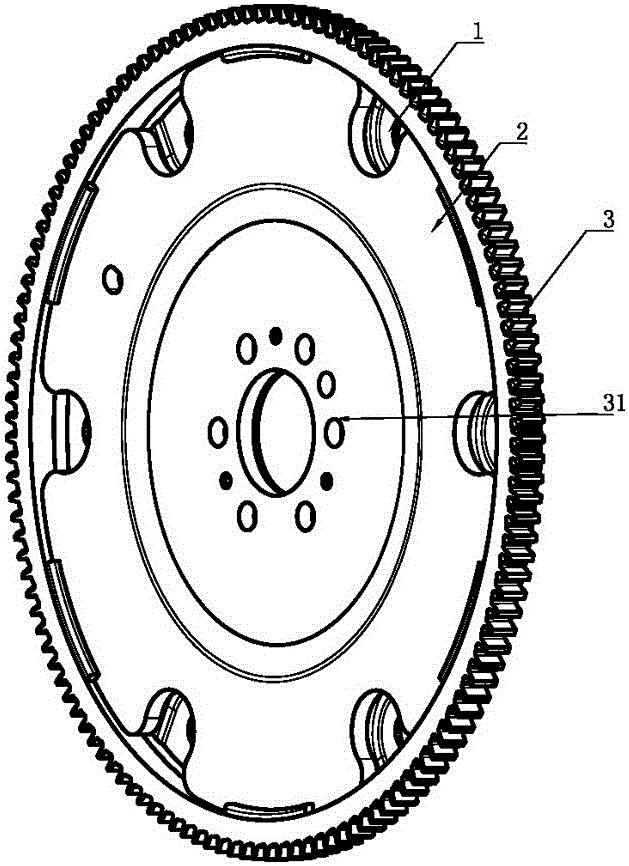

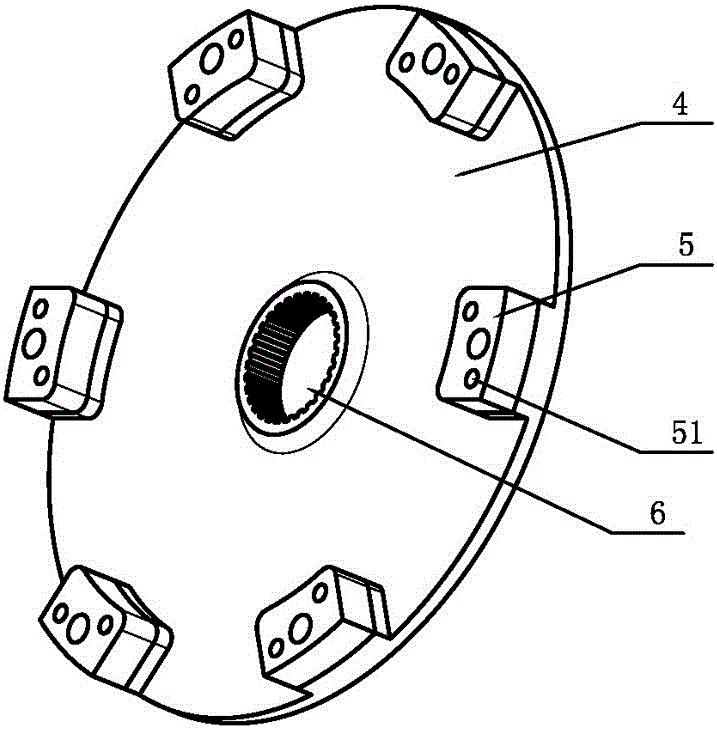

Spline flywheel assembly for double-clutch automatic transmission

A spline flywheel assembly for a dual-clutch automatic transmission, comprising a flexible flywheel disc and a spline flywheel connected to the flexible flywheel disc, the spline flywheel adopts a disc-shaped structure, and its outer ring is provided with a plurality of bosses in the circumferential direction , the boss is provided with a threaded hole, and the center of the spline flywheel disc is provided with a spline hole; the flexible flywheel disc includes a connecting plate, and the connecting plate is riveted with the flexible disc through rivets, and the outer part of the connecting plate The flange sleeve is provided with a ring gear, and the connecting plate and the flexible disk are provided with crankshaft flange connection holes. The flexible disc is connected to the dual-clutch automatic transmission through the spline flywheel, replacing the hydraulic torque converter for power transmission; under the premise of ensuring the use function, different sizes can be designed according to the structure and arrangement between the engine and the transmission The spline flywheel does not affect the overall layout of the transmission system in the body when it is equipped with different models.

Owner:HUBEI LIOHO TIANLUN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com