Bearing and spindle motor

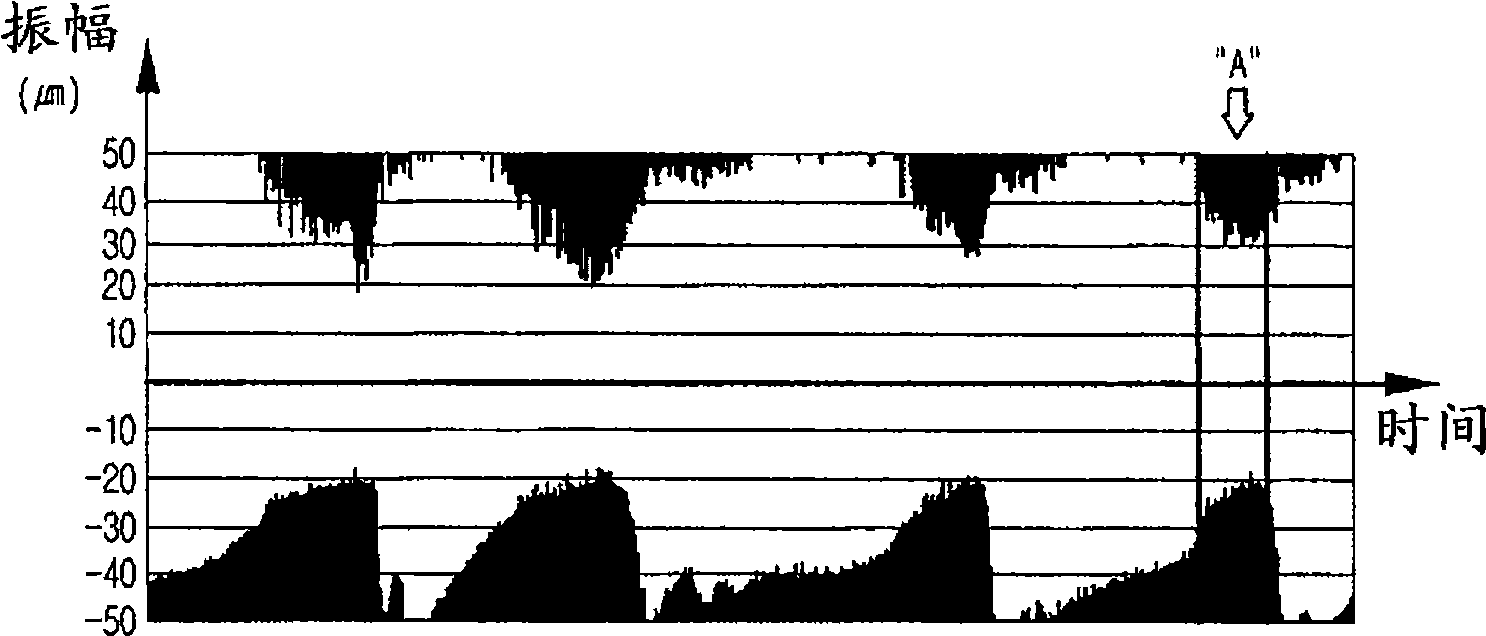

A technology for spindle motors and bearings, applied in the field of spindle motors and bearings, can solve problems such as unevenness and unreliable optical reading devices, and achieve the effect of reducing axial vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The accompanying drawings illustrate examples of embodiments of the invention, and the following description will refer to these embodiments in detail.

[0038] Figure 5 is a sectional view showing the spindle motor according to the embodiment.

[0039] refer to Figure 5 , the bearing seat 120 is installed on the base 110 . The bearing 130 is tightly fitted in the bearing housing 120 to support the lower portion of the rotatable shaft 140 . The bearing 130 is formed by sintering metal powder. Thus, the bearing 130 can include holes 131 on its surface and in its interior for receiving oil (cf. Figure 6 ).

[0040] The stator 150 is fixed to the bearing housing 120 and the rotor 160 is fixed to the shaft 140 . The stator 150 includes a core 151 and a coil 155 . The core 151 is fixed to the outer surface of the bearing housing 120 , and the coil 155 is wound around the core 151 . The rotor 160 includes a rotor yoke 161 and magnets 165 . The rotor yoke 161 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com