Double-damping thermal expansion valve with effect of reducing vibration and noise

A thermal expansion valve, vibration reduction and noise reduction technology, applied in the field of expansion valves, can solve the problems of high cost, ineffectiveness, and singleness, and achieve the effects of eliminating vibration and noise, reducing material usage, and reducing product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

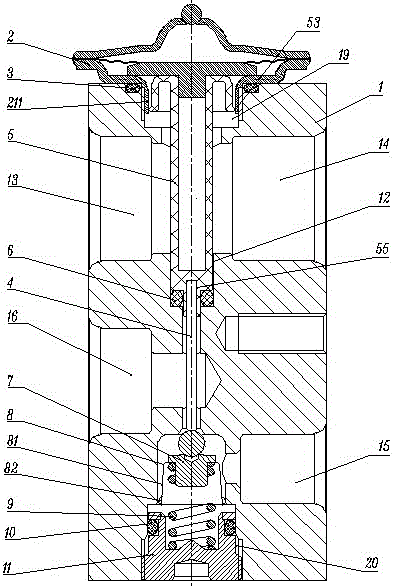

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

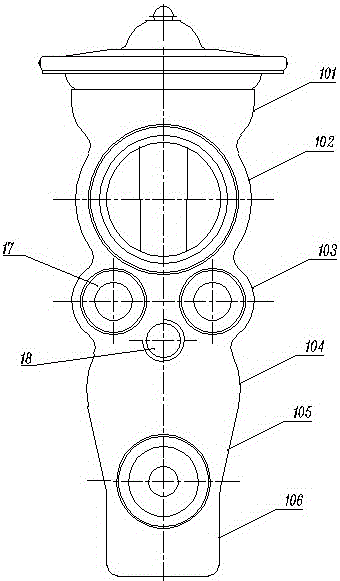

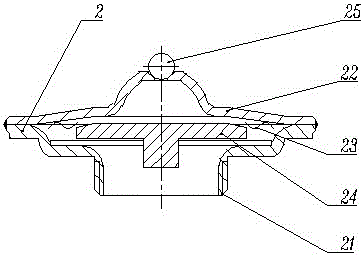

[0015] An expansion valve as shown in the figure, including valve body 1, power head 2, O-ring 3, thimble 4, ejector rod sleeve 5, O-ring 6, bead seat part 7, damping clip 8, spring 9, O-shaped ring 10, adjusting cap 11; the valve body 1 is provided with an intermediate cavity 12, an air inlet 13, an air outlet 14, a liquid inlet 15, a liquid outlet 16, a fixing hole 17, a screw hole 18, and a power head installation Holes 19, adjusting cap mounting holes 20; the valve body 1 is made of aluminum profiles, and the two sides of the aluminum profiles for making the valve body 1 are left and right symmetrical, and the two sides are composed of arc surfaces 101, arc surfaces 102, arc surfaces 103, and arc surfaces. 104, an inclined surface 105 and a straight surface 106 are formed, and the four arc surfaces are transitioned by rounded corners. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com