Patents

Literature

842 results about "Thermal expansion valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal expansion valve or thermostatic expansion valve (often abbreviated as TEV, TXV, or TX valve) is a component in refrigeration and air conditioning systems that controls the amount of refrigerant released into the evaporator thereby keeping superheat, that is, the difference between the current refrigerant temperature at the evaporator outlet and its saturation temperature at the current pressure, at a stable value, ensuring that the only phase in which the refrigerant leaves the evaporator is vapor, and, at the same time, supplying the evaporator's coils with the optimal amount of liquid refrigerant to achieve the optimal heat exchange rate allowed by that evaporator. In addition, some thermal expansion valves are also specifically designed to ensure that a certain minimum flow of refrigerant can always flow through the system. Thermal expansion valves are often referred to generically as "metering devices".

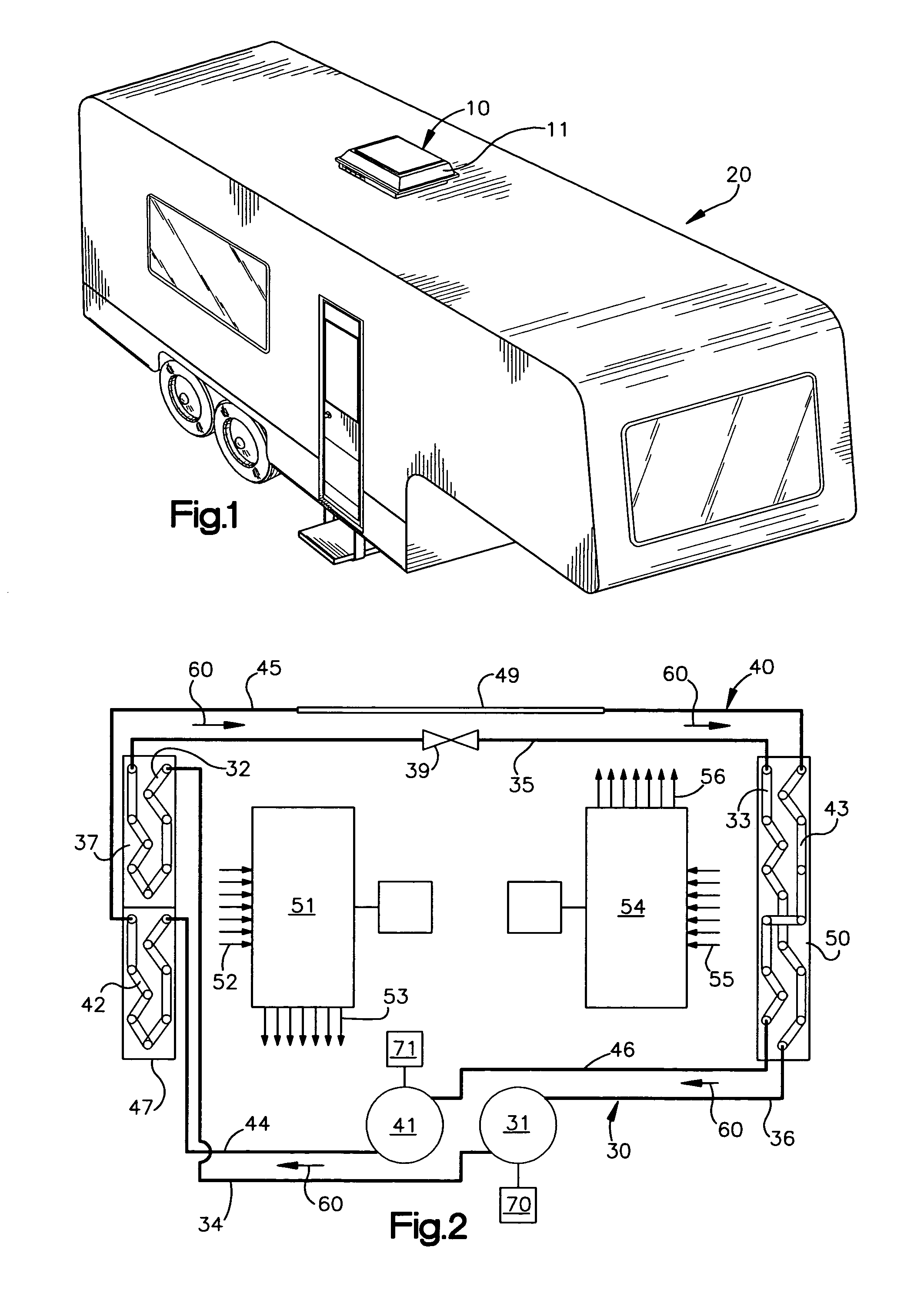

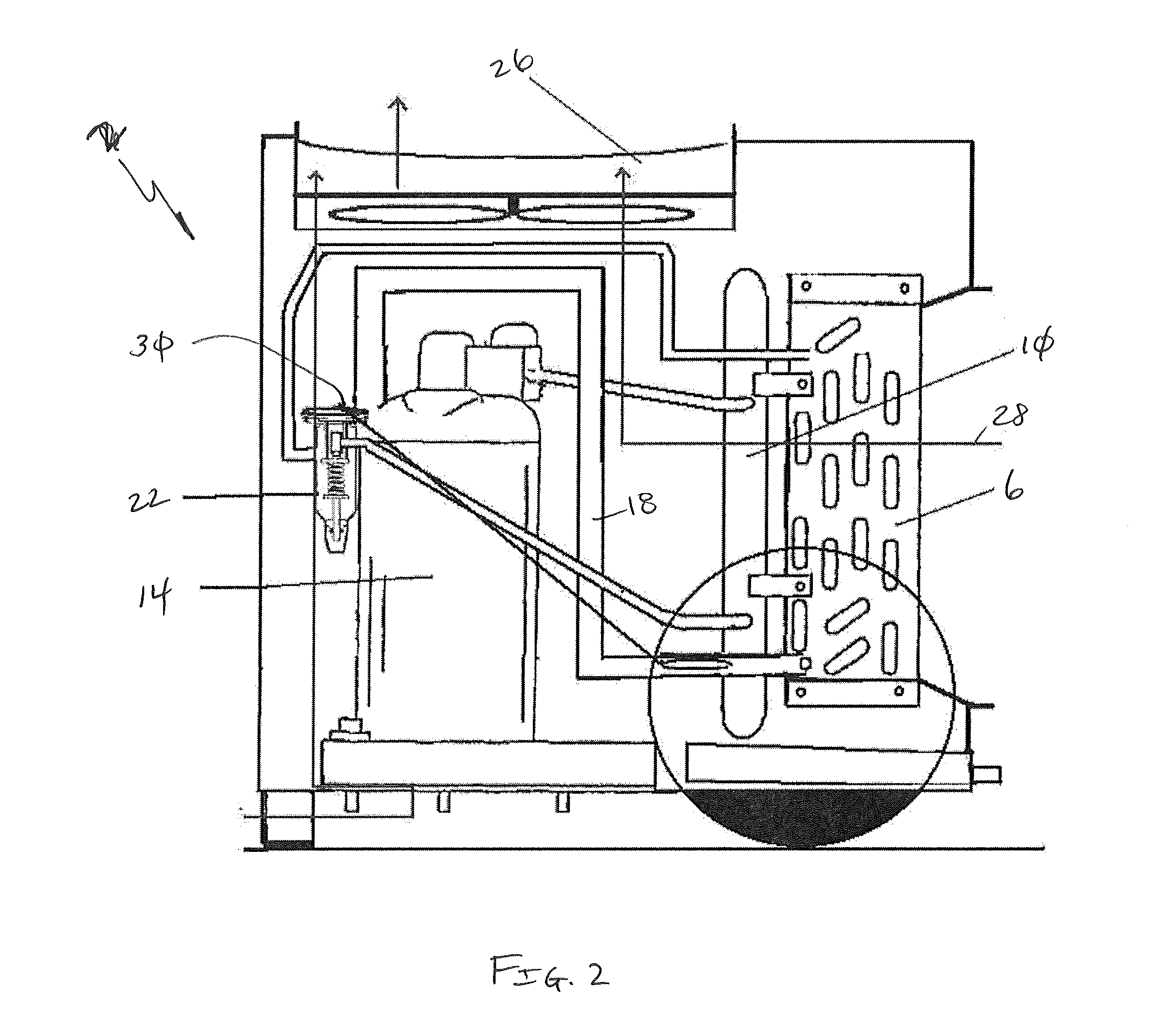

Method and apparatus for cooling

ActiveUS20080245083A1Increase loopHigh trafficMechanical apparatusTemperatue controlEngineeringCooling capacity

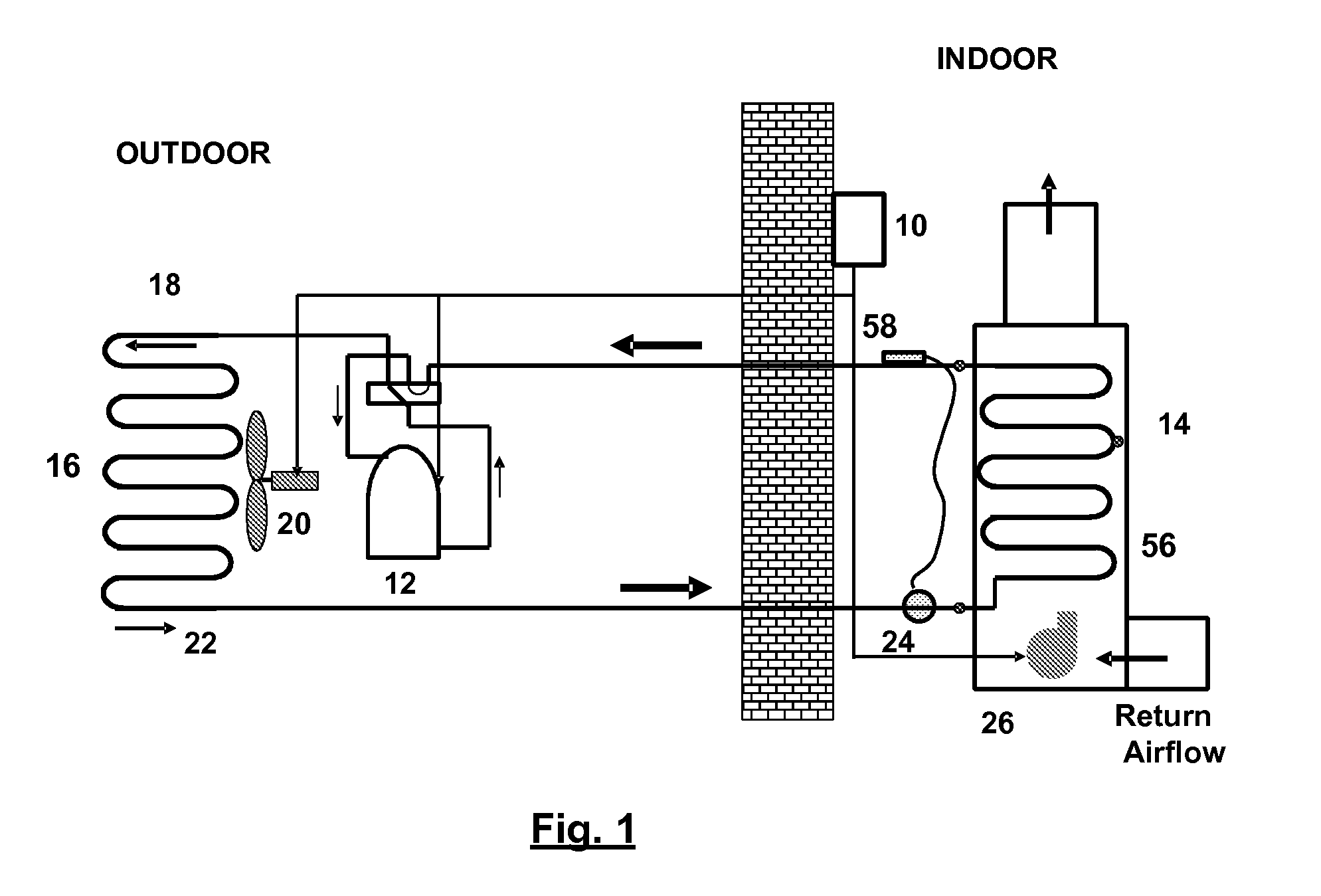

A method of calculating net sensible cooling capacity of a cooling unit includes measuring a discharge pressure from of fluid from a compressor and a suction pressure from an evaporator, calculating a condensing temperature of fluid flowing from the compressor and an evaporating temperature of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing from the compressor, calculating enthalpy of fluid flowing from the compressor, of fluid flowing from the thermal expansion valve, and of fluid flowing from the evaporator, calculating a mass flow rate of fluid flowing through the hot gas bypass valve, and calculating net sensible cooling capacity. Embodiments of cooling units and other methods are further disclosed.

Owner:AMERICA POWER CONVERSION CORP

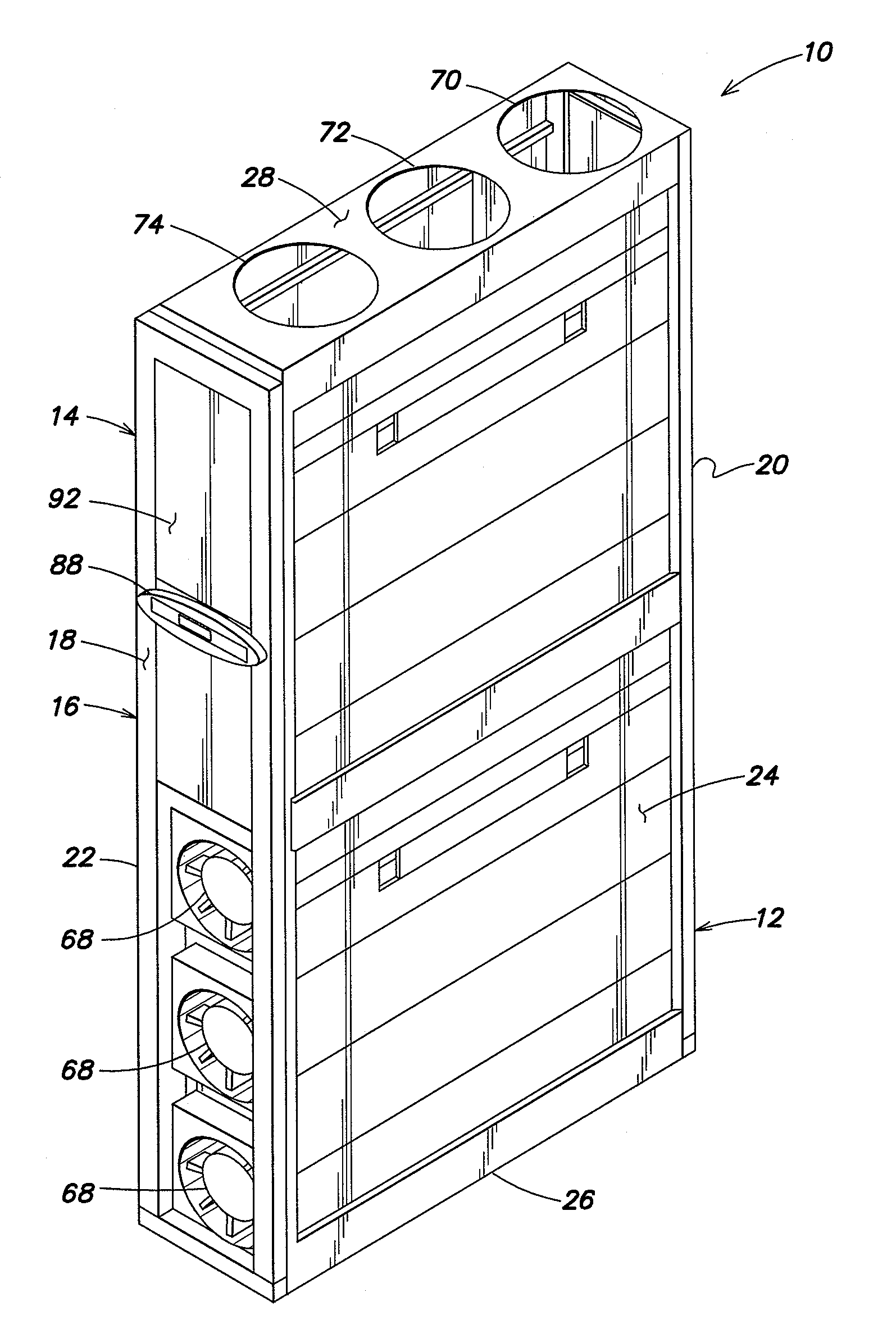

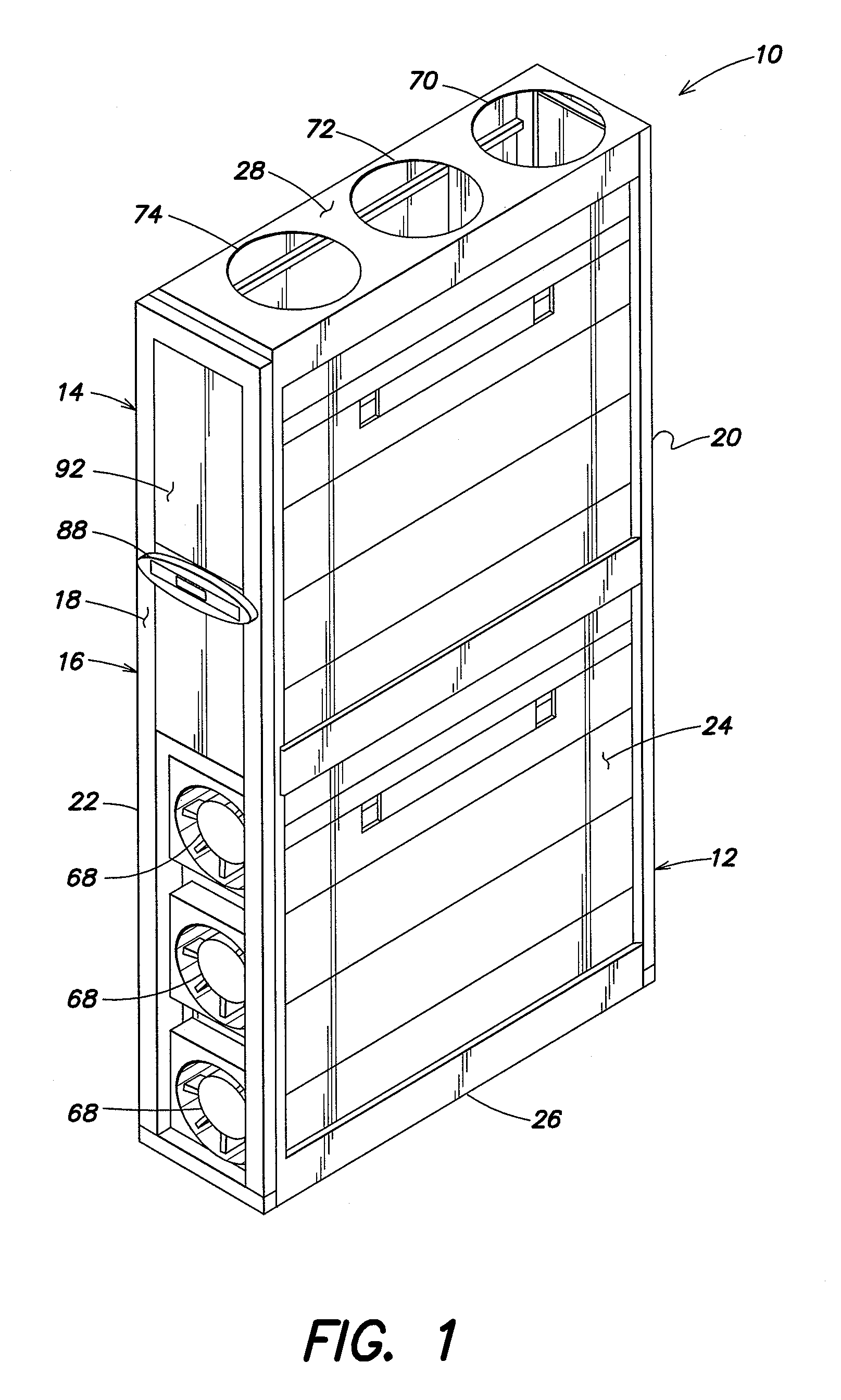

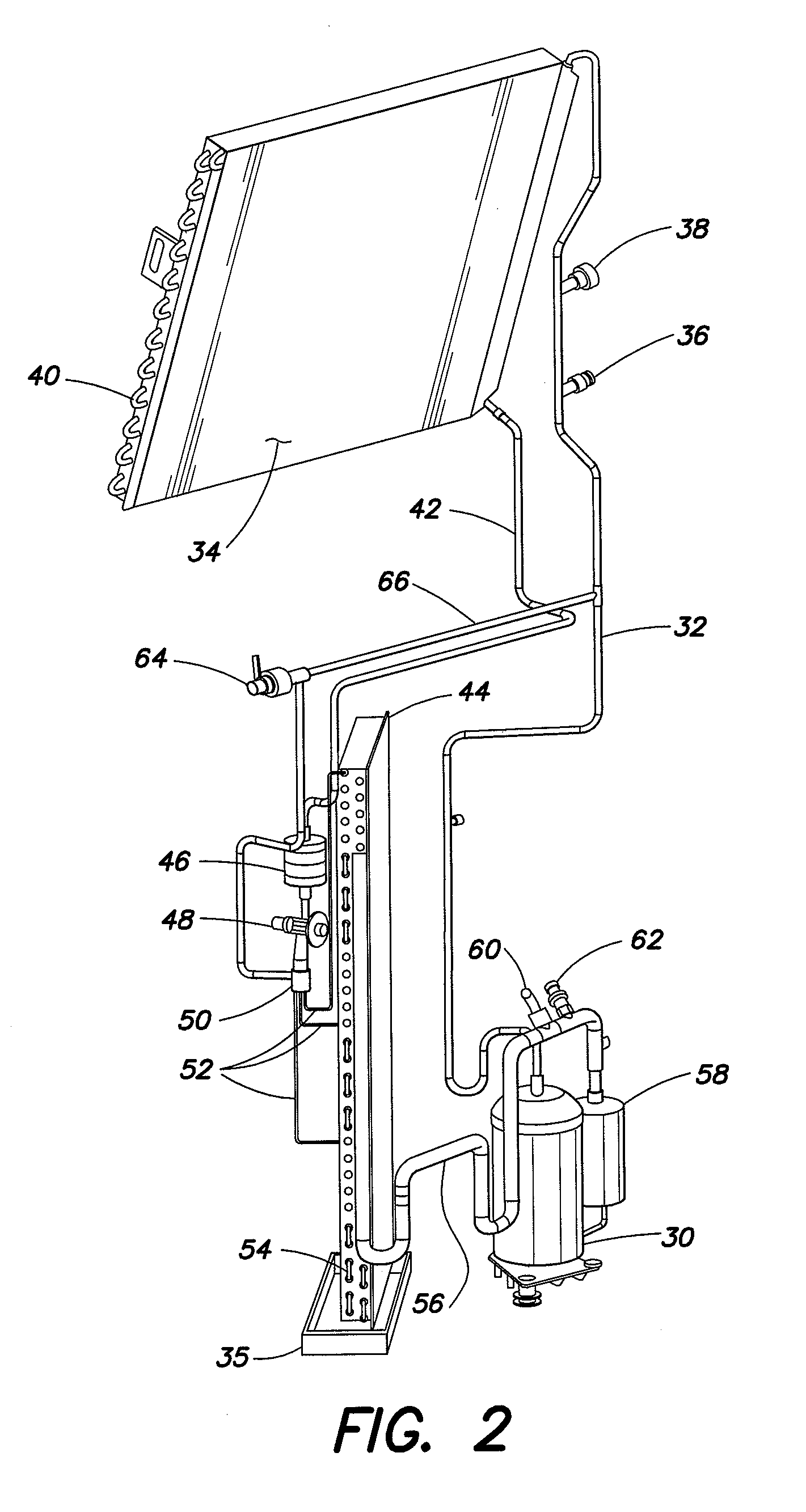

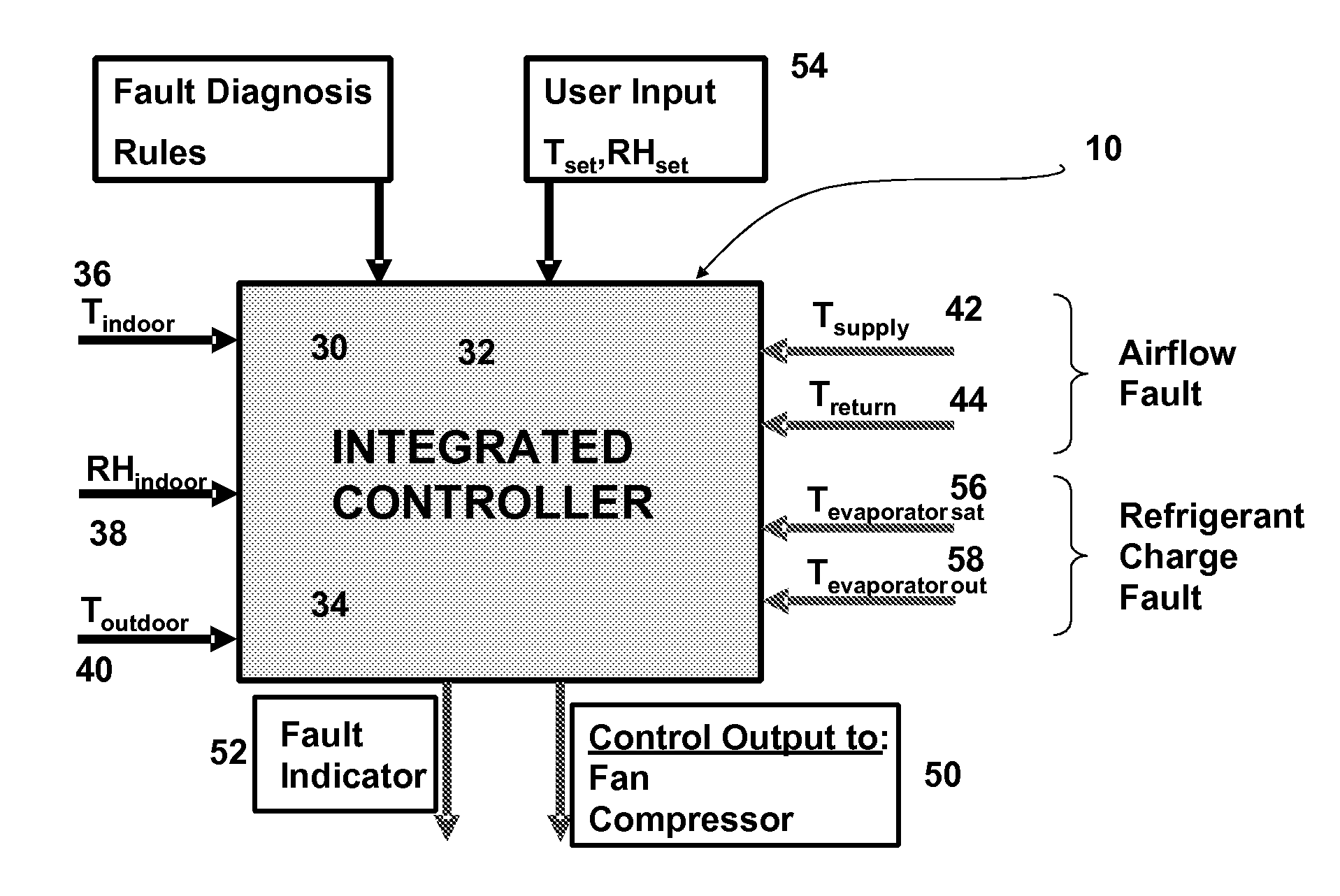

Integrated Controller And Fault Indicator For Heating And Cooling Systems

InactiveUS20080315000A1Promote mold growthShorten speedTemperature control using plurality of sensorsTesting/monitoring control systemsFault indicatorEngineering

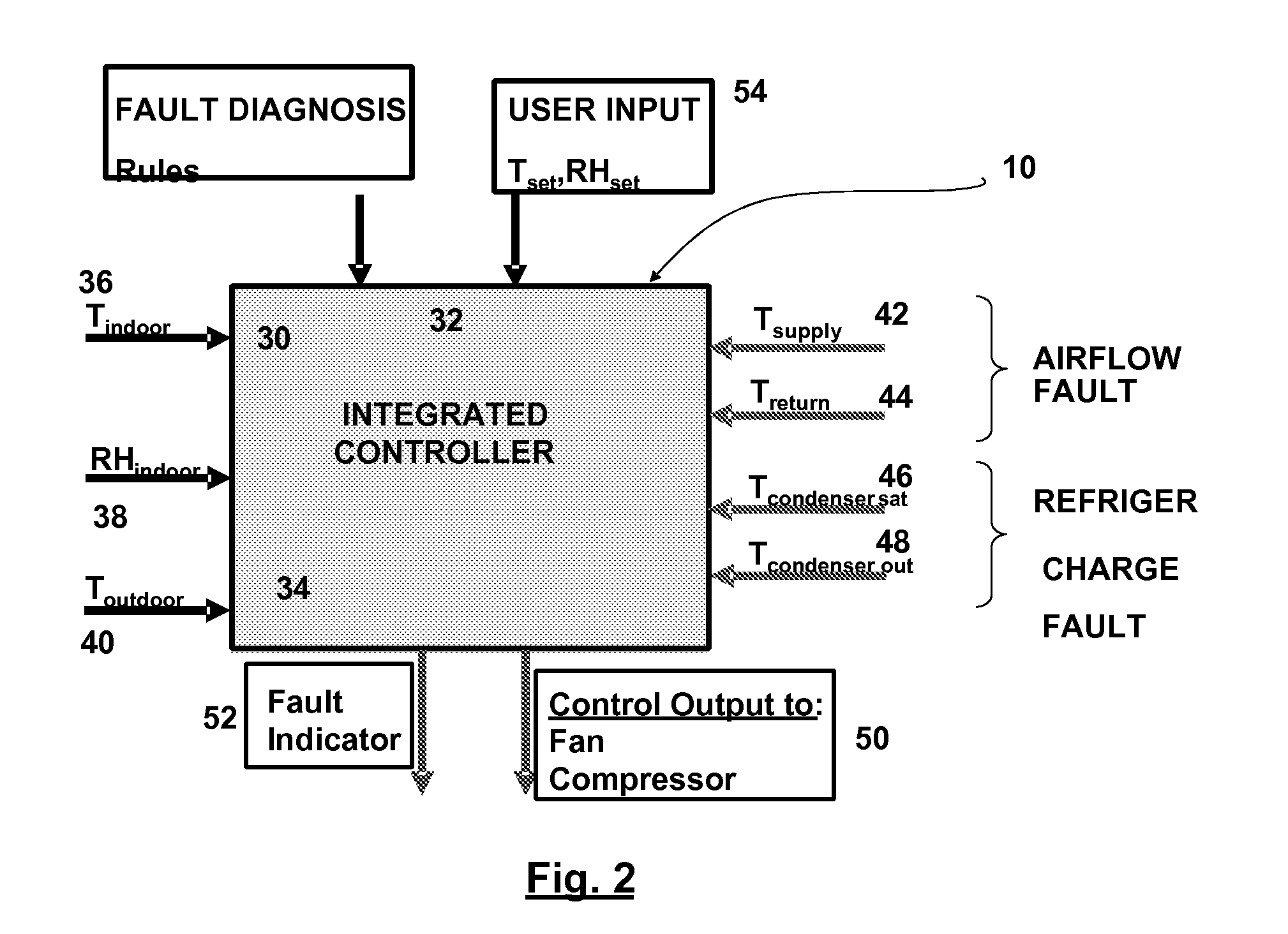

An integrated controller for controlling a vapor compression based heating and cooling system. The integrated controller includes modules for independently controlling dry bulb temperature, humidity level, and incorporating a fault detection module therewith. The fault detection module being capable of detecting abnormal refrigerant levels using only temperature sensors on the condenser with thermal expansion valve or evaporator with fixed orifice type of expansion valve.

Owner:HOME AUTOMATION INC

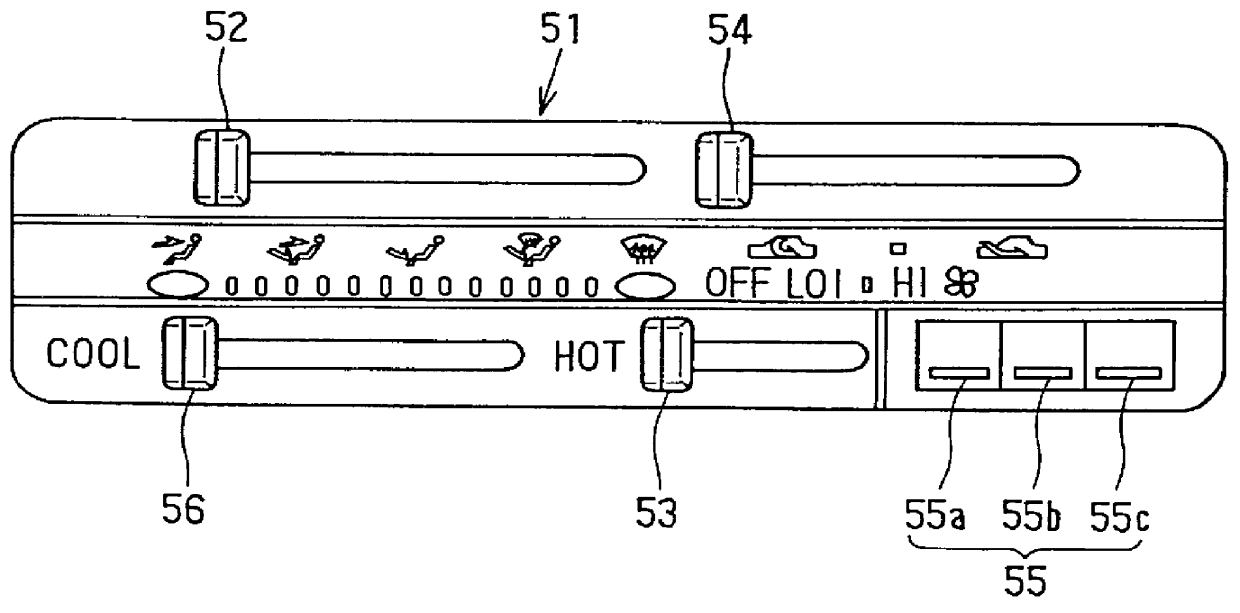

Air conditioner

InactiveUS6035653AMinimizing temperature overshootMinimization needsAir-treating devicesMechanical apparatusResponsivityEngineering

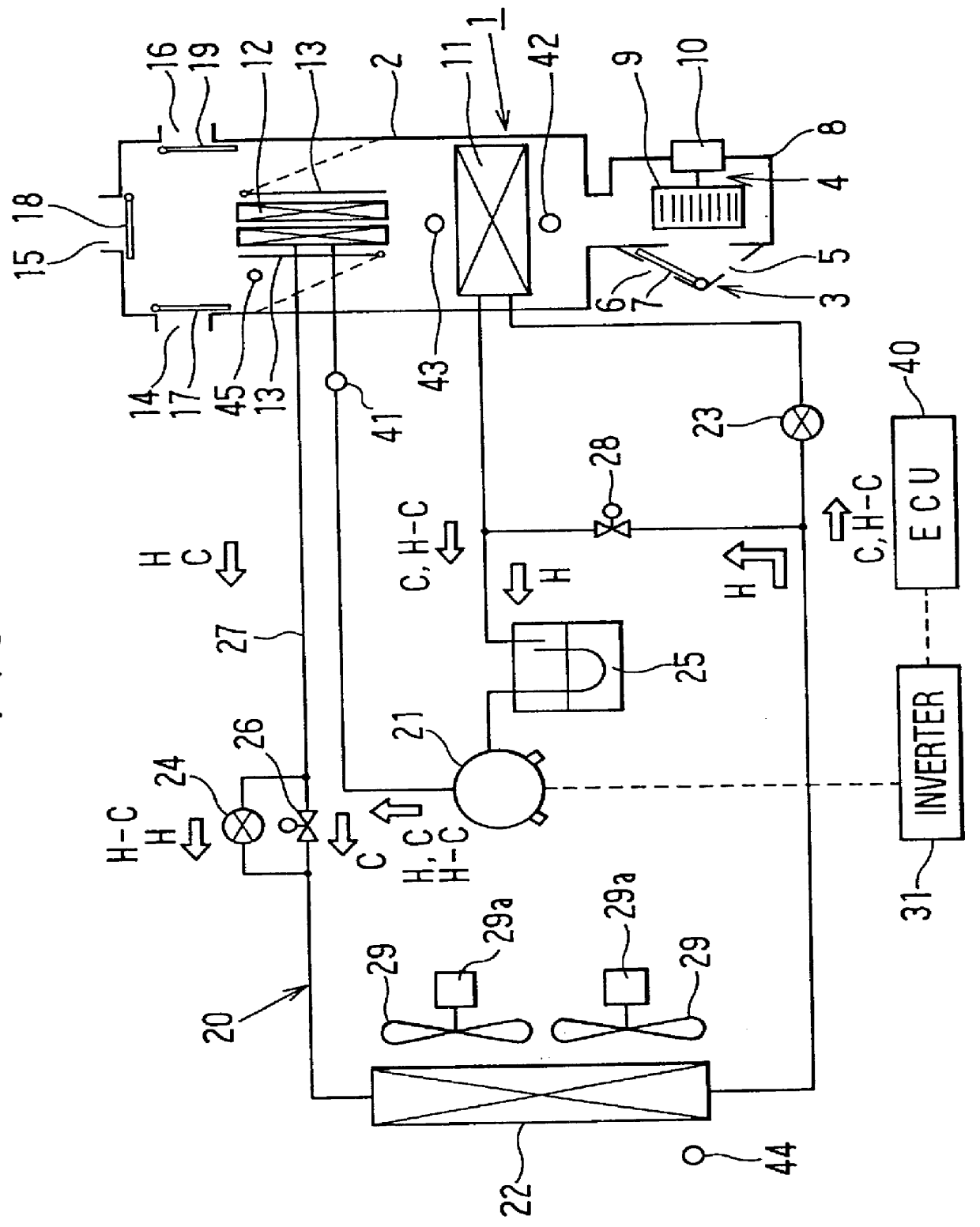

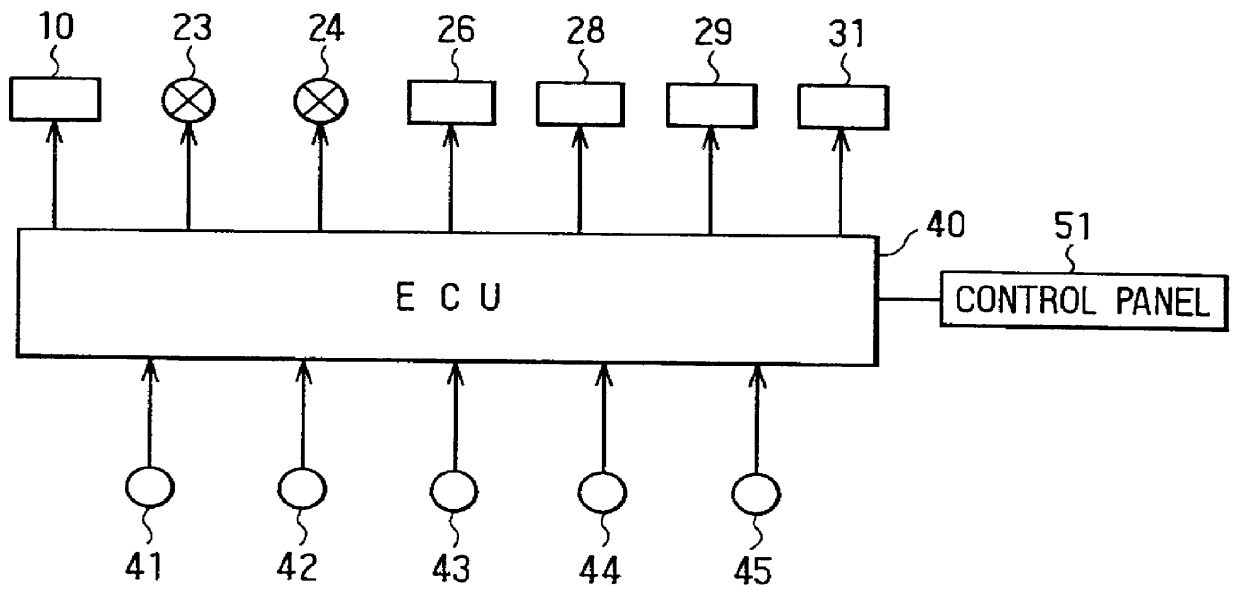

An air conditioner capable of enhancing responsivity of a blowout temperature of conditioned air while preventing occurrence of an overshoot or undershoot condition of the blowout temperature when a user gives an instruction to change the blowout temperature in a dehumidifying operation mode. In a control state, if a set temperature level is adjusted to increase a blowout temperature of conditioned air by increasing the target condenser outlet temperature, the rotating speed of the refrigerant compressor is increased, while the restriction opening of the heating expansion valve is maintained. Thus, the condenser outlet temperature is regulated to the target temperature with minimal undershoot or overshoot of the target temperature.

Owner:DENSO CORP

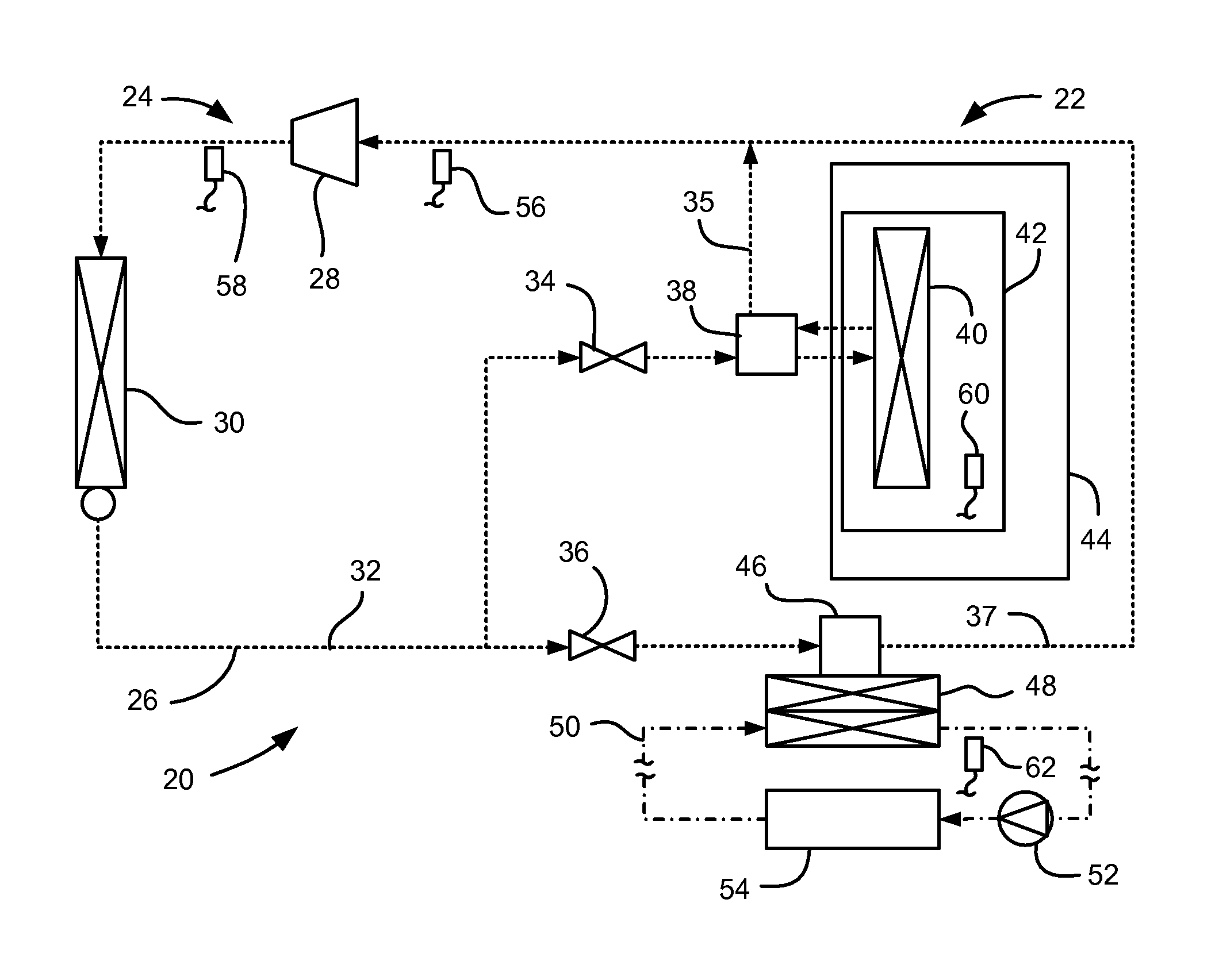

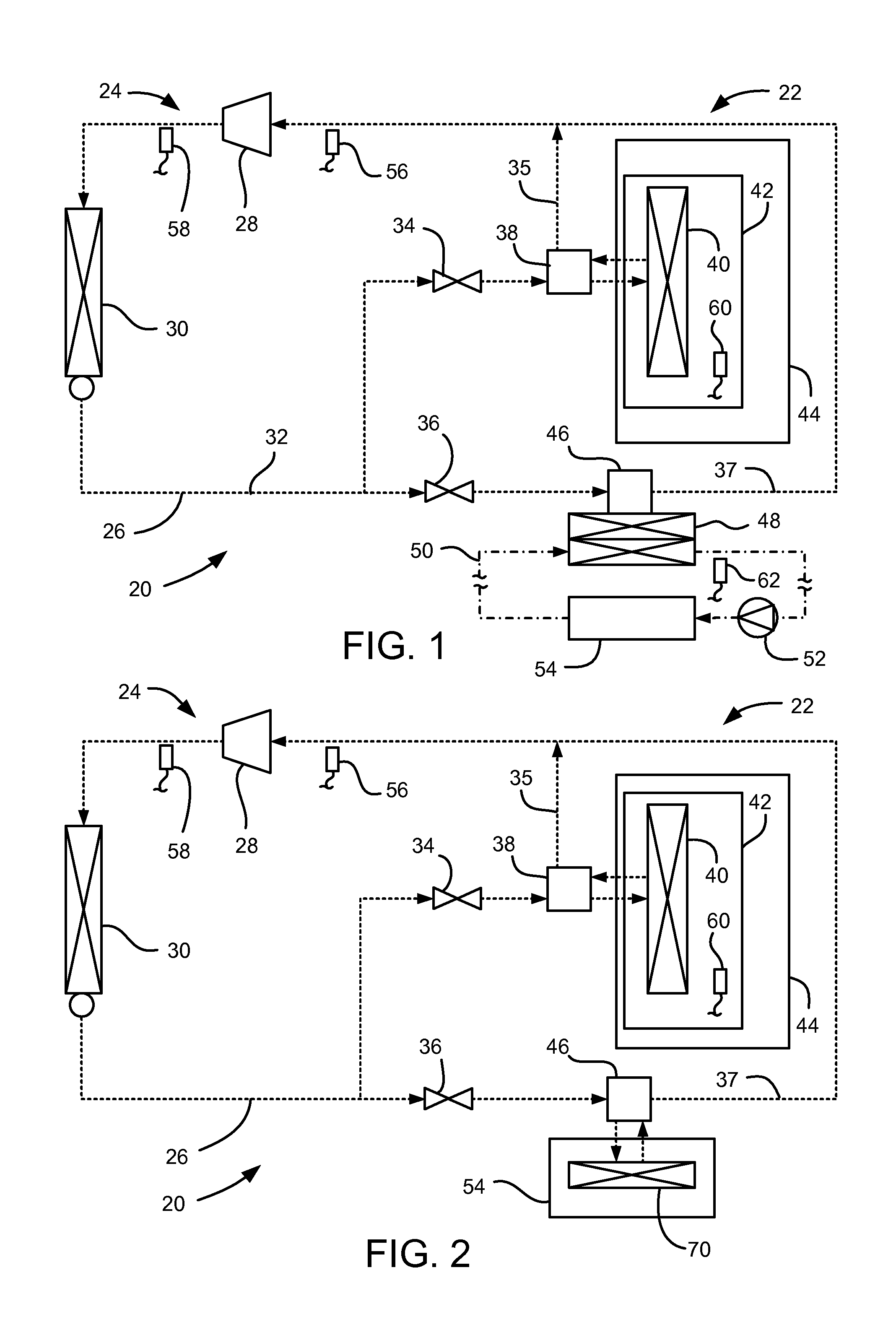

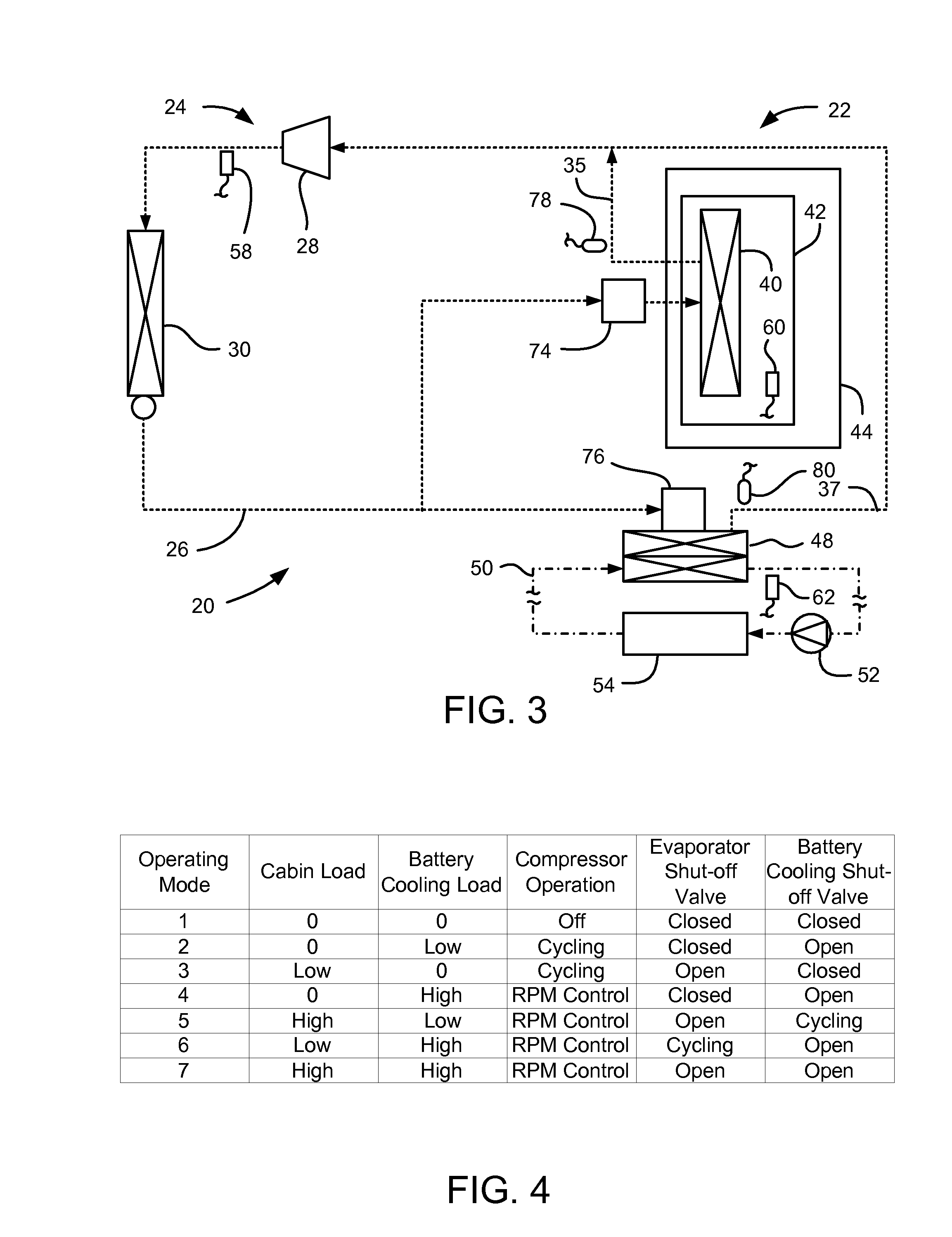

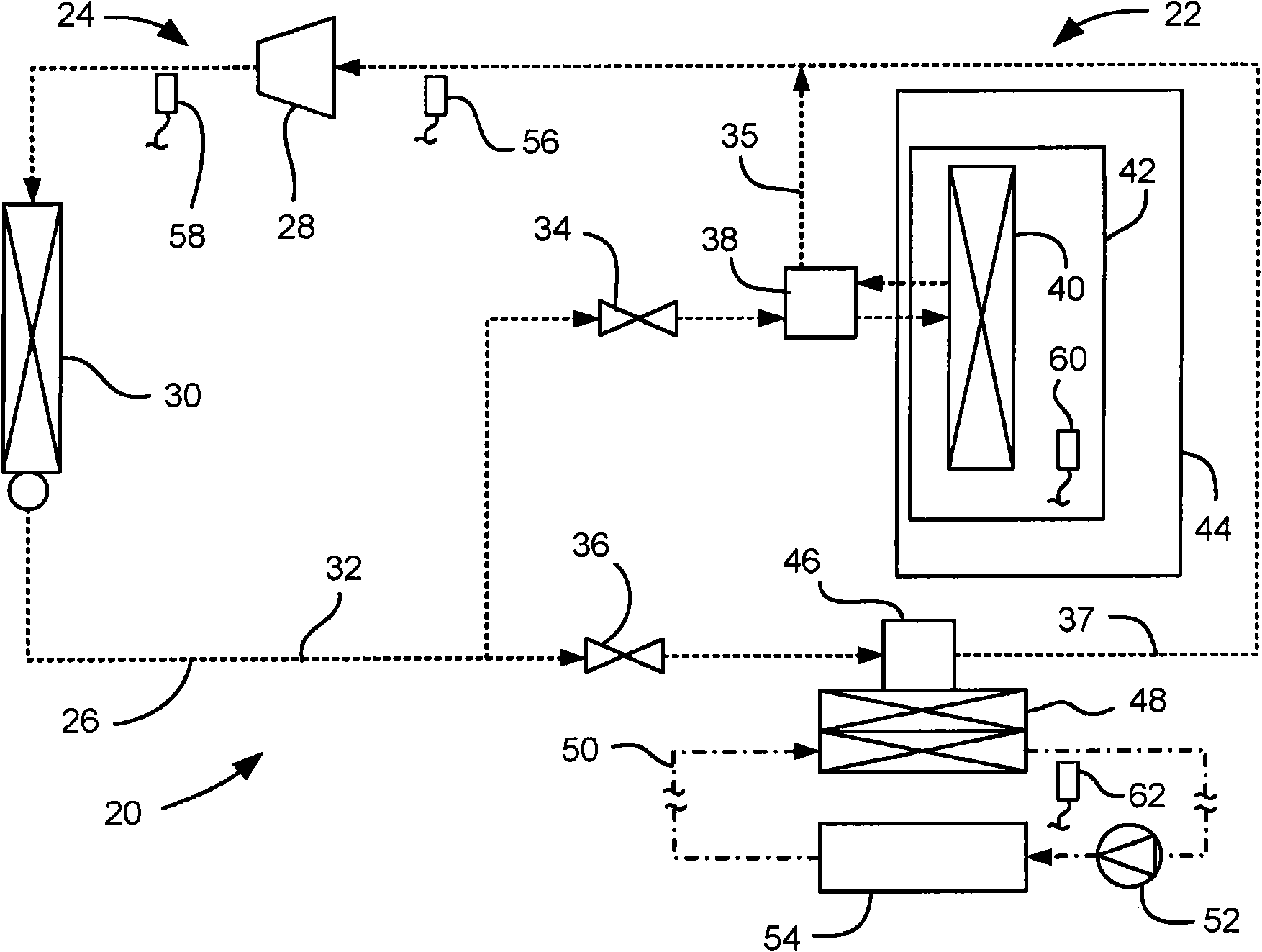

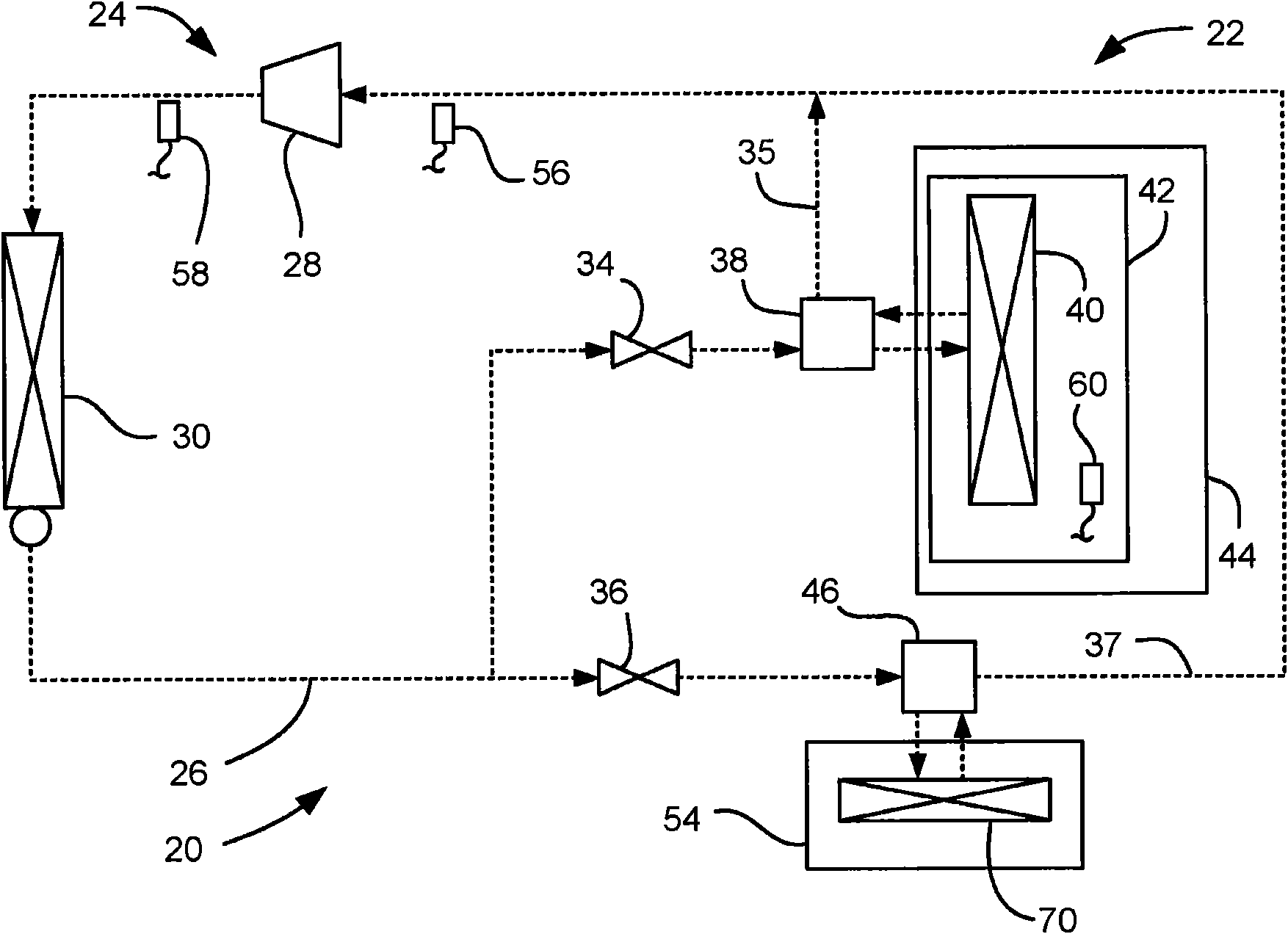

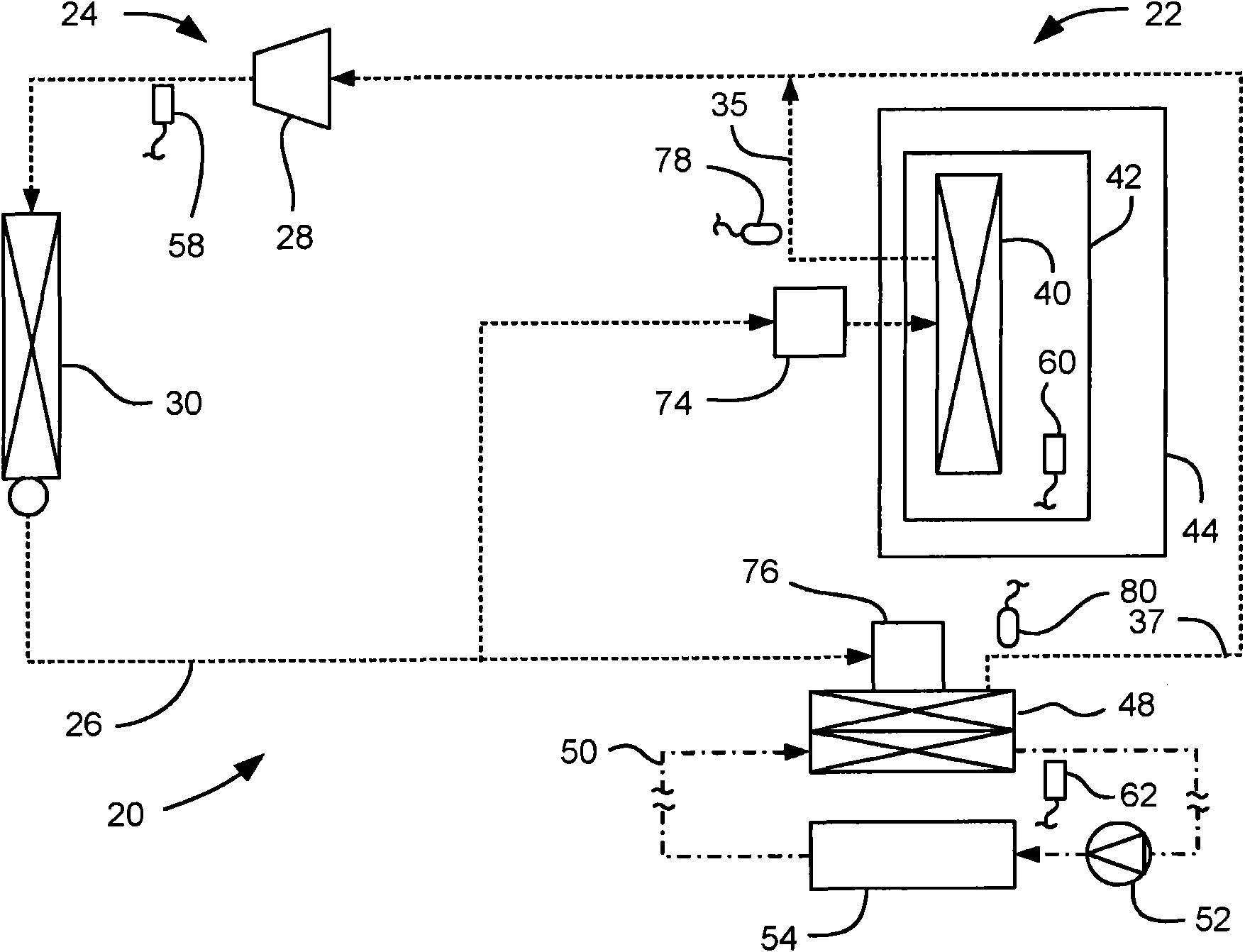

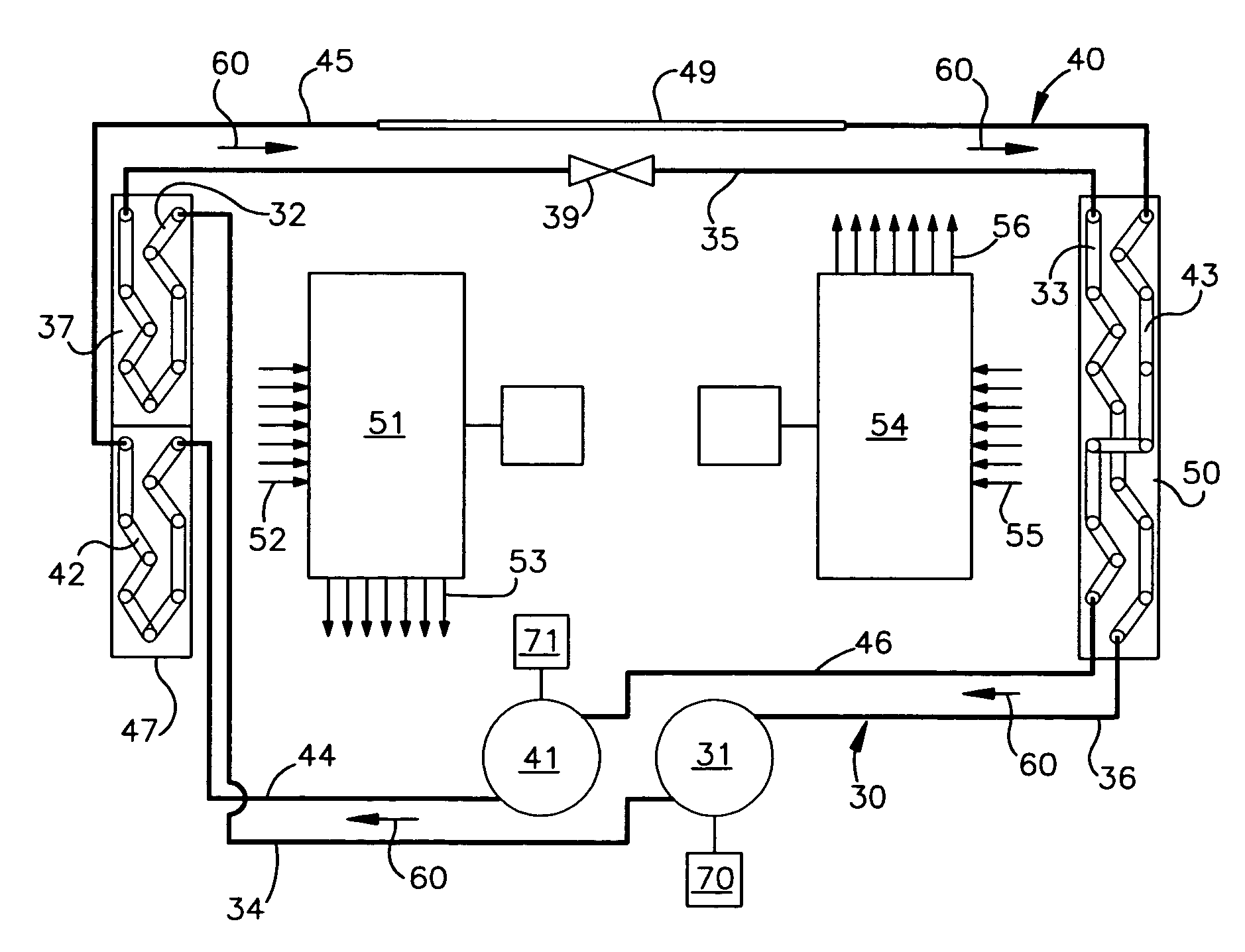

Vehicle HVAC and Battery Thermal Management

InactiveUS20090249802A1Maximize ability to accountMaximize battery lifeAir-treating devicesDomestic cooling apparatusPlate heat exchangerElectrical battery

An HVAC system for a vehicle having a battery pack, and a method of operation, is disclosed. The HVAC system may comprise a refrigerant loop having a first leg and a second leg, and a refrigerant compressor in the refrigerant loop. In the first leg, an evaporator provides cooling to a passenger cabin of the vehicle, an evaporator shut-off valve selectively blocks the flow of refrigerant through the evaporator, and an evaporator thermal expansion valve is upstream from the evaporator. In the second leg, a battery heat exchanger receives the refrigerant, a battery thermal expansion valve is located upstream from the battery heat exchanger, and a battery cooling shut-off valve selectively blocks the flow of refrigerant through the battery heat exchanger. The shut-off valves and compressor are controlled to control the cooling of the passenger cabin and the battery pack.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vehicle hvac and battery thermal management

ActiveCN101551174AImprove operating statusLife maximizationCompression machines with non-reversible cycleSecondary cellsPlate heat exchangerEngineering

An HVAC system for a vehicle having a battery pack, and a method of operation, is disclosed. The HVAC system may comprise a refrigerant loop having a first leg and a second leg, and a refrigerant compressor in the refrigerant loop. In the first leg, an evaporator provides cooling to a passenger cabin of the vehicle, an evaporator shut-off valve selectively blocks the flow of refrigerant through the evaporator, and an evaporator thermal expansion valve is upstream from the evaporator. In the second leg, a battery heat exchanger receives the refrigerant, a battery thermal expansion valve is located upstream from the battery heat exchanger, and a battery cooling shut-off valve selectively blocks the flow of refrigerant through the battery heat exchanger. The shut-off valves and compressor are controlled to control the cooling of the passenger cabin and the battery pack.

Owner:GM GLOBAL TECH OPERATIONS LLC

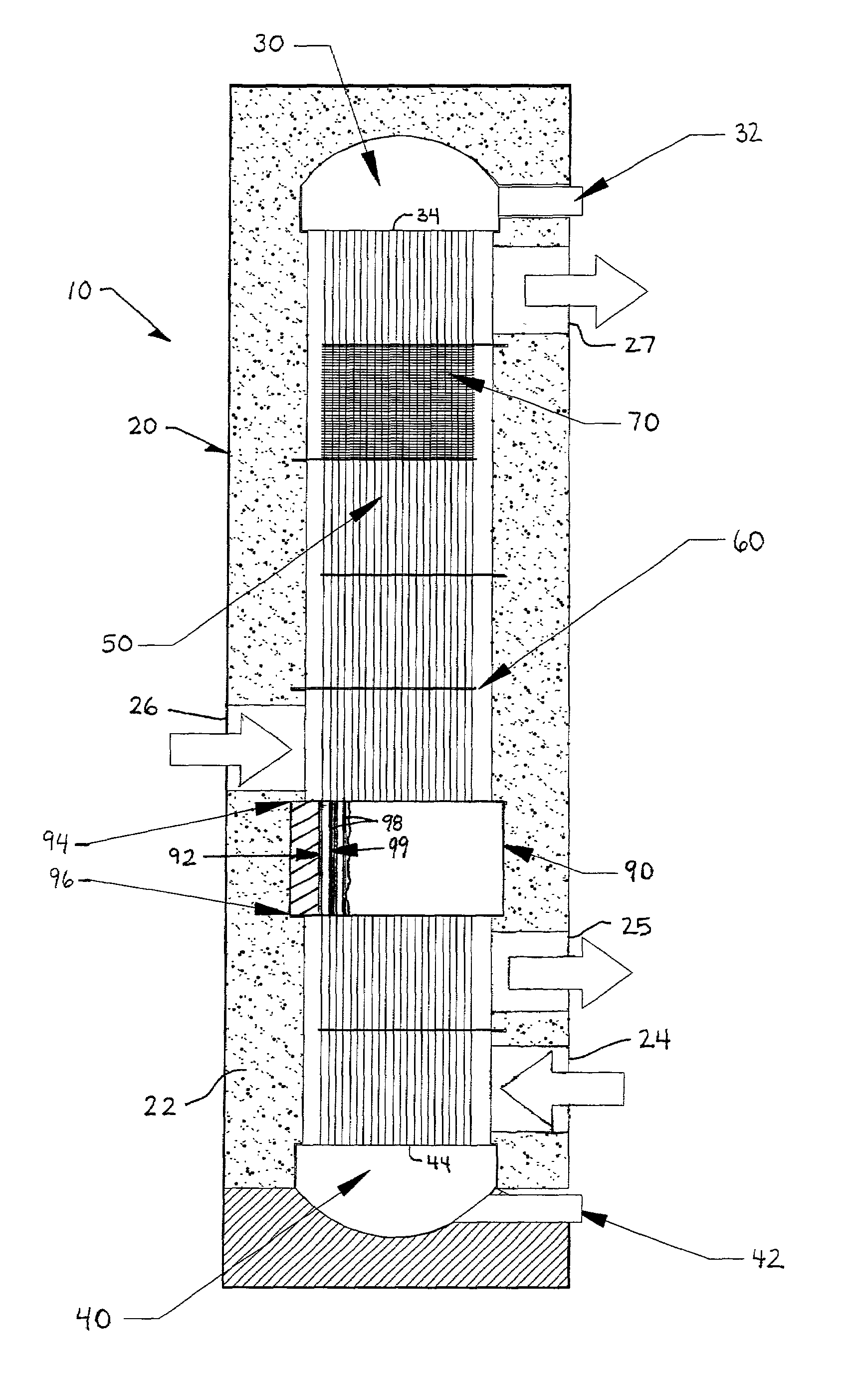

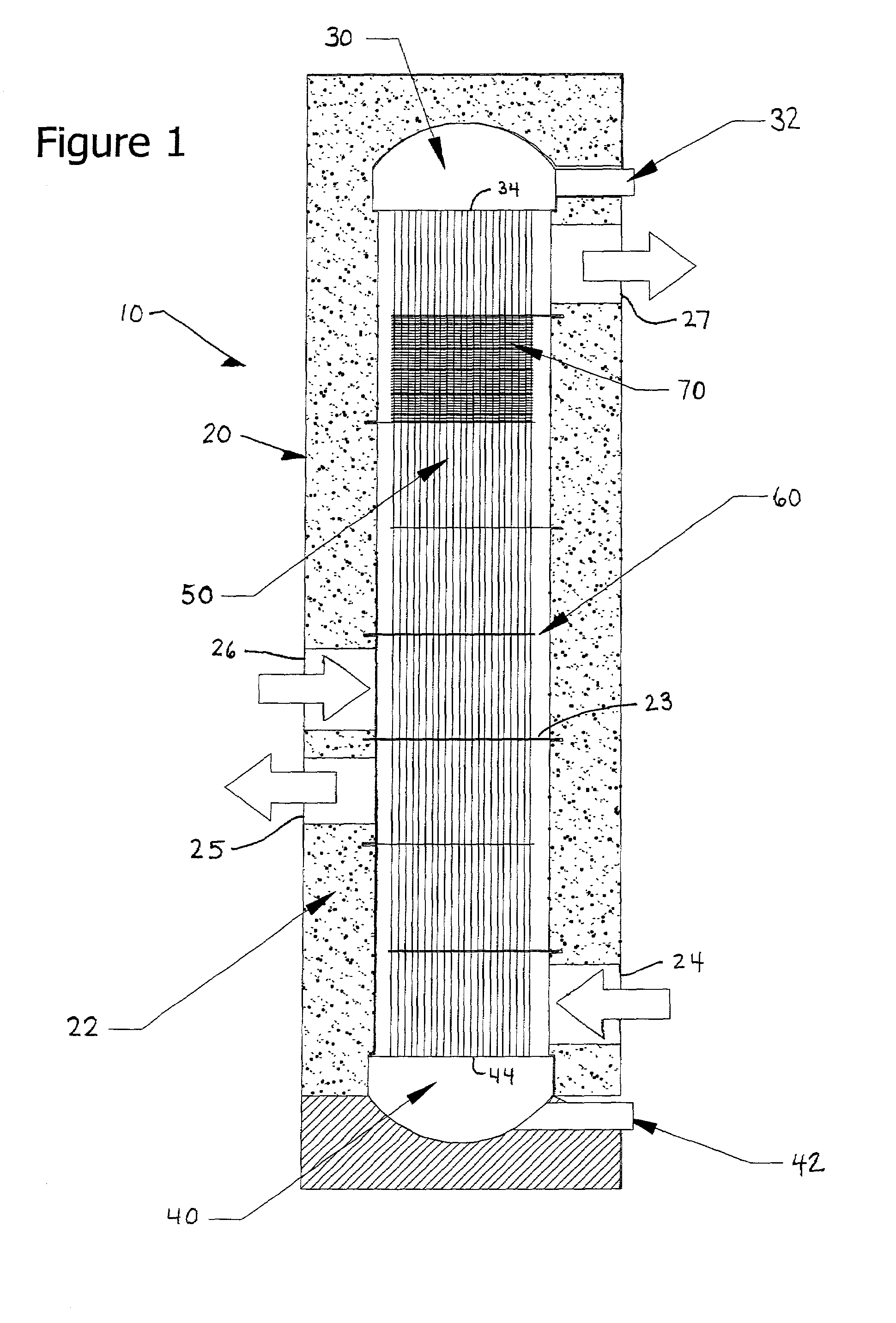

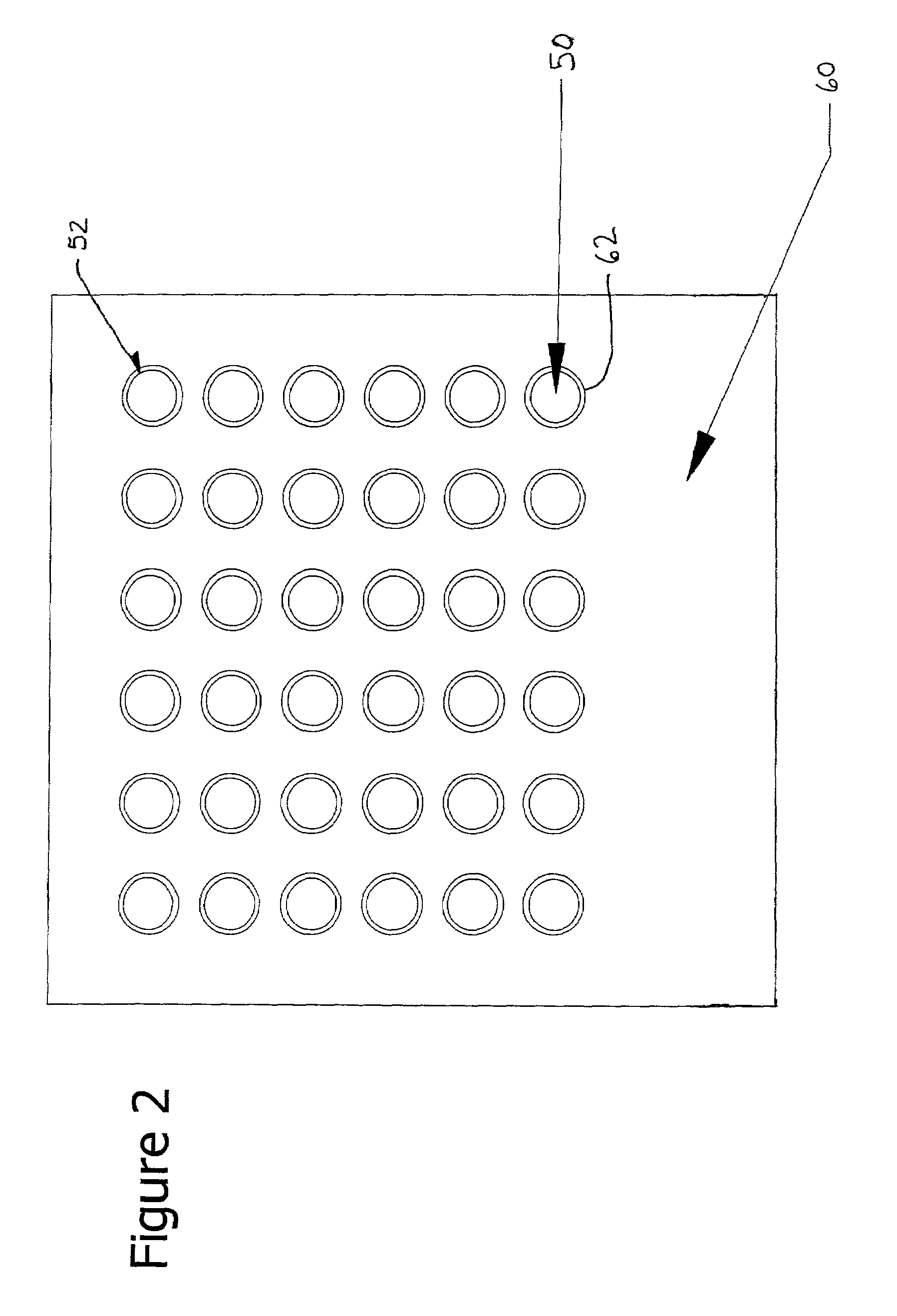

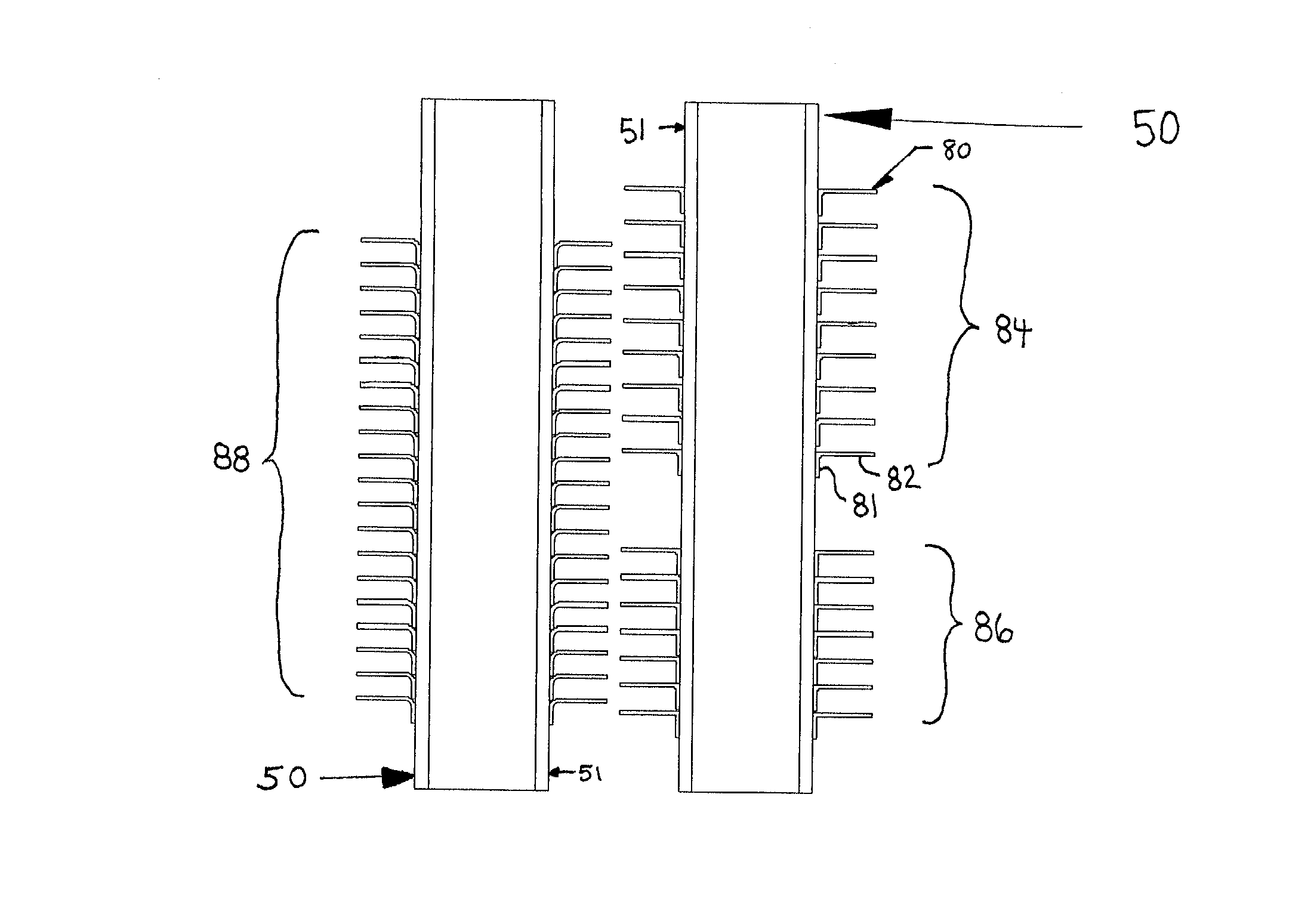

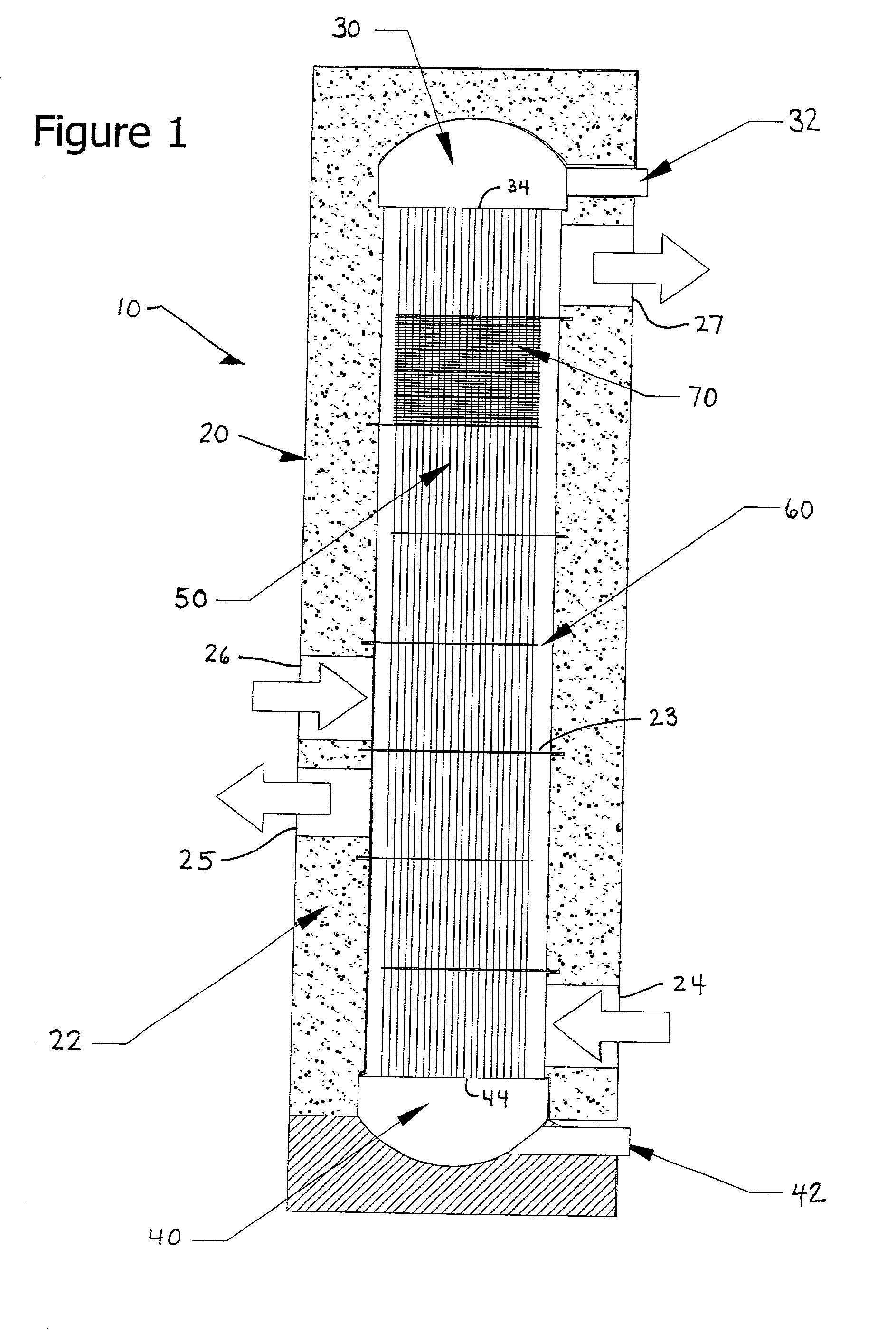

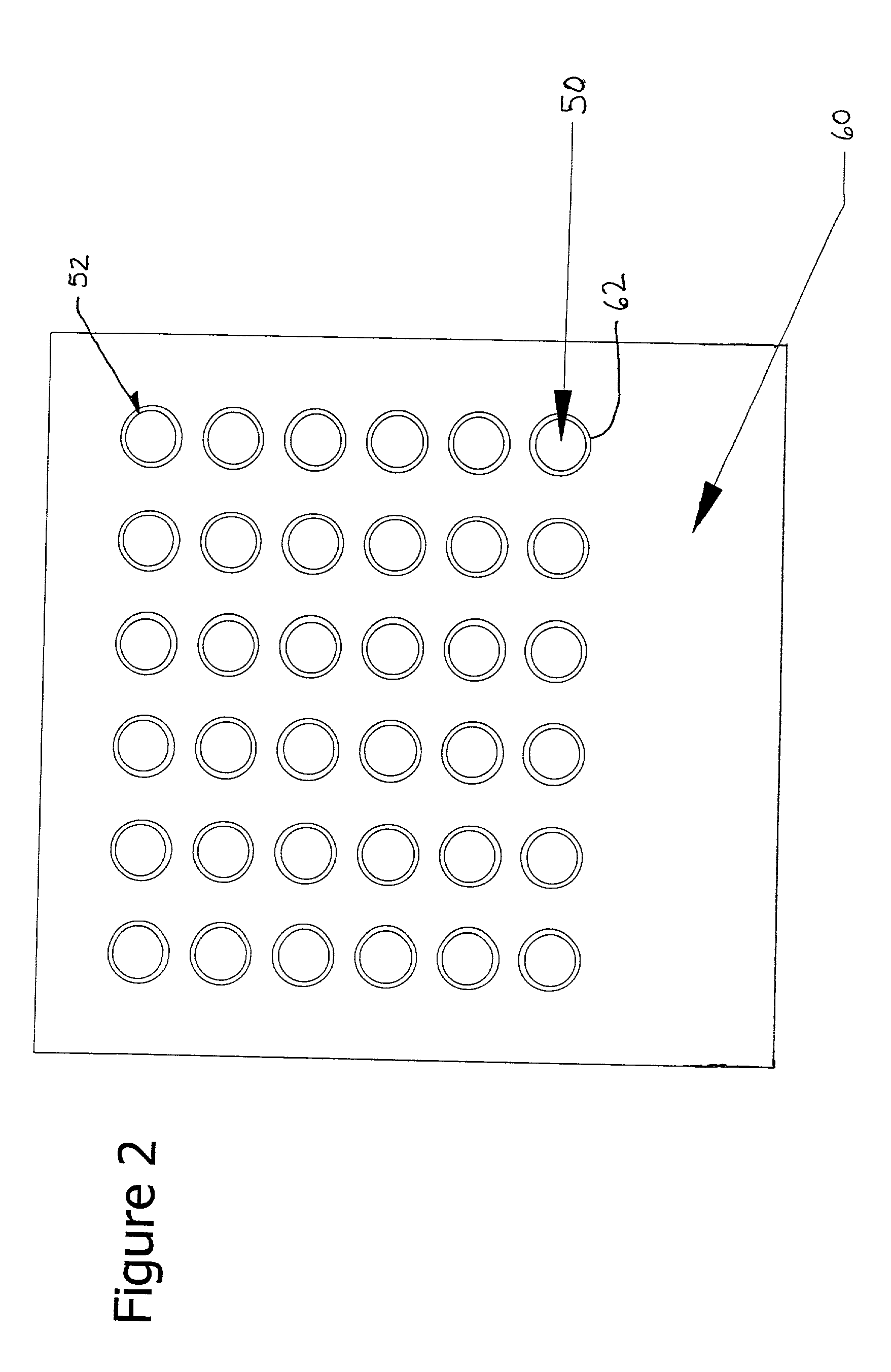

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS7117934B2Improve corrosion resistanceHigh strengthChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS20030173062A1Minimize adverse effectsMinimize thermal expansion differencesChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

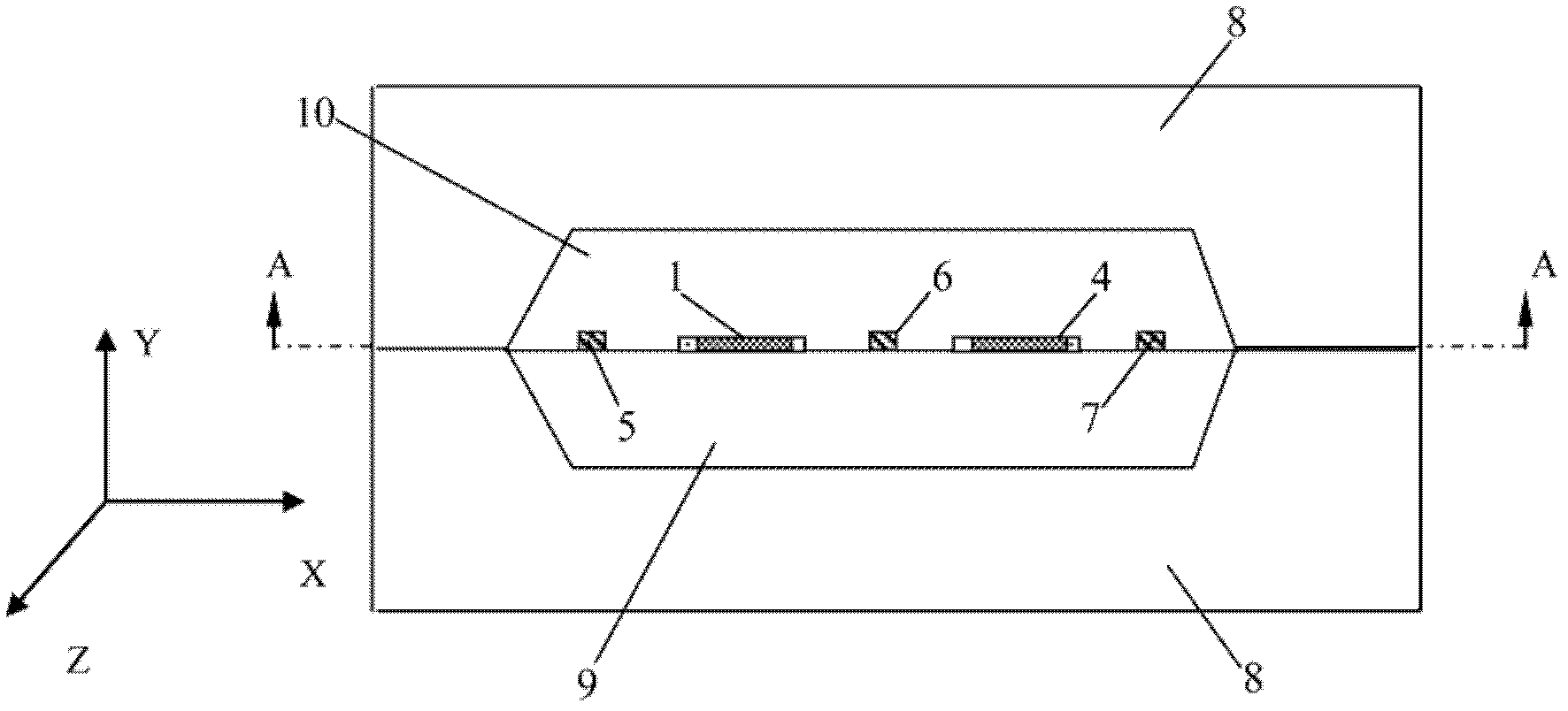

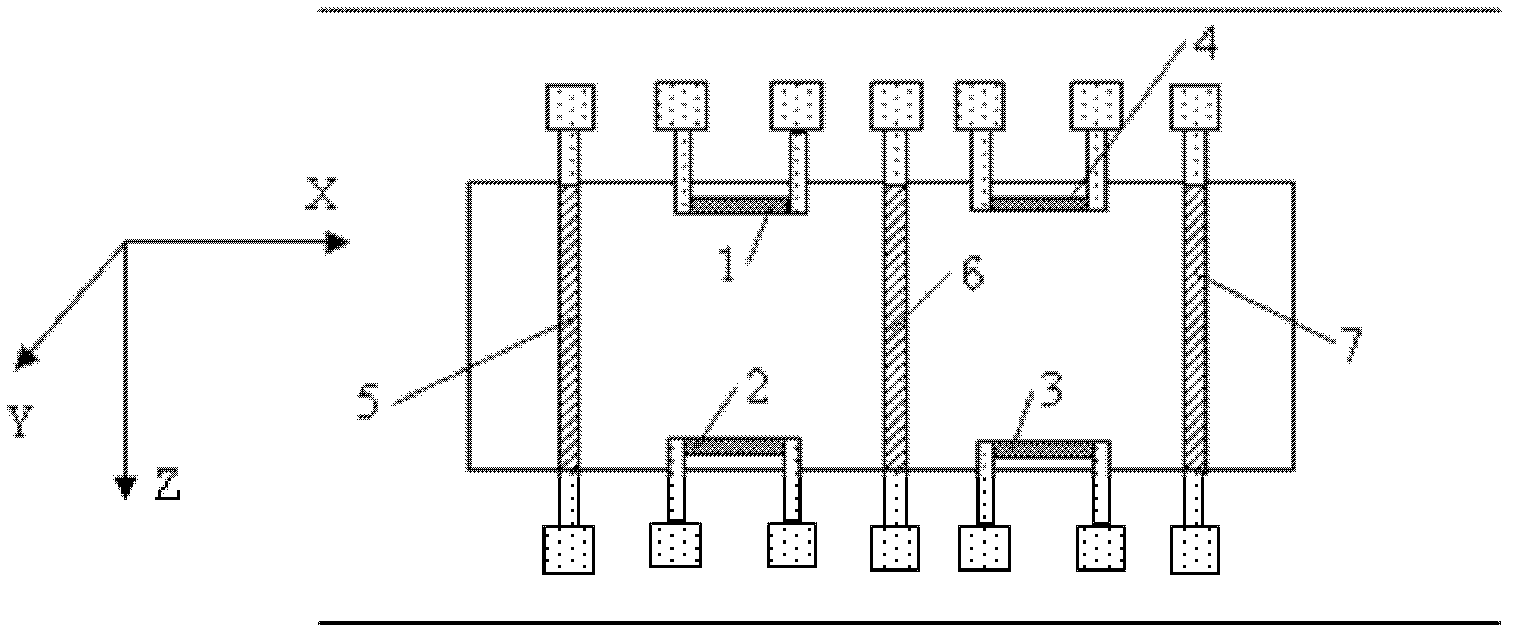

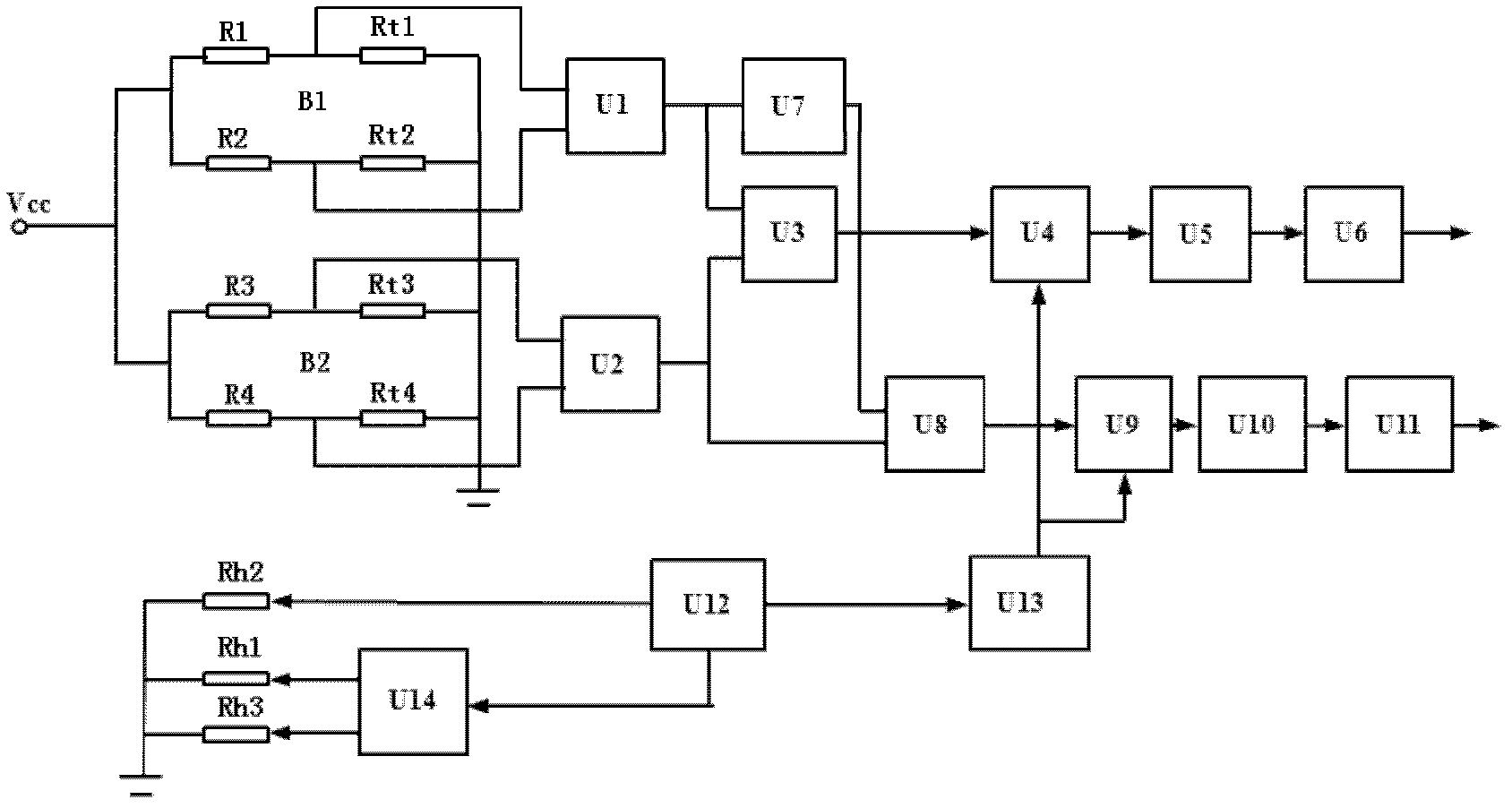

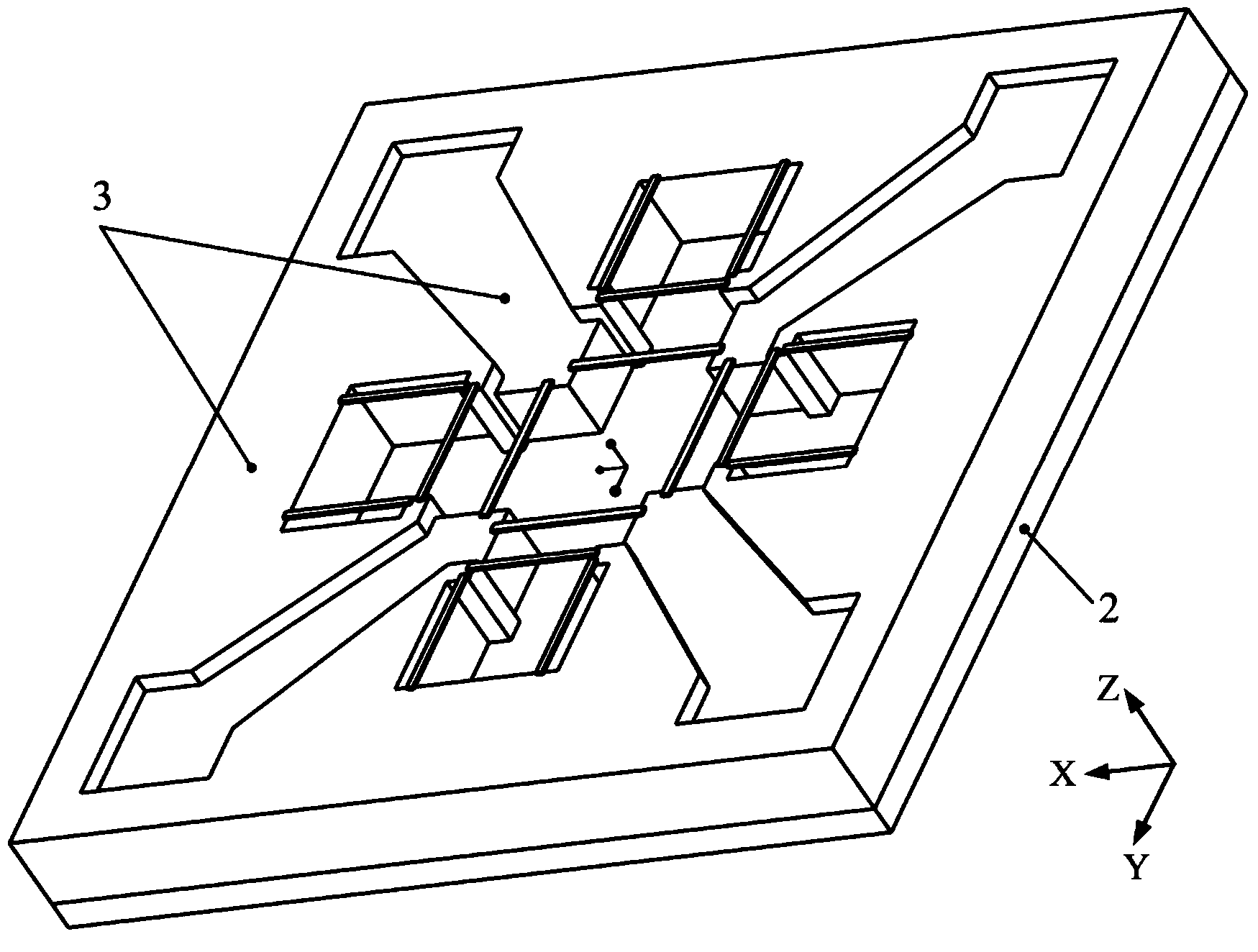

Micro thermal drive airflow gyro and manufacture method thereof

ActiveCN102645212AReduced Sensitivity EffectsInhibition of heat convectionTurn-sensitive devicesComputer moduleThermal expansion

The invention relates to a micro angle speed sensor, in particular to a micro thermal drive airflow gyro, which comprises a micro cavity body, three heating elements, two pairs of thermosensitive elements, a detection circuit and a control circuit module. The height of the micro cavity body is 100mu-1000mu, the heating elements and the thermosensitive elements are fixed in the micro cavity body in a suspended mode, the heating elements are parallelly arranged in the micro cavity body in a left-and-right mode, a pair of thermosensitive elements is arranged between two adjacent heating elements, and each pair of thermosensitive elements is symmetrically distributed on the front side and the rear side of the micro cavity body. The detection circuit can detect temperature signals of the thermosensitive elements, and the control circuit can control heating of the heating elements. By means of the micro thermal drive airflow gyro, a thermal expansion flow or a contraction flow of air in the micro cavity body is stable, controllability of the air flow is good, thermal convection is effectively inhibited, and influences of outside acceleration on sensitivity of the sensor are reduced.

Owner:TSINGHUA UNIV

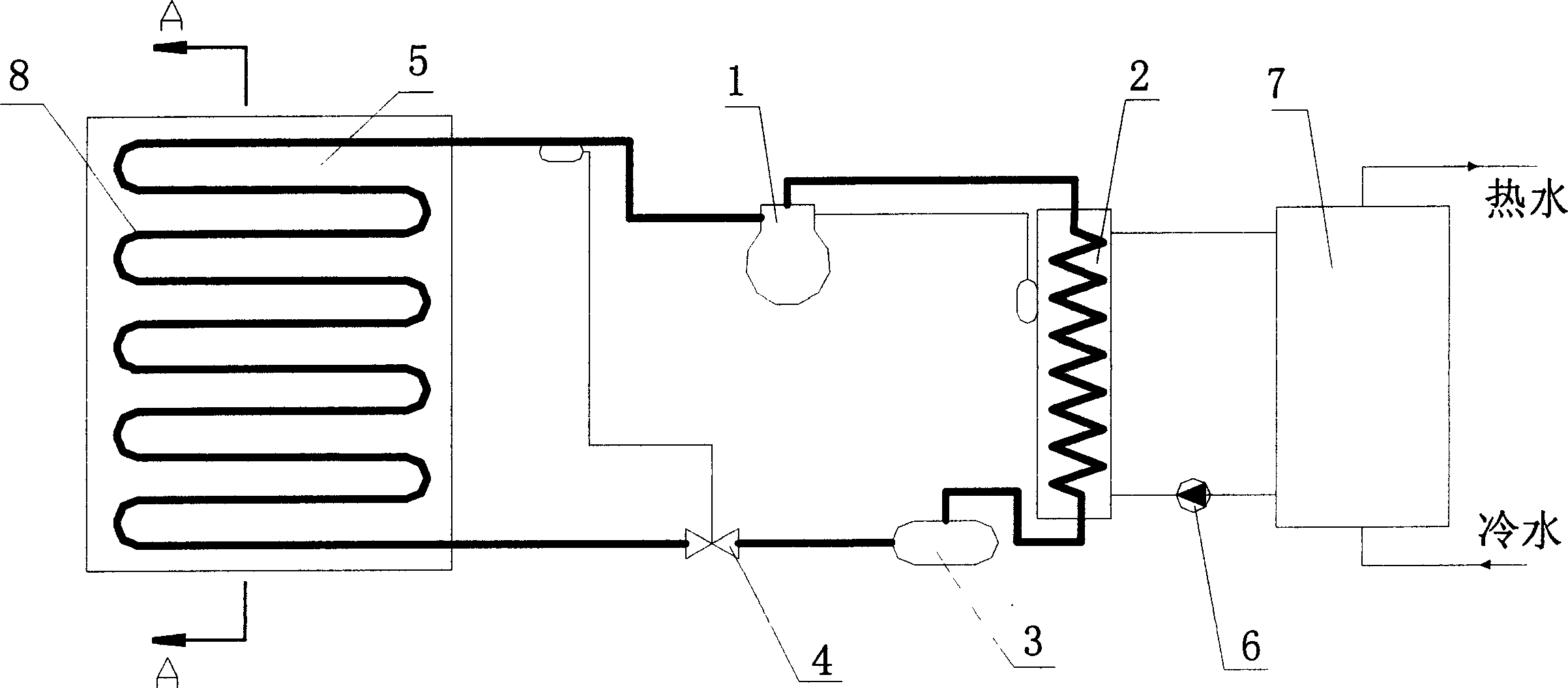

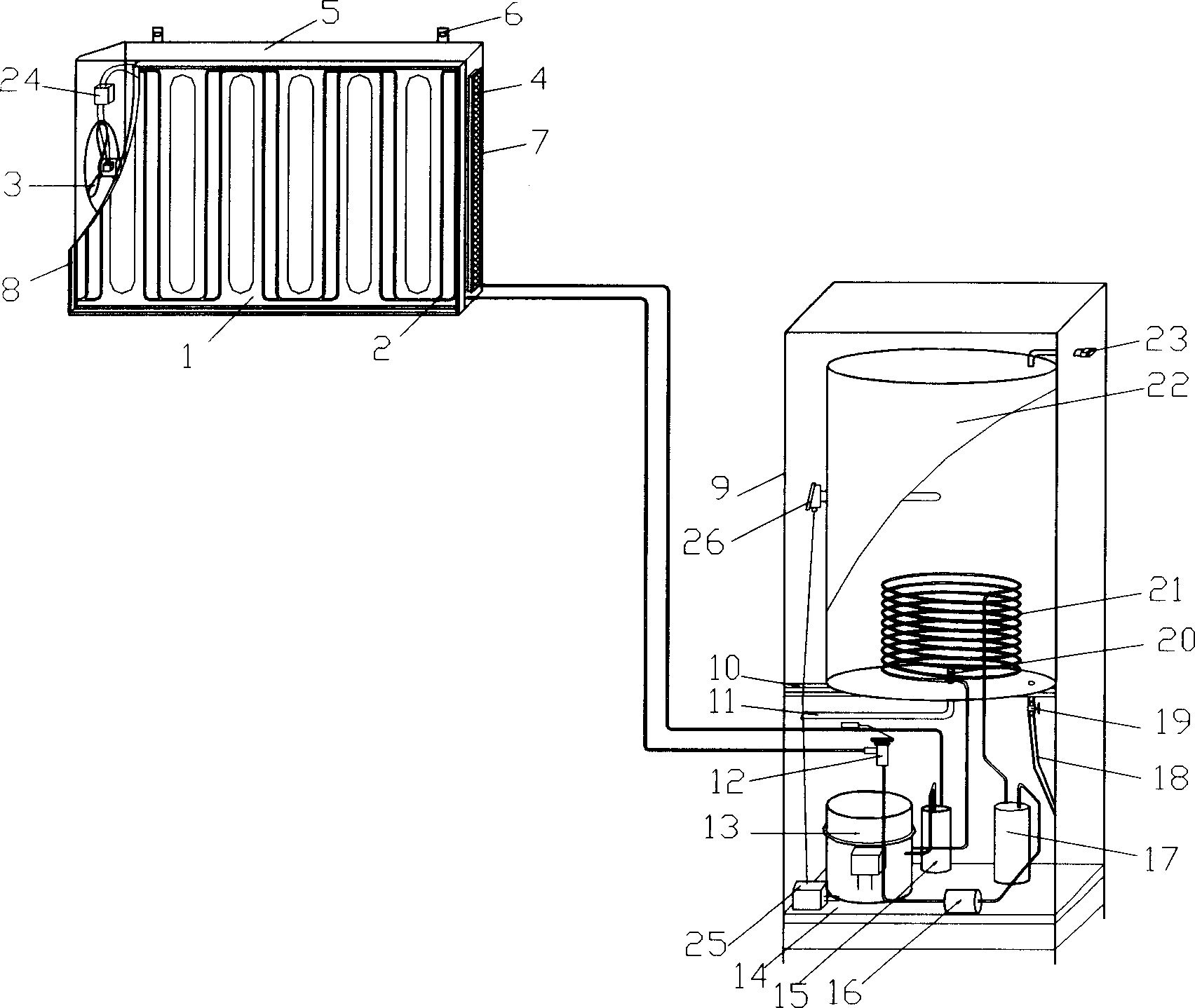

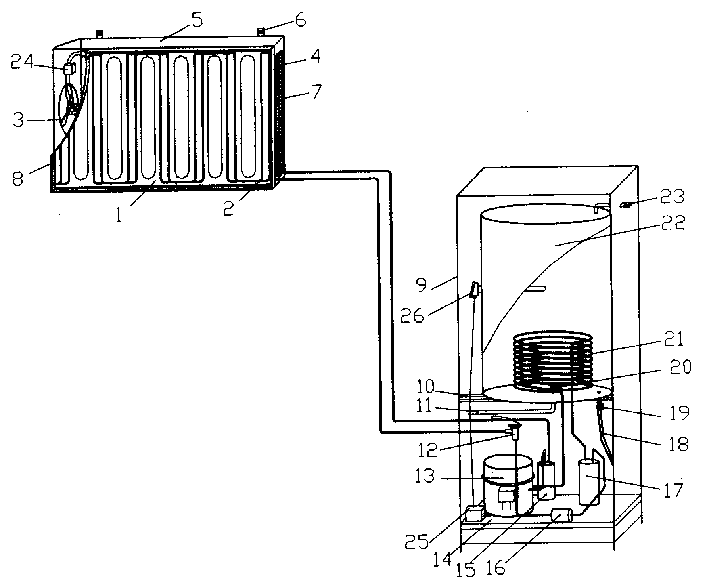

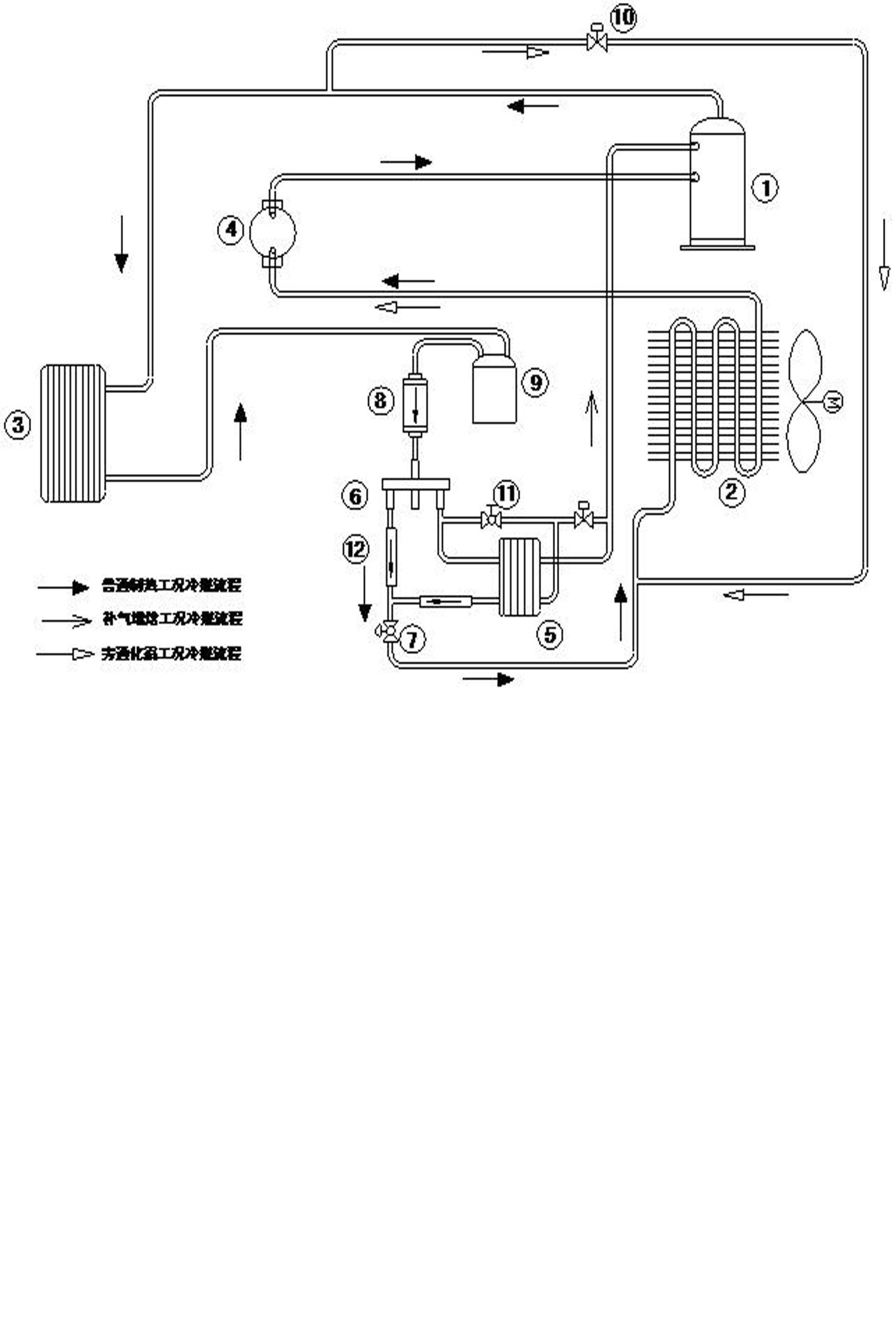

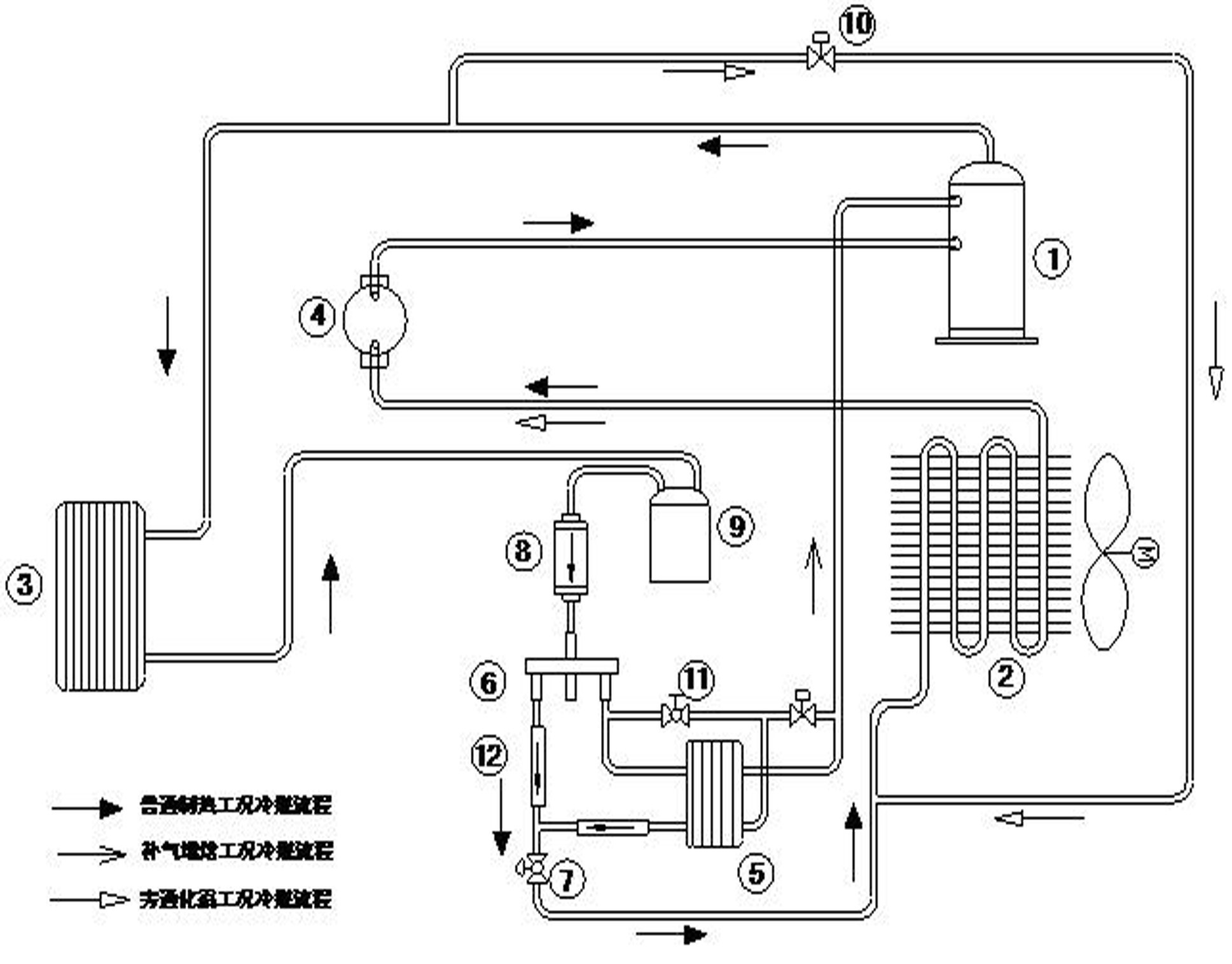

Air source low-temperature heat pump water heater

InactiveCN101650075APlay a key roleIncrease enthalpy differenceFluid heatersFour-way valveEngineering

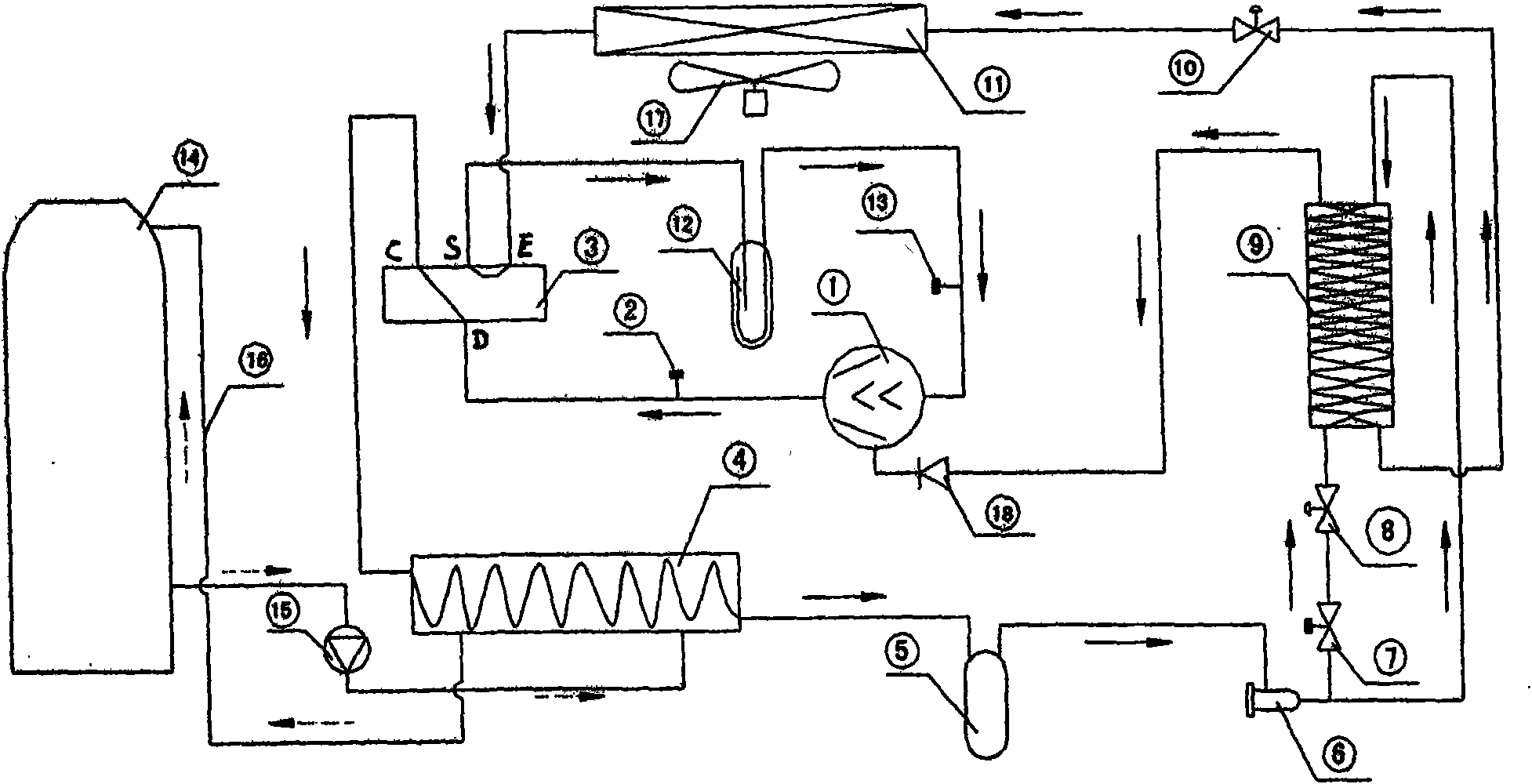

The invention discloses an air source low-temperature heat pump water heater, comprising a main machine, a thermal storage heat insulating water tank, a controller, a four-way valve, a jet enthalpy increasing compressor, a high-pressure switch, a sleeve condenser, a reservoir, a drying filter, an electromagnetic valve, an assistant thermal expansion valve, an economizer, a main expansion valve, afin evaporator, a gas-liquid separator, a low-pressure switch and a check valve. The D direction of the four-way valve is connected with a gas discharging pipe of the jet enthalpy increasing compressor through the high-pressure switch, the C direction is connected with a gas inlet of the sleeve condenser, the S direction is connected with a gas absorbing port of the jet enthalpy increasing compressor through the gas-liquid separator and the low-pressure switch, the E direction is connected with a gas outlet of the fin evaporator, an outlet of the sleeve condenser is divided into two paths after passing through the reservoir and the drying filter, the main path directly enters the economizer and then enters a liquid inlet of the fin evaporator through a main thermal expansion valve, the secondary path enters the economizer through a liquid path electromagnetic valve and the assistant thermal expansion valve, and then enters an assistant gas inlet of the jet enthalpy increasing compressor through the check valve. The invention can ensure the supply of hot water all day in every season in northern places.

Owner:ZHEJIANG AMA & HIEN TECH

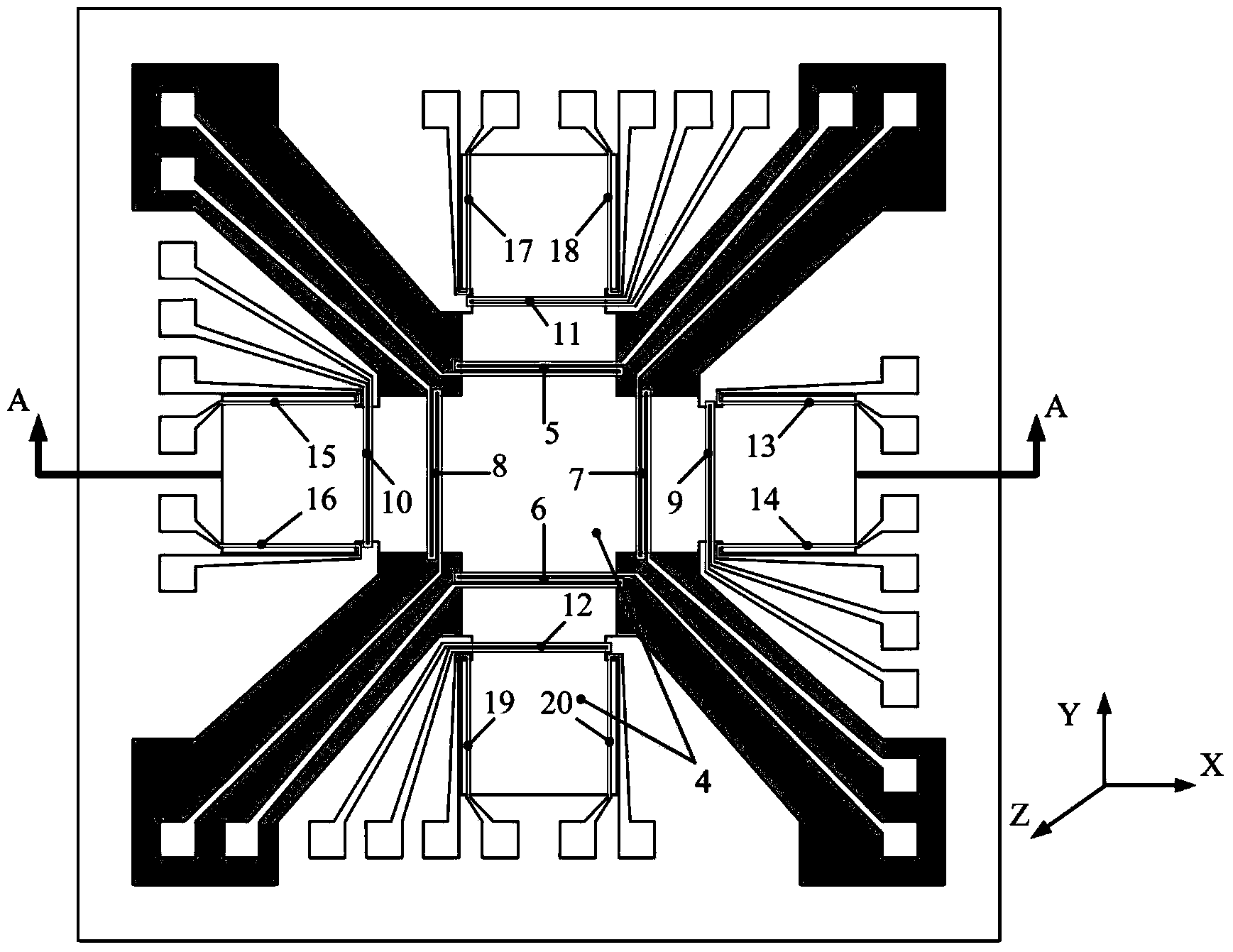

MEMS three-axis gyroscope based on thermal expansion flow and machining method thereof

ActiveCN103900544ARealize multi-degree-of-freedom measurementHighly integratedDecorative surface effectsSolid-state devicesElectrical resistance and conductanceGyroscope

The invention discloses an MEMS three-axis gyroscope based on a thermal expansion flow and a machining method thereof and belongs to the field of inertia measurement. The gyroscope mainly comprises an upper sealing layer, a lower base layer and a middle detection layer, wherein the middle detection layer is provided with a cross-shaped detection cavity, and a metal resistance bridge heating element and a metal resistance bridge thermosensitive element which are located in the detection cavity. According to the MEMS three-axis gyroscope based on the thermal expansion flow disclosed by the invention, the detection layer with a ladder structure, the cross-shaped detection cavity and a suspended metal resistance bridge are arranged so as to realize simultaneous measurement of a space three-axis angular speed; the MEMS three-axis gyroscope has a very high integration level; the interferences on the measurement of an angular speed signal by a Z-axis acceleration input can be eliminated, so that the multi-degree of freedom measurement of the MEMS three-axis gyroscope based on the thermal expansion flow is realized. Furthermore, the detection layer, the base layer and the cross-shaped detection cavity of the micro-gyroscope can be formed by adopting an MEMS silicon micro-processing process, so that the MEMS three-axis gyroscope based on the thermal expansion flow has the advantages of small size, low power consumption, low cost and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

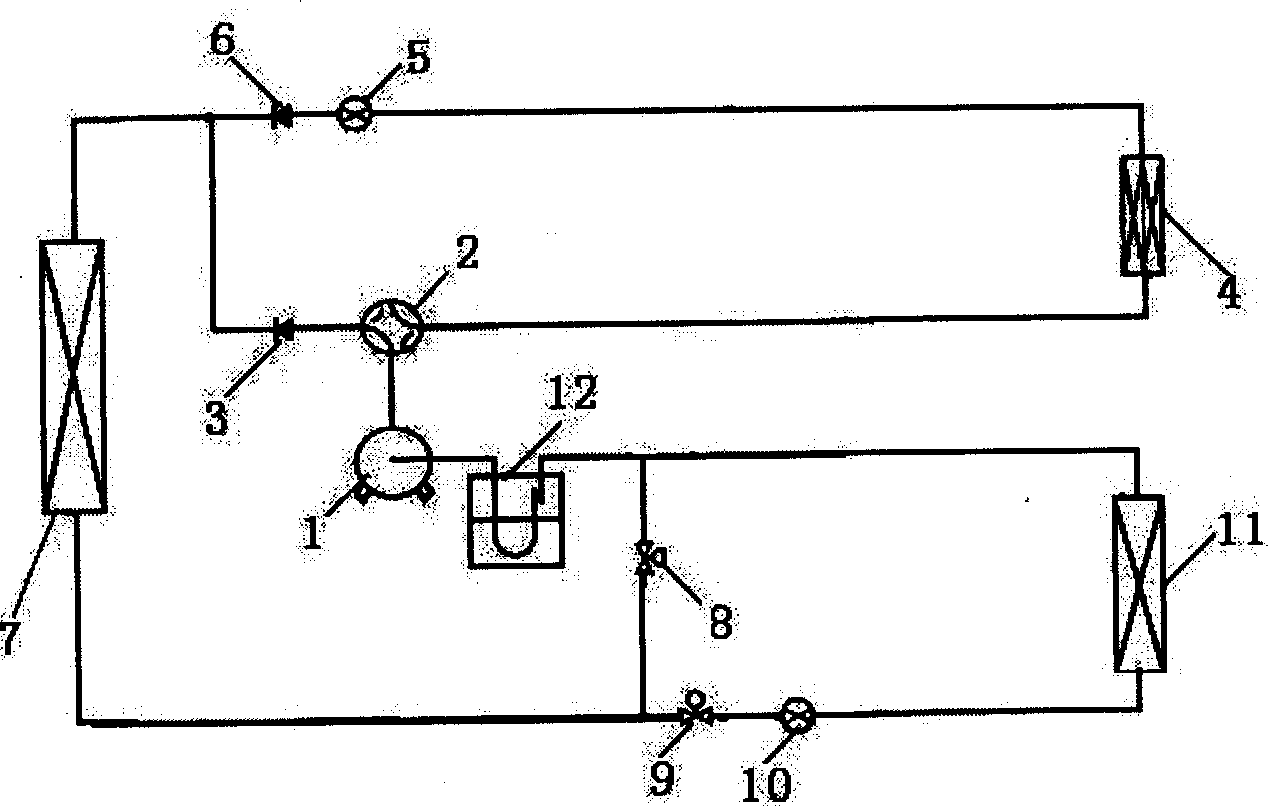

Air source heat pump ultrasound wave defrosting system

InactiveCN101144669AAchieve Ultrasonic DefrostEnsure continuous heating operationCorrosion preventionRefrigeration componentsVapor–liquid separatorFour-way valve

The invention discloses an air source heat pump ultrasonic defrosting system, which relates to the defrosting system of the products such as household and commercial air source heat pump, etc. The invention comprises a compressor, a four-way valve, an indoor heat exchanger, a heating cone-way valve, a heating expansion valve, a refrigeration cone-way valve, a refrigeration expansion valve, an outdoor heat interchanger, and an air-fluid separator, wherein, the four-way valve is respectively connected with the compressor, the indoor heat exchanger, the outdoor heat interchanger and the air-fluid separator, the indoor heat exchanger is connected with the heating cone-way valve and the heating expansion valve, the heating cone-way valve and the heating expansion valve are connected with one end of the refrigeration cone-way valve and the refrigeration expansion valve through a pipeline, and the other ends of the refrigeration cone-way valve and the refrigeration expansion valve are connected with the outdoor heat interchanger. The invention is characterized in that an ultrasonic launcher and a temperature sensor are respectively arranged on the outdoor heat interchanger, and the ultrasonic launcher is connected with the temperature sensor through a controller. The invention realizes the purposes of improving the defrosting speed, reducing the energy consumption of the defrosting, and improving the operation efficiency of the heat pump.

Owner:SOUTHEAST UNIV

Air source heat pump water heater unit with phase change heat accumulation

InactiveCN102798214AIncrease steam flowIncrease heating capacityFluid heatersHeat storage plantsThermal expansionEngineering

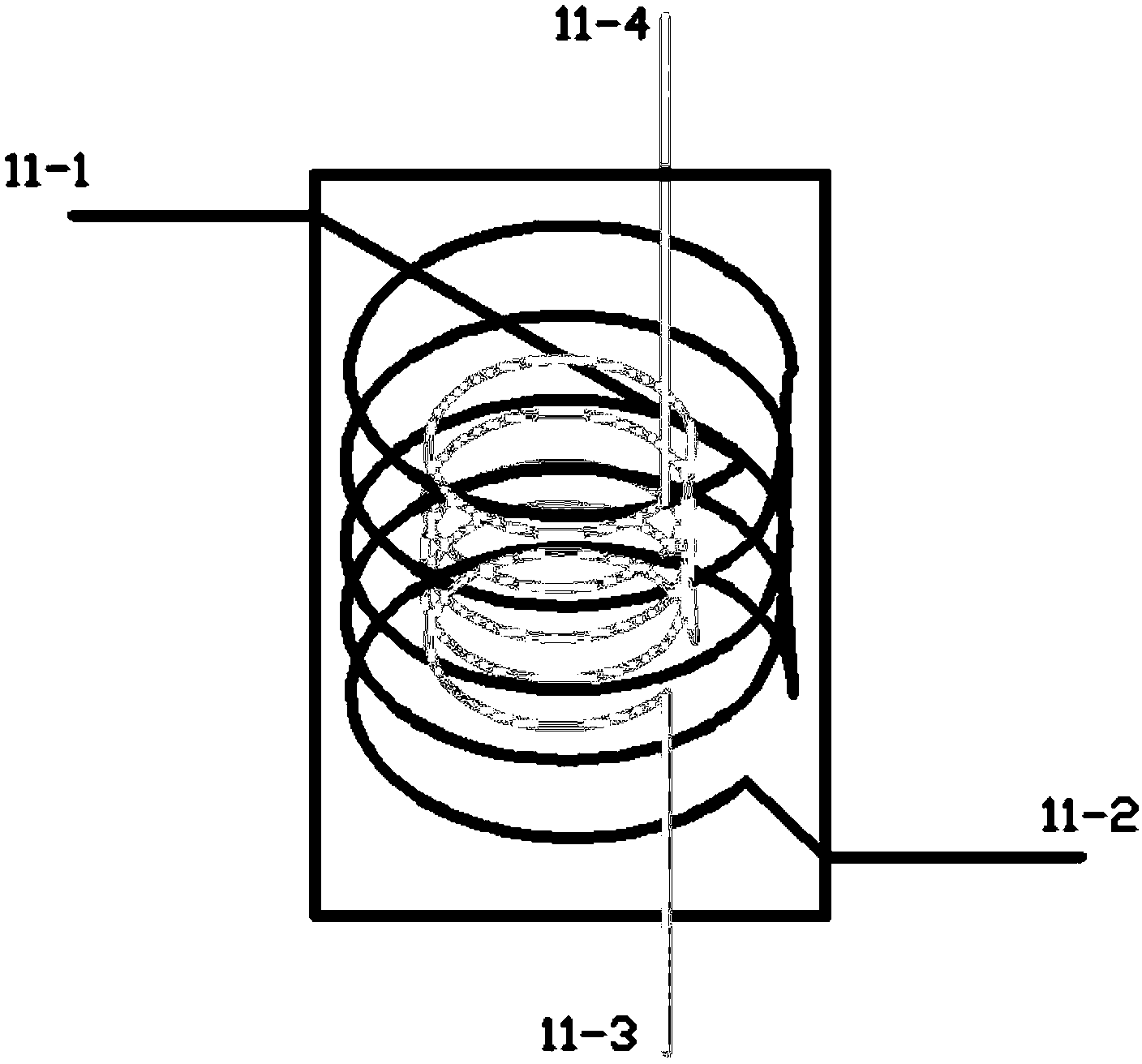

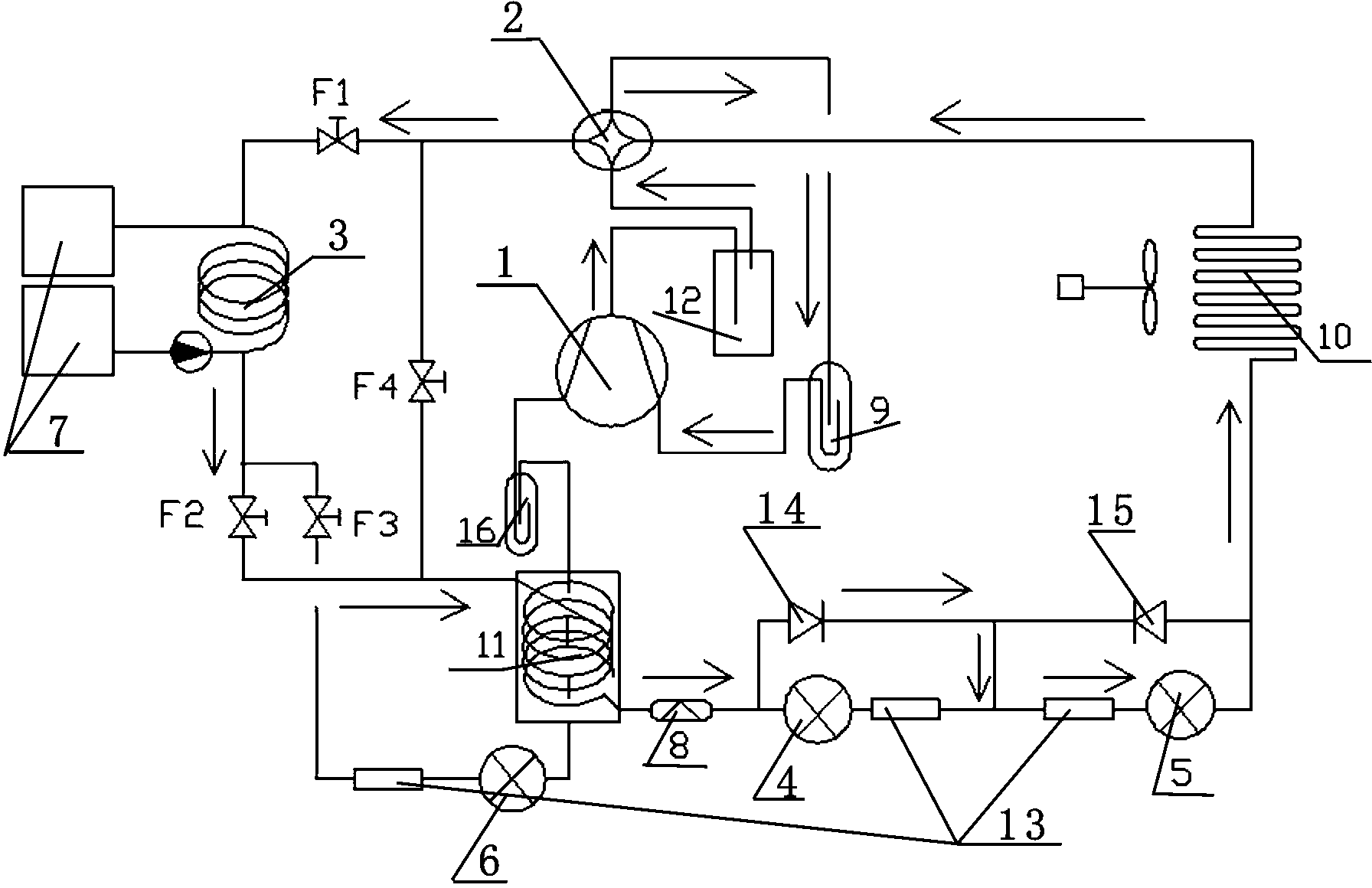

The invention relates to an air source heat pump water heater unit, and particularly to an air source heat pump water heater unit with a phase change heat accumulator. An air source heat pump water heater unit with phase change heat accumulation is provided, which comprises a scroll compressor, an oil separator, a plurality of gas-liquid separators, a four-way reversing valve, a plurality of electromagnetic valves, a plurality of check valves, a double-pipe condenser, a water tank, a phase change heat accumulator, an evaporator, a dry filter, a liquid sight glass, and a plurality of thermal expansion valves, wherein the scroll compressor is provided with an air suction port, an air supplement port and an air exhaust port, the air suction port is connected with the evaporator via a pipeline, the air supplement port is connected with the phase change heat accumulator via a pipeline, and the air exhaust port is connected with the double-pipe condenser via a pipeline. Even if in a low-temperature environment (of lower than minus 25 DEG C), because the phase change heat accumulator is used as an auxiliary evaporator for the system, for providing heat to the system and supplementing air to the compressor, thus increasing the air input of the compressor, optimizing the running working condition of the compressor, and ensuring the stable and safe low-temperature running of the compressor.

Owner:TAIYUAN UNIV OF TECH

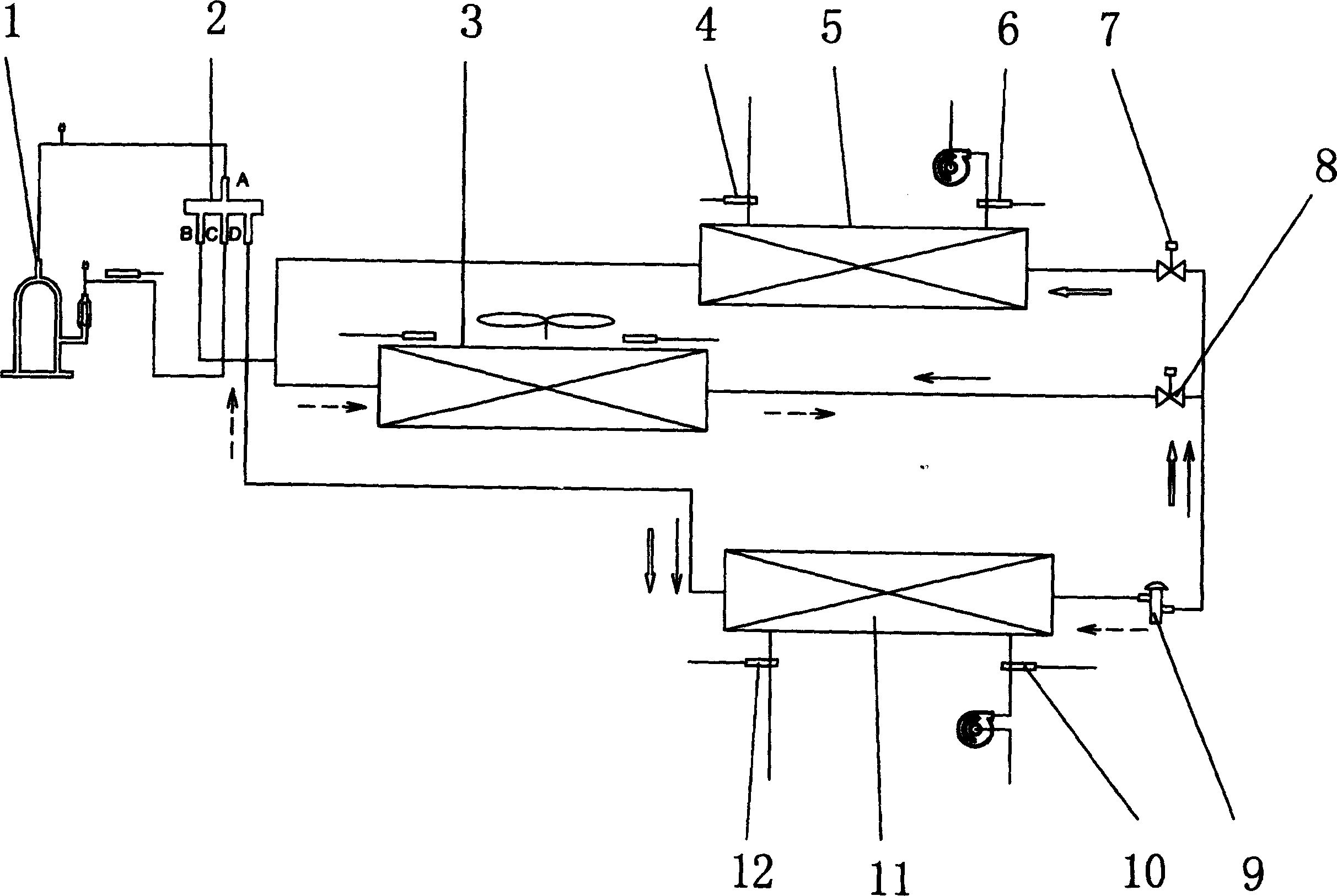

Air-cooled water-cooled two-evaporimeter hot-water machine set

InactiveCN101089518AIncrease heating capacityTo achieve the purpose of supplying domestic hot waterCompression machines with several evaporatorsEnergy industryWater sourcePulp and paper industry

The present invention relates to a kind of air-cooled water-cooled double-evaporator hot-water machine unit for recovering after heat of waste water. It is characterized by that it has a refrigeration circulating loop composed of compressor, water-cooled condenser, air-cooled evaporator and water-cooled evaporator. On said loop a controller is set. Said invention also provides the working principle of said air-cooled water-cooled double-evaporator hot-water machine unit and its concrete operation method.

Owner:扬州辛普森中央空调制造有限公司

Frequency-variable flux-changing heat pump water heater

InactiveCN101319818AGood performance parametersFestive stream statusFluid heatersFuel oilEngineering

The invention provides a frequency and flow changing heat pump water heater, relates to a liquid heater with a heat generation device by using a heat pump. The frequency and flow changing heat pump water heater comprises a unit part, a water circulating part, water tubes and communication lines connected inside the water circulating part. The unit part comprises a frequency-changing compressor, a cross tee change valve, a double pipe condenser, an unloading valve, an electronic expansion valve, an evaporator, a fan, a controller, various temperature sensors and pressure sensors. The water circulating part comprises a pump, an outlet valve, a ball valve, a water tank, a water temperature sensor and a filter. The frequency and flow changing heat pump water heater takes the frequency-changing compressor as the power source of the system, takes the electronic expansion valve as a throttling device and uses the water temperature sensor to prevent freezing. Compared with combustion gas, fuel oil, coal or electronic water heater, the frequency and flow changing heat pump water heater has safety, environmental protection and energy saving properties. Compared with the heat pump hot water units, the throttling of which uses rated frequency compressor and thermostatic expansion valve or capillary tubes, the frequency and flow changing heat pump water heater has high heating output power, good heating effect and good environmental adaptability.

Owner:SHANGHAI MO & ELECTRICAL APPLIANCE

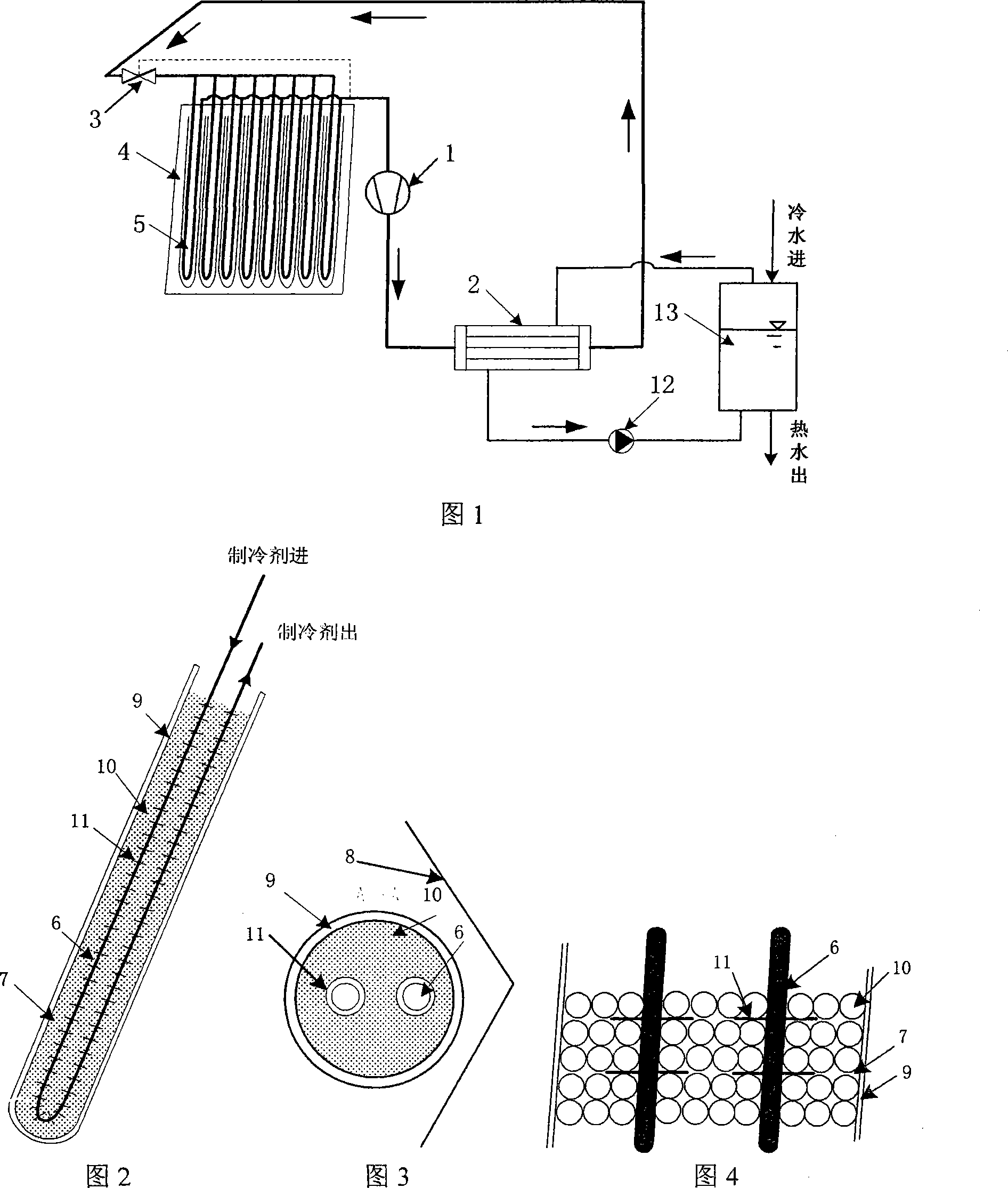

Heat-collecting energy-storage evaporation integral solar energy heat pump system

InactiveCN101169297AAvoid separationUniform heat exchangeSolar heating energyHeat pumpsEvaporationEngineering

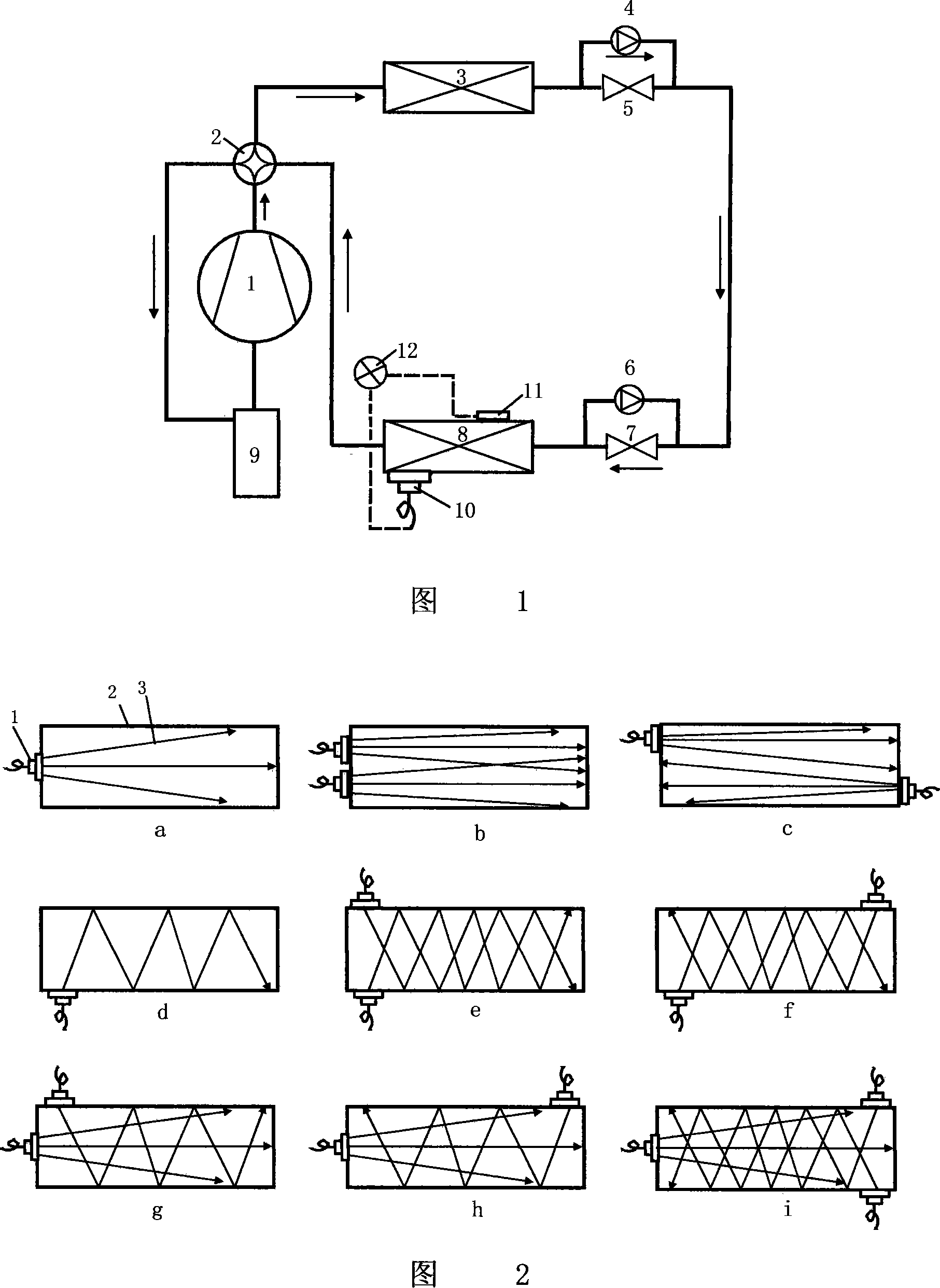

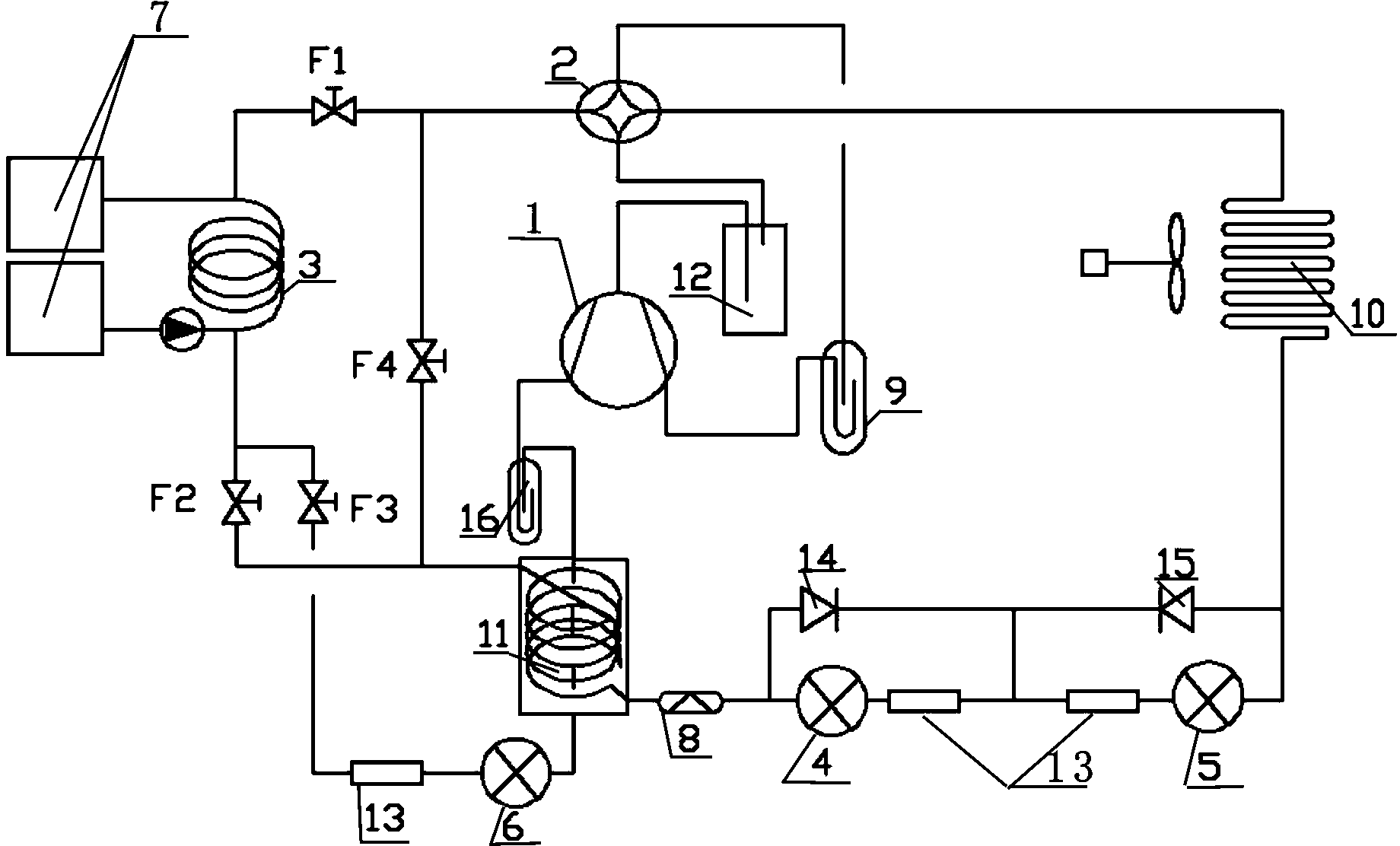

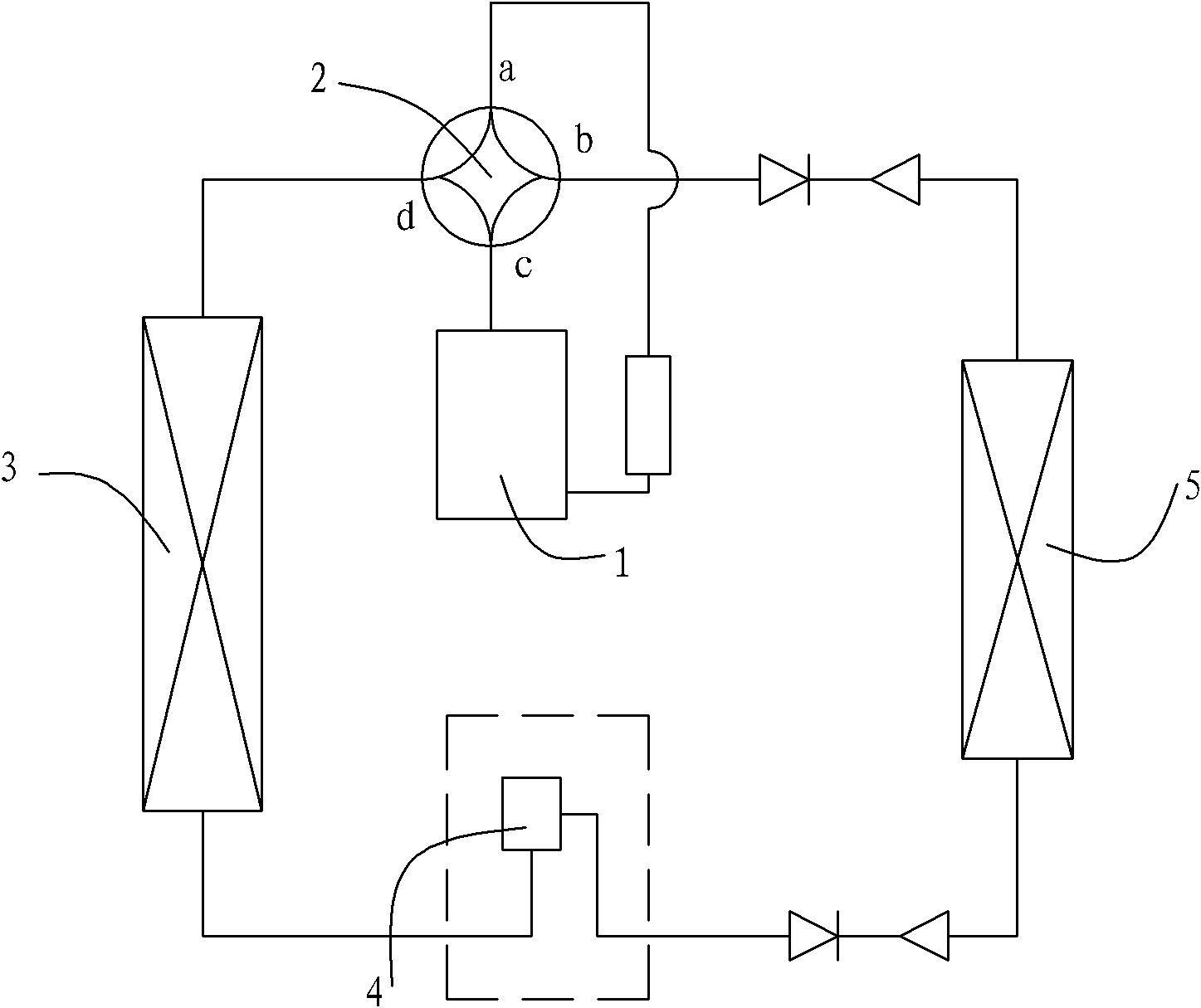

The invention relates to a solar energy hot pump device integrating the functions of heat collection, energy storage and evaporation. Combining a solar energy heat collector, an energy storing container and an evaporator of a hot pump system to a whole, the invention accelerates the heat collecting efficiency of the solar energy heat collector, strengthens the heat exchanging efficiency between the refrigerating fluid in the evaporating tube of the hot pump system and the energy storing medium, thereby ensuring the running with high efficiency and stable ability of the whole energy sorting solar energy hot pump device. The solar energy hot pump device comprises a compressor(1), an enclosed loop which consists of a coolant tube of a water-cooling condenser(2), a heat swelling valve(3), an evaporator(4), a water pump(12) and a water tank(13), wherein, the compressor(1), the coolant tube of the water-cooling condenser(2), the heat swelling valve(3), and the evaporator(4) are serially connected with an enclosed loop, while the water-cooling tube of the water-cooling condenser(2), the water pump(12) and the water tank(13) are connected in series with an enclosed loop, wherein, the evaporator(4) adopts the solar energy heat collecting / hot pump evaporator.

Owner:SOUTHEAST UNIV

Electric automobile heat-pump air-conditioning system

InactiveCN1709734ASimple structureCompact partsAir-treating devicesVehicle heating/cooling devicesFour-way valveVapor–liquid separator

An air conditioning system of the dynamoelectric automotive heat pump belongs to the field of the heat pump system structure. The invention contains the compressor, the four-through valve, the first unilateralism valve, the inner condensator, the F type heating power inflatable valve, the second unilateralism valve, the outer condensator, the first ending valve, the second ending valve, the H type heat power inflatable valve, the inner evaporator and the gas and liquid segregator. The exit of the compressor connects with the intake of the four-through valve. Two exits of the four-through valve separately connect with the intake of the first unilateralism valve and the inner condensator. The exit of the first unilateralism valve connects with the intake of the outer condensator. The exit of the inner condensator connects with the intake of the F type heating power inflatable valve. The exit of the F type heating power inflatable valve connects with the intake of the second unilateralism valve. The exit of the second unilateralism valve connects with the intake of the outer condensator. The exits of the outer condensator connect separately with the intakes of the first ending valve and the second ending valve. The exit of the first ending valve connects with the intake of the gas and liquid segregator. The structure of the invention is easy.

Owner:SHANGHAI JIAO TONG UNIV

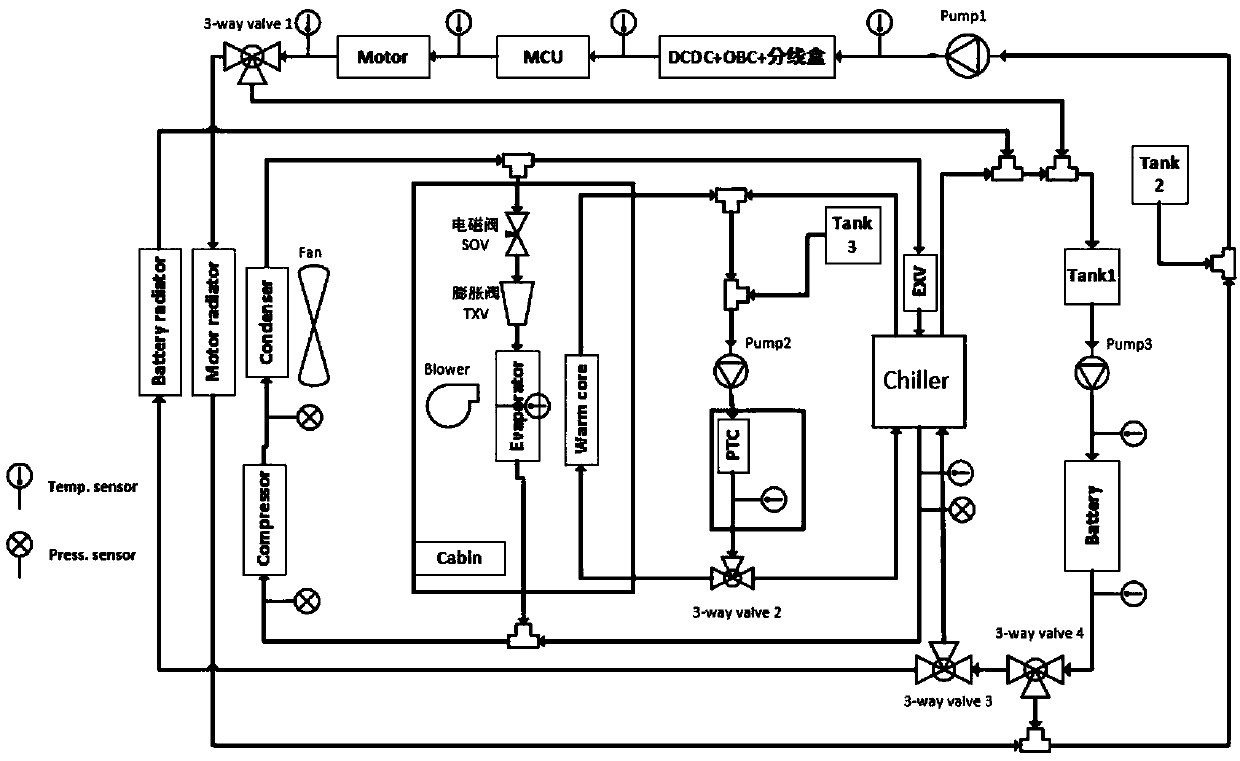

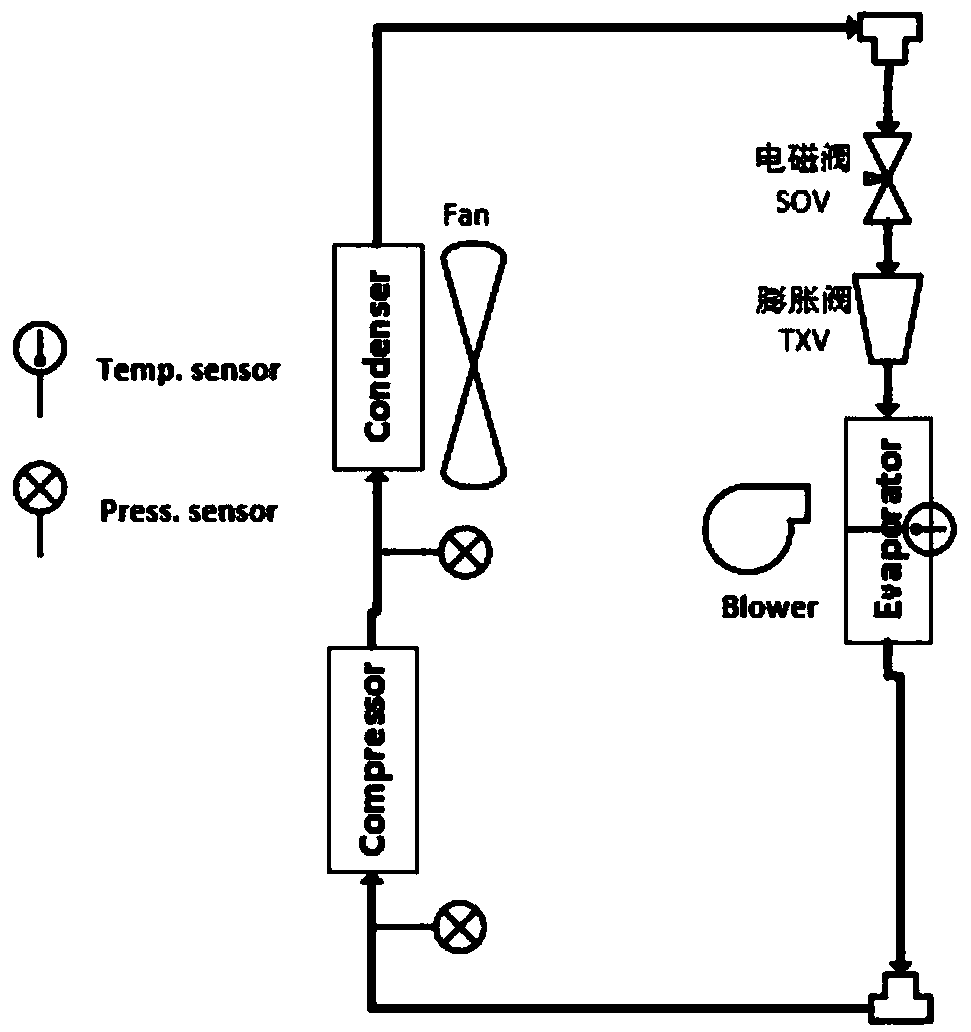

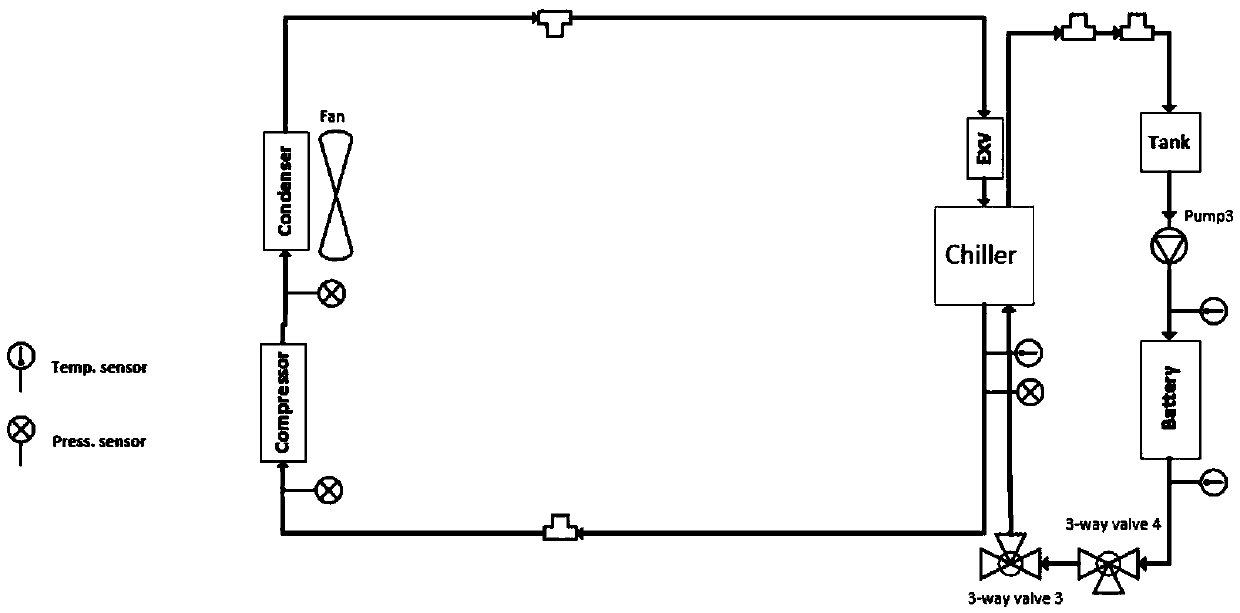

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

Dual-circuit refrigeration system

ActiveUS6978630B2Air-treating devicesCompression machines with non-reversible cycleEngineeringAir conditioning

A refrigeration system and method of refrigeration employ dual refrigeration circuits. Each circuit has an independent compressor, condenser and evaporator. In one refrigeration circuit, the flow of the refrigerant from the condenser to the evaporator is regulated in response to variations in the heat load at the evaporator while, in the other refrigeration circuit, the refrigerant is passed from the condenser to the evaporator at a substantially constant rate of flow. The refrigeration system can be used as a cooling system, including an air conditioning system, and as a heat pump. The evaporator in both circuits may be incorporated within a common heat exchanger as may the two condensers. Additionally, the flow of the refrigerant from the condenser to the evaporator in one refrigeration circuit may be regulated in response to variations in the heat load in the evaporator in that refrigeration circuit by a thermal expansion valve.

Owner:DOMETIC CORP

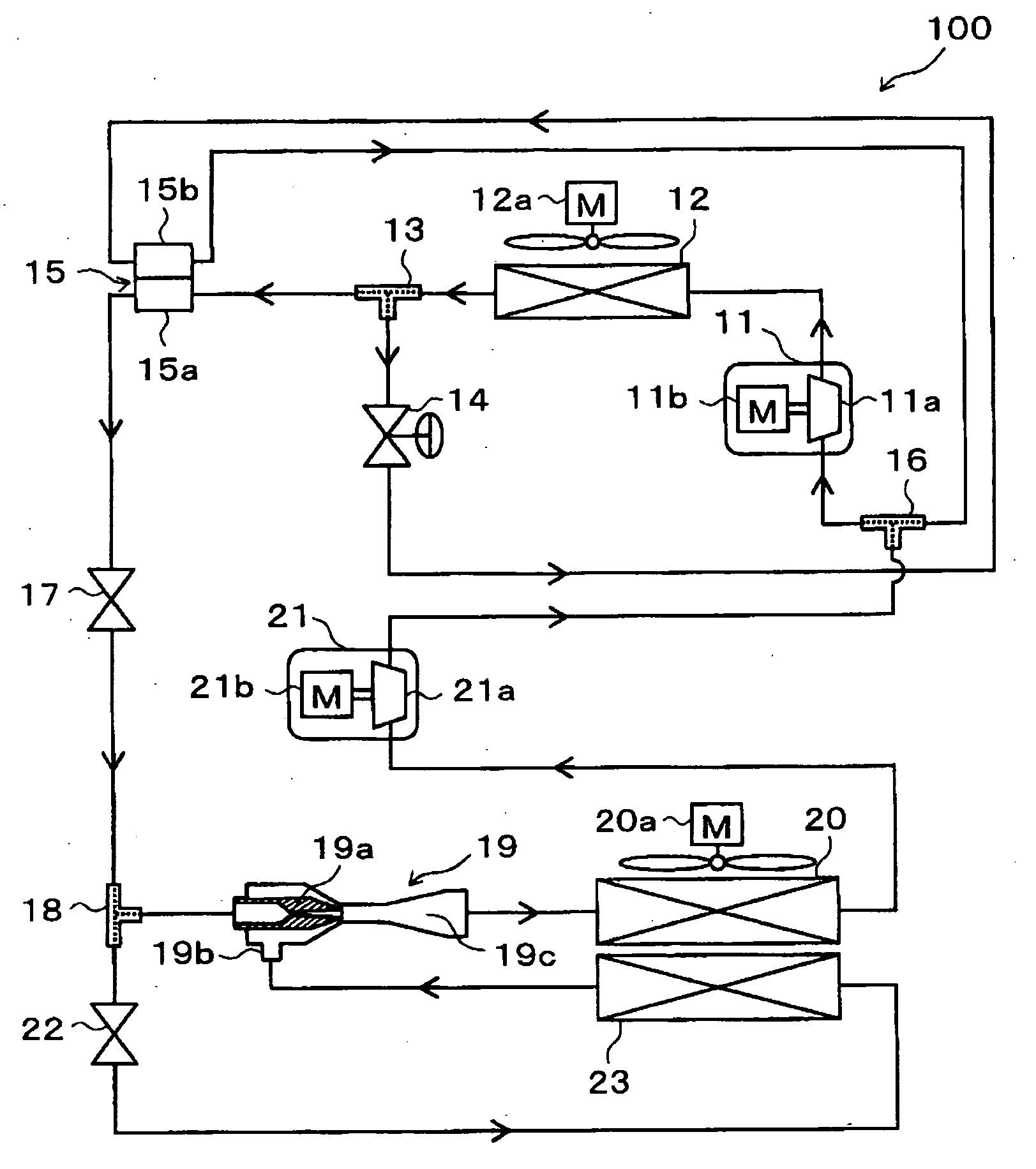

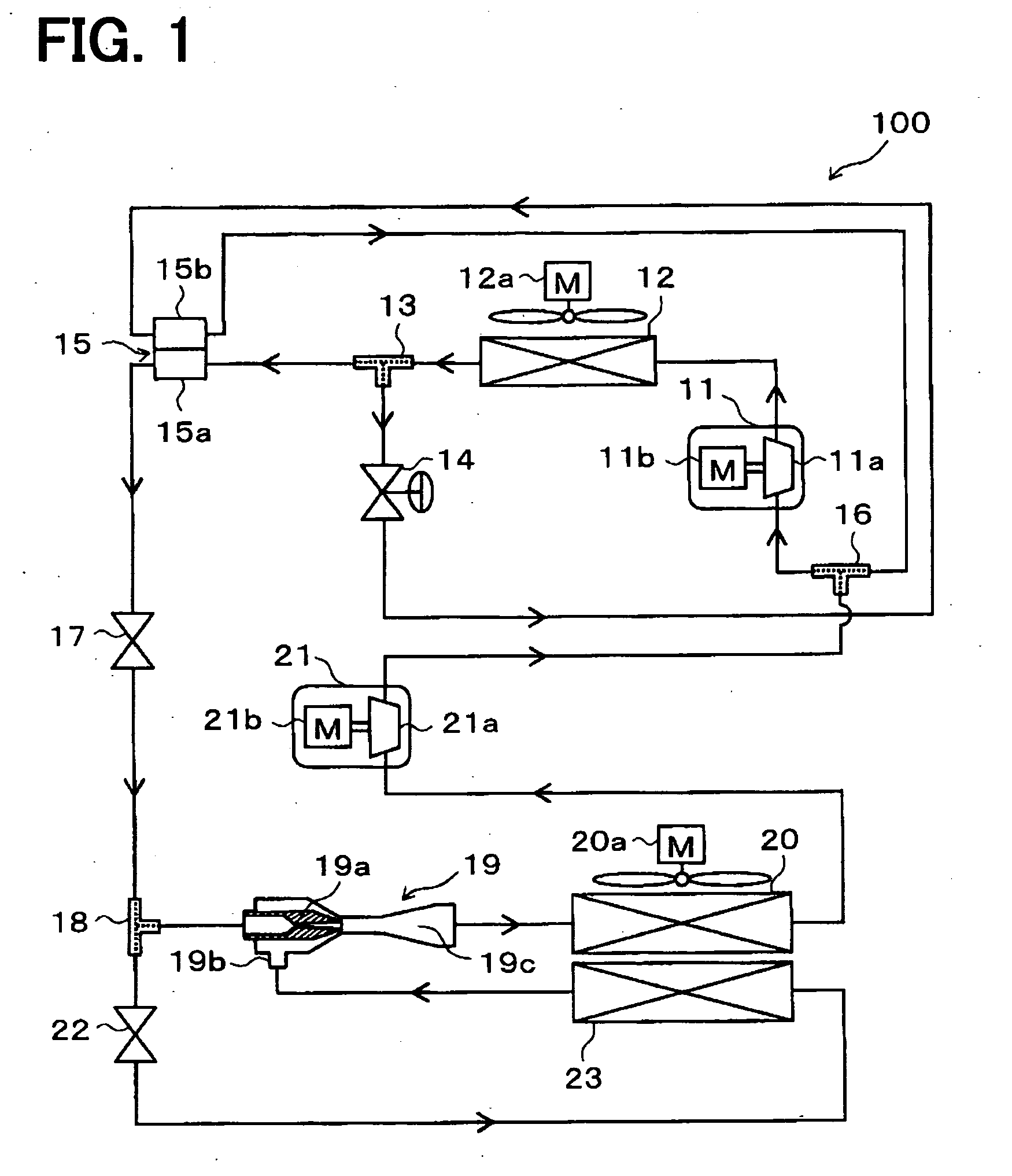

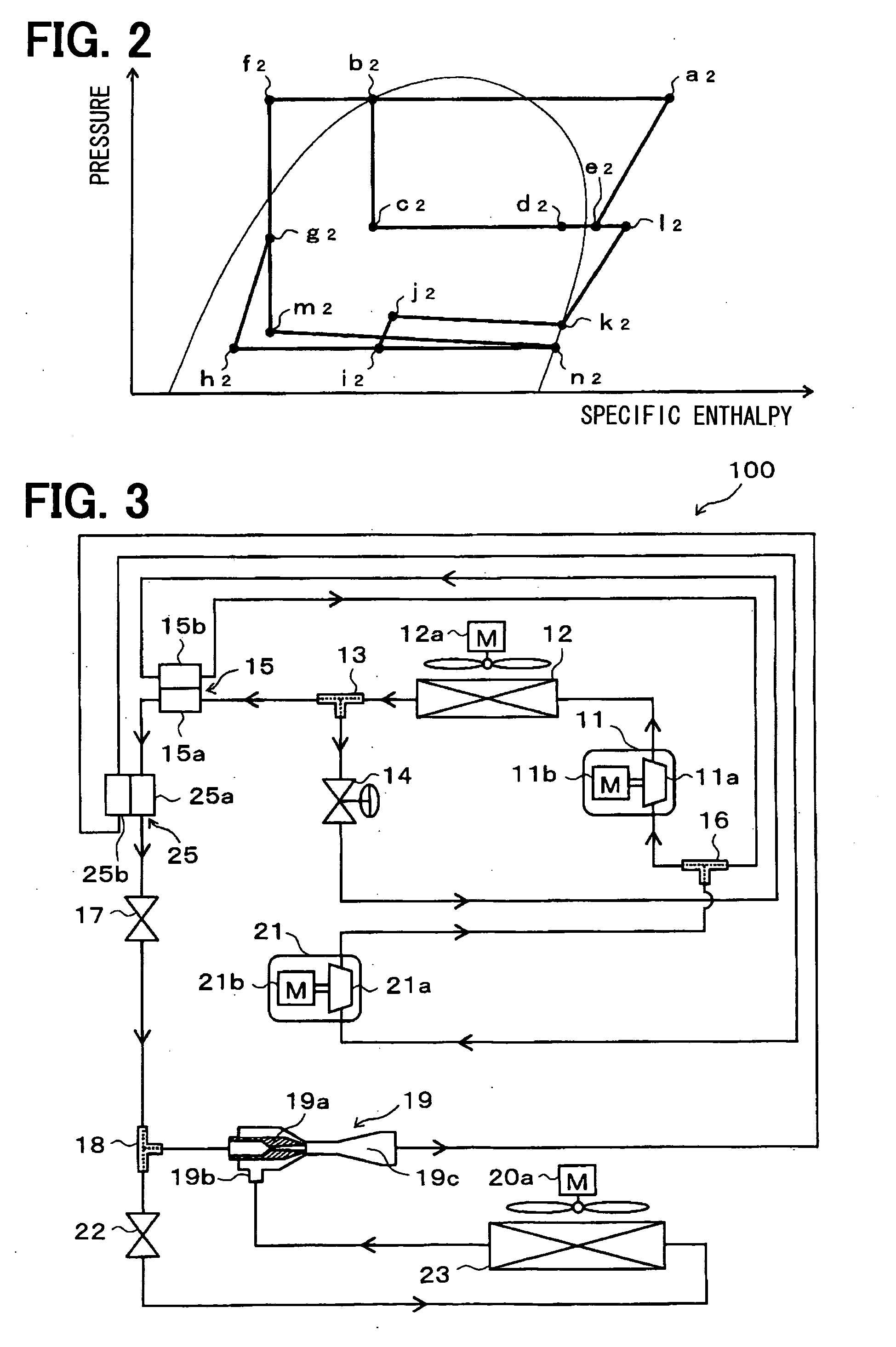

Ejector-type refrigerant cycle device

InactiveUS20100162751A1Decreasing recovery energyReduced suction capacityCompression machines with non-reversible cycleCompression machines with several evaporatorsHeat spreaderInjector

A flow of refrigerant discharged from a first compressor and cooled by a radiator is branched by a first branch portion, and the branched refrigerant of one side is decompressed and expanded by a thermal expansion valve and is heat exchanged with the branched refrigerant of the other side in an inner heat exchanger. Therefore, the branched refrigerant of the other side supplied to the suction side evaporator and a nozzle portion of an ejector can be cooled, thereby improving COP. Furthermore, a suction port of a second compressor is coupled to an outlet side of the ejector so as to secure a drive flow of the ejector, and the refrigerant discharged from the second compressor and the refrigerant downstream of the thermal expansion valve are mixed to be drawn into the first compressor so that an ejector-type refrigerant cycle device can be operated stably.

Owner:DENSO CORP

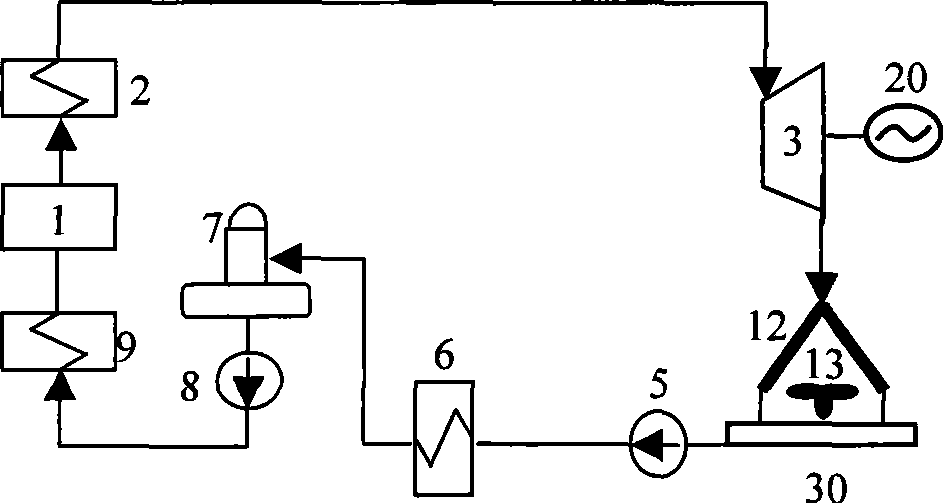

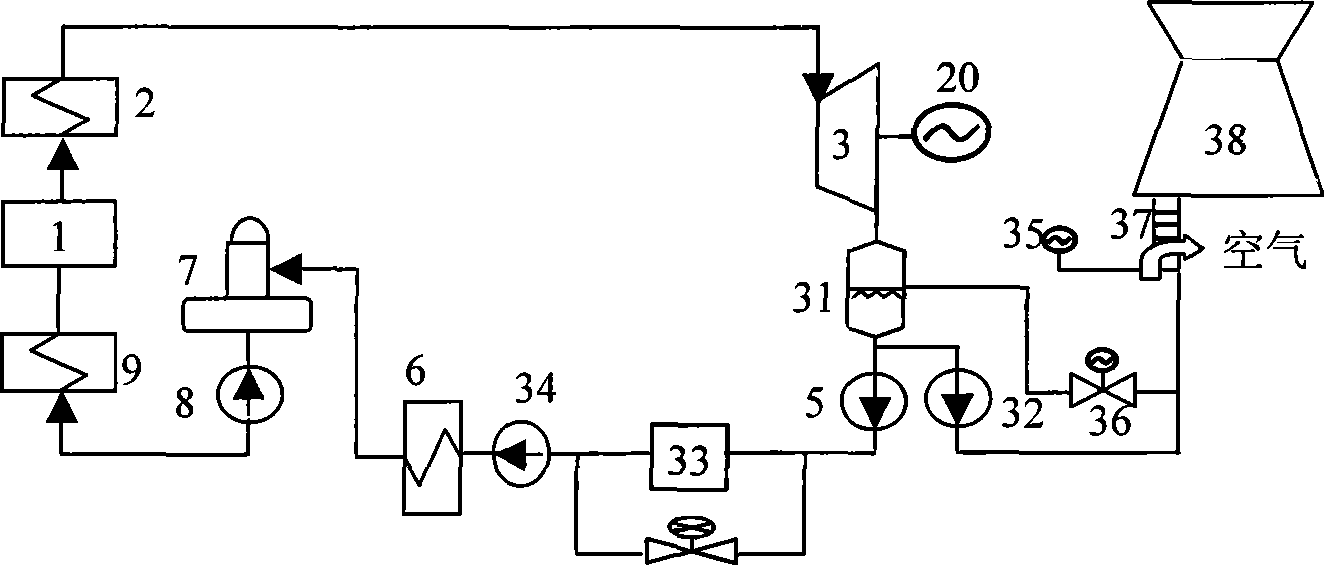

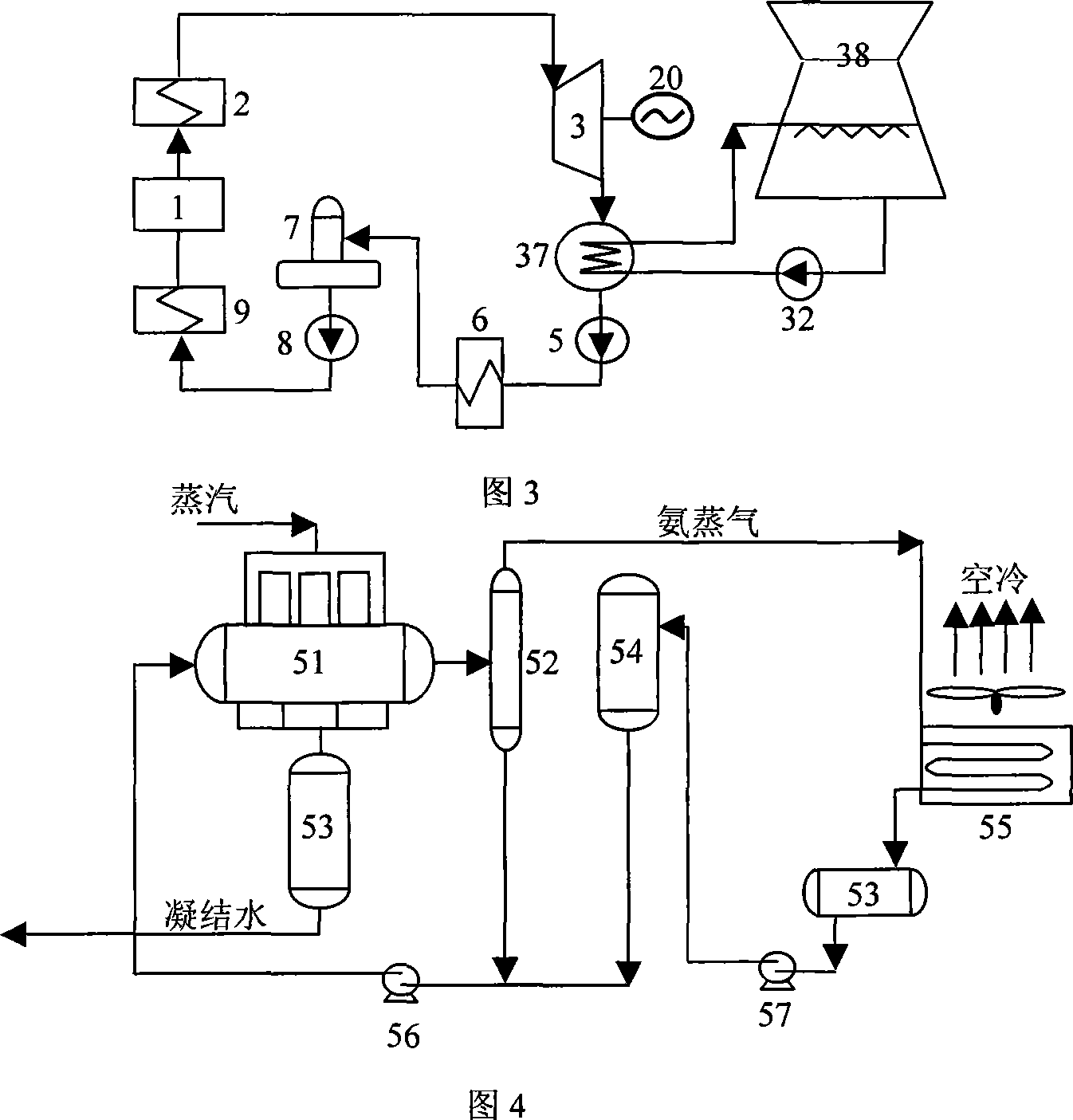

Indirect air cooling method and system for working medium adopting parallel-connection positive and reverse refrigeration cycle

InactiveCN101368767AEasy to implementNovel ideaCompression machines with reversible cycleWorking fluidNuclear power

The invention discloses an indirect air cooling method and a system with the working fluid of parallel-connected obverse and inverse refrigeration cycles. Based on the phase transition in the working fluid cooling process, a double-phase transition heat exchanger and a single-phase transition heat exchanger are respectively coupled with an obverse refrigeration cycle and an inverse refrigeration cycle which are connected in parallel; the saturated gaseous refrigerant from the phase-transition heat exchangers is compressed, boosted and then sent to an air-cooled radiator for exothermic condensation, then the condensed refrigerant enters a liquid storage tank and is decompressed through a throttle valve and sent to the phase-transition heat exchangers so as to complete the obverse refrigeration cycle; or the saturated gaseous refrigerant from the phase-transition heat exchangers is throttled and decompressed through a thermal expansion valve and then sent to the air-cooled radiator and the liquid storage tank, pressurized by a booster pump and finally sent back to the phase-transition heat exchangers so as to complete the inverse refrigeration cycle. The method and the system can be widely applied to the cooling systems of the condensers in thermal power, nuclear power and other turbine-generator units or the cooling systems of the intercoolers in petroleum, chemical and other industries to reduce energy consumption, save investments, as well as improve water-saving rate and the adaptability of the cooling system to the environment; therefore, the method and the system are provided with promotional values and can produce larger social environmental benefits and economic benefits after implementation.

Owner:NORTHEAST DIANLI UNIVERSITY

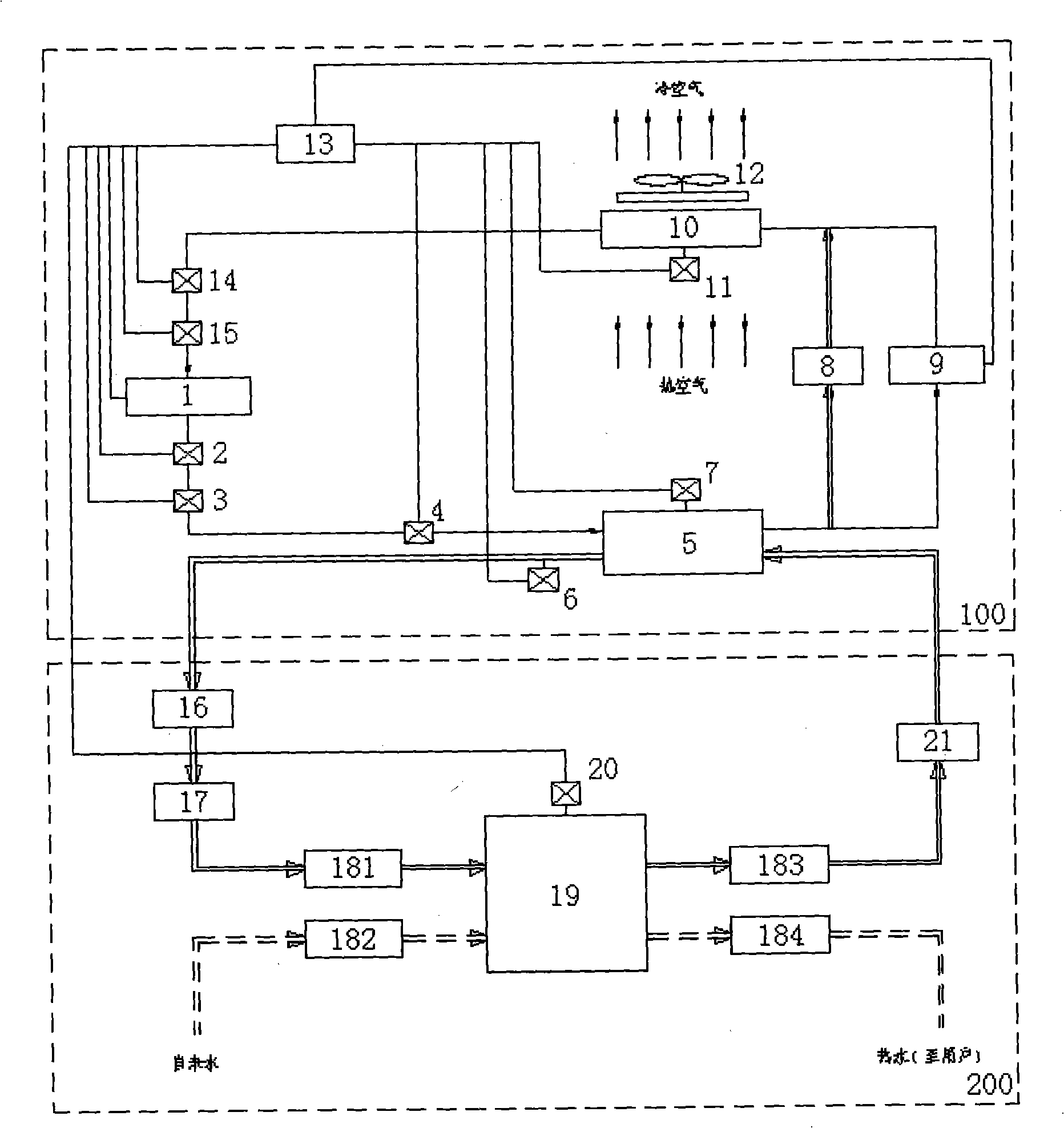

Integrated apparatus of solar heat pump heating and photovoltaic generating

InactiveCN1862148ATake advantage ofEfficient use ofHeat pumpsSemiconductor devicesEvaporationEngineering

The present invention relates to a solar heat pump heat production and photovoltaic power generation integral equipment, belonging to the field of solar photovoltaic power generation technology and heat pump technology. It is aimed at making solar photovoltaic component obtain higher photoelectric conversion efficiency, at the same time utilizing heat pump device to effectively utilize solar radiation energy to supply heat and hot water for building. Said integral equipment includes the following several portions: solar photovoltaic / collecting plate, photovoltaic cell, evaporation coiled tube, compressor, condenser, liquid storage device, thermal expansion valve and water tank, etc.

Owner:SOUTHEAST UNIV

Air conditioner and control method thereof

ActiveCN102062448AMeet real needsFlexible operationSpace heating and ventilation safety systemsLighting and heating apparatusFour-way valveEngineering

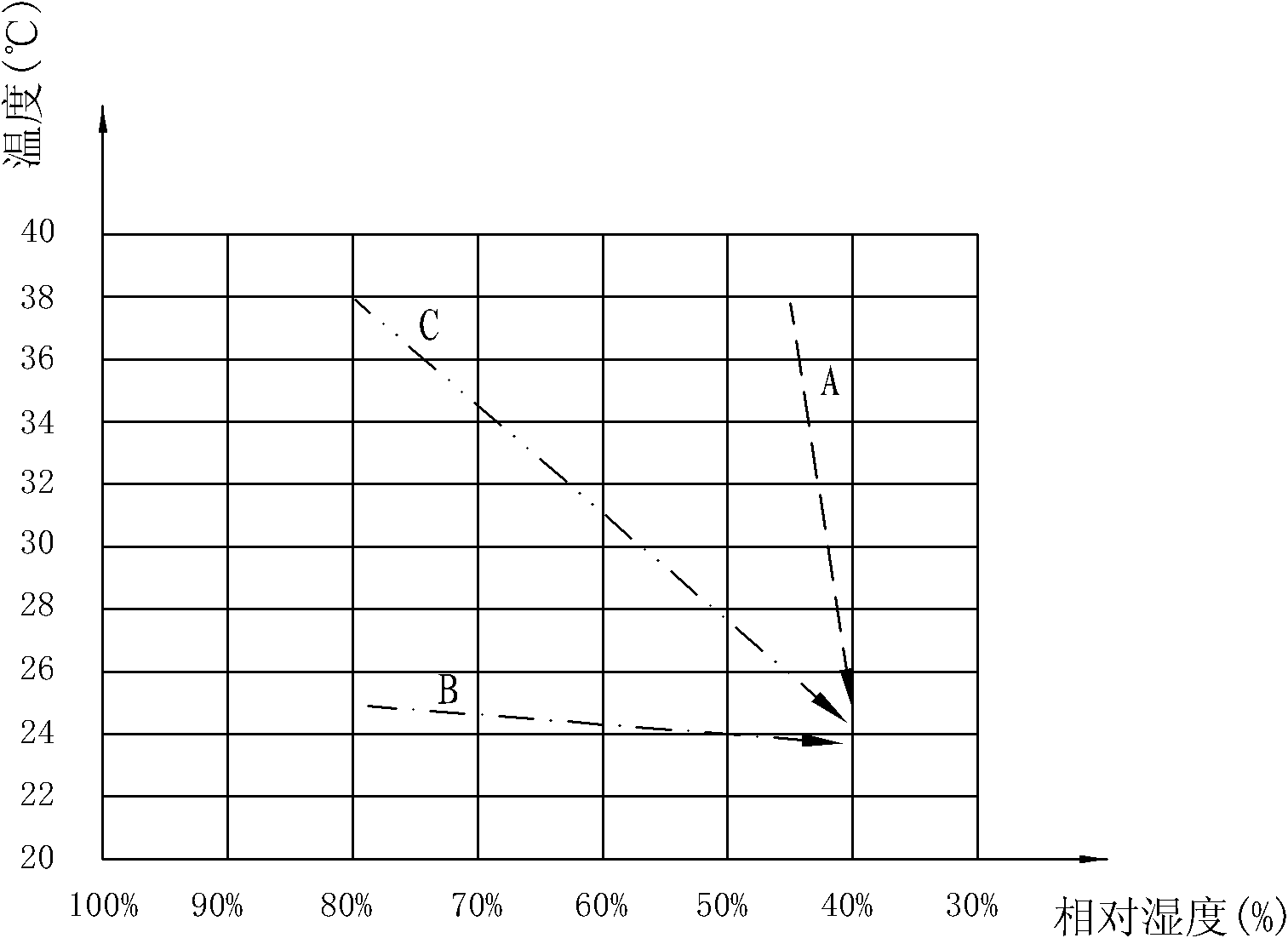

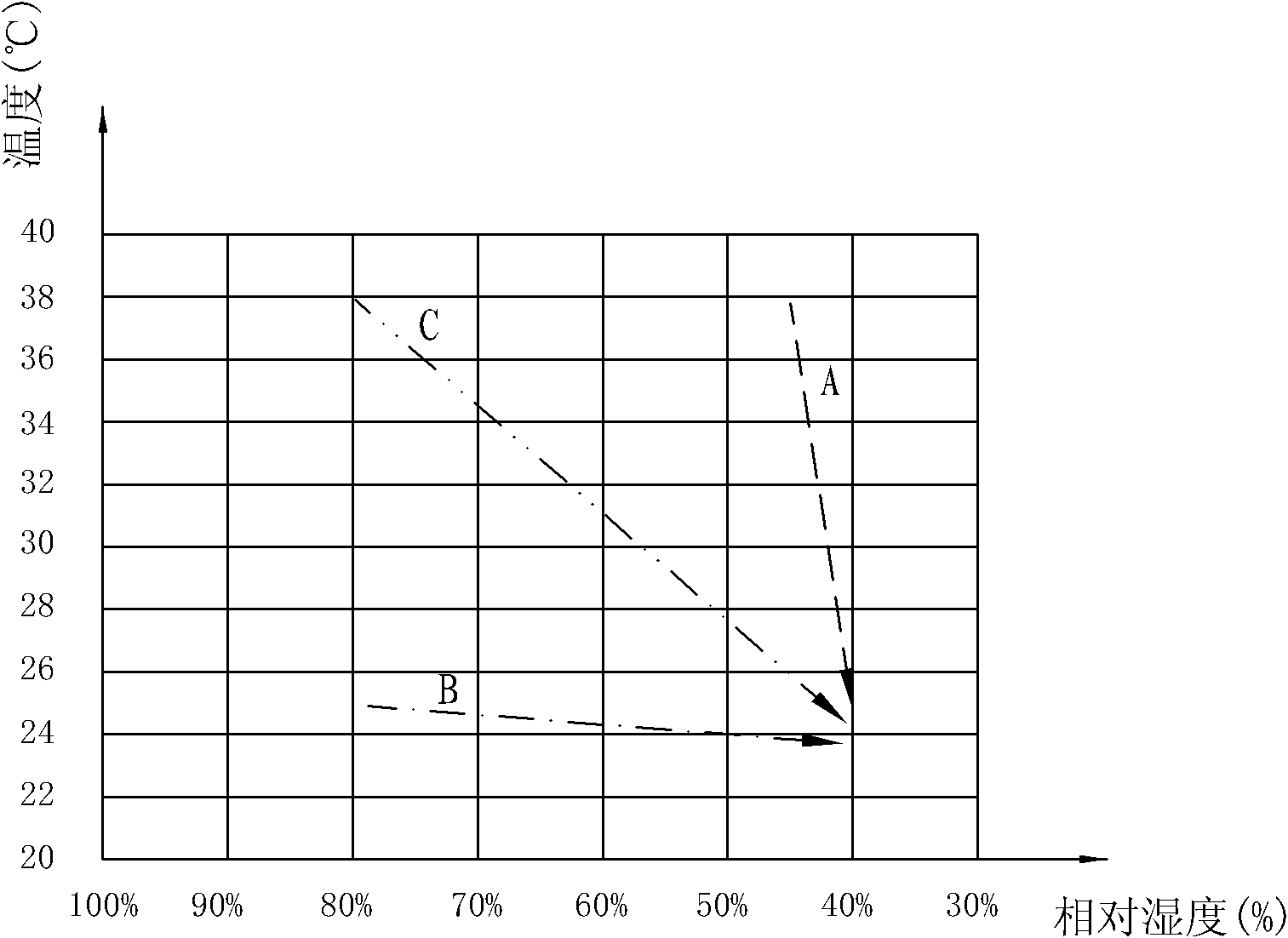

The invention relates to an air conditioner and a control method thereof. The air conditioner comprises a compressor, a four-way valve, an outdoor heat exchanger, a throttling device and an indoor heat exchanger, wherein the outdoor heat exchanger and the indoor heat exchanger are selectively communicated with the compressor by virtue of the four-way valve, the throttling device is arranged between the indoor heat exchanger and the outdoor heat exchanger, and the indoor heat exchanger is also provided with a first sensor used for detecting the indoor ambient temperature and humidity and a second sensor used for detecting the evaporating temperature of refrigerant in the indoor heat exchanger. The throttling device is an electronic expansion valve, a thermostatic expansion valve or silicon valve. The control method of the air conditioner comprises the following steps of: regulating the frequency of the compressor according to the refrigeration requirement of a room when refrigeration and dehumidification or temperature reduction and no dehumidification are required by a user to realize temperature stability control; and regulating the flow of the throttling device to be more than the flow required by the conventional refrigeration to increase the evaporating temperature and achieve the aim of no dehumidification or less dehumidification. The invention has the characteristics of flexibility of operation, comfortableness and wide application range.

Owner:MIDEA GRP CO LTD

Solar energy-air heat pump water heater

InactiveCN1515848AApplicable requirementsSimple structureSolar heat devicesAir conditioning systemsBuilding integrationAutomatic control

The present invention relates to a solar-air heat pump water heater, including a solar-air evaporator, a hot-water tank containing submerged condenser coil, a small heat pump compressor and related refrigerating fittings of thermodynamic expansion valve, gas-liquid separator, drying filter and liquid storage device. The solar-air evaporator is formed from the components of solar heat-collecting plate, air conditioning fan, air vent and shell body. The solar heat collector and air heat-exchanger are combined together by adopting compact structure form. The automatic control device of the water heater includes a temperature difference controller for controlling starting and stopping of the fan and a water tank constant temperature device for controlling starting and stopping of compressor.

Owner:SHANGHAI JIAO TONG UNIV

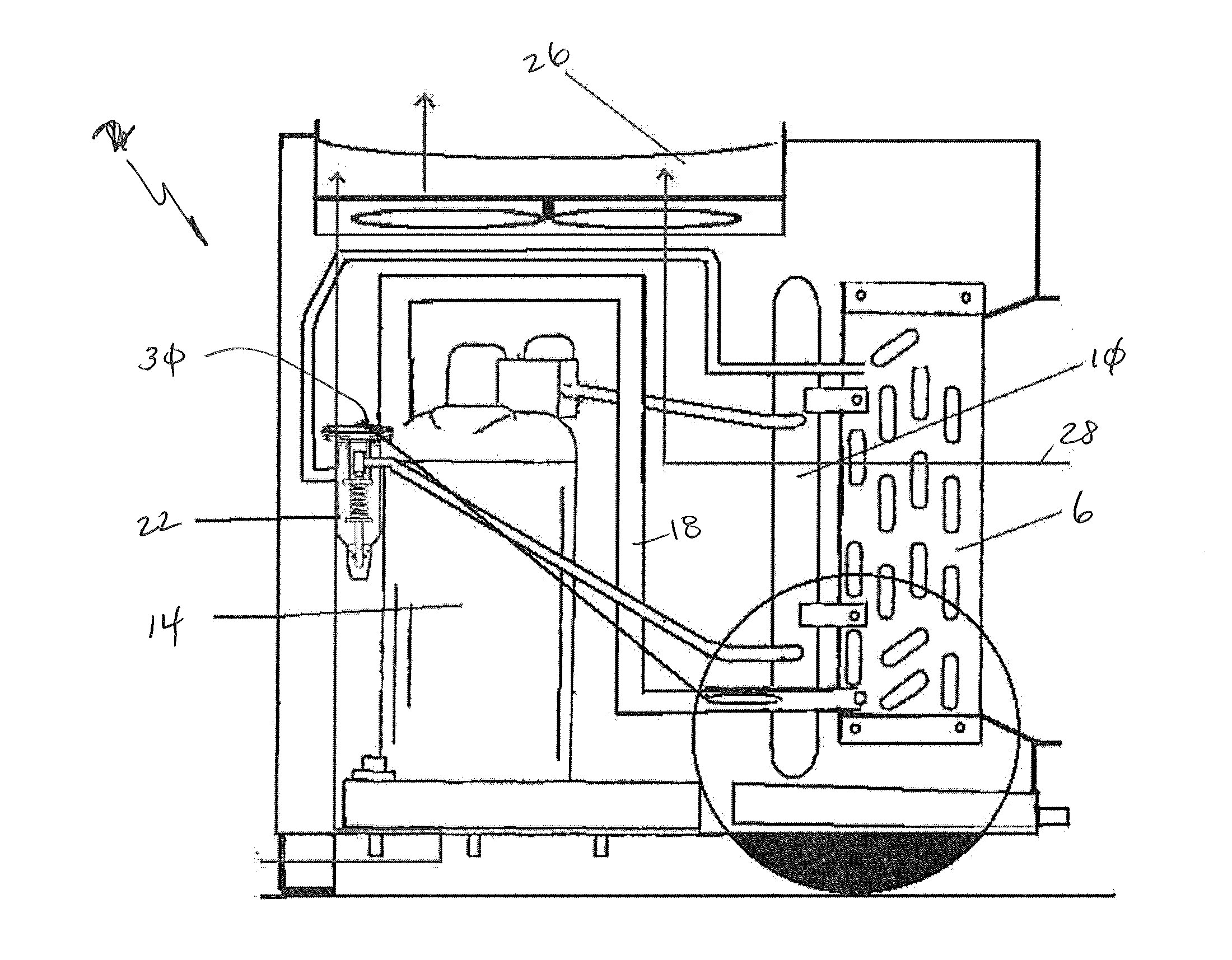

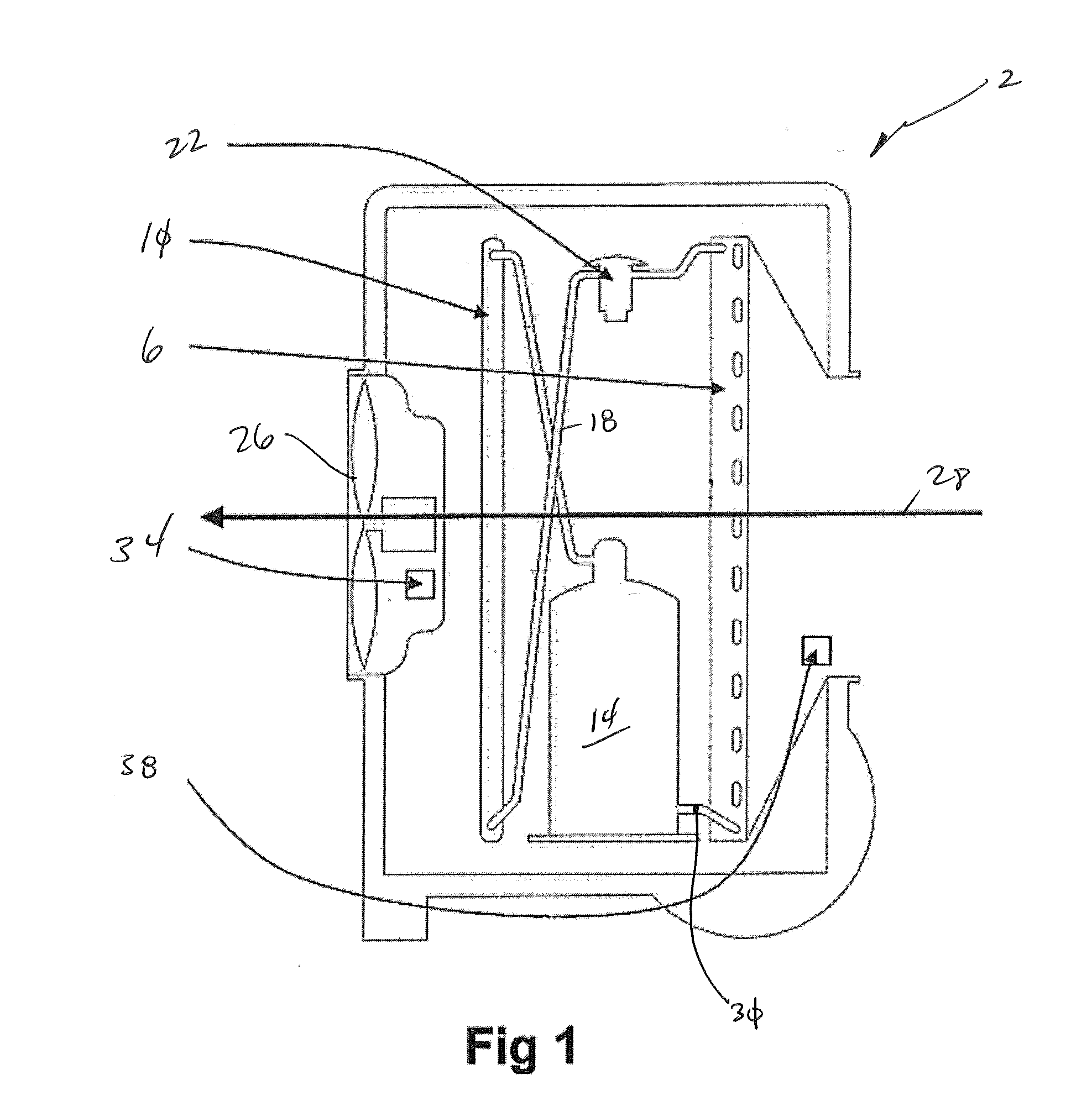

Dehumidifier for Use in Water Damage Restoration

InactiveUS20100326103A1Maximum performanceRestored quickly and efficientlyCompression machines with non-reversible cycleFluid circulation arrangementWater damageWaste management

A transportable dehumidifier system is provided that employs a thermal expansion valve to control the flow of refrigerant therethrough.

Owner:KARCHER NORTH AMERICA INC

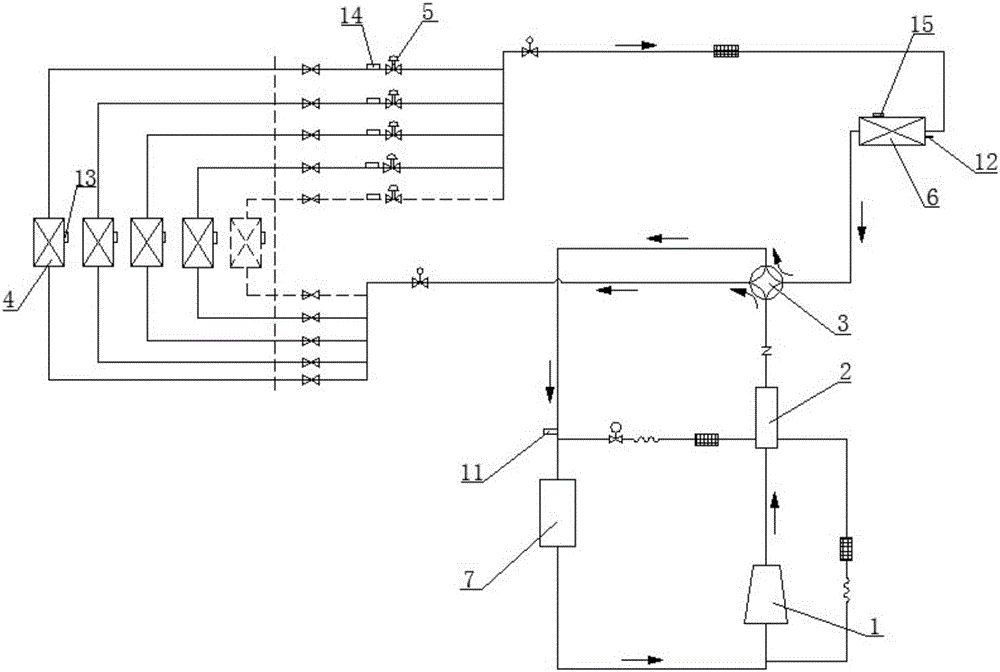

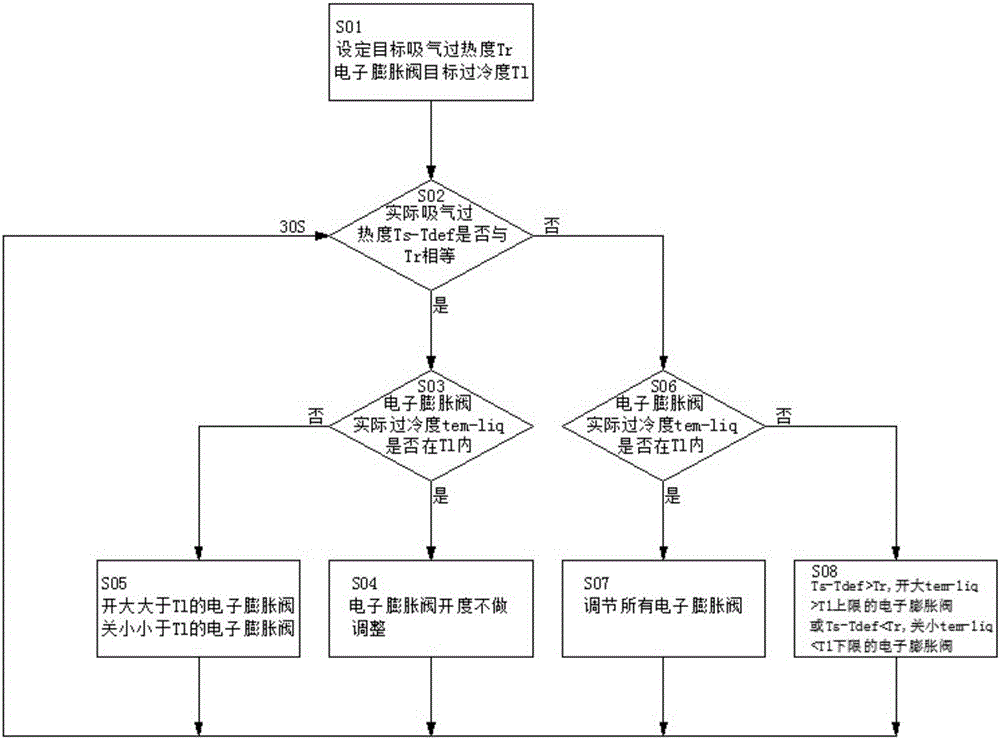

Method for controlling electronic expansion valves during multi-connected air conditioning unit heating

ActiveCN106052216AUniform heating effectMechanical apparatusSpace heating and ventilation safety systemsLower limitHeating effect

The invention discloses a method for controlling an electronic expansion valves during multi-connected air conditioning unit heating. The method includes the following steps that firstly, the target air suction superheat degree Tr and the target supercooling degrees Tl of the expansion valves are set; secondly, whether the actual air suction superheat degree Ts-Tdef is equal to Tr or not is judged, if the actual air suction superheat degree Ts-Tdef is equal to Tr, the third step continues to be executed, and if the actual air suction superheat degree Ts-Tdef is not equal to Tr, the sixth step is executed; thirdly, whether the actual supercooling degrees tem-liq of the expansion valves are all in the Tl range or not is judged, if the actual supercooling degrees tem-liq of the expansion valves are all in the Tl range, the fourth step is executed, if the actual supercooling degrees tem-liq of the expansion valves are not all in the Tl range, the fifth step is executed, no adjustment is made, and the second step is executed; fifthly, when the actual supercooling degree tem-liq of a certain expansion valve is larger than the upper limit of T1, the valve is opened to a certain degree, when the actual supercooling degree tem-liq of a certain expansion valve is smaller than the lower limit of Tl, the valve is closed to a certain degree, and the second step is executed after adjustment is completed; sixthly, whether the actual supercooling degrees tem-liq of the expansion valves are all in the Tl range or not is judged, if the actual supercooling degrees tem-liq of the expansion valves are all in the Tl range, the seventh step continues to be executed, and if the actual supercooling degrees tem-liq of the expansion valves are not all in the Tl range, the eighth step is executed; seventhly, the step numbers of all the expansion valves are adjusted, and the second step is executed after adjustment is completed; and eighthly, when Ts-Tdef is larger than Tr, the expansion valves with tem-liq larger than the upper limit of Tl are opened to a certain degree, if Ts-Tdef is smaller than Tr, the expansion valves with tem-liq smaller than the lower limit of Tl are closed to a certain degree, and the second step is executed after adjustment. The method has the beneficial effects that a refrigerant is reasonably distributed, and a balance heating effect is achieved.

Owner:NINGBO AUX ELECTRIC

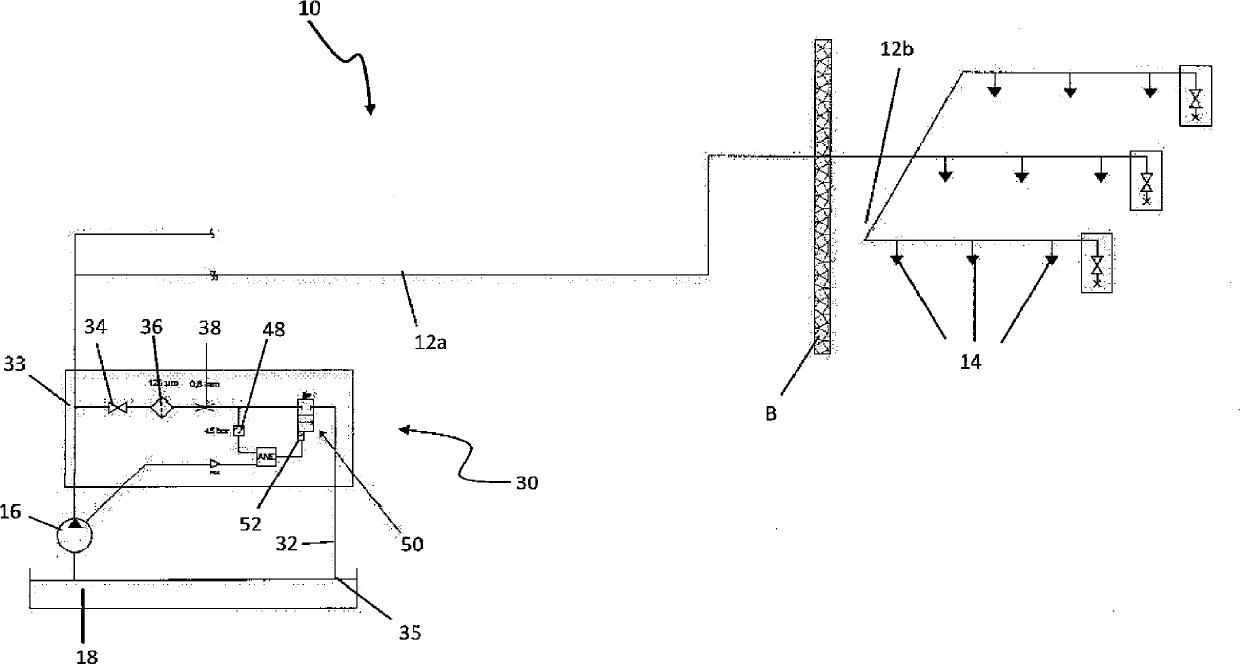

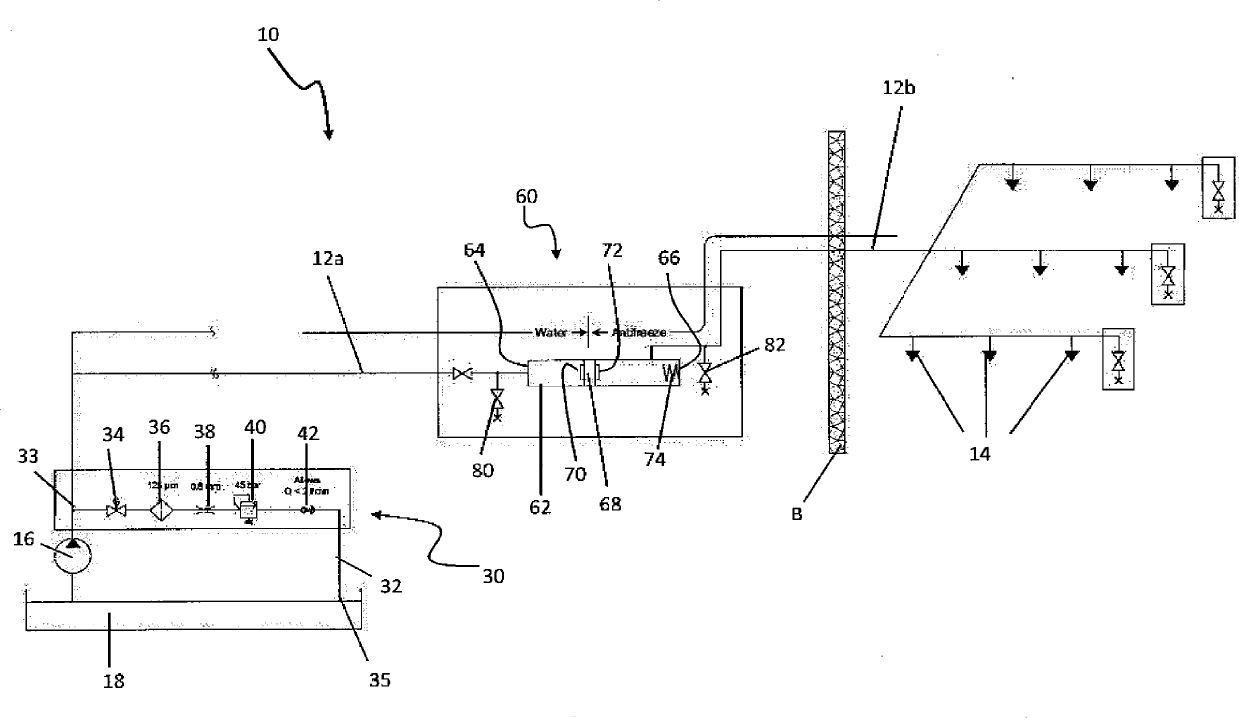

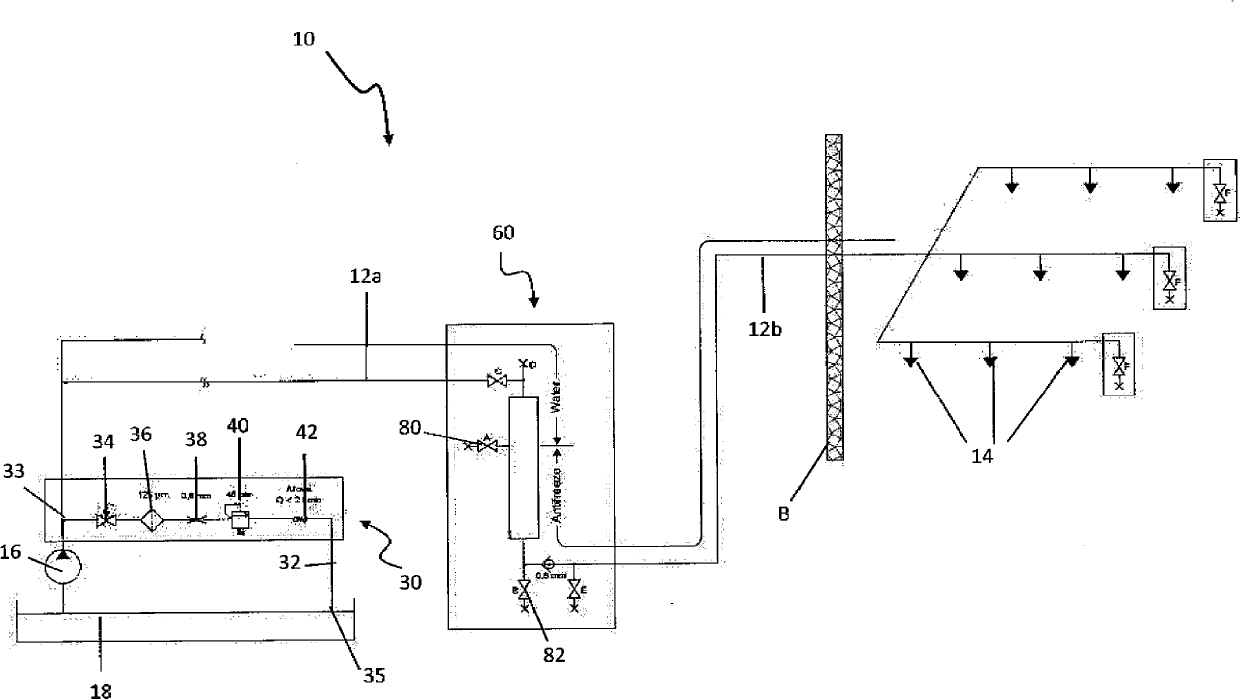

Thermal expansion assembly for water mist fire suppression system

An apparatus and method are provided for maintaining a standby pressure in a fire suppression system. The fire suppression system includes at least on spray head and a drive source coupled to the at least one spray head by a supply line. The supply lines delivers extinguishing medium to the spray head. The drive source maintains a standby pressure of the extinguishing medium in the supply line when the system is inactive. A release line is coupled at a first end to the supply line. The release line includes a thermal expansion assembly. When the system is inactive and the standby pressure exceeds a first threshold, the thermal expansion assembly releases extinguishing medium from the system to reduce the standby pressure. When the system is active and the standby pressure exceeds the first threshold, the thermal expansion assembly does not release extinguishing medium from the system.

Owner:MARIOFF CORP OY

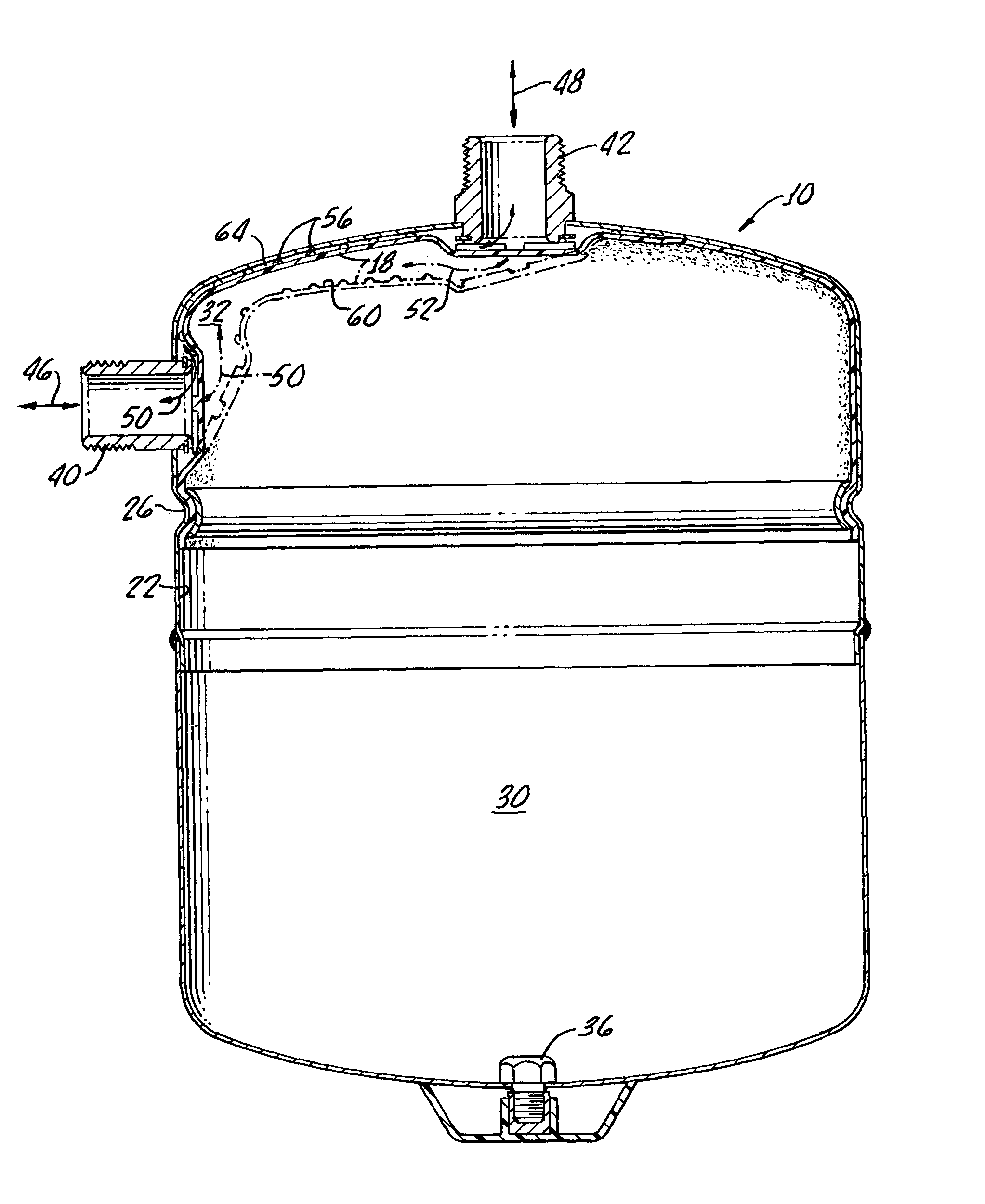

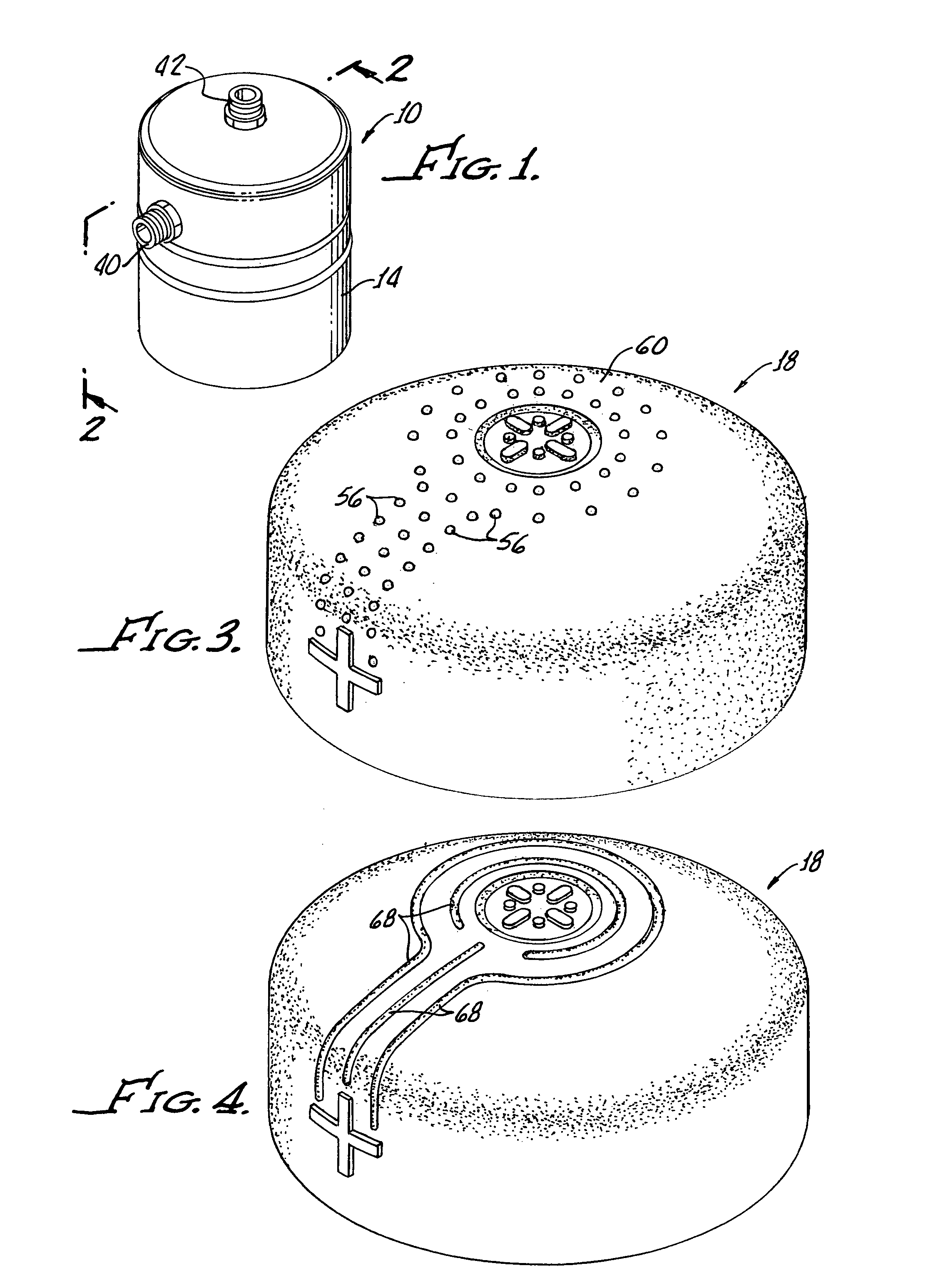

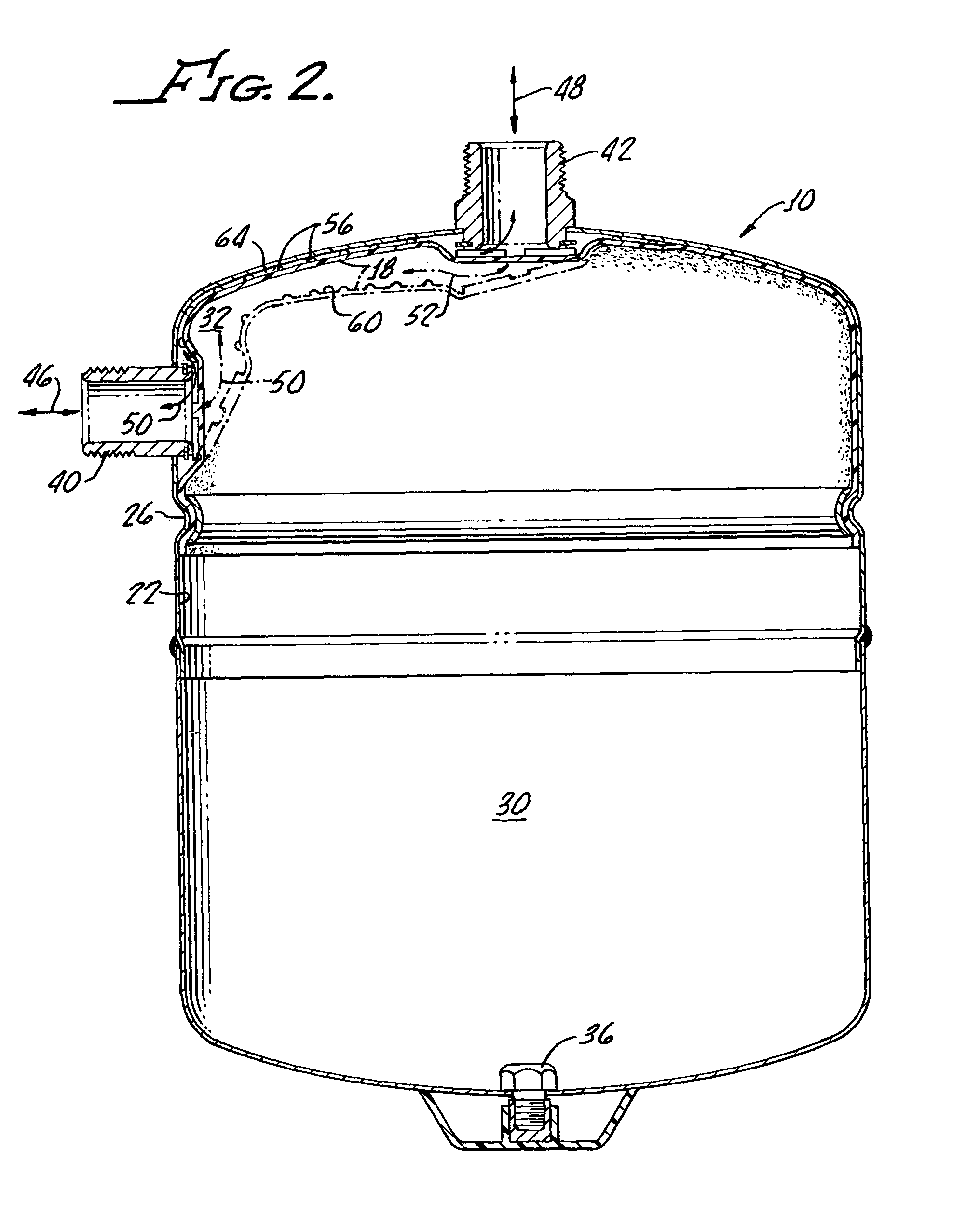

Thermal expansion/surge reduction water tank

ActiveUS8523001B2Avoid Sealing ProblemsControl flowEngine diaphragmsLighting and heating apparatusAbutmentEngineering

A thermal expansion / surge reduction water tank includes a hollow housing with a bladder sealed to an inside of the housing forming two compartments therein. A compressed air inlet in communication with a first of the compartments is provided for expanding the first compartment by focusing the bladder into an abutting relationship with the housing inside. A water inlet and a water outlet in communication with a second of the compartments is provided and disposed for causing non-laminar flow of water through the second compartment for both expanding the second compartment by forcing said bladder into the first compartment and flushing the second compartment to effect self-cleaning thereof. A plurality of protuberances disposed on a side of said bladder facing the second compartment are provided for preventing sealing of the bladder in an area of abutment with the housing inside between the water inlet and outlet thereby enabling fluid flow between the water inlet and outlet with said bladder abutting the housing inside.

Owner:ADVANCED CONSERVATION TECH DISTRIBUTION

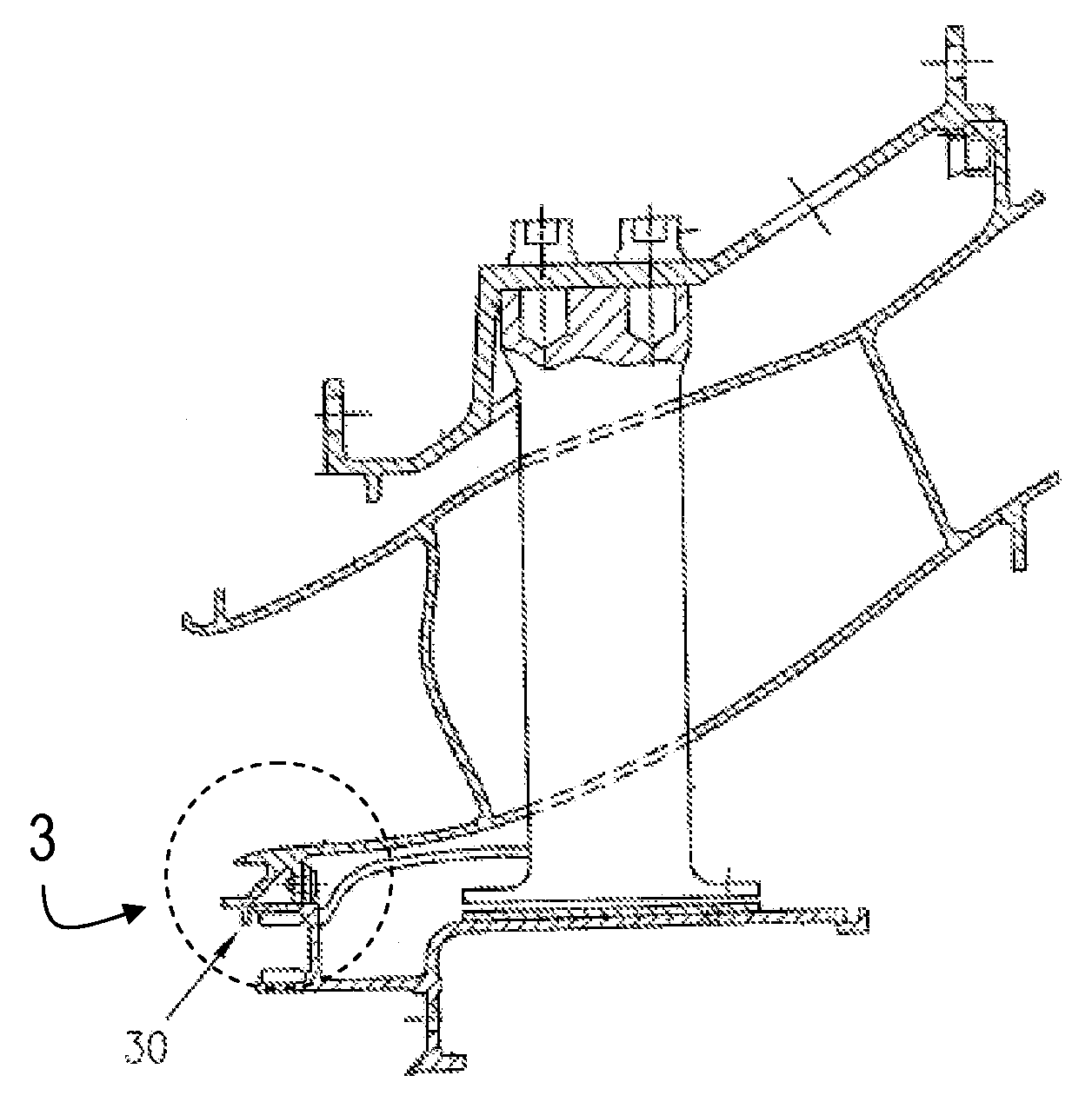

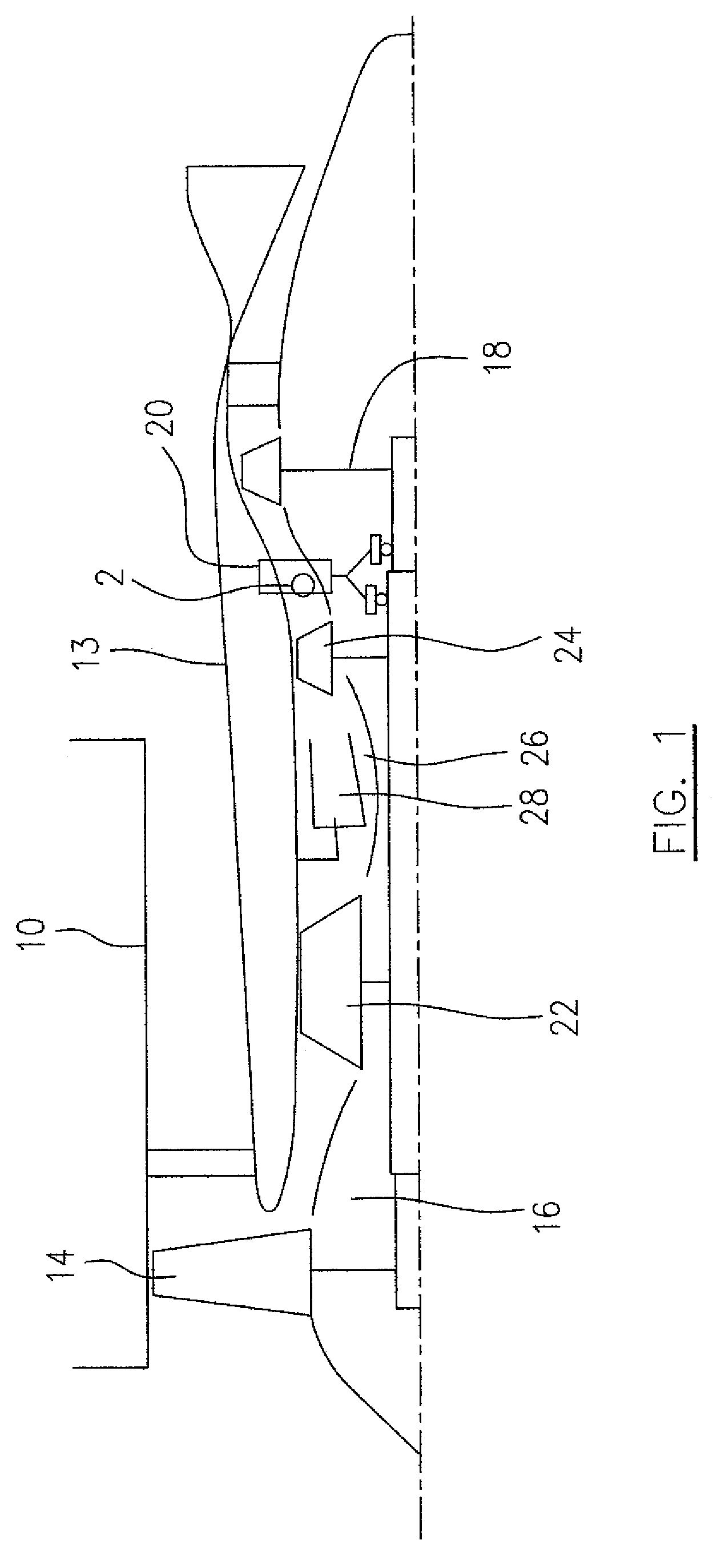

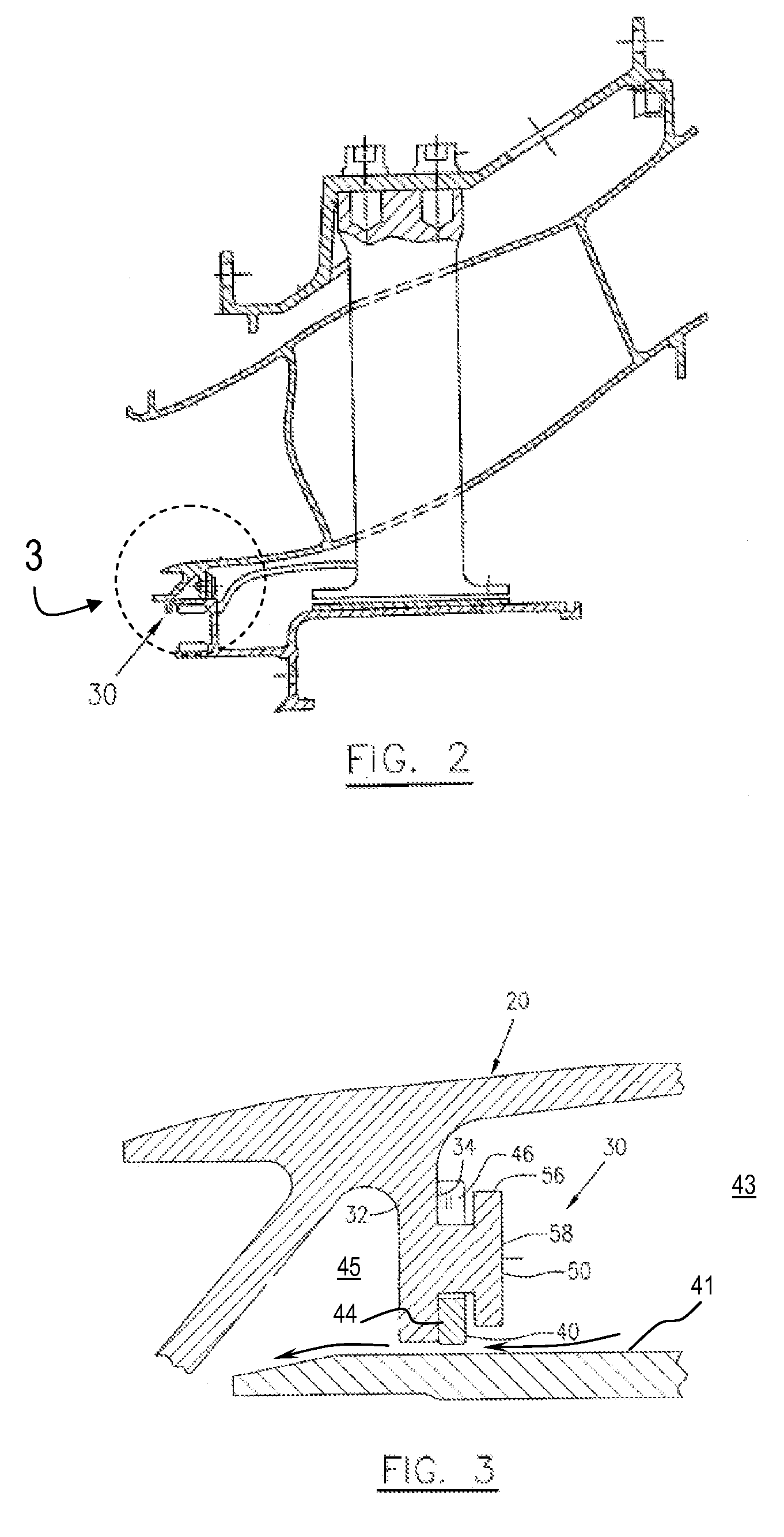

Air metering device for gas turbine engine

An air metering apparatus for a secondary air system of gas turbine engine includes a metering gap defined between surfaces comprised of one or more metals having one of similar coefficients of thermal expansion or similar thermal expansions at an operating temperature. Provided is an air metering gap which undergoes thermal growth in a way which provides a suitable air metering gap during engine running conditions.

Owner:PRATT & WHITNEY CANADA CORP

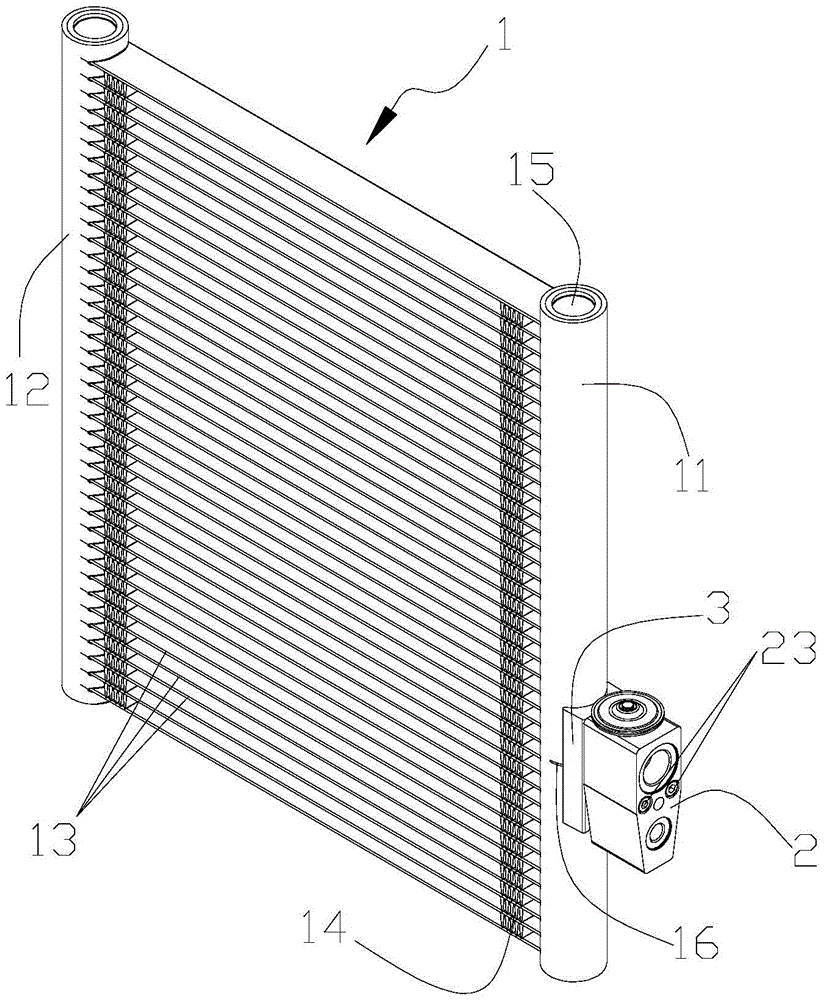

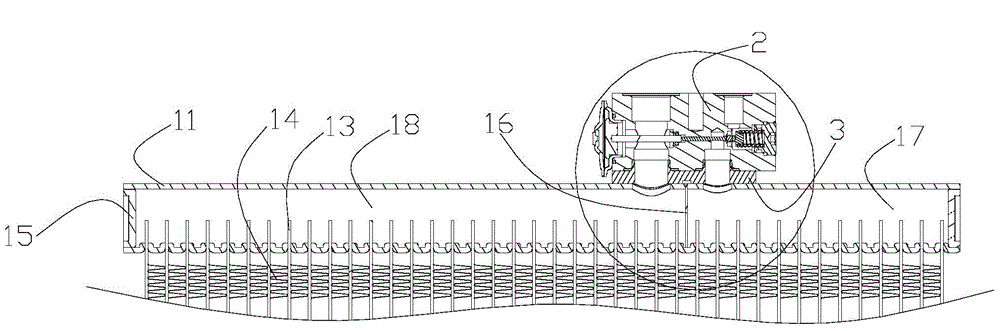

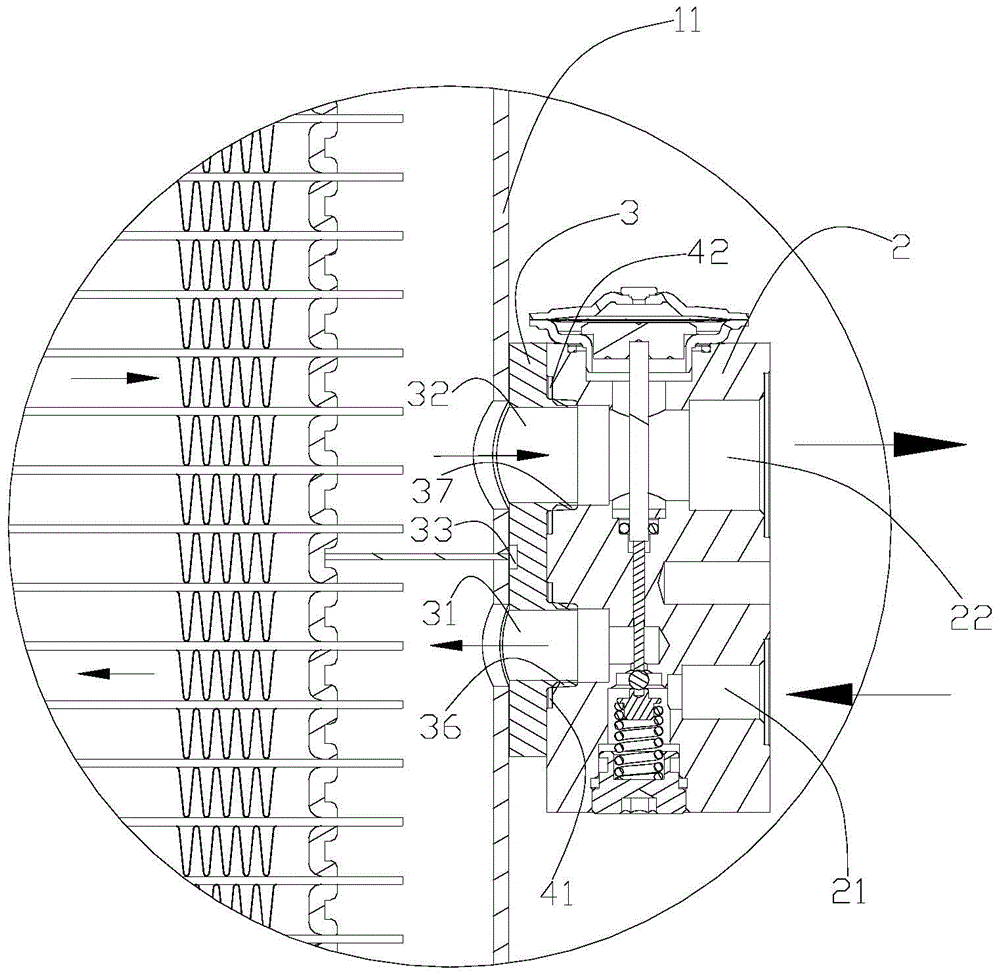

Evaporator integrated component

InactiveCN104457037AShort tripReduce energy lossMechanical apparatusEvaporators/condensersEngineeringAir conditioning

The invention provides an evaporator integrated component. The evaporator integrated component comprises a heat exchanger, connecting blocks and a thermal expansion valve, wherein the connecting block is fixed and mounted on a collecting main of the heat exchanger through welding; the thermal expansion valve is fixed and mounted on the connecting block through a screw; the collecting main is provided with a spacing plate for sealing and dividing the collecting main into a first cavity and a second cavity; and an inlet and an outlet of the heat exchanger are respectively positioned in the first cavity and the second cavity, and are communicated with the thermal expansion valve through the connecting blocks. The evaporator integrated component can realize no-pipeline connection between the expansion valve and the inlet and the outlet of the heat exchanger which serves as an evaporator, so that refrigerant is evenly distributed in the evaporator, and the energy loss of the refrigerant in the connecting pipelines is prevented; and the evaporator integrated component is simple in structure, and can effectively improve the efficiency of an air conditioning system and the energy saving performance.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Quasi-two-stage compression ultralow temperature air source heat pump water heater with economizer

InactiveCN101957061ASolve the problem of frost in winterIncrease spacingFluid heatersEvaporators/condensersFour-way valveEngineering

The invention discloses a quasi-two-stage compression ultralow temperature air source heat pump water heater with an economizer, which mainly comprises a gas-supply enthalpy-rise compressor, an air-cooling evaporator, a water side heat exchanger, a gas-liquid separator, an economizer, a four-way valve, an electronic expansion valve, a drying and filtering device, a liquid accumulator, an electromagnetic valve, a thermal expansion valve and a one-way valve. The invention is characterized by adopting a quasi-two-stage compression technology, optimizing the structure of the evaporator, widening spaces between fins of the evaporator and using the reverse defrosting technology. Proved by system property test experiments and engineering practices, the quasi-two-stage compression ultralow temperature air source heat pump water heater with the economizer can improve energy efficiency ratio by 10% at the ambient temperature of 0 DEG C, by 15% at the ambient temperature of -5 DEG C and by about 30% at the ambient temperature of -10 DEG C and can still work normally to supply hot water even in ultralower ambient temperature of -15 DEG C; and in a frosting temperature range from 2 DEG C to -2 DEG C, the quasi-two-stage compression ultralow temperature air source heat pump water heater with the economizer can defrost quickly, evenly and thoroughly, thereby effectively solving the problem of frosting in winter in humid and cold area in the south of china.

Owner:HUNAN LINENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com