Dehumidifier for Use in Water Damage Restoration

a dehumidifier and water damage technology, applied in the field of dehumidifiers, can solve problems such as unfavorable operation, and achieve the effect of maximum performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

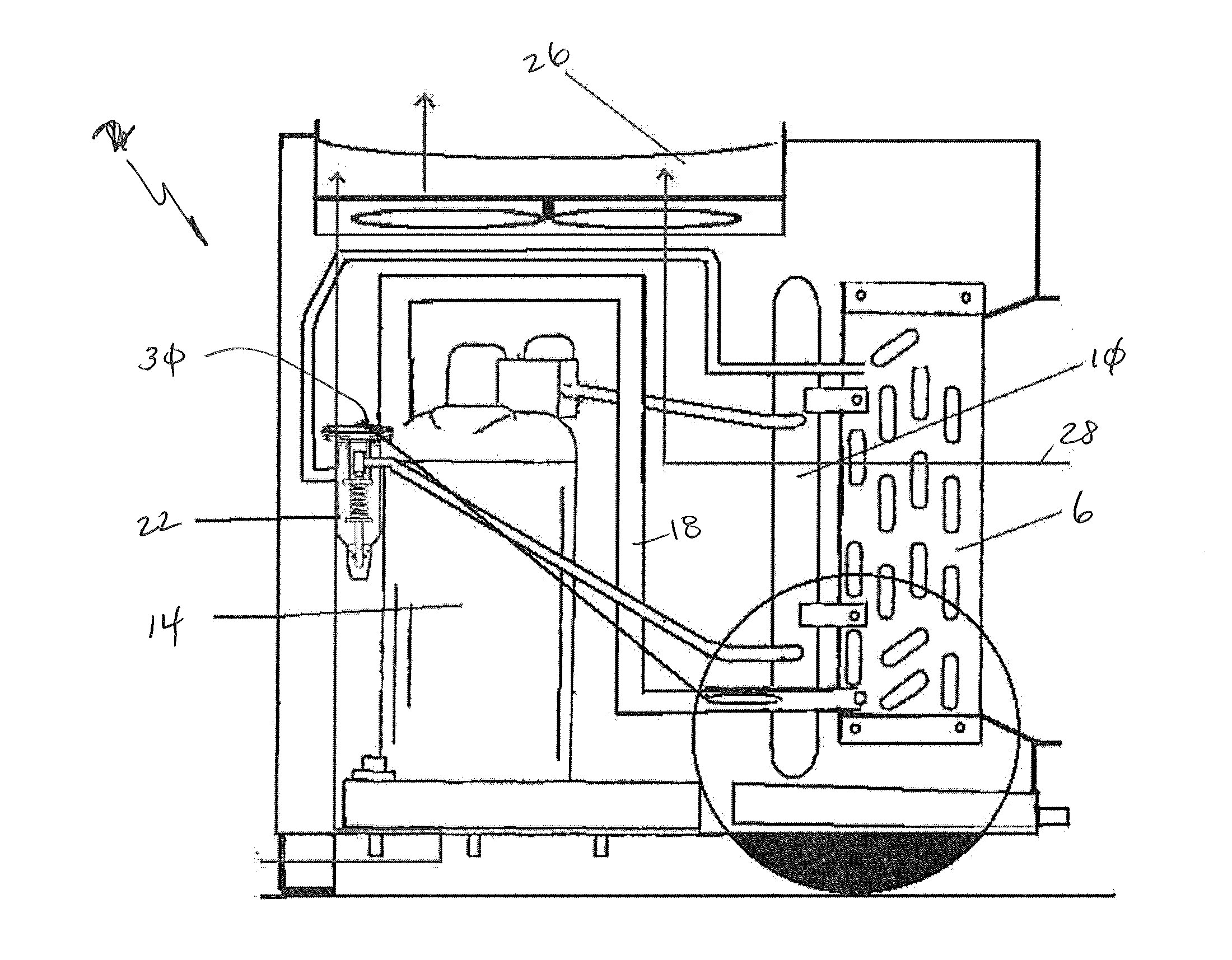

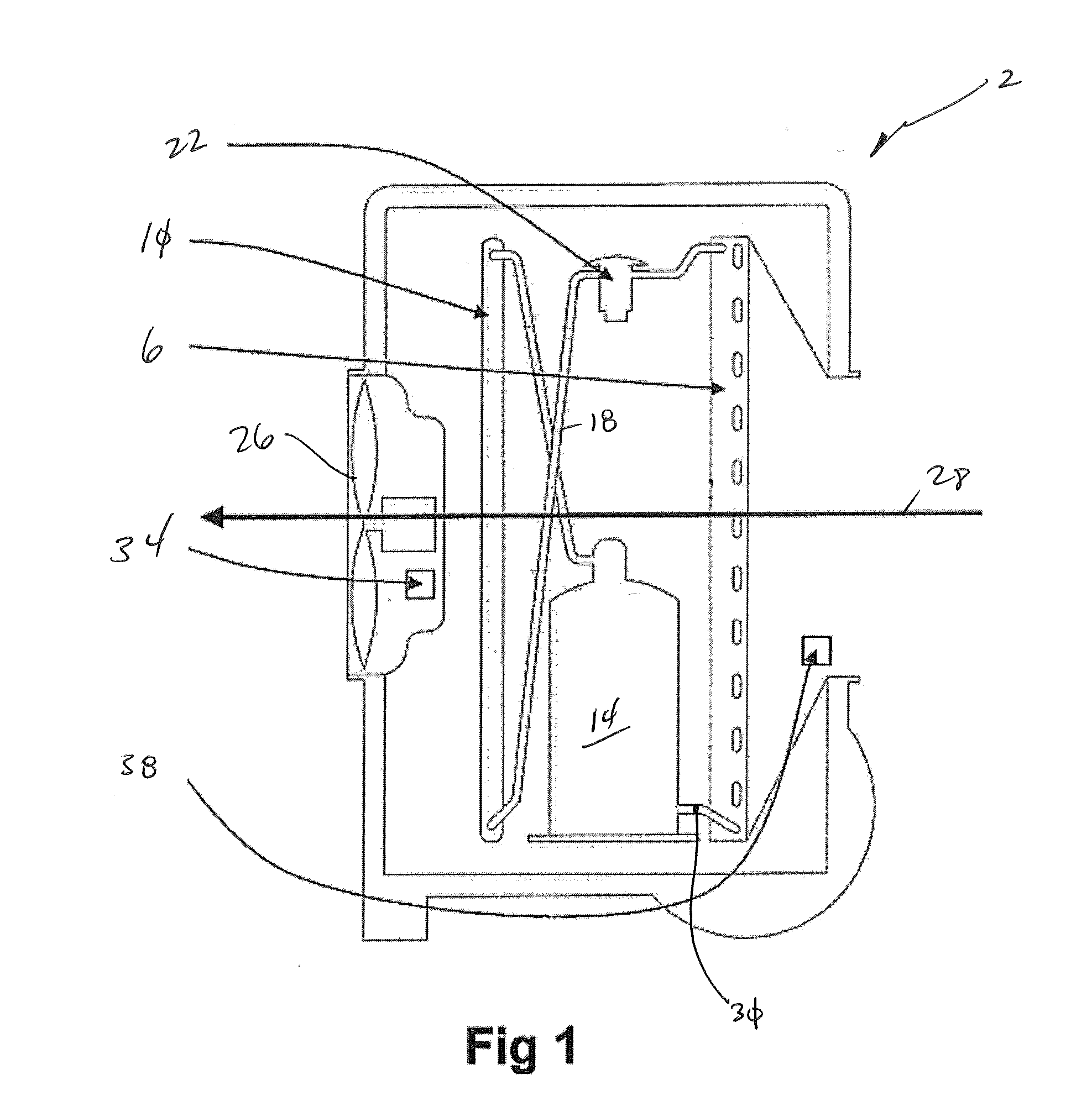

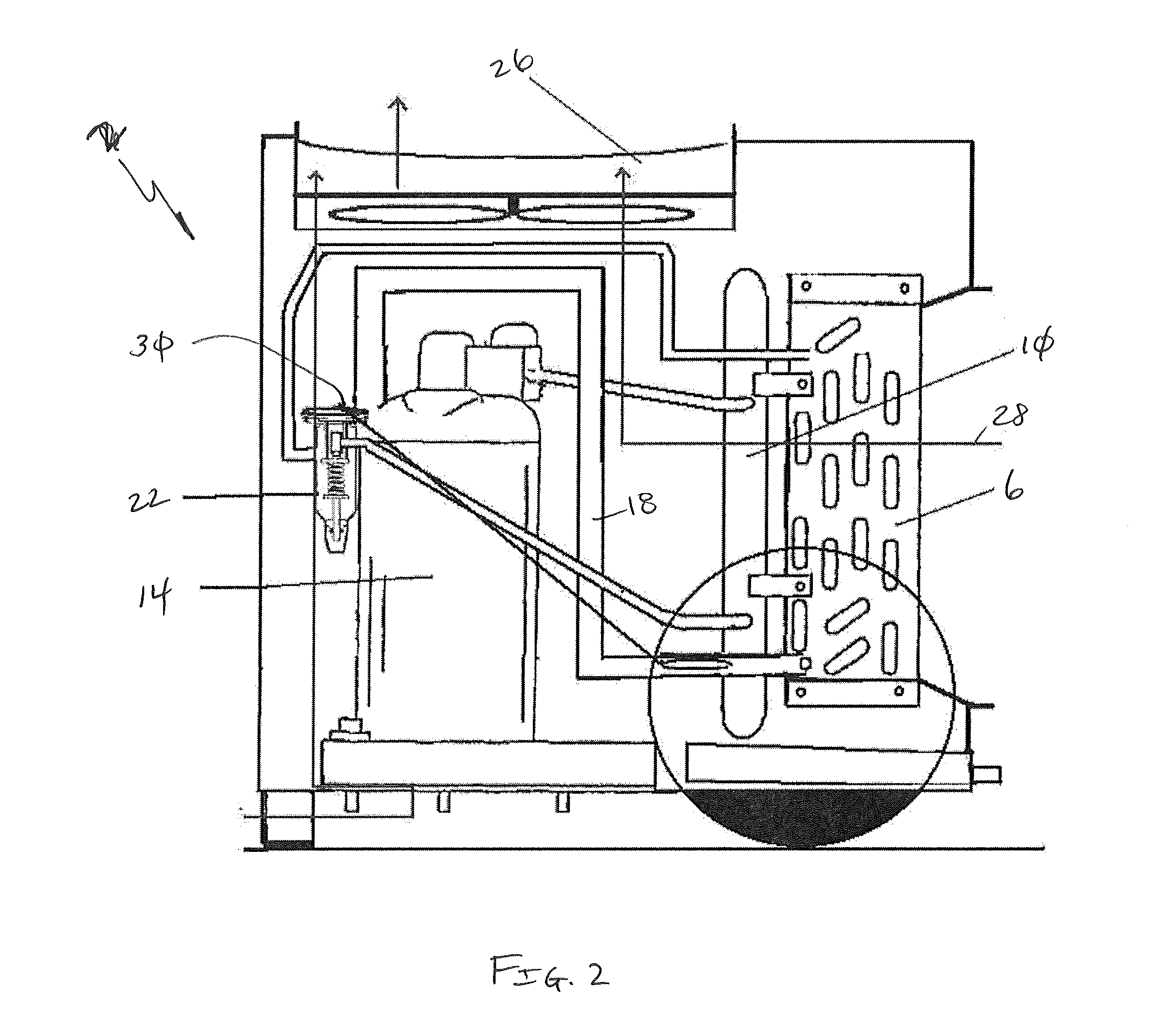

[0049]Referring now to FIGS. 1 and 2, one embodiment of the dehumidifier 2 is shown that includes a fin / tube evaporator 6, a micro channel condenser 10, a compressor 14 and related tubing 18 connecting those components. In addition, a thermal expansion valve (TEV) 22 is associated with the tubing 18 that connects the evaporator 6 to the condenser 10.

[0050]In operation, a fan 26 draws air 28 into the dehumidifier 2 wherein warm, humid air passes over the fins and tubes of the evaporator 6. Refrigerant within the evaporator 6 then is heated, exits the evaporator 6, and is directed to the TEV 22. The refrigerant directed to the TEV 22 is of a greater temperature as result of its heat transfer from the intake air. The temperature of the refrigerant exiting the evaporator 6 is related to varying ambient conditions and is monitored by a sensor 30. Warm vaporized refrigerant is directed to the compressor 14 that compresses the refrigerant and directs it to the condenser 10. Air exiting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com