Patents

Literature

76results about How to "Significant performance improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

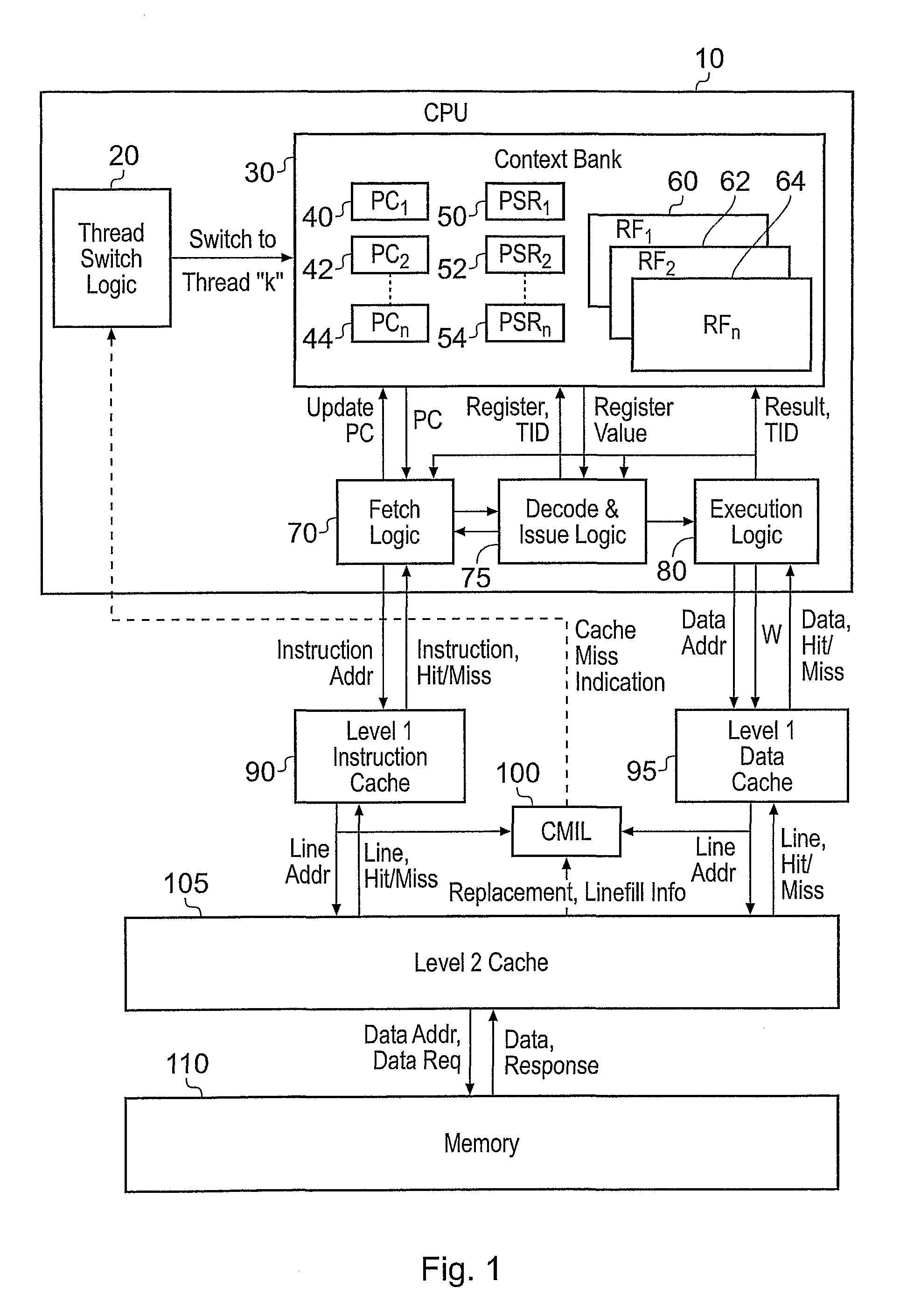

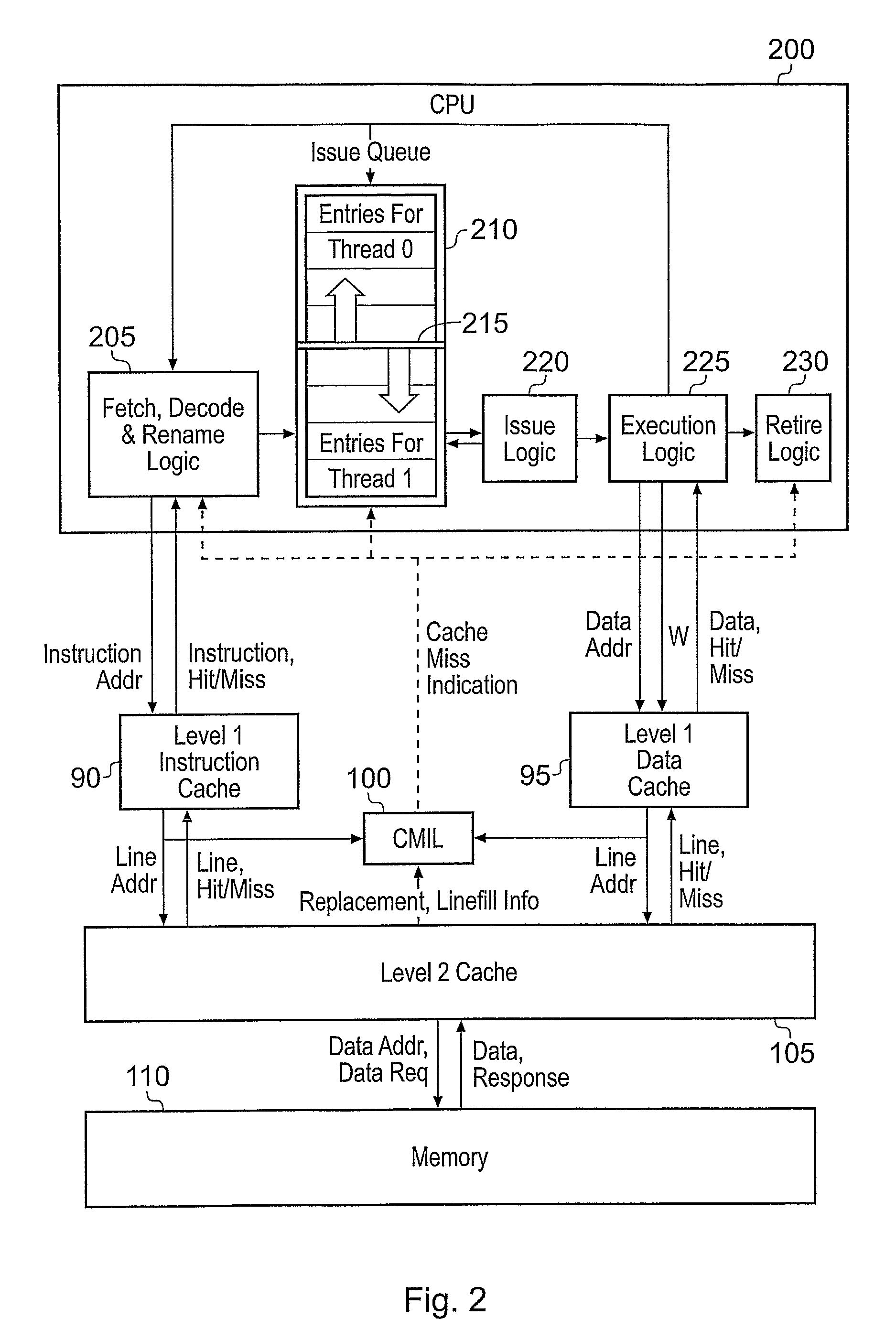

Cache miss detection in a data processing apparatus

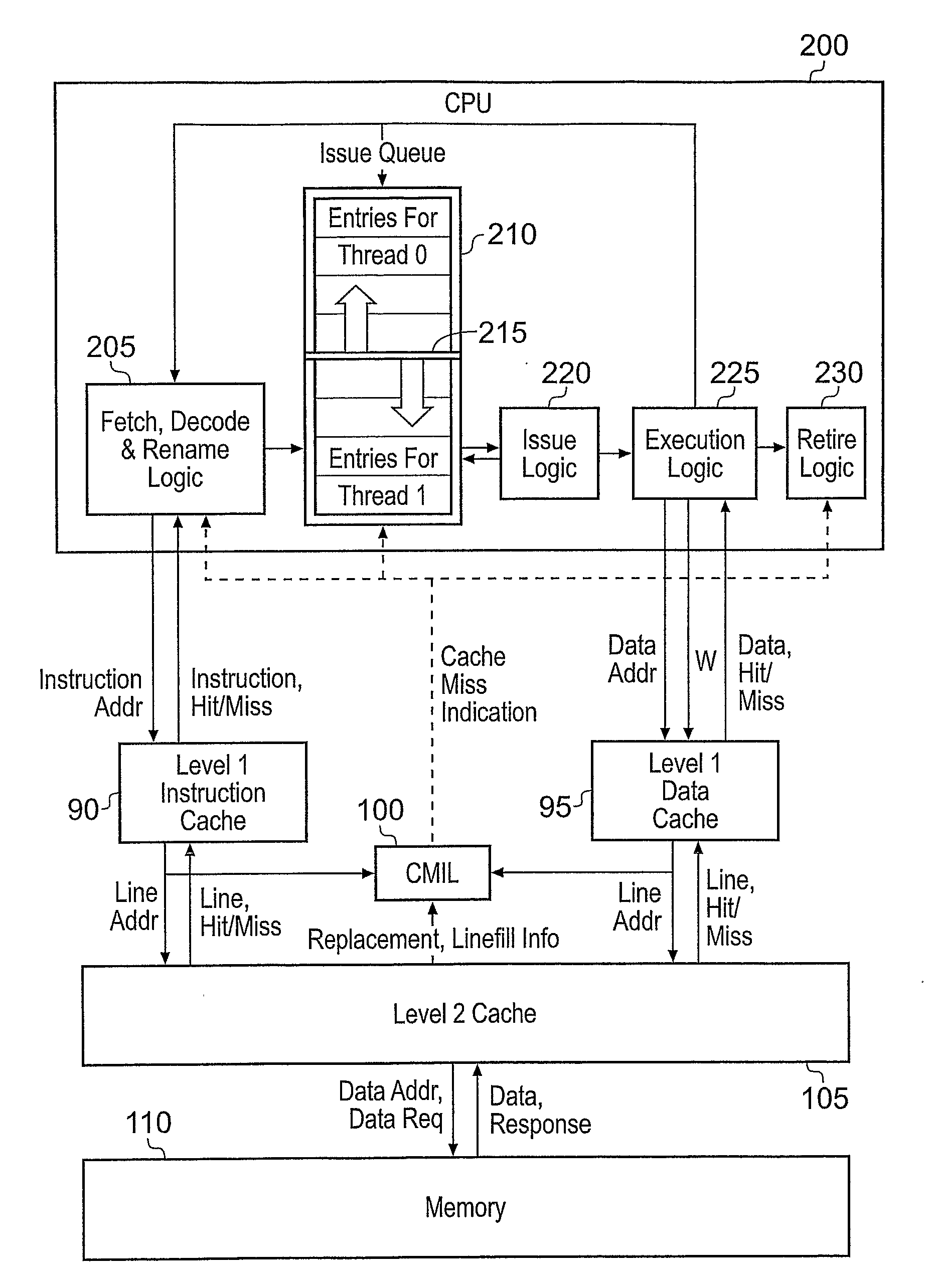

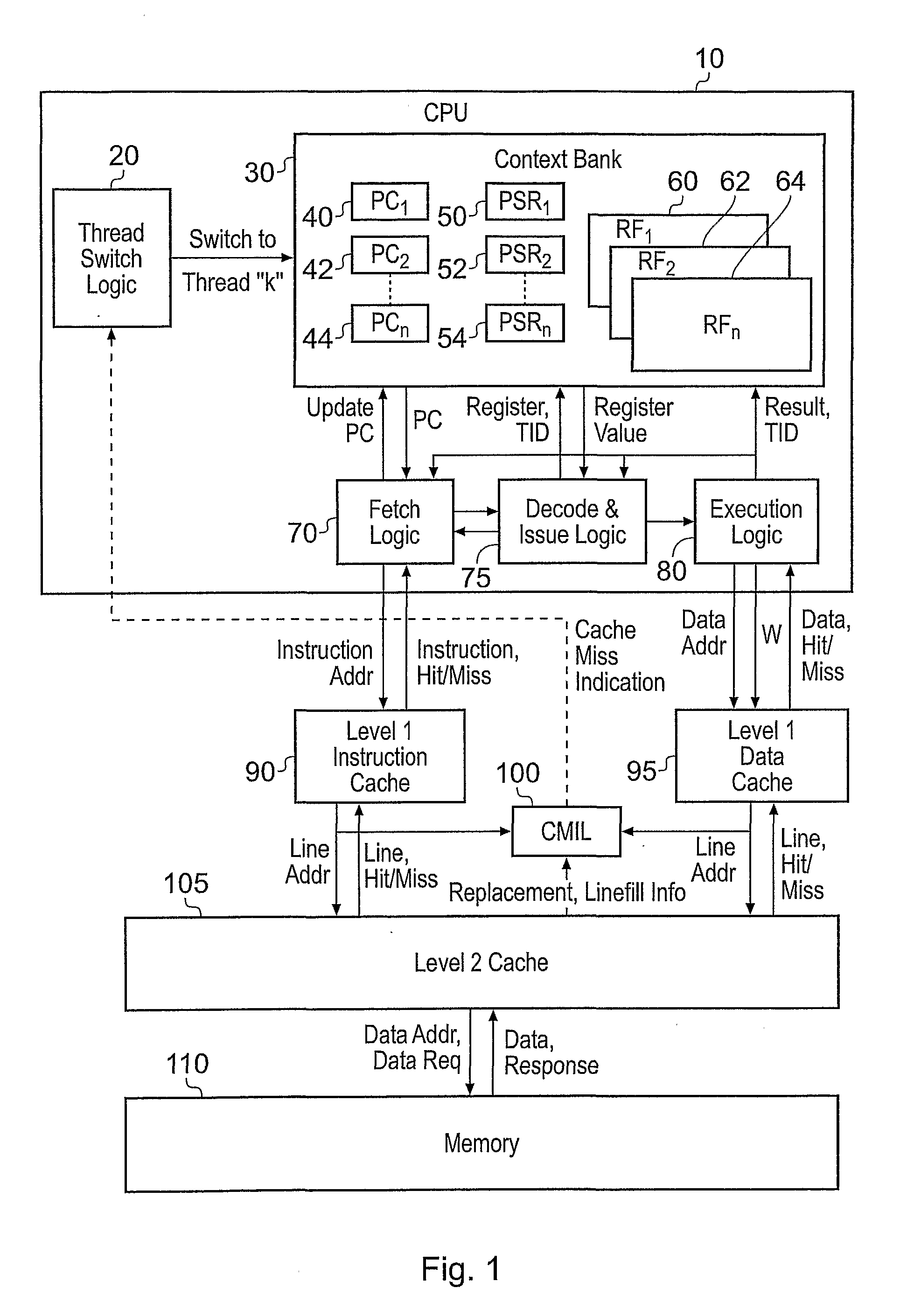

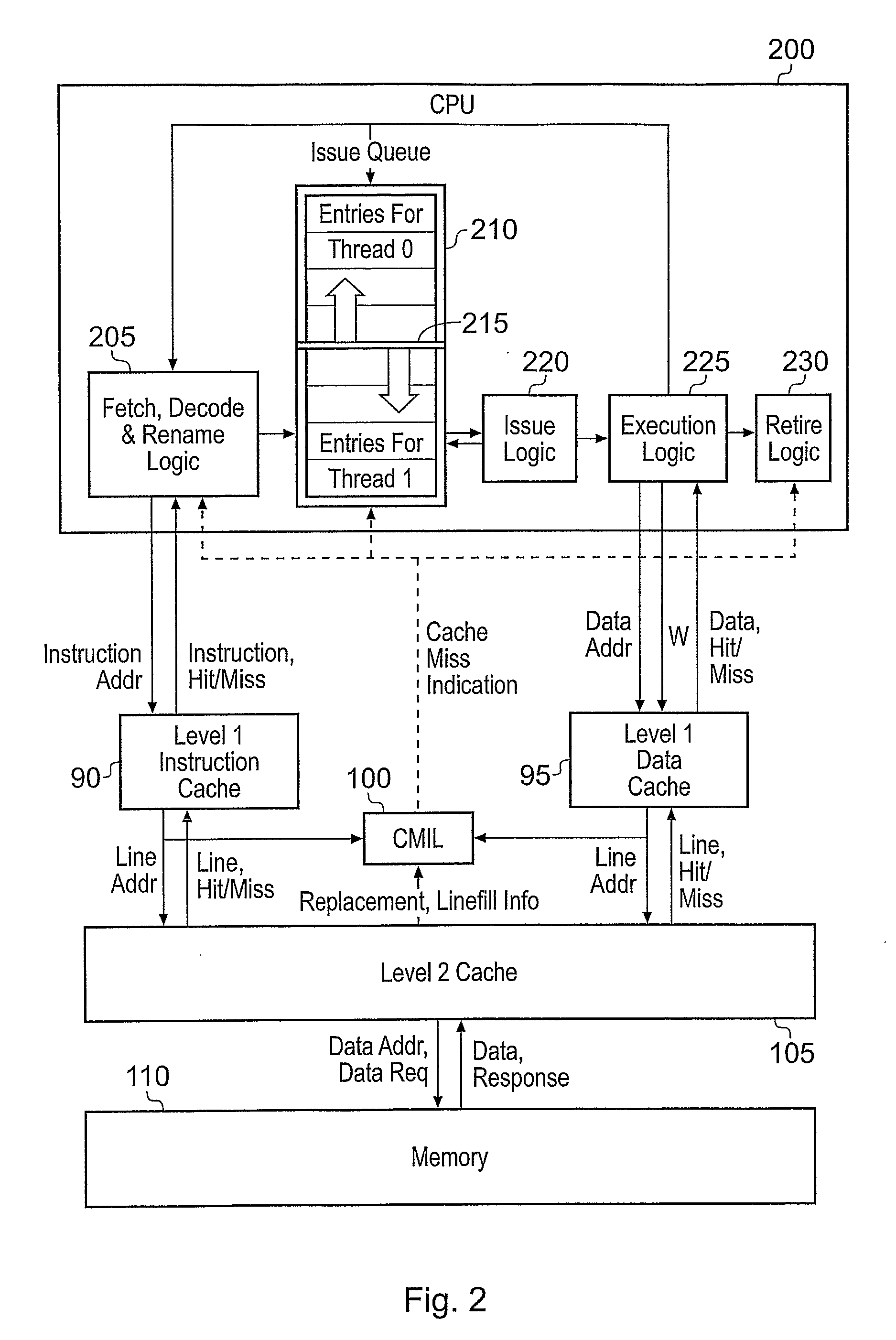

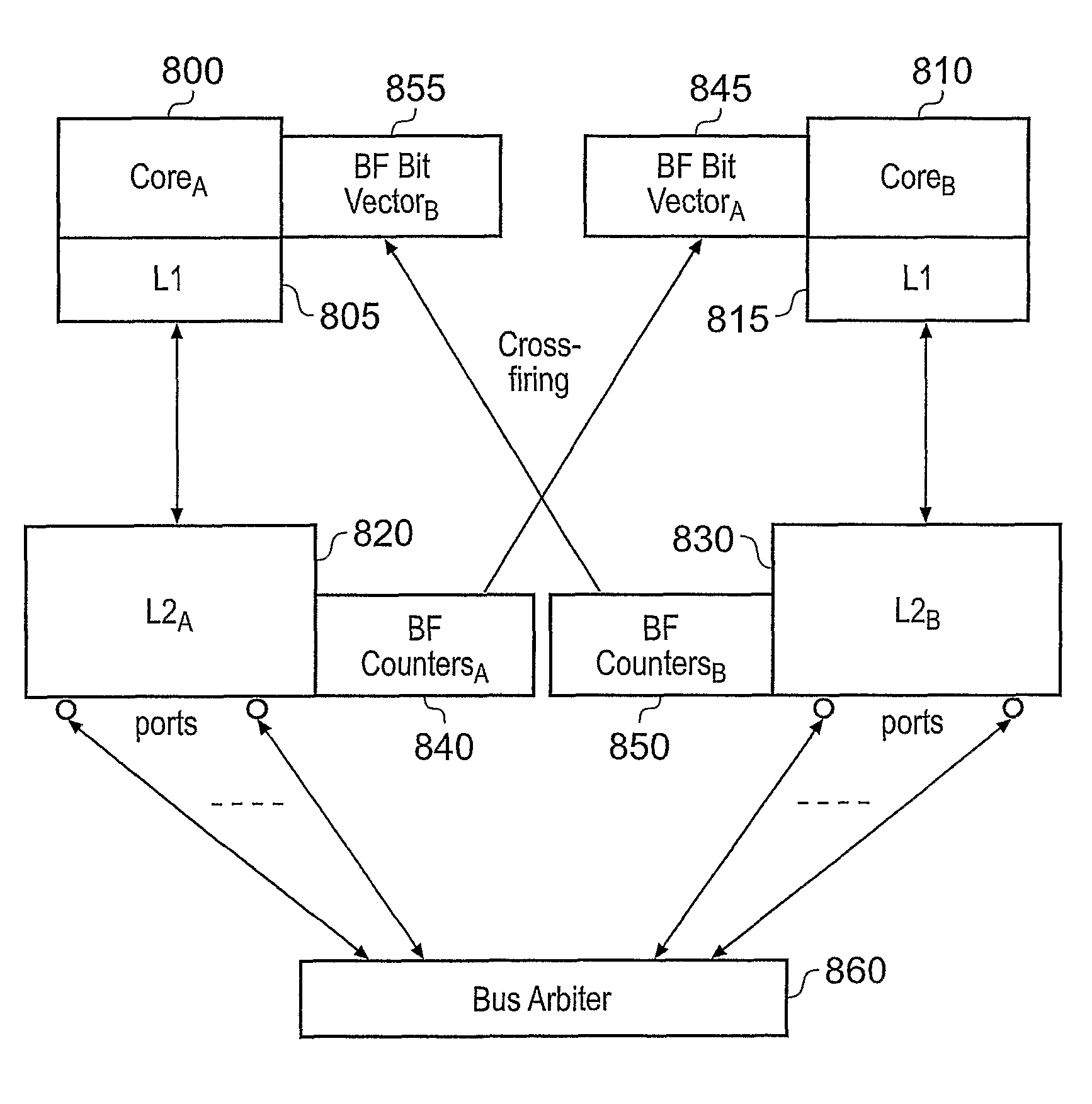

ActiveUS20090222625A1Significant performance improvementReduce in quantityMemory adressing/allocation/relocationMultiprogramming arrangementsParallel computingProgram Thread

A data processing apparatus and method are provided for detecting cache misses. The data processing apparatus has processing logic for executing a plurality of program threads, and a cache for storing data values for access by the processing logic. When access to a data value is required while executing a first program thread, the processing logic issues an access request specifying an address in memory associated with that data value, and the cache is responsive to the address to perform a lookup procedure to determine whether the data value is stored in the cache. Indication logic is provided which in response to an address portion of the address provides an indication as to whether the data value is stored in the cache, this indication being produced before a result of the lookup procedure is available, and the indication logic only issuing an indication that the data value is not stored in the cache if that indication is guaranteed to be correct. Control logic is then provided which, if the indication indicates that the data value is not stored in the cache, uses that indication to control a process having an effect on a program thread other than the first program thread.

Owner:ARM LTD

Cache miss detection in a data processing apparatus

ActiveUS8099556B2Significant performance improvementReduce in quantityMemory adressing/allocation/relocationMultiprogramming arrangementsProgram ThreadData value

A data processing apparatus and method are provided for detecting cache misses. The data processing apparatus has processing logic for executing a plurality of program threads, and a cache for storing data values for access by the processing logic. When access to a data value is required while executing a first program thread, the processing logic issues an access request specifying an address in memory associated with that data value, and the cache is responsive to the address to perform a lookup procedure to determine whether the data value is stored in the cache. Indication logic is provided which in response to an address portion of the address provides an indication as to whether the data value is stored in the cache, this indication being produced before a result of the lookup procedure is available, and the indication logic only issuing an indication that the data value is not stored in the cache if that indication is guaranteed to be correct. Control logic is then provided which, if the indication indicates that the data value is not stored in the cache, uses that indication to control a process having an effect on a program thread other than the first program thread.

Owner:ARM LTD

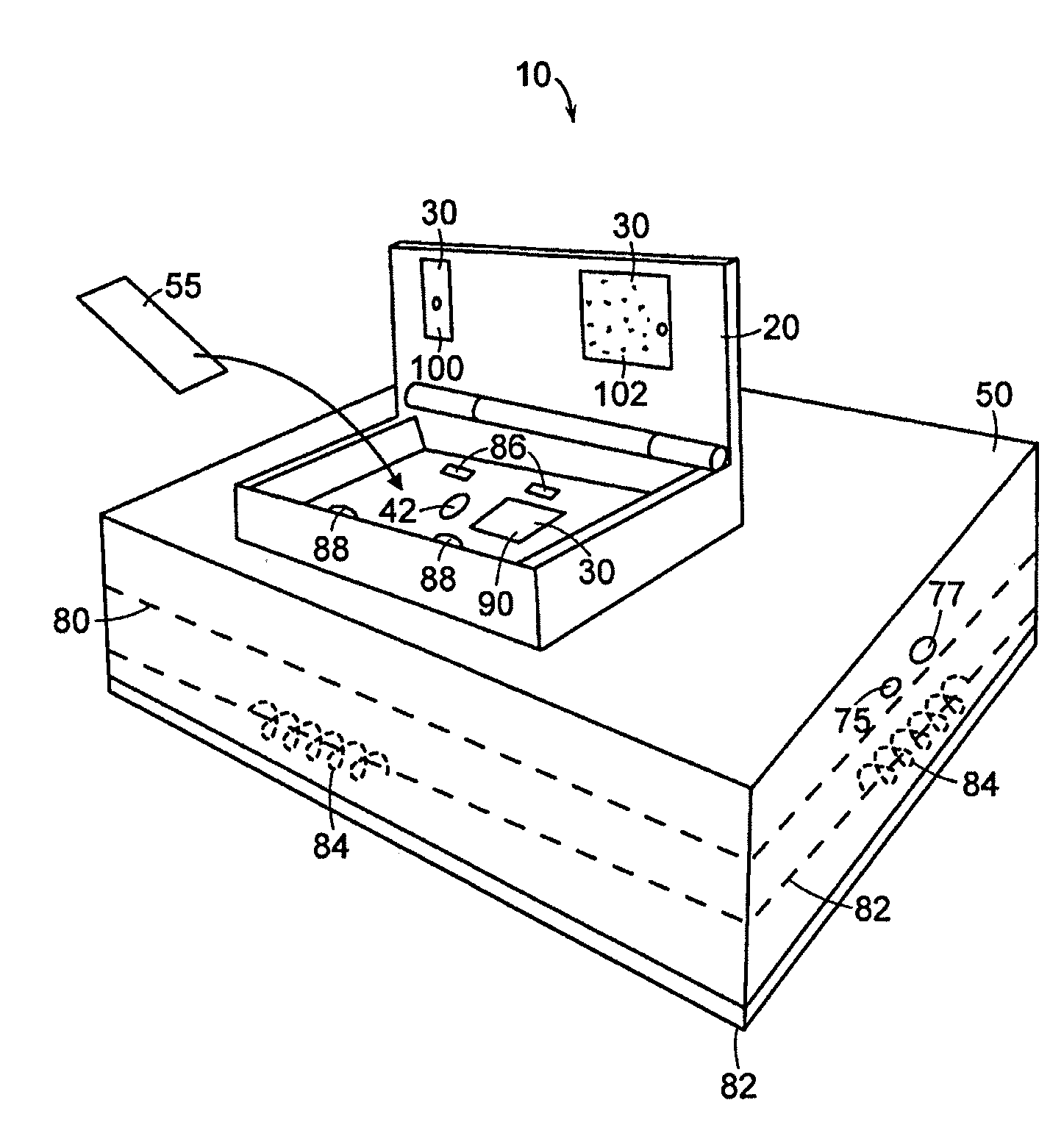

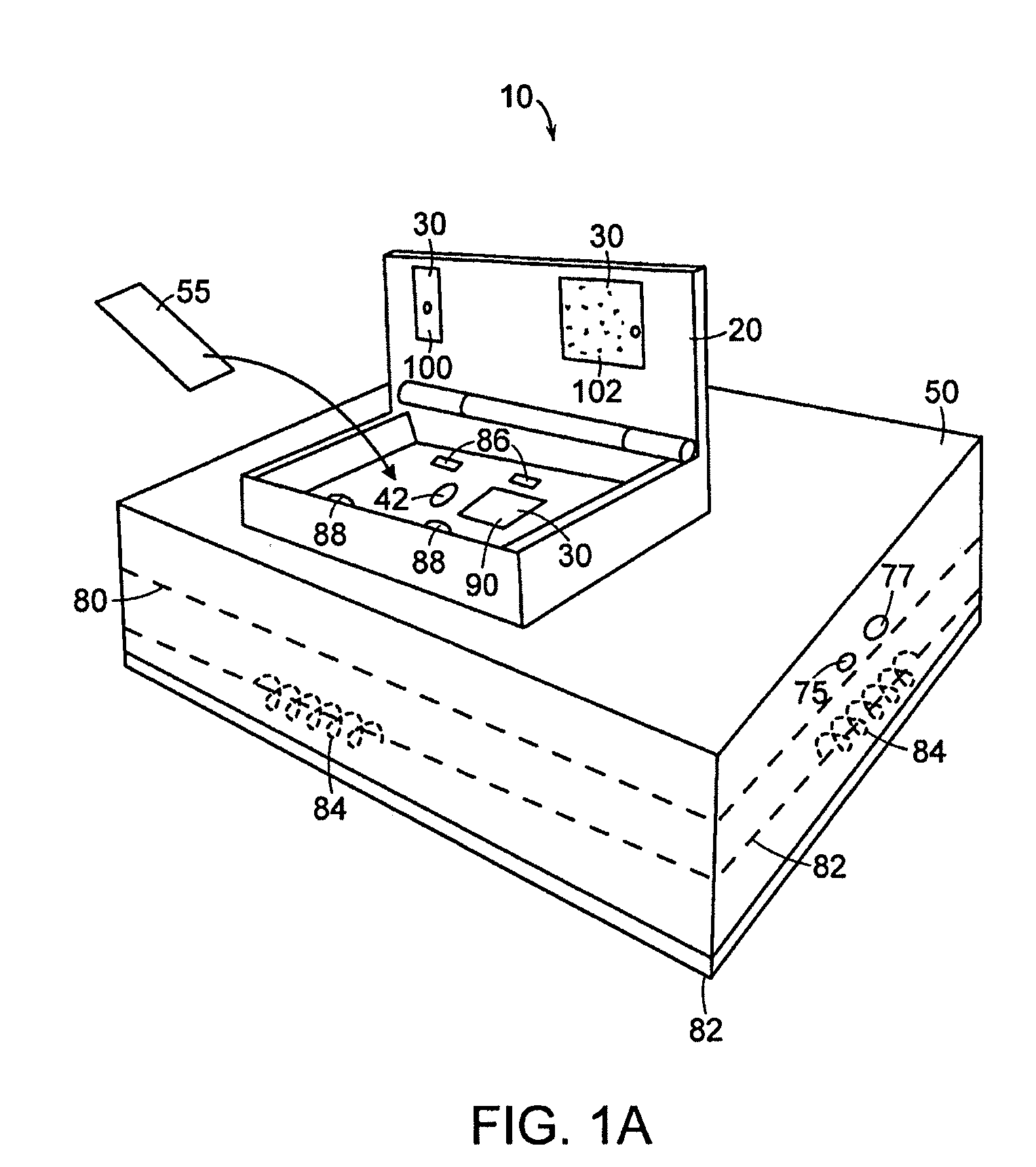

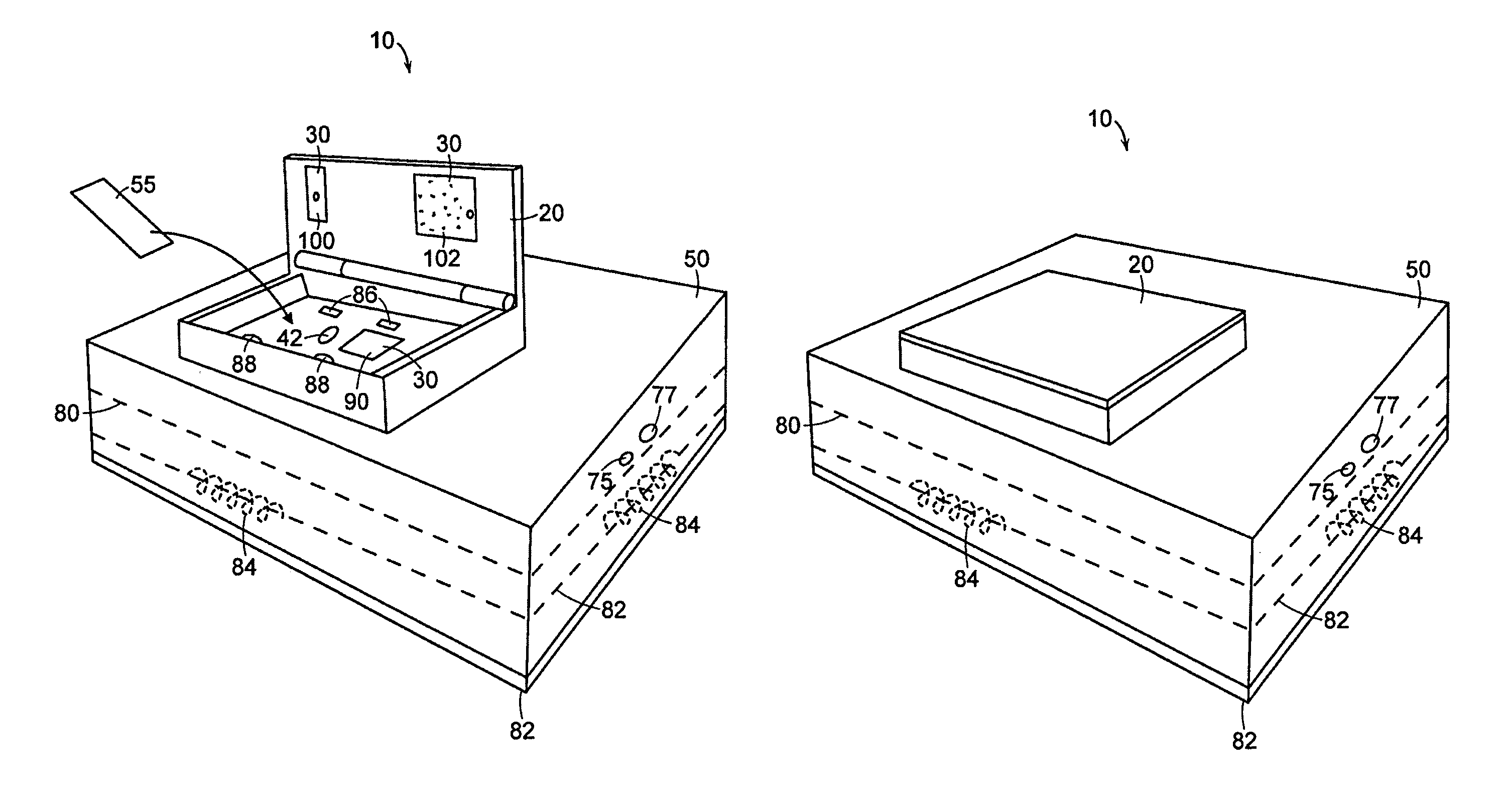

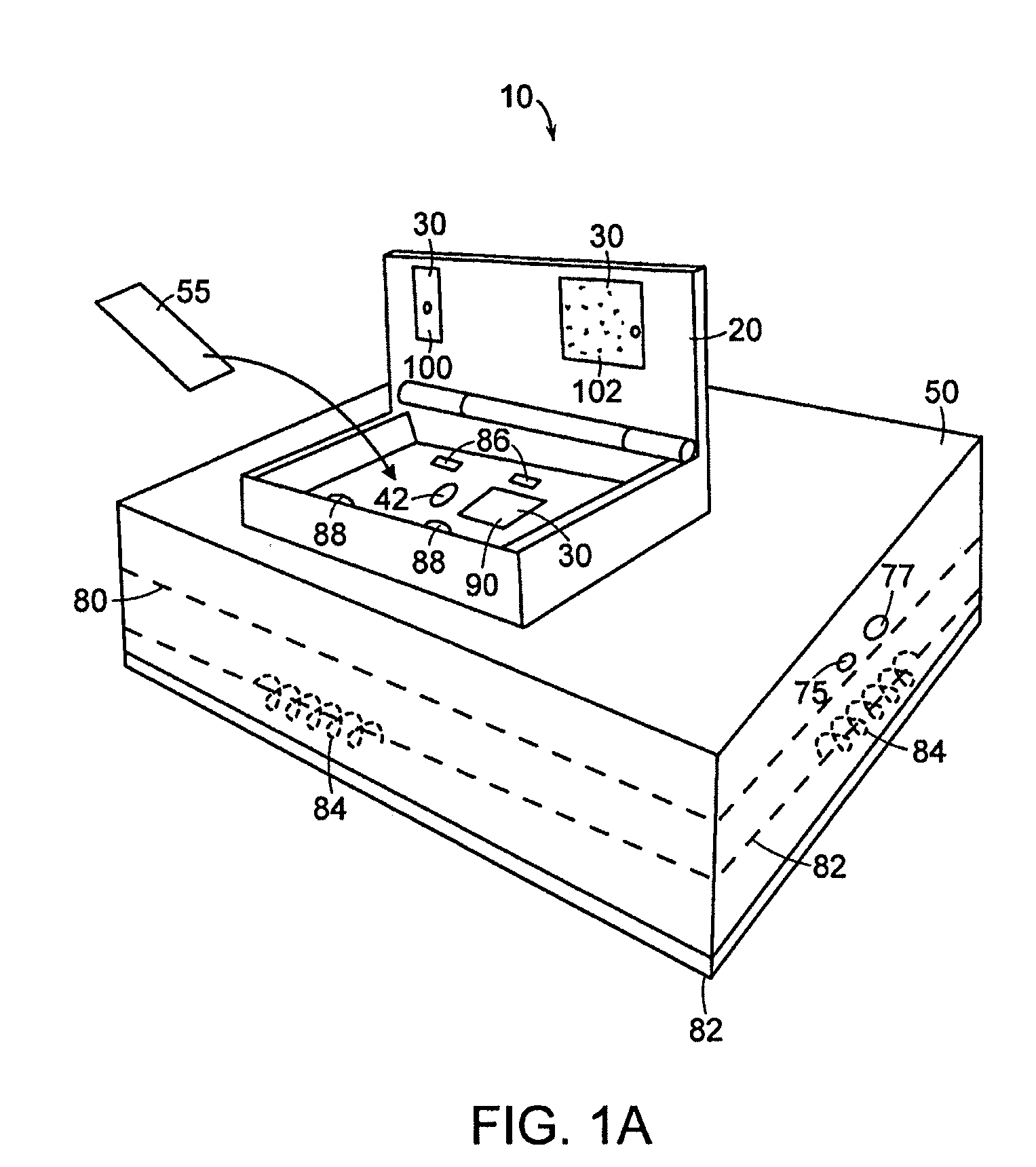

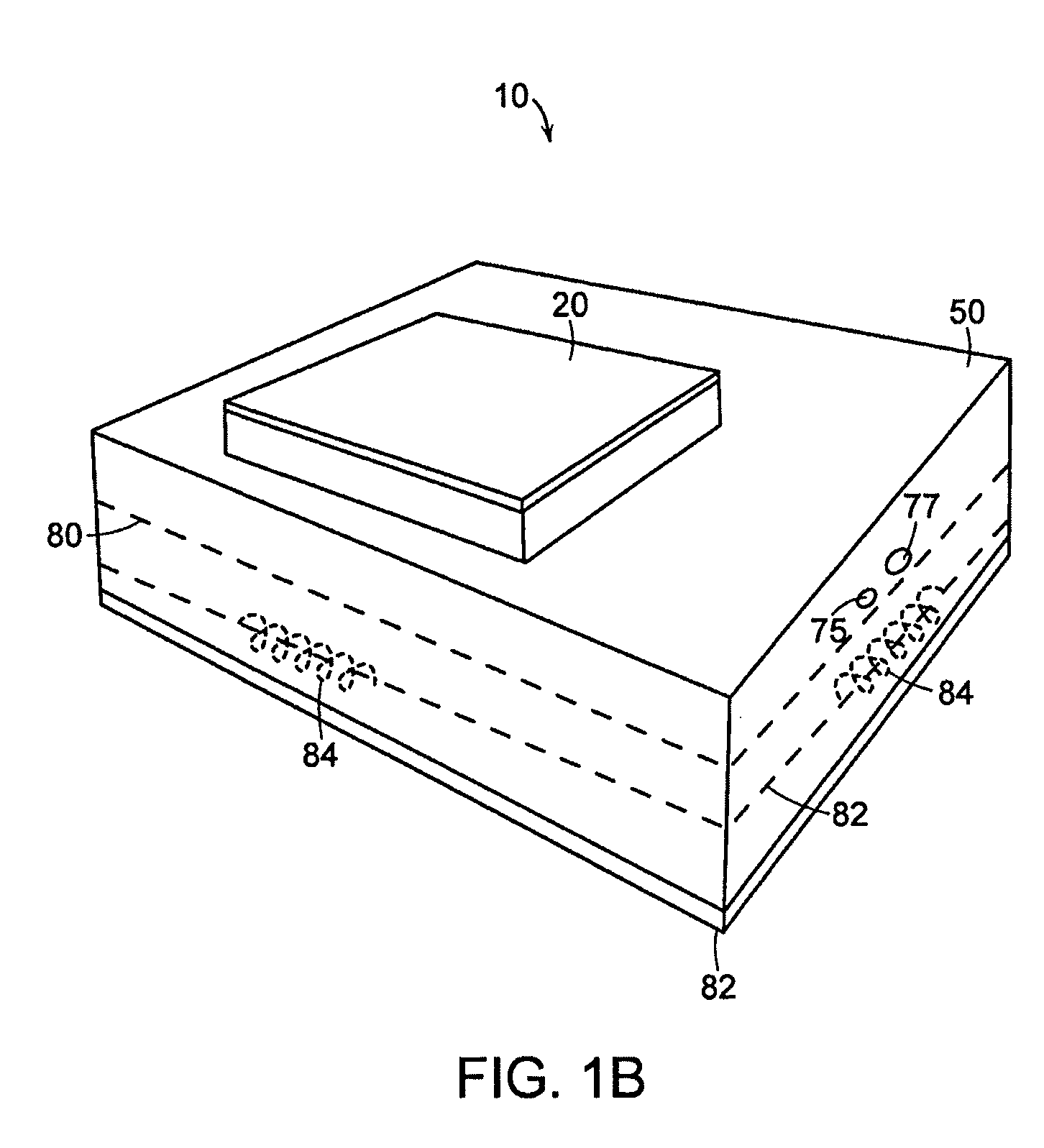

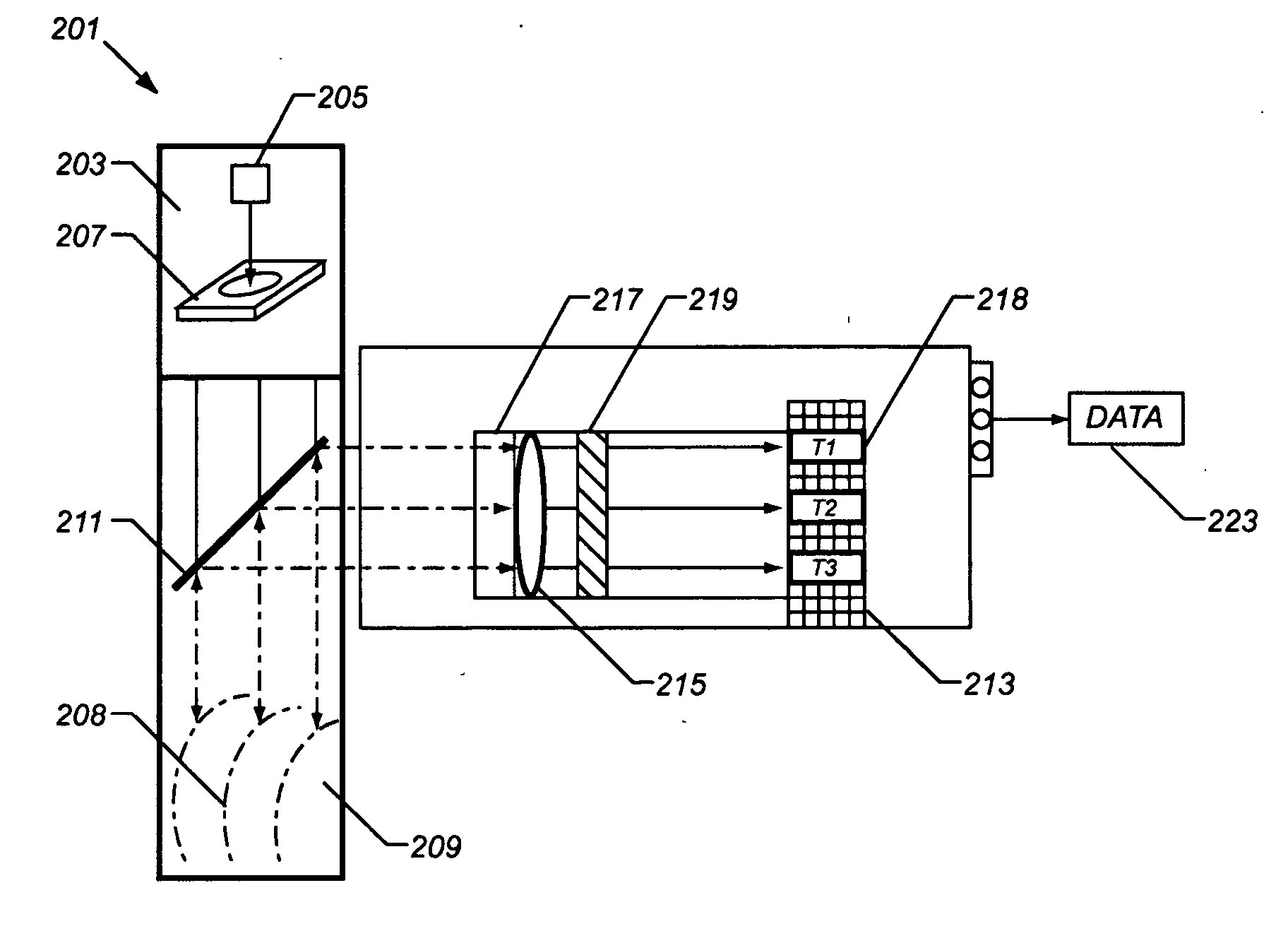

Ruggedized apparatus for analysis of nucleic acid and proteins

ActiveUS20090229983A1Significant performance improvementReduce amountSludge treatmentVolume/mass flow measurementPoint of careADAMTS Proteins

Owner:ANDE CORP

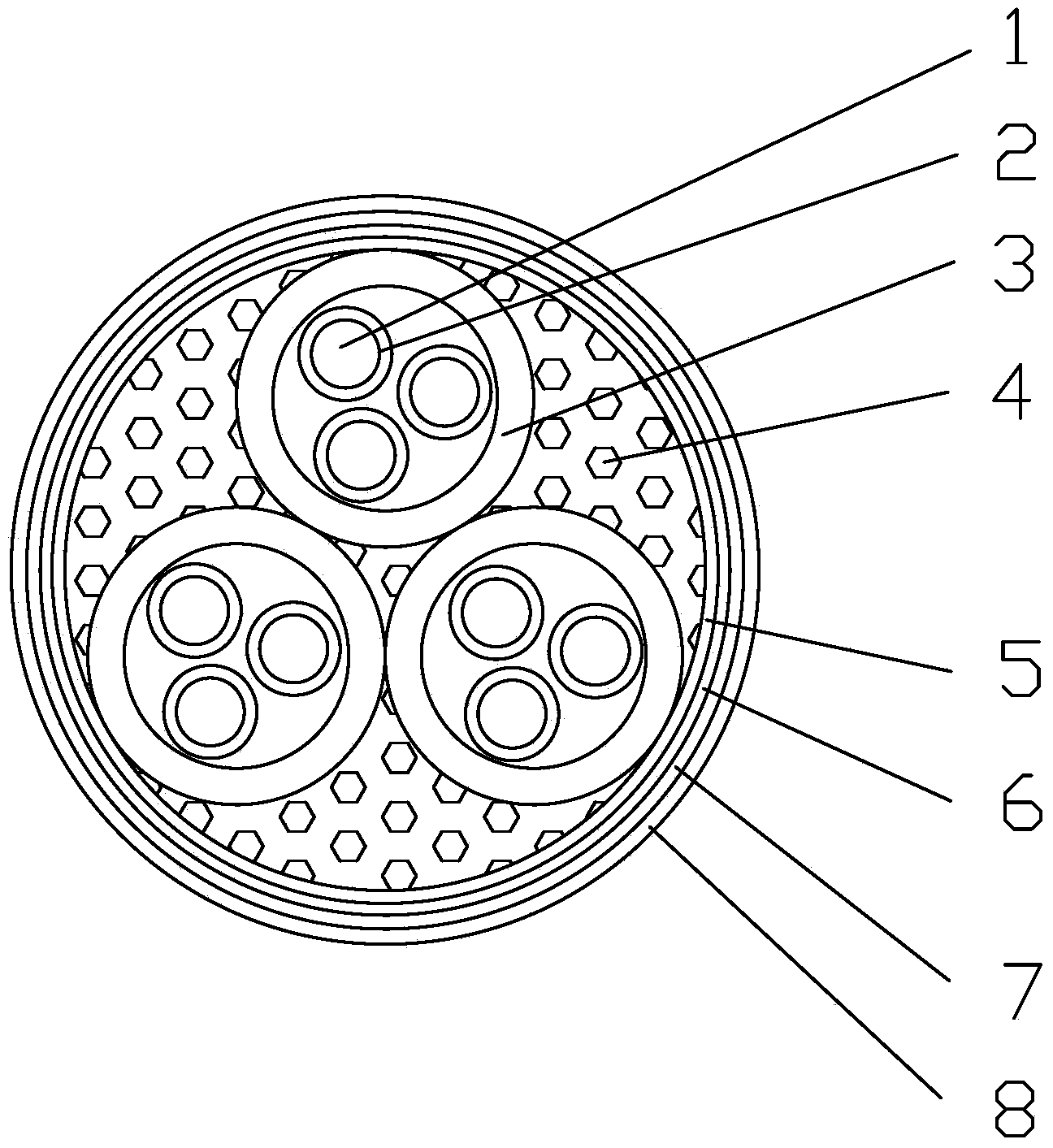

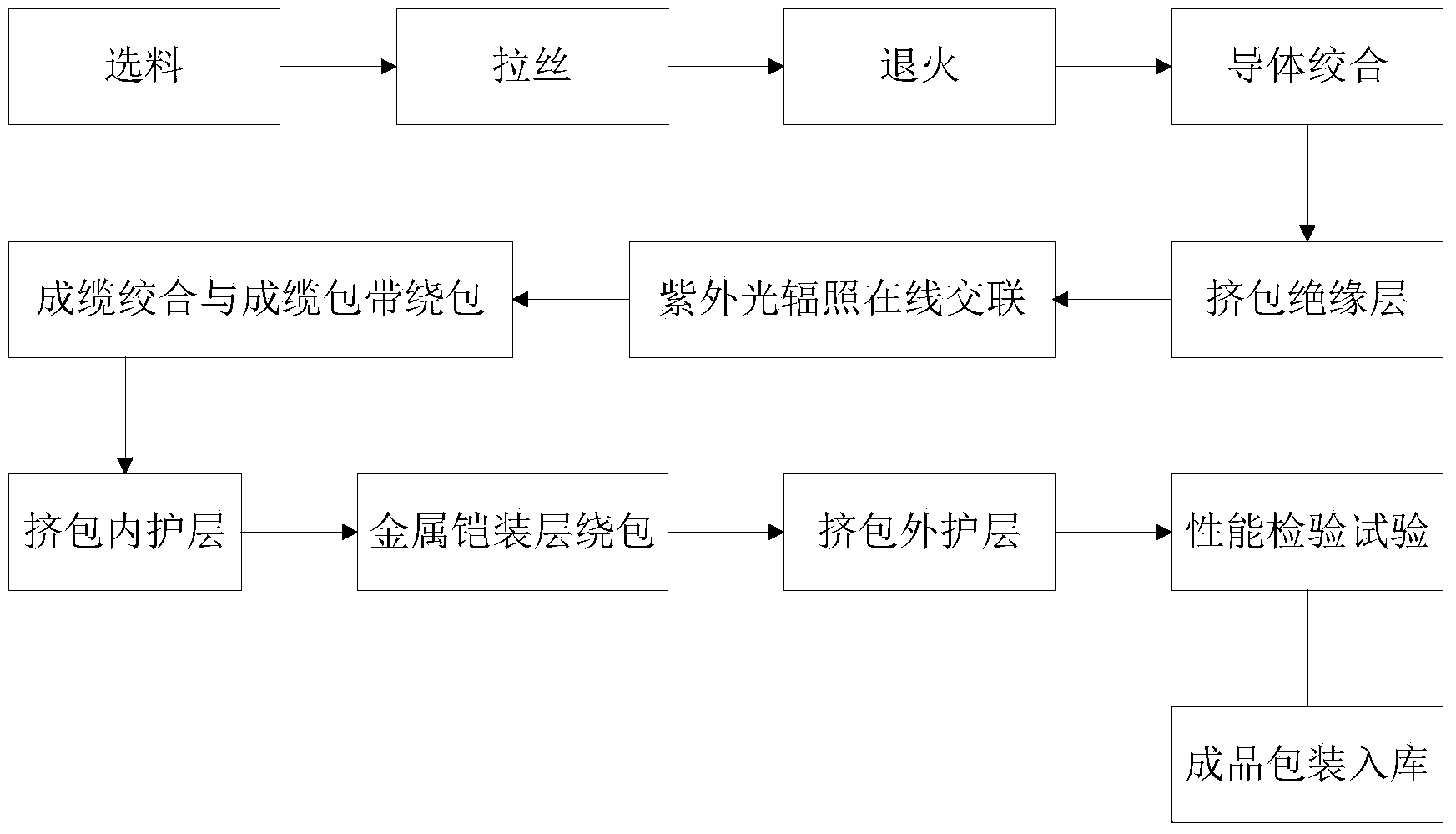

Irradiation cross-linking polyethylene insulated low-voltage power cable preparing method

InactiveCN104319015AImprove physical mechanicsImprove electrical performanceInsulating conductors/cablesElectrical conductorInsulation layer

The invention discloses an irradiation cross-linking polyethylene insulated low-voltage power cable preparing method and belongs to the technical field of cable manufacturing. A cable comprises a conductor, an insulation wire core which is formed in an insulation mode and is extruded on the outer edge of the conductor, a cable core formed by the insulation wire core, filling materials at a gap of the cable core, a cable forming wrapping belt layer wrapped outside the cable core, an inner protecting layer extruded outside the cable forming wrapping belt, a wrapped metal armoring layer and an extruded outer protecting sleeve from inside to outside. The cable is prepared through the following steps of material selecting, wire drawing, annealing, conductor intertwisting, insulation layer extruding and irradiation, cable forming intertwisting and cable forming wrapping belt wrapping, inner protecting layer extruding, metal armoring layer wrapping and outer protecting sleeve layer extruding in sequence. According to the novel irradiation cross-linking polyethylene insulated low-voltage power cable preparing method, energy loss can be lowered, and production cost can be lowered.

Owner:SICHUAN MINGXING CABLE

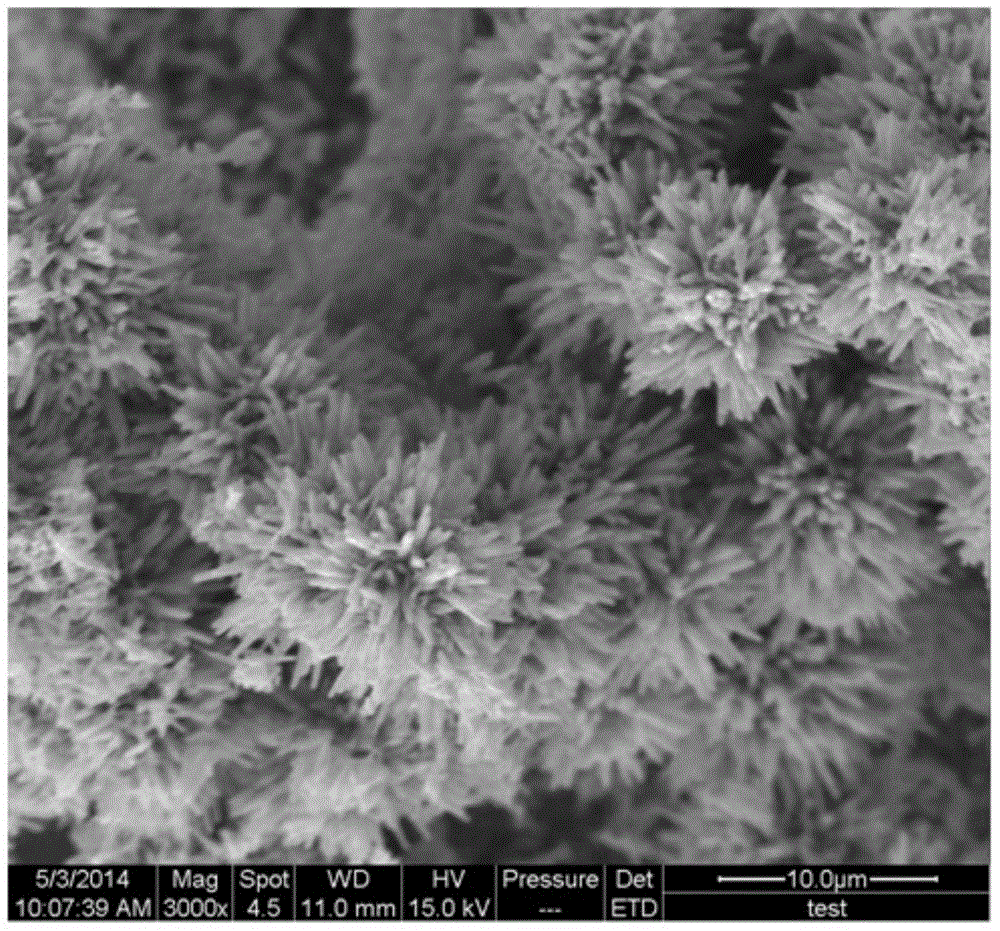

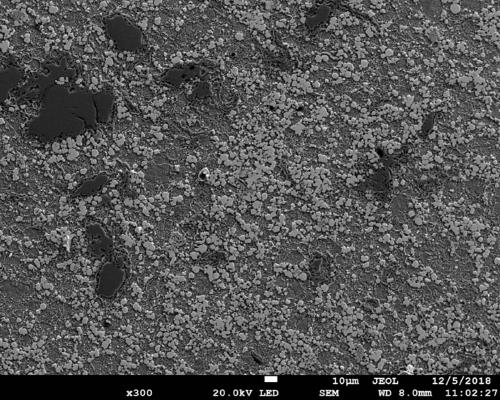

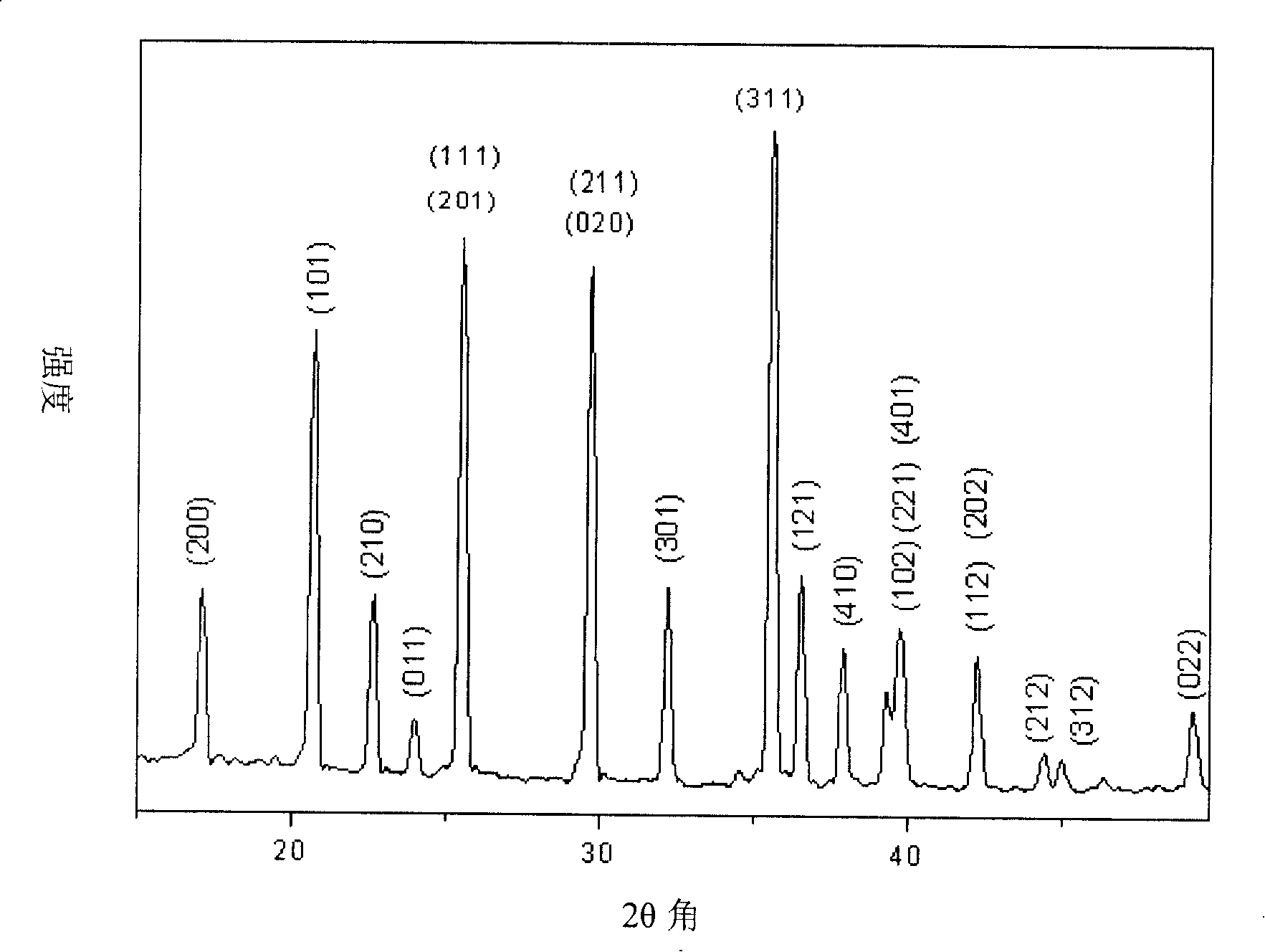

High magnifying power lithium-rich manganese-based cathode material with nano/microstructure

ActiveCN104157844ASimple processSignificant performance improvementMaterial nanotechnologyCell electrodesSodium chlorateChemical stability

The invention relates to a high magnifying power lithium-rich manganese-based cathode material with a nano / microstructure, which belongs to the technical field of material synthesis. A chemical reaction of the cathode material is aLi2MnO3.(1-a)LiMO2, wherein a is greater than or equal to 0.3 and less than 1, M is NixCoyMn1-x-y, wherein x is greater than or equal to 0 and less than 0.5, and y is greater than or equal to 0 and less than 0.5. A preparation method comprises the following steps: 1)weighing manganese salt, a surfactant and sodium chlorate, uniformly mixing, performing a hydrothermal reaction to obtain radicalized hollow nano / microstructure formed by self assembly of a manganese dioxide nanorod; 2)uniformly mixing manganese dioxide with the nano / microstructure obtained in the step 1) with lithium salt, cobalt salt and nickel salt to obtain a precursor; and 3)calcining the precursor at high temperature to obtain the lithium-rich manganese-based cathode material with nano / microstructure. The method uses the advantage of short diffusion path of a carrier of a nanostructure in the nano / microstructure to effectively increase the multiplying power capacity of the material, and the method also uses characteristics of low surface energy, difficult agglomeration and high chemical stability of a micrometer structure for keeping the cycle performance of the material.

Owner:哈尔滨博尔特能源科技有限公司

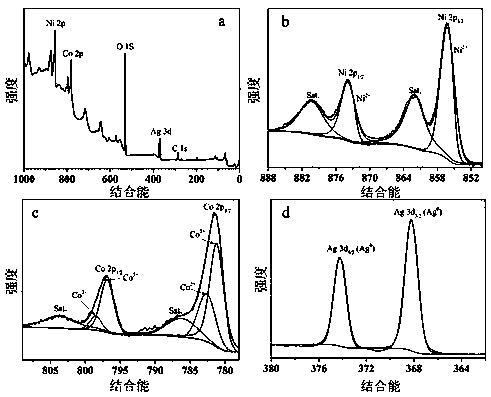

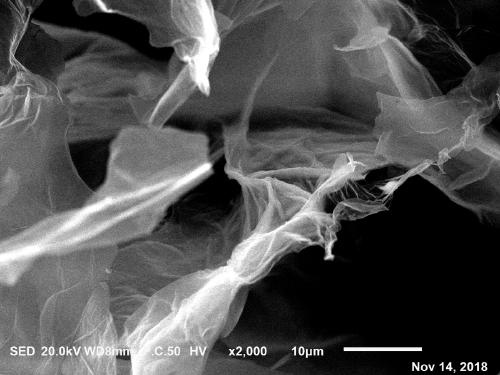

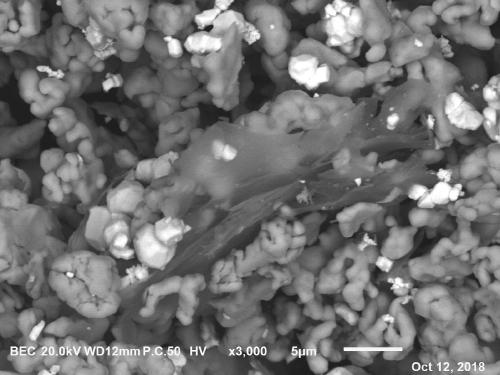

Preparation method and application of metallic Ag nano-particle deposited NiCo-LDH composite photocatalyst

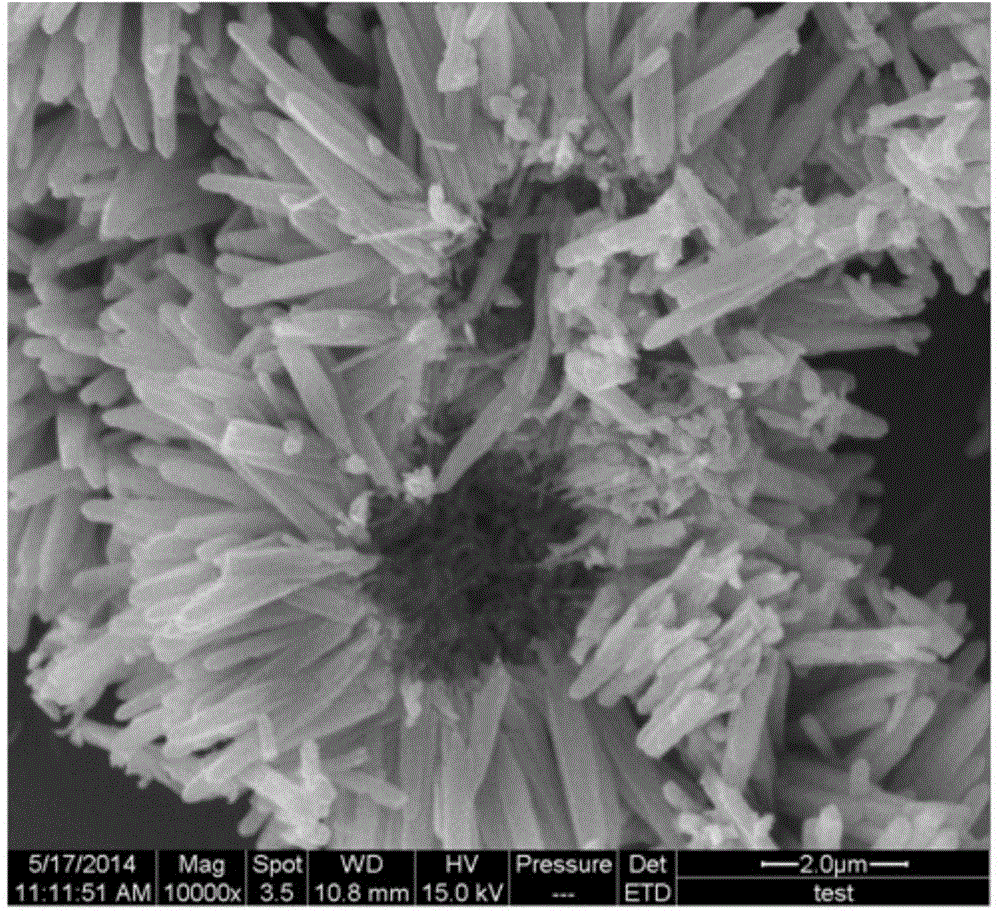

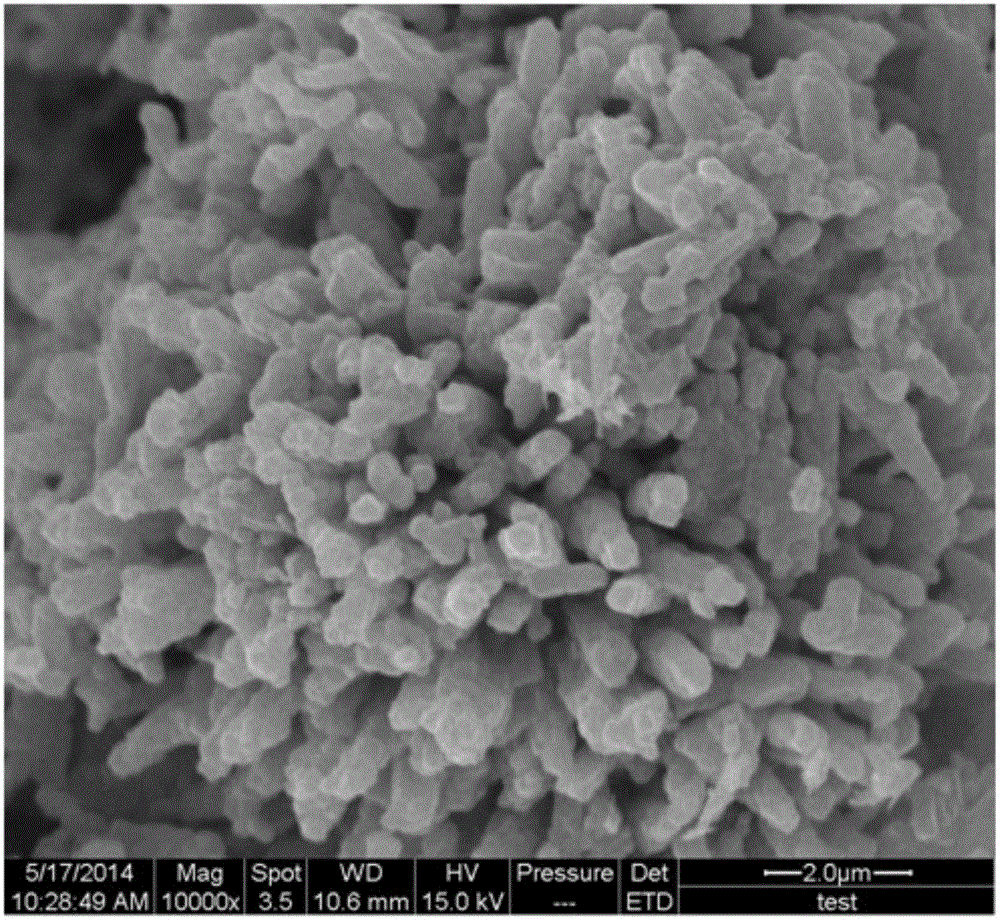

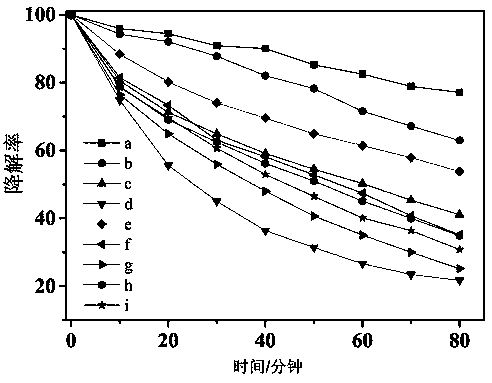

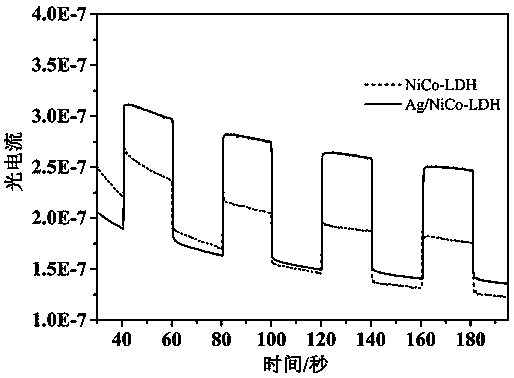

ActiveCN107899590AIncrease the active siteEasy to separateWater/sewage treatment by irradiationWater treatment compoundsWater useWater baths

The invention belongs to the technical field of preparation of environment materials, and concretely relates to a preparation method and an application of a metallic Ag nano-particle deposited NiCo-LDH composite photocatalyst. The preparation method of the metallic Ag nano-particle deposited NiCo-LDH composite photocatalyst mainly comprises the following steps: heating nickel nitrate, cobalt nitrate, ammonium chloride, sodium hydroxide and deionized water used as raw materials in a water bath to obtain a NiCo-LDH material; and radiating the NiCo-LDH material, silver nitrate and water which areused as raw materials under an ultraviolet lamp for a certain time to prepare the metallic Ag nano-particle modified NiCo-LDH composite photocatalyst used for photocatalytic degradation of tetracycline. A low-temperature water bath process is adopted, so the energy consumption in the synthesis process is low; and the synthesized NiCo-LDH composite material has a ball flower-shaped structure, anddeposition of silver makes the obtained metallic Ag nano-particle deposited NiCo-LDH composite photocatalyst have a greatly improved electron-hole pair separation efficiency and an excellent tetracycline photocatalytic degradation performance.

Owner:JIANGSU UNIV

Ruggedized apparatus for analysis of nucleic acid and proteins

ActiveUS8173417B2Significant performance improvementReduce amountSludge treatmentVolume/mass flow measurementPoint of careBiology

The invention provides methods and systems for ruggedizing a nucleic acid analyzing apparatus. The ruggedized apparatus can be used reliably and effectively in uncontrolled environments, such as, for example at a crime scene to collect and analyze forensic data, as well as in semi-controlled environments, such as, for example at a point of care location.

Owner:ANDE CORP

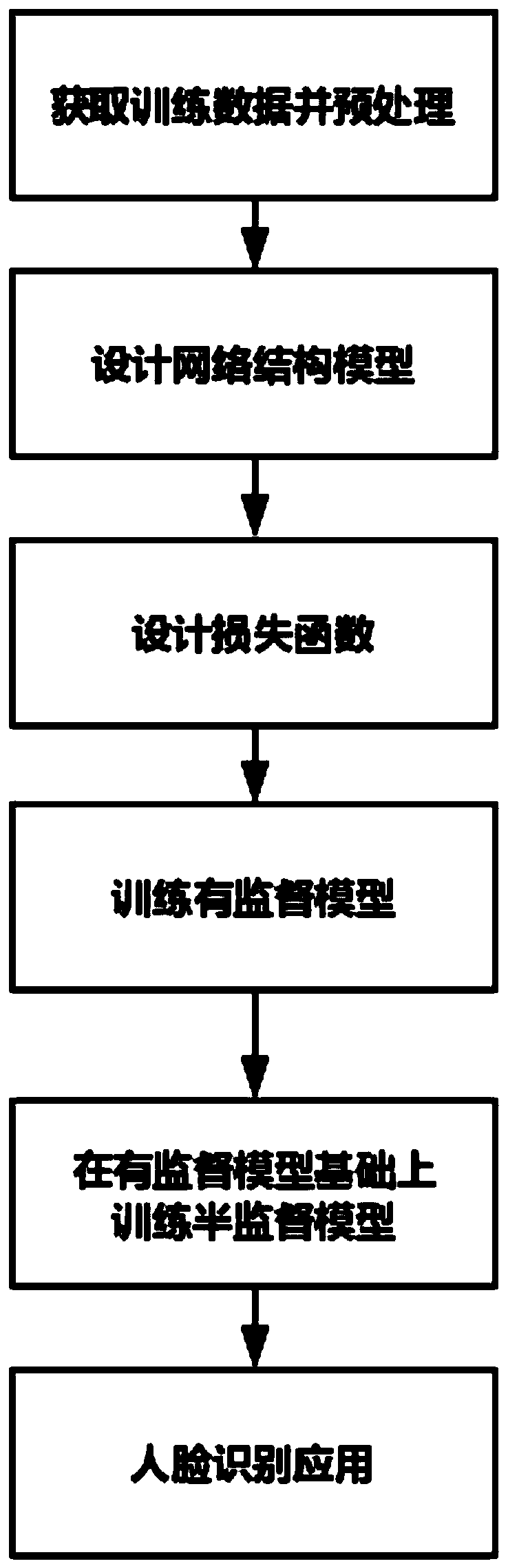

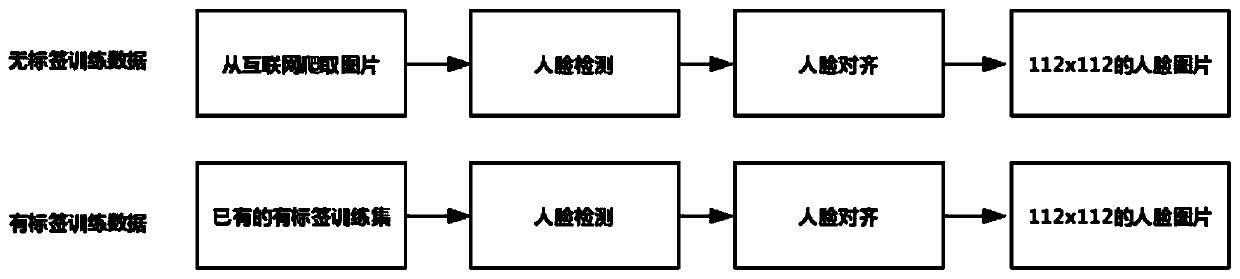

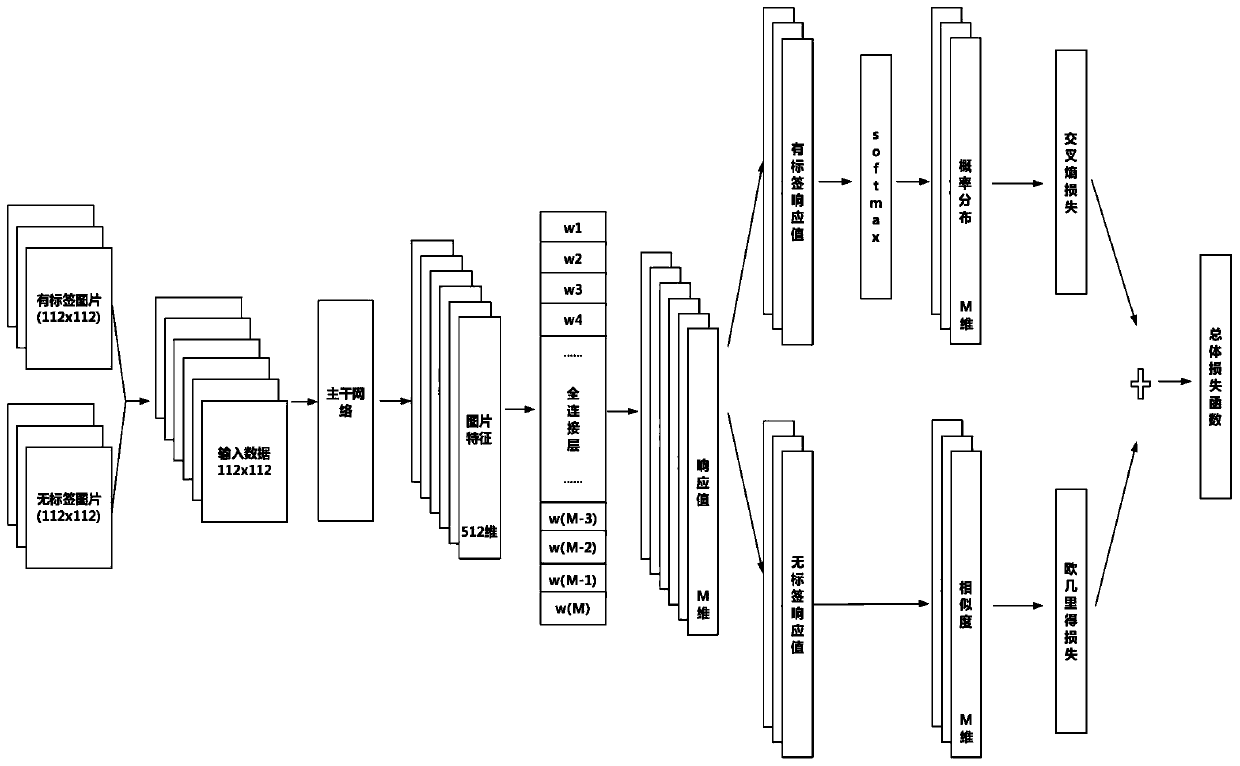

Face recognition method based on semi-supervised training

ActiveCN110472533AImprove performanceReduce performanceCharacter and pattern recognitionFace detectionData set

The invention relates to a face recognition method based on semi-supervised training, and belongs to the field of computer vision. The method includes: firstly, using a face recognition data set as labeled data, obtaining face pictures from the Internet to serve as label-free data, and obtaining training data through face detection and alignment for the labeled data and the label-free data; introducing a loss function based on a label-free picture, and carrying out semi-supervised training together with the loss function of the labeled picture; introducing a task balance factor alpha and a data balance factor beta to balance the relationship between a supervised task and an unsupervised task. Compared with other face recognition methods using label-free data, the method has the advantagesthat label-free pictures do not need to be clustered, the mode of using the label-free pictures is more efficient, and the performance of the model is better; according to the method, good performanceimprovement is achieved on a plurality of face recognition test sets, and good universality is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

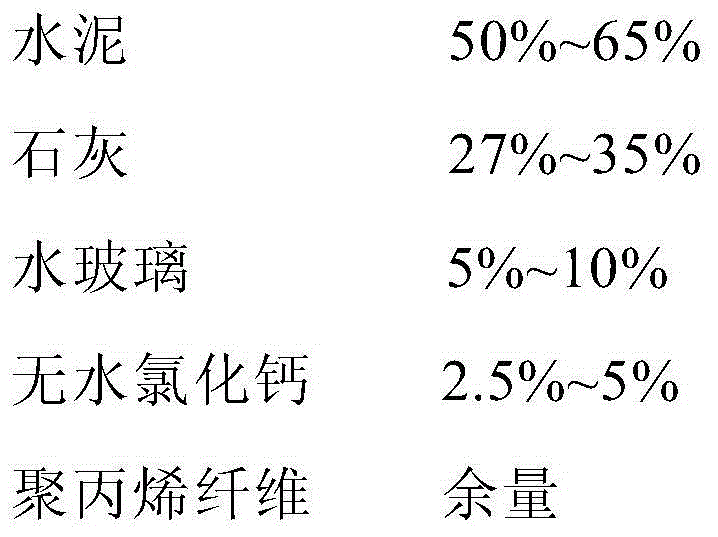

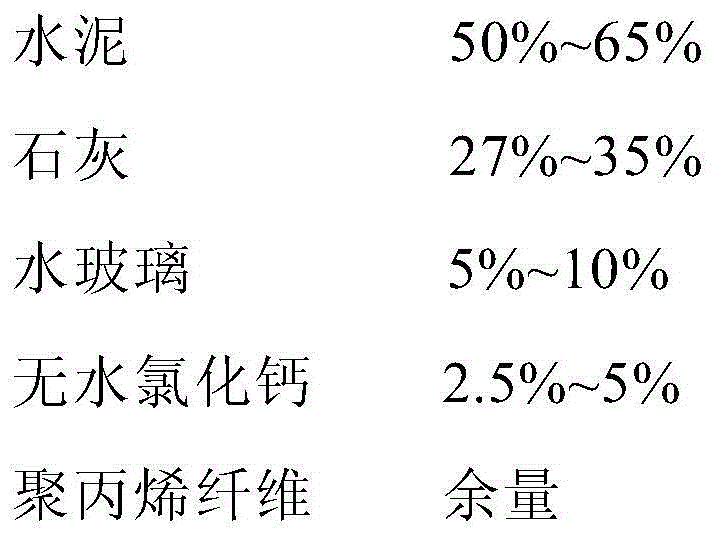

Raw soil building material modification method and method for preparation of building block by use of modified raw soil

The invention discloses a raw soil building material modification method, belongs to the technical field of building materials, solves the technical problem that traditional raw soil building materials have low strength, high brittleness, poor resistance to water, and the like, first the performance of a raw soil material is improved by a chemical modification agent, a modified raw soil building block is prepared by physical pressure moulding technology, the performance of the raw soil material is improved significantly, especially aiming at vast raw soil resources in urgent need of development and utilization in Northern Shaanxi area, the method can largely use local raw soil materials, is convenient in material taking, economical and practical, strong in integrity, excellent in thermal processing property, simple in operation, easy in implementation and popularization, and to be more important, in line with the requirements of green building, and broad in application prospect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

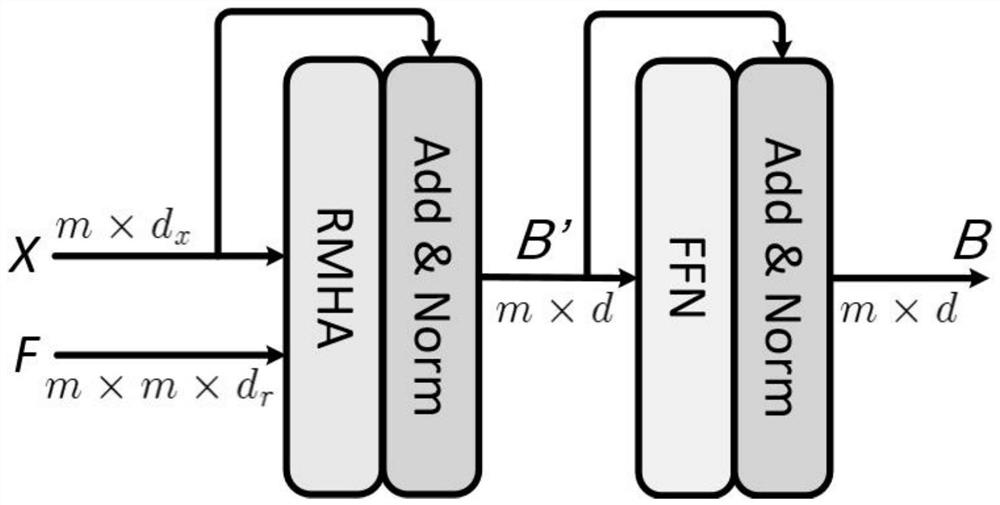

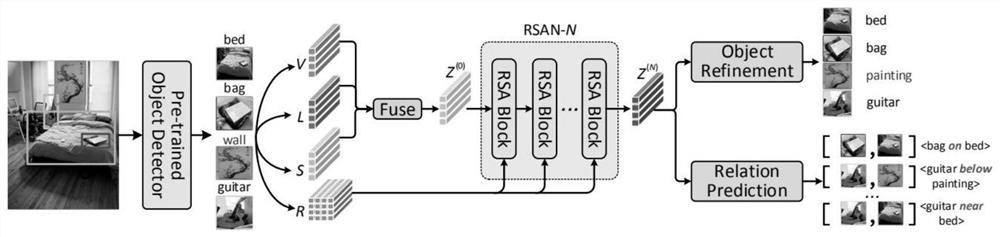

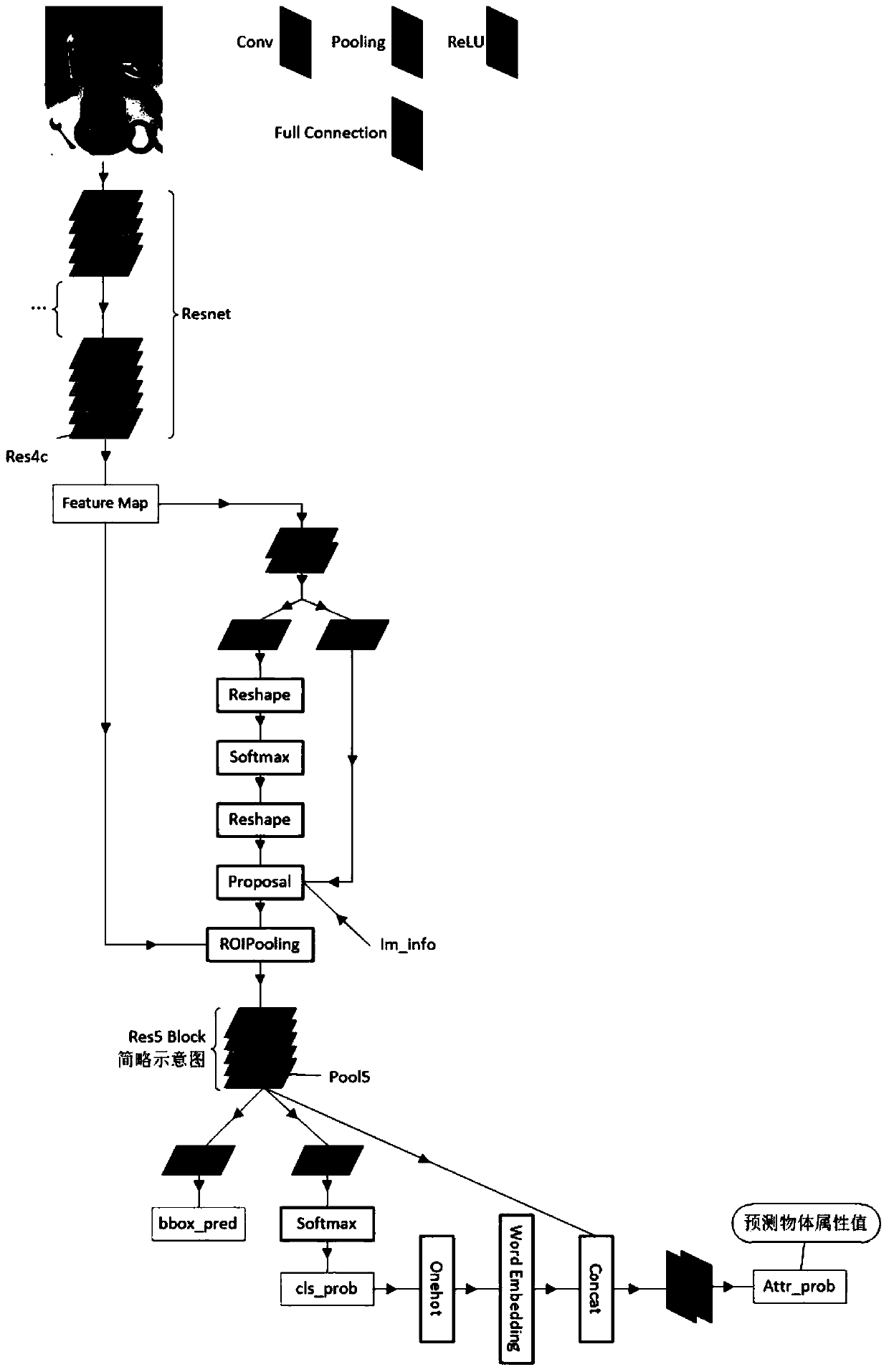

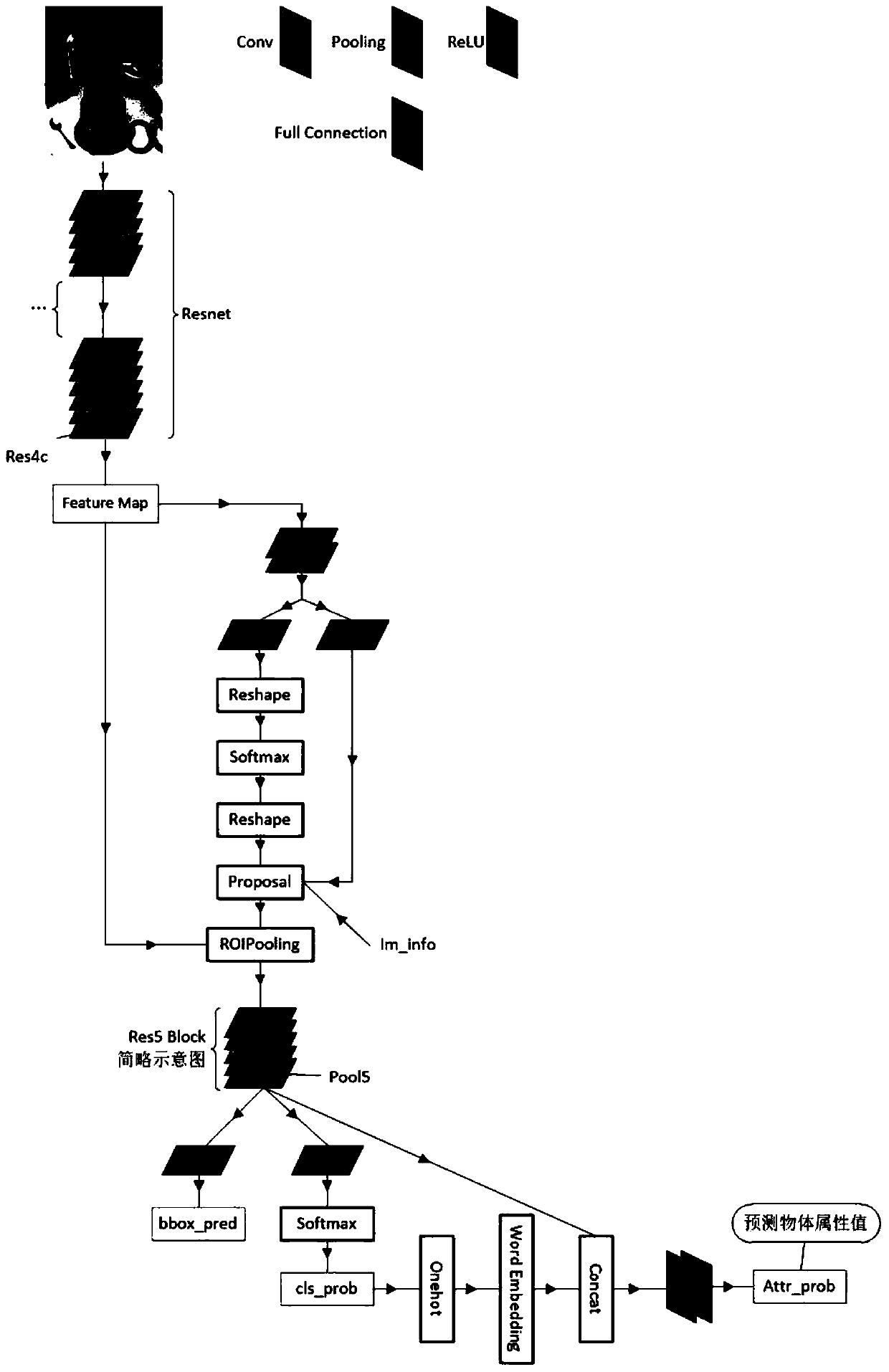

Scene graph generation method based on depth relation self-attention network

ActiveCN112464016AFully understand contextual informationFully understand target relevanceDigital data information retrievalCharacter and pattern recognitionImage extractionData set

The invention discloses a scene graph generation method based on a depth relation self-attention network. The method comprises the following steps: 1, data preprocessing and data set division; 2, feature extraction of an image by using a pre-trained target detection network; 3, construction of spatial features of a target; 4, construction of language features of the target; the method is used formodeling the RSAN network of the target context and the relation context at the same time, achieves a significant improvement effect on a task generated by a scene graph, and surpasses most mainstreammethods on the task. In addition, the RSAN network also has very important application value and huge potential in other cross-modal related fields such as image content questioning and answering andvisual relationship detection.

Owner:HANGZHOU DIANZI UNIV

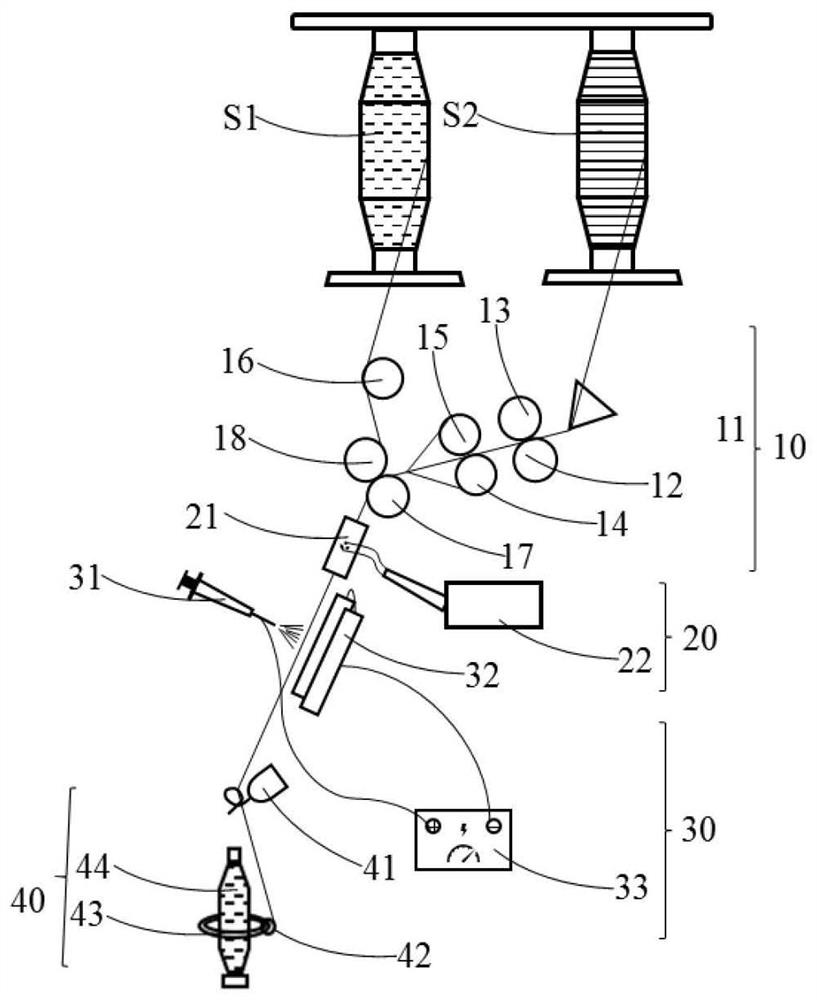

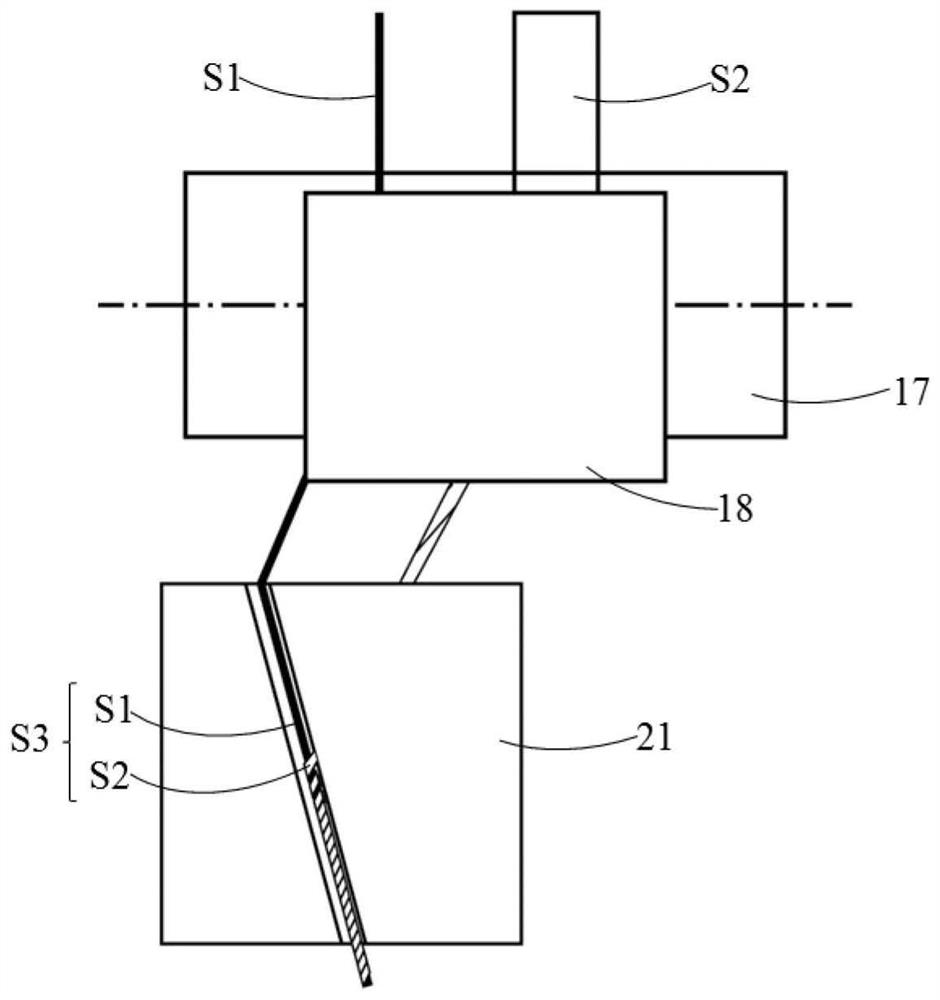

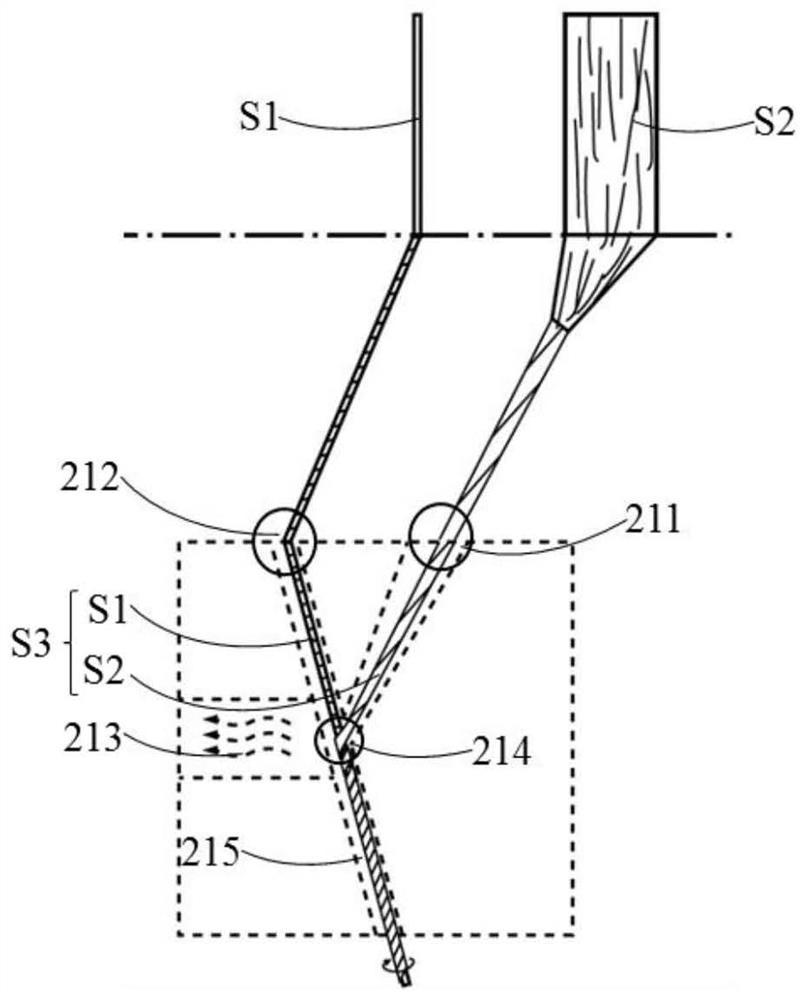

Core spinning device and new-structure core spinning method for full wrapping of macro core

The invention provides a core spinning device and a new-structure core spinning method for full wrapping of a macro core. According to the core spinning device, an auxiliary core wrapping device is additionally arranged between a front roller jaw and a yarn guide hook of a common ring spinning frame; and the auxiliary core wrapping device comprises a first yarn channel used for conveying an outer wrapping material, a second yarn channel used for conveying a core layer material and a wrapping point used for wrapping and converging. In a spinning process, short fiber strands and filaments form a y-shaped twisting structure with the filaments in a straightened state, the filaments are kept in the straightened state at the wrapping point, and the short fiber strands wrap outer layers of the filaments at the wrapping point by means of twisting rotation of the filaments and partial twist of the short fiber strands, so that core spun yarn with a good wrapping effect is formed, and the problem of core exposure of the ring-spun core spun yarn is solved. According to the invention, through coating of nanofibers, the hairiness of resultant yarn is completely eliminated, and the performance of the resultant yarn is comprehensively improved. The operation is convenient, the transformation cost is low, and the performance of the ring-spun core spun yarn is obviously improved.

Owner:WUHAN TEXTILE UNIV

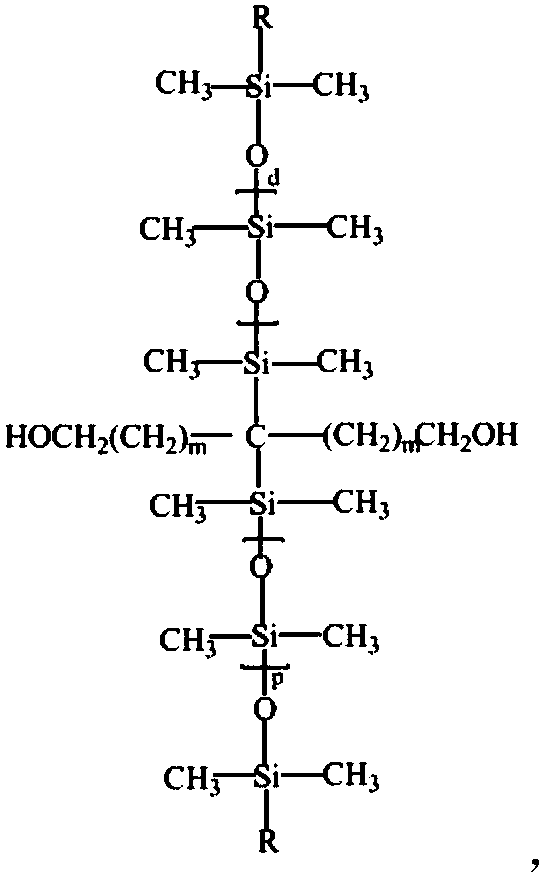

Amphoteric wool grease leather fatliquoring agent and preparation method thereof

InactiveCN101864500AEnvironmentally friendlyGood biodegradabilityLeather impregnationWoolPolymer chemistry

The invention relates to an amphoteric wool grease leather fatliquoring agent and a preparation method thereof. At present, the existing wool grease modifying mode is mainly modification reaction based on hydroxy in wool grease, has direct influence on the quality of leather-making and fur products and has non-ideal effect on the improvement of performance. The amphoteric wool grease leather fatliquoring agent and the preparation method thereof comprise the steps of wool grease amidation reaction, condensation reaction of amidated wool grease and sodium chloroacetate in sequence, specificallytaking down materials in parts by weight for mixing, heating to 40-60 DEG C, insulating and stirring for 25-35min to lead oil phases to be mixed uniformly, then mixing 15-20 parts of water, 0.8-1.2 parts of penetrating agent JFC, 4-6 parts of Tween-80, heating the mixture to be 60-70 DEG C, then adding the obtained mixture into a product of step 3 by times, continuing to heat and stir for 15-25min and discharging. The invention is environment-friendly, has wide application range and simultaneously and greatly improves leather property.

Owner:SHAANXI UNIV OF SCI & TECH

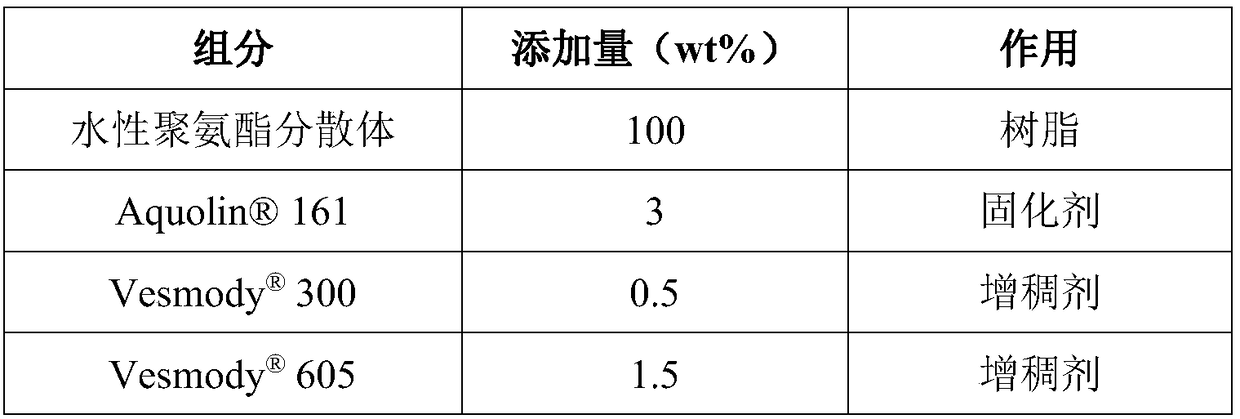

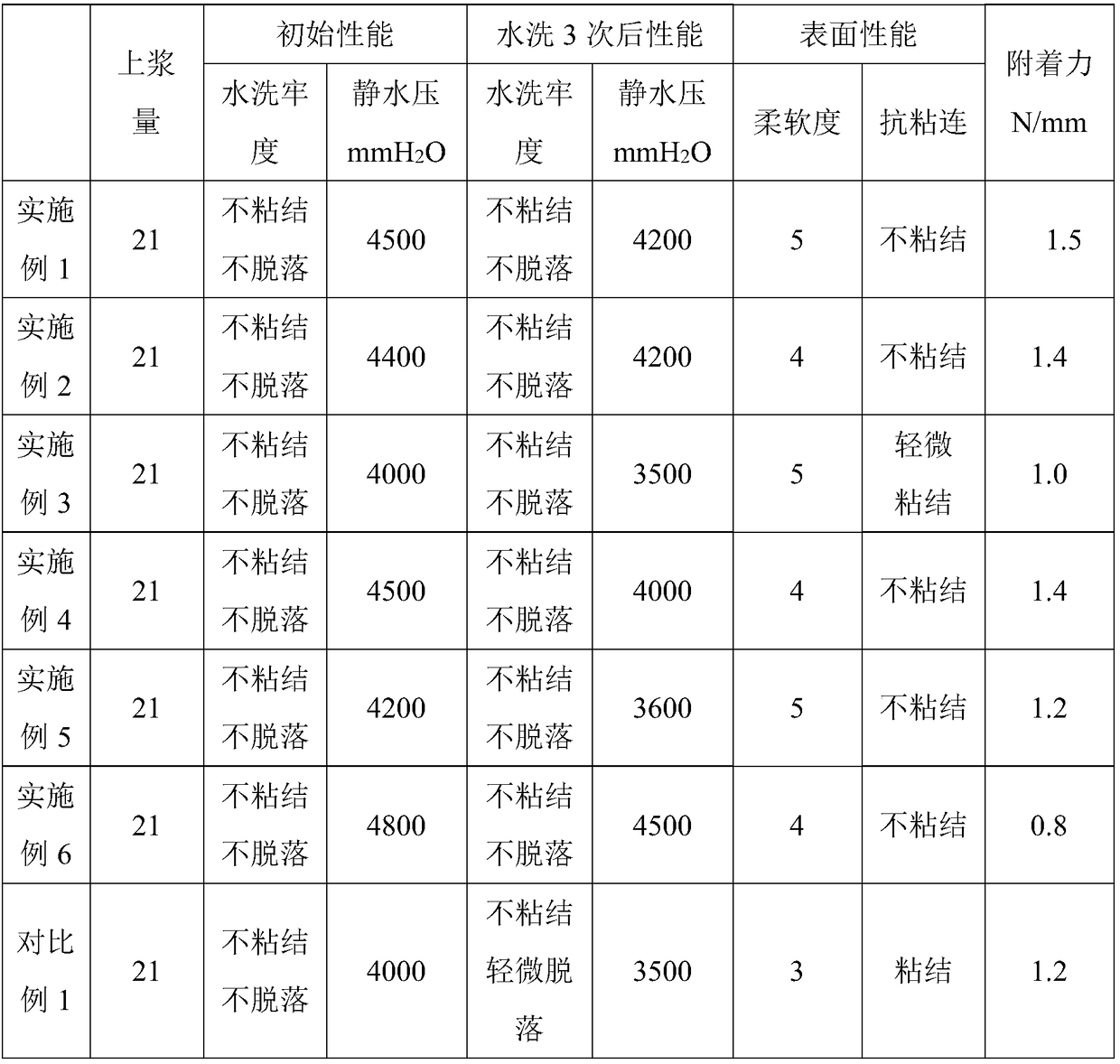

Water-based polyurethane dispersoid for dry coating primer as well as preparation method and application thereof

The invention discloses a water-based polyurethane dispersoid for a dry coating primer as well as a preparation method and application thereof. The polyurethane is obtained by polymerizing the following raw materials: a) at least one diisocyanate; b) at least one polyether glycol and / or polyester glycol; c) at least one polyether or polyester polyol with functionality degree more than or equal to3; d) at least one micromolecular polyol chain extender containing active hydrogen; e) at least one carboxylic acid hydrophilic chain extender containing active hydrogen; f) at least one polyamine micromolecular chain extender containing active hydrogen; and g) at least one organosilicone polyol containing active hydrogen, wherein the molecule side chain contains organosilicone. The water-based polyurethane dispersoid for the dry coating primer can achieve good anti-adhesion effect on the premise of guaranteeing soft hand feeling of resin.

Owner:WANHUA CHEM GRP CO LTD

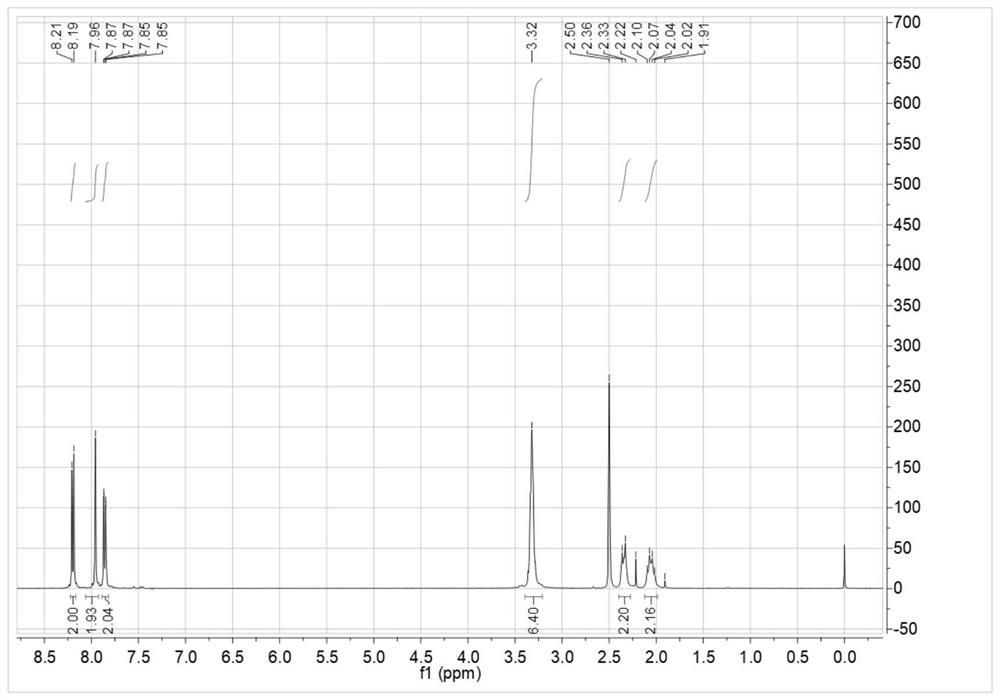

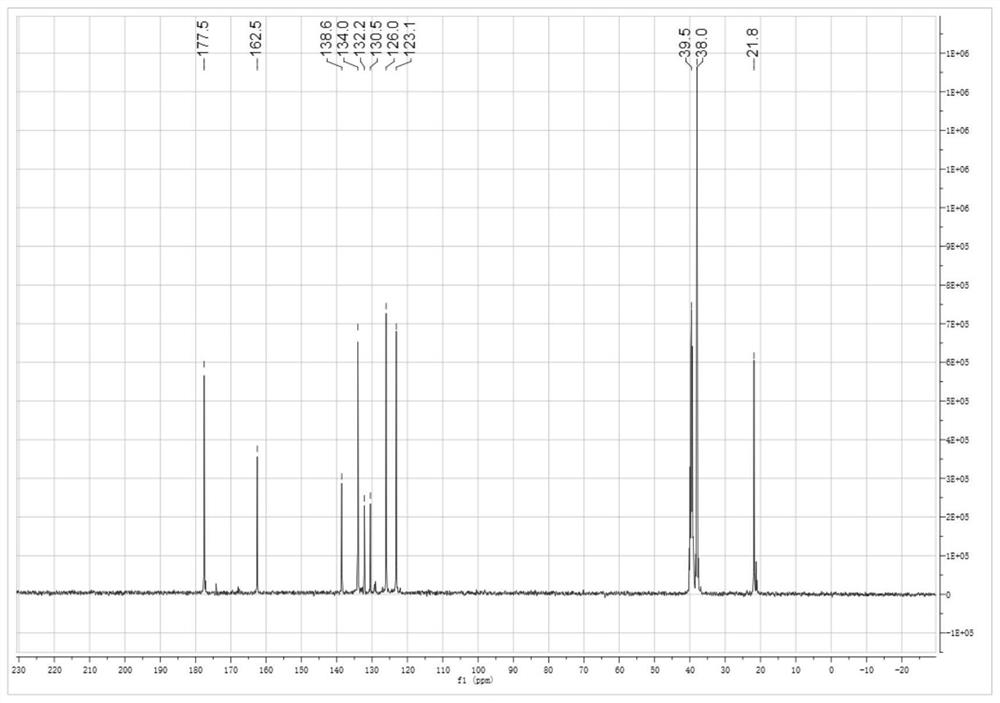

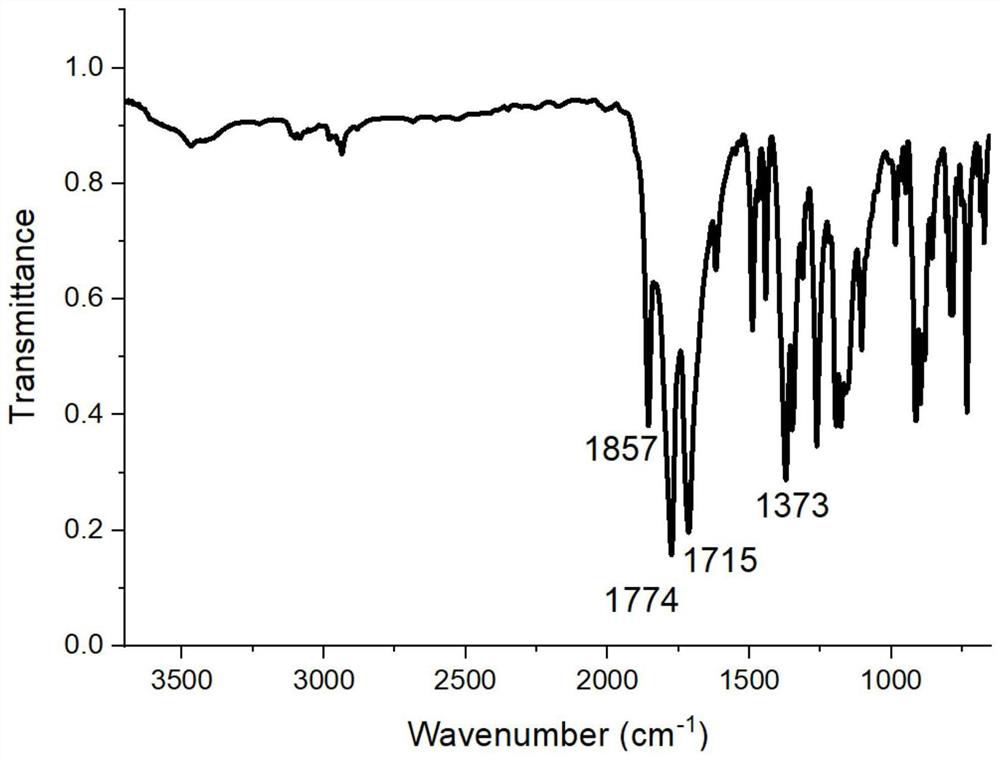

Transparent polyimide film and preparation method thereof

The invention provides a transparent polyimide film, which is prepared from a diamine compound and a dianhydride compound containing an imide structure and an alicyclic structure at the same time, wherein the dianhydride compound with the structure has the plane characteristic of a bisimide structure so as to improve the stacking density of a molecular chain is improved and reduce the thermal expansion coefficient, the dianhydride monomer has very high reaction activity so as to obtain high-molecular-weight polyimide to make the transparent film have very good mechanical properties, and particularly due to the introduction of the aryl structure, the heat resistance of the polyimide is also improved. The film provided by the invention has the advantages of high strength, low thermal expansion coefficient, heat resistance and enough transparency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

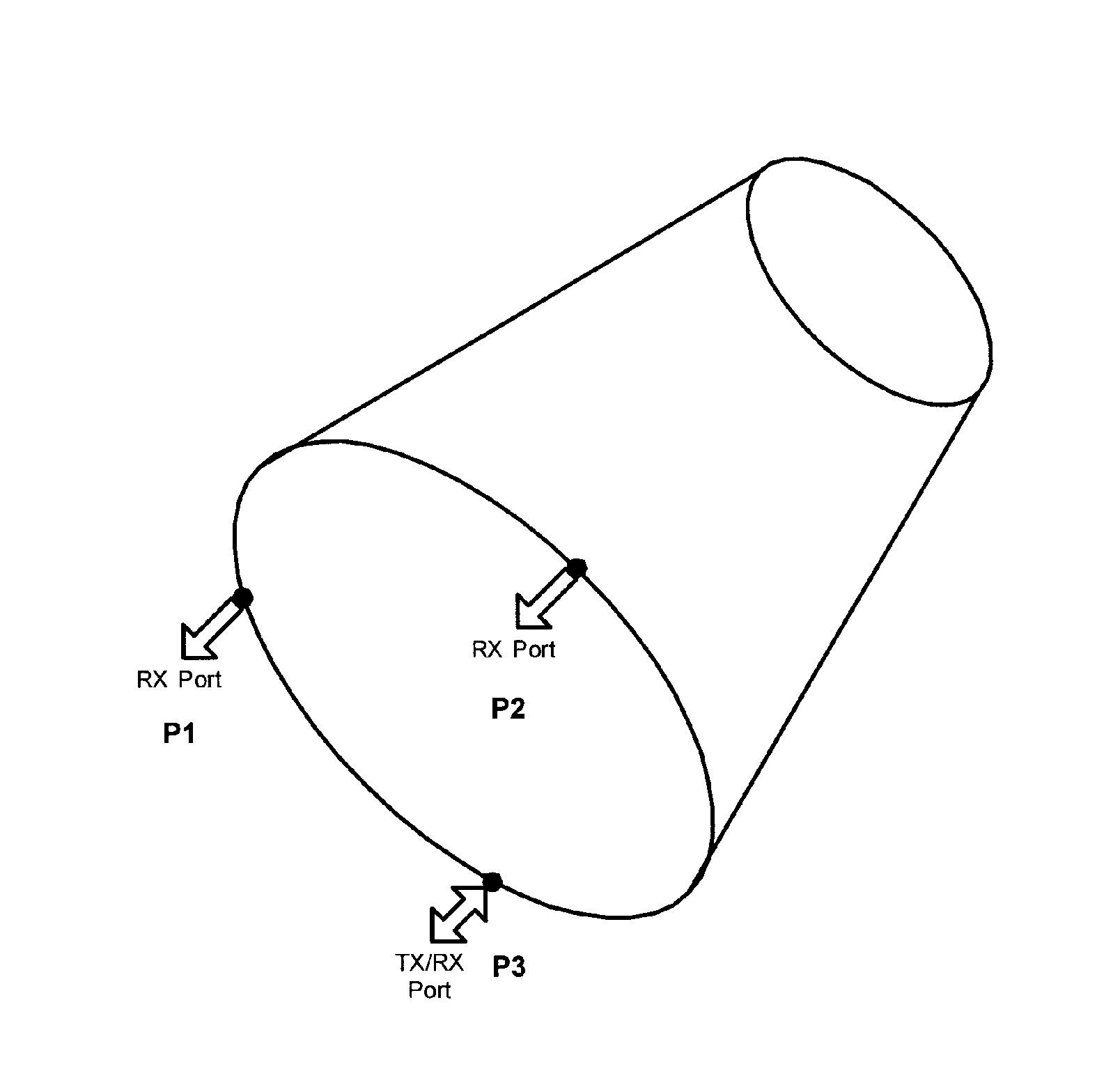

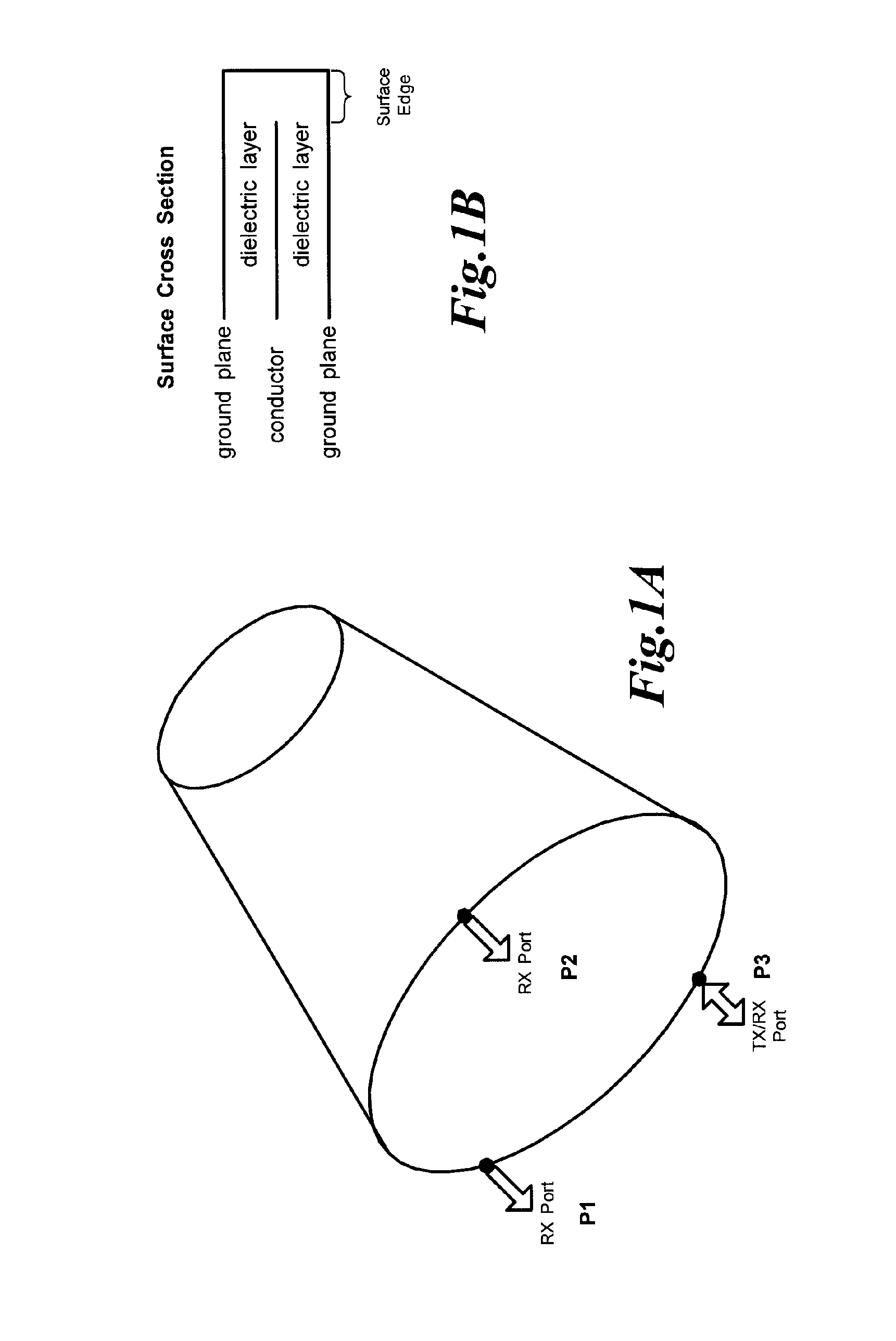

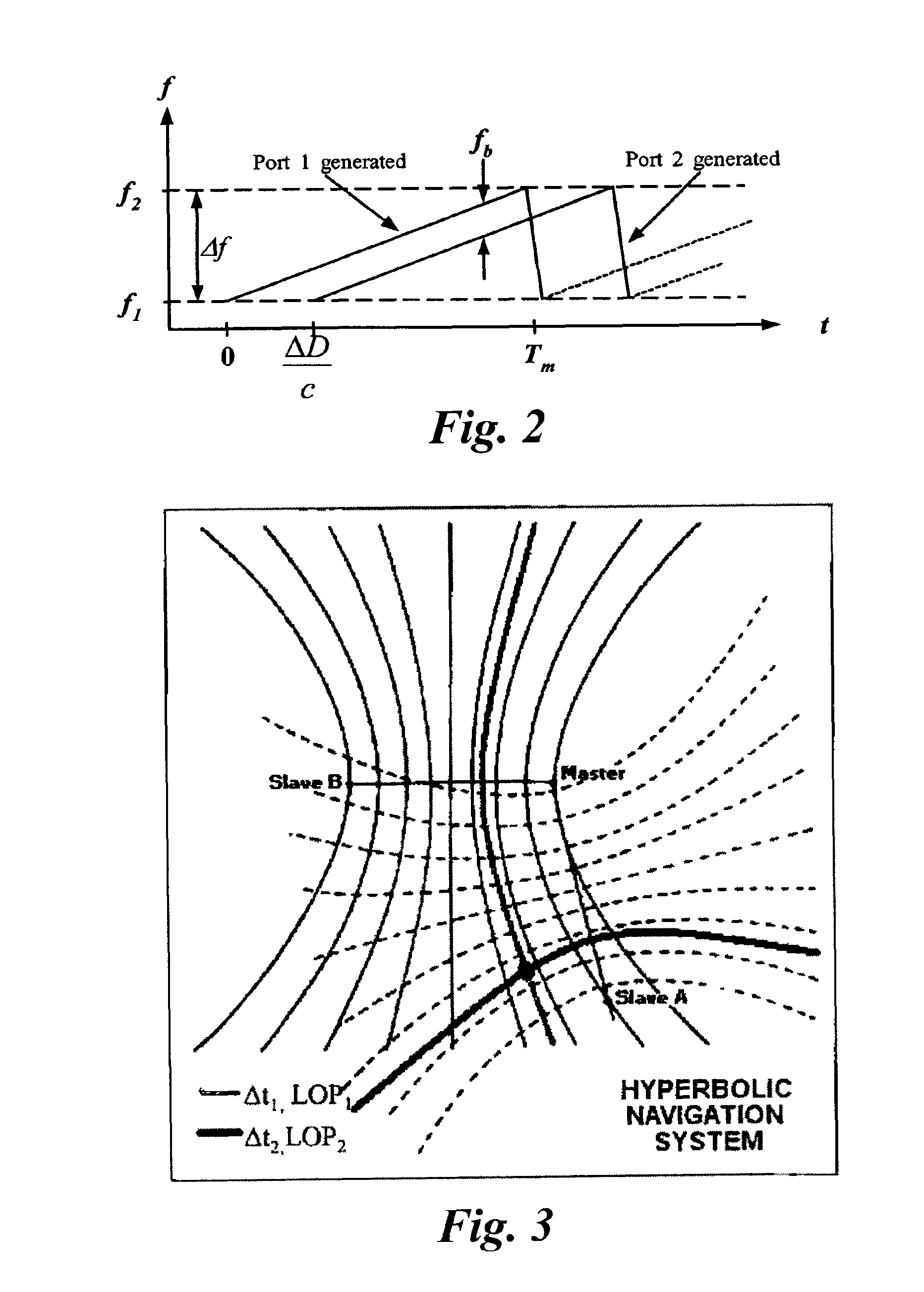

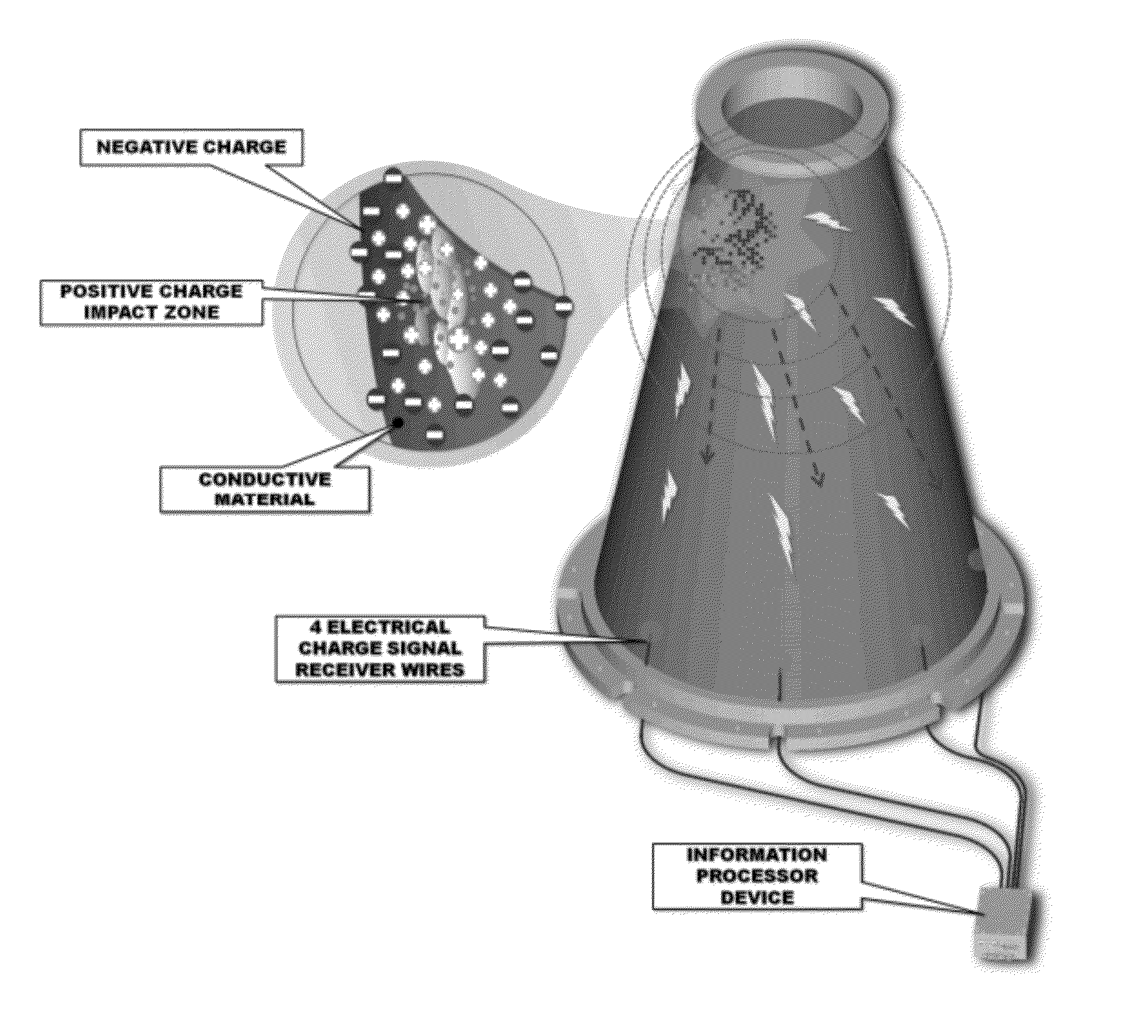

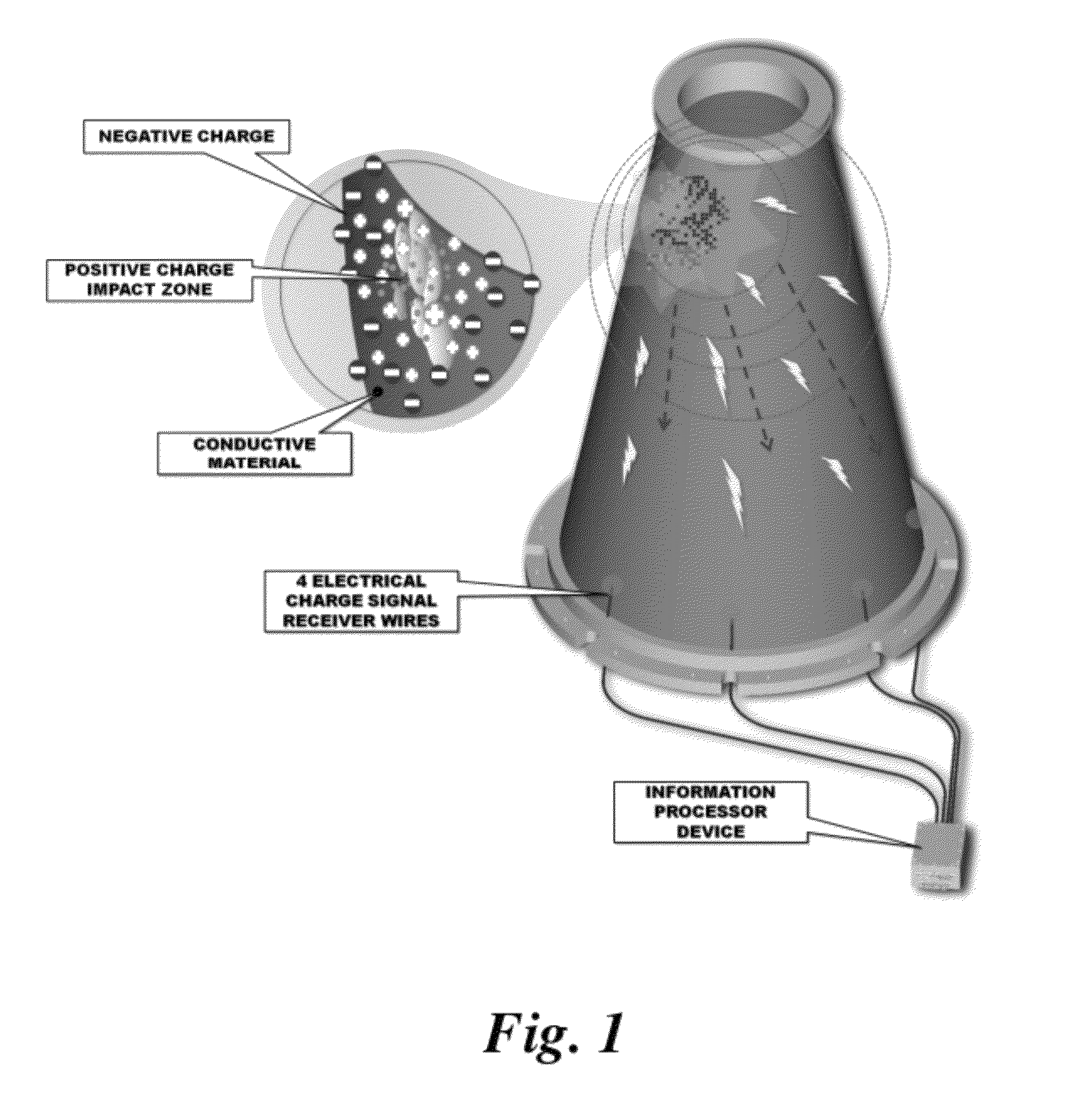

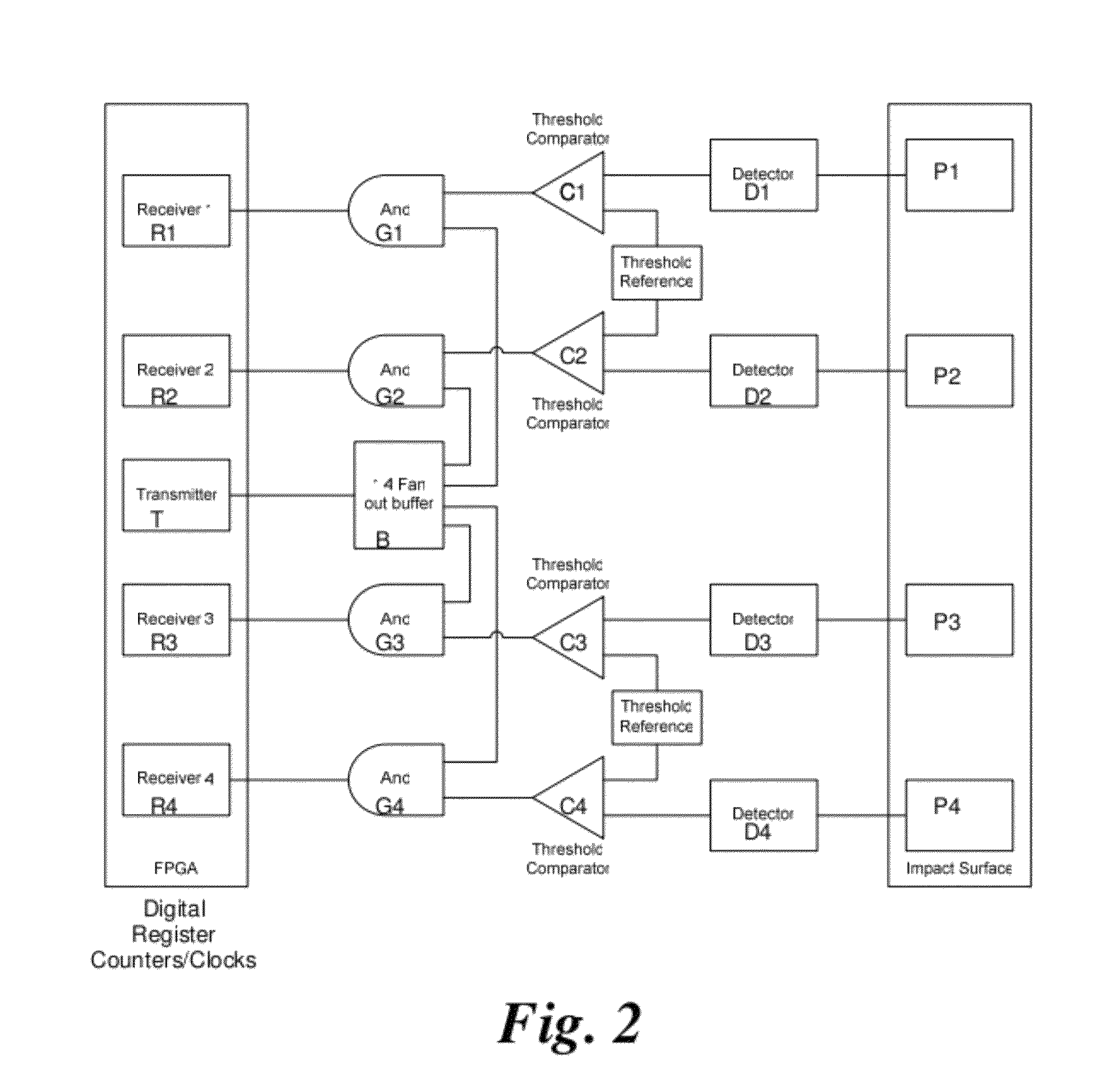

Hypervelocity impact detection method and system for determining impact location in a detection surface

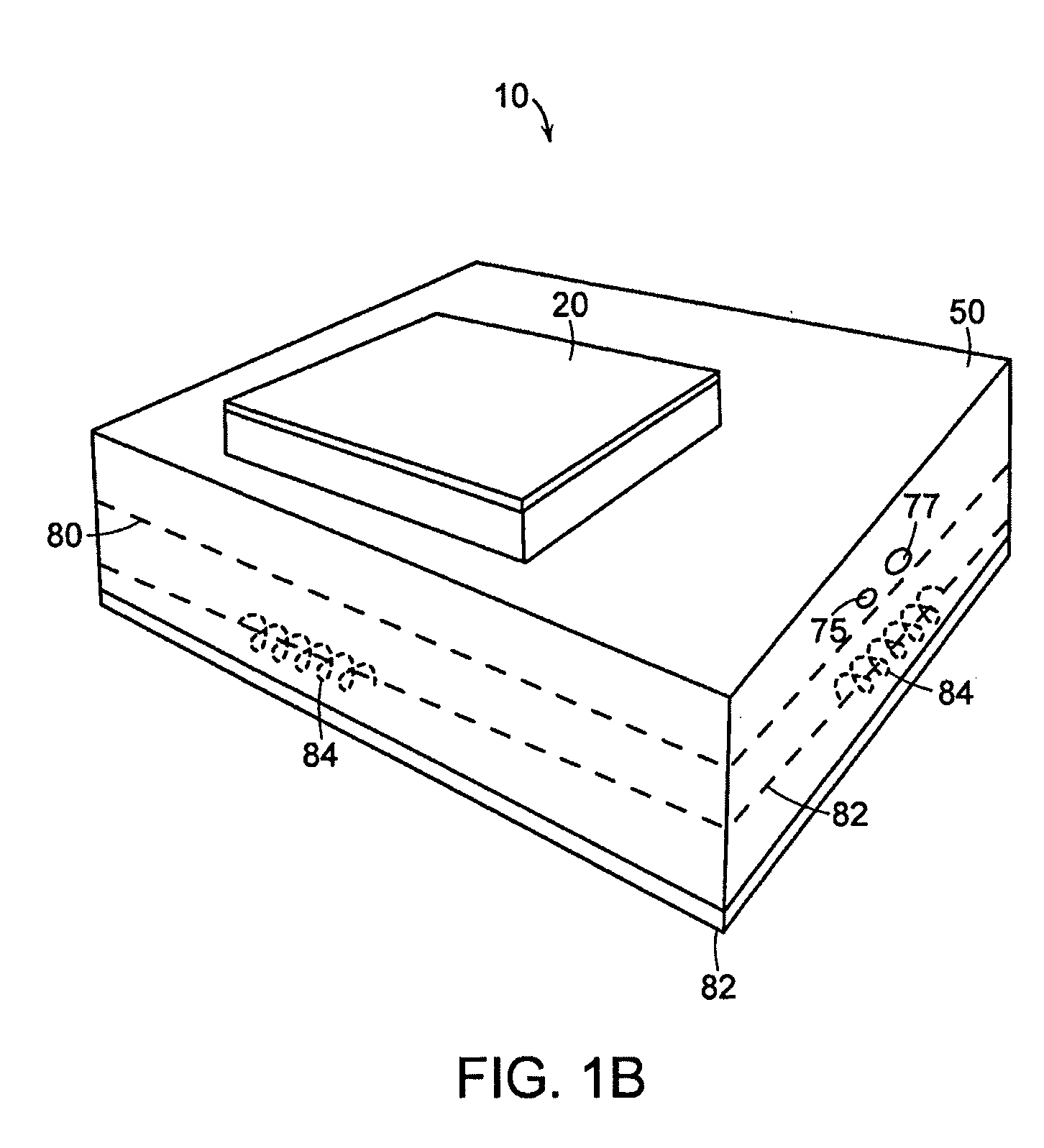

ActiveUS8307694B1Increase in sizeSignificant costPosition fixationAcceleration measurementTechnology impactHypervelocity

A hypervelocity impact detection method and system for determining the precise impact location in a detection surface, of impacts such as ballistic missile intercepts, micrometeoroids and orbital debris (MMOD) or other shock events, utilizes a gridless detection surface capable of propagating radio frequency (RF) impact detection signals responsive to receiving hypervelocity impacts from objects, and multiple sensors on the detection surface that directly measure radio frequency RF emissions generated by the hypervelocity impacts on the surface, and a time of arrival (TOA) position measurement technique for determining the precise impact location in the detection surface.

Owner:INVOCON

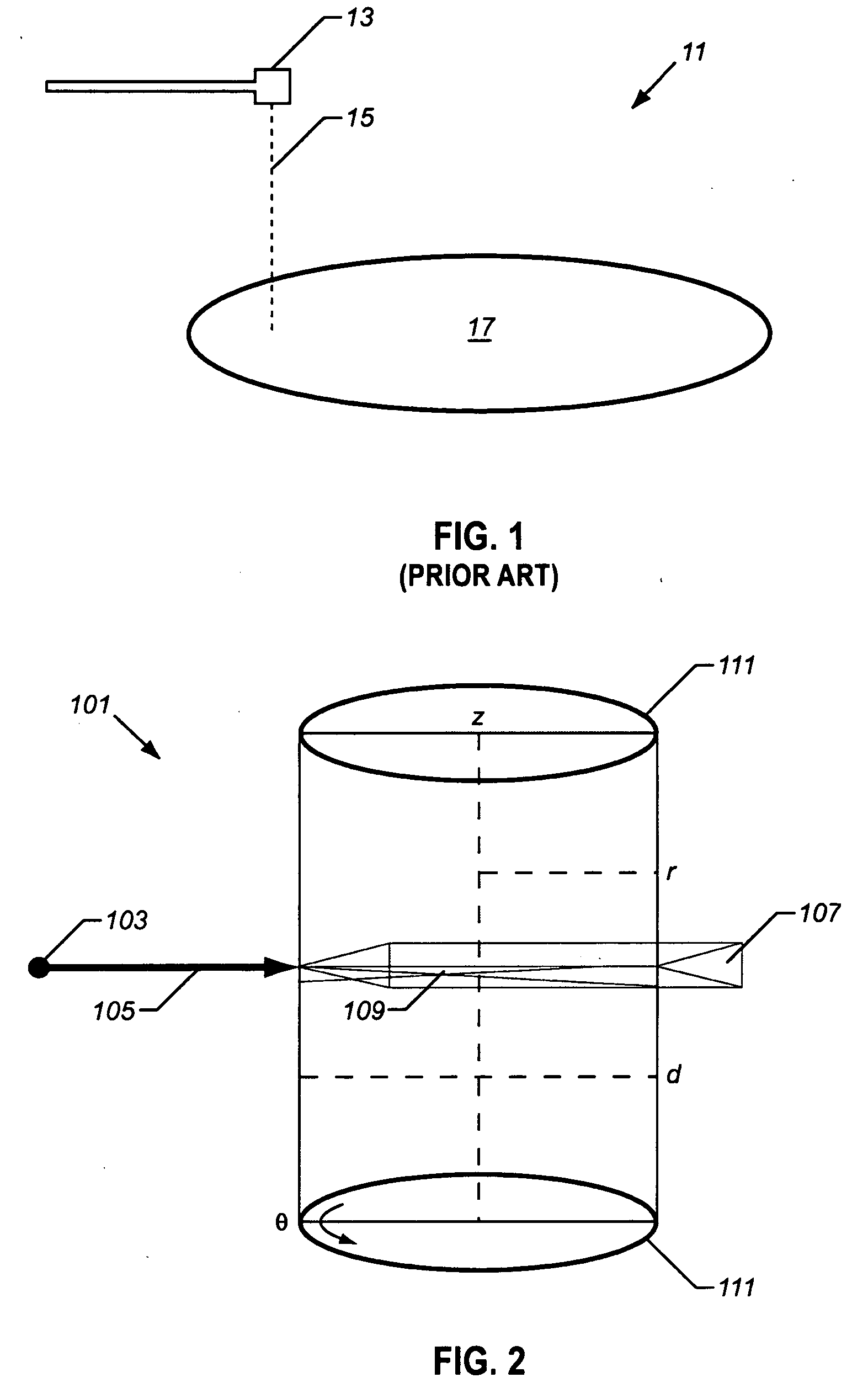

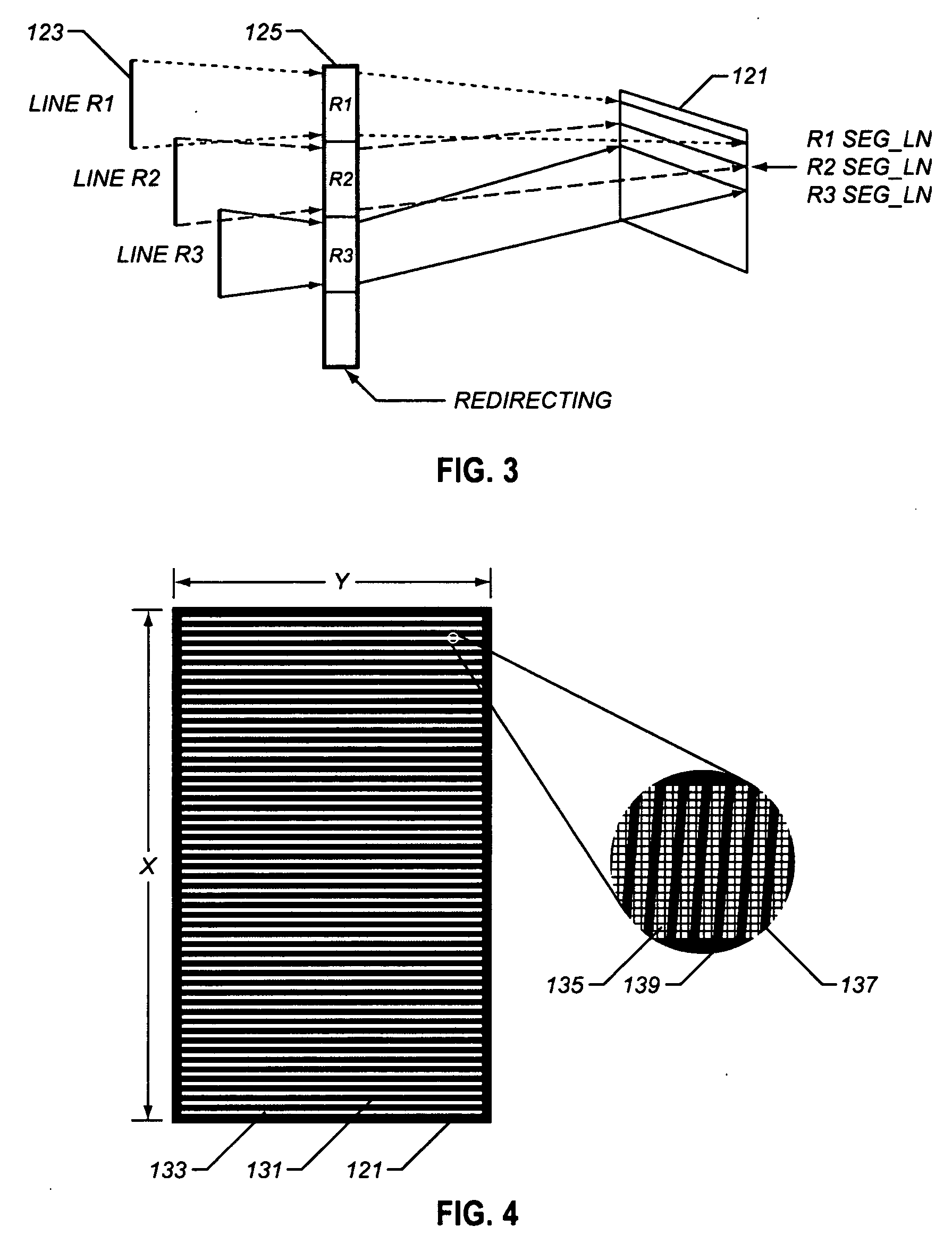

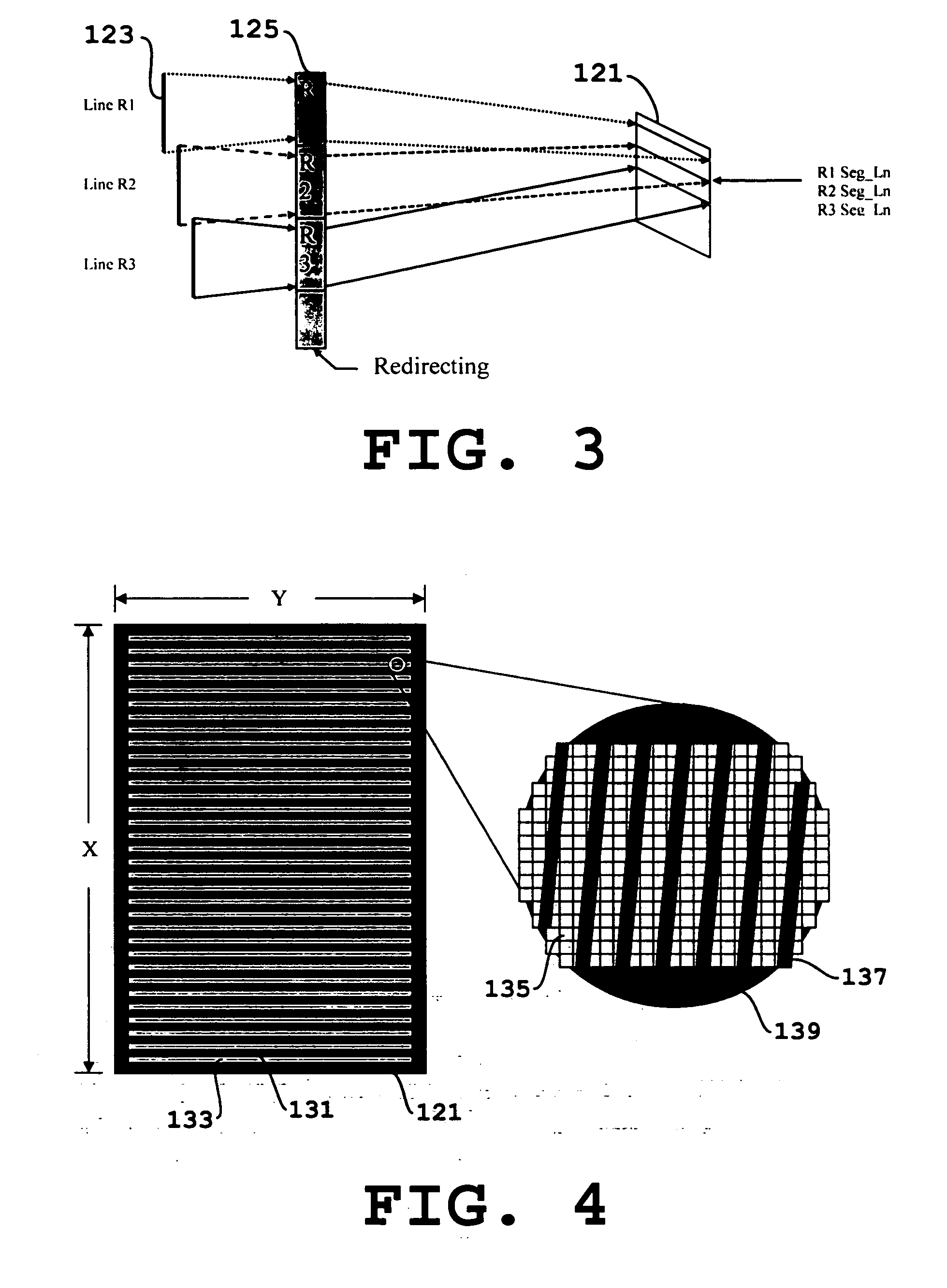

Multi-dimensional data signal and systems for manipulating the same

InactiveUS20060182000A1Significant performance improvementLow costOptical beam sourcesOptical detectorsLogical operationsOptical data processing

A device for retrieving multidimensional data from a data storage medium is provided. The device (103) comprises a source of electromagnetic radiation, an optical data processing system (401) adapted to perform logical operations on an input optical data array, and an optical device or devices (125) adapted to direct electromagnetic radiation onto the surface of a data storage medium and to transmit reflections of the electromagnetic radiation, in the form of multidimensional data patterns, to said optical data processing system. The data may be formatted in multiple dimensions.

Owner:LUCERE LP

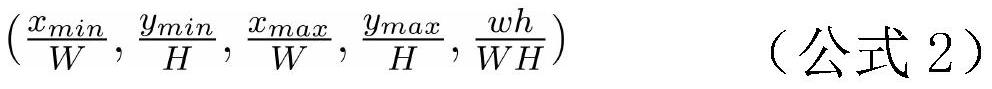

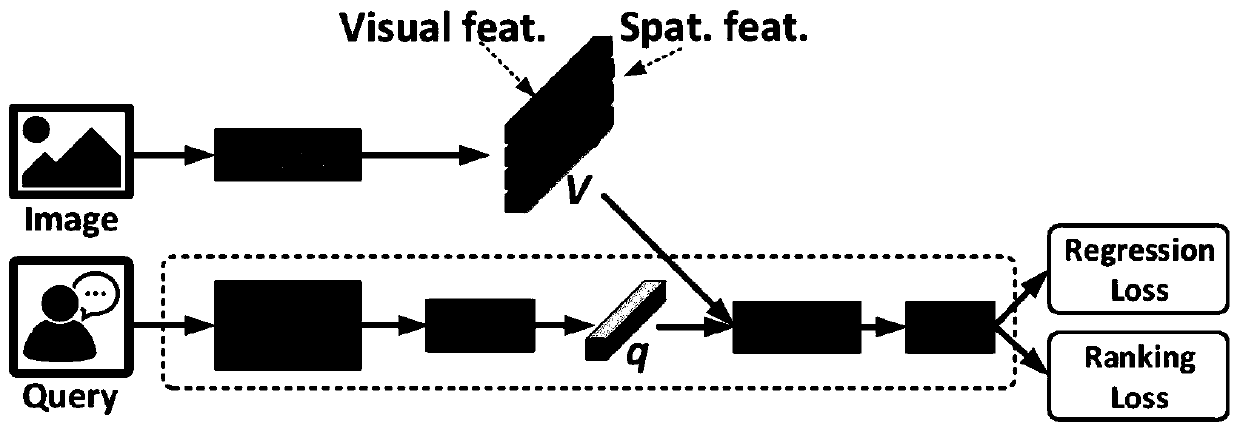

A visual positioning method based on a diverse identification candidate box generation network

The invention discloses a visual positioning method based on a diverse identification candidate box generation network. The method comprises the following steps: 1, training a diverse identification candidate box generation network; 2, extracting features of the image by using the trained DDPN network,3, extracting text data characteristics,4, constructing a target vector and a target value of a regression frame,5, constructing a deep neural network,6, setting a loss function, 7, training the model,8, calculating a network prediction value. According to the algorithm provided by the invention,especially the DDPN network-based algorithm for extracting the features of the image, a significant improvement effect is achieved on an image visual positioning task, and all mainstream methods on the task at present are greatly exceeded. In addition, the feature extraction algorithm has very important application value and huge potential in other cross-modal related fields such as image contentquestion answering and image description.

Owner:HANGZHOU DIANZI UNIV

Preparation method of poly (arylene ether nitrile) resin low in dielectric constant and high in glass-transition temperature

The invention discloses a preparation method of a poly (arylene ether nitrile) resin low in dielectric constant and high in glass-transition temperature. The preparation method comprises following steps: potash and 2, 6-dichlorobenzonitrile are added into N-methyl pyrrolidone successively; a dihydric phenol and toluene are added successively, heating polymerization is carried out, evaporation is carried out to remove toluene, and cooling is carried out for precipitation of a solid material; washing is carried out to obtain a powder particle material; the powder particle material is dissolved in N-methyl pyrrolidone for purifying so as to obtain a purified sample; the purified sample is dissolved in N, N-dimethyl formamide, gauze filtering, tape casting film forming, and gradient heating are carried out to obtain poly (arylene ether nitrile) resin film. The preparation method is capable of increasing the glass-transition temperature and reducing the dielectric constant and loss of conventional poly (arylene ether nitrile), and satisfying basic using requirements of resin adopted in 5G high frequency base materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of silicon carbide-oxide composite refractory product

The invention belongs to the field of refractory materials, and mainly relates to a preparation method of a silicon carbide-oxide composite refractory product. The firing process in the preparation method is a two-step firing method and comprises the steps: uniformly mixing silicon carbide particles and oxide fine powder with a liquid binding agent, pressing the mixture into a green body with a certain size and shape; drying the green body, and sintering the dried green body in an oxidizing atmosphere; and firing in a reducing atmosphere, wherein in the first step, firing is carried out in theoxidizing atmosphere, the firing temperature is 1300-1400 DEG C, the oxygen partial pressure in the firing atmosphere is 10000-50000 Pa, in the second step, firing is carried out in a reducing atmosphere, the firing temperature is 1600-1650 DEG C, and the oxygen partial pressure in the firing atmosphere is smaller than or equal to 1000 Pa. The method is high in operability, small in device investment and remarkable in effect of improving the performance of the composite refractory product.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

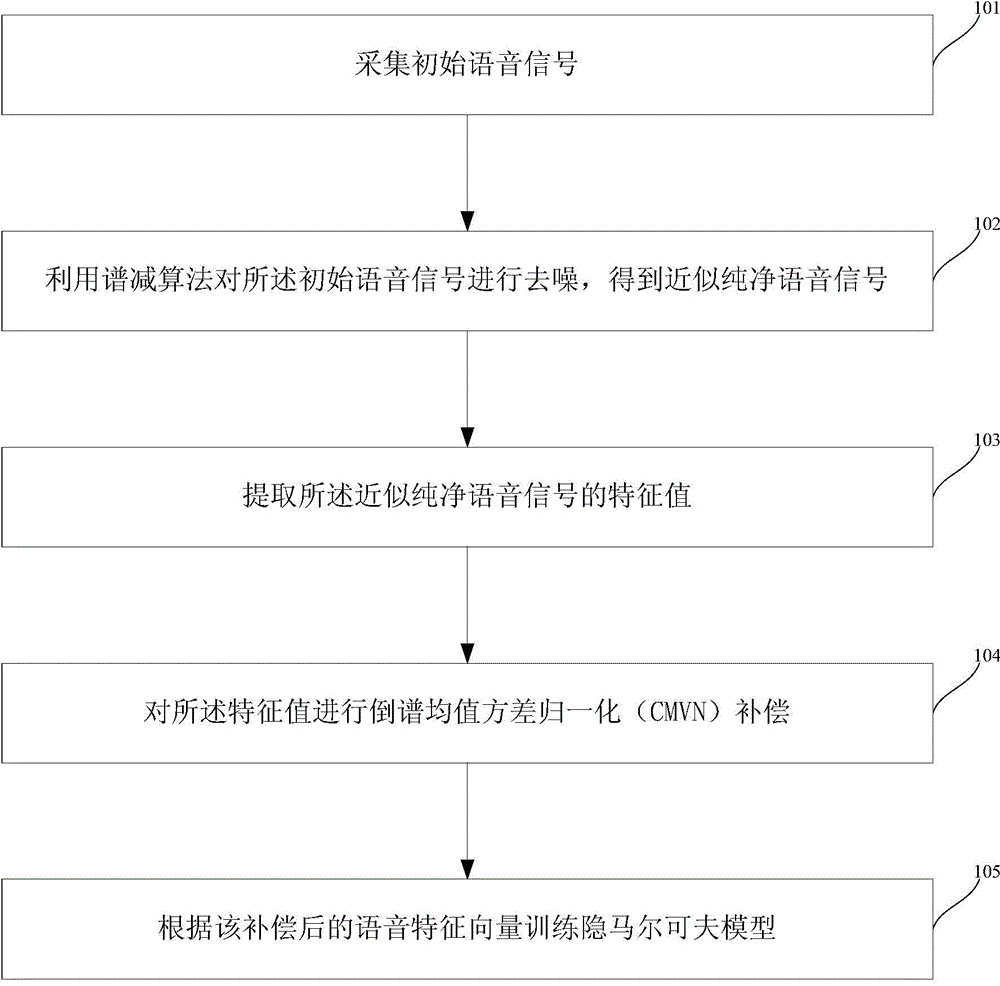

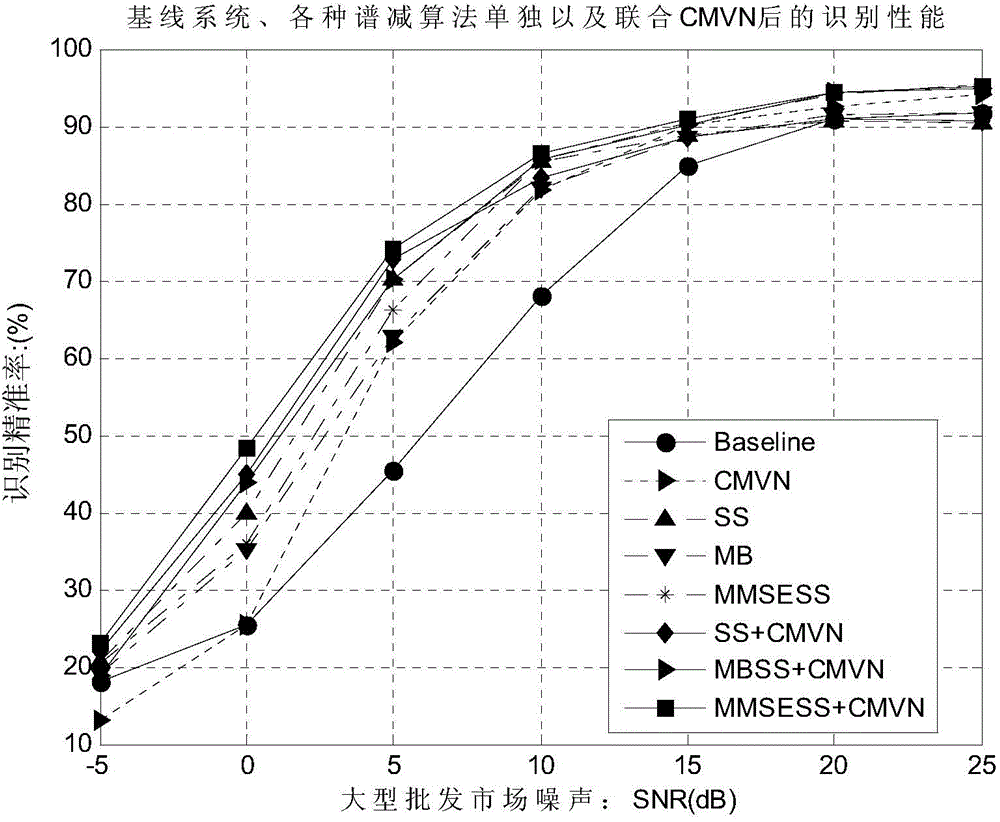

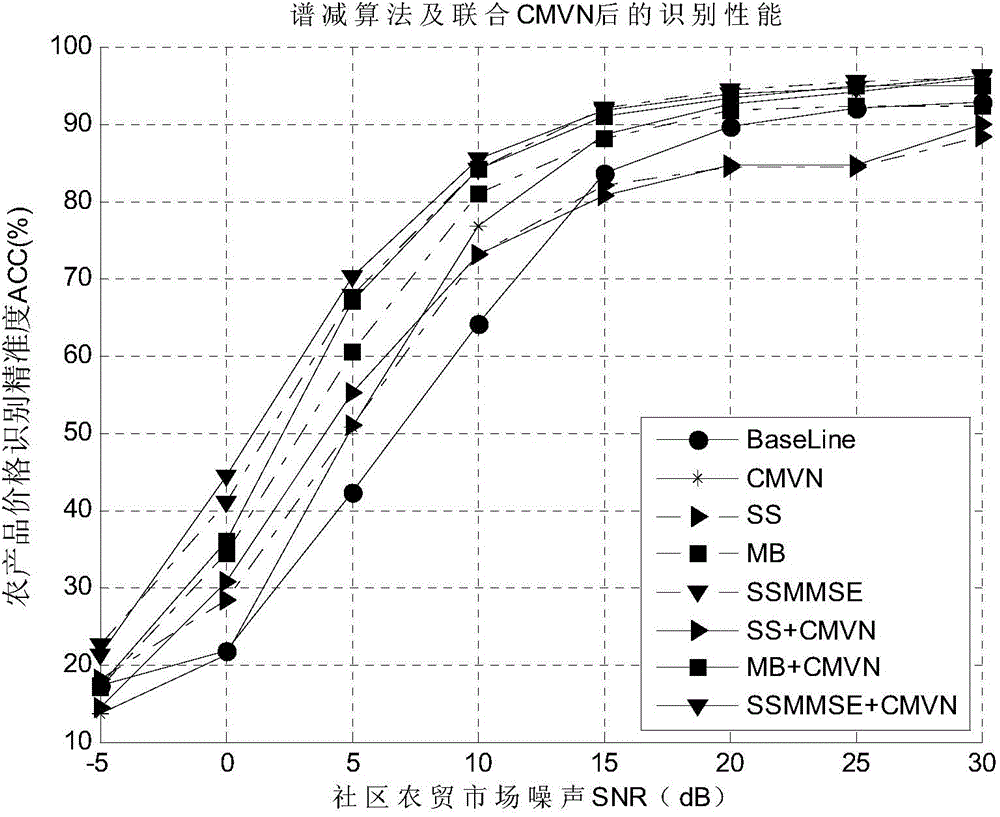

Robustness speech recognition method for agricultural product market element information collection

ActiveCN104157294AImprove recognition rateSignificant performance improvementData processing applicationsSpeech recognitionFeature vectorSpectral subtraction

The invention relates to the technical field of speed recognition, in particular to a robustness speech recognition method for agricultural product market element information collection. The method includes the steps that initial speech signals are collected; denoising is conducted on the initial speech signals through an MMSE spectral subtraction algorithm, and approximately-pure speech signals are obtained; the feature value of the approximately-pure speech signals is extracted; CMVN compensation is conducted on the feature value, and an HMM is trained according to a speech feature vector obtained after the compensation is conducted. By means of the method, the algorithm adopted for a continuous speech recognition system facing non specific people with medium vocabulary is simple, and the method is easy to implement and small in calculation amount.

Owner:AGRI INFORMATION INST OF CAS

Graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material and preparation method thereof

InactiveCN110172632AMeet the use requirementsImprove performanceUltrasonic dispersionCopper–tungsten

The invention relates to a graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material. A preparation process comprises the following steps of uniformly mixing copper aluminumalloy powder, tungsten powder, chromium powder and cuprous oxide powder for standby application; adding ultrasonically dispersed graphene oxide into pre-mixed powder and transferring the mixture to aball-milling tank to be ball-milled; then freezing and drying the mixture; and carrying out vacuum hot press sintering to obtain the graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material. According to the graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material, by adding the graphene oxide into the copper aluminum tungsten chromium mixedpowder for vacuum hot press sintering, an internal oxidization process is simplified. The defects that the affinity and the interface bonding force of graphene and a copper matrix are poor and the electric conducting ability of the graphene oxide is poor are overcome, and the graphene oxide reduced in a vacuum high-temperature condition improves the comprehensive performance of the dispersed copper-tungsten-chromium electric contact material. In addition, the experimental process is simple, small in energy consumption, obvious in performance improvement, high in production efficiency and easyfor industrial production.

Owner:HENAN UNIV OF SCI & TECH

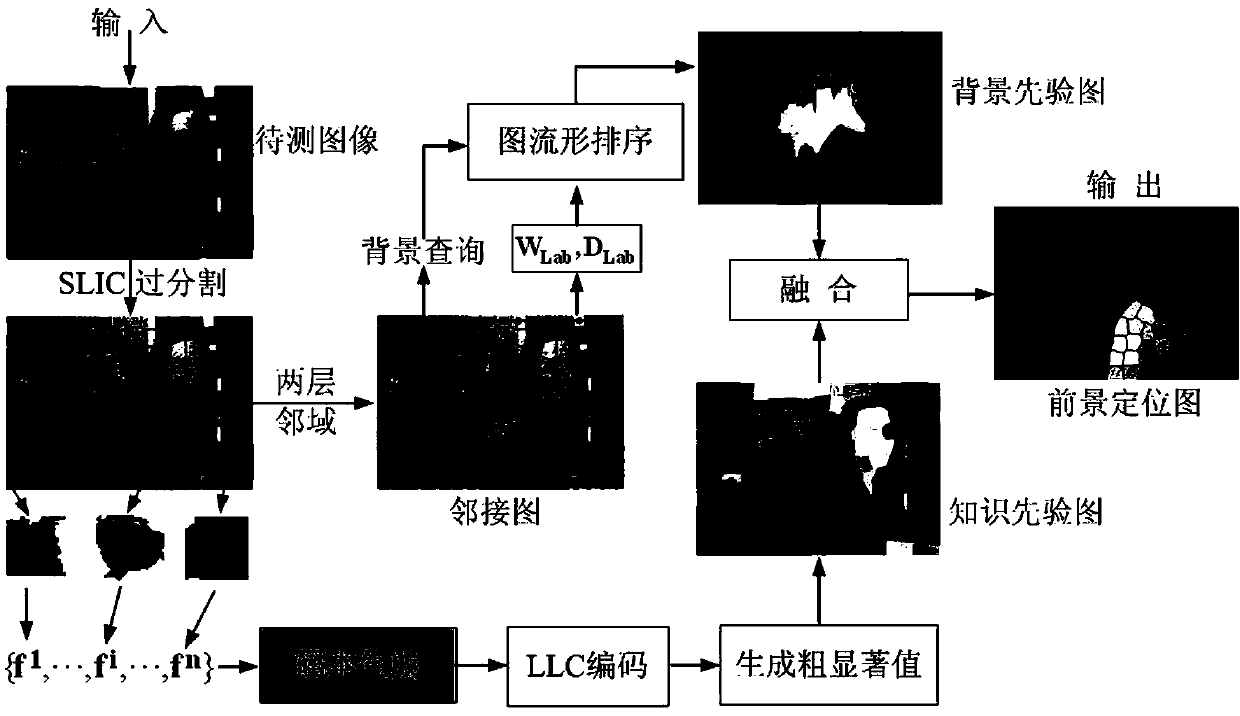

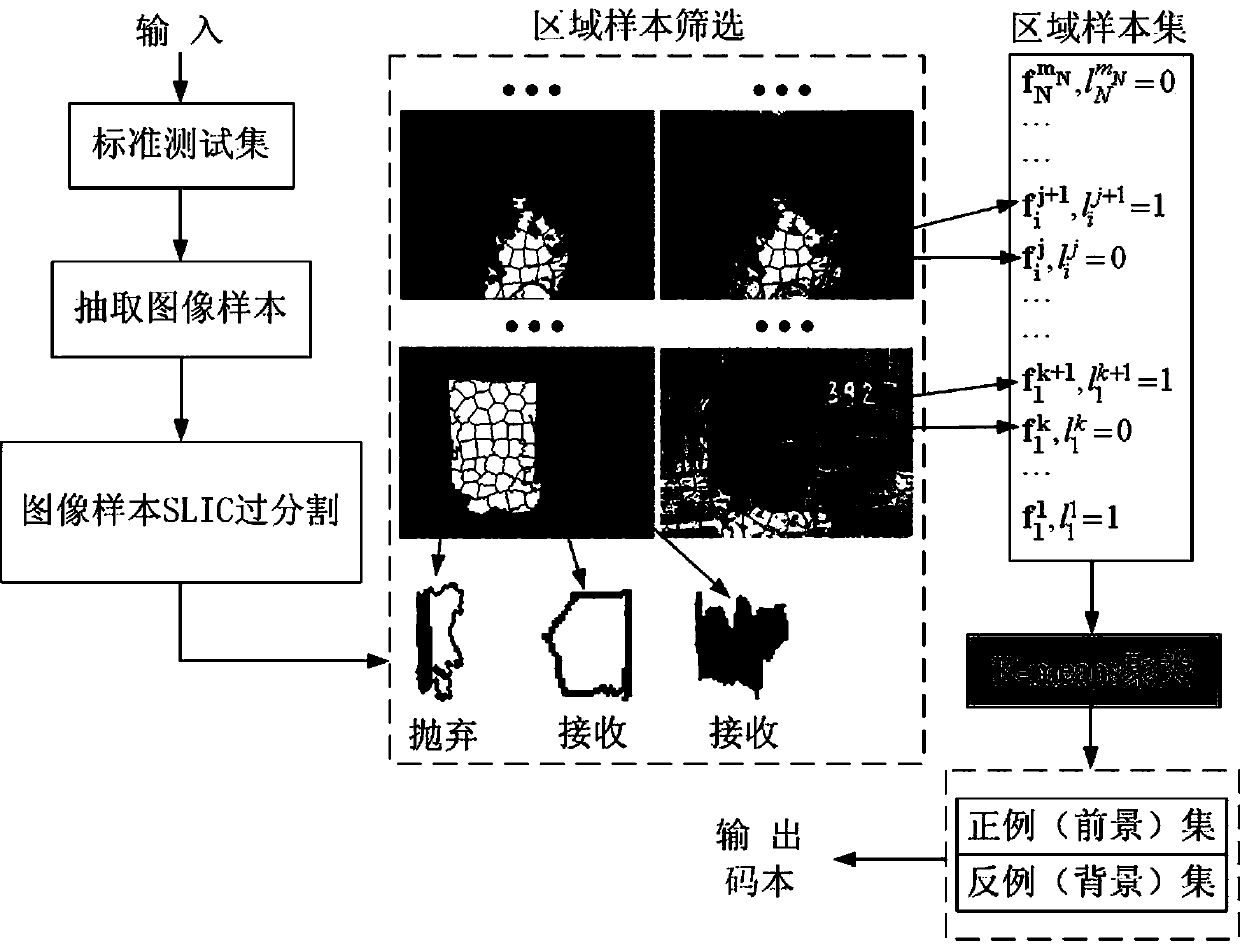

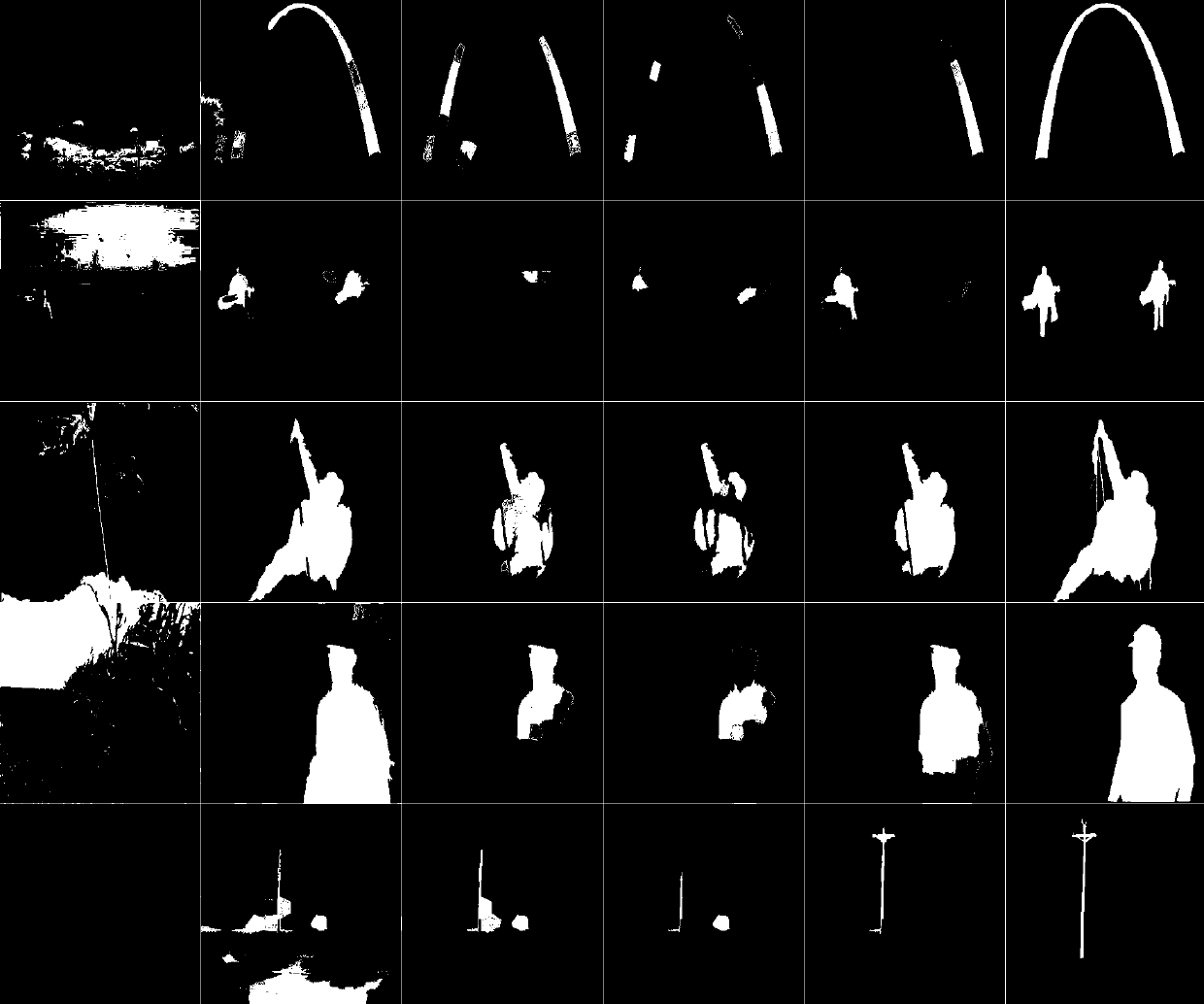

Method of locating image foreground by using LLC (Locality-constrained Linear Coding) criterion

ActiveCN107067037ASpeed up foreground positioningForeground boundaries are clearCharacter and pattern recognitionSaliency mapTruth value

The invention relates to a method of locating an image foreground using LLC (Locality-constrained Linear Coding) criterion. A large number of random images are selected from a standard test set, in combination of the salient region truth value annotation graph, the priori knowledge of the image foreground is extracted, an LLC codebook is formed, the LLC criterion is used for carrying out rough classification on whether each area of a to-be-detected image belongs to the foreground, and a corresponding salience probability value is given; contrast-based features such as a centroid distance away from an image center, a local Lab color contrast value and a global Lab color contrast value are used for describing image super pixel regions, typical features for learning the foreground / background serve as the priori knowledge for guiding classification of the image super pixel regions, high-level knowledge is acquired from an empirical perspective, region classification can be guided for multiple times as long as one-time learning is needed, the foreground locating speed is greatly quickened compared with a method of extracting high-level knowledge only from the current image, and due to advantage query for extraction, the foreground boundary in the acquired salience map based on manifold ranking can be more clear and has less noise.

Owner:HENAN UNIV OF SCI & TECH

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

ActiveCN101209825AQuality improvementIncrease in sizeElectrode manufacturing processesPhosphorus compoundsLithium compoundMaterials science

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the iron compound is ferric iron compound; the sintering method is carried out in inert atmosphere or reducing atmosphere; the mixture is sintered at a first constant sintering temperature, and then the sintering product is acquired; the sintering product acquired from sintering at the first sintering temperature is cooled to room temperature and ground; the mixture is sintered at a second constant sintering temperature, and is cooled to room temperature in inert atmosphere or reducing atmosphere; the second sintering temperature is at least 100 DEG C higher than the first sintering temperature. The lithium iron phosphate acquired by the method of the invention has relatively high specific discharge capacity and specific volumetric capacity, and the produced batteries have small size, high capacity and good discharge performance at high current, and the invention can combine the advantages of lithium iron phosphate prepared by taking ferrous iron and ferric iron as iron sources respectively, thus the performance can be remarkably improved.

Owner:BYD CO LTD

Hypervelocity impact and time of arrival detection method and system

ActiveUS8316690B1Increase in sizeSignificant costPosition fixationAcceleration measurementPower flowHypervelocity

A method and system for detecting hypervelocity impacts on a detection surface utilizes multiple sensors that directly measure electrical pulse radio frequency (RF) emissions generated by hypervelocity impacts on a detection surface and time of arrival (TOA) position measurements for determining the precise impact location on the detection surface. The detection surface material is compressed differentially in such a way that the inherent equalization of the compressed electron density in one area of the impact is directed to the uncompressed area of the material causing an electrical current that flows until the redistribution of the electrical charge has been completed and the rapid redistribution of charge and inherent current that results emits the radio frequency pulse that is induced into the detection surface.

Owner:INVOCON

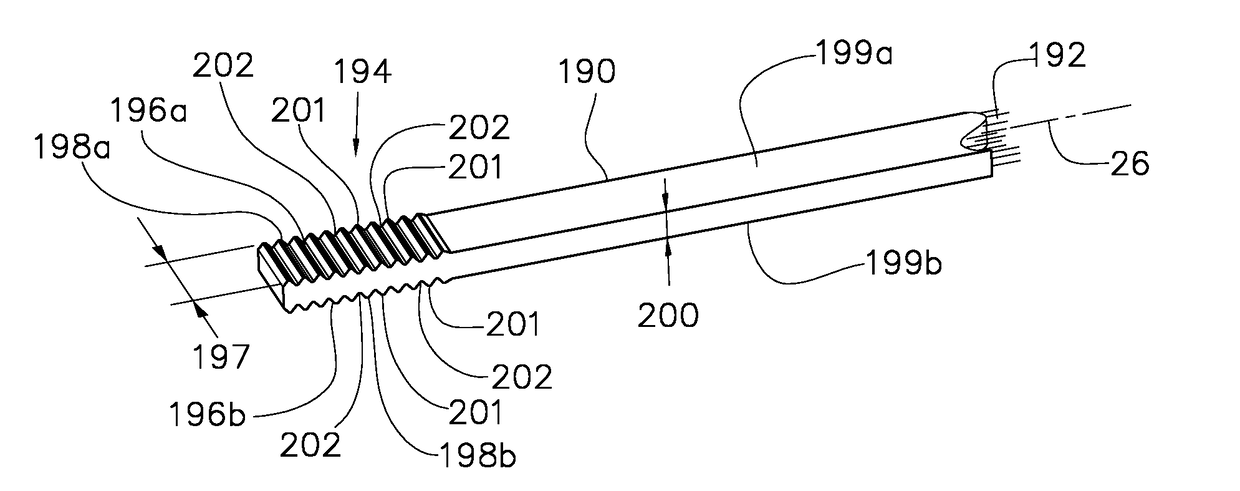

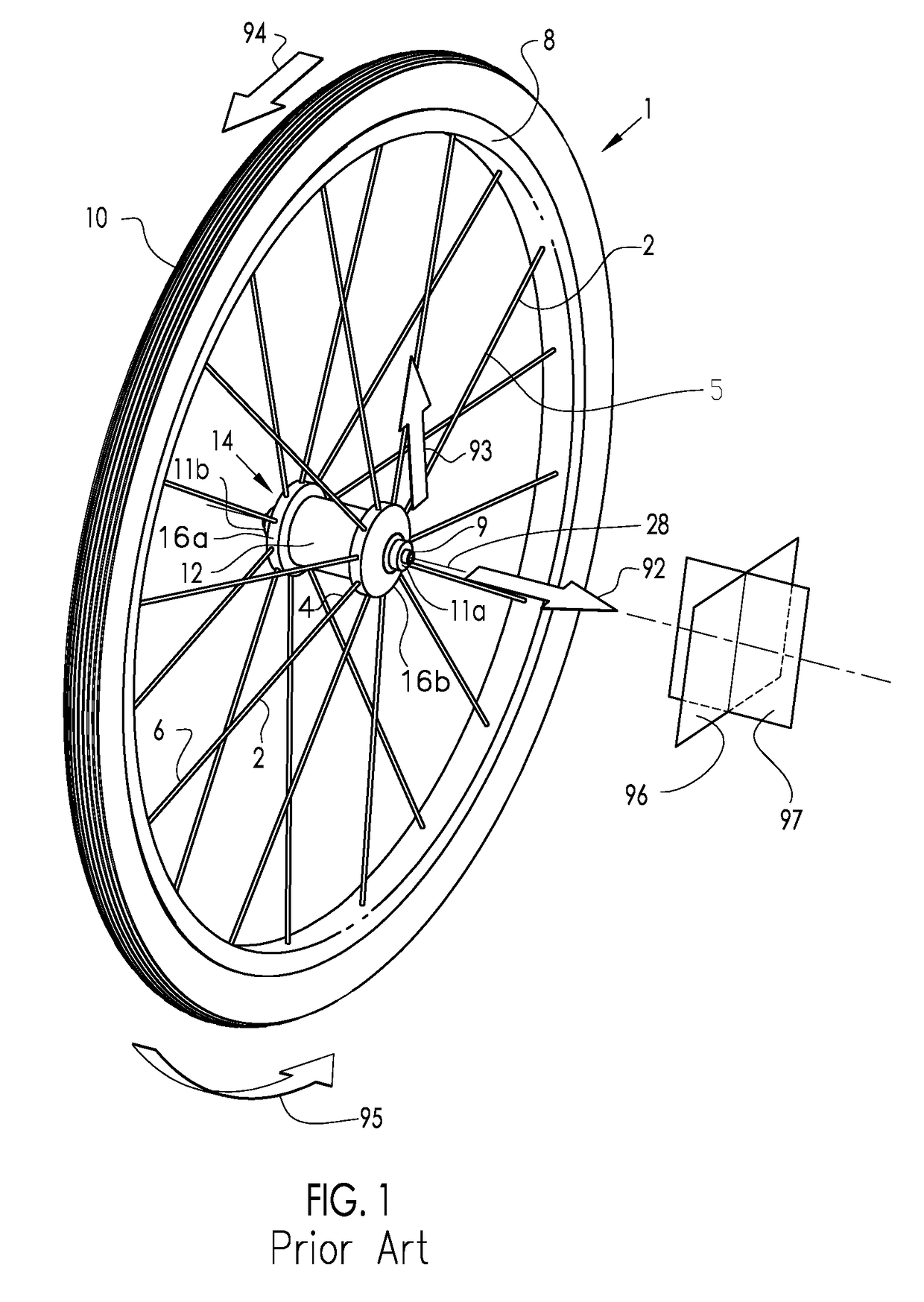

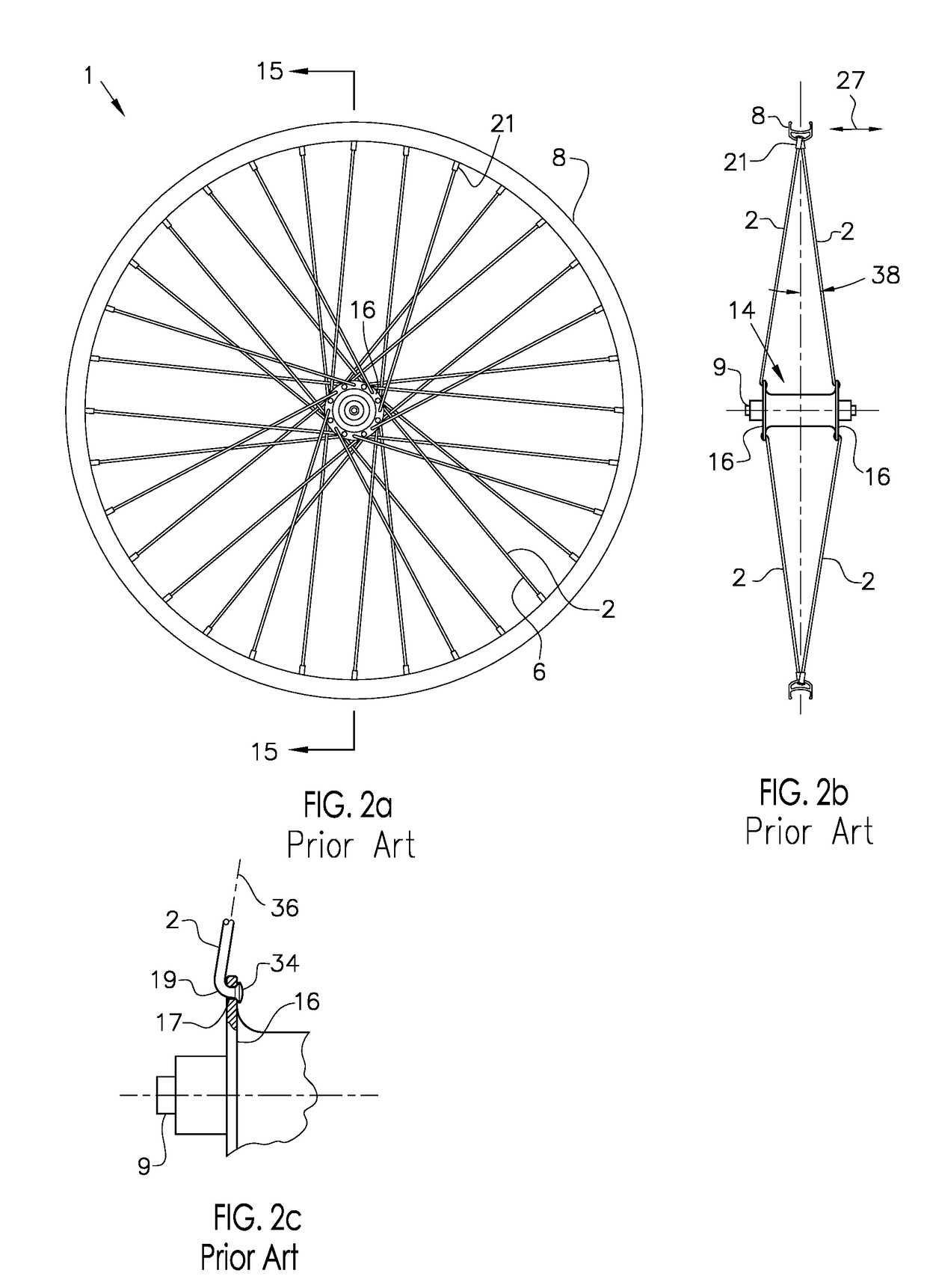

Vehicle wheel spoke connection

A vehicle wheel spoke connection, including: a rim; a hub; a plurality of spokes extending between the rim and hub with a first portion connected to the rim, a second portion opposed to said first portion and connected to the hub, a span portion between the rim and the hub, and an applied tensile load along the span portion; a bracing element including the rim and / or hub. The spoke has a longitudinal axis and is composed of reinforcement fibers in a matrix. The external surface of the spoke includes a pre-formed configured surface comprising a multiplicity of laterally outwardly projecting engagement surfaces that are longitudinally spaced. The spoke is connected to the bracing element by a longitudinal engagement comprising a multiplicity of longitudinally spaced overlie engagements associated with the spoke engagement surfaces. The longitudinal engagement supports the tensile load.

Owner:SCHLANGER RAPHAEL

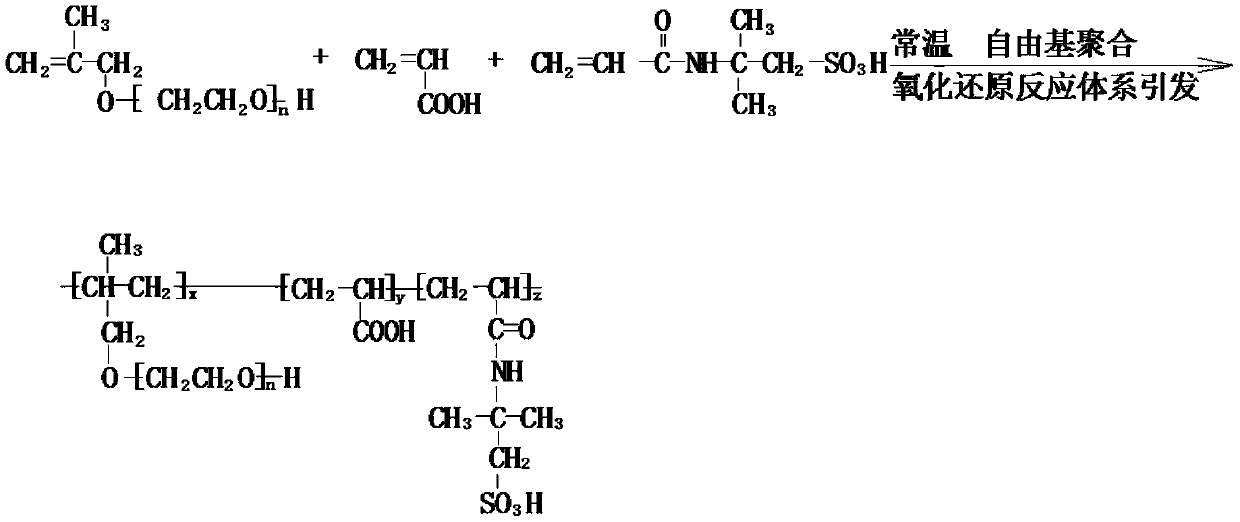

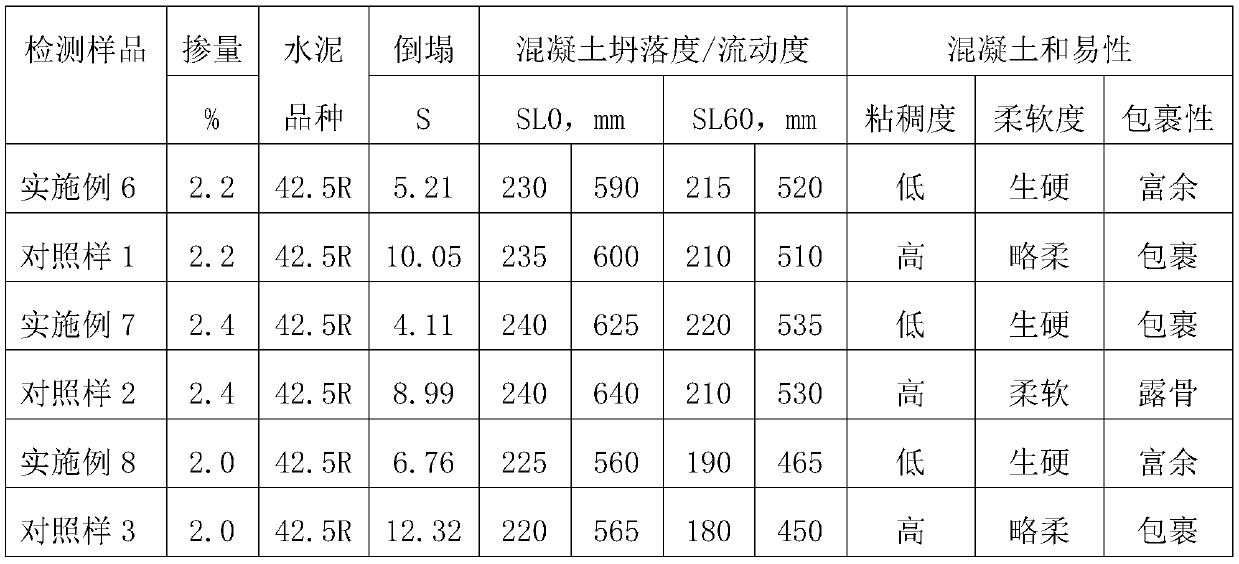

Viscosity-reduction polycarboxylate-type water reducer mother liquor, water reducer and preparation method

The invention provides a viscosity-reducing polycarboxylate-type water reducer mother liquor, a water reducer and a preparation method. The invention aims to overcome the technical problems of large viscosity of concrete and difficult construction in the prior art. The water reducer mother liquor is prepared from the following raw materials in parts by weight: 45-50 parts of an ether macromonomer,3.5-6.6 parts of acrylic acid, 0.5-0.8 part of a functional small monomer, 0.1-0.3 part of a reducing agent, 0.6-0.8 part of hydrogen peroxide, 0.2-0.4 part of a chain transfer agent and 60-85 partsof water. Concrete using the water reducer is greatly reduced in viscosity and well improved in softness and wrapping property, and the technical problems that the viscosity of the concrete is large and construction is difficult are solved; meanwhile, the slump retaining capacity of the polycarboxylate-type water reducer is obviously improved; and after the polycarboxylate-type water reducer is added, the collapse time of the concrete is obviously shortened, with an amplitude reaching 100%.

Owner:眉山海螺新材料科技有限公司

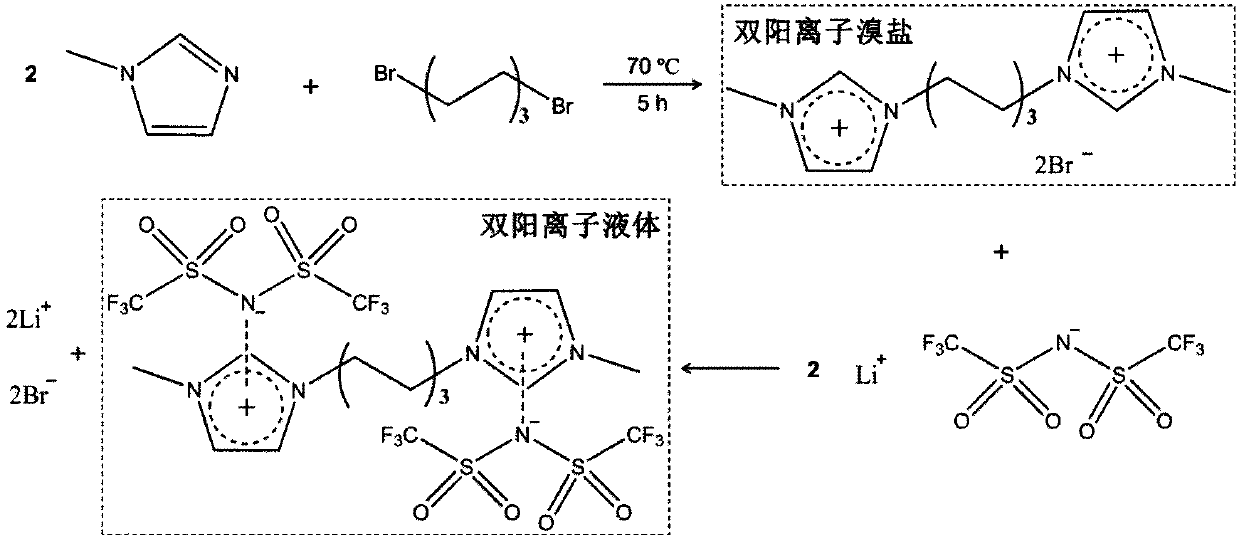

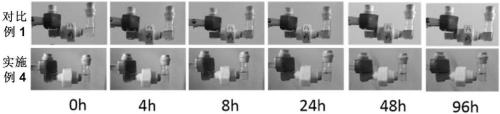

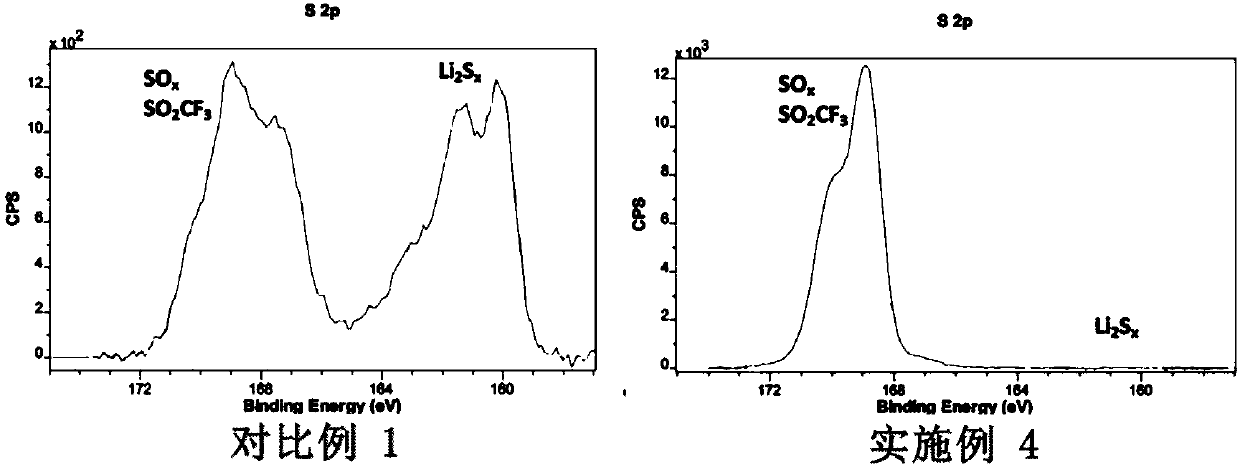

Dication liquid electrolyte, and preparation and application thereof

ActiveCN109873200AInhibited DiffusionImprove Coulombic efficiencyOrganic chemistryLi-accumulatorsLithium–sulfur batteryIon exchange

The invention relates to a dication liquid electrolyte, and preparation and application thereof. The dication uses a nitrogen-containing aromatic compound, a halogenated substance and lithium salt asraw materials, and the dication liquid electrolyte is prepared by a substitution reaction and an ion exchange reaction. The dication liquid electrolyte has the effect of suppressing the shuttle effectby being applied to a lithium-sulfur battery, can inhibit the corrosion of the lithium negative electrode by the polysulfide ion and the growth of lithium dendrites at the same time, and effectivelyimproves the cycle life of the lithium-sulfur battery through the anion-cation synergistic action, thereby having a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

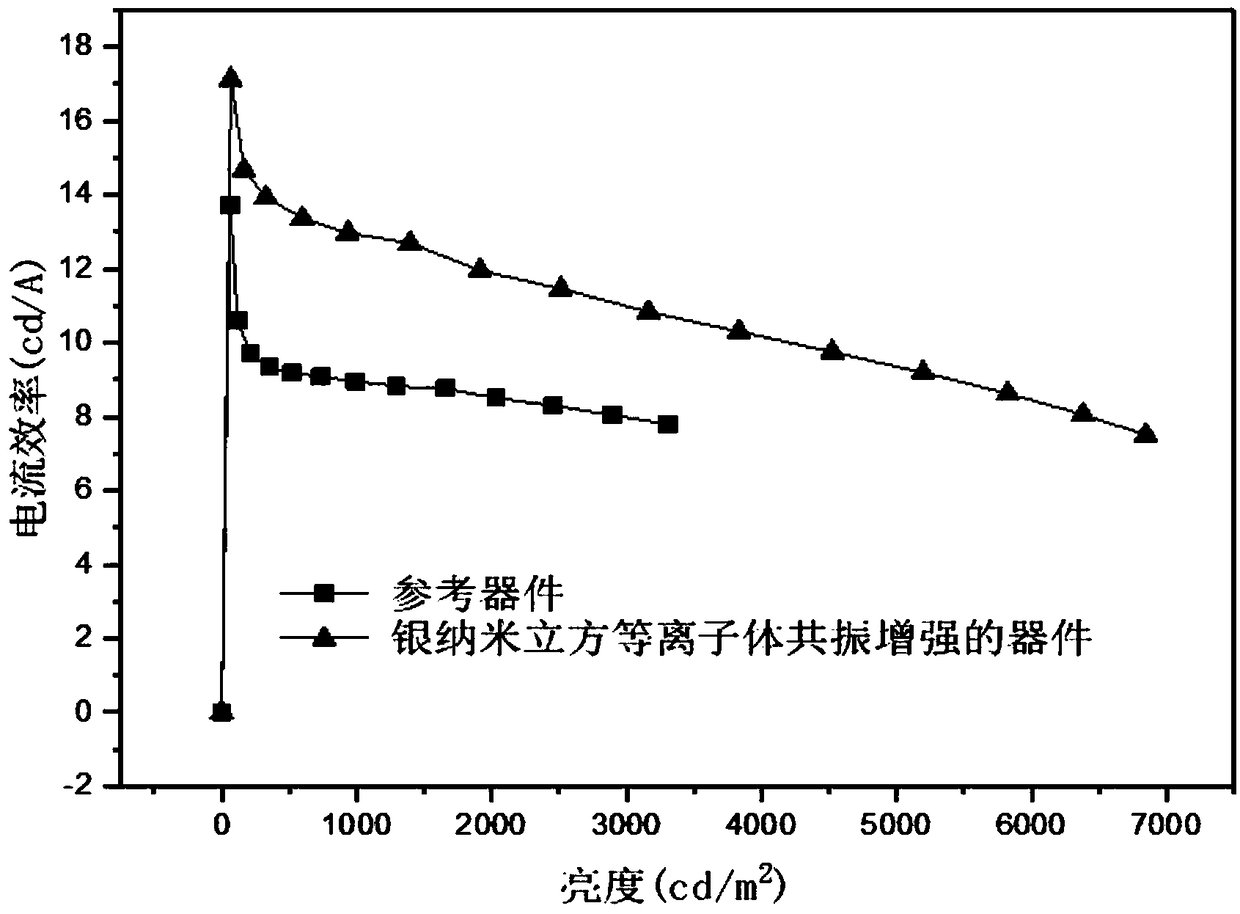

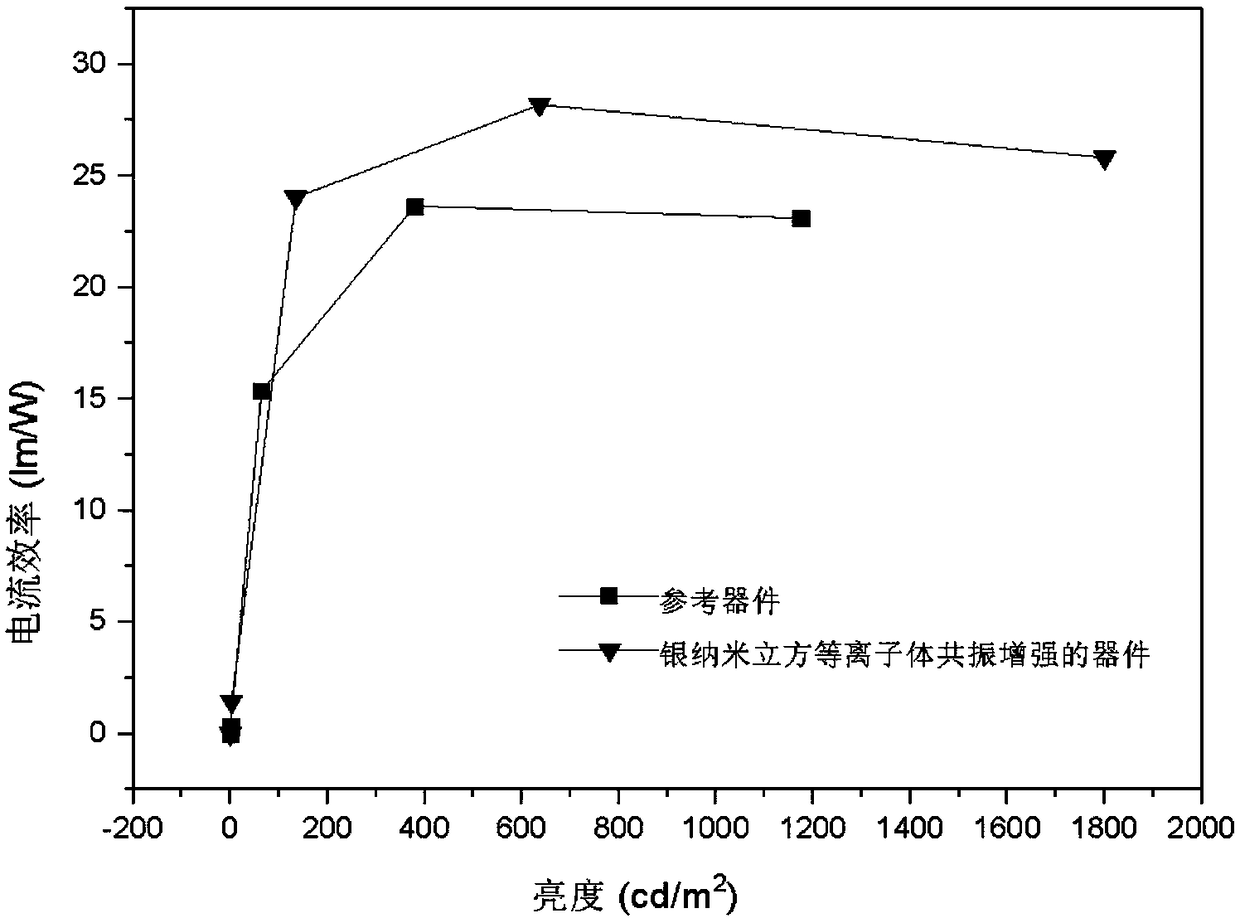

Silver nanocube-based solution organic light emitting diode and preparation method thereof

ActiveCN109273617AImprove luminous efficiencyGood resonance effectMaterial nanotechnologyNanoinformaticsEvaporationSpins

The invention discloses a solution organic light emitting diode based on a silver nanocube, comprising a sequentially laminated anode, a hole transport layer, a light emitting layer containing silvernanocube, an electron transport layer, and a cathode. The invention also discloses a preparation method of a solution organic light emitting diode based on silver nanocube: firstly, the ITO glass substrate is thoroughly cleaned, then a hole transport layer is spin-coated to prepare the hole transport layer, the hole transport layer comprises a silver nanocube light emitting layer, and then an electron transport layer and a metal electrode are sequentially prepared by evaporation in vacuum. The invention has the advantages that the silver nano cube is dispersed in the light emitting layer, theluminous efficiency of the organic light emitting diode is effectively improved by utilizing the plasma resonance effect of the silver nano cube, the preparation method is simple and easy, and has potential application value.

Owner:NANJING UNIV OF POSTS & TELECOMM

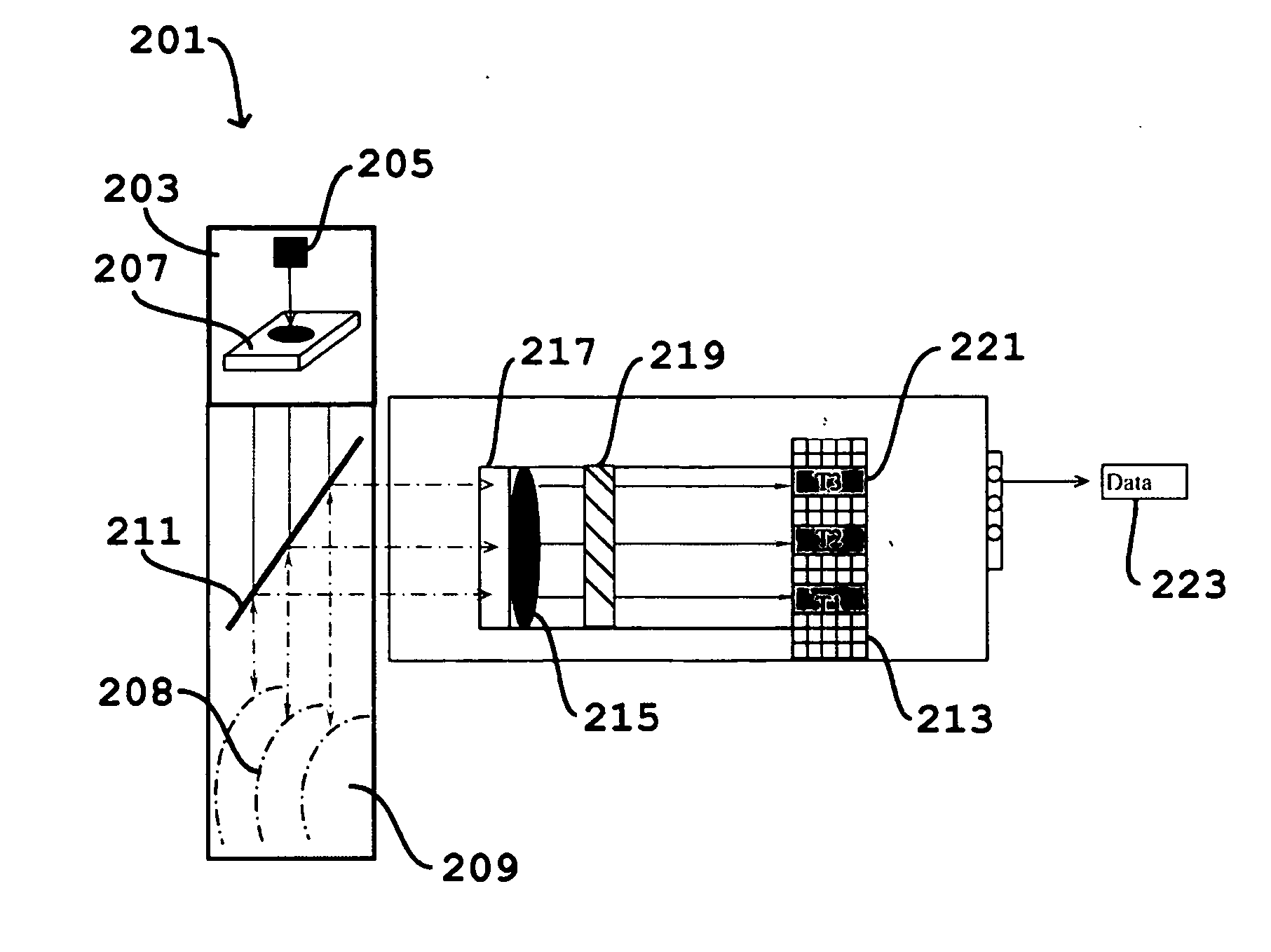

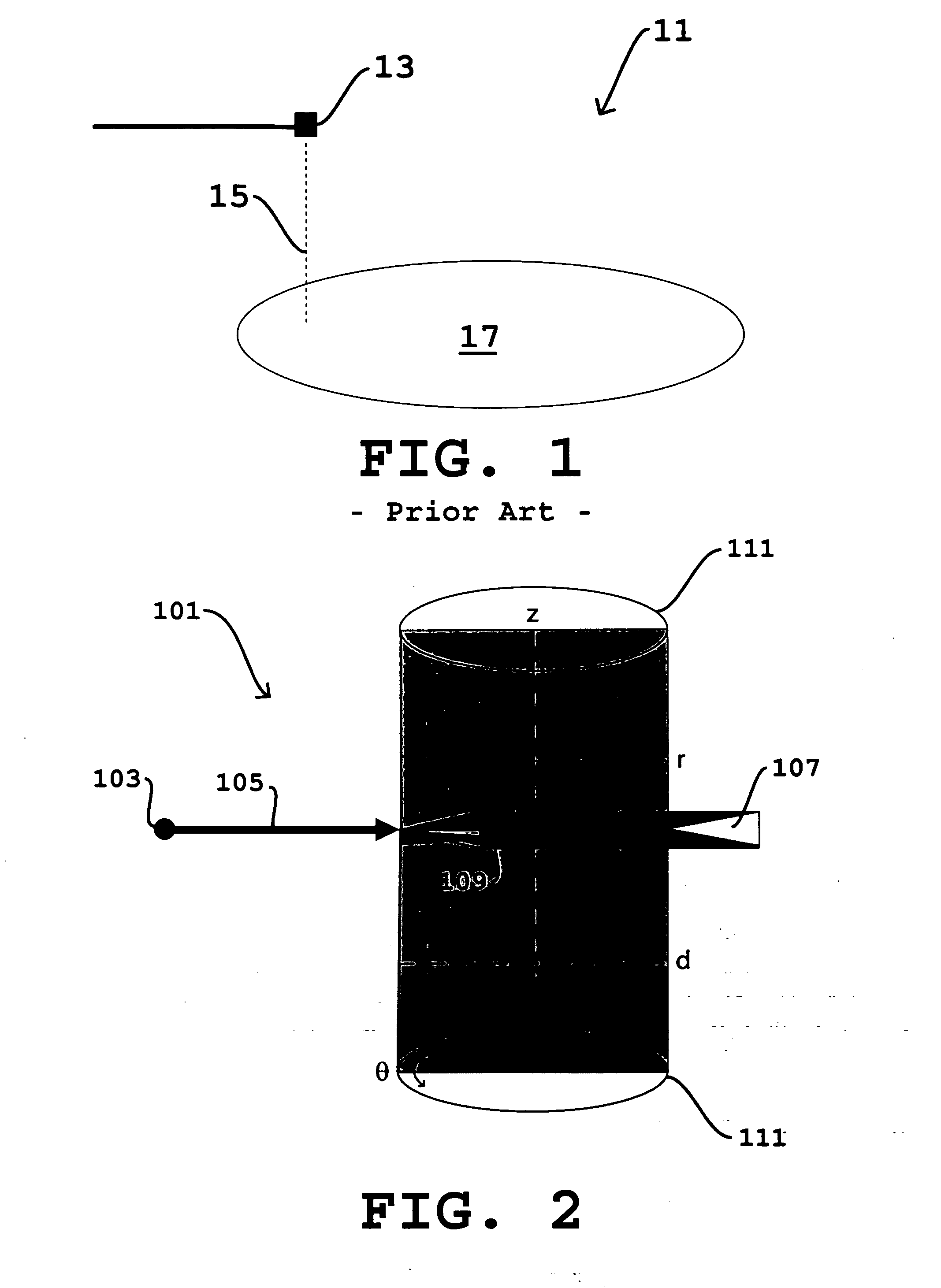

Virtual head for generating a multi-dimensional data signal

InactiveUS20050052982A1Significant performance improvementIncreasingDigital data processing detailsOptical detectorsMultiple dimensionElectromagnetic radiation

A device for retrieving data from a data storage medium is provided. The device (103) comprises a source of electromagnetic radiation and a holographic lens element (125) which is adapted to generate a hologram in the form of a multidimensional data pattern. The device is adapted to direct the electromagnetic radiation onto the surface of a data storage medium and to transmit reflections of the electromagnetic radiation, in the form of multidimensional data patterns, to a detector.

Owner:LUCERE LP

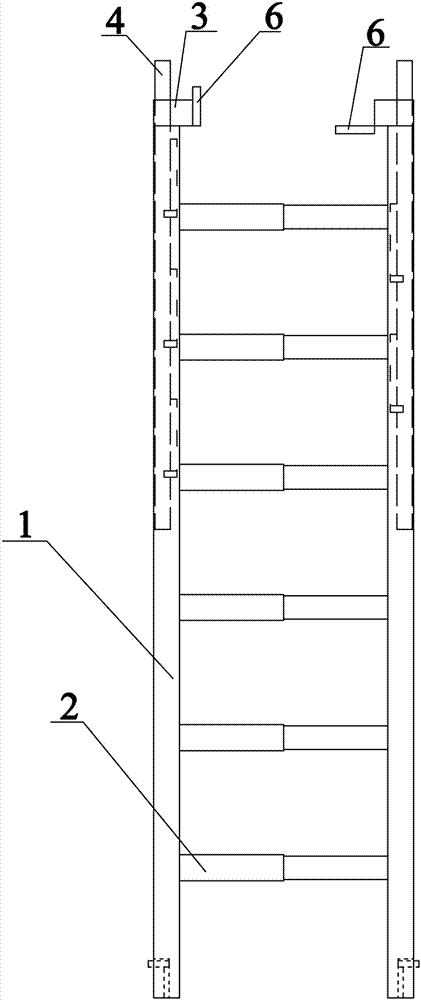

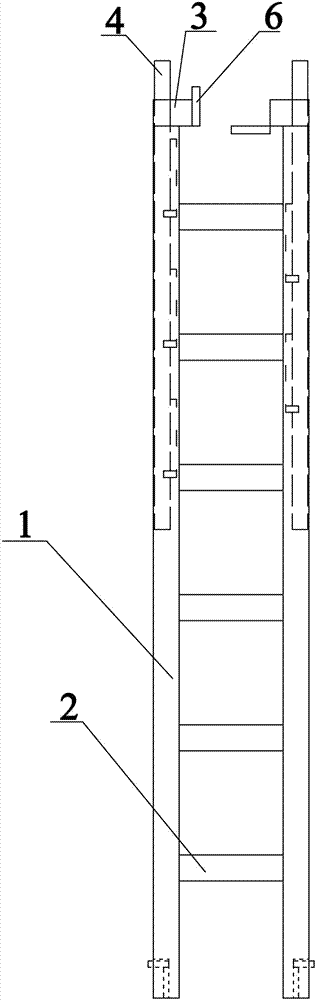

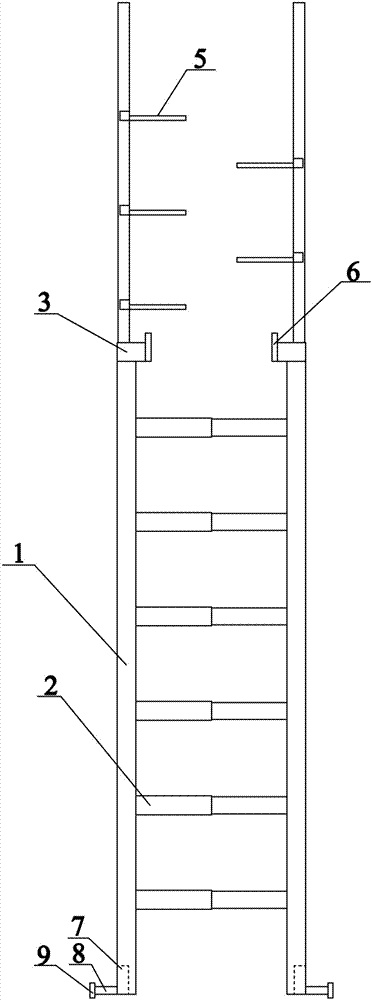

Electric insulated ladder

ActiveCN107313709ASmall footprintSimple structurePolyamide coatingsEpoxy resin coatingsMiddle lineEngineering

The invention relates to an insulated ladder, in particular to an electric insulated ladder. The electric insulated ladder comprises a ladder body. The ladder body comprises two vertical rods and transverse rods connected between the two vertical rods. Connecting blocks are hinged to the top ends of the two vertical rods correspondingly. Supporting rods capable of being pulled penetrate through the two vertical rods and the connecting blocks correspondingly. Limiting blocks are arranged at the lower ends of the supporting rods. Pedals are oppositely arranged on the inner sides of the two supporting rods in a staggered mode, the tail ends of the pedals are close to the median line of the two vertical rods, and the pedals can be folded upwards by 90 degrees. Carrying discs are hinged to the tail ends of the connecting blocks. Grooves are formed in the outer sides of the lower ends of the vertical rods. Connecting rods are rotatably connected in the grooves. Universal wheels are arranged at the tail ends of the connecting rods. Each transverse rod is formed by sleeving of two telescopic rods. The vertical rods, the transverse rods, the connecting blocks, the supporting rods and the pedals are all coated with insulated paint. The insulated ladder is simple in structure, low in manufacturing cost, diverse in function, adjustable in height and width, convenient to use and safe in operation.

Owner:国网河南省电力公司桐柏县供电公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com