High magnifying power lithium-rich manganese-based cathode material with nano/microstructure

A cathode material, lithium-rich manganese-based technology, which is applied in the field of high-rate lithium-rich manganese-based cathode materials and their preparation, can solve the problems of rapid capacity decay, low conductivity of lithium-rich manganese-based cathode materials, and poor high-rate performance. Achieve the effect of reliable performance improvement, obvious performance improvement and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

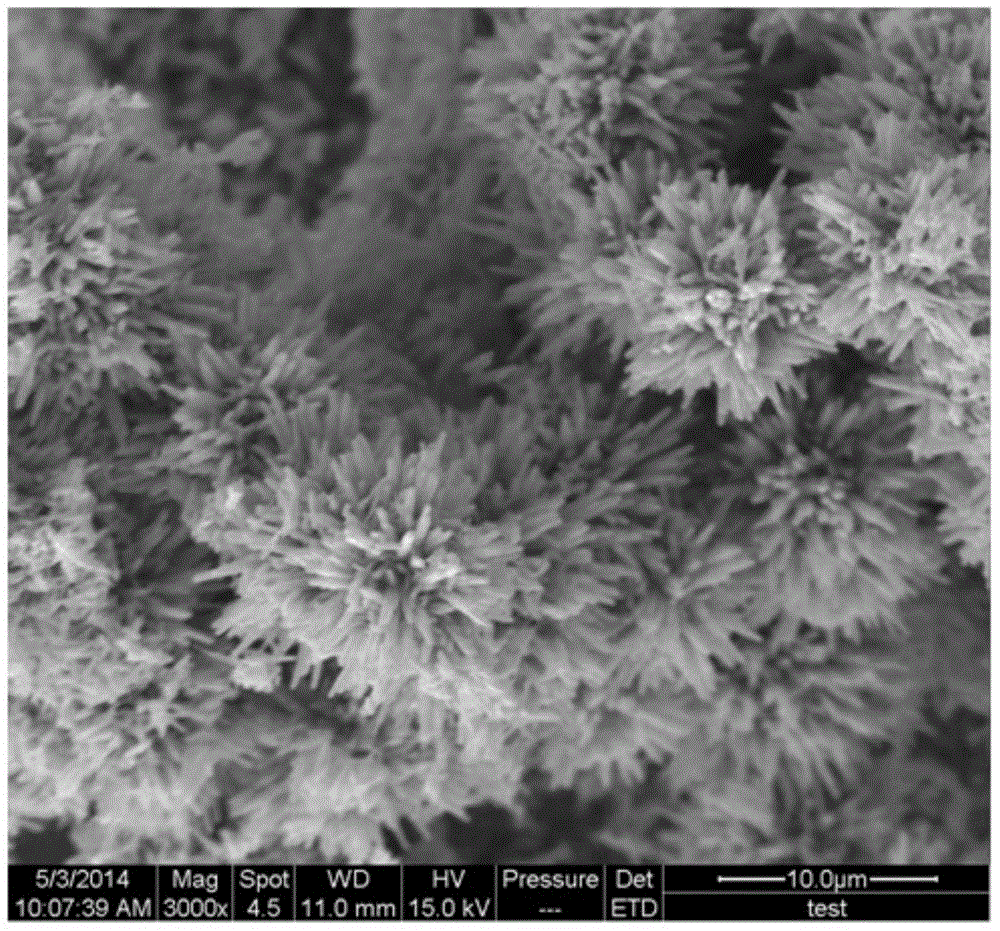

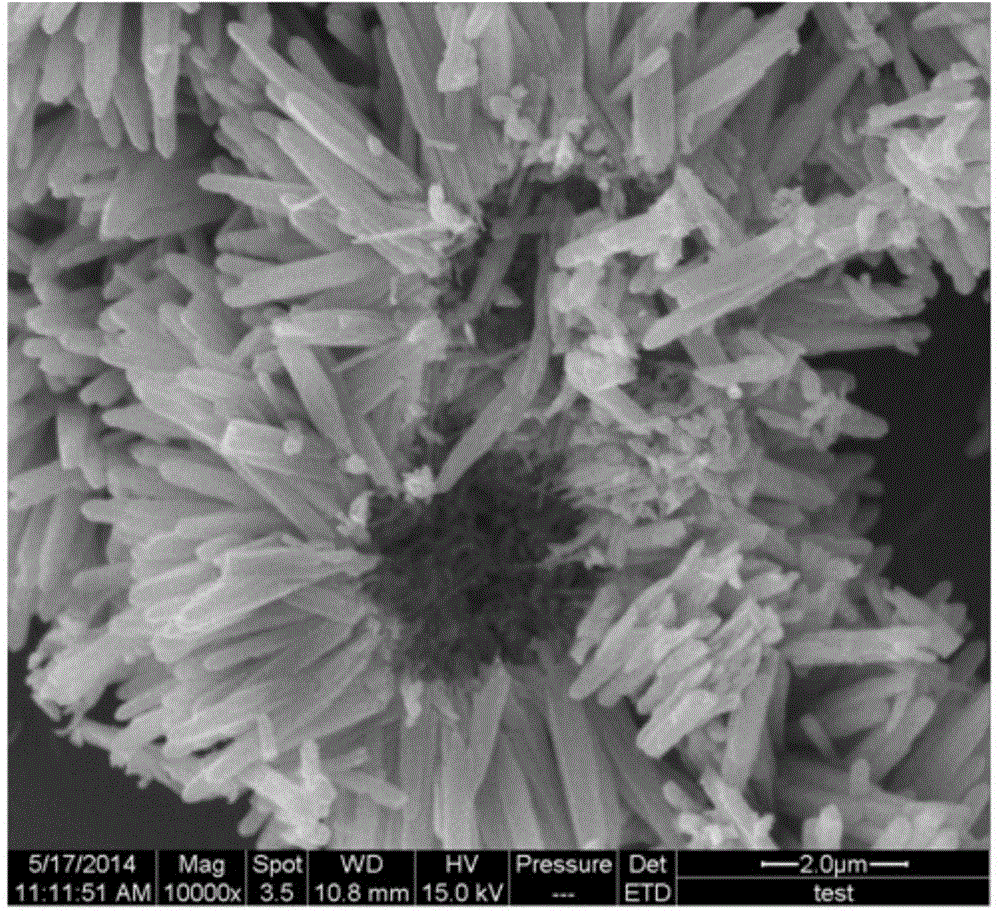

[0031] Weigh manganese sulfate, polyvinylpyrrolidone and sodium chlorate in a molar ratio of 1:1.1:3, stir and dissolve with an appropriate amount of deionized water until clear, transfer the mixed solution into a high-pressure reactor lined with polytetrafluoroethylene, and Place in an oven at 180°C, control the reaction time for 12 hours, wait for the reaction kettle to cool down to room temperature naturally, filter to obtain a black precipitate, wash it repeatedly with deionized water and ethanol until the pH is 7, and place it in an oven at 110°C to dry for 48 hours , the obtained black manganese dioxide powder has a radial hollow nanostructure formed by the self-assembly of nanorods, such as figure 1 , 2 shown;

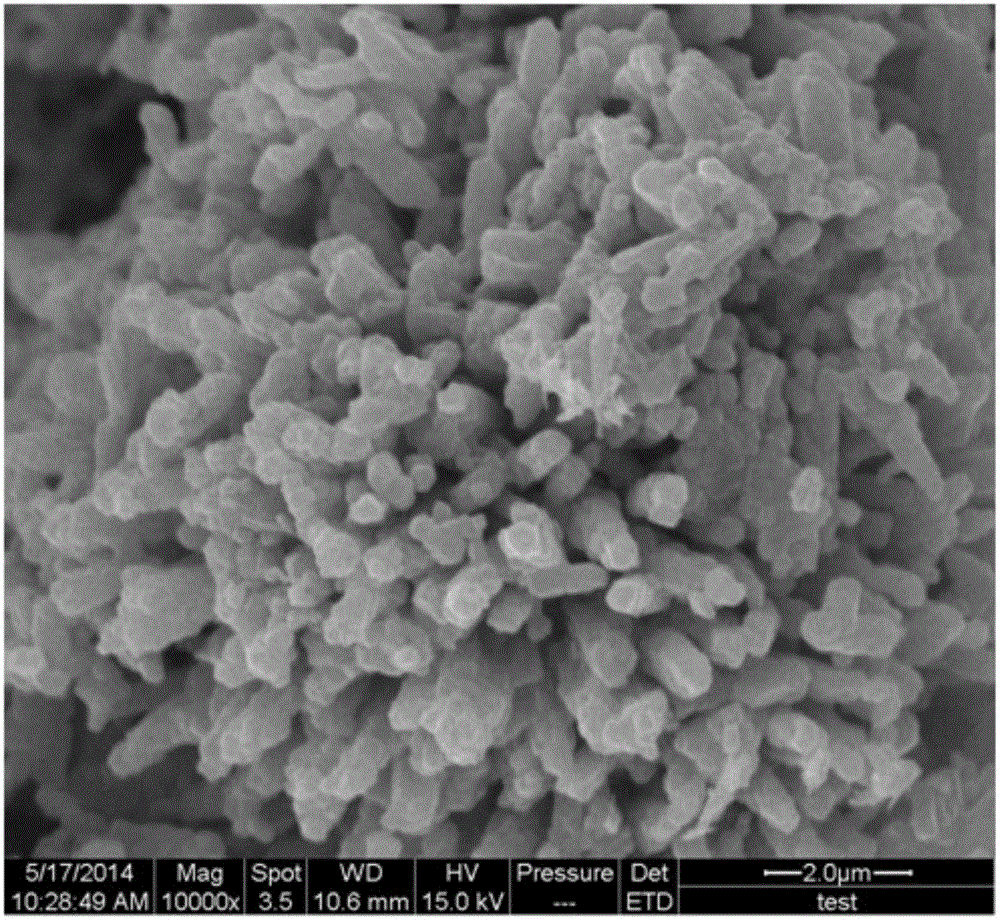

[0032] Weigh lithium hydroxide, nickel acetate, and manganese dioxide at a molar ratio of Li:Ni:Mn=1.2:0.2:0.6, and mix them uniformly in a mixed solution of deionized water and ethanol; Raise it to 500°C, pre-calcine for 5 hours, then raise it to 750°C at the...

Embodiment 2

[0035] Weigh manganese nitrate, polyvinylpyrrolidone and sodium chlorate in a molar ratio of 1:1:4, stir and dissolve with an appropriate amount of deionized water until clear, transfer the mixed solution into a high-pressure reactor lined with polytetrafluoroethylene, and Place in an oven at 200°C, control the reaction time for 10 hours, wait for the reaction kettle to cool down to room temperature naturally, filter to obtain a black precipitate, wash it repeatedly with deionized water and ethanol until the pH is 7, and place it in an oven at 110°C to dry for 48 hours , the obtained black manganese dioxide powder has a radial hollow nanostructure formed by self-assembly of nanorods;

[0036]Weigh lithium acetate, cobalt acetate, and manganese dioxide in a molar ratio of Li:Co:Mn=1.2:0.2:0.6, and mix them uniformly in a mixed solution of deionized water and ethanol; to 500°C, pre-calcined for 5 hours, then raised to 750°C at the same heating rate, and calcined for 8 hours to o...

Embodiment 3

[0039] Weigh manganese oxalate, cetyltrimethylammonium bromide and sodium chlorate in a molar ratio of 1:1:4, stir and dissolve with an appropriate amount of deionized water until clear, and transfer the mixed solution into a polytetrafluoroethylene-lined In a high-pressure reaction kettle, place it in an oven at 200°C, and control the reaction time for 10 hours. After the reaction kettle is naturally cooled to room temperature, filter to obtain a black precipitate, wash it repeatedly with deionized water and ethanol until the pH is 7, and place it in Dry in an oven at 110°C for 48 hours to obtain a black manganese dioxide powder with a radial hollow nanostructure formed by self-assembly of nanorods;

[0040] Weigh lithium oxalate, nickel oxalate, and manganese dioxide at a molar ratio of Li:Mn:Ni=1.13:0.3:0.57, and mix them uniformly in a mixed solution of deionized water and ethanol; to 500°C, pre-calcined for 5 hours, then raised to 800°C at the same heating rate, and calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com