Raw soil building material modification method and method for preparation of building block by use of modified raw soil

A technology of building materials and raw soil, applied in the field of building materials, can solve the problems of slow formation of solidified body strength, poor volume stability, unfavorable recycling and reuse, etc., to achieve cheap and easy to obtain, improved performance, and increased flexural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

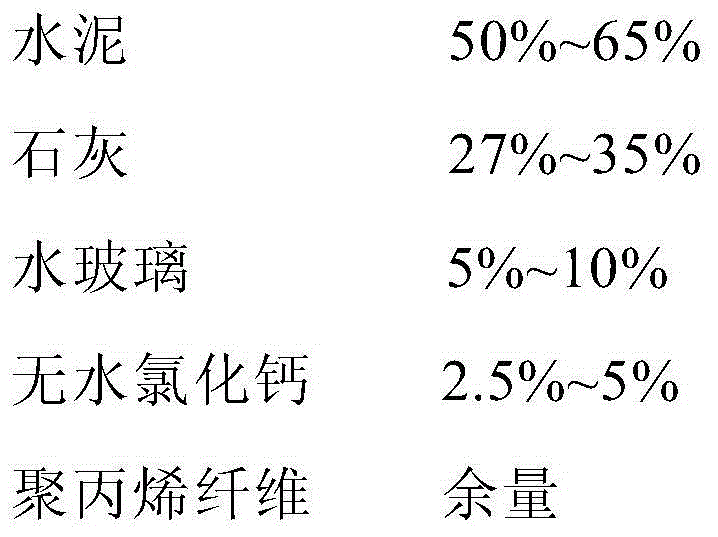

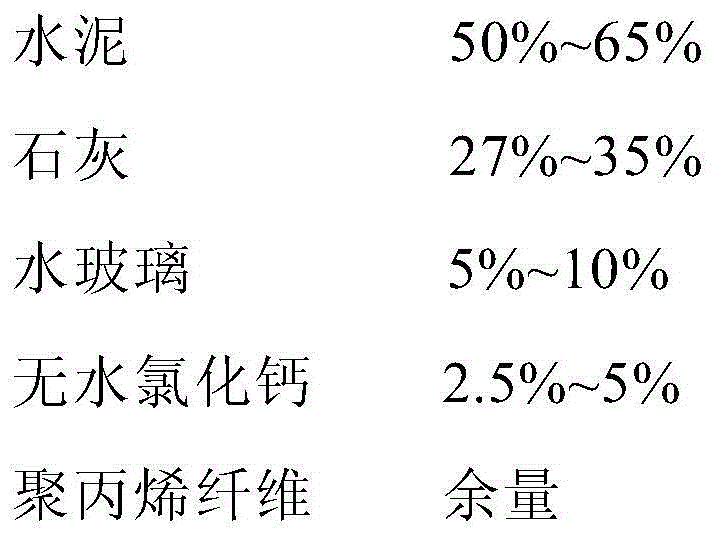

Embodiment 1

[0032] Add 254.0g of cement, 136.7g of lime, 17.3g of calcium chloride and 6g of polypropylene fiber modifier into 2550g of raw soil and stir for 1min, then dissolve 36g of water glass in 600g of aqueous solution, then pour it into a stirring pot, and stir 2 minutes to make it uniform; put the uniformly stirred raw soil modified powder into the required mold, press it with a pressure of 6 MPa, and put it into the indoor natural curing for 28 days after demoulding.

Embodiment 2

[0034] Add 260.0g of cement, 130.0g of lime, 22.5g of calcium chloride and 6g of polypropylene fiber modifier into 2550g of raw soil and stir for 1min, then dissolve 31.5g of water glass in 600g of aqueous solution, and then pour it into a stirring pot. Stir for 2 minutes to make it uniform; put the uniformly stirred raw soil modified powder into the required mold, press it with a pressure of 6MPa, and put it in the room for natural curing after demoulding for 28 days before use, that is, the raw soil block with improved properties is obtained.

Embodiment 3

[0036] Add 260.5g of cement, 130.2g of lime, 17.3g of calcium chloride and 6g of polypropylene fiber modifier into 2550g of raw soil and stir for 1min, then dissolve 36g of water glass in 600g of aqueous solution, then pour it into a stirring pot, and stir 2 minutes to make it uniform; put the uniformly stirred raw soil powder into the required mold, press it with a pressure of 6Mpa, and put it in the indoor natural curing for 28 days after demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com