Viscosity-reduction polycarboxylate-type water reducer mother liquor, water reducer and preparation method

A technology of viscous polycarboxylic acid and water reducing agent, which is applied in the field of viscosity reducing type polycarboxylic acid series water reducing agent mother liquor, water reducing agent and preparation field, can solve the problems of difficult construction and high viscosity of concrete, and achieves the improvement of market competition. strength, improved slump retention, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

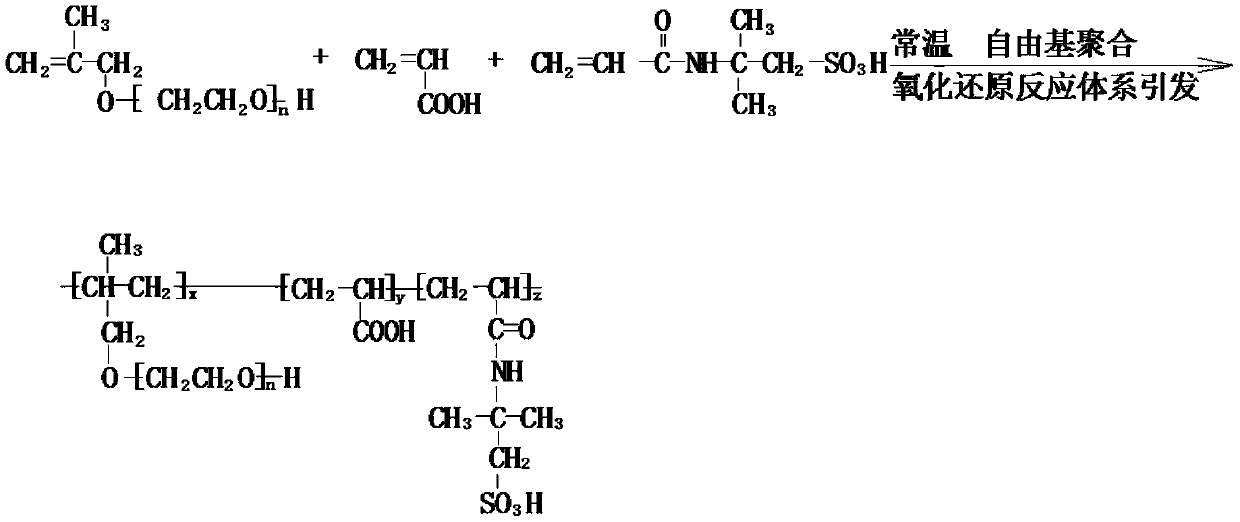

Method used

Image

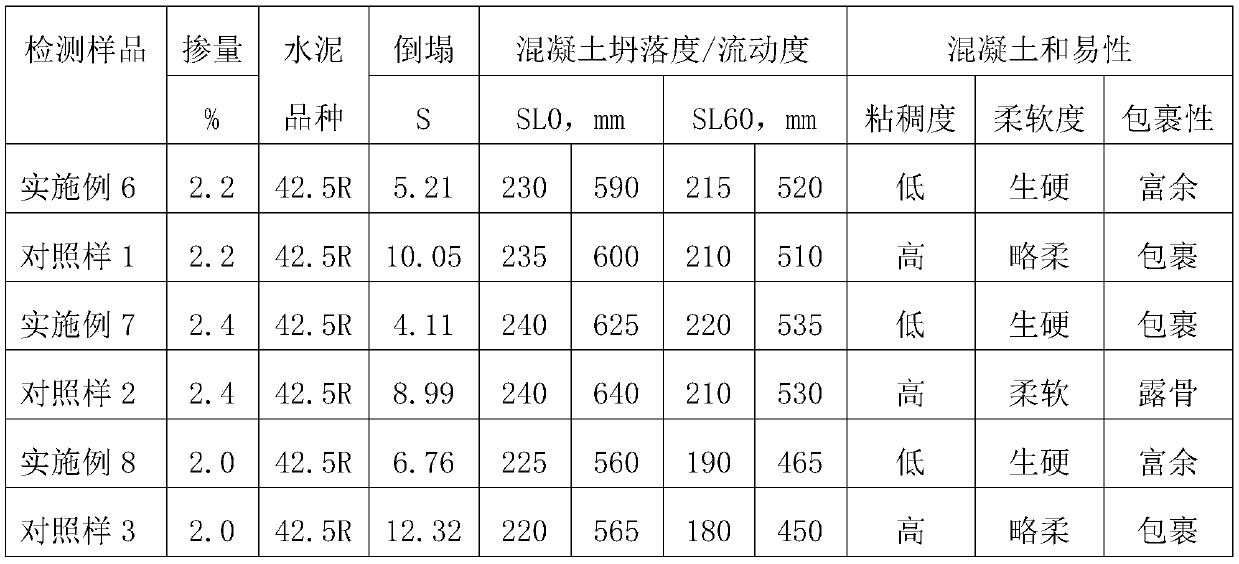

Examples

Embodiment 1

[0051] Preparation of viscosity-reducing polycarboxylate water-reducer mother liquor:

[0052] 1.1 Raw materials (by weight):

[0053]47 parts of ether macromers; 4.5 parts of acrylic acid; 0.7 parts of functional small monomers; 0.2 parts of reducing agent; 0.7 parts of hydrogen peroxide; 0.3 parts of chain transfer agent; 75 parts of water.

[0054] 1.2 Preparation method:

[0055] Include the following steps:

[0056] (1) Prepare A solution:

[0057] Weigh 3 parts of acrylic acid, 0.7 parts of functional small monomers, 0.3 parts of chain transfer agent and 25 parts of water, stir and dissolve to make A solution;

[0058] (2) Configure B solution:

[0059] Weigh 0.2 parts of reducing agent; dissolve in 15 parts of deionized water, stir and dissolve to make B solution;

[0060] (3) Add 35 parts of deionized water into the reaction kettle, and then add 47 parts of ether macromonomer under stirring; heat to 30°C, and keep the temperature at 30°C; after all dissolve, add 1...

Embodiment 2

[0067] Preparation of viscosity-reducing polycarboxylate water-reducer mother liquor:

[0068] 2.1 Raw materials:

[0069] 50 parts of ether macromonomer; 3.5 parts of acrylic acid; 0.8 parts of functional small monomer; 0.1 part of reducing agent; 0.6 part of hydrogen peroxide; 0.4 part of chain transfer agent; 60 parts of water.

[0070] 2.2 Preparation method:

[0071] Include the following steps:

[0072] (1) Prepare A solution:

[0073] Weigh 2 parts of acrylic acid, 0.8 parts of functional small monomers, 0.4 parts of chain transfer agent and 20 parts of water, stir and dissolve to make A solution;

[0074] (2) Configure B solution:

[0075] Weigh 0.1 part of reducing agent, dissolve in 10 parts of deionized water, stir and dissolve to make B solution;

[0076] (3) Add 30 parts of deionized water into the reaction kettle, and then add 50 parts of ether macromonomer under stirring; heat to 25°C, and keep the temperature at 25°C; after all dissolve, add 1.5 parts of a...

Embodiment 3

[0083] Preparation of viscosity-reducing polycarboxylate water-reducer mother liquor:

[0084] 3.1 Raw materials:

[0085] 45 parts of ether macromers; 6.6 parts of acrylic acid; 0.5 parts of functional small monomers; 0.3 parts of reducing agent; 0.8 parts of hydrogen peroxide; 0.2 parts of chain transfer agent; 85 parts of water.

[0086] 3.2 Preparation method:

[0087] Include the following steps:

[0088] (1) Prepare A solution:

[0089] Weigh 5 parts of acrylic acid, 0.5 part of functional small monomer, 0.2 part of chain transfer agent and 30 parts of water, stir and dissolve to make A solution;

[0090] (2) Configure B solution:

[0091] Weigh 0.3 parts of reducing agent; dissolve in 20 parts of deionized water, stir and dissolve to make B solution;

[0092] (3) Add 35 parts of deionized water into the reaction kettle, and then add 45 parts of ether macromonomer under stirring; heat to 35°C, and keep the temperature at 35°C; after all dissolve, add 1.6 parts of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com