Indirect air cooling method and system for working medium adopting parallel-connection positive and reverse refrigeration cycle

An air cooling system and refrigeration cycle technology, which is applied to compressors with reversible cycles, refrigeration and liquefaction, refrigerators, etc. Implement, apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

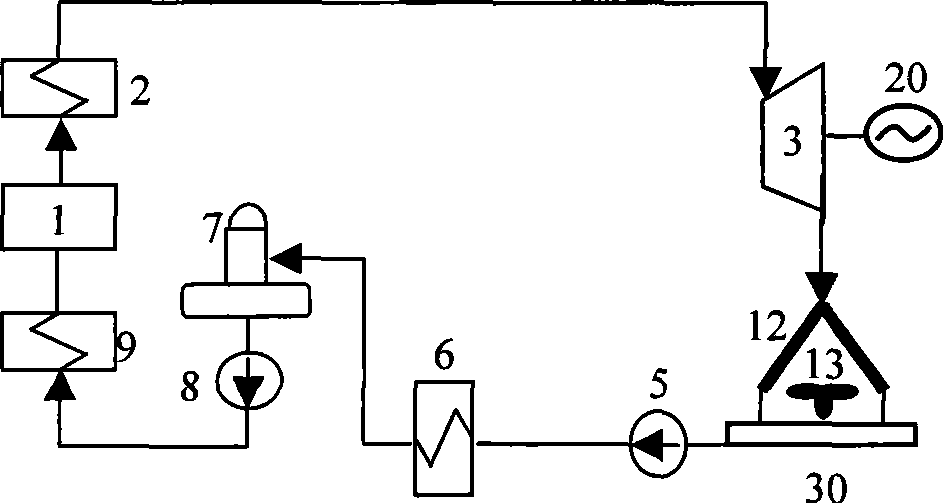

[0072] Indirect air cooling system for working medium of steam power cycle using parallel forward and reverse refrigeration cycles

[0073] refer to Figure 5 , the present invention adopts the indirect air cooling system of the working medium of the steam power cycle of the parallel forward and reverse refrigeration cycle, and replaces the wet condenser in the steam power cycle system with the two-phase conversion heat exchanger 4 . Between the output end a and the input end b of the refrigerant on the low temperature side of the two-phase conversion heat exchanger, there is an indirect air cooling system (the operation route shown by the solid line in the figure) and an indirect air cooling system of the working medium of the positive refrigeration cycle coupled in parallel with the reverse refrigeration cycle. The indirect air cooling system of the working fluid (the operation route shown by the dotted line in the figure). The output end of the refrigerant of the two-phase...

Embodiment 2

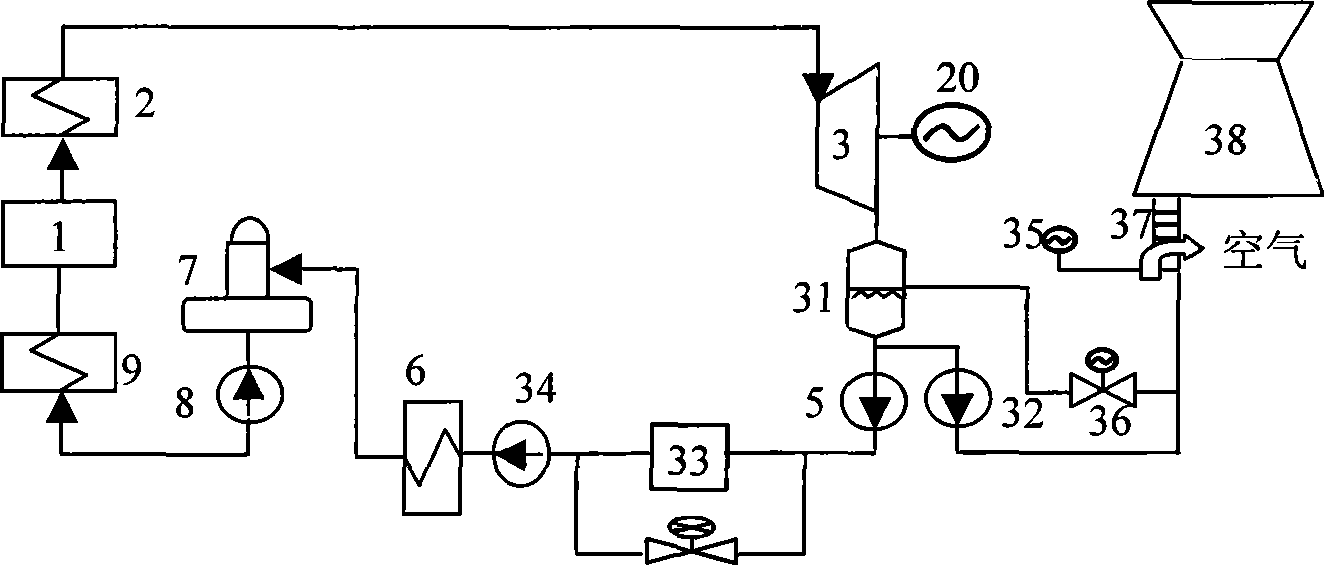

[0079] The indirect air cooling system of the working medium of the steam power cycle of the parallel forward and reverse refrigeration cycle using a simple reverse refrigeration cycle

[0080] refer to Figure 6 In the indirect air cooling system of the working medium of the steam power cycle of the parallel forward and reverse refrigeration cycle of the simple reverse refrigeration cycle (also called the indirect air cooling system of the working medium of the high temperature parallel forward and reverse refrigeration cycle), the positive refrigeration The indirect air cooling system (operating route shown by the solid line in the figure) of the circulating working medium is basically the same as that of Embodiment 1, including a two-phase heat exchanger 4, a shut-off valve 21, an electric motor 19 for driving the compressor, and a compressor 11 , cut-off valve 24, air-cooled radiator 12, air-cooled fan 13, liquid storage tank 14, throttle valve 16, etc.; the indirect air c...

Embodiment 3

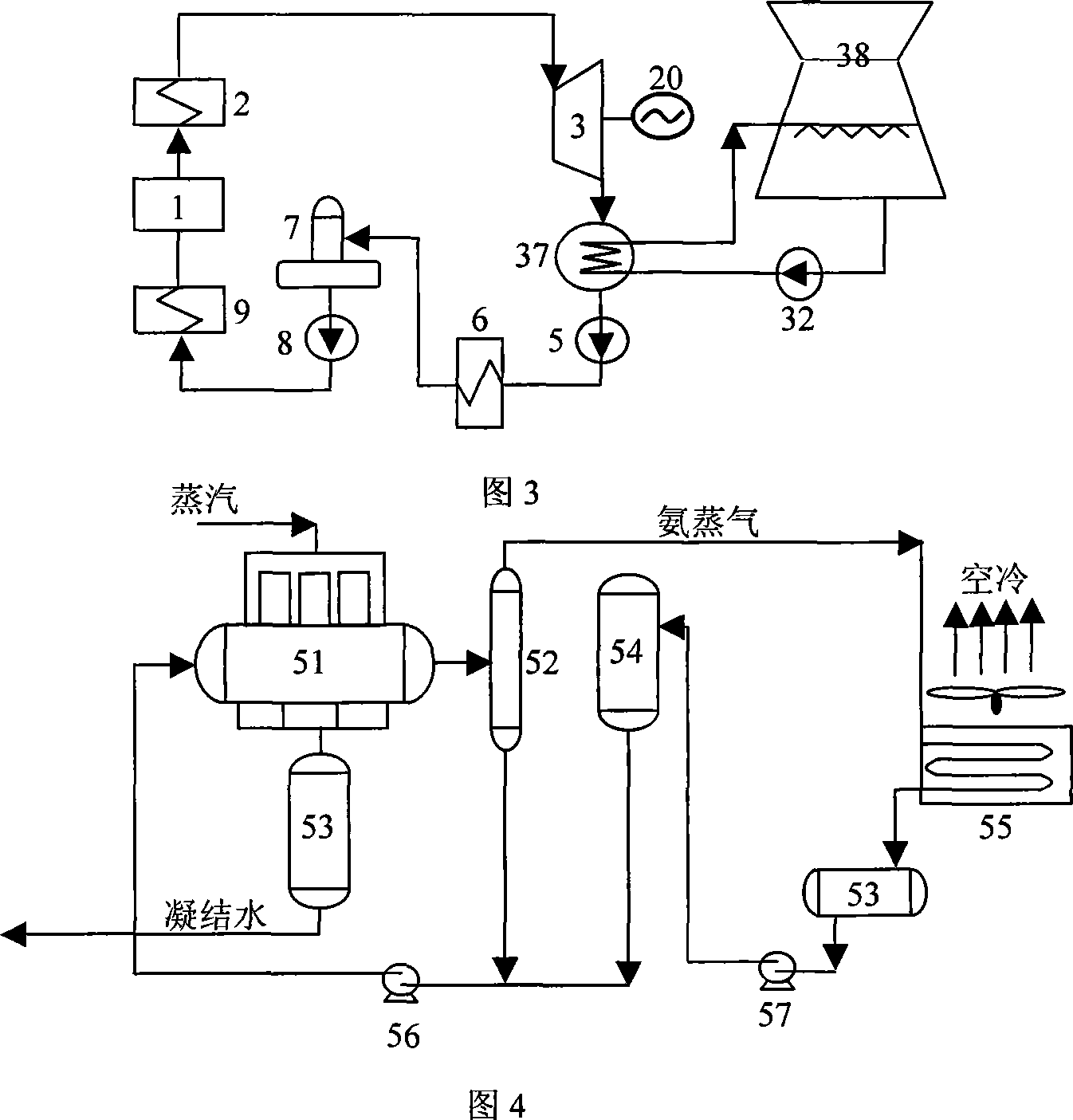

[0102] The indirect air cooling system of the working medium of the steam power cycle of the parallel forward and reverse refrigeration cycle using energy-saving reverse refrigeration cycle

[0103] refer to Figure 7 , in the indirect air cooling system of the working medium of the steam power cycle of the parallel forward and reverse refrigeration cycle of the energy-saving reverse refrigeration cycle (also known as the indirect air cooling system of the working medium of the low-temperature parallel forward and reverse refrigeration cycle), the positive refrigeration cycle The indirect air cooling system (operating path shown by the solid line in the figure) of the working fluid is basically the same as that of Embodiment 1, including a two-phase heat exchanger 4, a shut-off valve 21, a motor 19 that drives the compressor, a compressor 11, Stop valve 24, air-cooling radiator 12, air-cooling fan 13, liquid storage tank 14, throttle valve 16, etc.; the indirect air cooling sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com