MEMS three-axis gyroscope based on thermal expansion flow and machining method thereof

A technology of thermal expansion and gyroscope, applied in the field of inertial measurement, can solve the problems of low integration and achieve the effects of eliminating interference, low power consumption and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

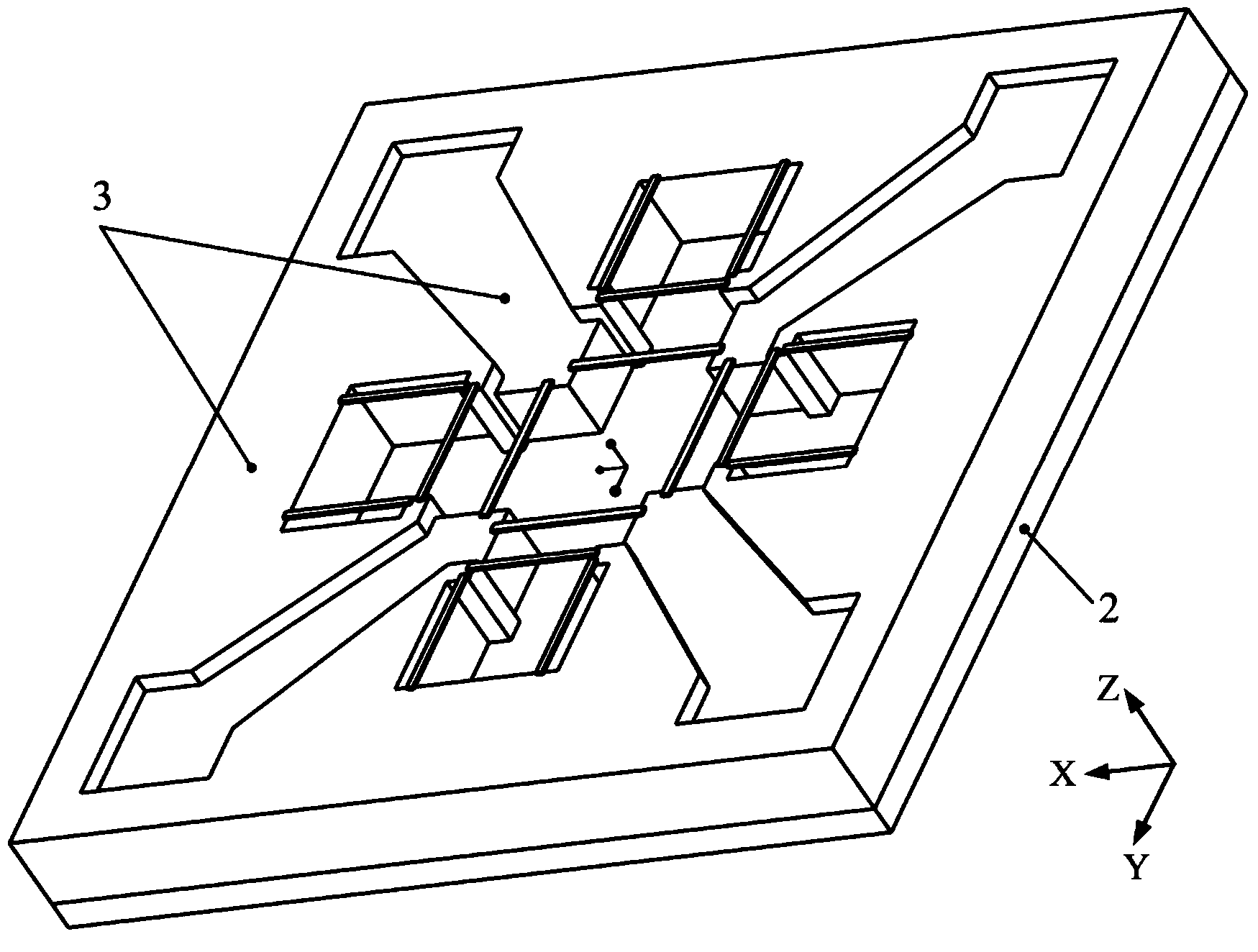

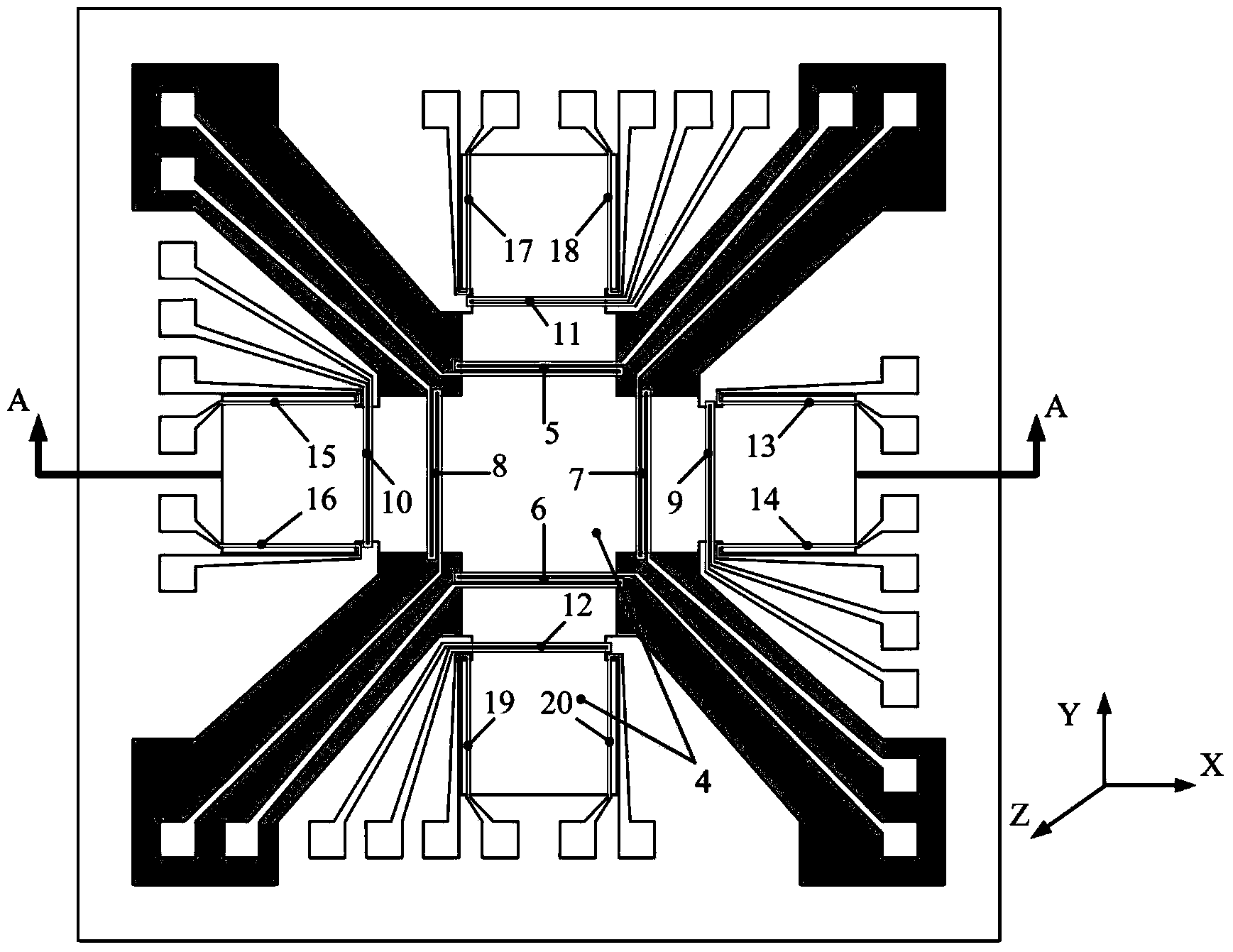

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 , the structure of the MEMS three-axis gyroscope based on thermal expansion flow in this embodiment includes an upper sealing layer 1 , a lower base layer 2 , and a middle detection layer 3 . Wherein, on the middle detection layer, there is a "ten" detection chamber 4, metal resistance bridge heating elements 5-8 and metal resistance bridge thermal elements 9-20 located in the detection chamber. The base layer 2 is at the bottom of the "ten" detection chamber 4, and the base layer 2 and the detection layer 3 are integrated; the upper sealing layer 1 is at the top of the "ten" detection chamber 4. The upper sealing layer 1 and the base layer 2 isolate the gas medium in the detection chamber from the outside, forming a sealed working system.

[0037] Such as figure 1 , image 3 , Figure 4 As shown, the middle detection layer 3 has a stepped structure, that is, the detection layer 3 includes two parallel layers w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com