Thermal expansion type fluid triaxial accelerometer and processing method thereof

A thermal expansion, axial acceleration technology, applied in the field of inertial measurement, can solve the problems of the inability to improve the sensitivity of thermal convection accelerometers, limit the application of thermal accelerometers, and be easily affected by the external environment. Strong impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

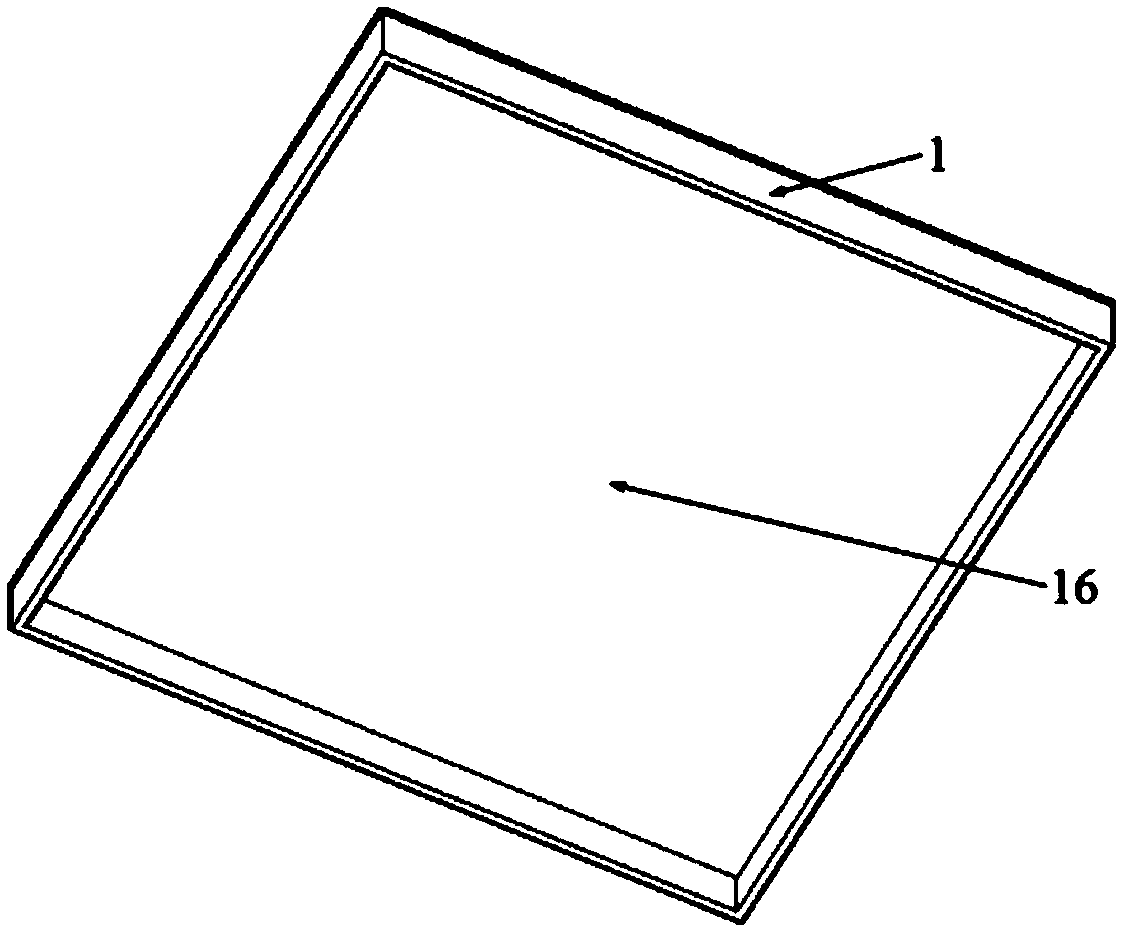

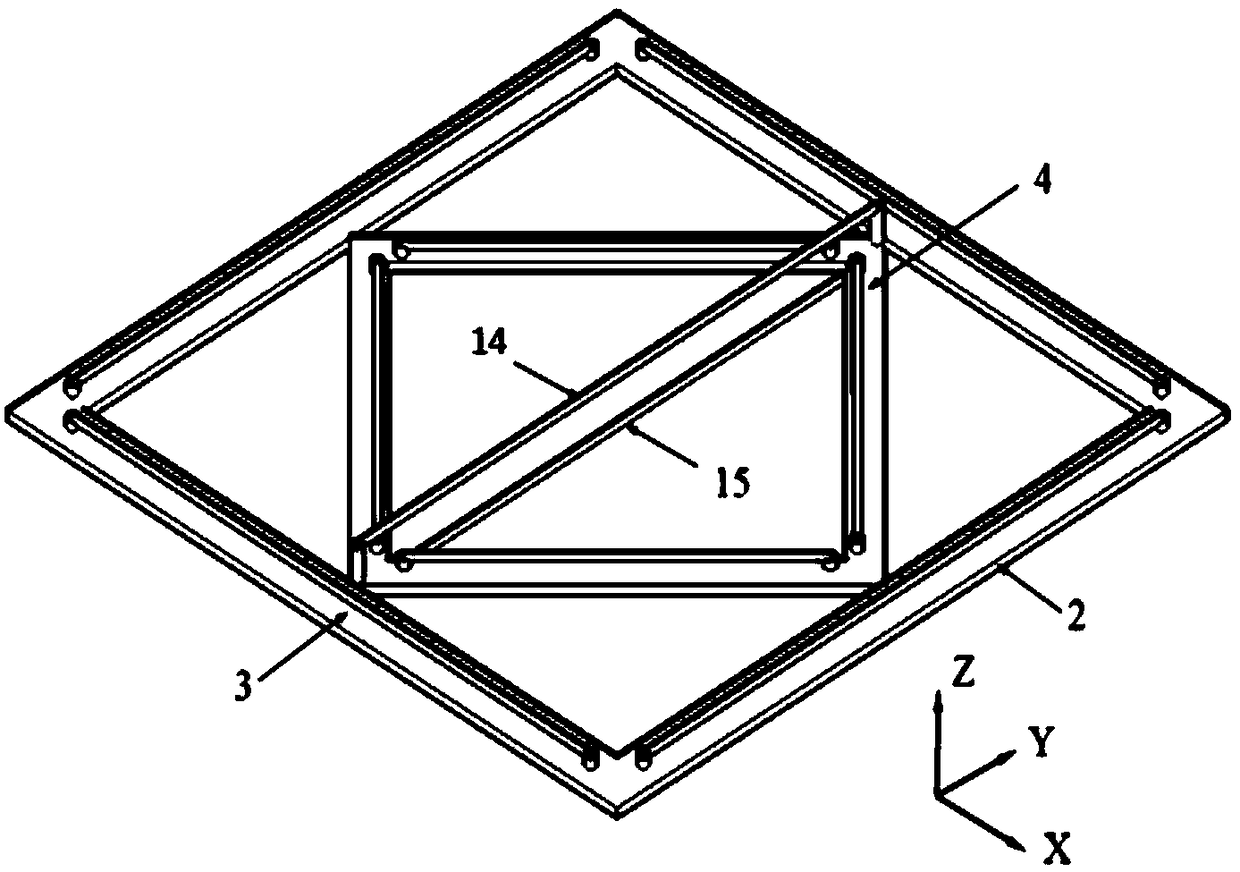

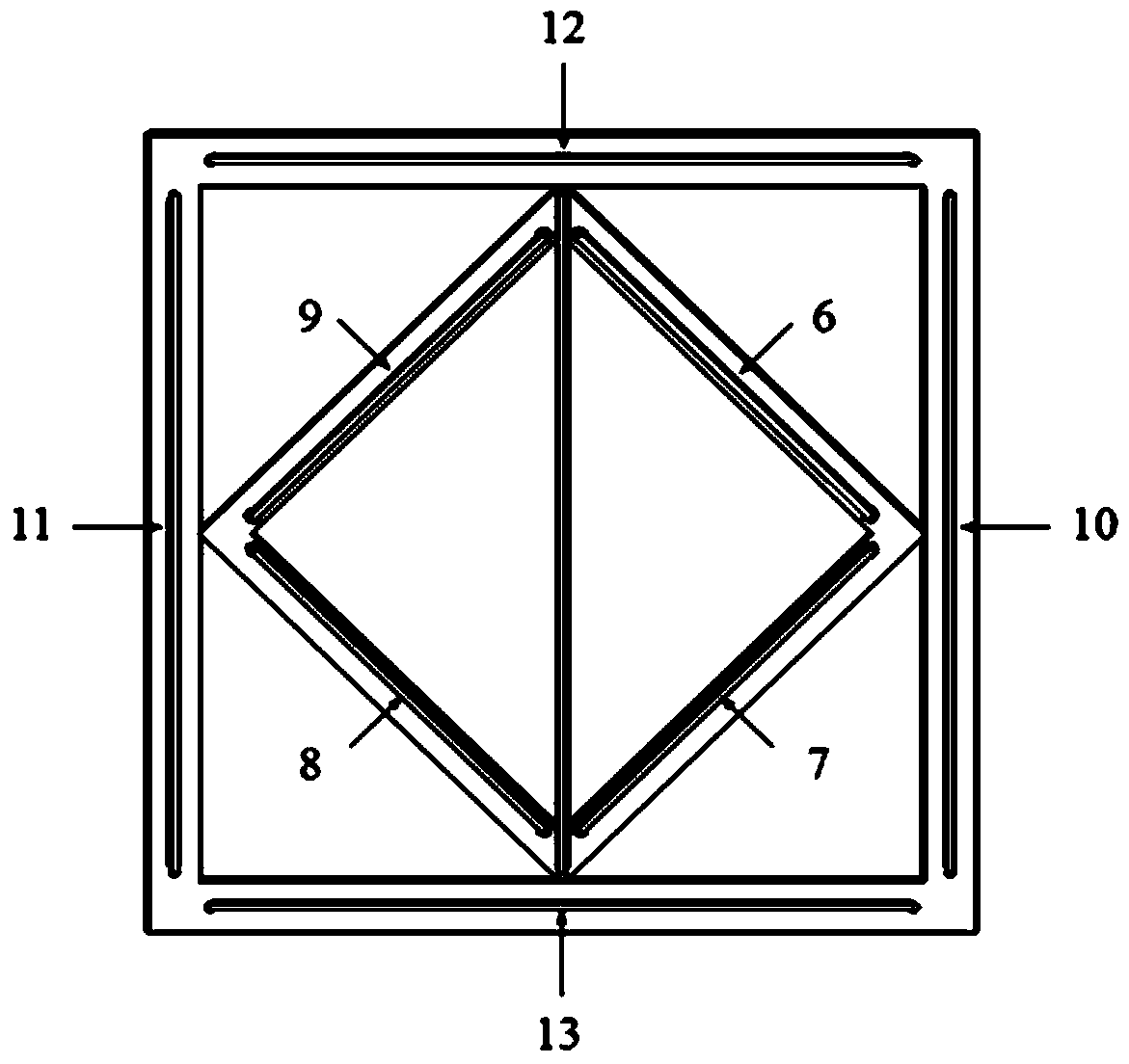

[0043] refer to Figure 1 to Figure 8 As shown, the thermal expansion fluid triaxial accelerometer in this embodiment includes an upper sealing layer 1 , a middle detection layer 2 and a lower sealing layer 5 . Among them, there is a square nesting (outer square structure 3 and inner square structure 4) on the middle detection layer 2 and metal resistance bridge thermal wires 10, 11, 12, 13 on the outer square structure 3 and on the inner square structure 4 Metal resistance bridge heating wires 6,7,8,9 and metal resistance bridge thermal wires 12,13. Inside the upper sealing layer 1 is an inner groove 16 , and inside the lower sealing layer 5 is an inner groove 17 . The upper sealing layer 1 and the lower sealing layer 5 isolate the gas in the airtight chamber from the outside, forming a sealed working environment.

[0044] Such as figure 2 , image 3 , Figure 4 As shown, there is a square nesting in the middle detection layer 2, including an outer square structure 3 an...

Embodiment 2

[0053] This embodiment also provides a processing method for the thermal expansion type fluid triaxial accelerometer according to Embodiment 1, which includes:

[0054] S1: Make an intermediate detection layer on the aluminum material to form an inner and outer square nest, and drill holes with the same diameter and height as the size of the insulator at the corresponding position of the square structure for installing the insulator terminal;

[0055] S2: Install gold-plated insulator terminals on 20 holes to suspend the heating wire of the metal resistance bridge and the thermal wire of the metal resistance bridge;

[0056] S3: Cut the lead wires of the metal resistance bridge thermosensitive wire insulator binding posts used to suspend and detect the acceleration of the X and Y axes to the same length as the lead wires used to suspend the heating wire insulator binding posts of the metal resistance bridge, so that X and Y can be detected The metal resistance bridge thermal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com