Multi-degree-of-freedom displacement measurement system based on two-dimensional grating

A two-dimensional grating and displacement measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of restricting the application of two-dimensional grating measurement systems, improve signal quality and displacement measurement accuracy, reduce debugging difficulty, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

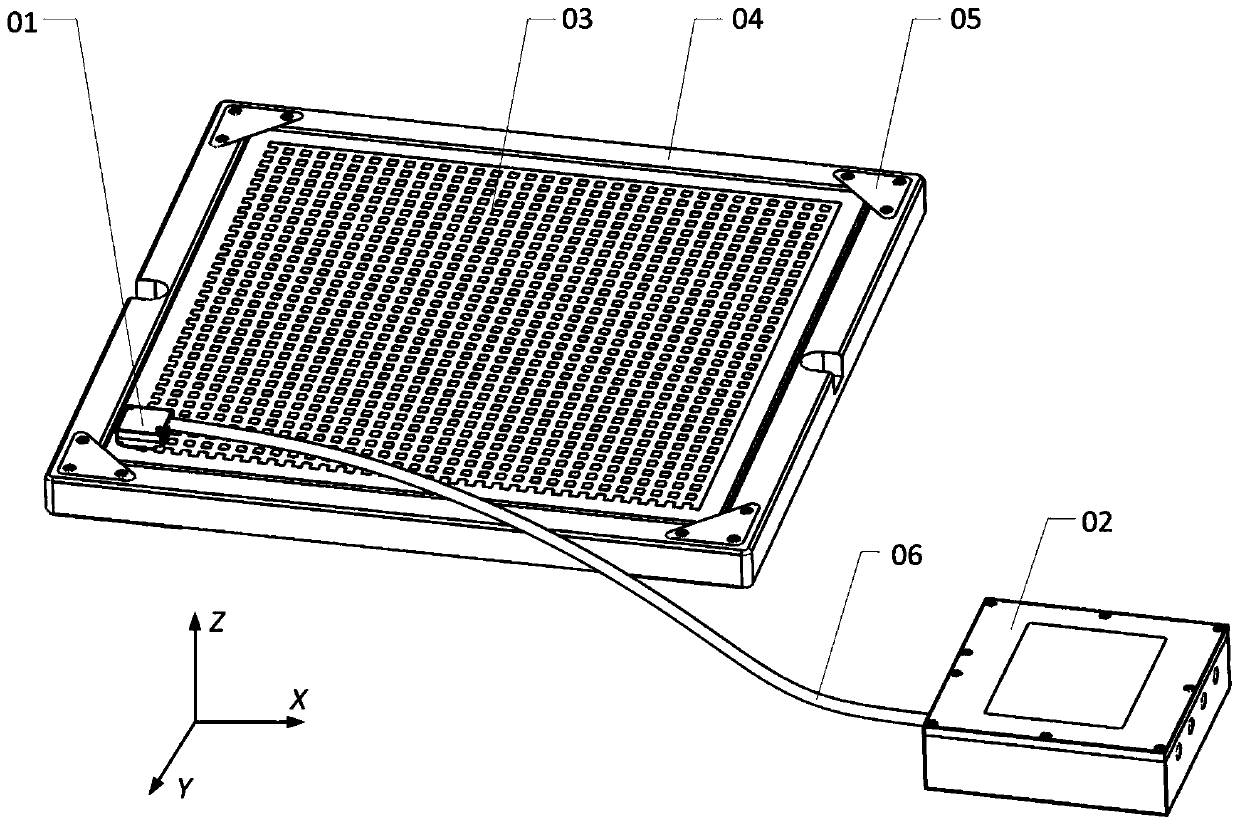

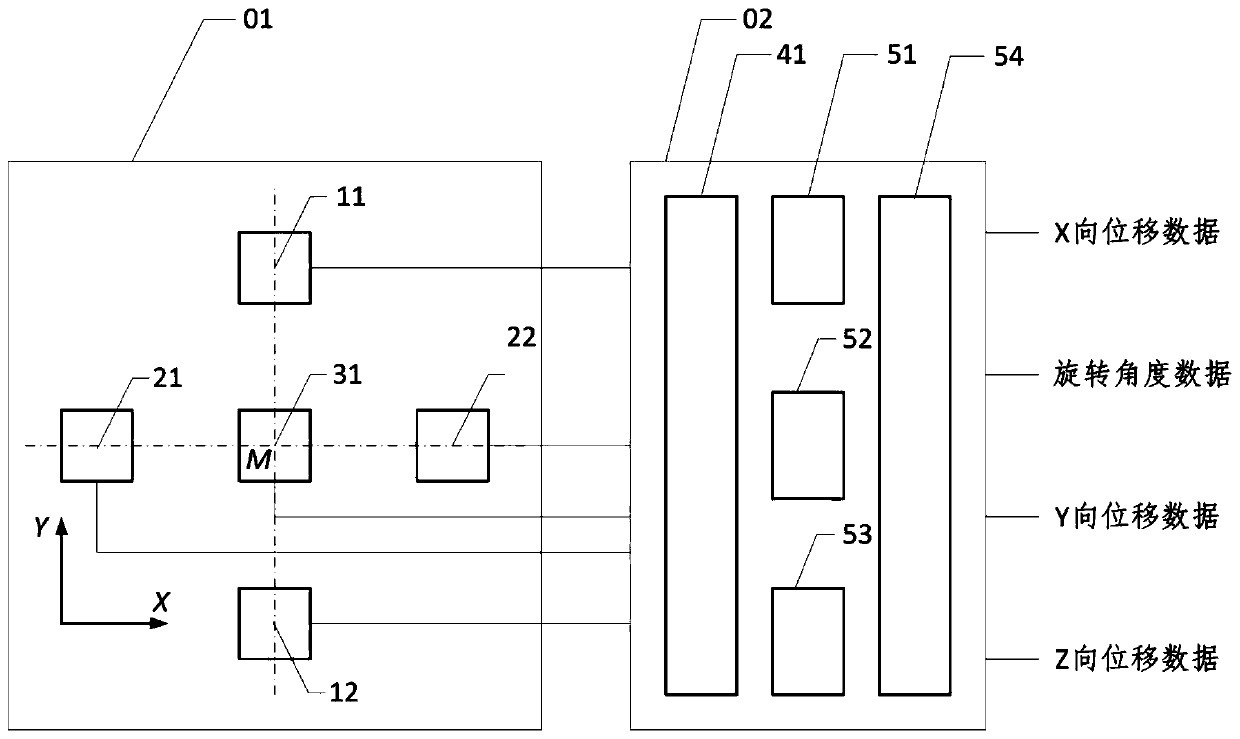

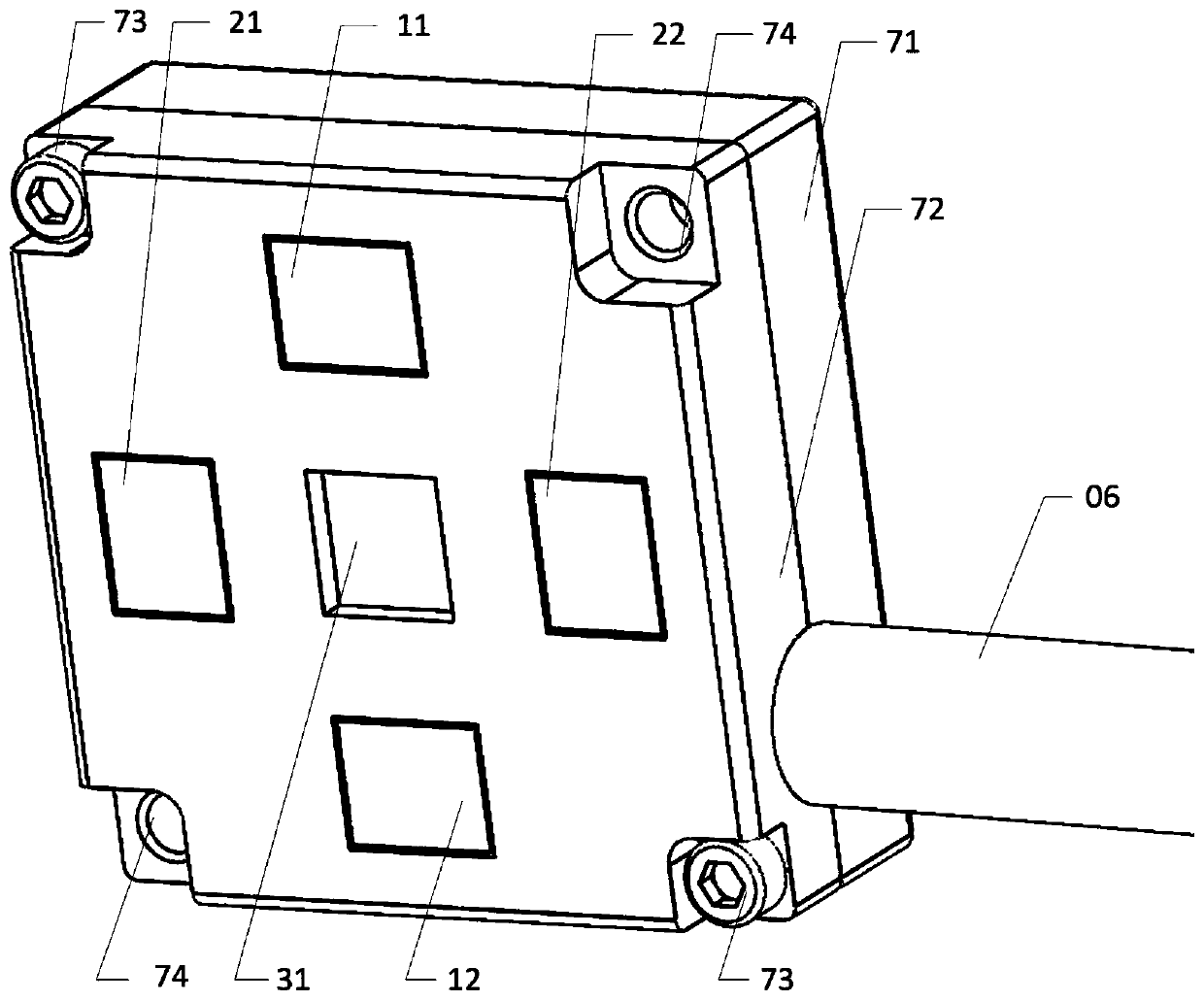

[0031] see Figure 1 to Figure 7 . The present invention proposes a two-dimensional grating-based multi-degree-of-freedom displacement measurement system for measuring the displacement between a fixed part and a moving part. Specifically, the measurement system includes a reading module 01 and a two-dimensional grating 03, wherein the The reading module 01 and the two-dimensional grating 03 are respectively arranged on the fixed part and the moving part, that is, in one embodiment, the reading module 01 is arranged on the moving part, and the two-dimensional grating 03 is arranged on the fixed part , in another embodiment, the reading module 01 is fixedly arranged on the fixed part, and correspondingly, the two-dimensional grating 03 is fixedly arranged on the movable part, and the data calculated by the reading module 01 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com