Patents

Literature

44results about How to "To achieve error compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

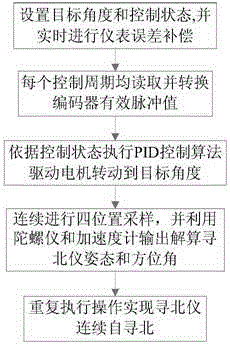

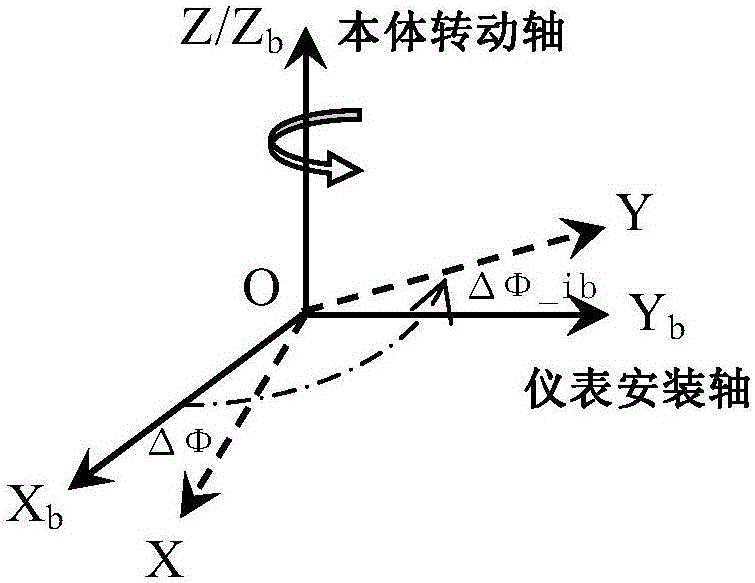

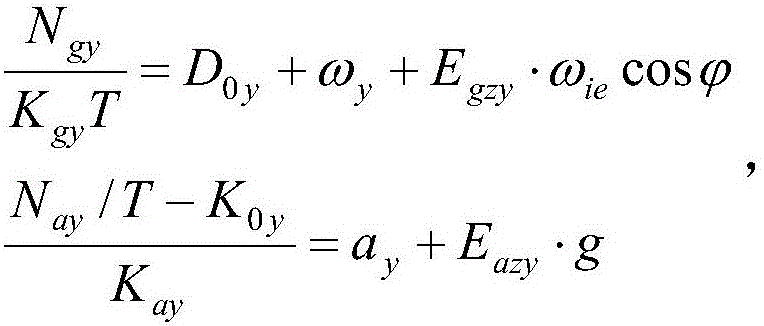

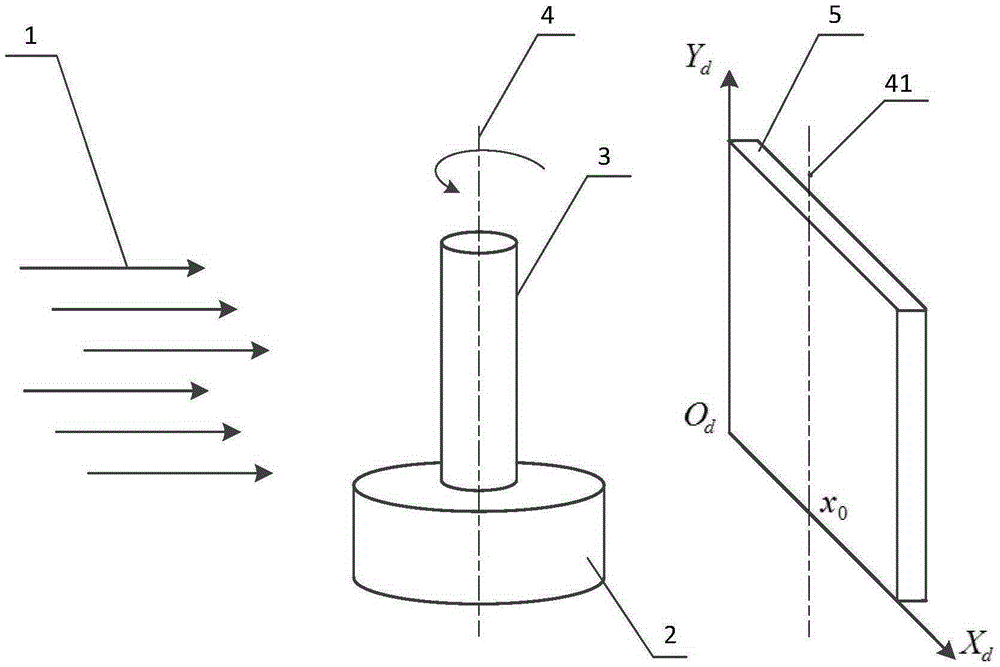

Multi-position automatic north-seeking method for uniaxial laser north seeker

ActiveCN105737812AGuaranteed North Finding AccuracyTo achieve error compensationSagnac effect gyrometersControl flowTime error

The invention discloses a multi-position automatic north-seeking method for a uniaxial laser north seeker. The multi-position automatic north-seeking method comprises the following steps: after receiving a north-seeking instruction, performing real-time error compensation on a gyroscope and an accelerometer; performing motor drive control according to a set target angle, sampling with an instrument after reaching the target angle; using a multi-position sampling result for resolving a attitude and an azimuth angle of the uniaxial laser north seeker; performing motor control and resolving repeatedly to realize the continuous multi-position automatic north-seeking of the north seeker. According to the invention, the automatic north-seeking method is high in reliability, low in hardware cost, reasonable and efficient in control process, can provide omnidirectional attitude and azimuth information for a carrier, and achieves an uninterrupted continuous north-seeking mode.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

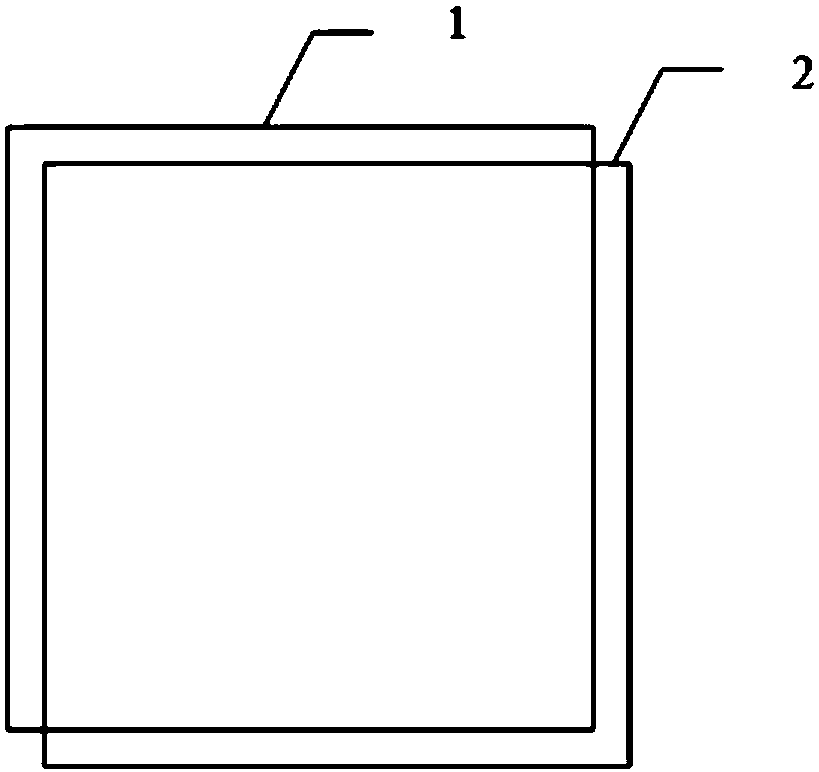

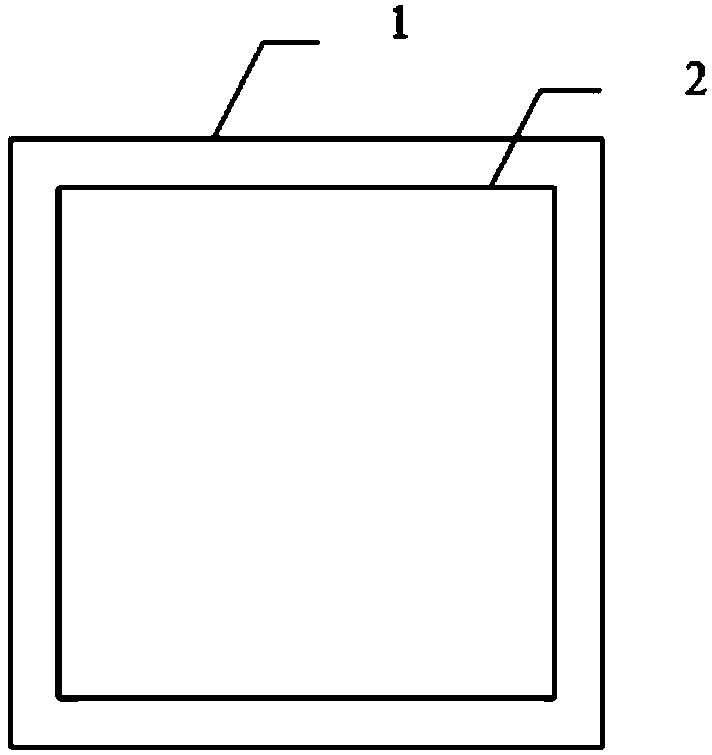

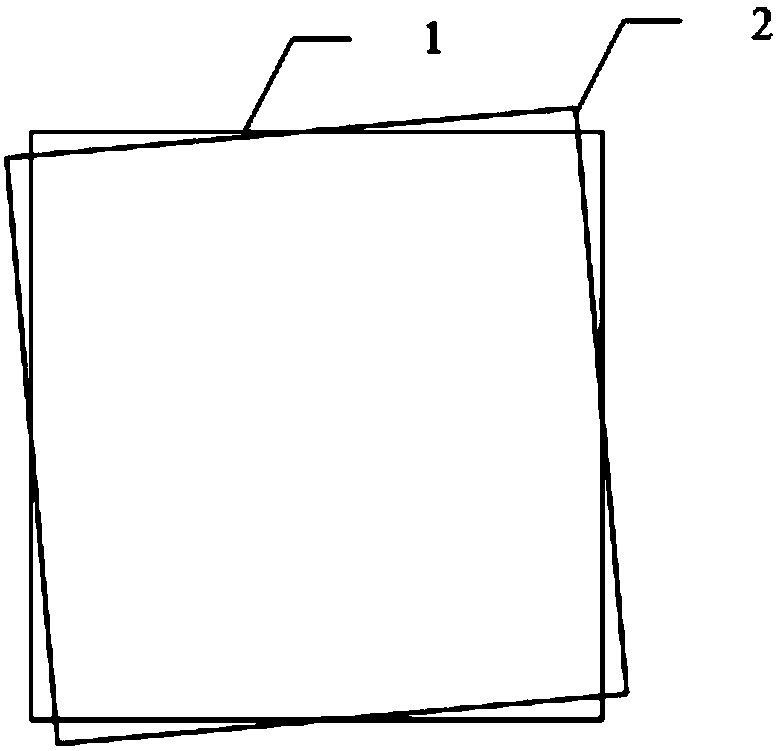

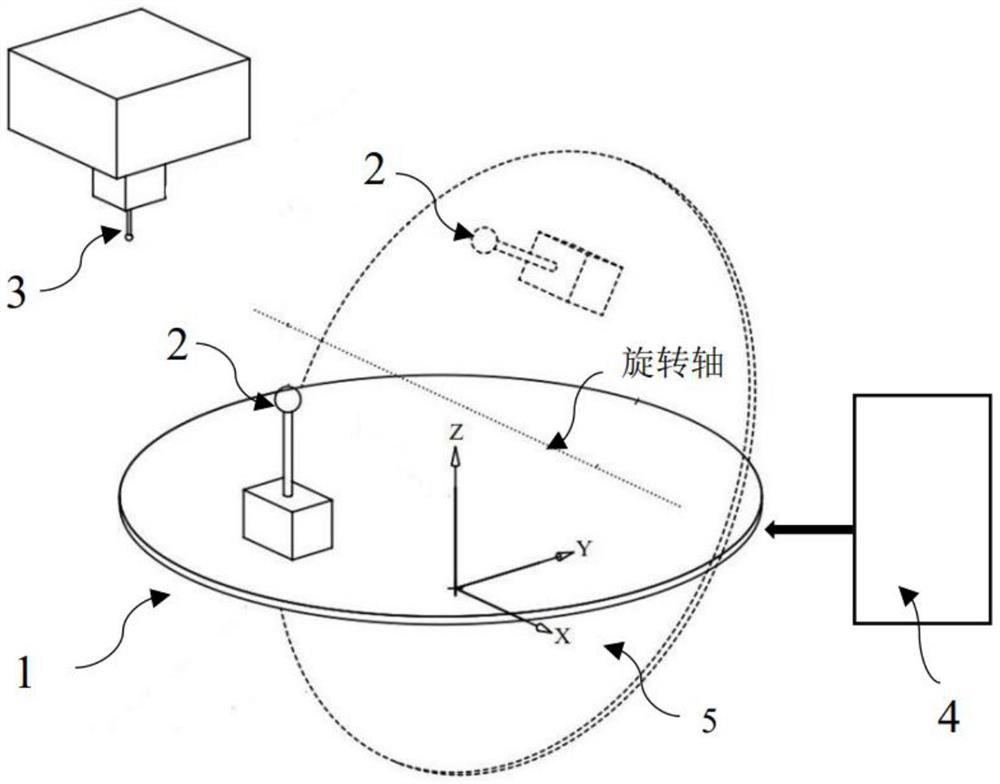

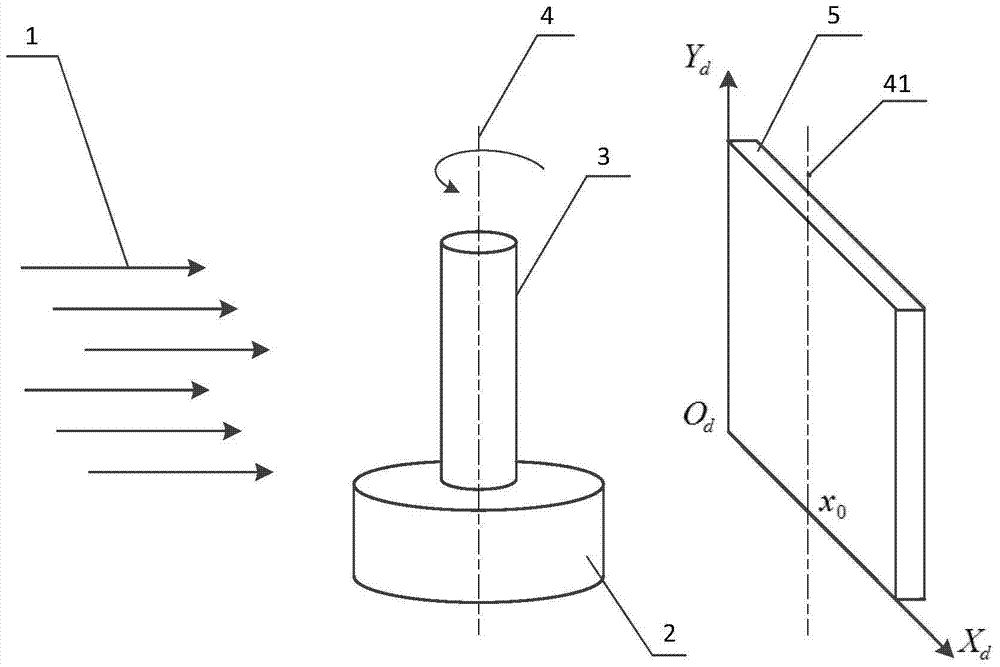

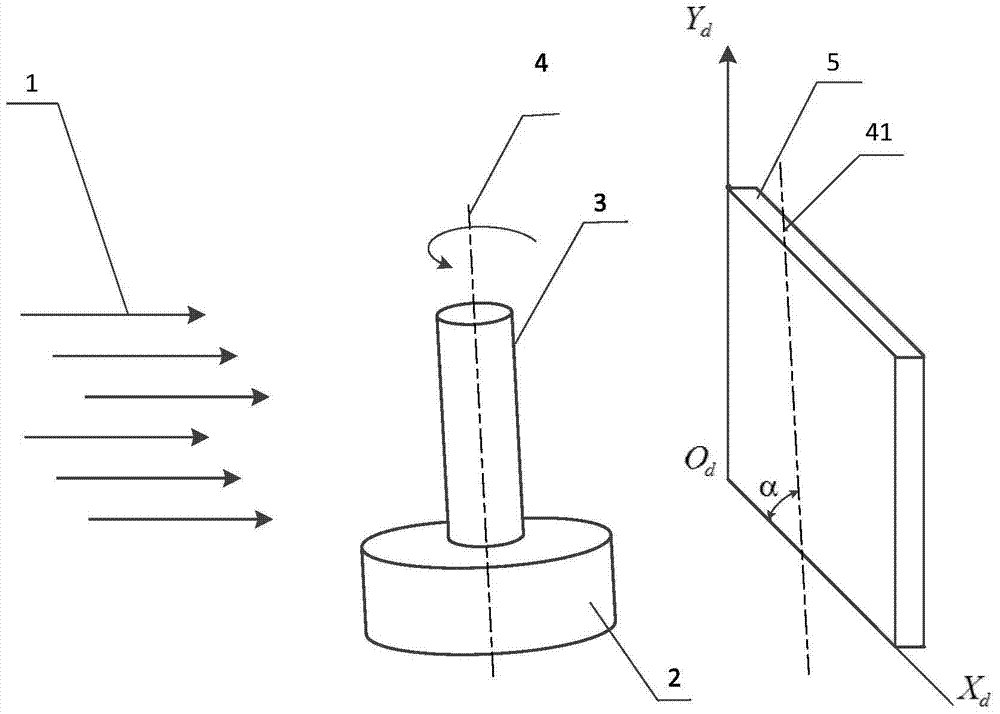

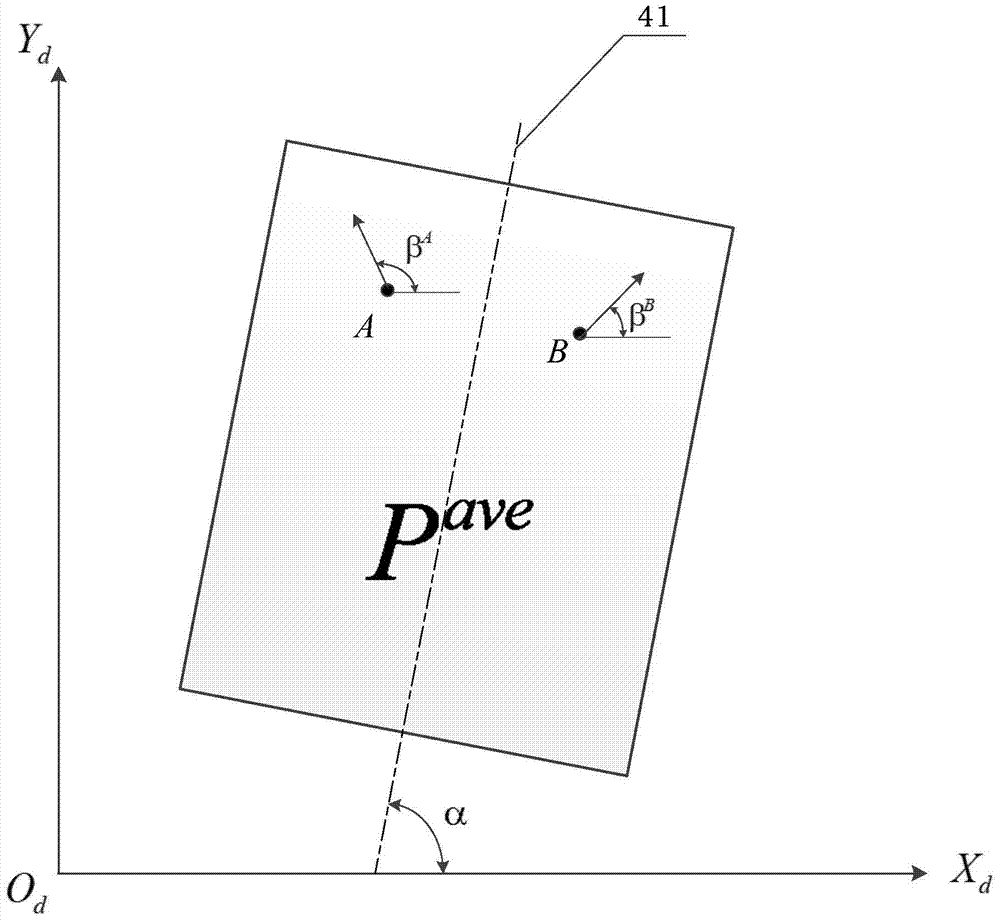

Visual-locating laser marking system correcting method

ActiveCN107486629AHigh precision calibrationMeet the accuracy requirements of visual positioning and markingLaser beam welding apparatusWorkloadVisual positioning

The invention discloses a visual-locating laser marking system correcting method. The method comprises the following steps that a galvanometric scanner is corrected, so that the laser marking effect is not distorted; the marking coordinate scaling multiple and the galvanometric scanner deflection angle are adjusted, and therefore image display can be obtained, wherein a marking object serves as a reference, and the image display is completely consistent with the marking object; a to-be-corrected marking region is determined on the marking object, the position of the marking object is compared with that of the image display, a clipping starting point of a to-be-corrected display region is determined, the position of the to-be-corrected display region is adjusted to enable the position of the to-be-corrected marking region to be completely consistent with that of the to-be-corrected display region, and therefore integrated display of the clipped to-be-corrected display region and the clipped to-be-corrected marking region is achieved finally. According to the visual-locating laser marking system correcting method, the defects that in the prior art, the correction manner is low in accuracy, and the personnel workload is large are overcome, and the marking object and image display integrated display manner is adopted, so that high-accuracy correction of a marking system and an image system is achieved, and the visual-locating marking accuracy requirements of all the current industries can be met.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

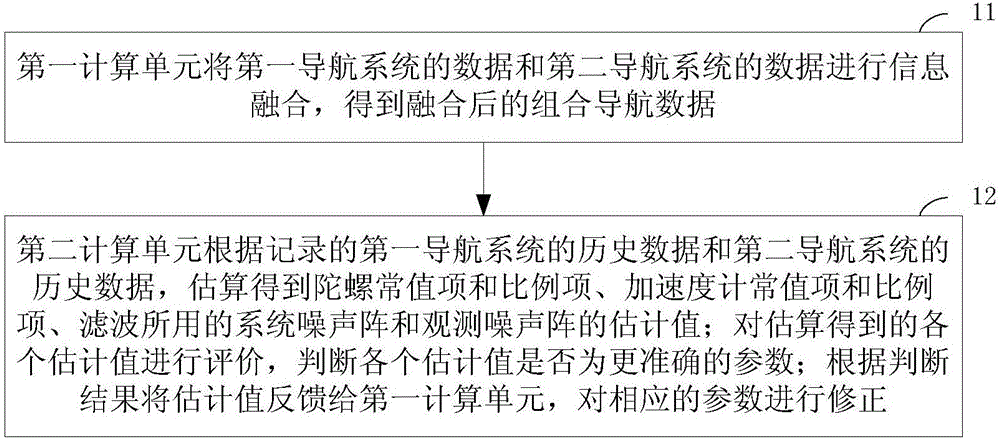

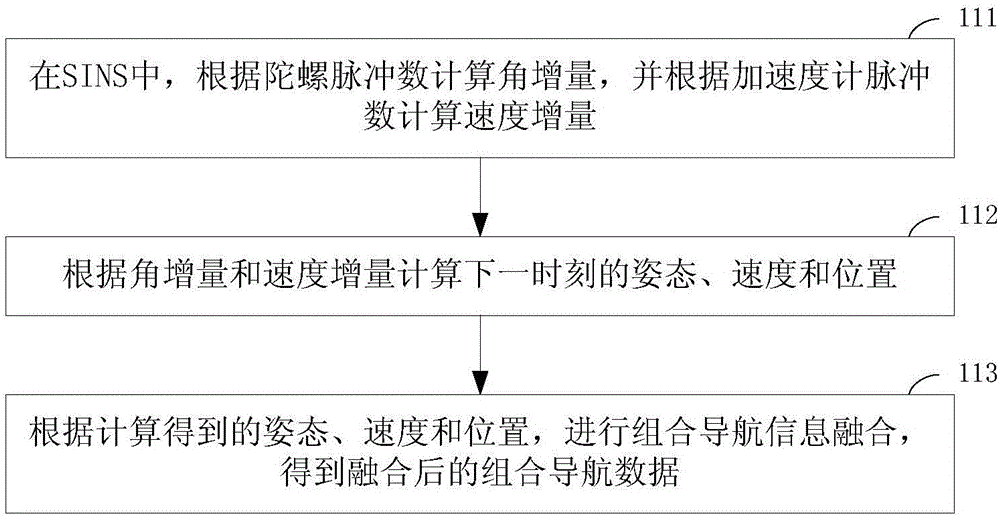

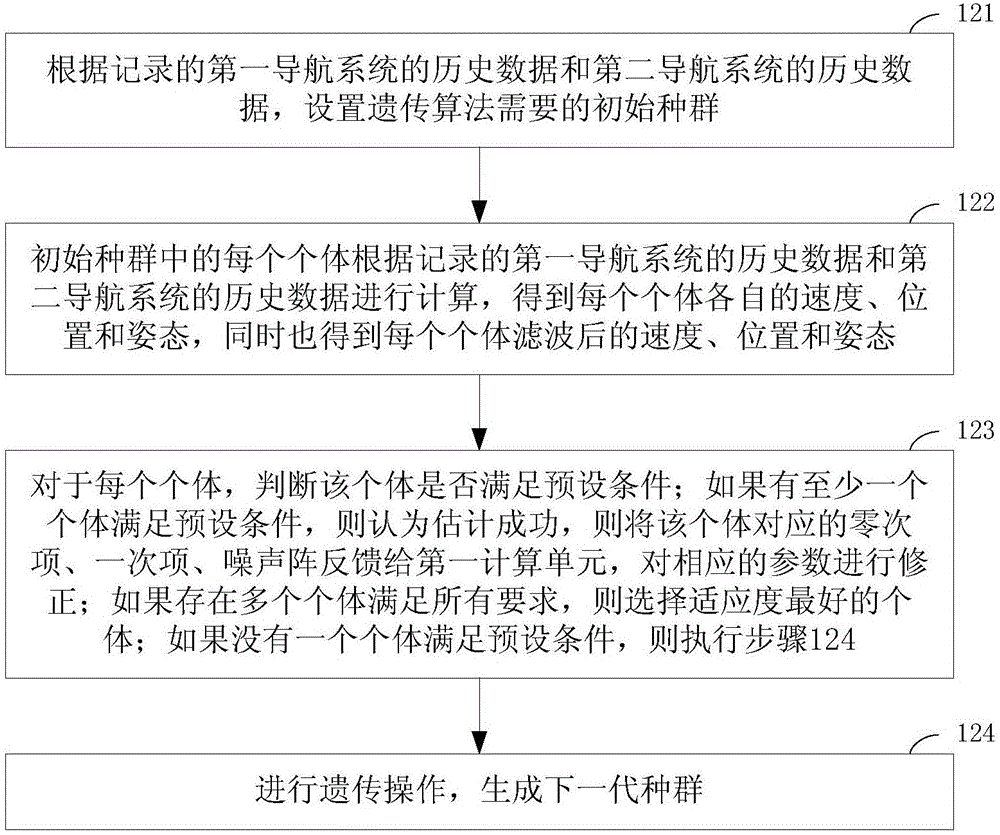

Integrated navigation method and system

InactiveCN106767788ATo achieve error compensationImplement optimized settingsNavigation by speed/acceleration measurementsSatellite radio beaconingAccelerometerNavigation system

The invention discloses an integrated navigation method and system. The method comprises the steps of allowing a first calculation unit to perform information fusion on data of a first navigation system and data of a second navigation system to form fused integrated navigation data, B, allowing a second calculation unit to estimate estimated values of constant terms and proportionals of a gyro and an accelerometer as well as a system noise array and an observation noise array for filtration according to recorded history data of the first navigation system and history data of the second navigation system, evaluating the estimated values, determining if the estimated values are more accurate parameters, and feeding the estimated values back to the first calculation unit to correct the corresponding parameters according to a determination result. With the adoption of the integrated navigation method and the system, the navigation accuracy and reliability can be improved.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

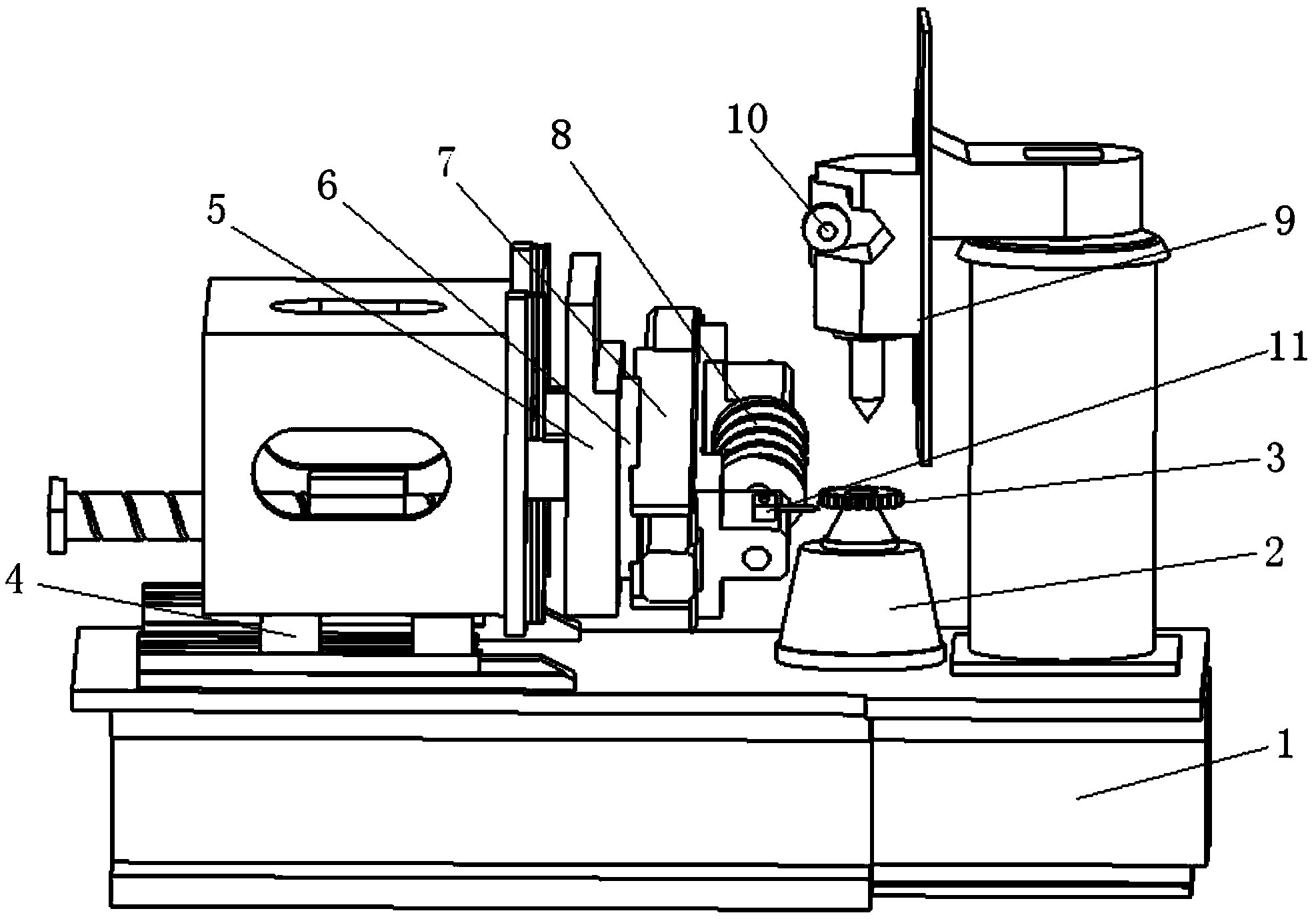

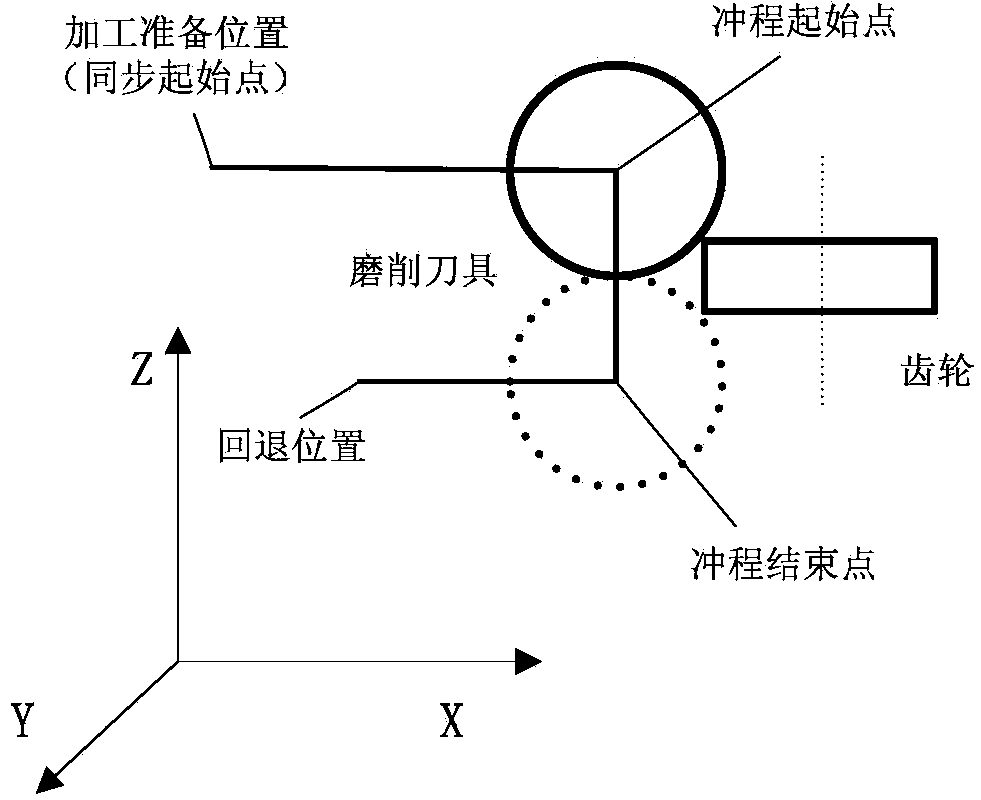

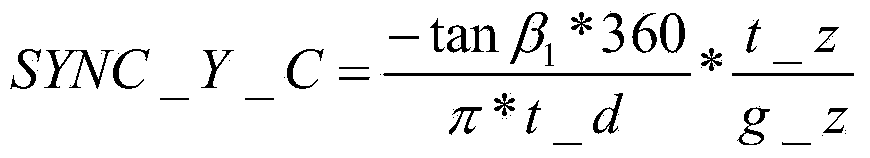

Synchronizing shaft error compensation method of numerical control gear manufacturing machine tool

ActiveCN103817380AImprove machining accuracyTo achieve error compensationGear-cutting machinesGear teethNumerical controlDrive shaft

The invention discloses a synchronizing shaft error compensation method of a numerical control gear manufacturing machine tool. A virtual shaft which is additionally arranged in an electronic gearbox of the numerical control gear manufacturing machine tool is taken as a driving shaft, and coincides with a following shaft in synchronizing shafts; the error compensation amount of each shaft in the synchronizing shafts is converted into an equivalent compensation amount of the virtual shaft by the corresponding synchronization coefficients; the total equivalent compensation amount of the synchronizing shafts is obtained by linear superposition, and finally, the error compensation of the synchronizing shafts is realized by utilizing the theoretical motion of the virtual shaft. According to the method, after the error of each shaft is obtained, the compensation to a single shaft is not needed, the hardware and system parameters of the machine tool are not changed, and the precision needed by the engagement motion of the gear manufacturing can be ensured by only arranging one virtual shaft in the electronic gearbox for compensation; the method is good in flexibility and adaptation, strong in expansion and high in compensation precision, and the composition error at any point in the coordinate system of the machine tool can be compensated; especially, when the dynamic error compensation of the machine tool is carried out, the real-time exchange data amount is small, and the response speed is rapid.

Owner:CHONGQING UNIV

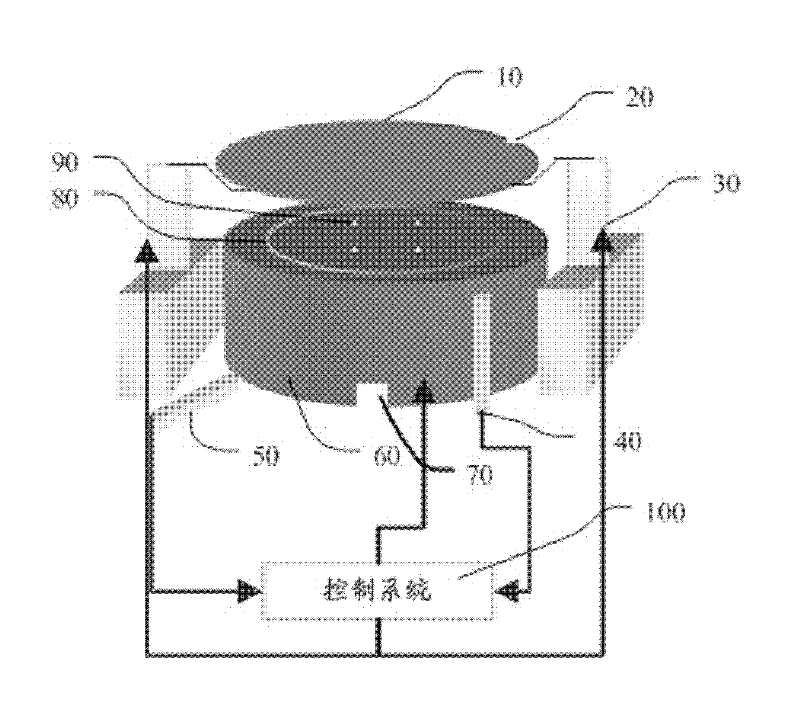

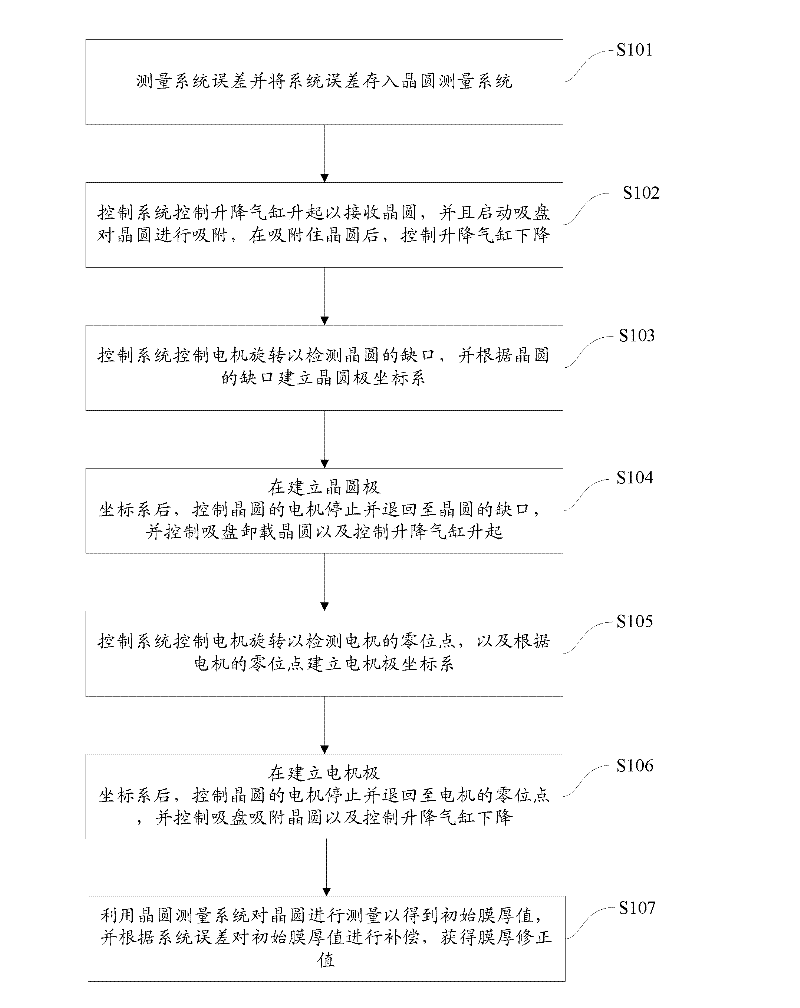

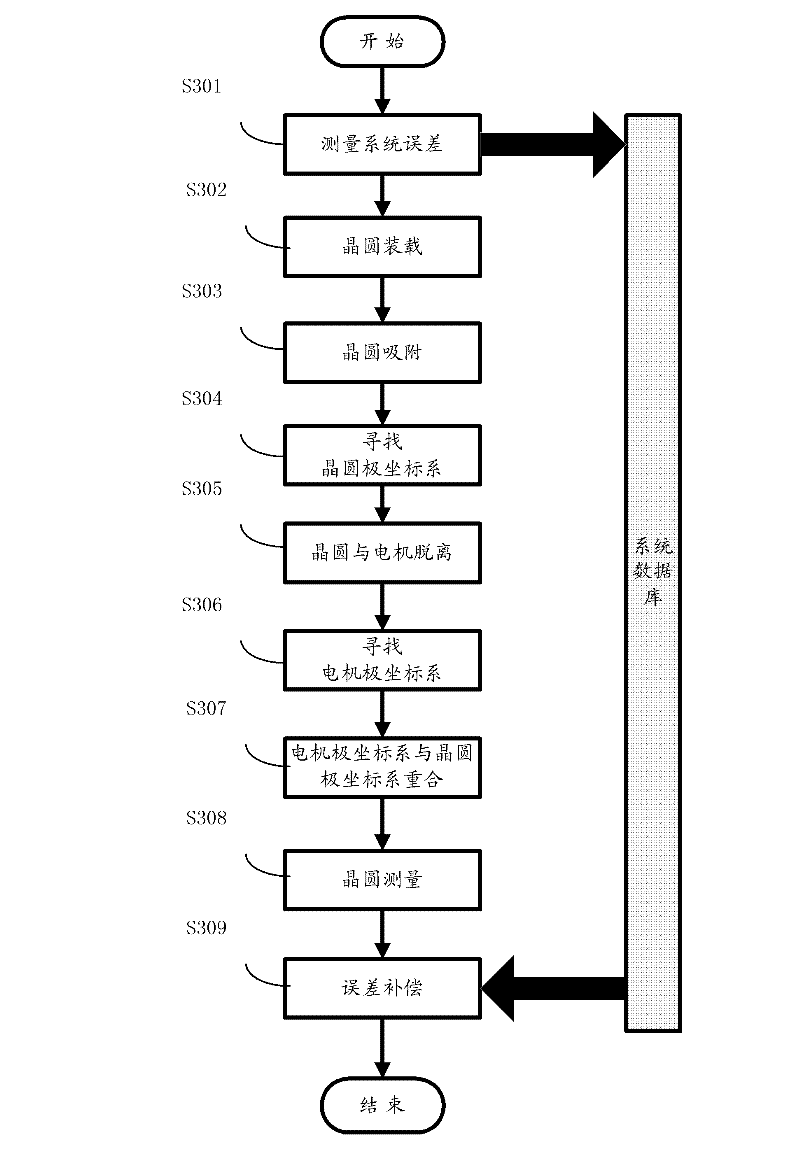

Error compensation method for measuring film thickness of wafer of wafer stage

ActiveCN102564378ALow communication requirementsAccurate film thickness valueMeasurement devicesSystem errorCompensation methods

The invention provides an error compensation method for measuring film thickness of a wafer of a wafer stage. The error compensation method comprises the following steps of: measuring system errors; controlling a lifting cylinder to lift so as to receive the wafer, and starting a sucker to suck the wafer; controlling the lifting cylinder to lower; controlling a motor to rotate so as to detect the notch of the wafer, and establishing a wafer polar coordinate system according to the notch of the wafer; controlling the motor to stop after establishing the wafer polar coordinate system, returning to the notch of the wafer, controlling the sucker to unload the wafer, and controlling the lifting cylinder to lift; controlling the motor to rotate so as to detect a zero site of the motor, and establishing a motor polar coordinate system according to the zero site of the motor; controlling the motor to stop, returning to the zero site of the motor, controlling the sucker to suck the wafer and controlling the lifting cylinder to lower; and measuring the wafer by means of a wafer measuring system so as to acquire an initial film thickness value, and compensating the initial film thickness value according to the system errors. According to the error compensation method, the errors of the measured film thickness of the wafer can be compensated, and more accurate film thickness of the wafer can be acquired.

Owner:TSINGHUA UNIV

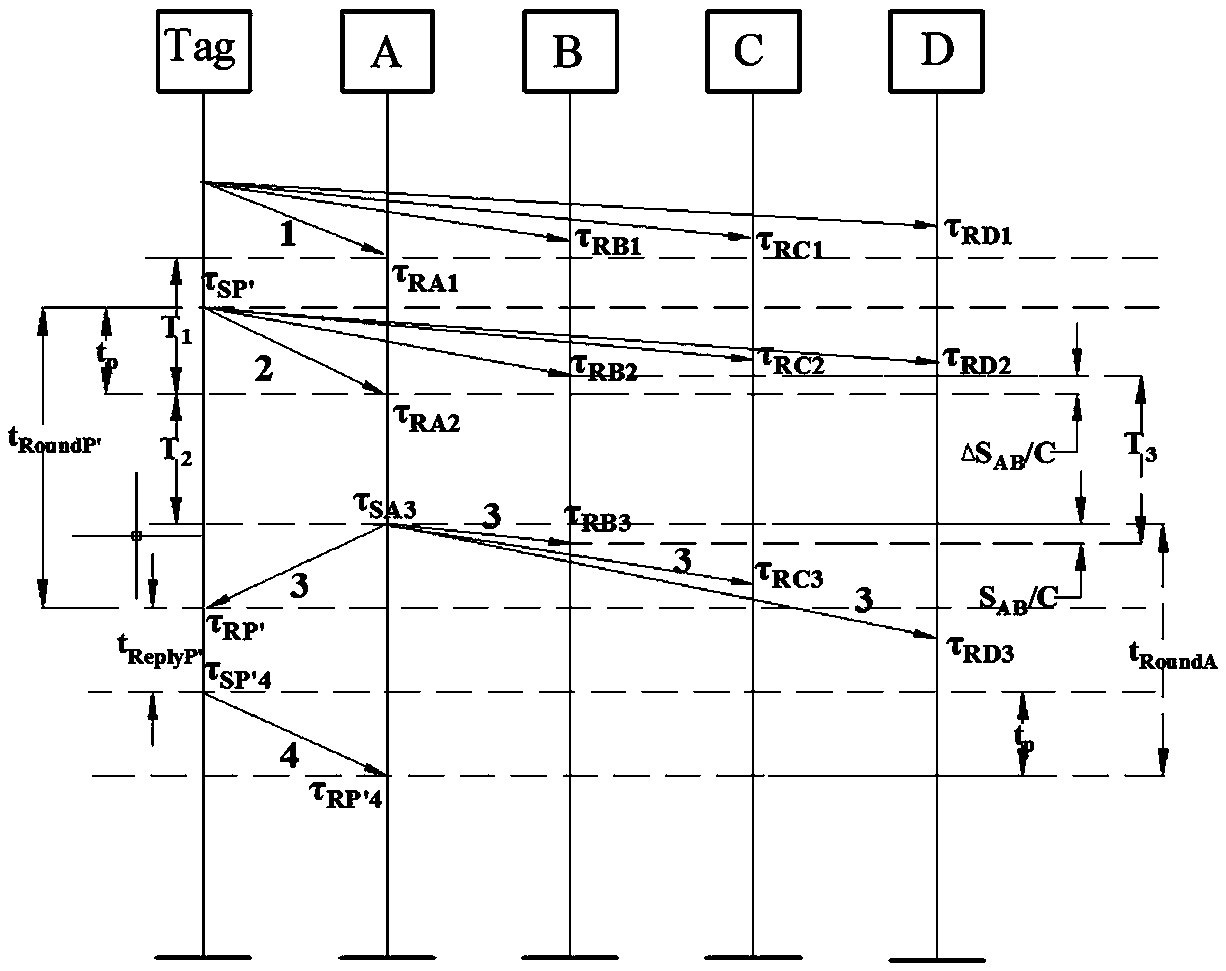

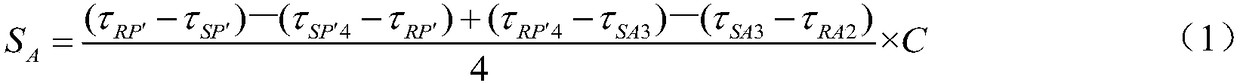

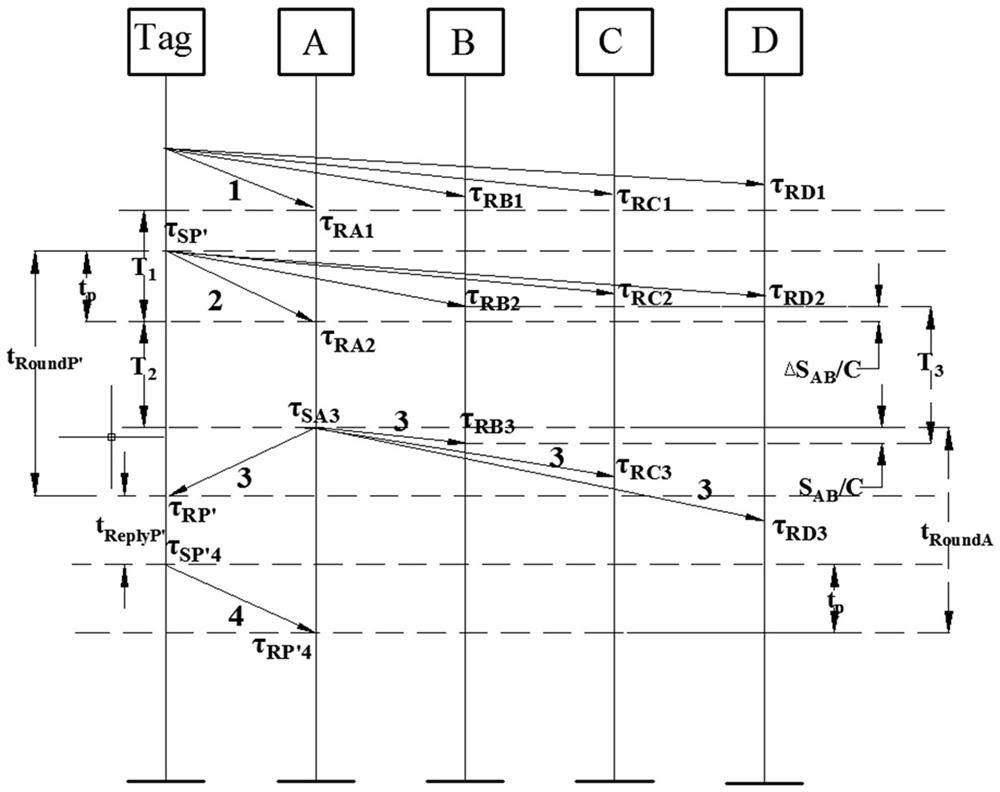

Improved bidirectional bilateral range-finding method

ActiveCN108828567AHigh positioning accuracyReduce power consumptionPosition fixationUsing reradiationComputer scienceReal-time computing

The invention provides an improved bidirectional bilateral range-finding method. According to the method, a moving node continuously transmits signals to all fixed reference nodes twice, wherein one of the fixed reference nodes is a main fixed reference node, and the other fixed reference nodes are slave fixed reference nodes. The moving node transmits timing signals twice, and the main fixed reference node transmits a timing response signal once, thereby completing the measurement of the distance difference between the moving node and the main and slave fixed reference nodes. Meanwhile, the second timing signal transmitted by the moving node and the timing response signal transmitted by the main fixed reference node serve as the former two signals in the bidirectional bilateral range-finding. According to the invention, the method is high in positioning precision. Meanwhile, the method can achieve the measurement of a plurality of distance differences through two timing signals transmitted by the moving node, so the method can achieve the measurement of the distances from the moving node to all fixed reference nodes through one operation. The method is lower in power consumption,and solves a problem that multiple bidirectional bilateral range-finding consumes a lot of time.

Owner:HEBEI UNIVERSITY

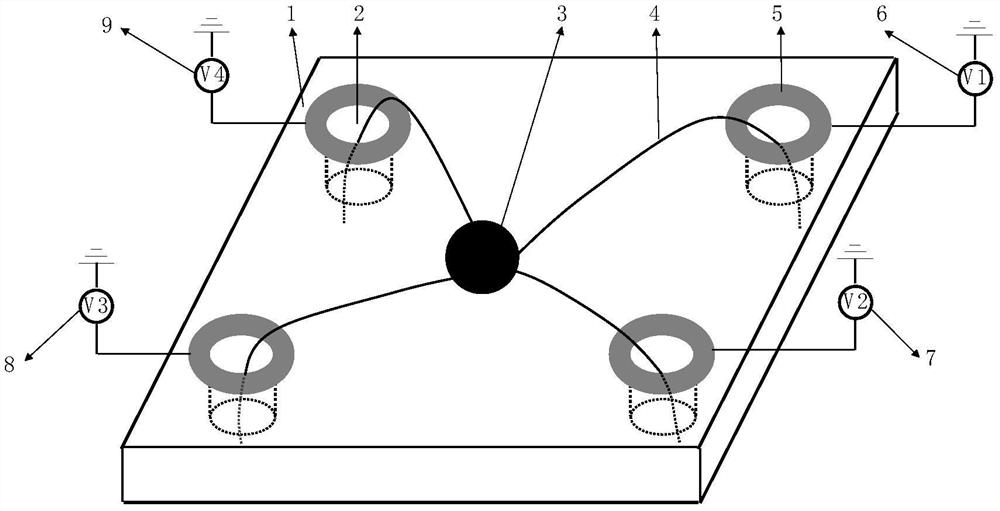

Three freedom degree position and pose regulating and error compensating apparatus

InactiveCN101387889AGuaranteed independenceAchieve independencePosition/direction controlThree degrees of freedomEngineering

Owner:SHANGHAI JIAO TONG UNIV

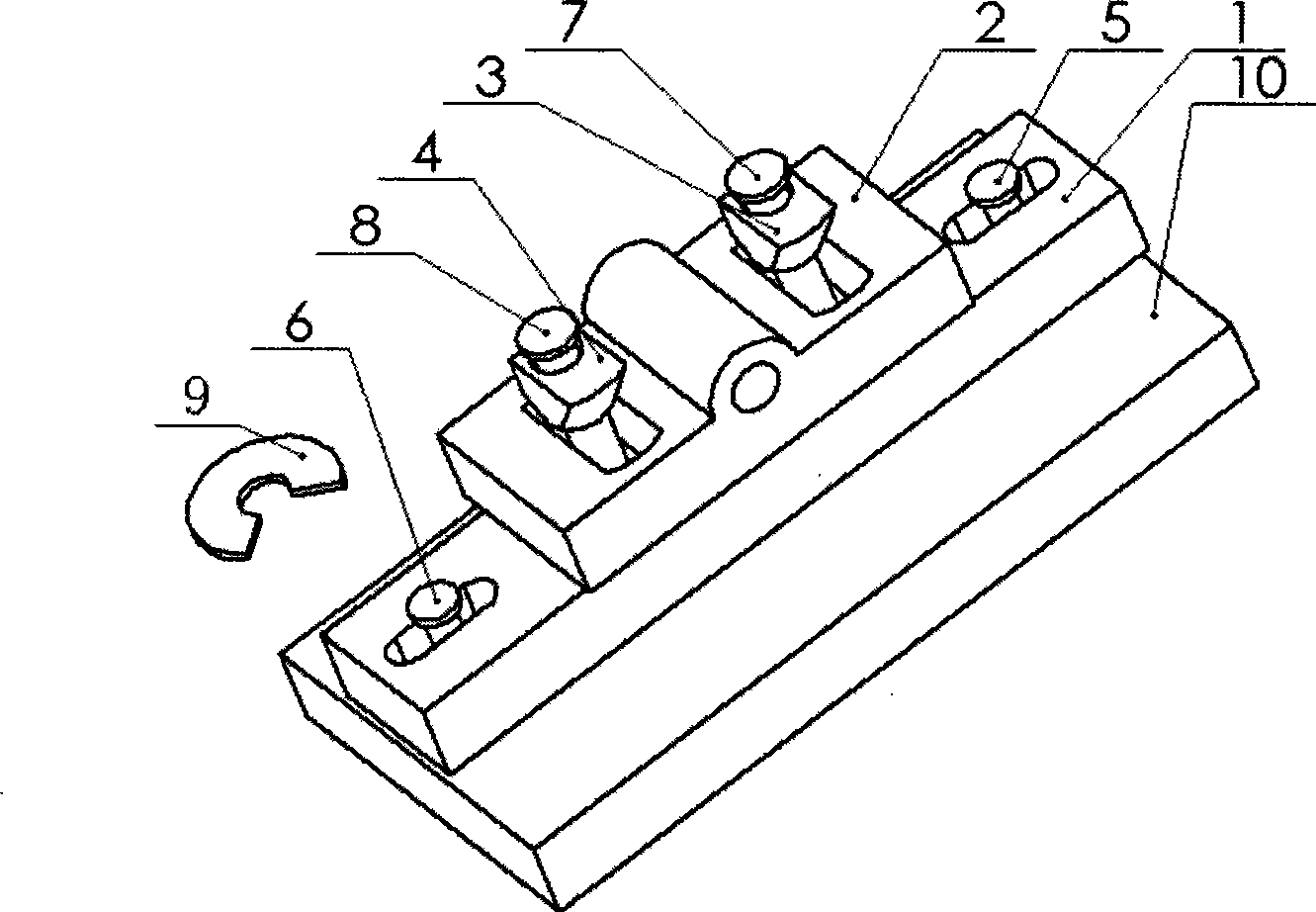

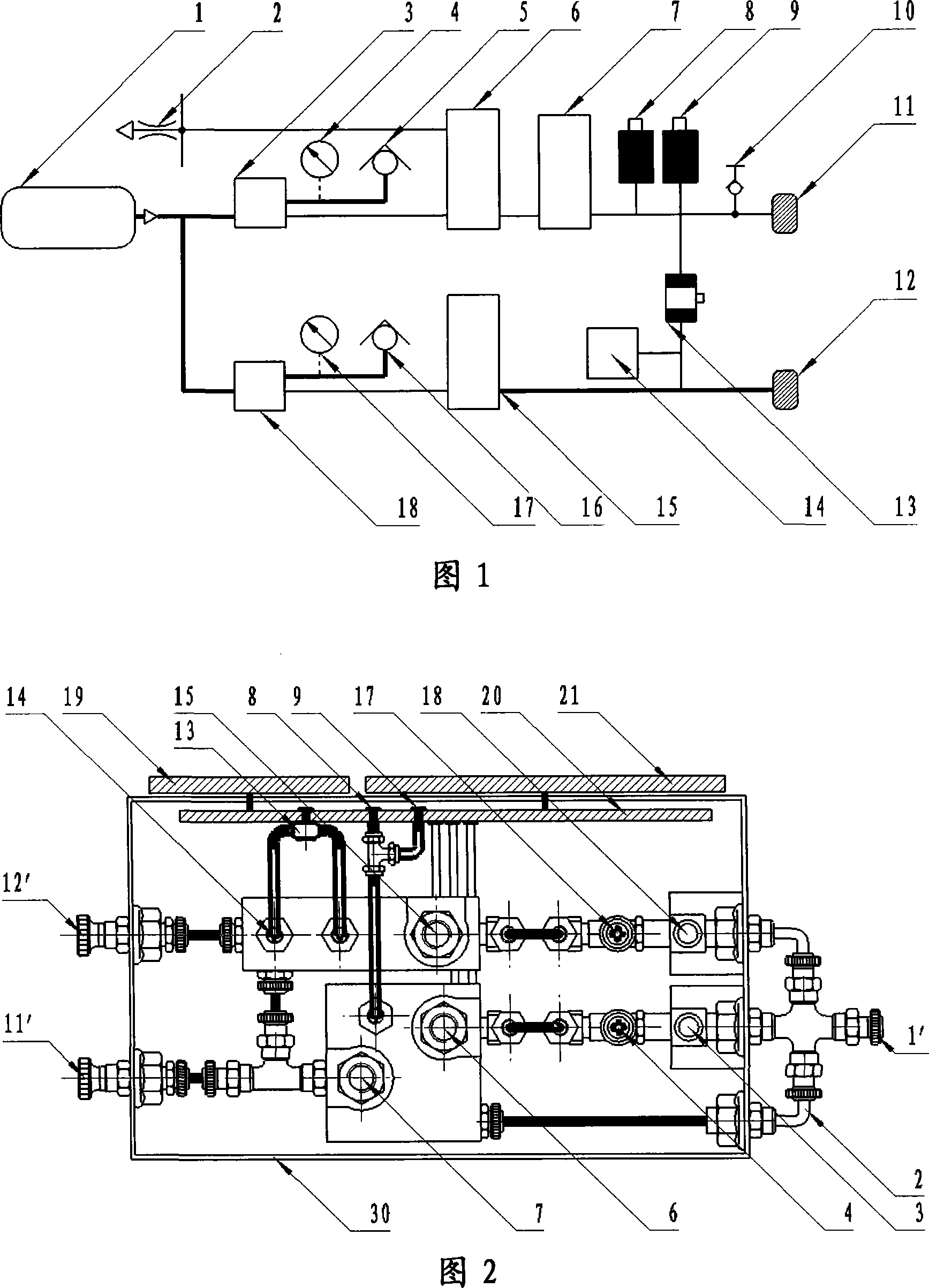

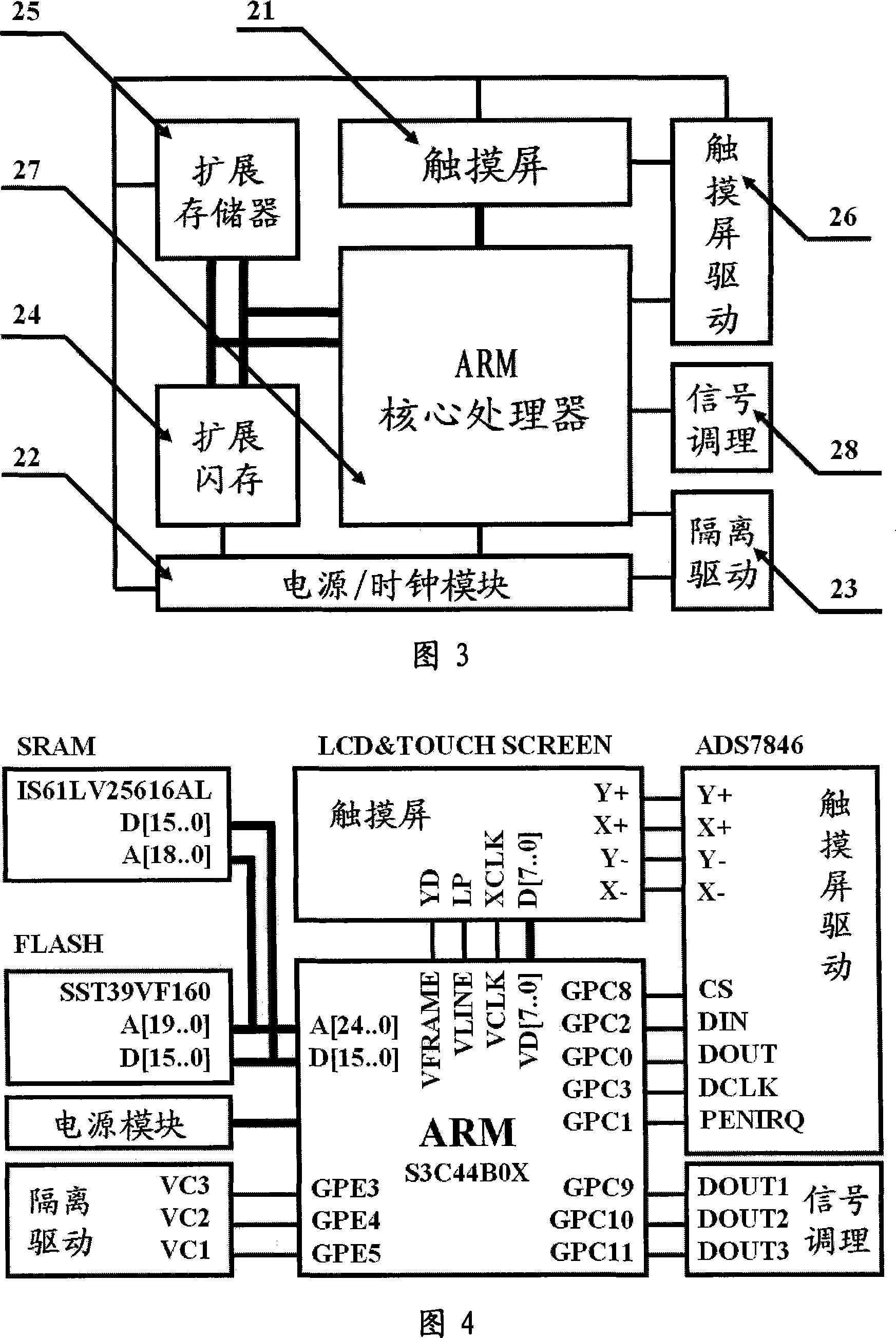

Embedded leakage detector

InactiveCN101236124ALow costEasy to operateMeasurement of fluid loss/gain rateElectromagnetic valvePressure sensor

The invention relates to a flush type leakage detector which comprises an air supply joint, a detecting member joint and a reference member joint. A direct method pneumatic control circuit from the air supply joint to the detecting member joint and a differential pressure method pneumatic control circuit from the air supply joint to the reference member joint are provided. An electromagnetic valve, a pressure sensor, a temperature sensor, a differential pressure sensor and a pressure switch are arranged on the two circuits and are connected to a core control panel to form a control system and a data acquisition and processing system. Through the pressure switch which controls the differential pressure method pneumatic control circuit to be conducted and closed, the flush type leakage detector can conveniently change and select the two detection methods with different detection principles. Furthermore, the flush type leakage detector can also remove the impact of temperature changes on detection results during the leakage detection.

Owner:SHANGHAI UNIV

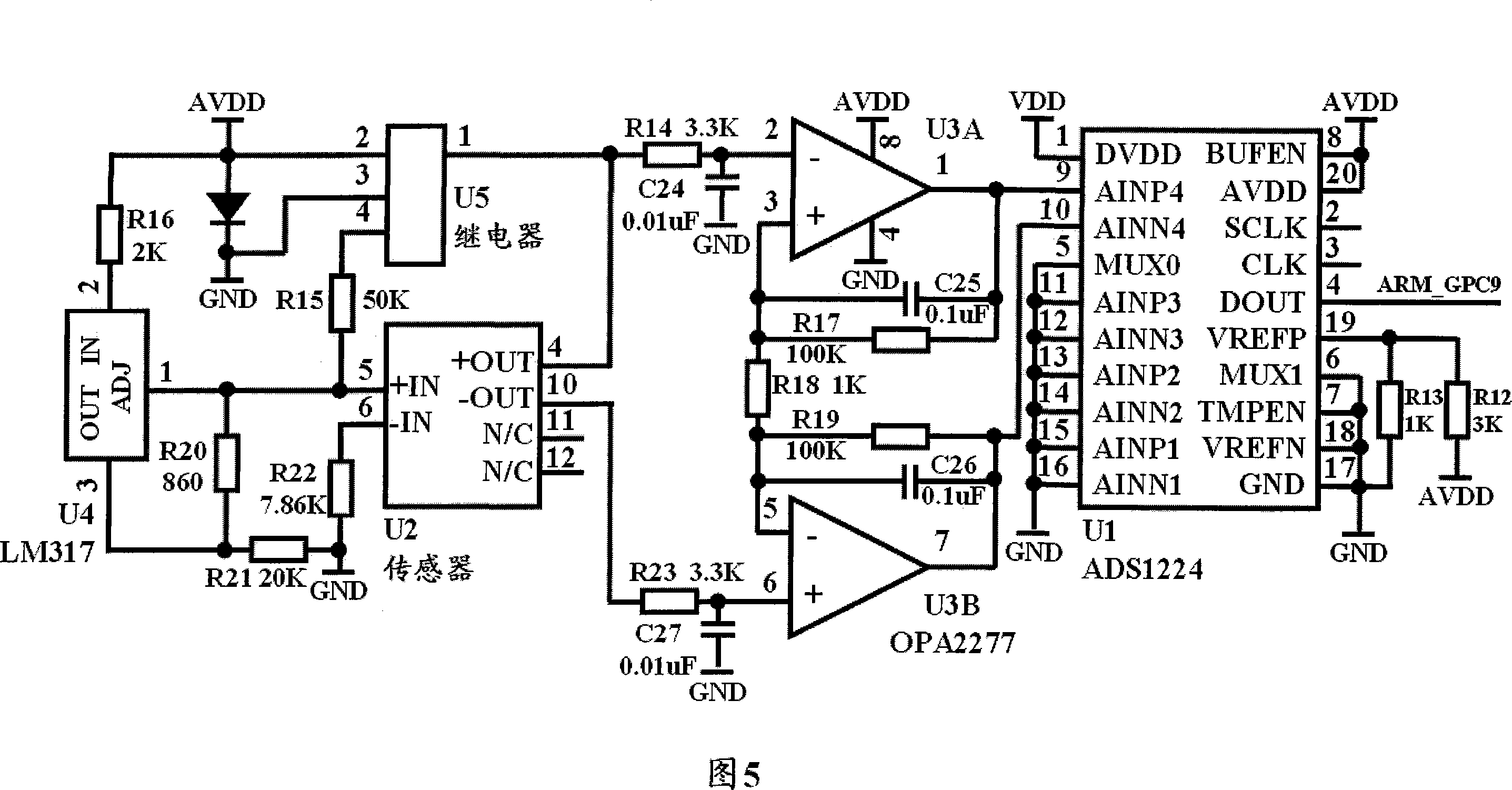

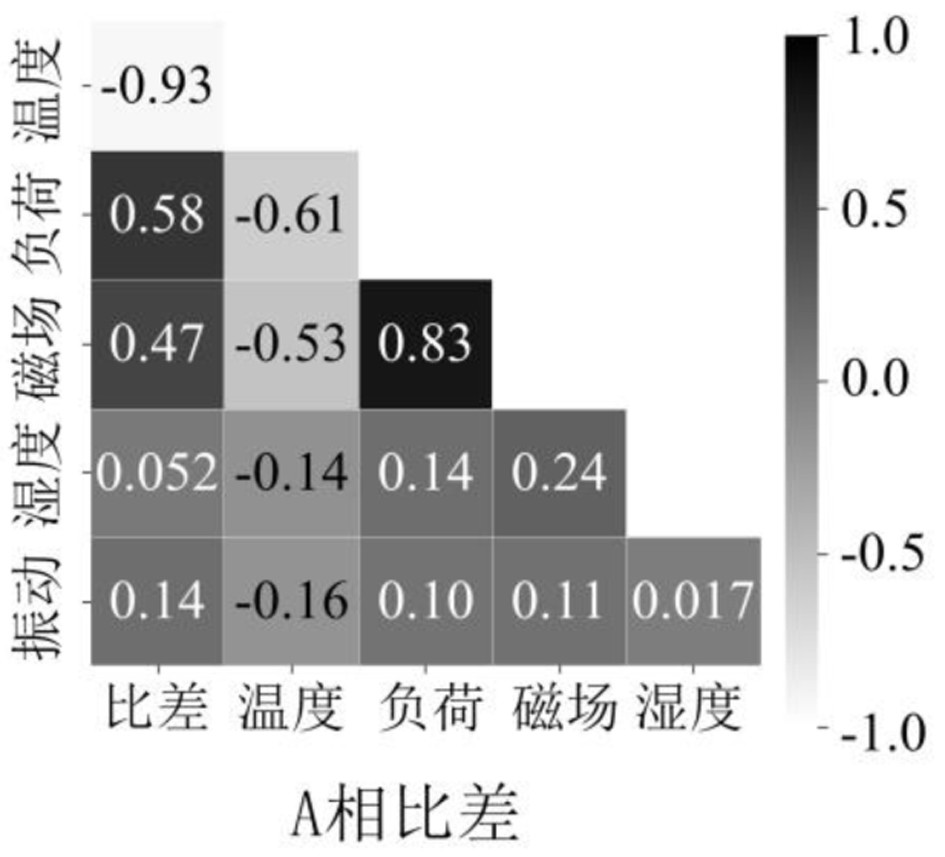

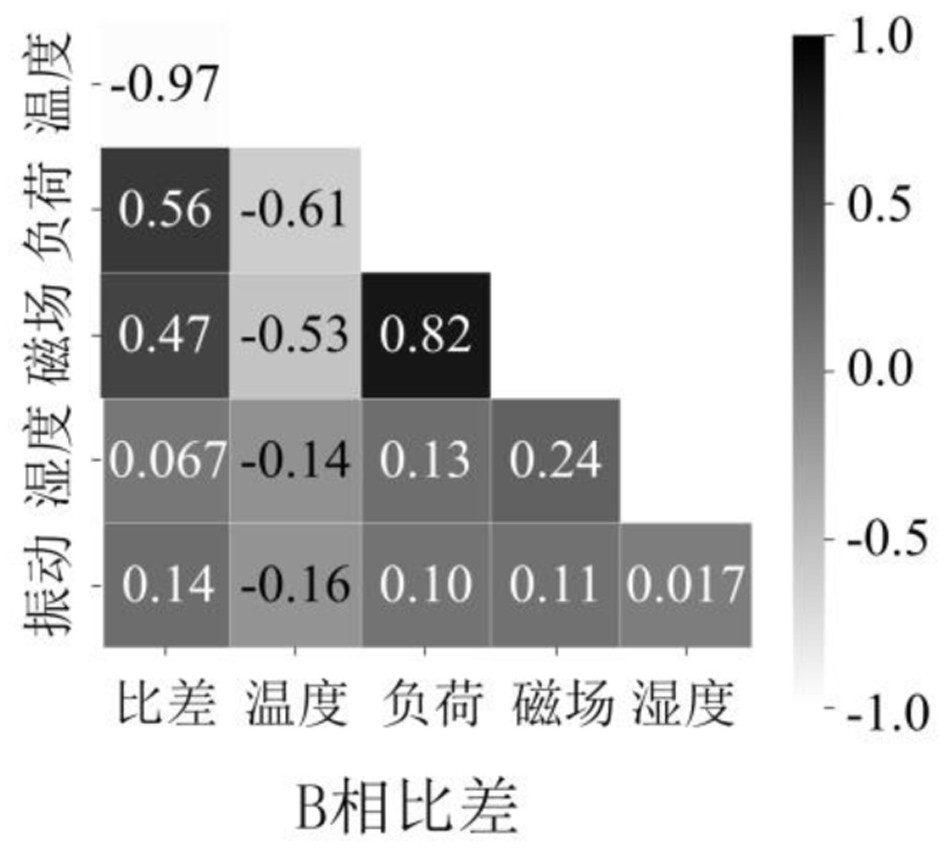

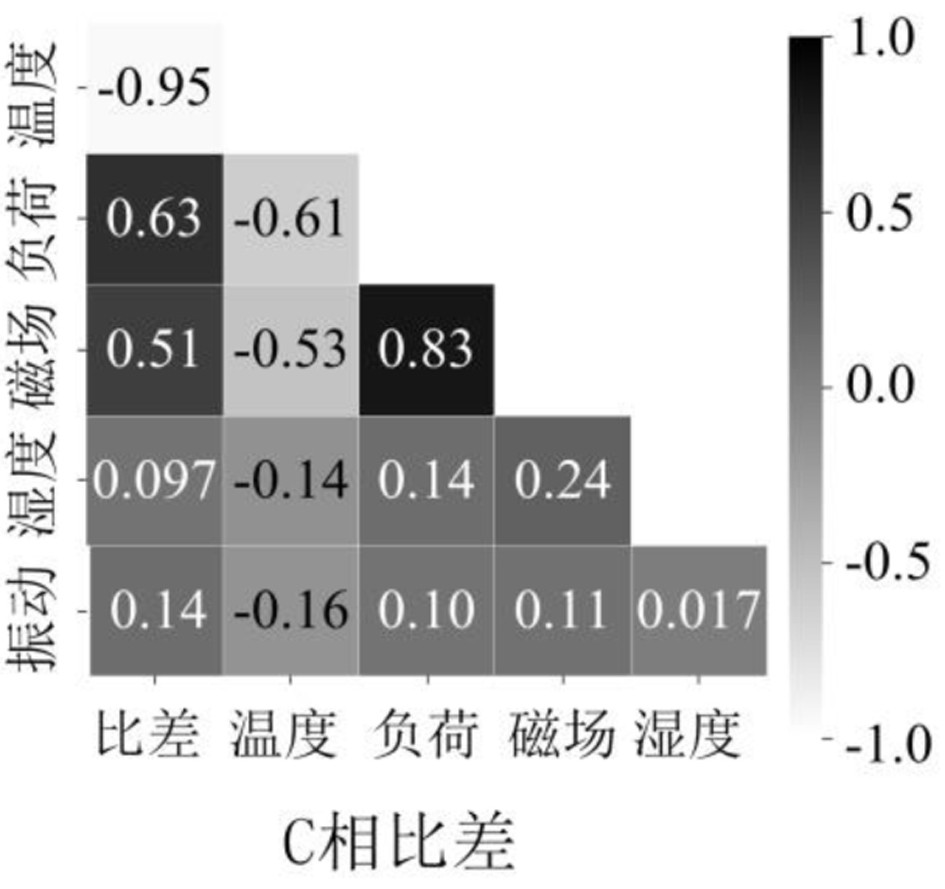

Hollow coil current transformer error compensation method based on elastic network

ActiveCN112014785ATo achieve error compensationLow costElectrical measurementsPolyphase network asymmetry reductionControl theoryInstrument transformer

The invention provides a hollow coil current transformer error compensation method based on an elastic network. The method comprises the steps that of collecting the influence quantity influencing three-phase error compensation of a hollow coil current transformer, wherein the influence quantity comprises environmental parameters and electrical parameters; collecting an error compensation quantity; normalizing the influence quantity and the error compensation quantity, calculating Pearson correlation coefficients of the influence quantity and the error compensation quantity, and performing feature selection on the main influence quantity by using a factor screening method based on an elastic network algorithm; taking dominant influence quantity of the hollow coil current transformer as aninput quantity, using an elastic network algorithm based on cross validation to carry out modeling prediction on error compensation, calculating a difference value between an actual compensation valueand a prediction compensation value, and taking an average absolute error and a root-mean-square error as prediction evaluation. According to the method, the error compensation trend of the hollow coil current transformer can be effectively predicted, and the measurement precision of the hollow coil current transformer can be effectively improved.

Owner:CHINA THREE GORGES UNIV

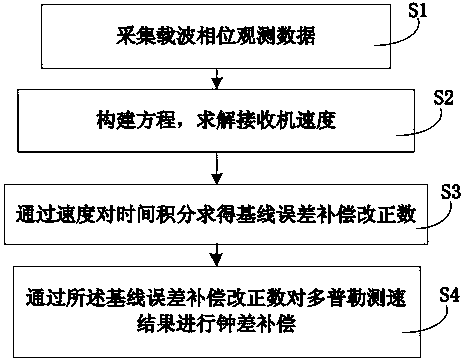

Clock difference compensation method and system based on receiver in Beidou dynamic positioning

InactiveCN110749907ATo achieve error compensationHigh precisionSatellite radio beaconingCarrier signalDynamic positioning

The invention provides a clock difference compensation method based on a receiver in Beidou dynamic positioning. The clock difference compensation method includes the steps that step S1, carrier phaseobservation data are collected, differential filtering is carried out on a carrier phase observation value, and a phase change rate of a carrier is calculated as a Doppler observation value at the time; step S2, an equation is constructed through the Doppler observation value and a geometric position relationship between a satellite and the receiver to solve the receiver speed; step S3, the real-time displacement is solved by the receiver speed, and a baseline error compensation correction number is calculated by integrating of the speed on the time; and step S4, a Doppler speed measurement result is subjected to clock difference compensation through the baseline error compensation correction number to obtain a baseline solution result after compensation. The clock difference is compensated by using the BDS Doppler speed measurement result so as to obtain a more accurate baseline solution result, so that application requirements such as highly dynamic and multi-complex mobile formations are met.

Owner:深圳微品致远信息科技有限公司

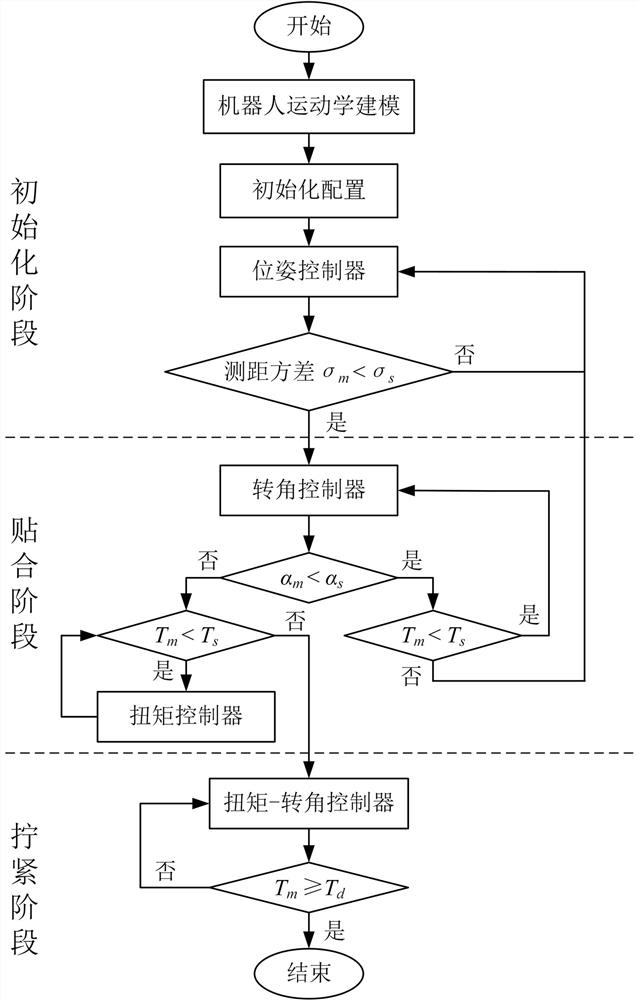

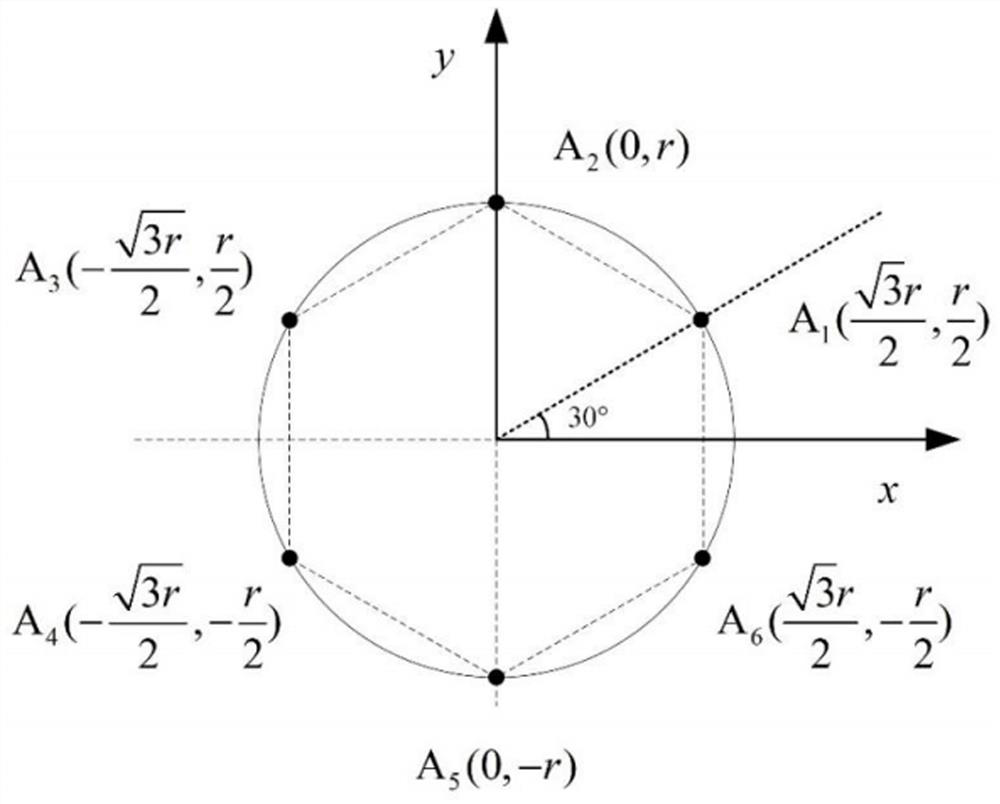

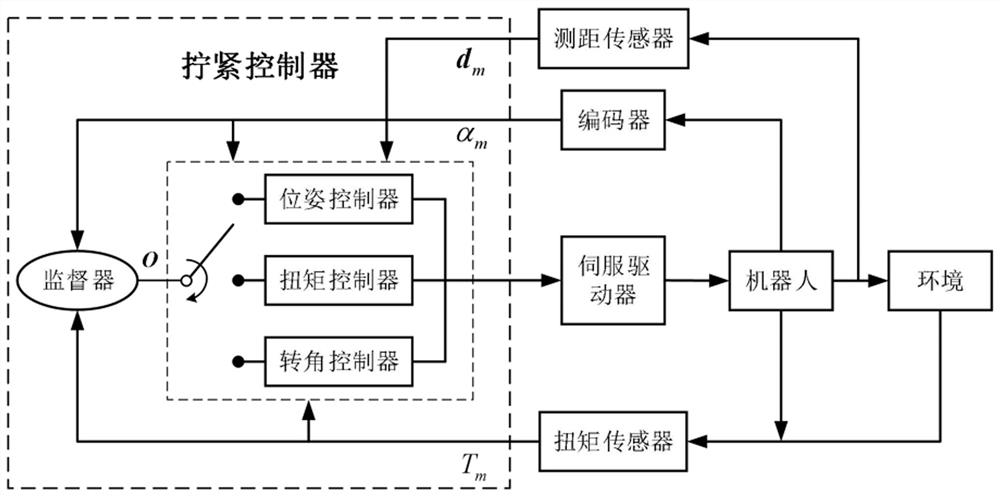

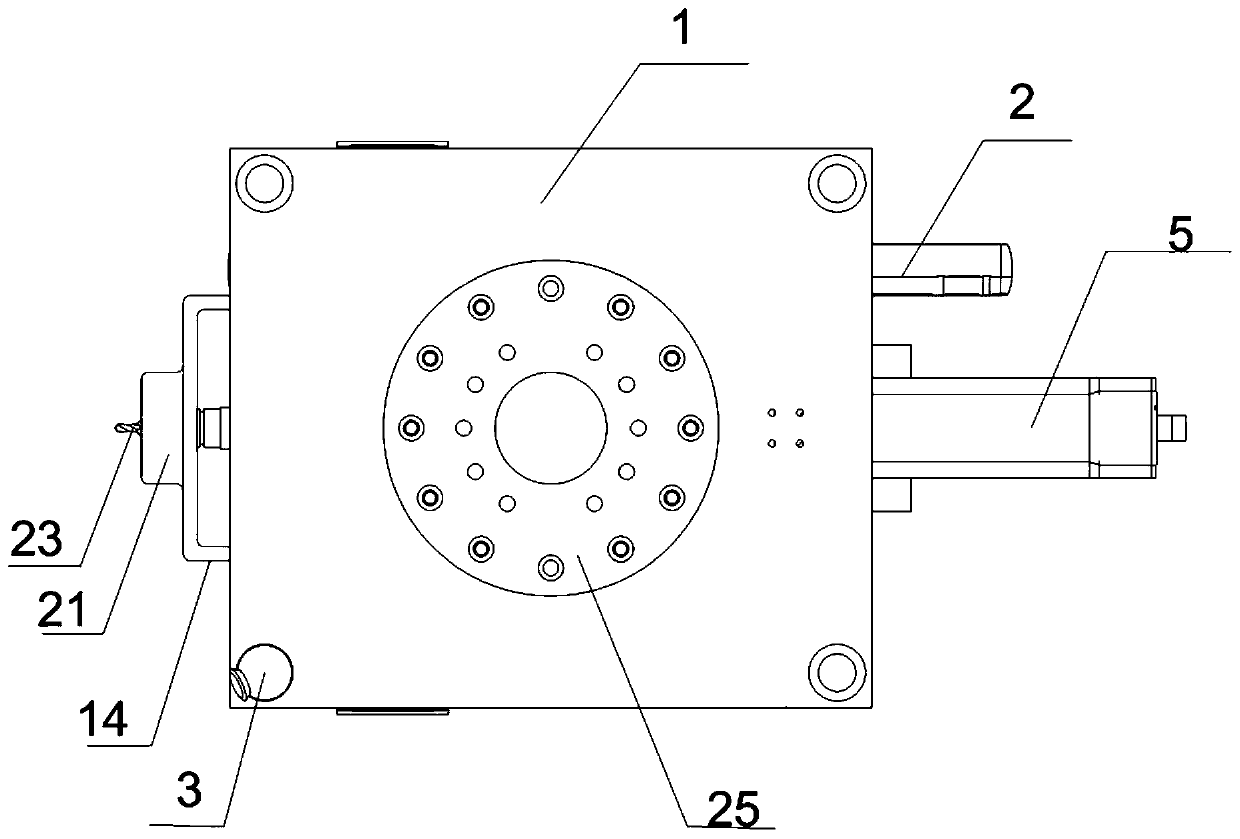

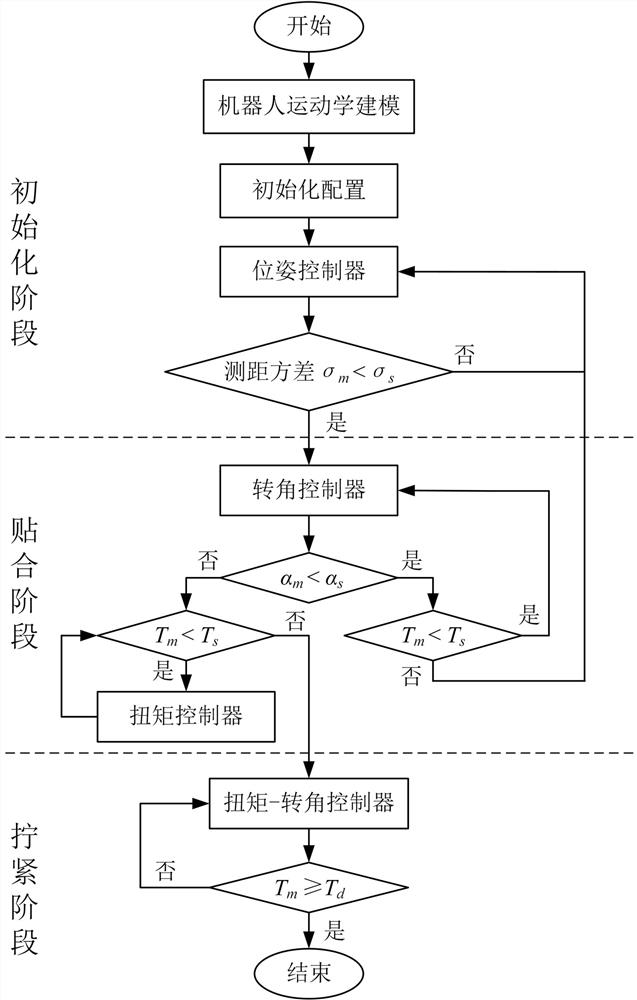

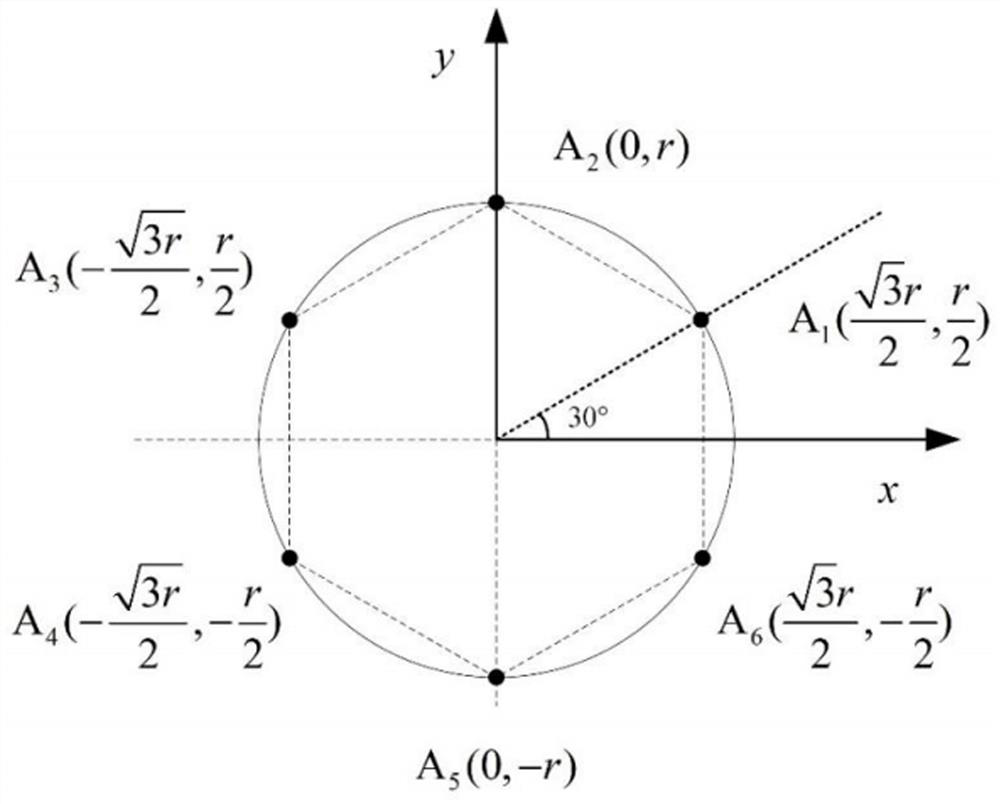

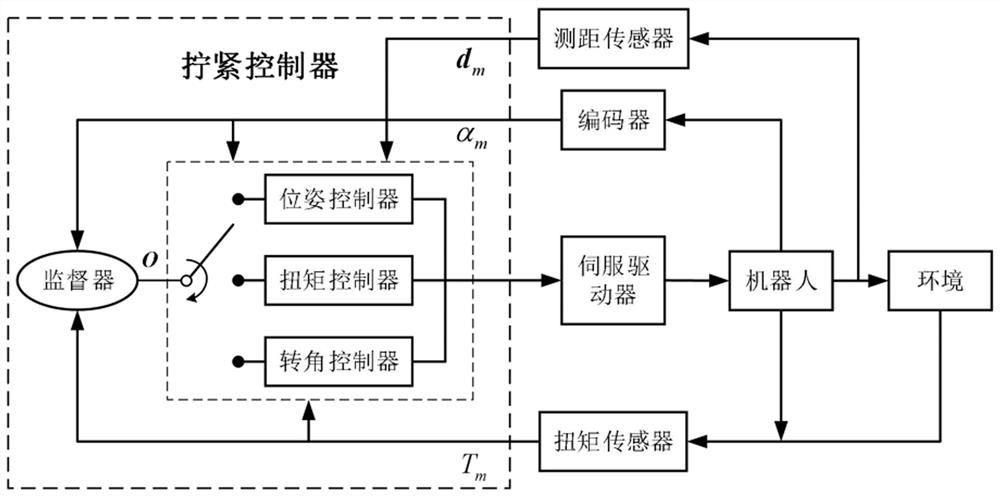

Nine-degree-of-freedom robot tightening control method for assembling thin-wall large threaded part

ActiveCN112720473AEnables automatic alignmentTo achieve error compensationProgramme-controlled manipulatorLaser rangingHandoff control

The invention discloses a nine-degree-of-freedom robot tightening control method for assembling a thin-wall large threaded part. The robot tightening control system comprises a tightening controller, a six-degree-of-freedom Stewart platform and a three-degree-of-freedom series mechanism, wherein the six-degree-of-freedom Stewart platform is located at the bottom and used for adjusting the pose of an upper platform tightening mechanism; the three-degree-of-freedom series mechanism is fixed to the six-degree-of-freedom Stewart platform and used for executing tightening control; a laser ranging module is used for collecting information about the distance between a shell and a to-be-assembled bolt piece, and axial alignment of the bolt piece and the shell and pose error correction in the fitting stage are achieved through a pose compensation algorithm; and a switching control method based on a pose / torque / corner controller is used, and a segmented switching control strategy is executed according to feedback information of various heterogeneous sensors. According to the method, automatic alignment, error compensation and tightening control operations in the assembly of the thin-wall large-thread part are realized, the occurrence probability of the thread pair jamming phenomenon can be reduced, and the assembly efficiency and quality of the thin-wall large-thread part are effectively improved.

Owner:HENAN UNIV OF SCI & TECH

A visual positioning laser marking system correction method

ActiveCN107486629BHigh precision calibrationMeet the accuracy requirements of visual positioning and markingLaser beam welding apparatusWorkloadVisual positioning

The invention discloses a visual-locating laser marking system correcting method. The method comprises the following steps that a galvanometric scanner is corrected, so that the laser marking effect is not distorted; the marking coordinate scaling multiple and the galvanometric scanner deflection angle are adjusted, and therefore image display can be obtained, wherein a marking object serves as a reference, and the image display is completely consistent with the marking object; a to-be-corrected marking region is determined on the marking object, the position of the marking object is compared with that of the image display, a clipping starting point of a to-be-corrected display region is determined, the position of the to-be-corrected display region is adjusted to enable the position of the to-be-corrected marking region to be completely consistent with that of the to-be-corrected display region, and therefore integrated display of the clipped to-be-corrected display region and the clipped to-be-corrected marking region is achieved finally. According to the visual-locating laser marking system correcting method, the defects that in the prior art, the correction manner is low in accuracy, and the personnel workload is large are overcome, and the marking object and image display integrated display manner is adopted, so that high-accuracy correction of a marking system and an image system is achieved, and the visual-locating marking accuracy requirements of all the current industries can be met.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

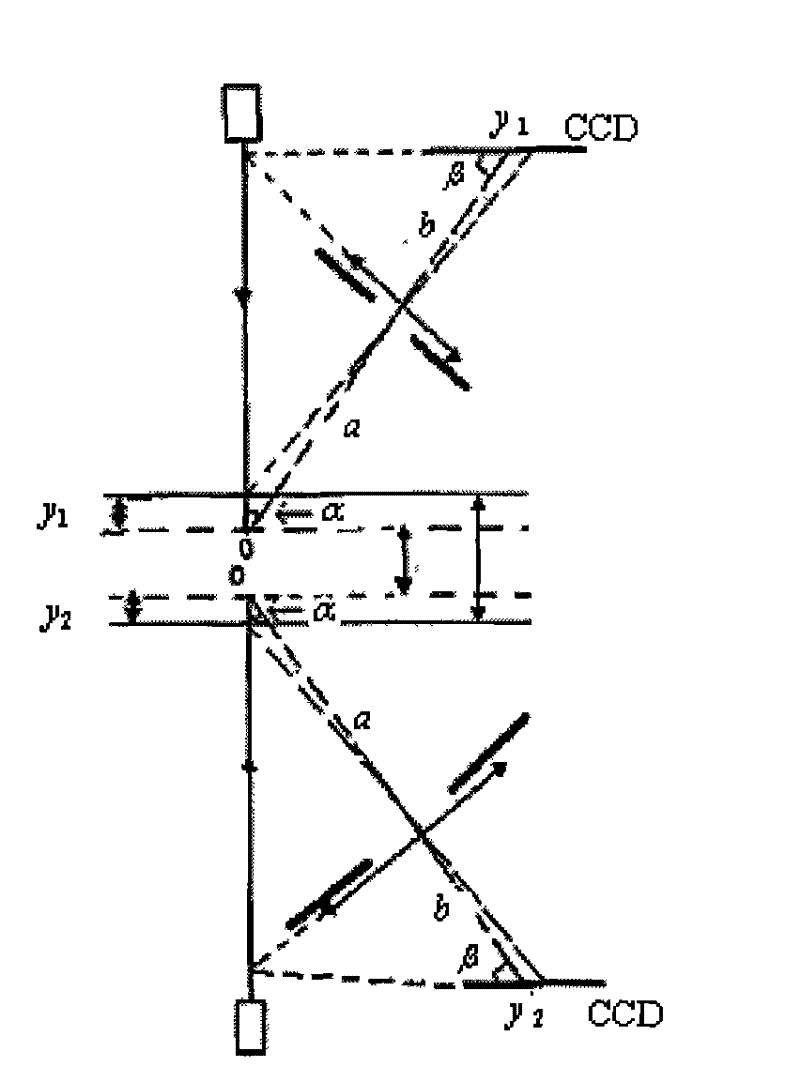

Error compensation method applicable to rotation axis swing angle of neutron chromatography imaging system

InactiveCN105321206ASolve the problem of shaft deflectionConsistent clarityImage analysis3D modellingSample rotationSynthetic projection

The present invention discloses an error compensation method of a rotation axis swing angle of a neutron chromatography imaging system. The method comprises: based on a projection geometrical symmetry principle of a parallel neutron beam, superimposing projection data within a range of 360 degree rotation of a sample to obtain a synthetic projection image with a unique symmetry axis, wherein, the symmetry axis of the synthetic projection image is a projection line of a rotation axis of the sample; further calculating out a pixel value gradient angle histogram of the synthetic projection image, wherein distribution of the histogram is an even function; and calculating a symmetry center of the even function, wherein a gradient angle corresponding to the symmetry center position is a swing angle of the rotation axis. By using the measured rotation angle as a correction parameter and introducing the correction parameter into a reconstruction algorithm, error compensation for the swing angle of the rotation axis can be realized, so that consistency of a definition of each reconstruction tomography of the sample is ensured, and reconstruction accuracy is effectively improved.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

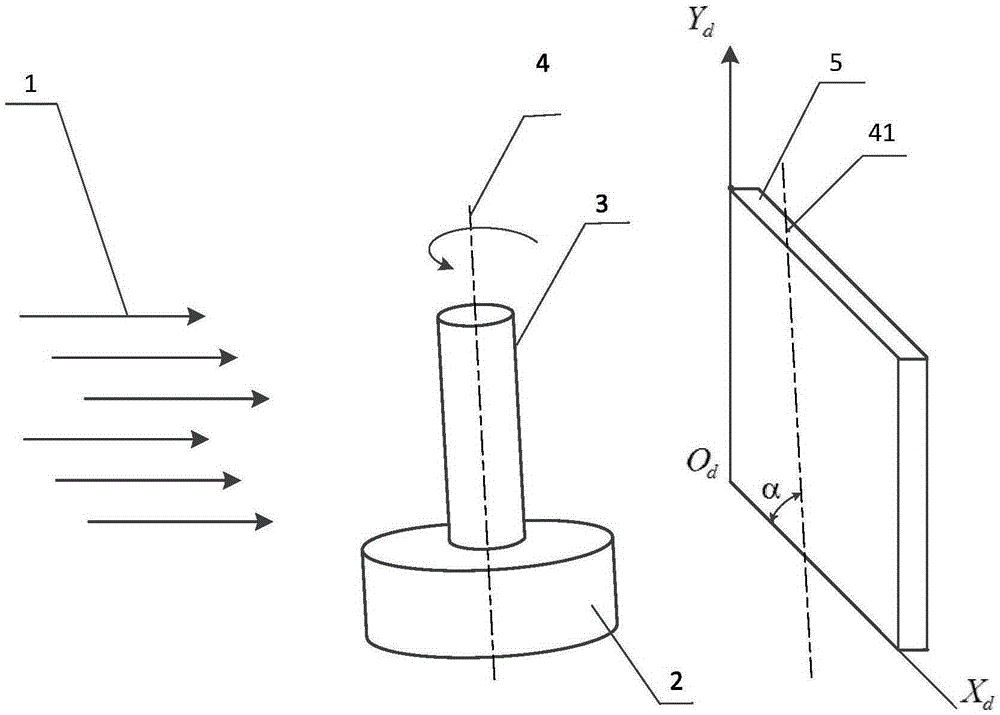

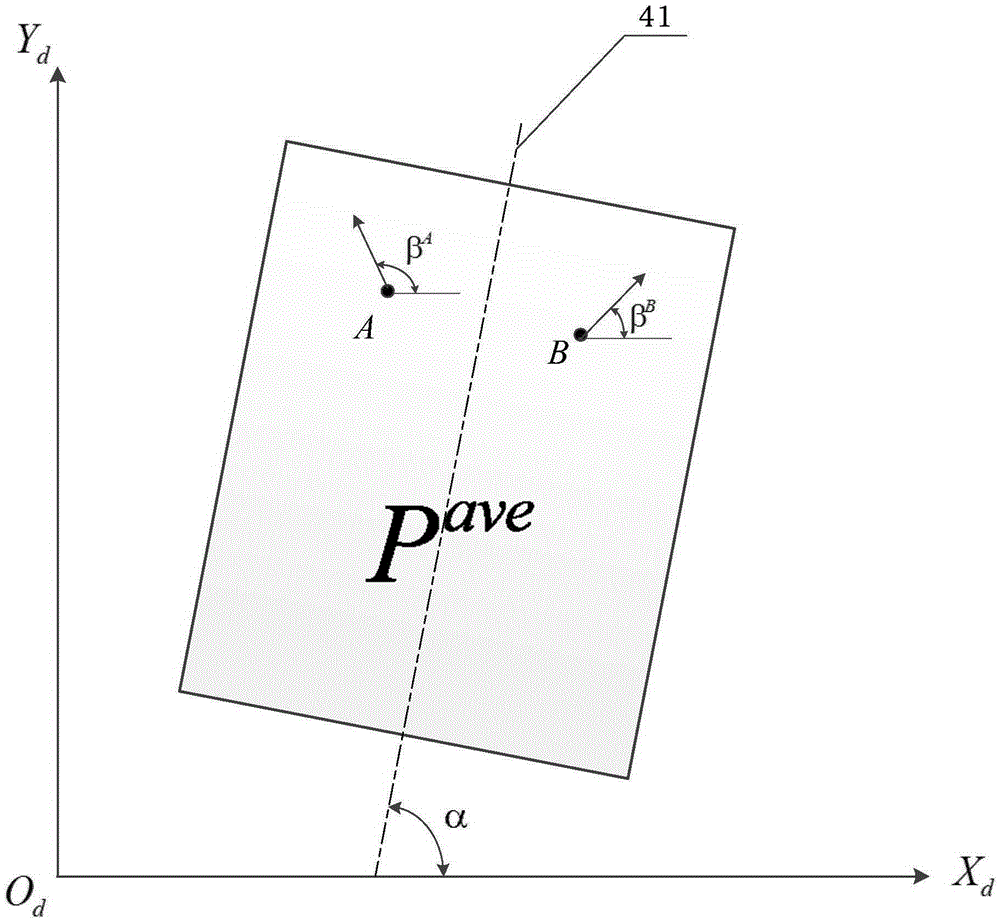

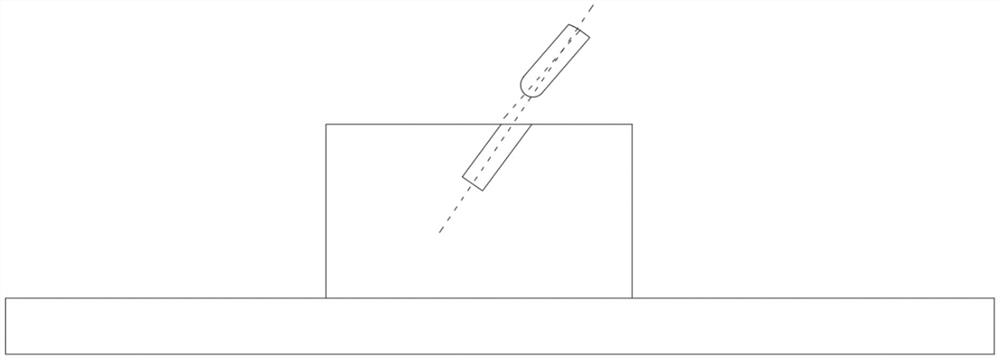

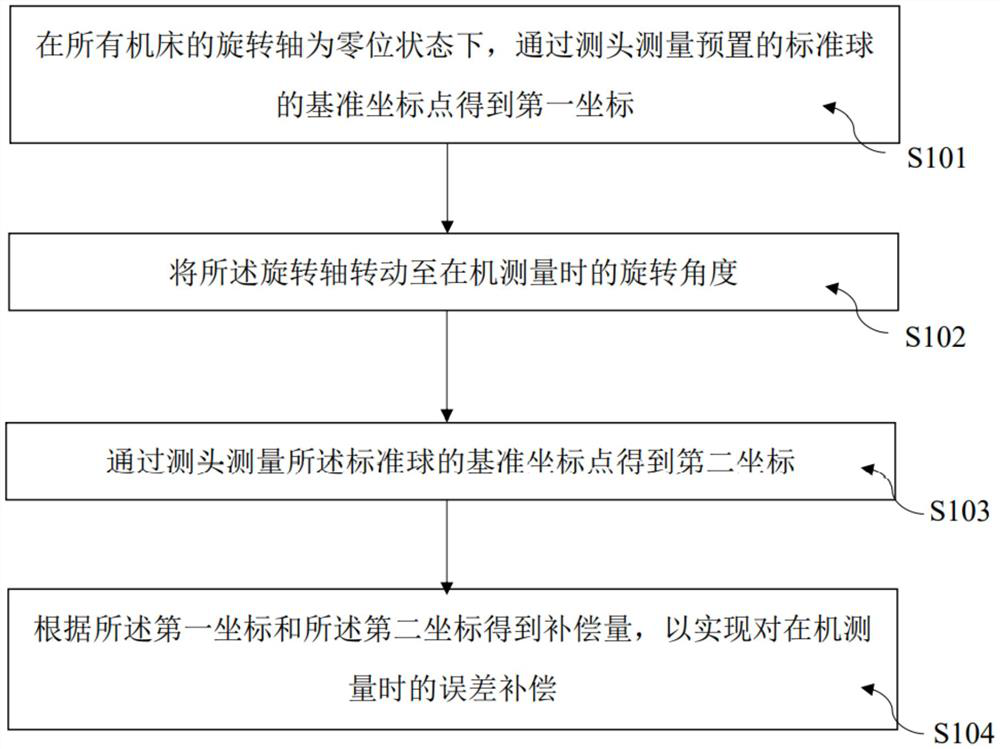

Multi-axis numerical control machine tool on-machine measurement data compensation method and system

PendingCN114859820ATo achieve error compensationSolve technical problems with low precisionProgramme controlComputer controlNumerical controlRotational axis

The embodiment of the invention discloses a multi-axis numerical control machine tool on-machine measurement data compensation method and system, and the method comprises the steps: measuring a reference coordinate point of a preset standard ball through a measuring head in a zero state of rotating shafts of all machine tools, and obtaining a first coordinate; rotating the rotating shaft to a rotating angle during on-machine measurement; measuring the reference coordinate point of the standard ball through a measuring head to obtain a second coordinate; and obtaining a compensation amount according to the first coordinate and the second coordinate so as to realize error compensation during on-machine measurement. The compensation amount is measured and calculated through the multiple rotating shafts and the preset standard ball, so that error compensation during on-machine measurement is achieved, and the technical problem that in the prior art, compensation is not provided for on-machine measurement of a workpiece, and consequently precision is not high is solved.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

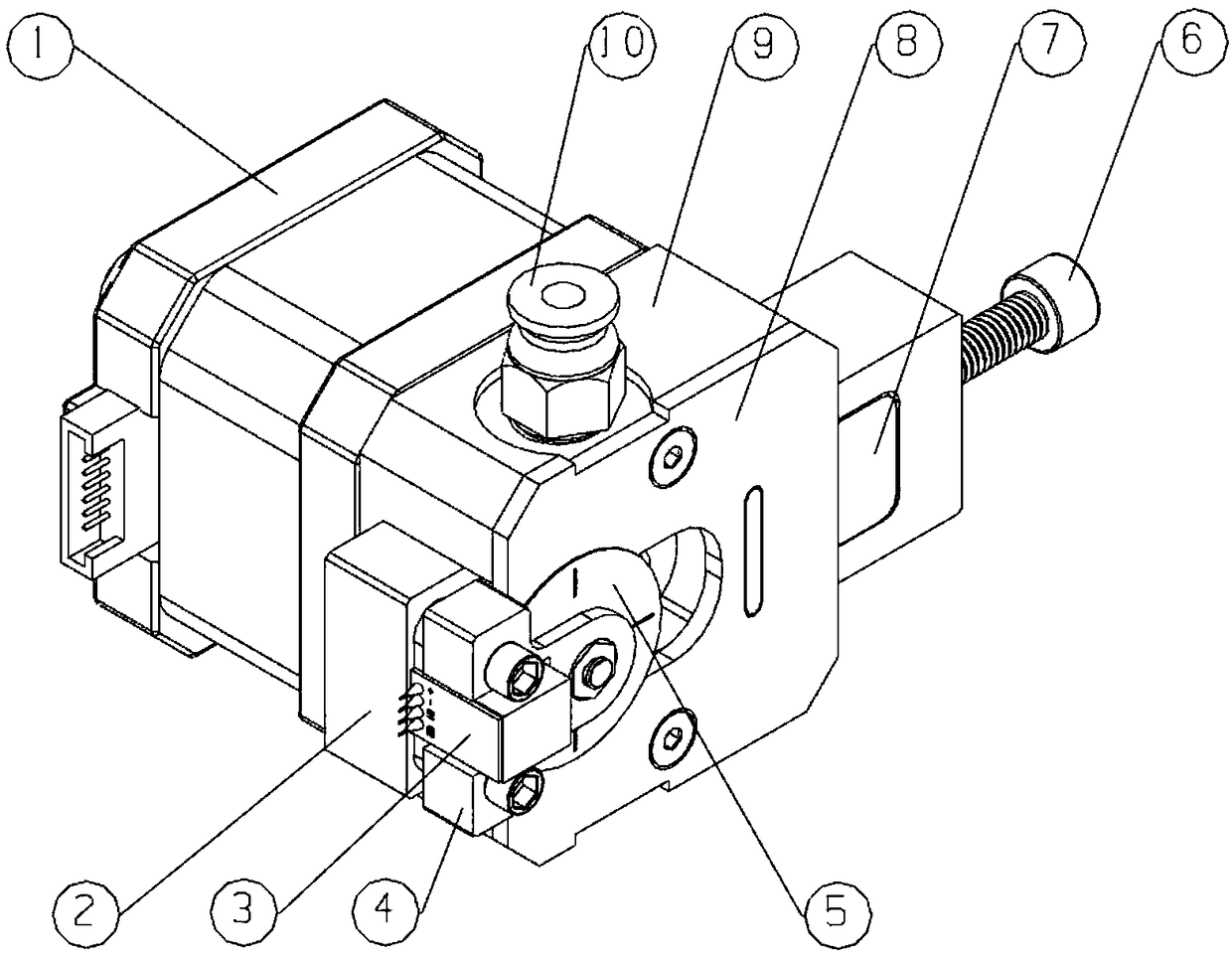

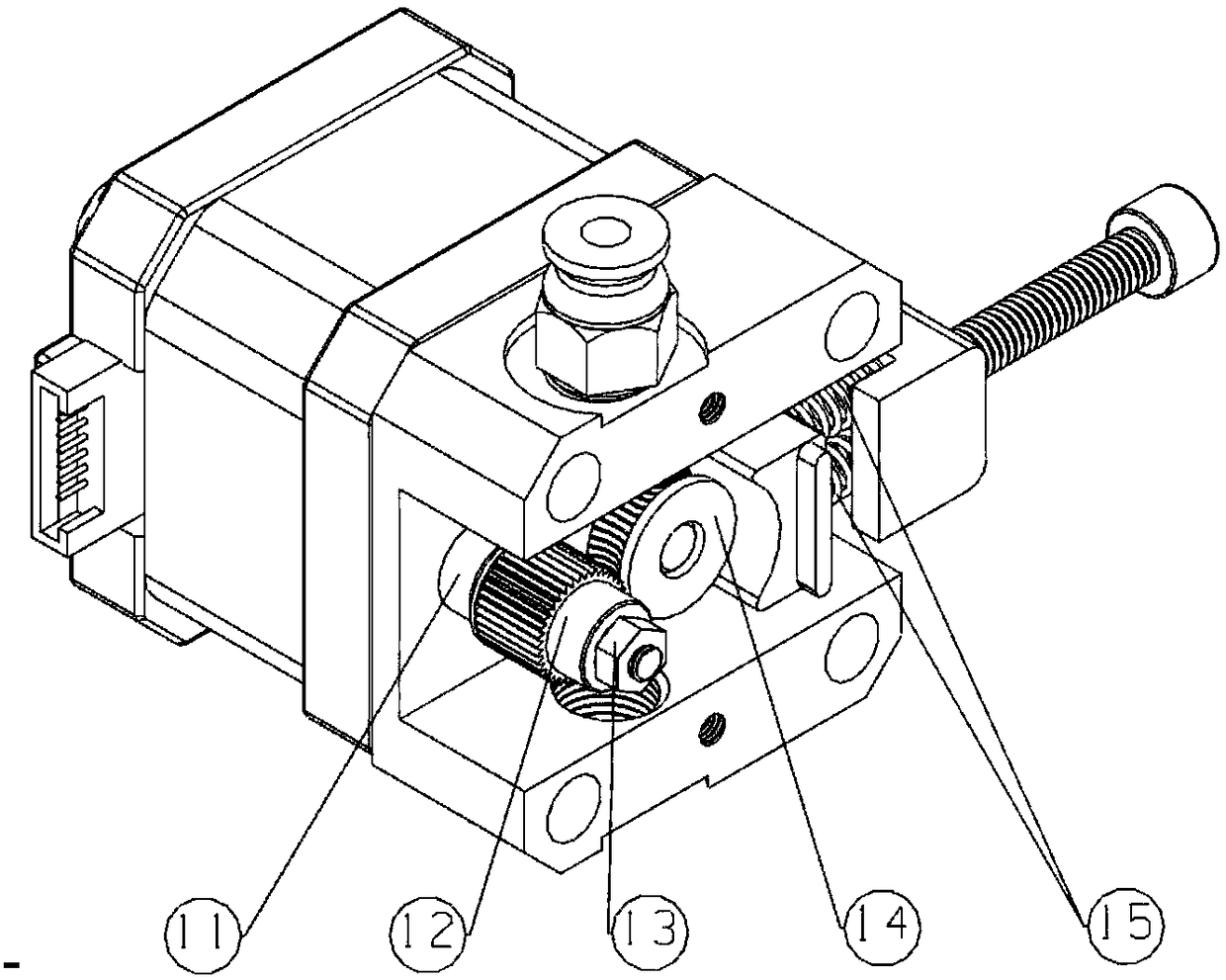

Adjustable wire extrusion monitoring alarm device

PendingCN108819226AReduce scrap rateHigh precisionAdditive manufacturing apparatusManufacturing material handlingModel qualityAlarm device

The invention discloses an adjustable wire extrusion monitoring alarm device. The device consists of a wire extrusion monitoring component, a tensioning regulation component and a motor component. Thewire extrusion monitoring component comprises a grooved wire extrusion wheel and a wire extrusion wheel without groove, a limit screw rod is inserted in the wire extrusion wheel, a code disc is fixedon a step at the end of the limit screw rod, holes are evenly distributed on the code disc, a photoelectric switch signal can be emitted after rotation of the code disc, through computing processingof the signal, wire material monitoring of the wire extrusion system can be realized. The tensioning regulation component comprises two tension springs arranged inside a motor support, a tensioning support is sleeved to one ends of the tension springs, a screw hole and a blind hole are respectively disposed at the central positions on the end faces of a tensioning regulation mechanism and the tensioning support, a knurling adjustment bolt is screwed into the screw hole of the tensioning regulation mechanism and abuts in the blind hole of the tensioning support, thus realizing the tensioning adjustment function on the wire material. The device provided by the invention improves the 3D printing precision and the printing model quality of, and increases the equipment reliability.

Owner:NANJING INST OF TECH

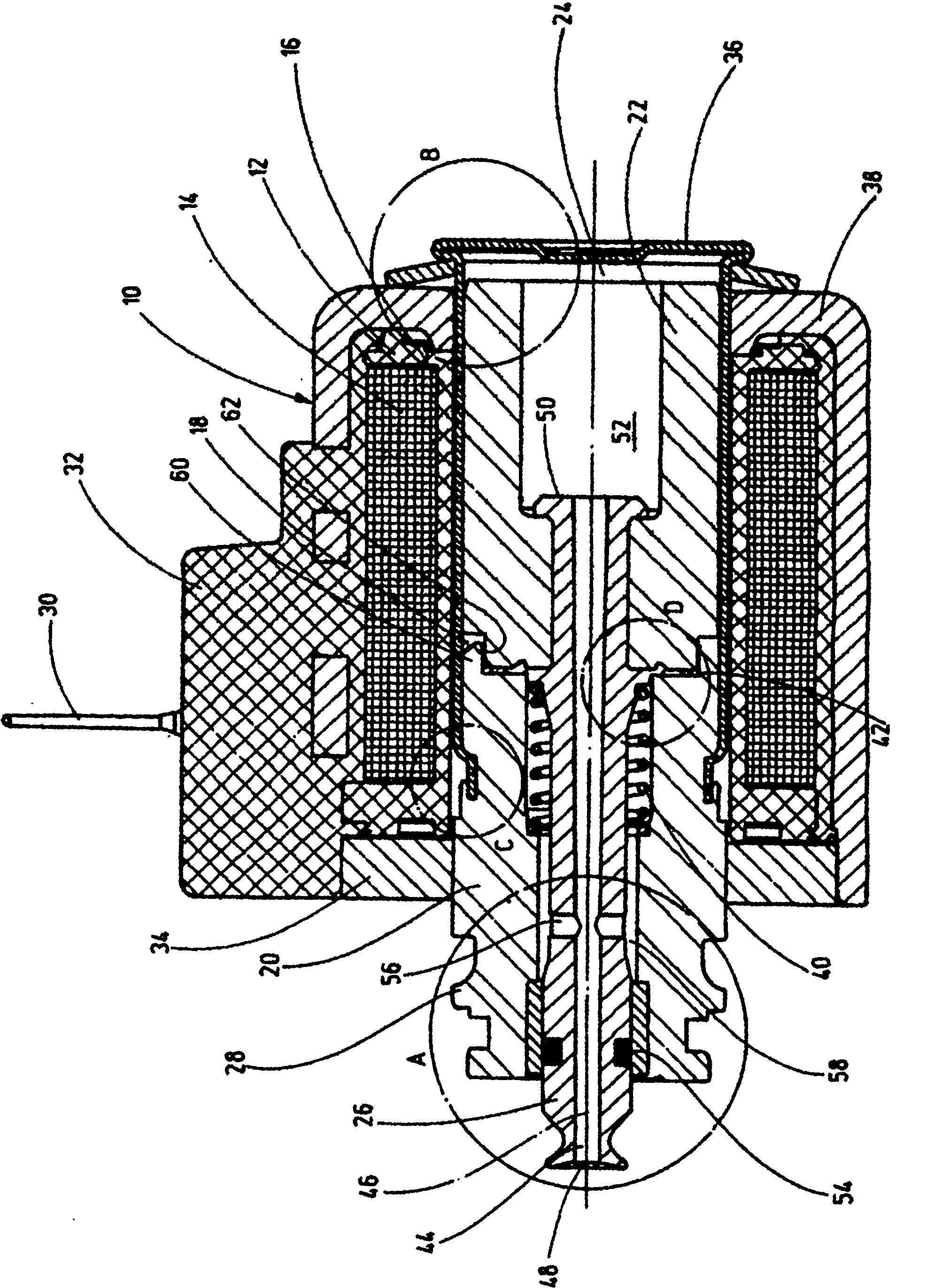

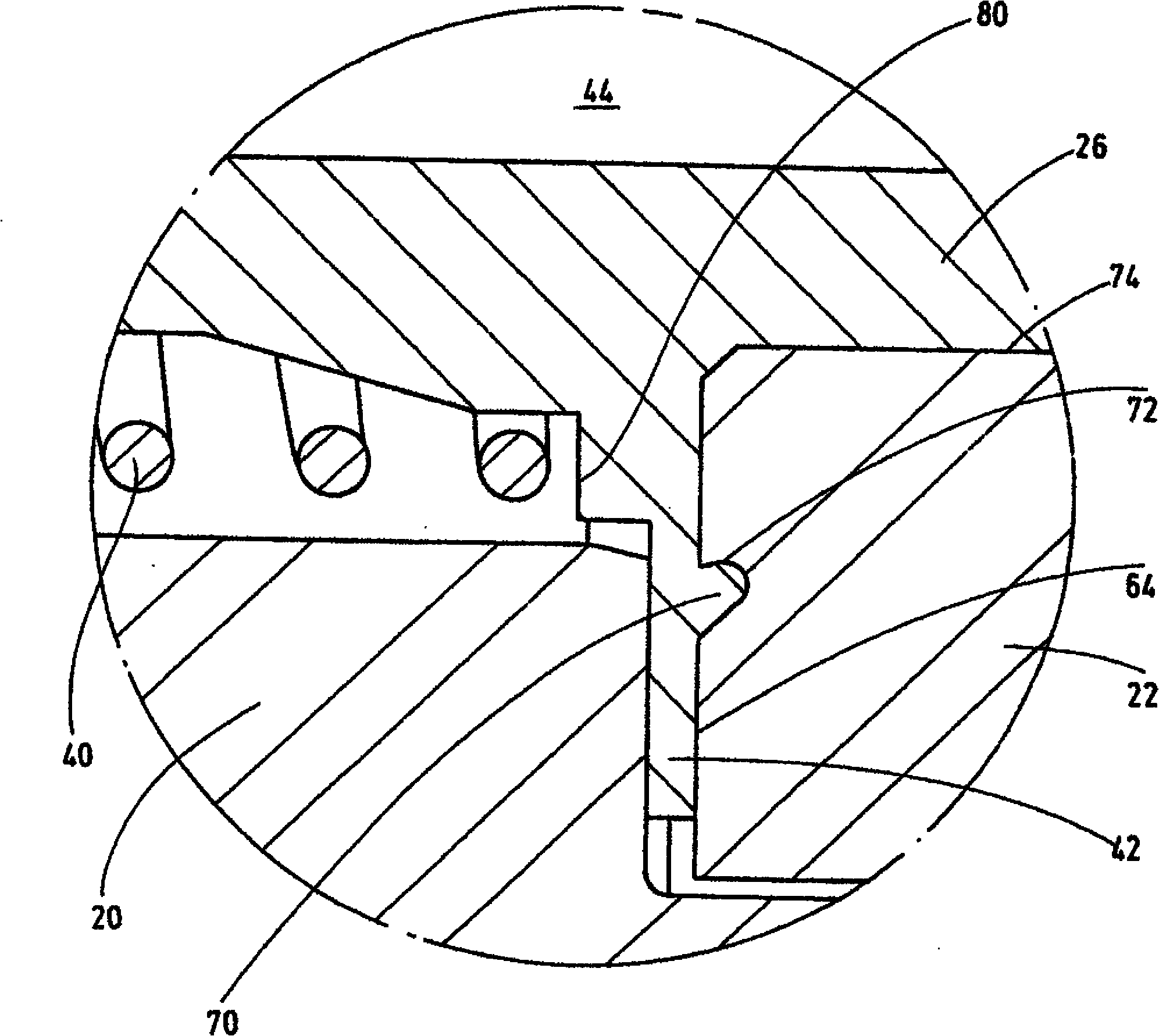

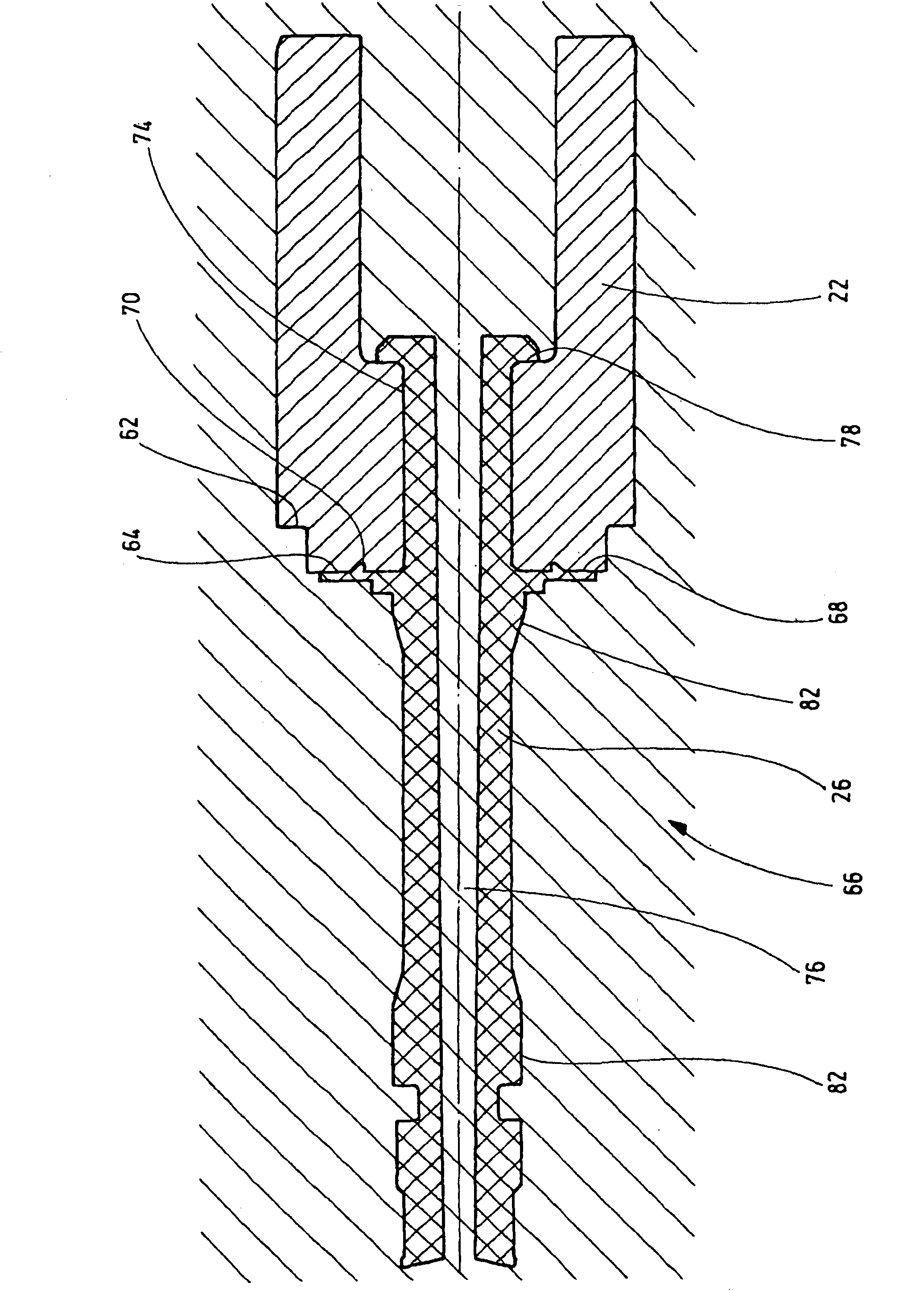

Actuating device

InactiveCN102057451ATo achieve error compensationReliable supportOperating means/releasing devices for valvesElectromagnets with armaturesEngineeringConductor Coil

The invention relates to an actuating device, particularly for actuating valves that can be connected externally, comprising a housing (10) and a coil body (12) arranged therein and having a coil winding (14), which encloses a pole tube (16) at least partially, having a pole core (20) connected at the free end thereof, further comprising an armature (22) that is guided in a longitudinally displaceable manner at least in the pole tube (16) within an armature chamber (24) and interacts with an actuating part (26) for actuating the respective valve part, wherein the pole tube (16) is designed in the form of a receiving sleeve for the armature (22), said sleeve being fixed to a fixed bearing point (124), wherein on a floating bearing point (116) for the receiving sleeve restoring means (112) engage thereon, effecting a force on the receiving sleeve that is directed away from the fixed bearing point (124).

Owner:HYDAC ELECTRONICS GMBH

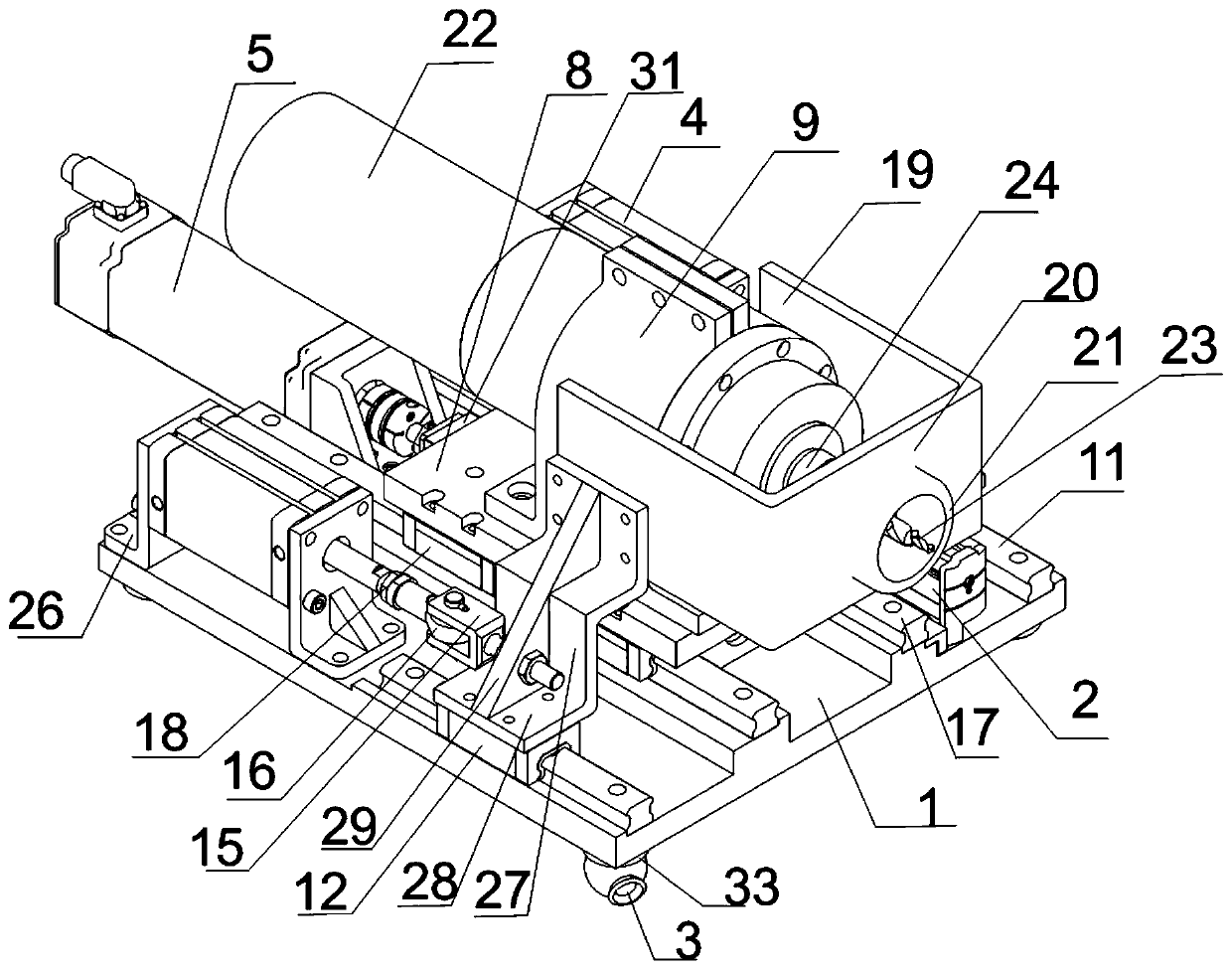

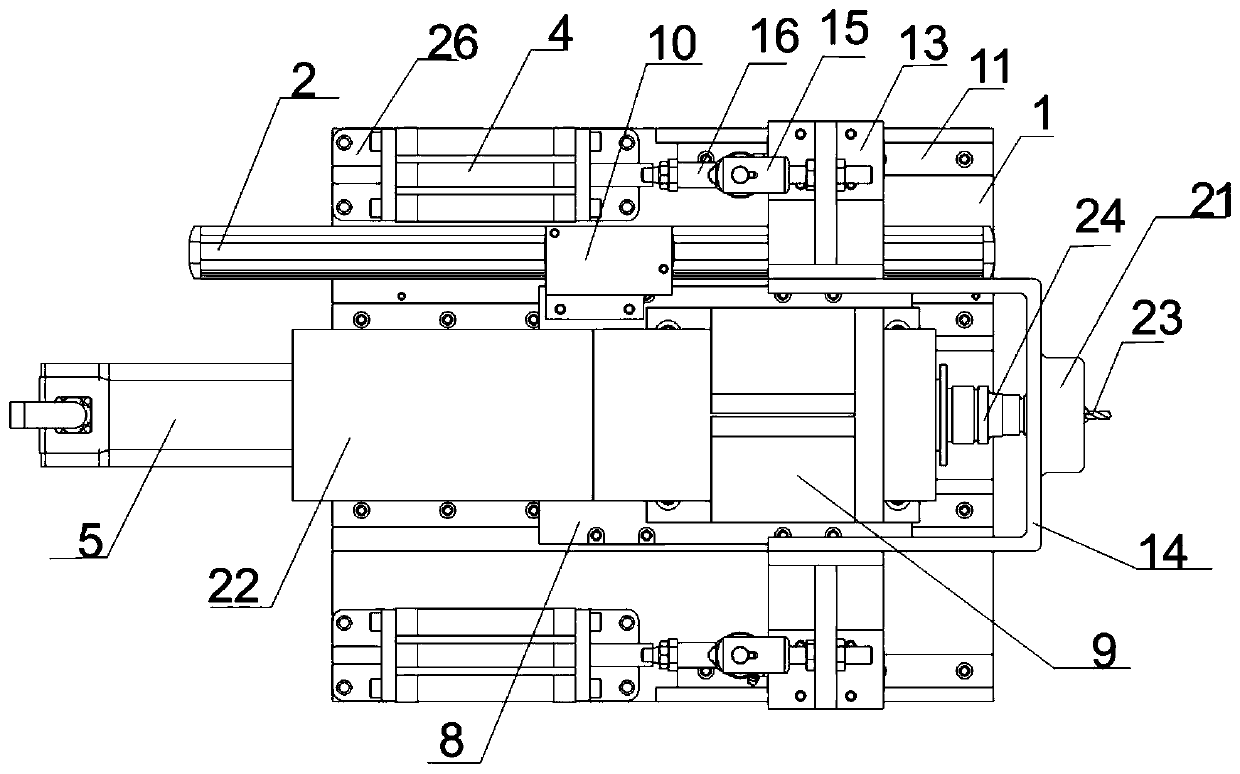

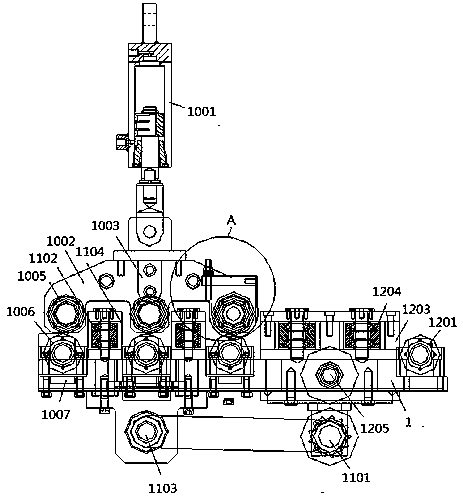

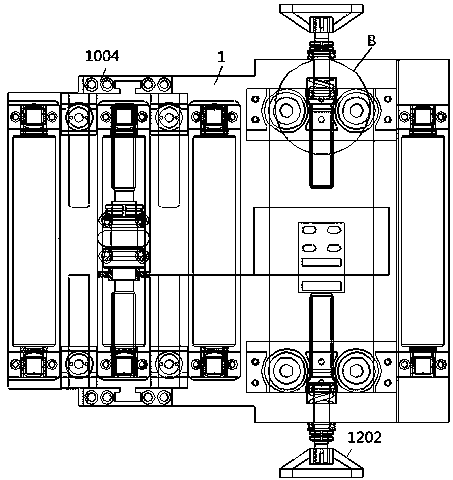

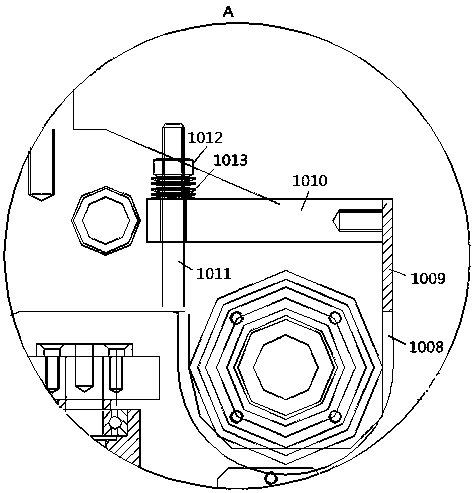

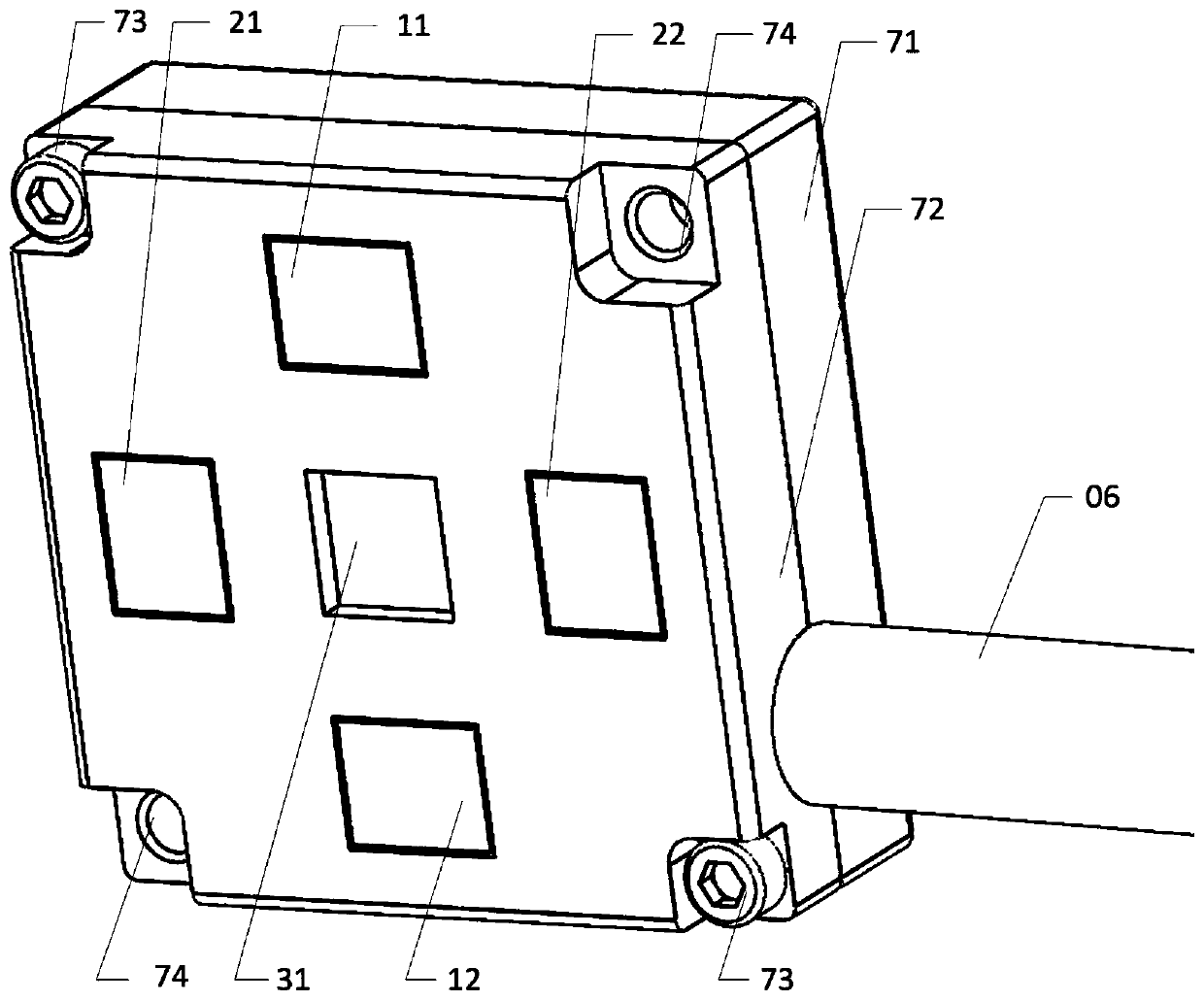

Robot tail end drilling actuator

InactiveCN110340683AHigh precisionImprove stabilityMeasurement/indication equipmentsAircraft assemblyGratingEngineering

The invention discloses a robot tail end drilling actuator. The robot tail end drilling actuator comprises a base, a drilling device, feeding devices and a propelling device, wherein the feeding devices and the propelling device are arranged on the base, the drilling device is fixedly connected with the feeding devices and the propelling device, a grating ruler and a target ball are further arranged on the base, each feeding device comprises an air cylinder and a slide device, a piston rod of each air cylinder is fixedly connected with each slide device, each slide device is further fixedly connected with the drilling device, each air cylinder and each slide device are fixedly connected with the base, two groups of the feeding devices are arranged, and respectively arranged on two sides ofthe drilling device, the propelling device comprises a servo motor, a lead screw and a lead screw nut holder which sleeves the lead screw, a feeding main plate is fixedly connected onto the lead screw nut holder, the feeding main plate is fixedly connected with the drilling device through a clamping part, and the feeding main plate is fixedly connected with the grating ruler through a connectionplate. The drilling actuator can effectively solve the problems that an existing drilling and riveting machine is large in size and poor in accuracy.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

A nine-degree-of-freedom robot tightening control method for the assembly of thin-walled large threaded parts

ActiveCN112720473BEnables automatic alignmentTo achieve error compensationProgramme-controlled manipulatorAssembly machinesLaser rangingHandoff control

The invention discloses a nine-degree-of-freedom robot tightening control method for assembling thin-walled large screw parts. The robot tightening control system includes a tightening controller, a six-degree-of-freedom Stewart platform at the bottom for adjusting the posture of the upper platform tightening mechanism, A three-degree-of-freedom series mechanism fixed on a six-degree-of-freedom Stewart platform for tightening control; the laser ranging module is used to collect the distance information between the shell and the bolts to be assembled, and the axis of the bolts and the shell is realized through the pose compensation algorithm. Pose error correction in the alignment and bonding stages; using a switching control method based on a pose / torque / rotation angle controller, and performing a segmented switching control strategy according to feedback information from various heterogeneous sensors; the invention realizes thin-walled large The automatic alignment, error compensation, and tightening control operations in the assembly of threaded parts can reduce the probability of thread pair jamming, and effectively improve the assembly efficiency and quality of thin-walled large threaded parts.

Owner:HENAN UNIV OF SCI & TECH

A strip steel finishing mill inlet guide device

ActiveCN107838202BLarge diameterSmall diameterGuiding/positioning/aligning arrangementsEngineeringStrip steel

The invention discloses a strip steel finishing mill entry guiding device and belongs to the technical field of cold-rolling and calendaring. The strip steel finishing mill entry guiding device disclosed by the invention comprises a front guide device, a rear guide device and a bottom plate, wherein the rear guide device and the front guide device are sequentially arranged on the bottom plate along a strip steel movement direction; the rear guide device comprises a carrier roller and a pair of rear side guide mechanisms; the carrier roller is arranged along the strip steel width direction; thetwo rear side guide mechanisms are arranged on two sides of the bottom plate opposite to each other; the front guide device comprises a top-bottom guide mechanism and a pair of front side guide mechanisms; the top-bottom guide mechanism comprises a plurality of upper pressing belt rollers and lower pressing belt rollers arranged corresponding to one another from top to bottom; the upper pressingbelt rollers and lower pressing belt rollers are arranged along the strip steel width direction; and the two front side guide mechanisms are arranged on two sides of the bottom plate opposite to eachother. The strip steel finishing mill entry guiding device disclosed by the invention has main purposes that the whole rolling process of thick and thin materials after one-time guide completion is realized, so that the strip steel finishing mill entry guiding device disclosed by the invention can be applicable to strip steel guide with a wider thickness range.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

An Error Compensation Method Applicable to the Swing Angle of the Rotation Axis of the Neutron Tomography System

InactiveCN105321206BSolve the problem of shaft deflectionConsistent clarityImage analysis3D modellingRotational axisAxis of symmetry

The invention discloses an error compensation method for neutron tomography rotation axis deflection angle. The method is based on the projection geometric symmetry principle of parallel beam neutron rays, and obtains by superimposing projection data within a 360-degree rotation range of a sample. A composite projected image with a unique symmetry axis, the symmetry axis of the composite projected image is the projection line of the sample rotation axis; the histogram of the pixel value gradient angle of the composite projected image is further calculated, and the histogram distribution is an even function. Find the symmetry center of the even function, and the gradient angle corresponding to the symmetry center position is the yaw angle of the rotation axis. By introducing the measured yaw angle as a correction parameter into the reconstruction algorithm, the error compensation for the yaw angle of the rotation axis can be realized, so as to ensure the consistency of the definition of each reconstructed slice of the sample and effectively improve the reconstruction accuracy.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

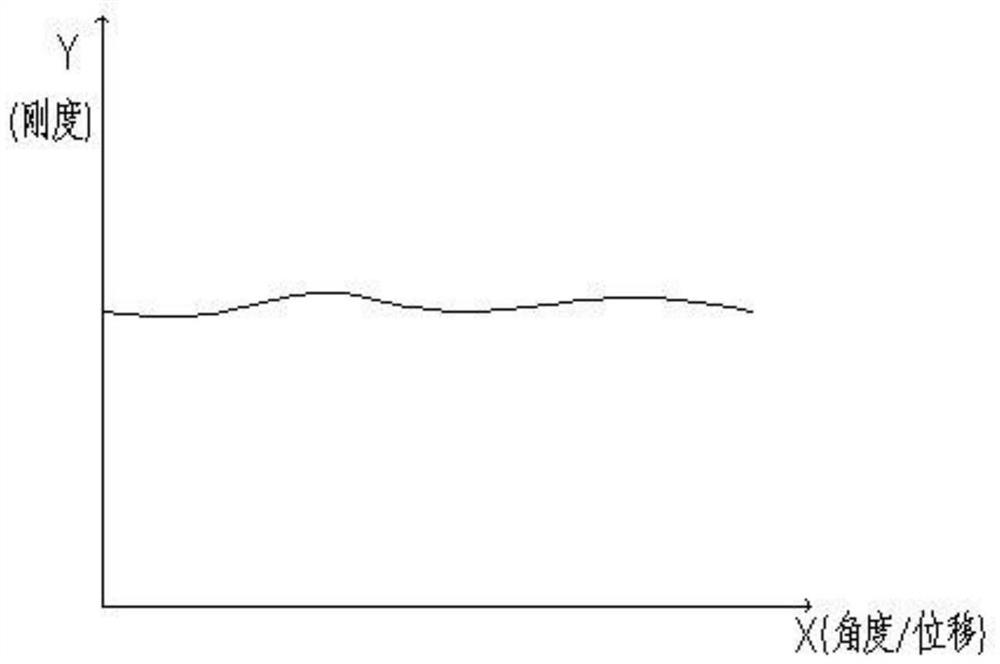

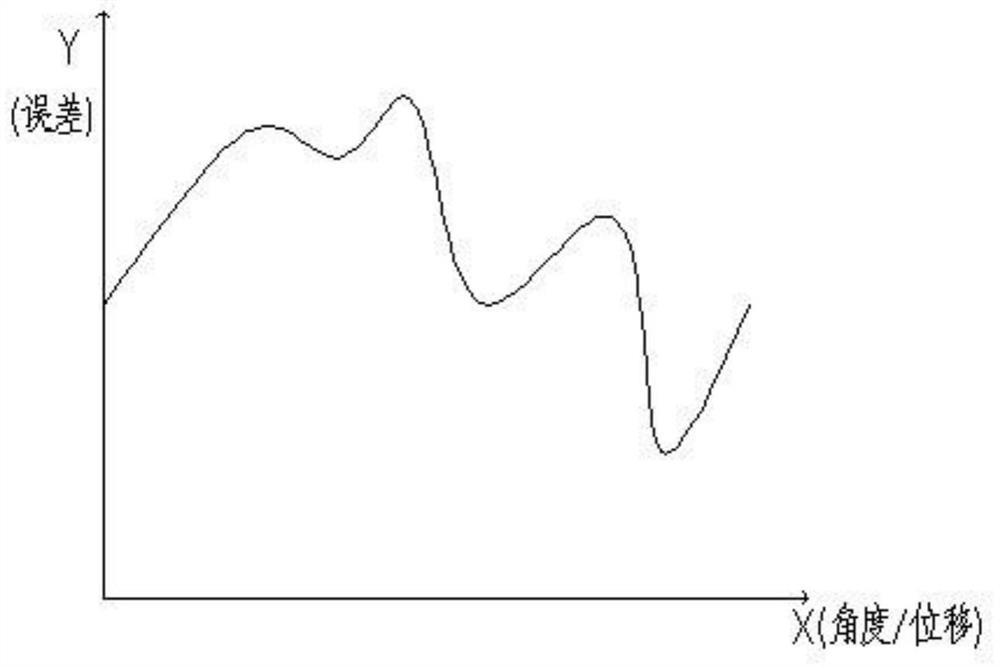

Gas-magnetic hybrid bearing error compensation method based on electromagnetic force adjustment

ActiveCN112610604ATo achieve error compensationReduce manufacturing difficultyGas cushion bearingsHydrostatic bearingsControl theoryMechanical engineering

The invention discloses a gas-magnetic hybrid bearing error compensation method based on electromagnetic force adjustment. According to the error and rigidity of each position, a controller outputs corresponding electromagnetic force to calibrate the error point by point. Compared with the prior art, the method has the following advantages and beneficial effects that in the whole effective stroke range, the calibration forces required by different positions are different, and error compensation is realized by measuring the error and rigidity point by point and adopting a certain force-displacement conversion algorithm; and on the premise of greatly reducing the manufacturing difficulty, the error is reduced, and the rigidity is improved.

Owner:四川龙天精工科技有限公司

Method for controlling working track of aerial work platform

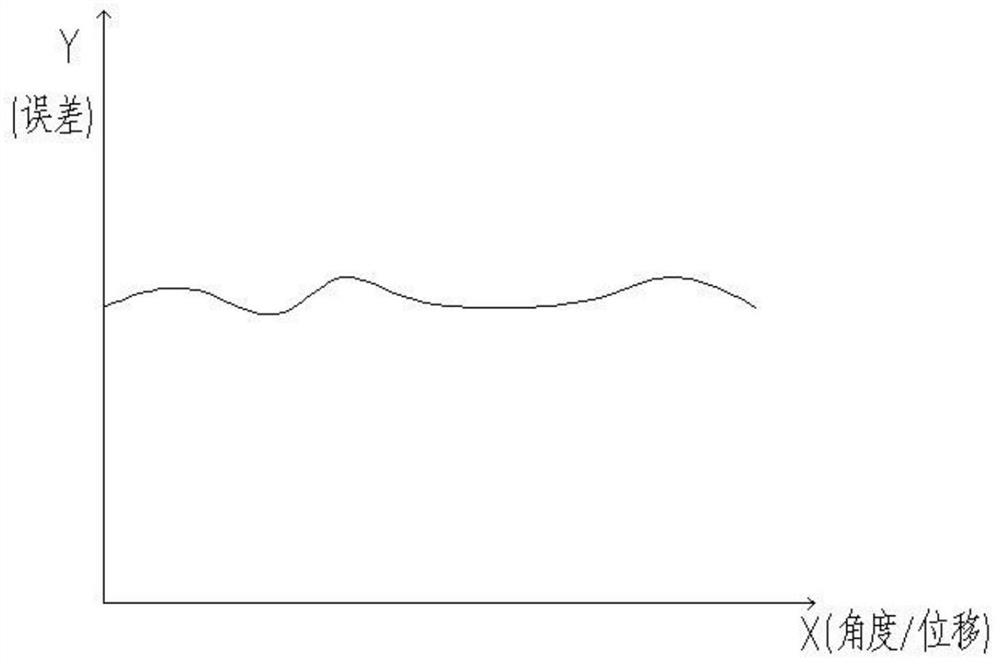

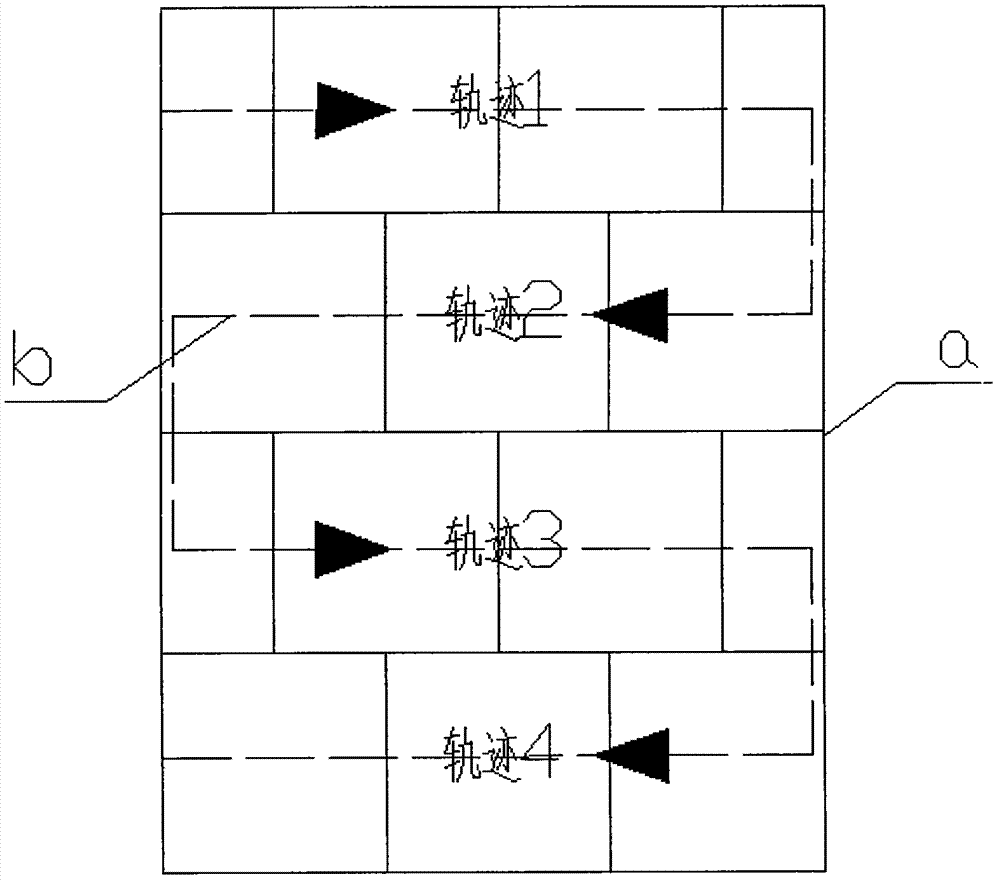

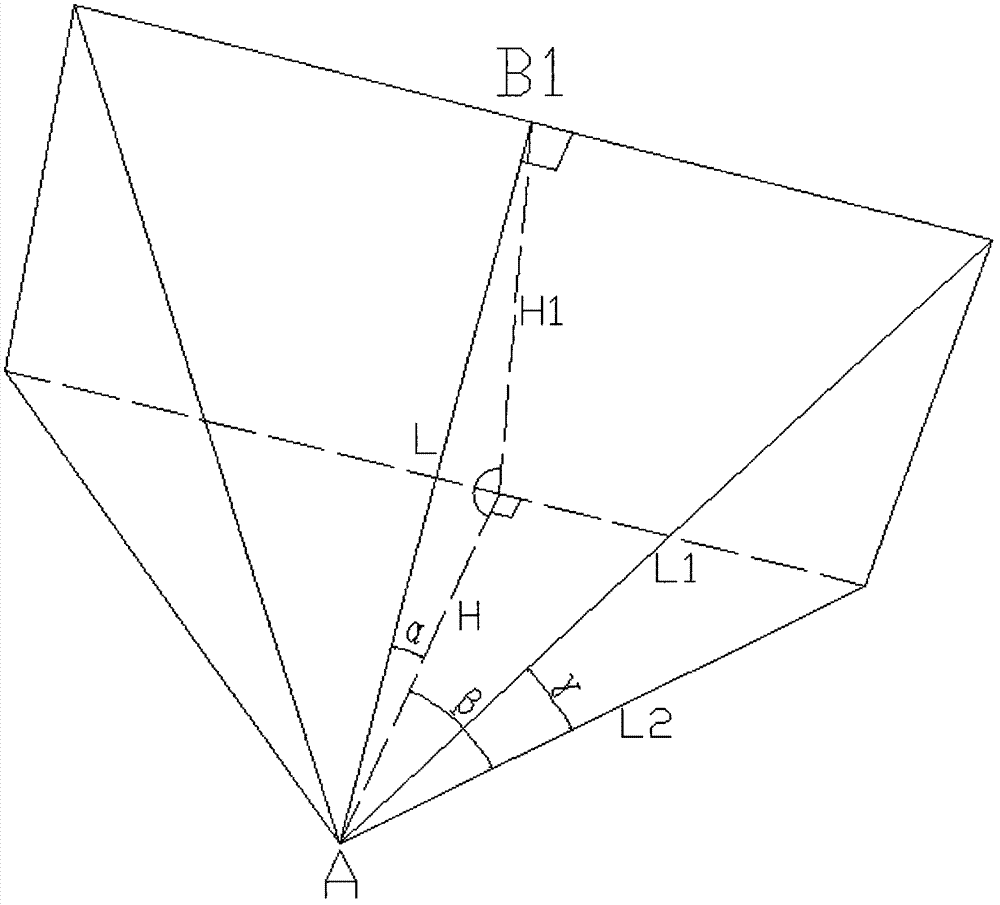

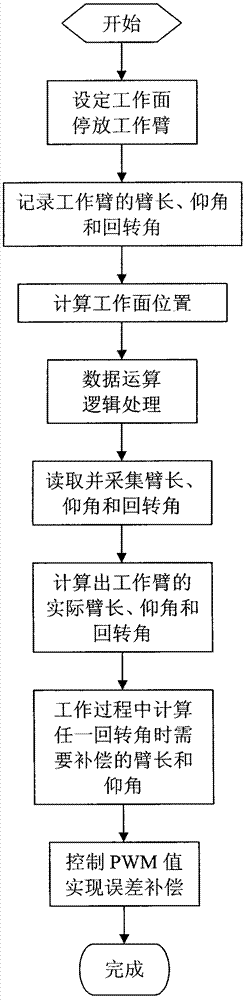

ActiveCN102183963BTo achieve error compensationRealize trajectory control working modeLifting devicesPosition/direction controlElevation angleData operations

The invention discloses a method for controlling a working track of an aerial work platform and belongs to the technical field of aerial work platform control. The method comprises the following concrete steps: (1) presetting a working surface, vertically placing a working arm on the working surface, recording an initial arm length, an elevation angle and a revolution angle of the working arm, and then calculating the position of the working surface; (2) performing data operation and logic treatment, and reading the arm length, the elevation angle and the revolution angle of the working arm; (3) acquiring the arm length, the elevation angle and the revolution angle of the working arm; (4) calculating the actually required arm length, elevation angle and revolution angle of the working arm; (5) calculating the arm length and the elevation angle of the working arm needed to be compensated at any revolution angle; and (6) outputting a PWM (pulse width modulation) value by a solenoid valve which controls the stretching and amplitude, thereby realizing the error compensation. The method provided by the invention has the beneficial effects that the motion on the whole working surface is realized, the trouble in frequently positioning in the operation process is reduced, the working process is smoother, safer and more reliable, and the collision accident is reduced.

Owner:XUZHOU HIRSCHMANN ELECTRONICS

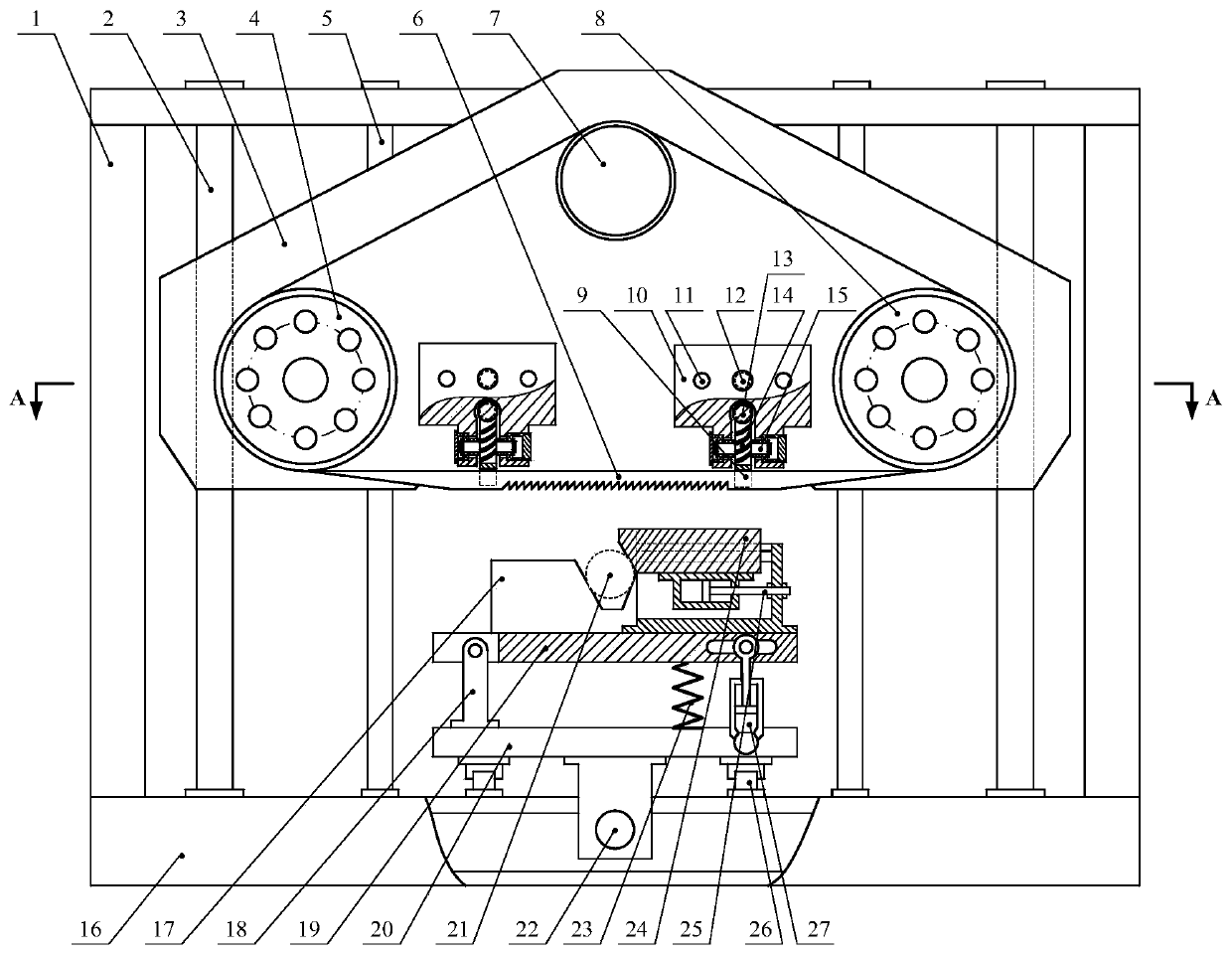

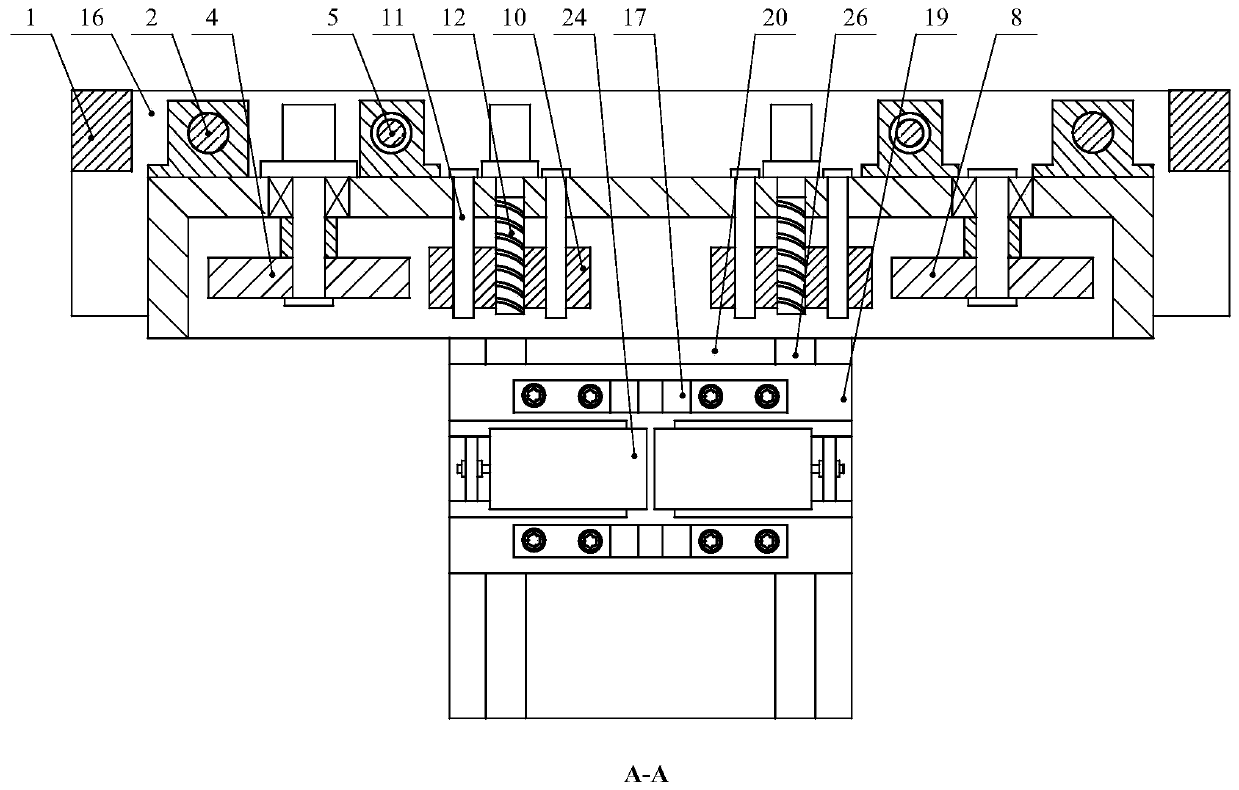

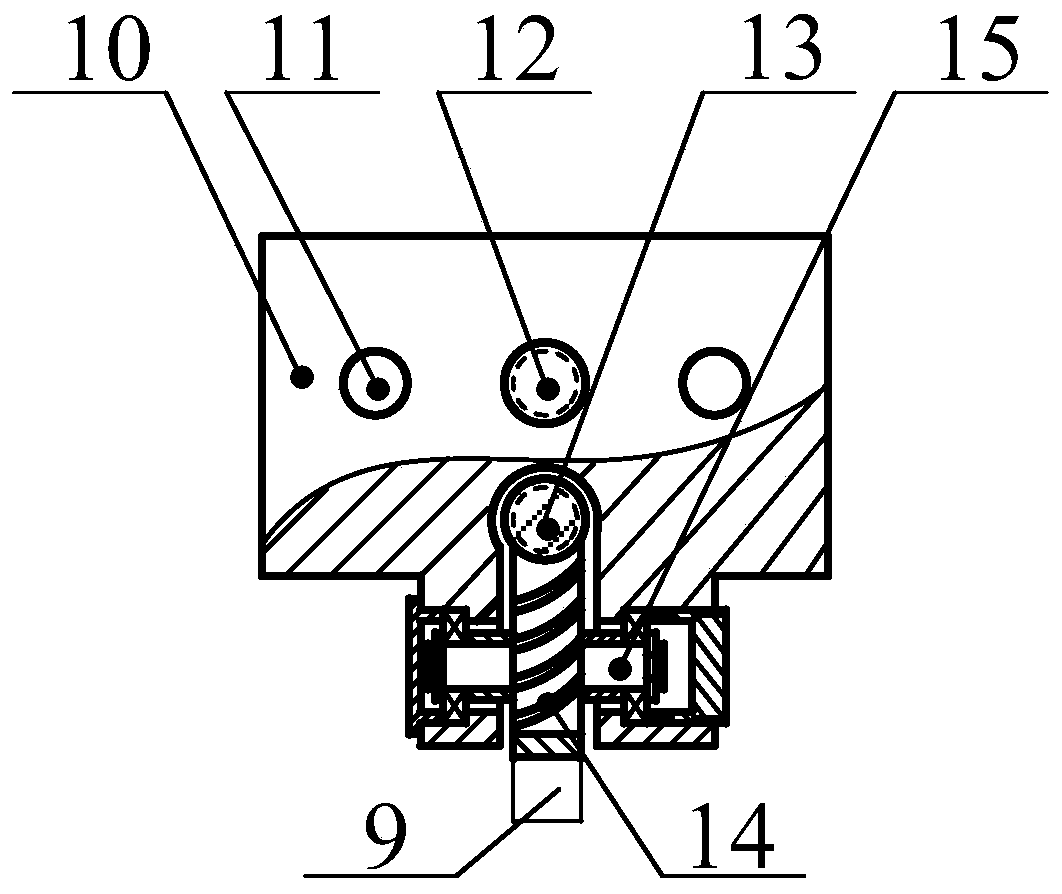

A sawing equipment and sawing method for heavy and extra-large structural parts

ActiveCN109967793BReduce volumeReduce the overall heightMetal sawing devicesHydraulic ramElectric machinery

The invention discloses a heavy and extra-large structural member saw-cutting device and a saw-cutting method thereof. A two-wheel type sawing machine for saw-cutting a large structural member requires the matching of large-dimensional saw belt wheels, so that the production cost is greatly improved. The invention relates to the heavy and extra-large structural member saw-cutting device which comprises a rack, a three-wheel saw-cutting mechanism, a feeding hydraulic oil cylinder, a working table, a guiding and correcting mechanism, a workbench and a clamping assembly. The three-wheel saw-cutting mechanism comprises a saw frame, a driving belt saw wheel, a saw belt, a middle saw belt wheel and a driven saw belt wheel. The guiding and correcting mechanism comprises a guiding block, a correcting movement plate, a correcting swinging worm, a correcting swinging worm wheel, a correcting drive piece and a torsion motor. The working table comprises a swinging table, a moving table, a transverse movement drive piece, a swinging spring and a swinging air cylinder. According to the heavy and extra-large structural member saw-cutting device and the saw-cutting method thereof provided by the invention, a traditional two-saw-belt-wheel transmission structure is changed into a three-saw-belt-wheel transmission structure, so that the defect that the conventional two-saw-belt-wheel sawing machine requires the diameter of each saw belt wheel to be larger than the diameter of a workpiece is overcome, and the volume and the height of the whole machine are greatly reduced.

Owner:HANGZHOU DIANZI UNIV

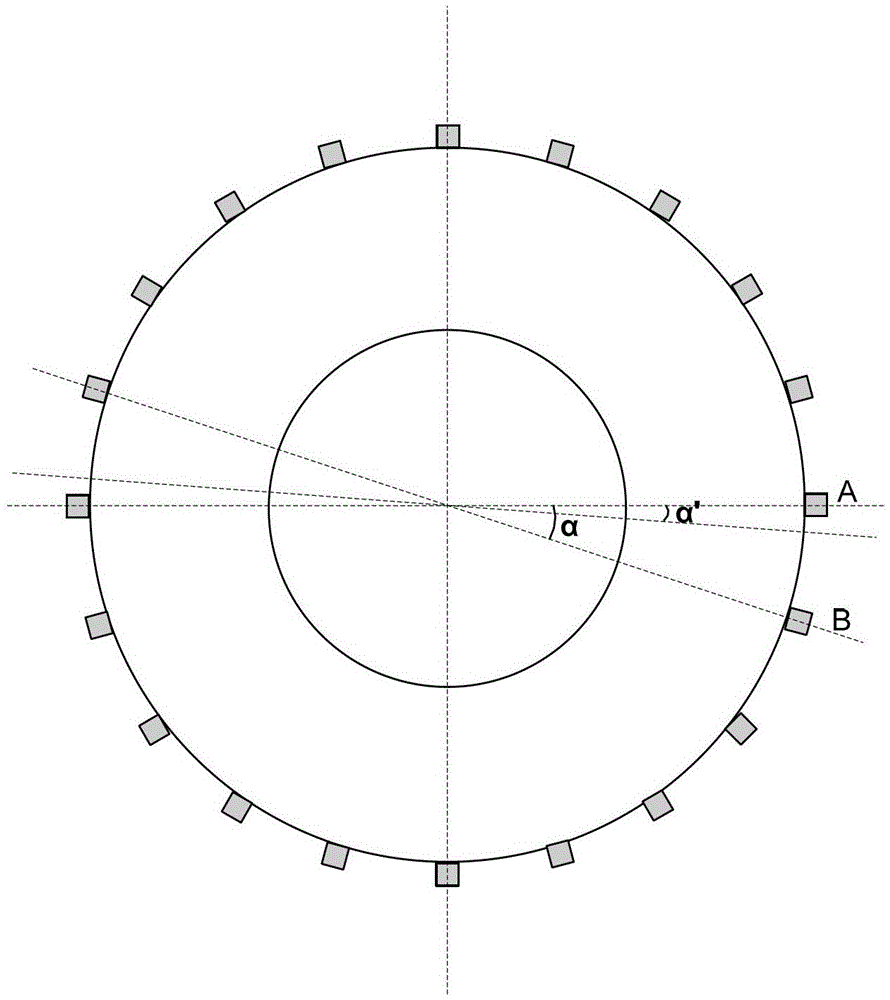

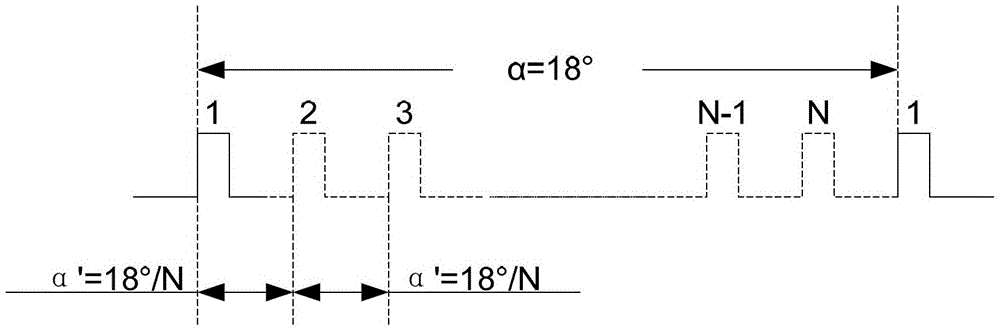

Scanning trigger control method and device of CT machine and CT machine

ActiveCN104068885BWill not cause accumulationCompensate speed errorComputerised tomographsTomographyComputed tomographyEngineering

The invention provides a scanning trigger control method and device of a CT machine and a CT machine. Among them, the rotation angle of a scan cycle is divided into M angle segments; and the reference sampling period, and the reference rotation duration and reference sampling quantity corresponding to each angle segment are determined in advance; when performing a CT scan, start from the first angle segment At the beginning, for each angle segment, when the sensing signal at the beginning of the angle segment is received, the timing of the current rotation duration of this angle segment is started, and after delaying the sampling time corresponding to several samples, the corresponding sampling of this angle segment is started , when receiving the sensing signal at the end of the angle segment, the current rotation duration of the angle segment is obtained; the difference between the current rotation duration of the angle segment and the reference rotation duration is calculated, and the difference is passed through the angular segment The sampling time corresponding to several samples in the corresponding remaining sampling quantity is compensated. The technical scheme of the invention can compensate the speed error of the rotating frame.

Owner:SIEMENS SHANGHAI MEDICAL EQUIP LTD

Multi-degree-of-freedom self-assembled nanorobot and its manufacturing control method

ActiveCN111077185BEasy to controlConvenient researchMaterial analysis by electric/magnetic meansNanotechnologyNanoholeEngineering

The invention relates to a multi-degree-of-freedom self-assembled nano-robot and a production control method thereof. The nano-robot is self-assembled by micro-nano particles and four deoxyribonucleic acid chains through the strong interaction between gold-sulfhydryl bonds or streptavidin and biotin. formed into quadruped nanorobots. By depositing circular gold electrodes on the four vertices of the square on the silicon-based material, four nanoholes are processed on the circular gold electrodes at the same time; the size of the nanoholes makes each nanohole only able to Captures a strand of DNA. Since the nano-gold electrode is connected to an external voltage source, by adjusting the direction and magnitude of the voltage on each nanopore, the electrical and intensity of the charge density on the nanopore can be adjusted, thereby controlling the direction and intensity of the electroosmotic flow through the nanopore, and it is compatible with deoxidation. The electric field force suffered by the ribonucleic acid chain forms a joint or competitive drive, thereby controlling the movement speed and direction of the nanorobot.

Owner:SOUTHEAST UNIV

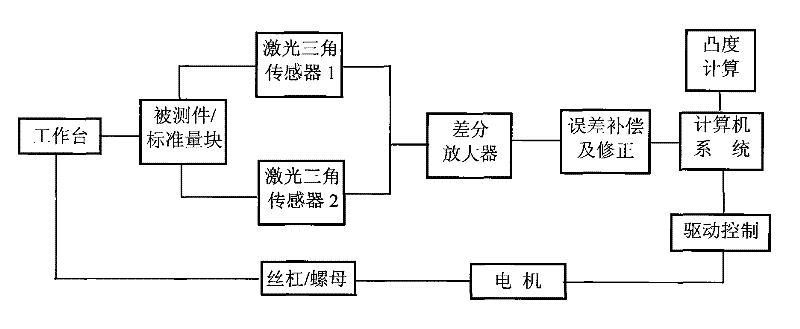

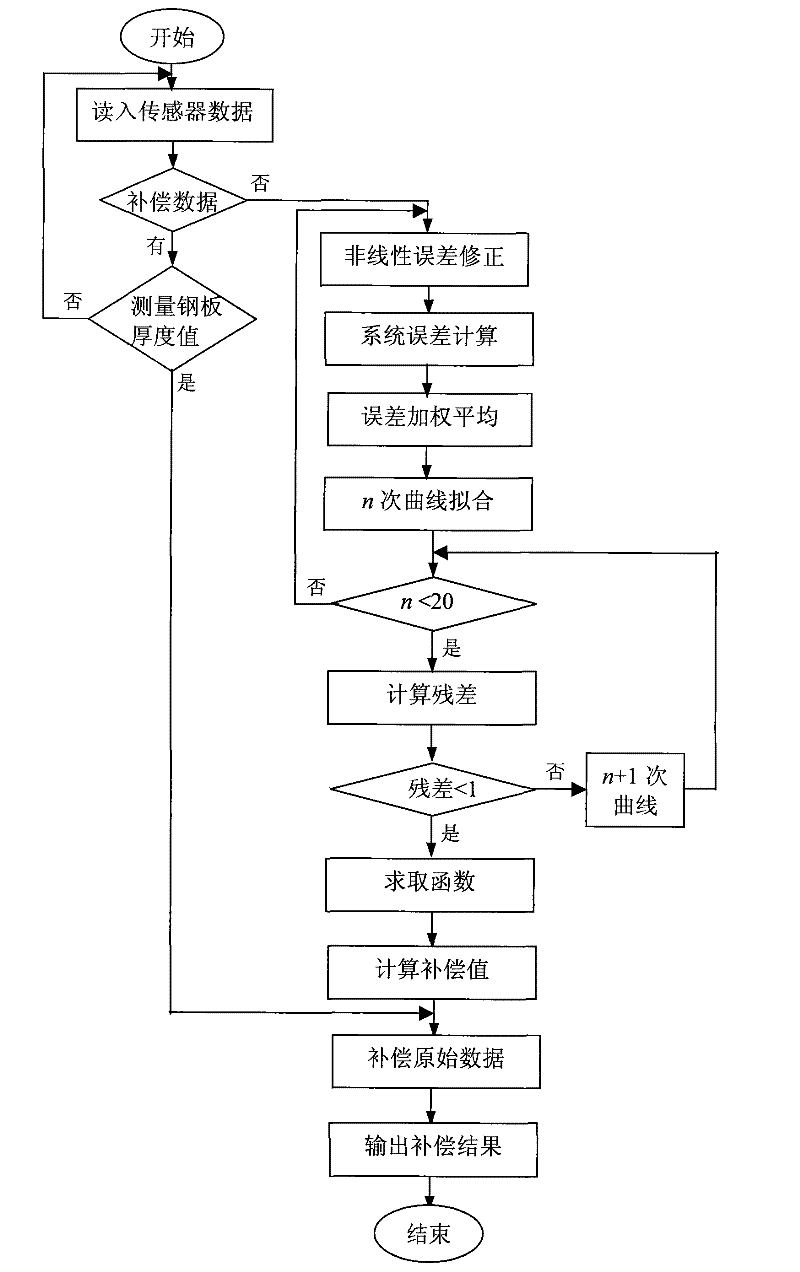

Steel plate crown measurement method with error compensation

ActiveCN101957177BAvoid disturbing influenceTo achieve error compensationUsing optical meansEngineeringMeasurement precision

The invention relates to the field of geometric quantity measurement, in particular to a steel plate crown measurement method. The steel plate crown measurement method with error compensation comprises the following steps of measuring a standard gauge block by using a laser convexity measurement system, comparing the obtained data with a gauge block nominal value to obtain error compensation quantity, fitting nonlinear error compensation quantities of multiple different standard gauge blocks through multiple measurements to obtain a linear error compensation curve, and then compensating the measurement data of a practical measured steel plate by utilizing the error compensation curve to finally obtain the real measurement result with high precision. The invention realizes the error compensation within whole measurement range, improves one order of magnitude on the precision in comparison with the traditional measurement method, and can guarantee the measurement precisions of the steelplates with different thickness changeless. The invention can realize the high-precision measurement on the convexity of the steel plate with random thickness within 1-30mm, and the measurement precision can be up to 3 micrometers; and the invention avoids the influence of inference from the site environment and is suitable for the popularization on the steel production line under various complexenvironments.

Owner:BAOSHAN IRON & STEEL CO LTD

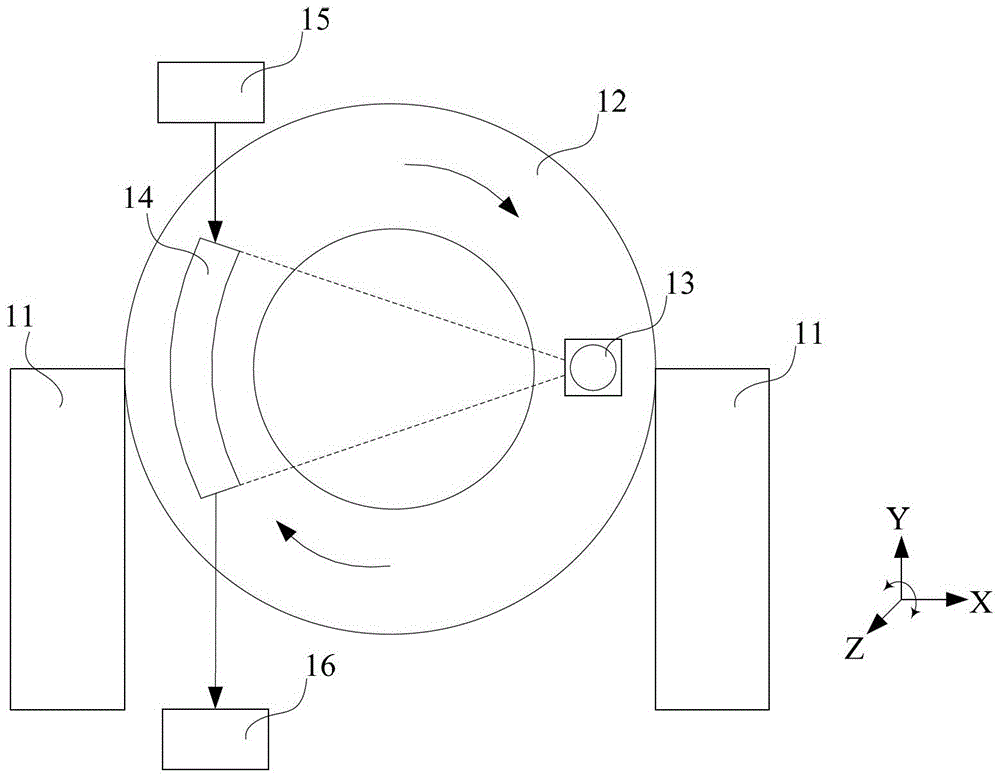

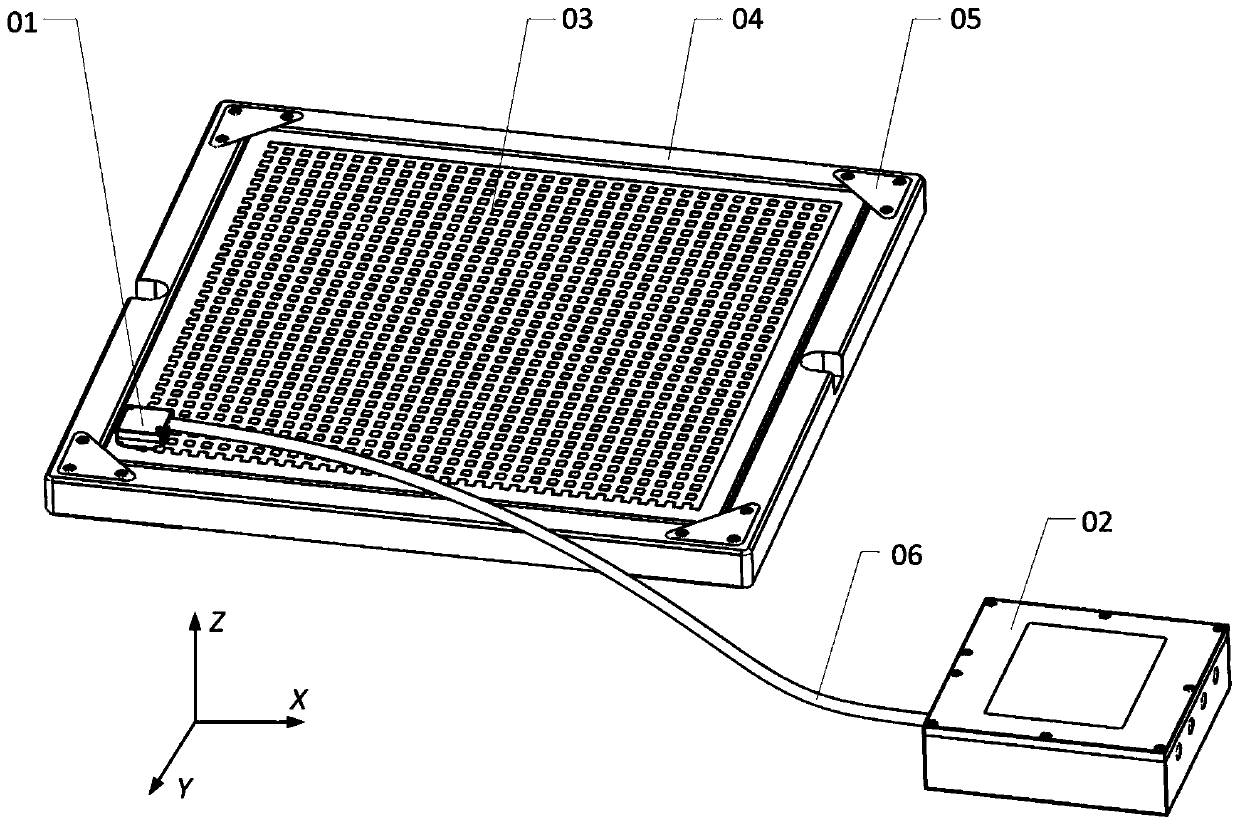

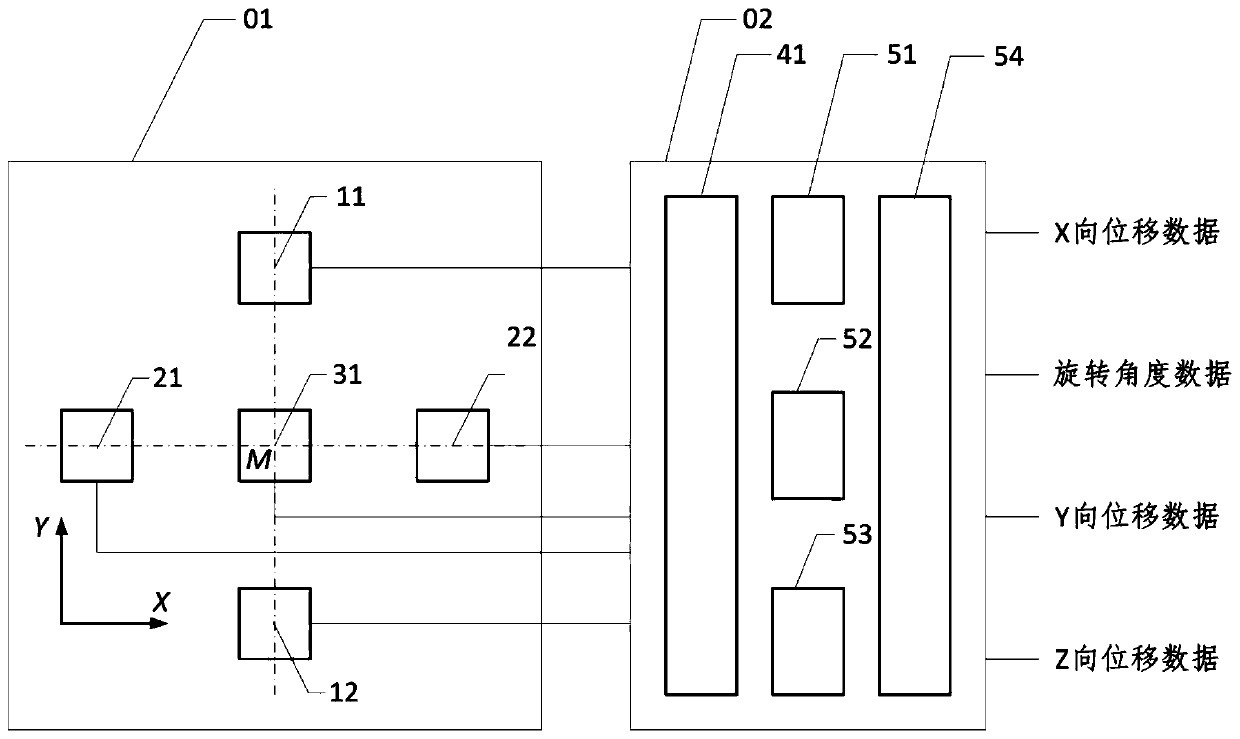

Multi-degree-of-freedom displacement measurement system based on two-dimensional grating

PendingCN111174714AExpand the scope of applicationRealize multi-degree-of-freedom measurementUsing optical meansGratingEngineering

The invention provides a multi-degree-of-freedom displacement measurement system based on a two-dimensional grating, wherein a reading module and a two-dimensional grating are arranged on a moving part and a moving part respectively. The reading module comprises two sets of first displacement sensors arranged in the first direction, two sets of second displacement sensors arranged in the second direction and a distance sensor located in the physical center of the first sensors and the second sensors. According to the invention, the problem that the traditional multi-degree-of-freedom measurement system needs multiple paths of sensing reading systems to be independently installed is solved; precise measurement of two-dimensional plane displacement, rotation amount and displacement in four-degree-of-freedom directions perpendicular to a two-dimensional plane can be realized. And by arranging the distance sensors, the optimal reading distance position of the reading module and the two-dimensional grating is directly adjusted and determined, the technological process of traditional two-dimensional grating installation and debugging is simplified, and meanwhile the technical difficultyof debugging is reduced.

Owner:苏州秦宁微纳光电科技有限公司

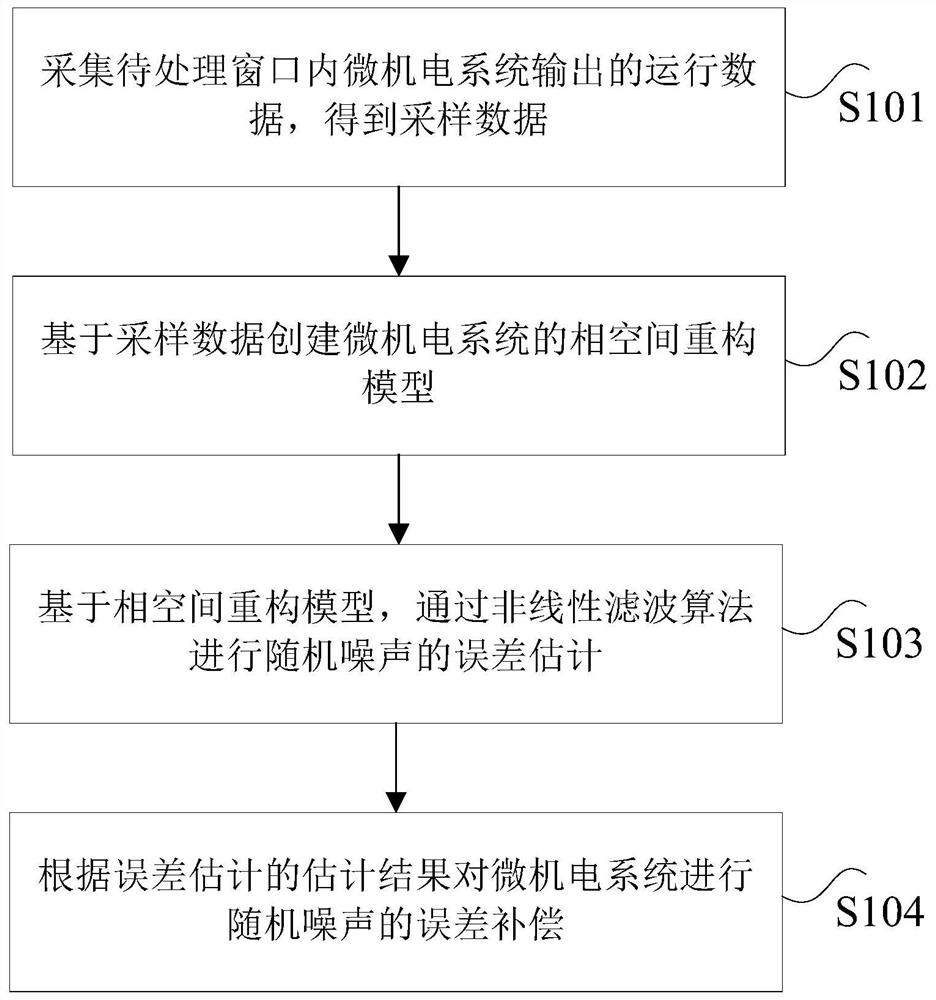

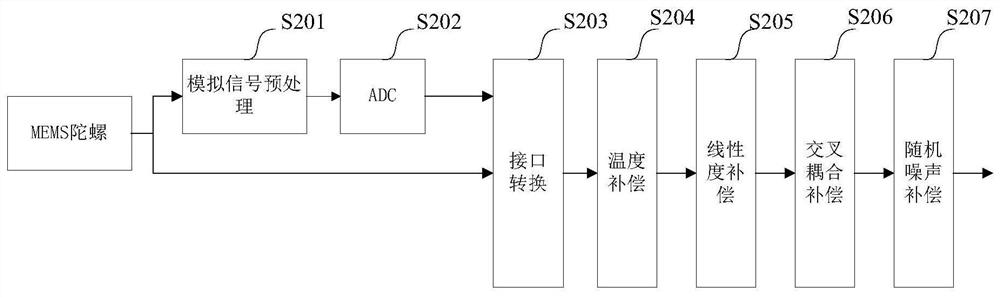

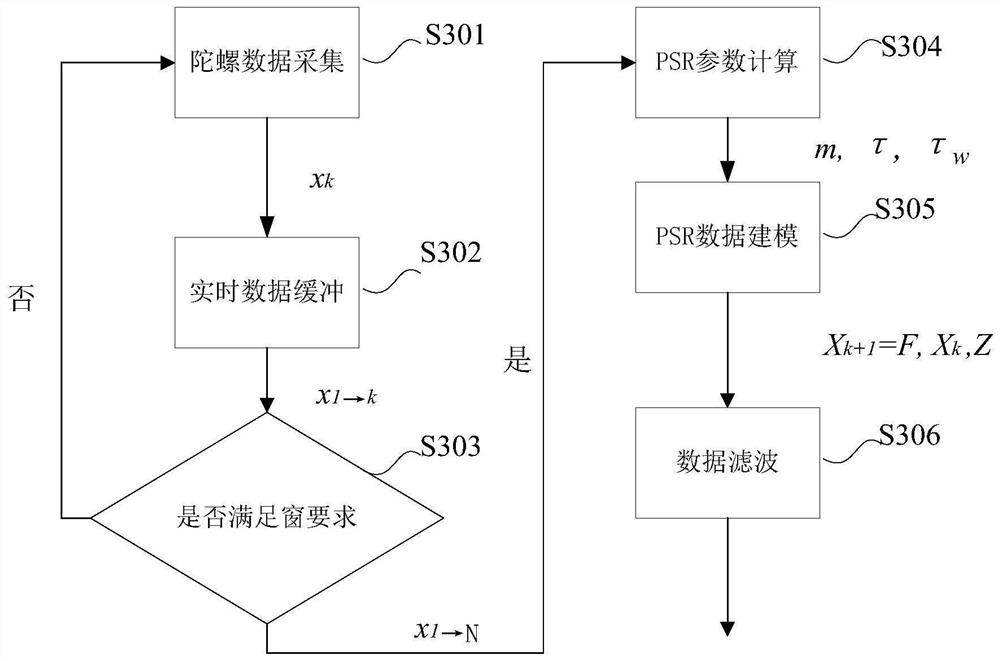

Processing method and processing device for random noise of micro-electro-mechanical system gyroscope

PendingCN112577478ATo achieve error compensationSolve the technical problem of poor suppression effectSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectrical and Electronics engineeringNonlinear filter

The invention discloses a processing method and processing device for random noise of a micro-electro-mechanical system gyroscope, a storage medium and a processor, and the method comprises the steps:collecting operation data outputted by a micro electro mechanical system in a to-be-processed window, and obtaining sampling data; creating a phase space reconstruction model of the micro electro mechanical system based on the sampling data; based on the phase space reconstruction model, carrying out error estimation of random noise through a nonlinear filtering algorithm; and performing error compensation of random noise on the micro electro mechanical system according to the estimation result of error estimation. According to the method, the gyro output signal model based on phase space reconstruction is established, and the volume Kalman filtering method is utilized to realize effective suppression of random noise, so that the technical problem of poor suppression effect of random noise of the MEMS gyro is solved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

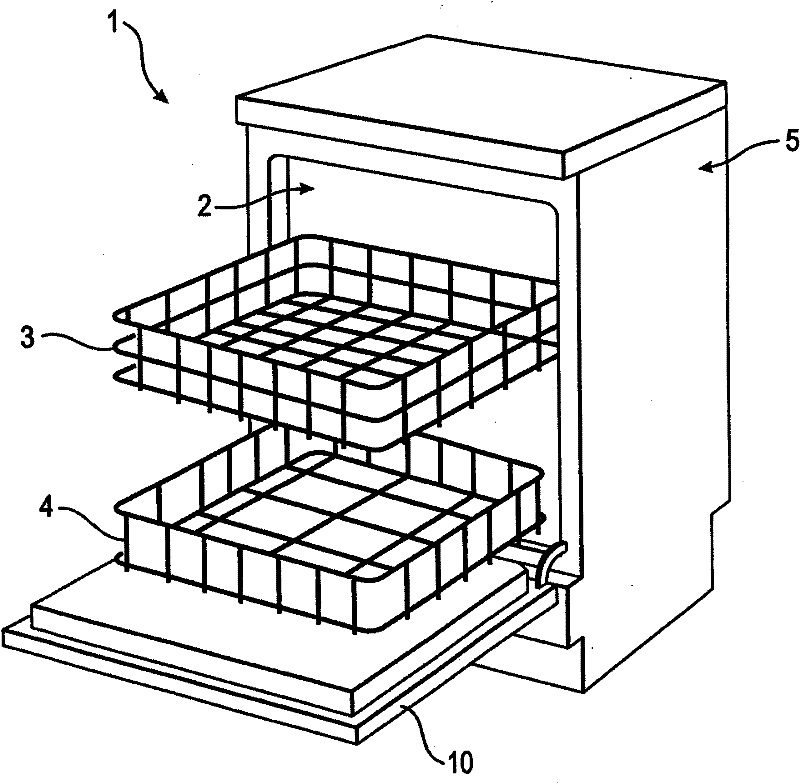

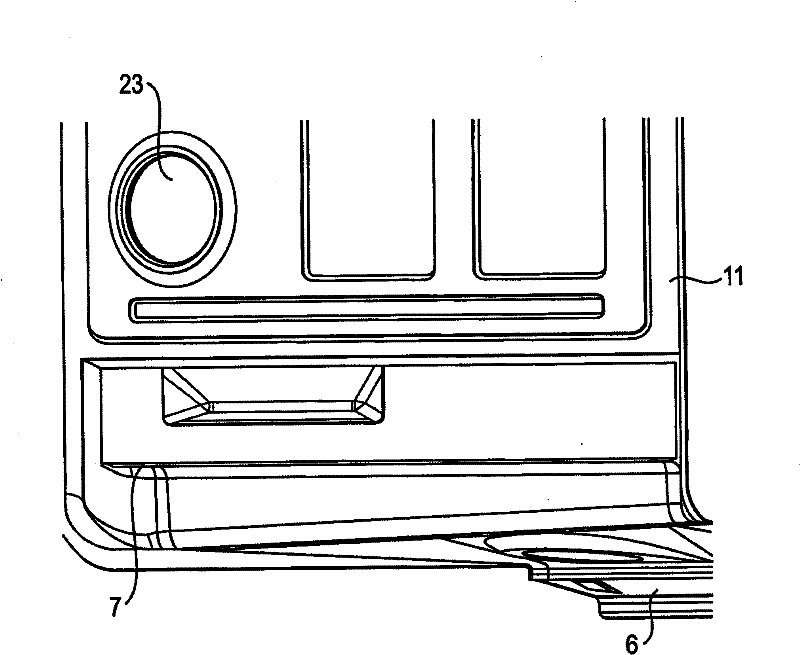

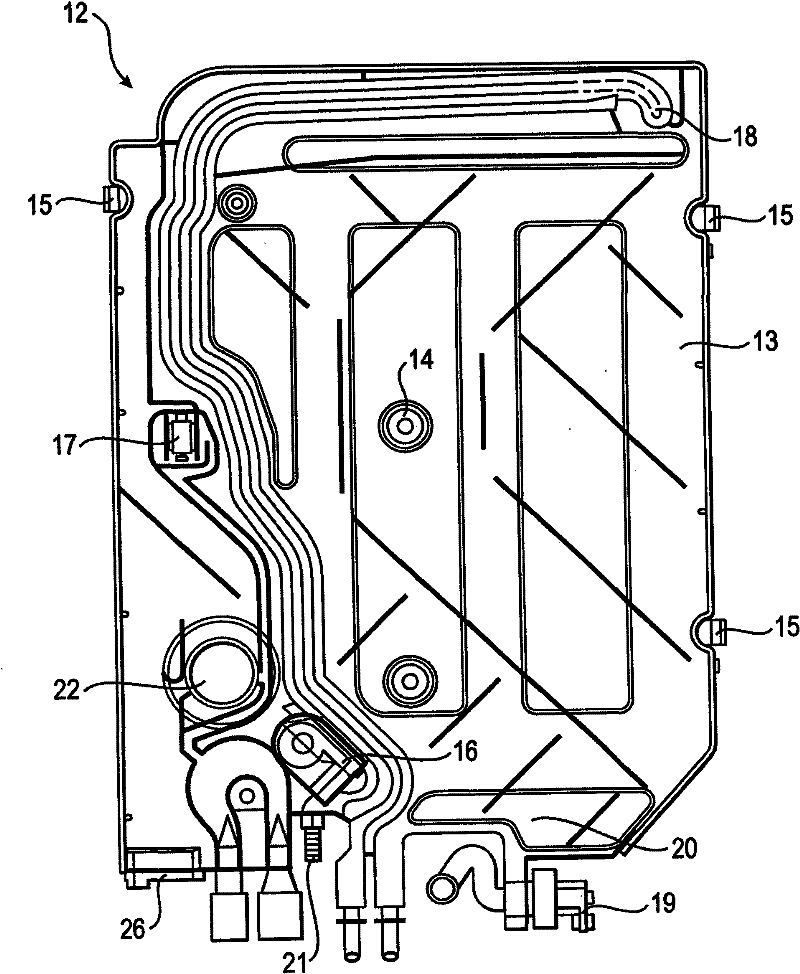

Water conducting domestic appliance

ActiveCN101790340BImprove stabilityImprove fastnessTableware washing/rinsing machine detailsHeat conductingEngineering

Owner:BOSCH SIEMENS HAUSGERATE GMBH

An Improved Two-way Bilateral Ranging Method

ActiveCN108828567BHigh positioning accuracyReduce power consumptionPosition fixationUsing reradiationEngineeringComputer science

The invention provides an improved bidirectional and bilateral ranging method. In this method, the mobile node continuously transmits two signals to all fixed reference nodes. Among these fixed reference nodes, one is the master fixed reference node, and the rest are slave fixed reference nodes. The mobile node transmits the time synchronization signal twice, and the main fixed reference node sends a time synchronization response signal to complete the measurement of the distance difference between the mobile node and the main and slave fixed reference nodes. At the same time, the second time synchronization signal sent by the mobile node and the main fixed reference node The time response signal sent by the reference node is used as the first two frame signals in the two-way bilateral ranging. The method in the present invention has the advantage of high positioning accuracy of the two-way bilateral ranging method; at the same time, multiple distance differences can be measured only by transmitting the time synchronization signal twice through the mobile node, and then can be measured at one time to obtain the distance between the mobile node and each distance. The distance of the reference node is fixed, and the power consumption is relatively low, which solves the problem of long time-consuming two-way and bilateral ranging.

Owner:HEBEI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com