A strip steel finishing mill inlet guide device

A finishing mill and position guiding technology, which is applied in the field of cold rolling and rolling, can solve the problems that the strip steel does not have the automatic adjustment function of the raw material width, the positive and negative difference of the strip steel, and cannot solve the whole process of rolling thick and thin materials, so as to avoid Dimensional error influence, realization error, and effect of avoiding guide damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

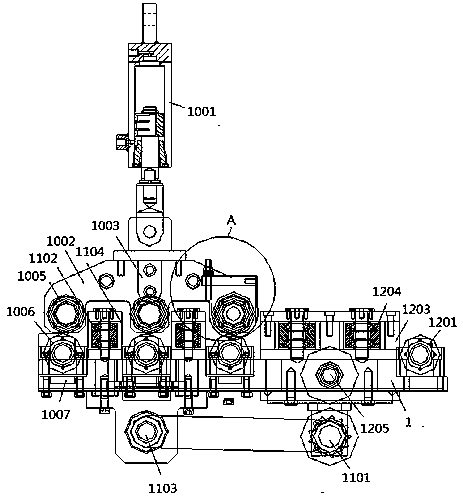

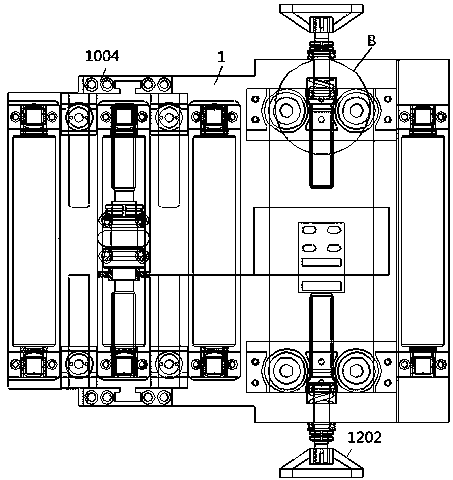

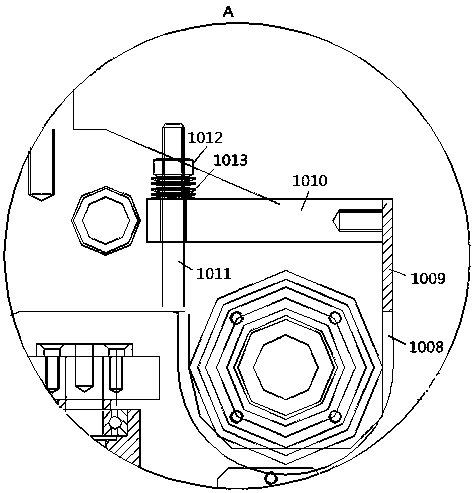

[0039] combine figure 1 , figure 2 , image 3 and Figure 4 , the entrance guide device of a strip finishing mill in this embodiment comprises a front guide device, a rear guide device and a bottom plate 1, wherein the rear guide device and the front guide device are sequentially arranged on the bottom plate 1 along the moving direction of the strip steel . In the present invention, the steel strip runs straight and smoothly along the transmission track of the rolling mill under the action of the front guide device and the rear guide device, which ensures the smooth progress of the uncoiling, rolling and winding processes, speeds up the production progress, and improves the production efficiency. At the same time, the use of the guide device at the entrance of the strip finishing mill ensures that the tail of the finished strip and the head of the unrolled strip can be rolled through the rolling mill, and the rolling effect is ideal, thus greatly The waste of raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com