Adjustable wire extrusion monitoring alarm device

A monitoring and alarming and adjustable technology, applied in the field of 3D printing, can solve the problems of reduced positive pressure of tensioning wire, poor quality of printing model, waste of consumables, etc., and achieve the effect of reducing scrap rate and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

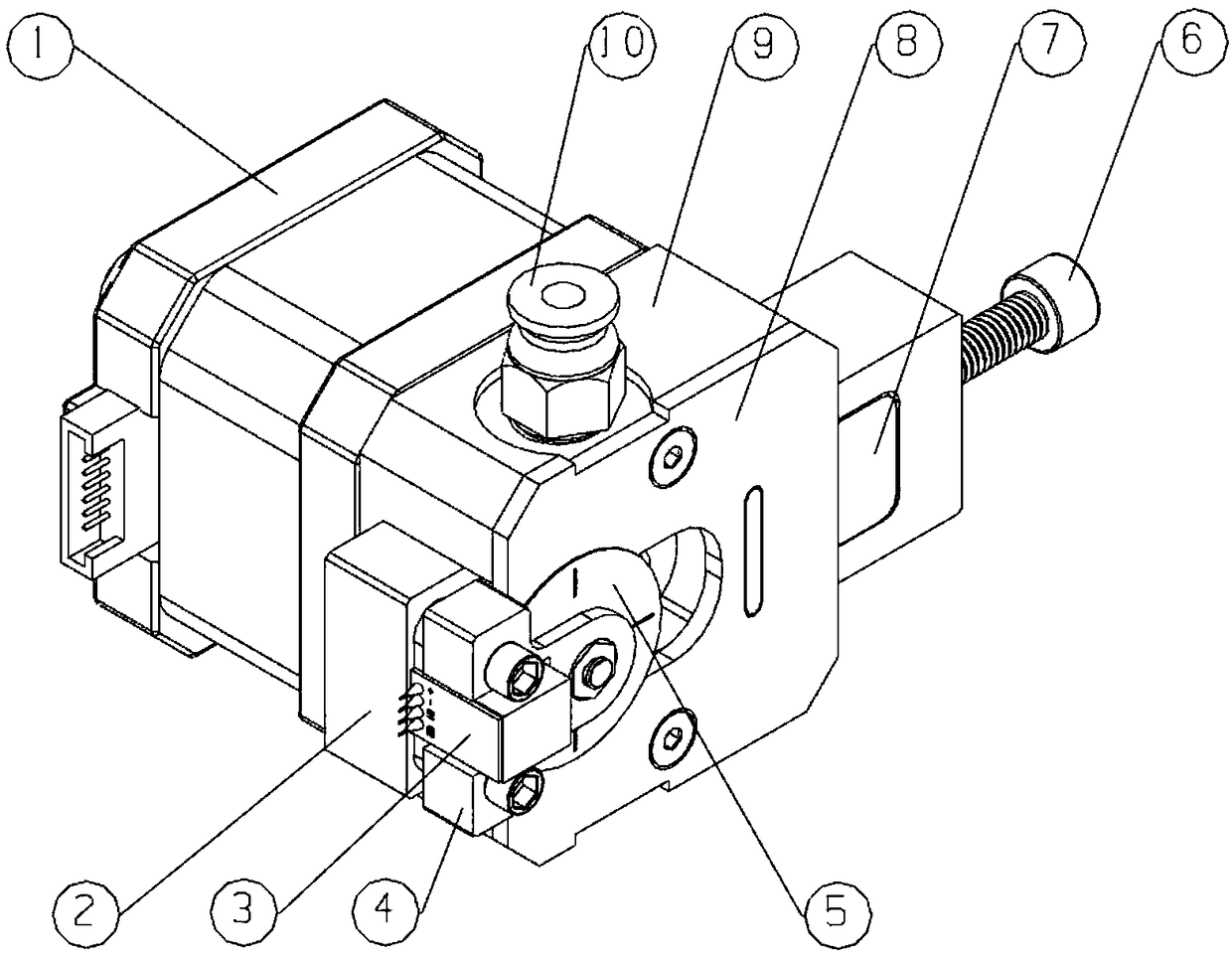

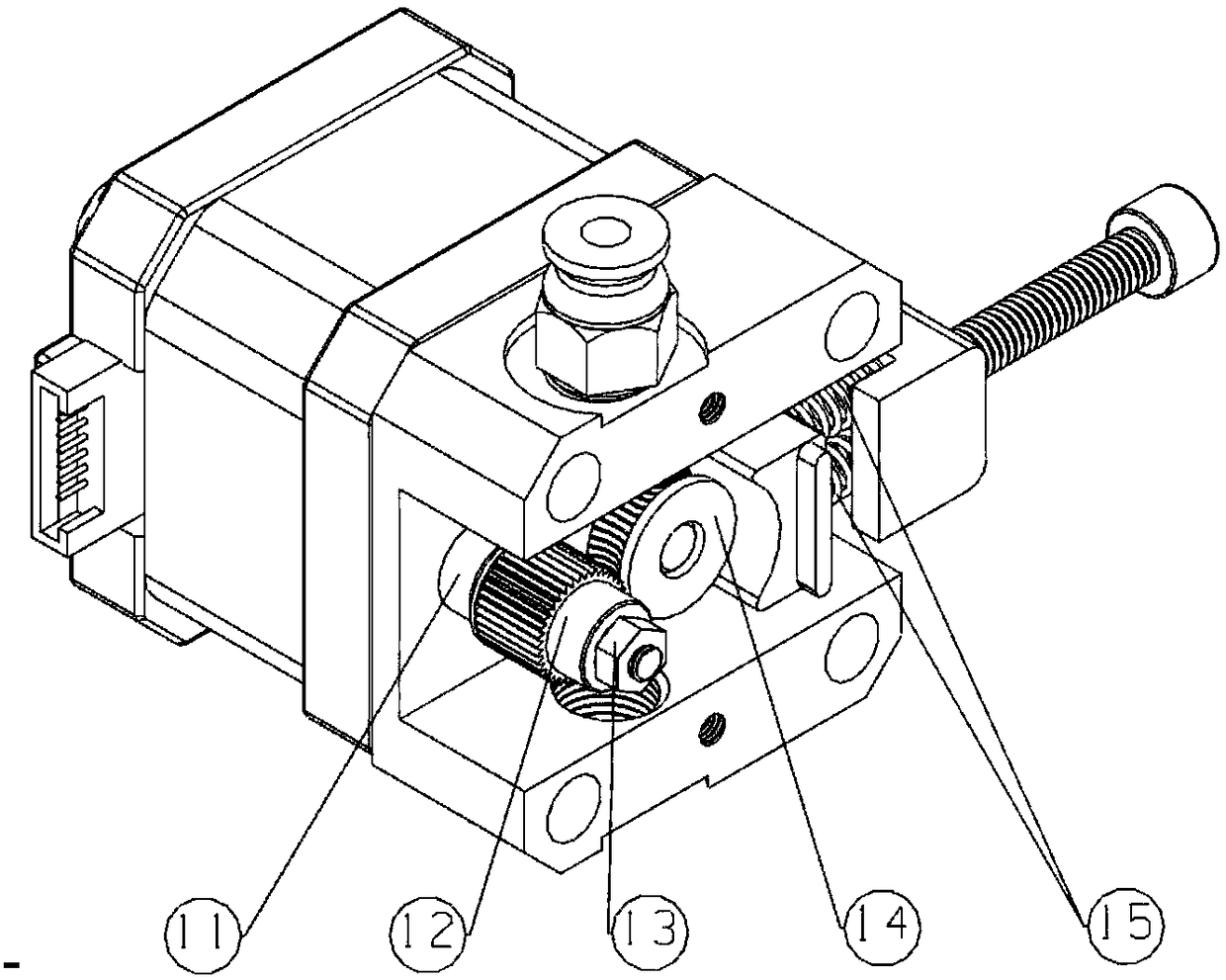

[0020] Such as Figure 1 to Figure 2 As shown, an adjustable wire extrusion monitoring and alarm device can be divided into three parts in terms of structure and function, including extrusion monitoring components, tension adjustment components, and motor components. The wire extrusion monitoring assembly of the adjustable wire extrusion monitoring and alarm device includes a code disk photoelectric switch 3, a code disk support 4, a code disk 5, a printing wire connection sleeve 10, a limit screw 11, a wire extrusion wheel 12, a pressing Nut 13, groove extrusion wire wheel 14. In the motor 1 shaft direction, a groove wire extrusion wheel 14 is fixed on the motor 1 shaft by set screws. A wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com